Rubber wheel road roller front wheel and back wheel oil brushing device

A technology of rubber-tyred road rollers and front and rear wheels, which is applied in the direction of roads, roads, and road repairs. It can solve the problems of construction progress, inconvenient use, and large manpower consumption, and achieve high work reliability, easy installation, and reduced processing and production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

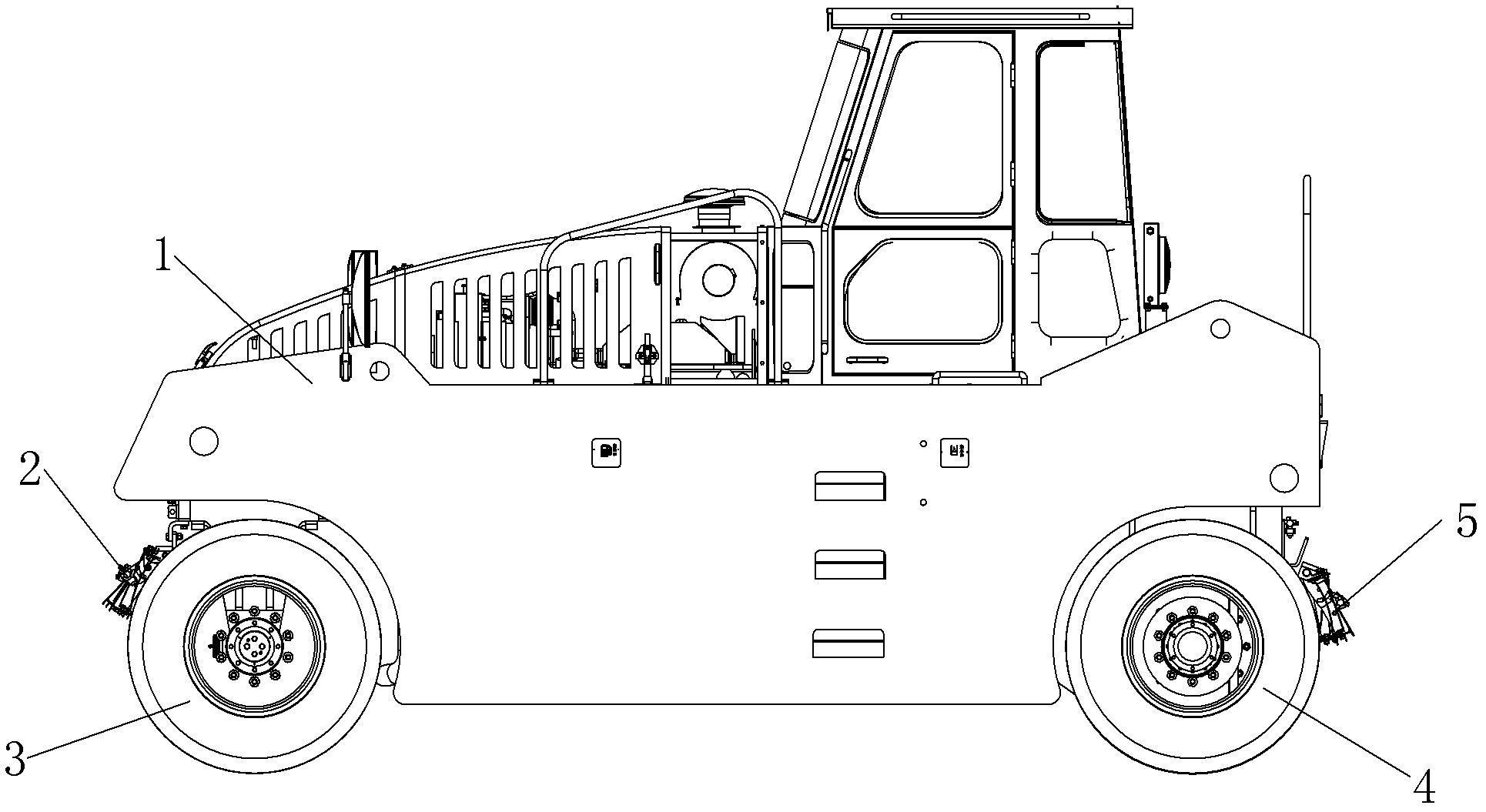

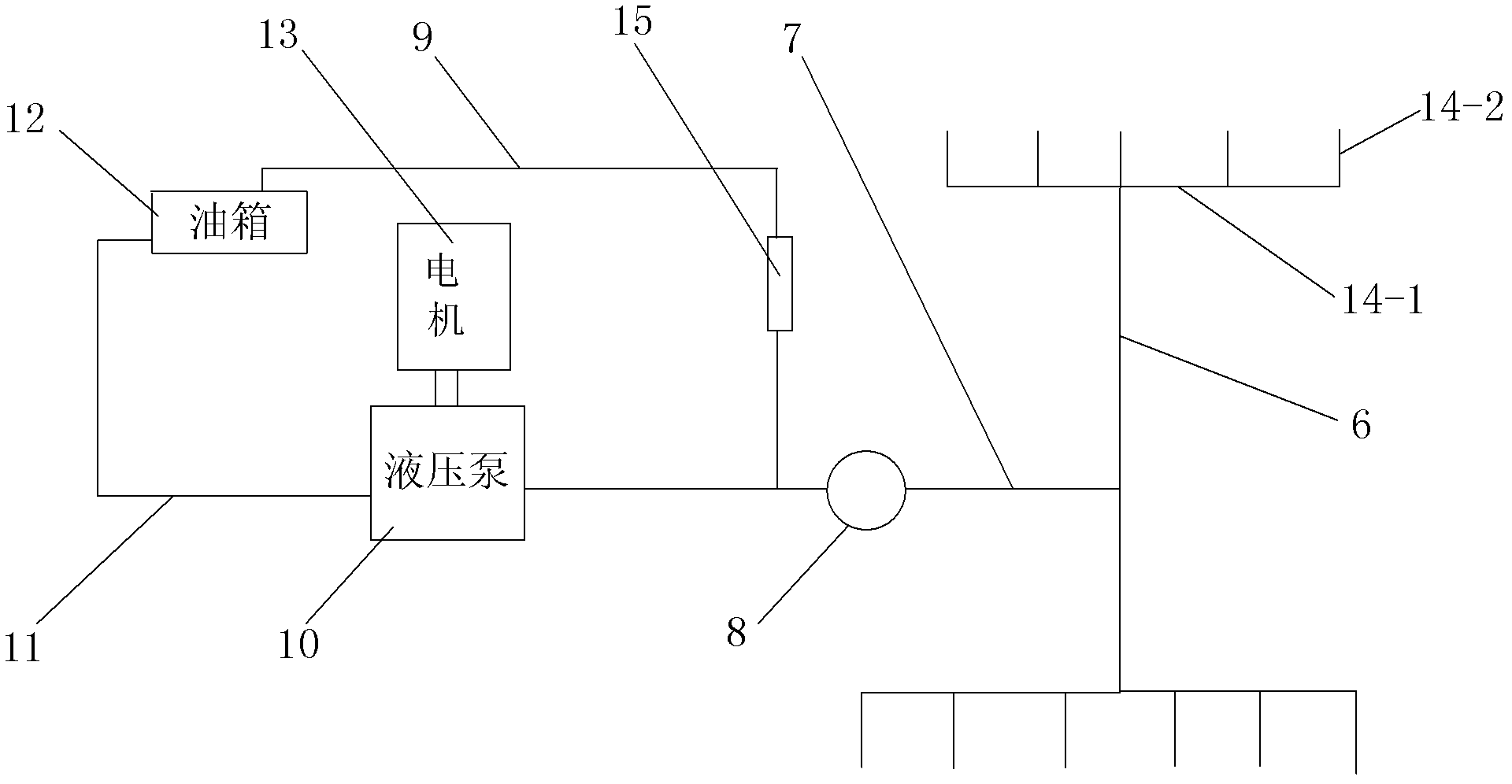

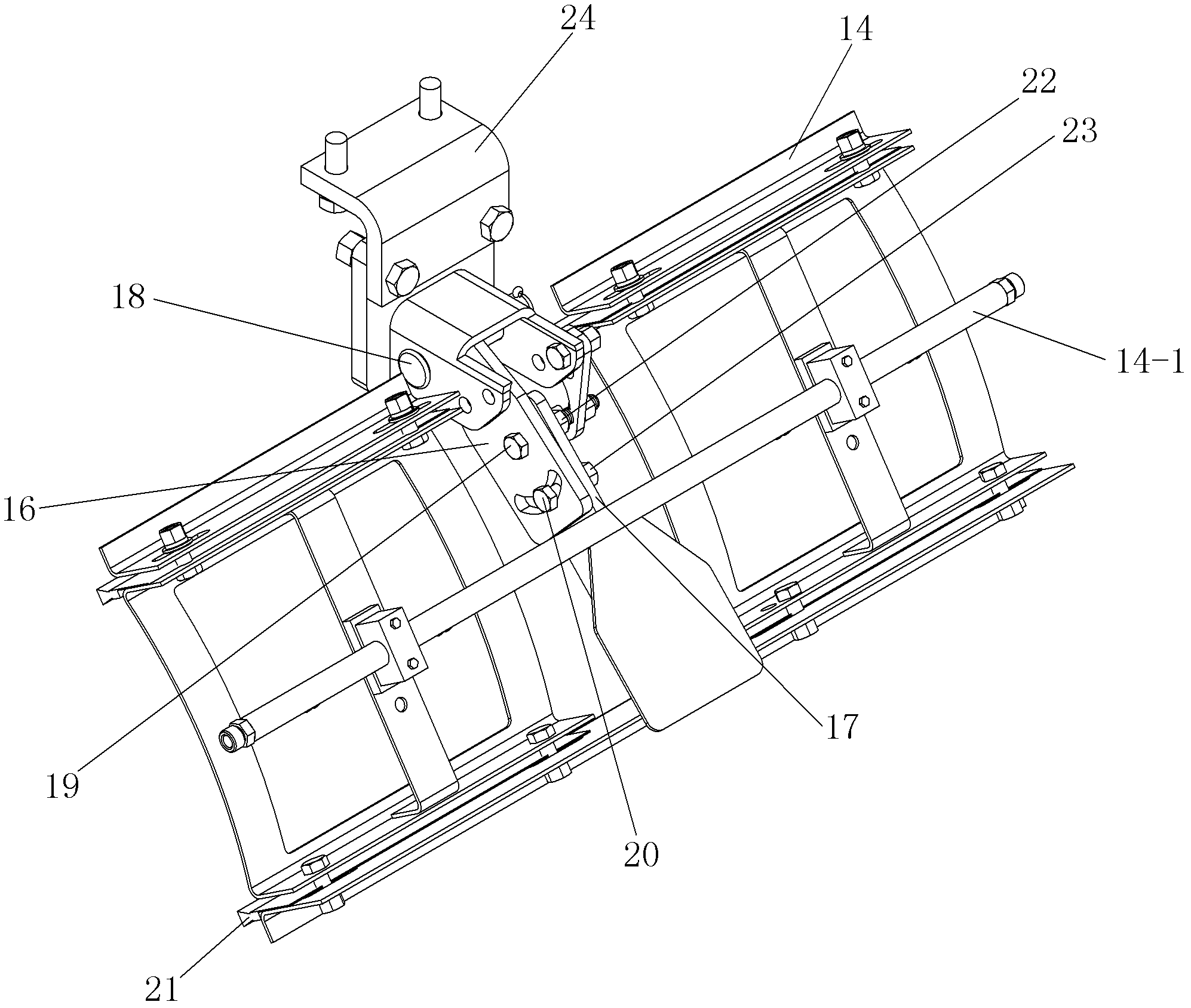

[0031] Such as figure 1 with figure 2 The oil brushing device for the front and rear wheels of the rubber roller roller shown includes an oil tank 12, a hydraulic pump 10, a motor 13 for driving the hydraulic pump 10, and a front oil brush holder 2 installed above the front wheel 3 of the roller and installed above the rear wheel 4 of the roller The rear oil brush holder 5, the front oil brush holder 2 and the rear oil brush holder 5 each include an oil brush holder body 14 and a fixing frame 24 for connecting the oil brush holder body 14 to the road roller body 1. The oil brush holder body 14 is equipped with an oil pipe 14-1, and the oil brush holder body 14 is equipped with an oil injection nozzle 14-2 connected with the oil pipe 14-1. The oil pipe 14-1 is connected to the pipe 14-1 through the pipe 6 Road 2 7 is connected, the pipe 2 7 is connected to the hydraulic pump 10, the hydraulic pump 10 is connected to the oil tank 12 through the pipe 3 11, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com