Potato multi-stage conveying separation excavator

A technology for conveying and separating potatoes, which is applied to excavators, digging harvesters, harvesters, etc., can solve the problems of difficult picking, inability to separate fruit stems and fruit films, and improper connection, so as to reduce the congestion of digging shovels The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, not to limit the scope of the present invention.

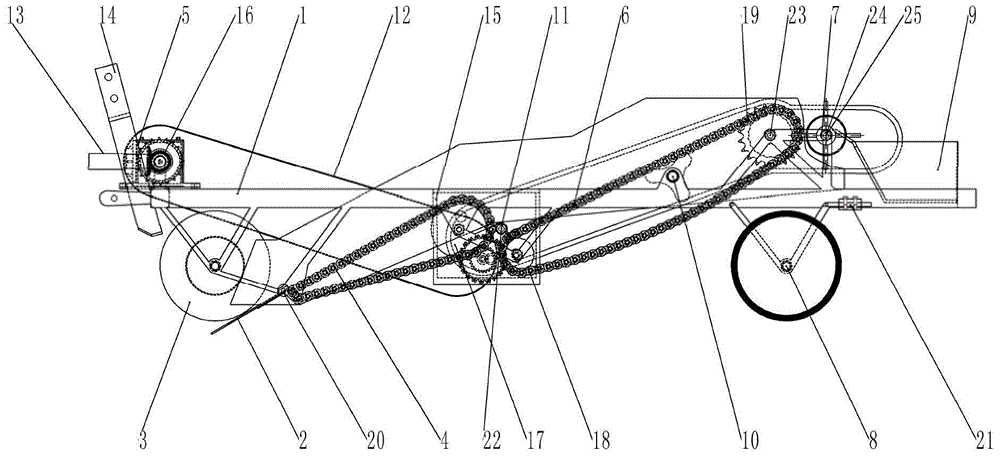

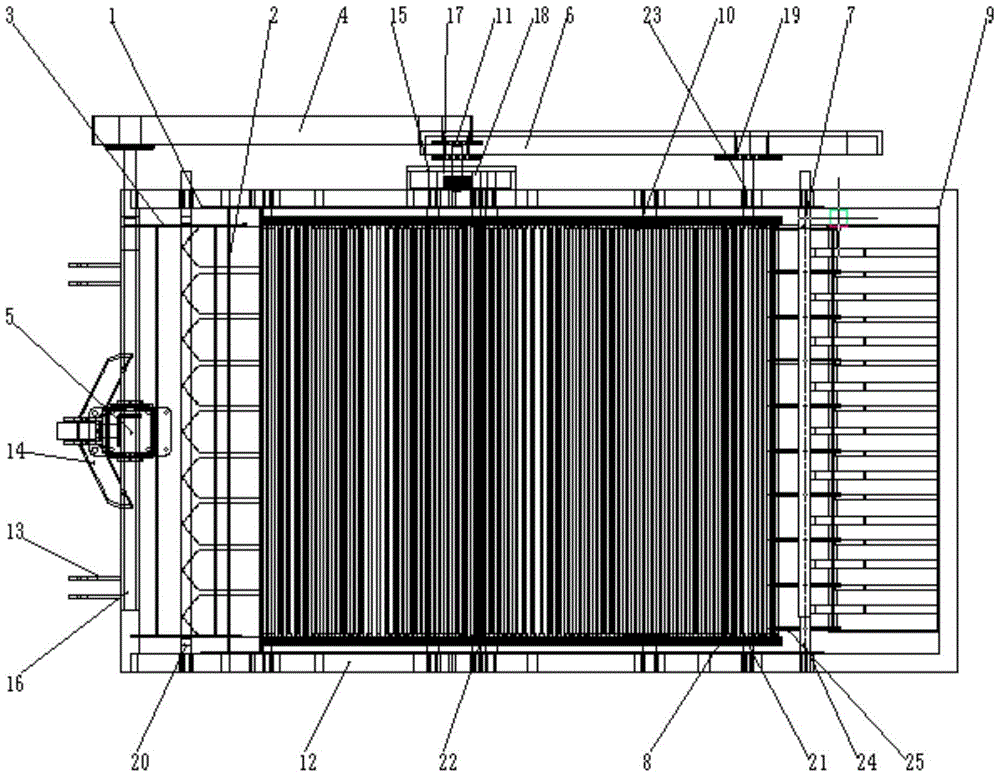

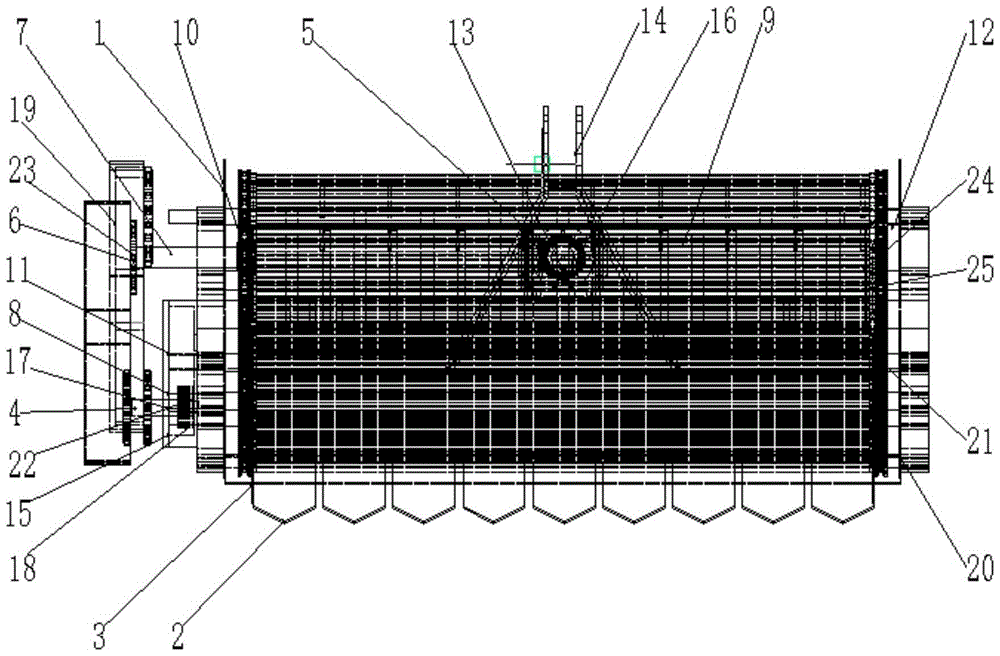

[0017] Such as Figure 1 to 6 As shown, the potato multi-stage conveying and separating excavator includes a frame 1, which is characterized in that an excavating shovel 2 is provided at the lower front of the frame 1, and a disc cutter 3 and a soil angle are provided on both sides of the shovel 2 Regulating mechanism 20, a conveyor chain 4 is arranged behind the shovel 2, a lifting conveyor separation chain 6 is arranged behind the conveyor chain 4, a vibration roller 10 is arranged in the middle of the lifting conveyor separation chain 6, and a lifting conveyor separation chain 6 is arranged behind Correspondingly, a residual film stalk separation device 7 is provided, and a collection box 9 is provided behind the residual film stalk s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com