Substrate conveying system

A substrate conveying and substrate technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of prolonging the time of multi-layer circuit boards and reducing efficiency, and achieve the effect of shortening the production cycle and increasing the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The substrate conveying system provided by the technical solution will be further described in detail below with reference to the accompanying drawings and multiple embodiments.

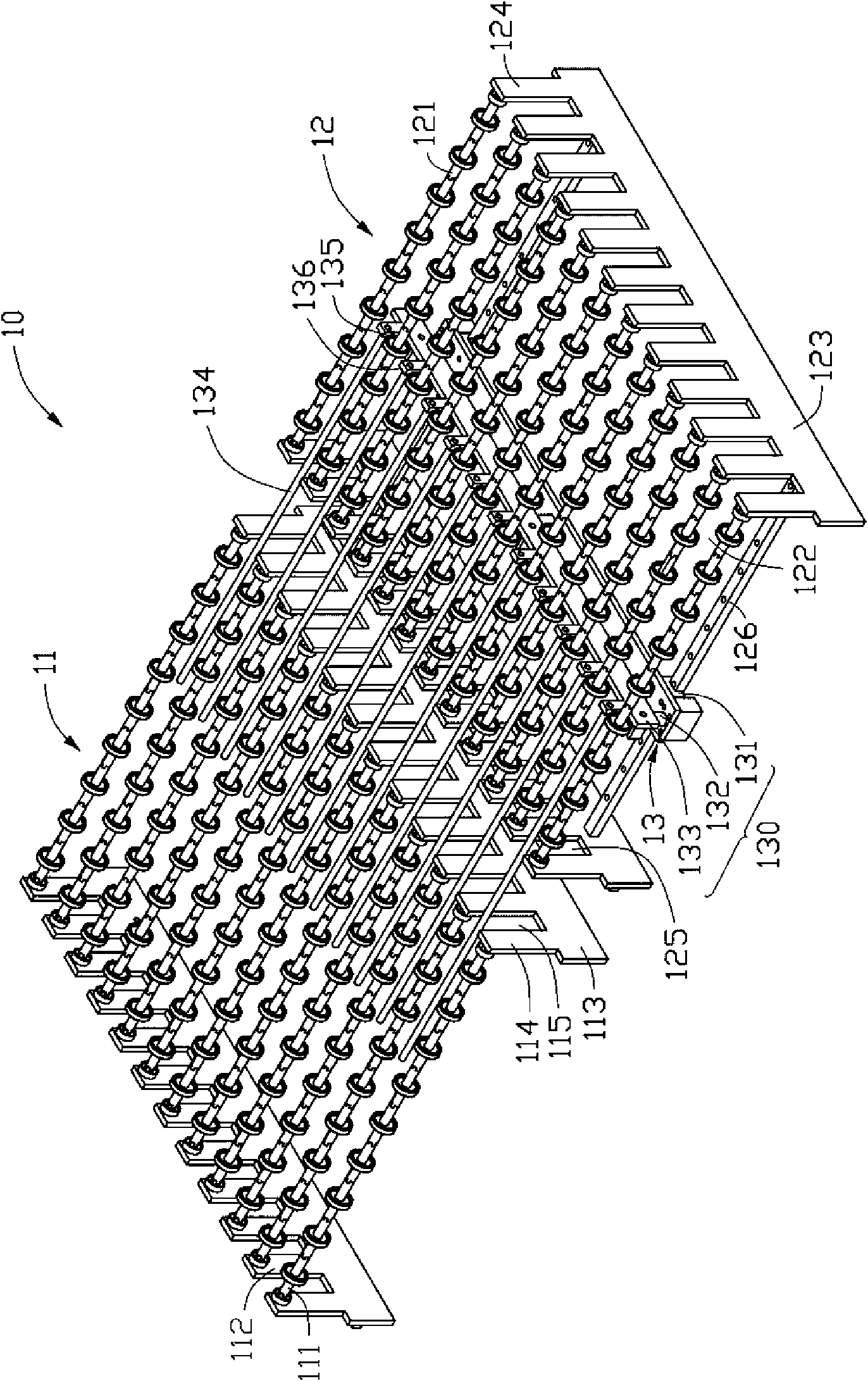

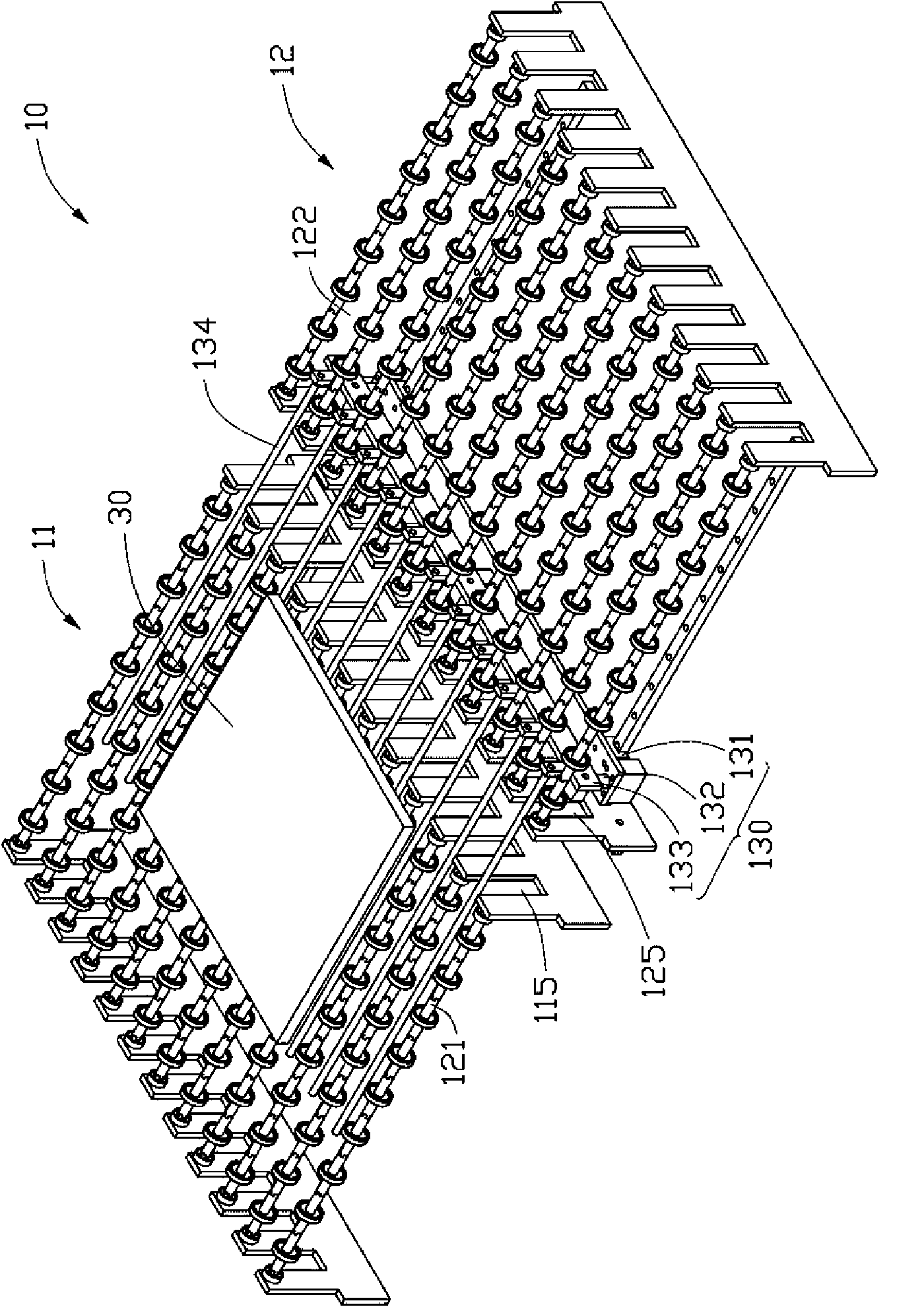

[0013] see figure 1 , the substrate conveying system 10 provided in the first embodiment of the technical solution includes a first conveying device 11 , a second conveying device 12 and a transfer device 13 .

[0014] The first conveying device 11 includes a plurality of first conveying units 111 for conveying the substrate along a first direction. The plurality of first delivery units 111 are distributed parallel to each other at intervals, and a first channel 112 is formed between two adjacent first delivery units 111 . The first conveying device 11 can be designed in different structures as required. In this embodiment, the first conveying device 11 includes two first support plates 113 parallel to each other for erecting the first conveying unit 111 . The first supporting board 113 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com