Double-phase twinborn induced plastic super-strength automobile steel plate and preparation method thereof

An ultra-high-strength, plastic-inducing technology, applied in the production of steel coils for automobiles, can solve the problems of high cost and difficult industrial production, achieve high yield strength and tensile strength, reduce fuel consumption, and reduce vehicle weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

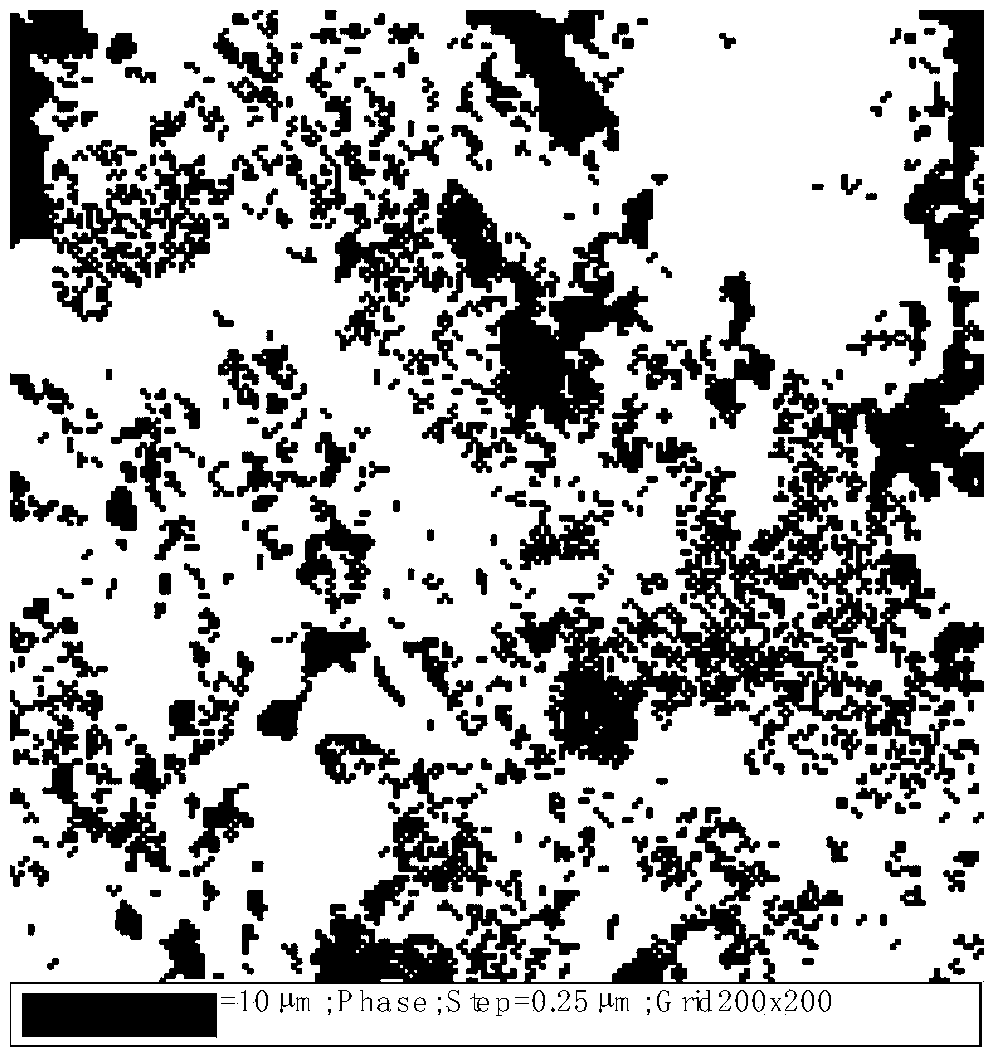

Image

Examples

Embodiment

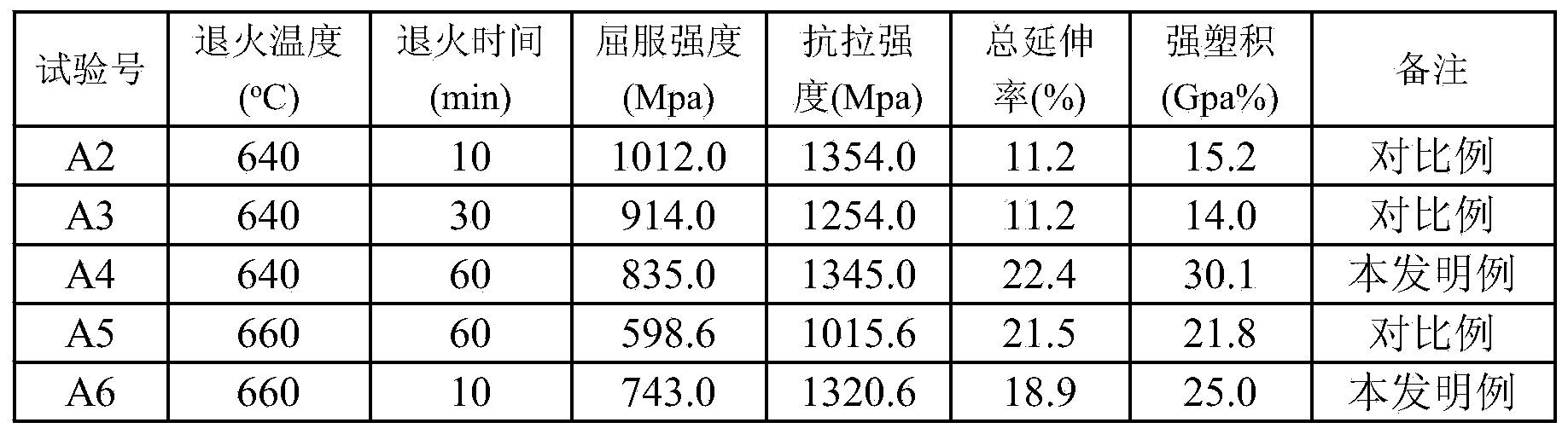

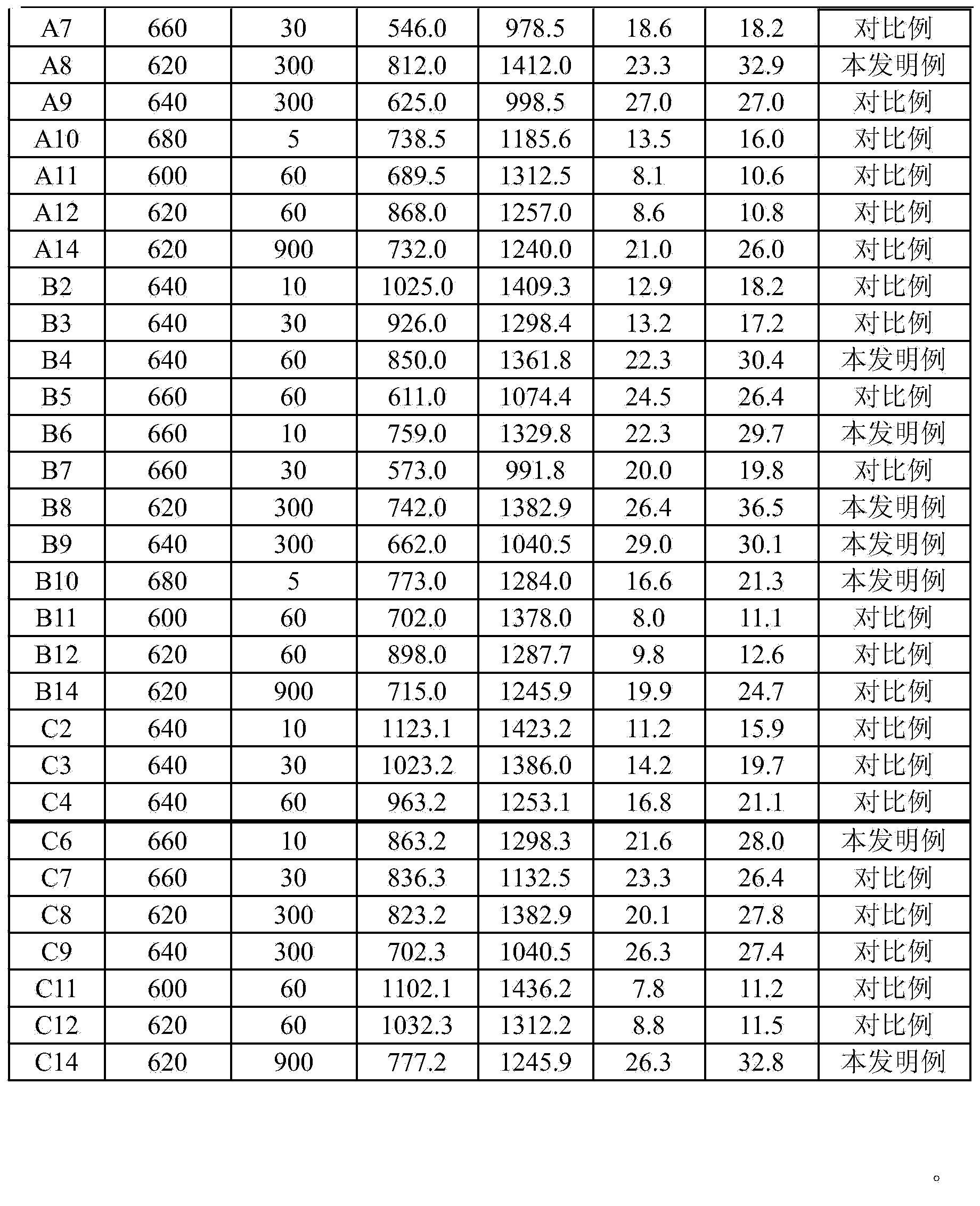

[0026] The test adopts three chemical compositions as shown in Table 1, among which A and B are C-Mn-Al alloy composition steel, without adding other alloy elements; while C is on the C-Mn-Al composition system, adding some Ni, Cr, Mo, Cu and other alloying elements.

[0027] Element

C

mn

Al

P

S

other elements

A

0.35

11.5

1.80

<0.005

<0.005

none

B

0.45

9.71

1.99

<0.005

0.0054

none

C

0.55

8.21

2.85

0.082

0.0095

Ni: 1%, Cr: 1%, Mo: 0.6%, Cu: 1.1%, B: 0.011%

[0028] Table 1 Chemical composition of the invented steel (wt%)

[0029]The above-mentioned alloy is smelted by induction furnace, poured into an ingot, hot-forged into a slab with a thickness of 50 mm, and then rolled to a hot-rolled plate with a thickness of 4 mm by a single-stand rolling mill for pilot use. The final rolling temperature is controlled at about 750 ° C, and then water-cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com