Forging device pipeline of complicated forging piece and forging production technique thereof

A complex forging and production process technology, which is applied in the thermal processing of mechanical parts, the forging equipment assembly line of complex forgings, and the field of forging production technology. It can solve the problems of poor surface quality of forgings, long production cycle, and increased production costs. Forming, fast heating speed and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

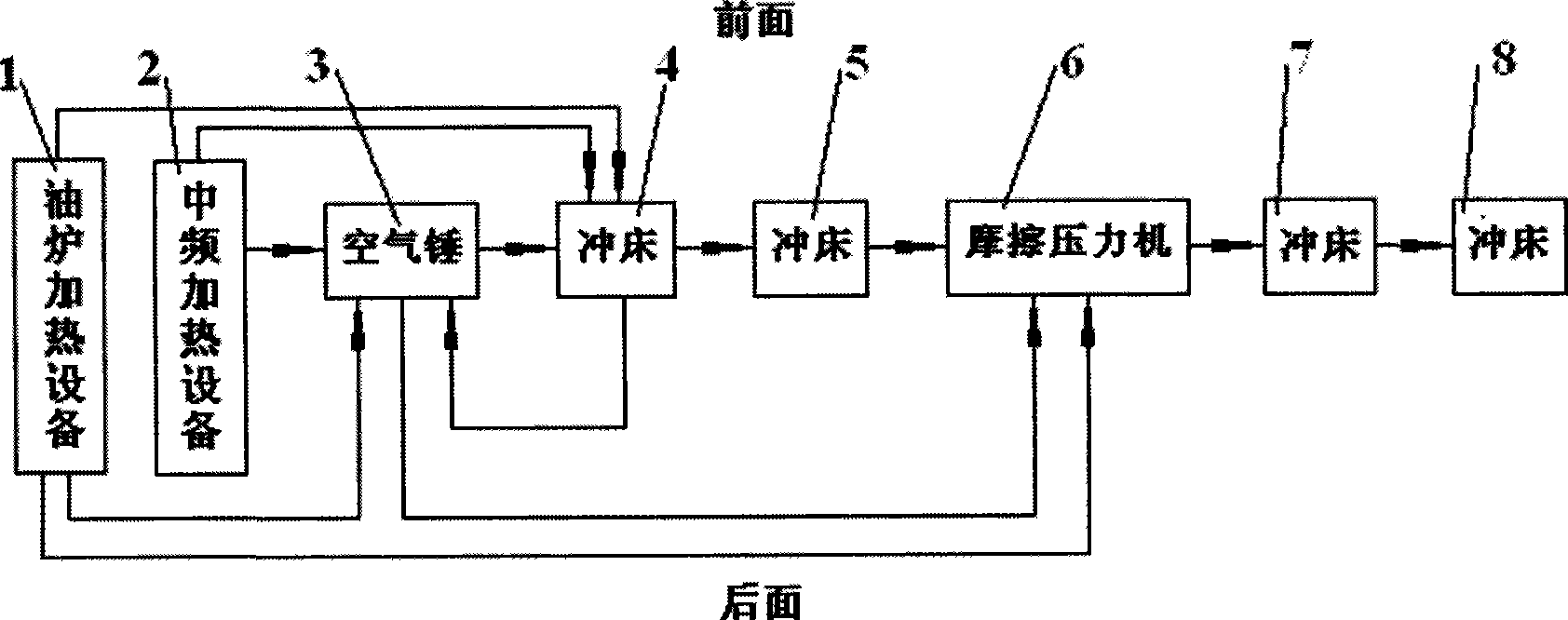

[0057] Such as figure 1 As shown, between the above-mentioned main heating equipment 1 and the friction press 6, an air hammer 3 is provided; between the above-mentioned air hammer 3 and the friction press 6, two punches are arranged, arranged in line order , are respectively punch one 4 and punch two 5; According to the assembly line order, in the rear of described friction press 6, establish two punches, be respectively punch three 7 and punch four 8.

[0058] Pneumatic Hammer 3 can be used to make blanks, thus increasing the types of products that can be produced. Since most forgings do not use the air hammer, but need to continuously use the first punch 4, the second punch 5 and the friction press 6, the air hammer 3 is arranged between the main heating equipment 1 and the first punch 4. In this way, in the case of most forging production, the forging production can be carried out continuously. If you need to use the air hammer 3, you can reverse it on the production lin...

Embodiment 2

[0062] The main heating device 1 of the present invention adopts a medium frequency induction heating device; the secondary heating device 2 is a fuel oil heating furnace.

[0063] The main heating equipment 1 is an intermediate frequency heating equipment with high heating efficiency and fast heating speed, and the heating and discharging speed can be adjusted according to production needs. The heating quality is stable and the material loss is less. The secondary heating device 2 is a fuel oil heating furnace with simple structure and low cost, and is suitable for secondary heating occasions that are not frequently used, and can be used at any time.

Embodiment 3

[0065] Punch one 4, punch two 5, punch three 7 and punch four 8 described in the present invention are double-column crank slider presses.

[0066] In the forging equipment assembly line provided by the present invention, the pressure of several processes using the punch press is smaller than that of die forging, so a double-column crank slider press can be used. Because the double-column crank slider press has a short stroke and a high stamping speed, it can improve production efficiency and meet the needs of some auxiliary work in forging, such as trimming, correction, and descaling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com