Textile machine and method of operation thereof

A textile machine and worsted spinning technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., which can solve the problems of rising purchase and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

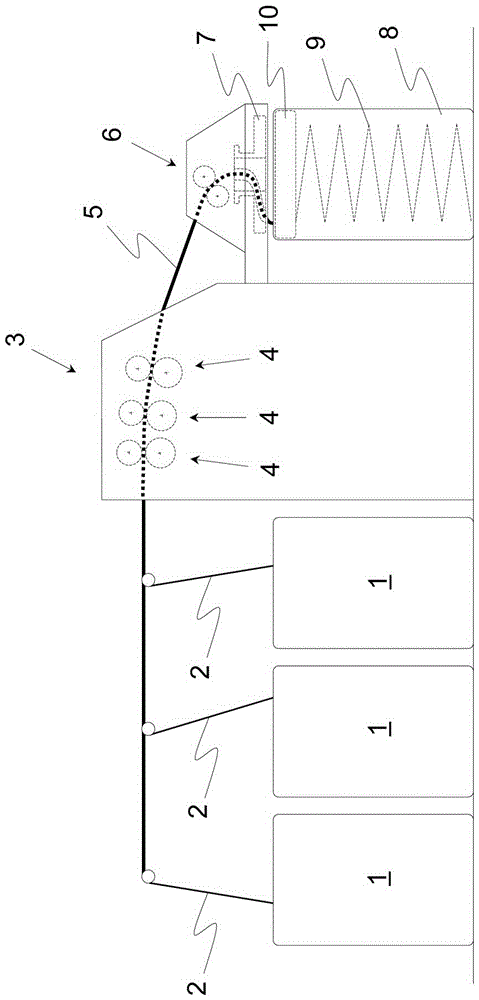

[0040] figure 1 A side view of a draw frame as an example of a textile machine according to the preamble of the independent claim is schematically shown. During the operation of the draw frame, fiber strips 2 are removed from a plurality of so-called storage cans 1 and fed into the drafting device 3 of the draw frame itself. The drafting device 3 generally consists of three or more roller pairs 4 , each of which includes a lower roller and an upper roller, and which draw through different rotational speeds and thus produce a homogeneous fiber strip 2 .

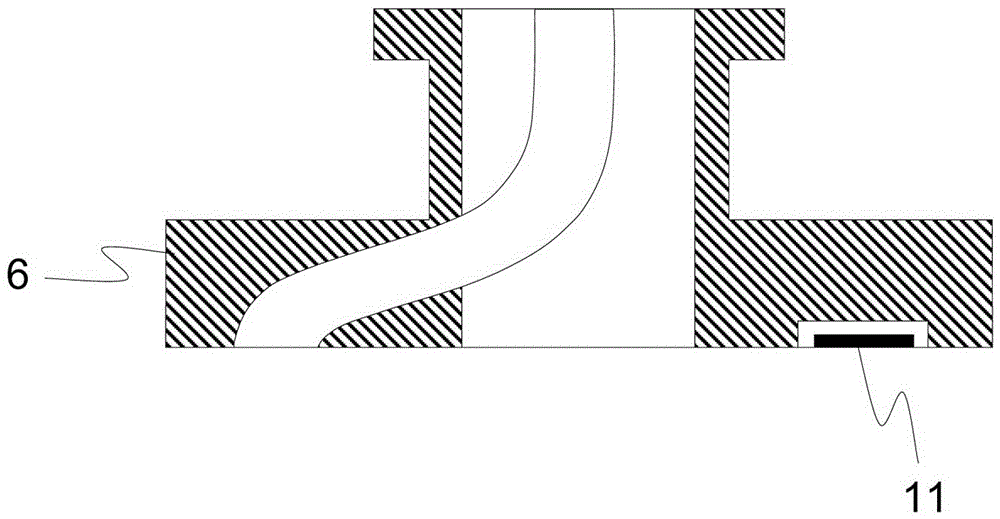

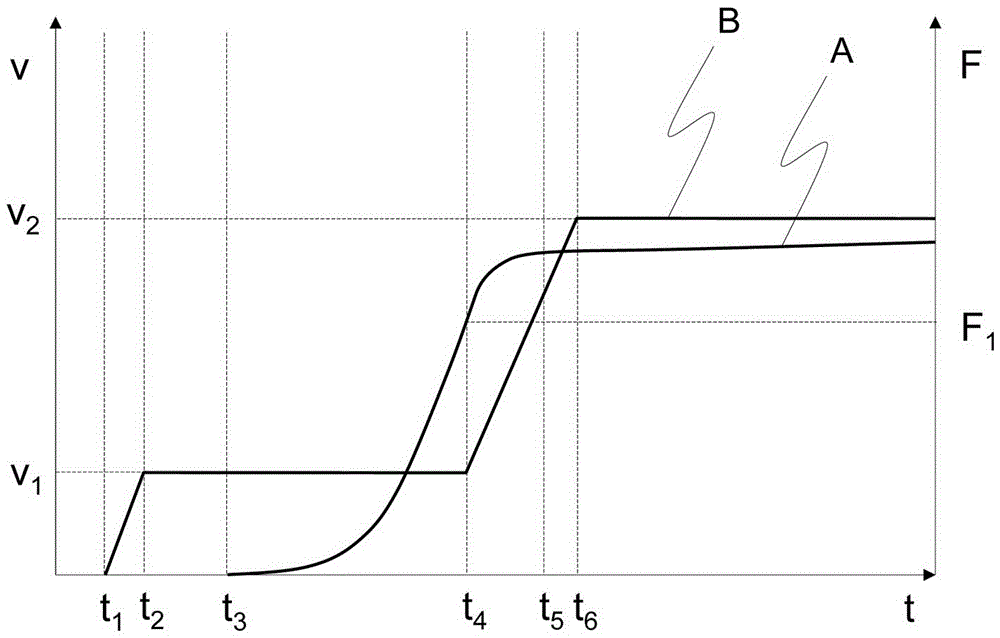

[0041] The drawn-out fiber material 5 connected to the drafting device 3 is finally conveyed by means of a pair of calender cylinders 6 to a rotating stacking pan 7 and is stacked coil-like by this into cans 8 . In order to prevent the fibrous material 5 from slipping uncontrollably into the can 8 , the can has a spring system 9 by means of which the can bottom 10 is pressed in the direction of the stacking disk 7 . This pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com