Refuse disposal system

A technology of garbage disposal system and garbage pool, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high investment cost, inapplicability, secondary environmental pollution, etc., and achieve low investment cost, The effect of saving resources, safe and efficient disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Describe in detail below in conjunction with specific embodiment according to accompanying drawing:

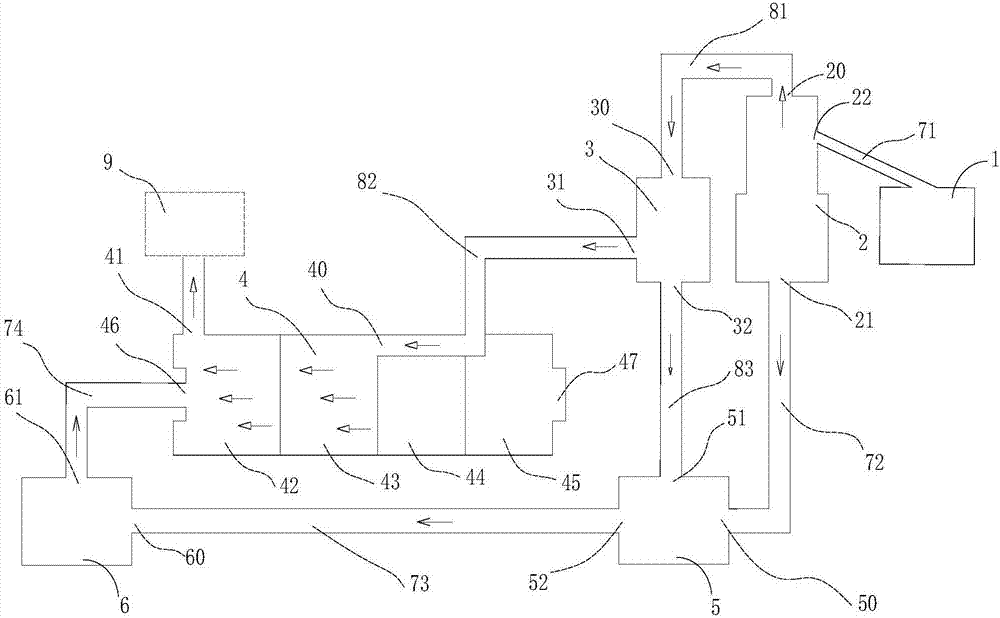

[0021] as attached figure 1 The shown a kind of garbage treatment system comprises garbage pool 1, incinerator 2, water processor 3 and tunnel brick kiln 4, and described garbage pool 1 transports the garbage to the first feed port of incinerator 2 through the first conveyor belt 71 22. The first smoke outlet 20 arranged on the incinerator 2 and the first smoke inlet 30 arranged on the water processor 3 are communicated through a first pipe 81, which is arranged on the water processor The second smoke outlet 31 on the 3 is communicated with the second smoke inlet 40 provided on the tunnel brick kiln 4 through a second pipe 82, the second pipe 82 is made of high temperature resistant material, and the tunnel The brick kiln 4 is provided with a drying section 42, a combustion section 43, a heat preservation section 44 and a cooling section 45 in sequence. 44 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com