Patents

Literature

94results about How to "Smooth production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

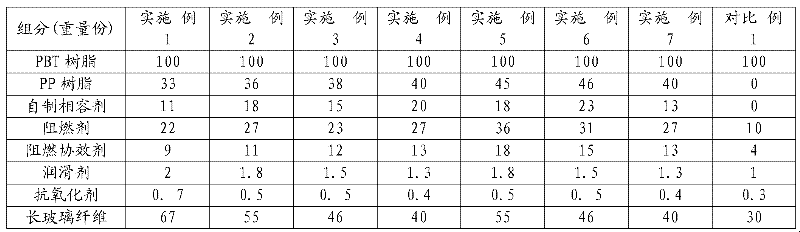

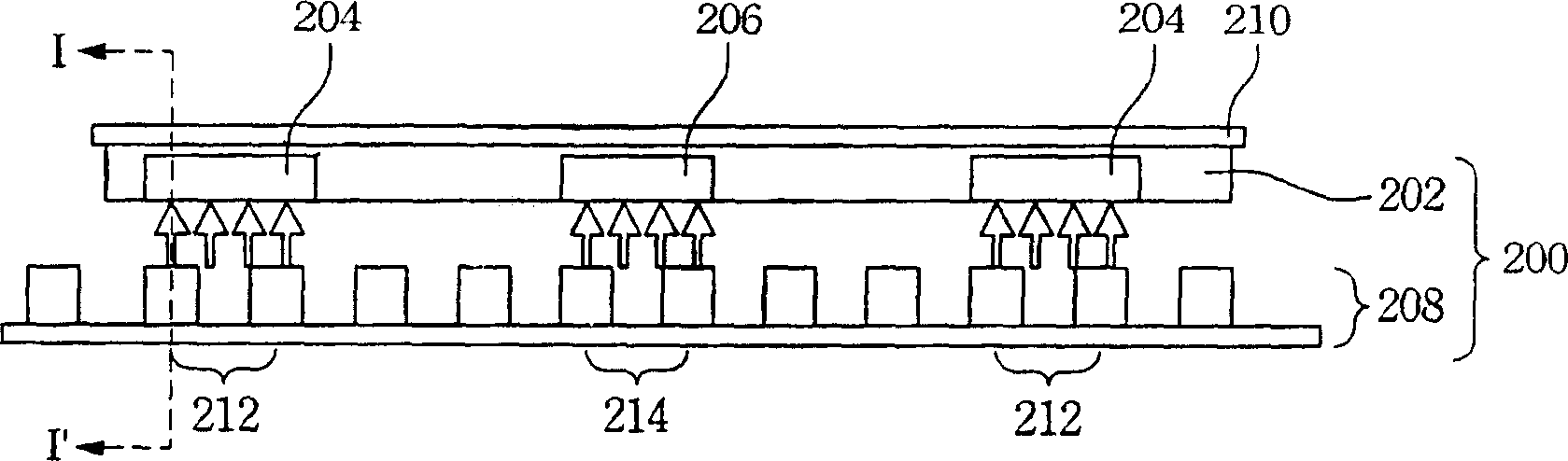

Glass fiber reinforced PBT (Poly Butylenes Terephthalate)/PP (Polypropylene) alloy material and preparation method thereof

The invention discloses a glass fiber reinforced PBT (Poly Butylenes Terephthalate) / PP (Polypropylene) alloy material and a preparation method thereof. The glass fiber reinforced PBT / PP alloy material consists of the following components in parts by weight: 100 parts of PBT resin, 30-50 parts of PP resin, 10-25 parts of home-made compatilizer, 20-40 parts of flame retardant, 8-20 parts of flame retardant synergist, 1-3 parts of lubricant, 0.2-1.5 parts of antioxidant and 35-70 parts of glass fiber, wherein the home-made compatilizer is one or more of PP-grafted maleic anhydride, POE (Polyolefin Elastomer)-grafted polyglycidyl acrylate or acrylic ester-grafted ternary ethylenepropylene elastomer. In the PBT / PP alloy material, the home-made PBT / PP alloy compatilizer is selected, so that the compatibility of a PBT / PP alloy is improved, the comprehensive mechanical performance is enhanced, and the technical problems of low gap impact performance, high production cost and poor PP size stability of the PBT in the prior art are solved greatly.

Owner:SHENZHEN KEJU NEW MATERIAL

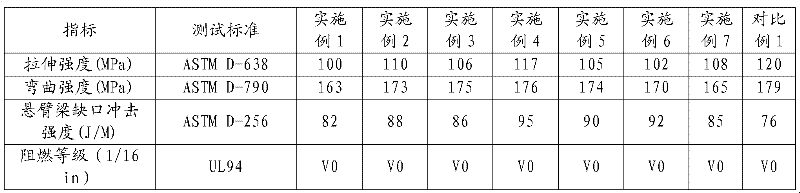

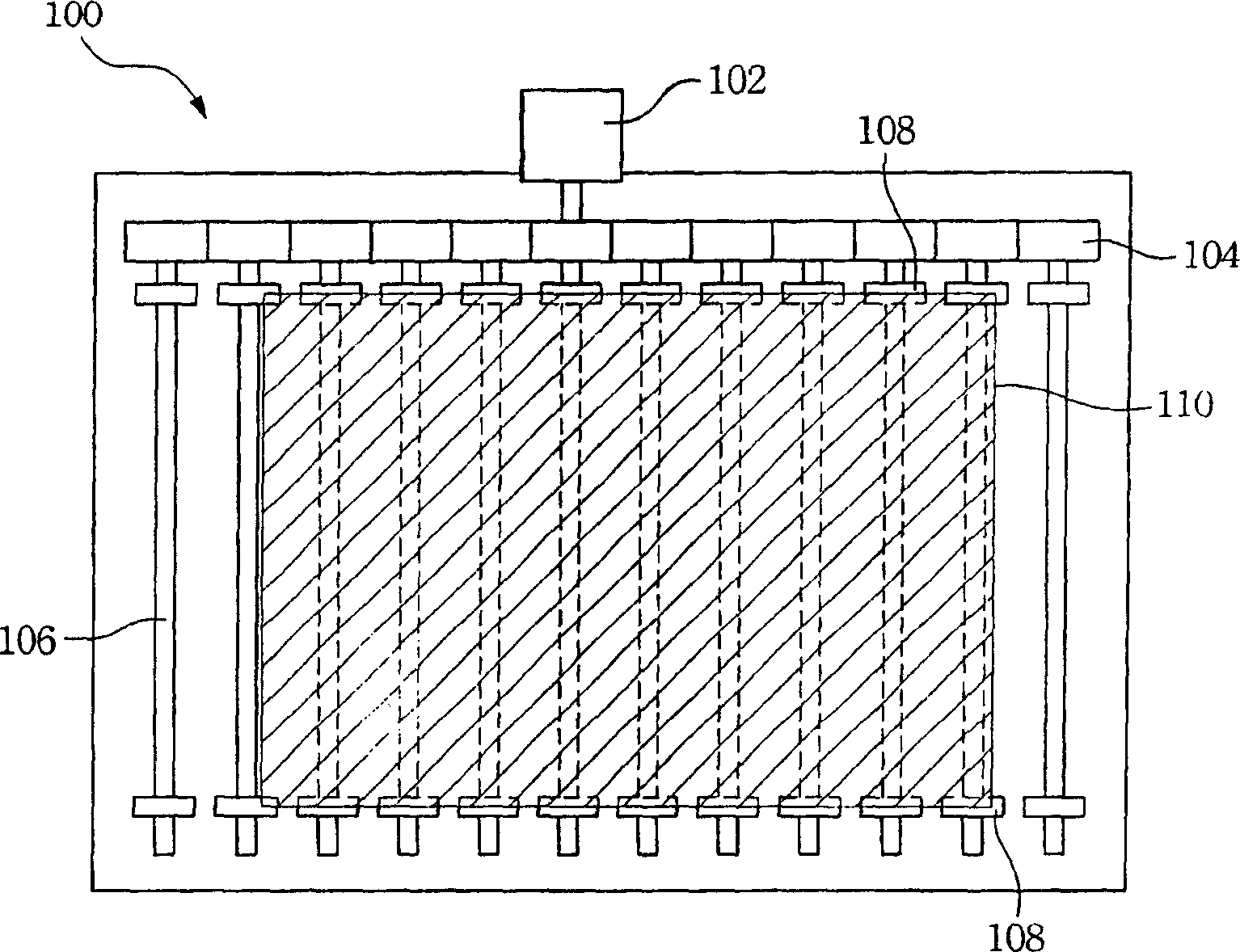

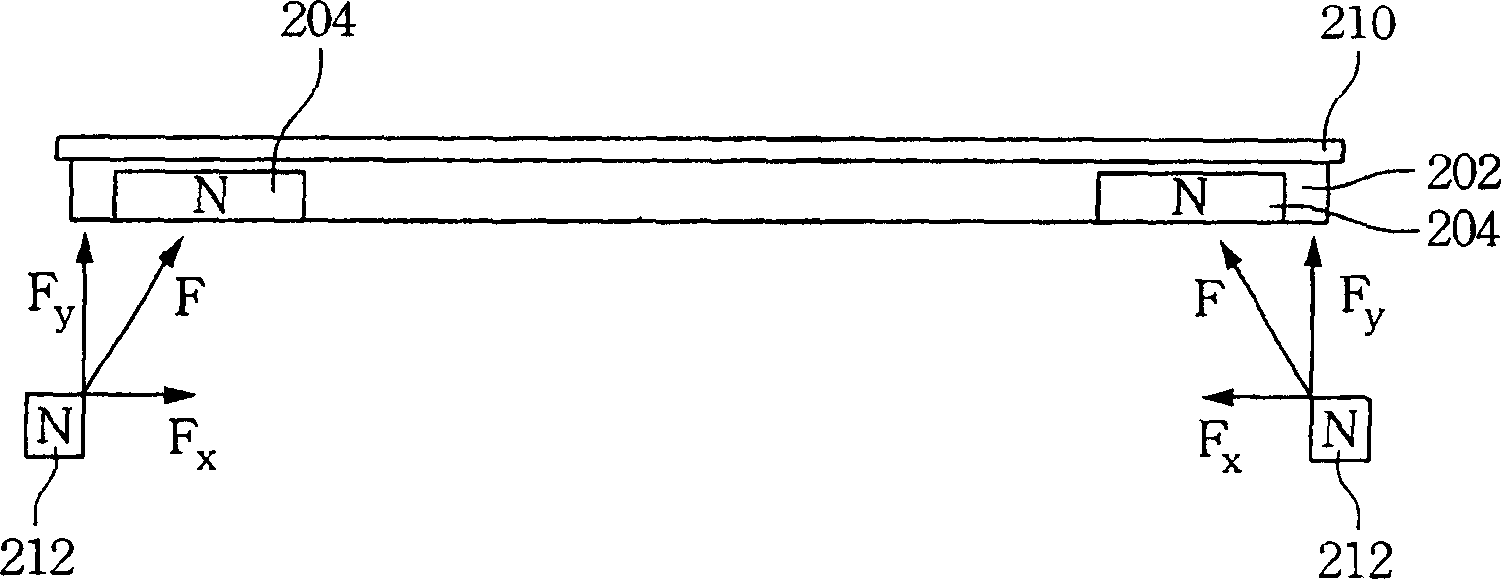

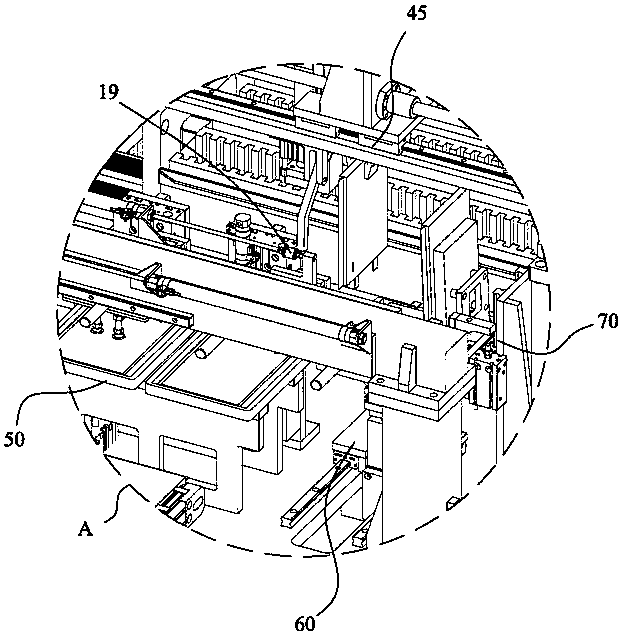

Substrate carrying device

InactiveCN1838397AStress averagingEliminate the problem of wear and tearCharge manipulationConveyor partsElectrical and Electronics engineering

Owner:AU OPTRONICS CORP

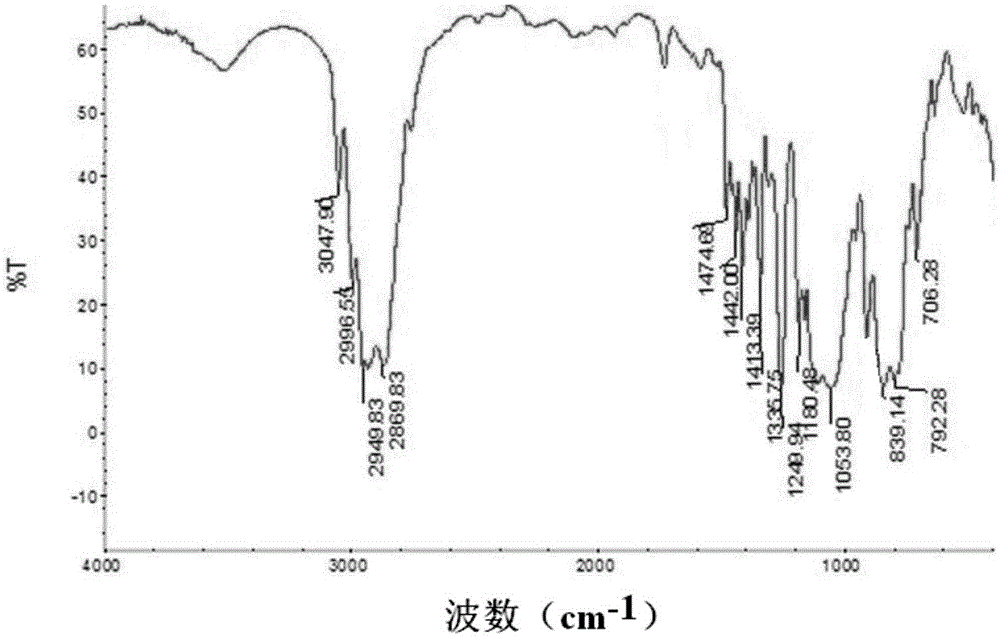

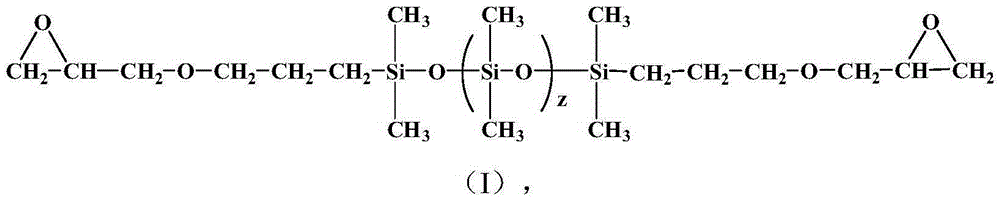

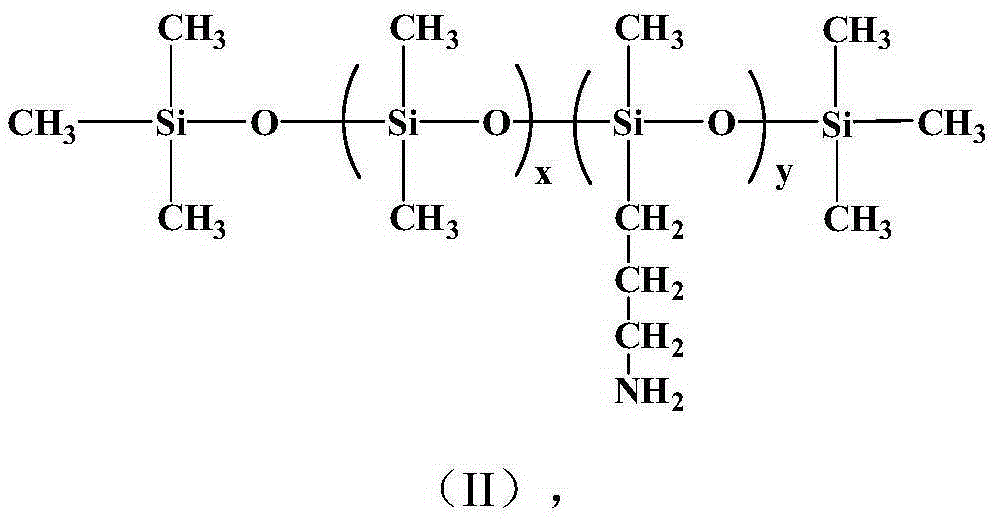

Compound for improving heat resistance of amino-modified silicone oil carbon fiber oil formulation and preparation and application thereof

ActiveCN105297427ASolve gelationSolve the problem of sticky rollerSilicon organic compoundsCarbon fibresFiberSide chain

The invention relates to a compound for improving the heat resistance of an amino-modified silicone oil carbon fiber oil formulation and preparation and application thereof. The compound has the structure shown in a formula (I). The compound is added into the oil formulation to be used by compounding with side chain aminopropyl-modified silicone oil with the kinematic viscosity of 80 cp-300 cp and the amino value of 0.15 mmol / g-0.20 mmol / g, the heat resistance of the oil formulation is greatly improved, and the problems of glue solidifying and roll sticking of the modified silicon oil formulation and modified silicon oil formulation embrittling and fracturing which occur in pre-oxidizing at 350 DEG C are solved.

Owner:新元化学(山东)股份有限公司

Health food for protecting liver and adjusting blood fat and method for preparing the same

InactiveCN1466990AHigh activityReduce cholesterolDigestive systemUnknown materialsCordycepsActive component

A health-care food for protecting liver and regulating blood fat is prepared through extracting active components from red sage root, peach kernel and gynostemma pentaphyllum in sub-boiling water, adding chitosan, flocculating setting, filter, mixing with fermented cordyceps powder, spray drying, adding starch and dextrin, mixing, granulating, drying, tabletting and coating.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

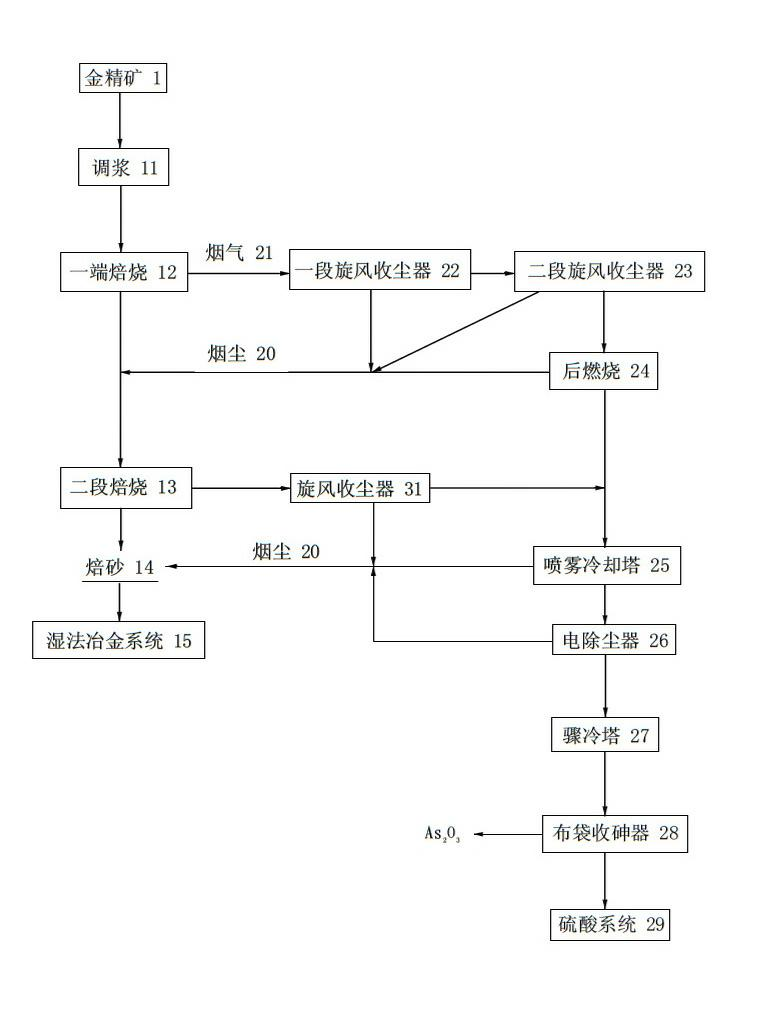

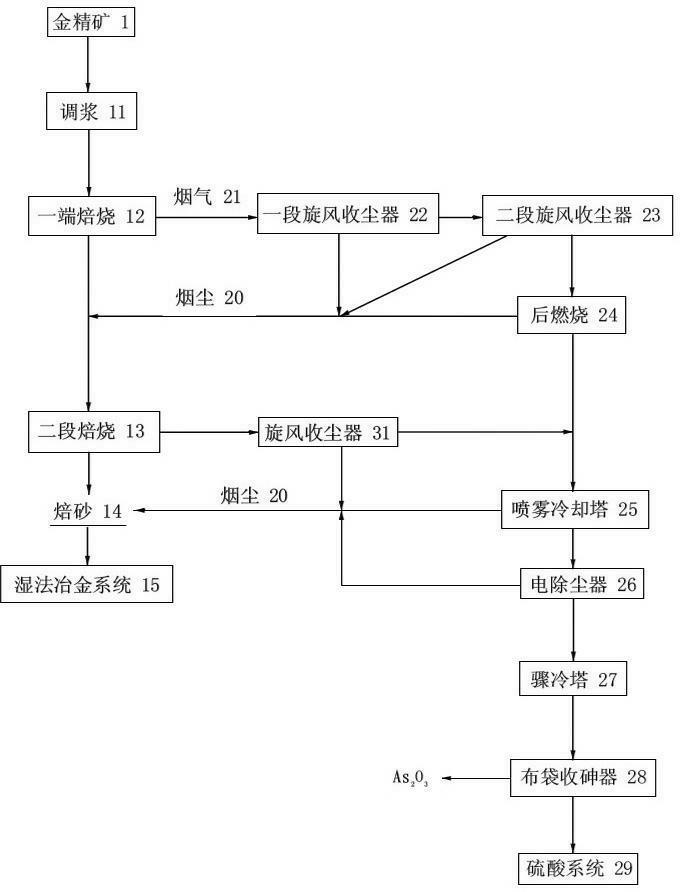

Arsenic removal process containing post-combustion technology

InactiveCN102560084ASmooth production processAdvanced process indicatorsProcess efficiency improvementChemistryPrecious metal

The invention relates to an arsenic removal process containing a post-combustion technology and belongs to the technical field of a gold and silver extraction method for precious metal smelting. The arsenic removal process comprises the following steps of: treating gold concentrate containing arsenic by adopting a two-stage roasting process, removing the arsenic as well as sulphur and changing an ore structure, generating porous roasted ore to facilitate next cyaniding operation and improve the leaching rate of gold, and recovering valuable elements in the concentrate; through controlling the air quantity, removing the arsenic and the sulphur in the first-stage roasting under the anoxic roasting atmosphere, carrying out sulfatizing roasting in the second-stage roasting under the oxygen atmosphere; and after flue gas generated by roasting is subjected to arsenic removal, producing sulfuric acid and generating the arsenic into thick white arsenic for sales. The arsenic removal process has the beneficial effects that a traditional process is improved, a post-combustion process is increased on the basis of the traditional process, the problems of initial sulfur condensation and non-arsenic trioxide (As2S3) compound deposition caused by incomplete combustion of roasted flue gas are solved, and the effects of smooth production process and advanced process index are achieved.

Owner:长春黄金设计院有限公司

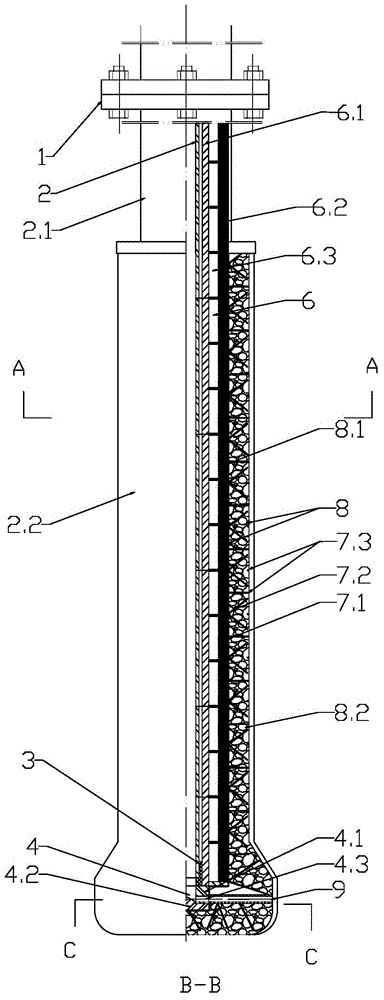

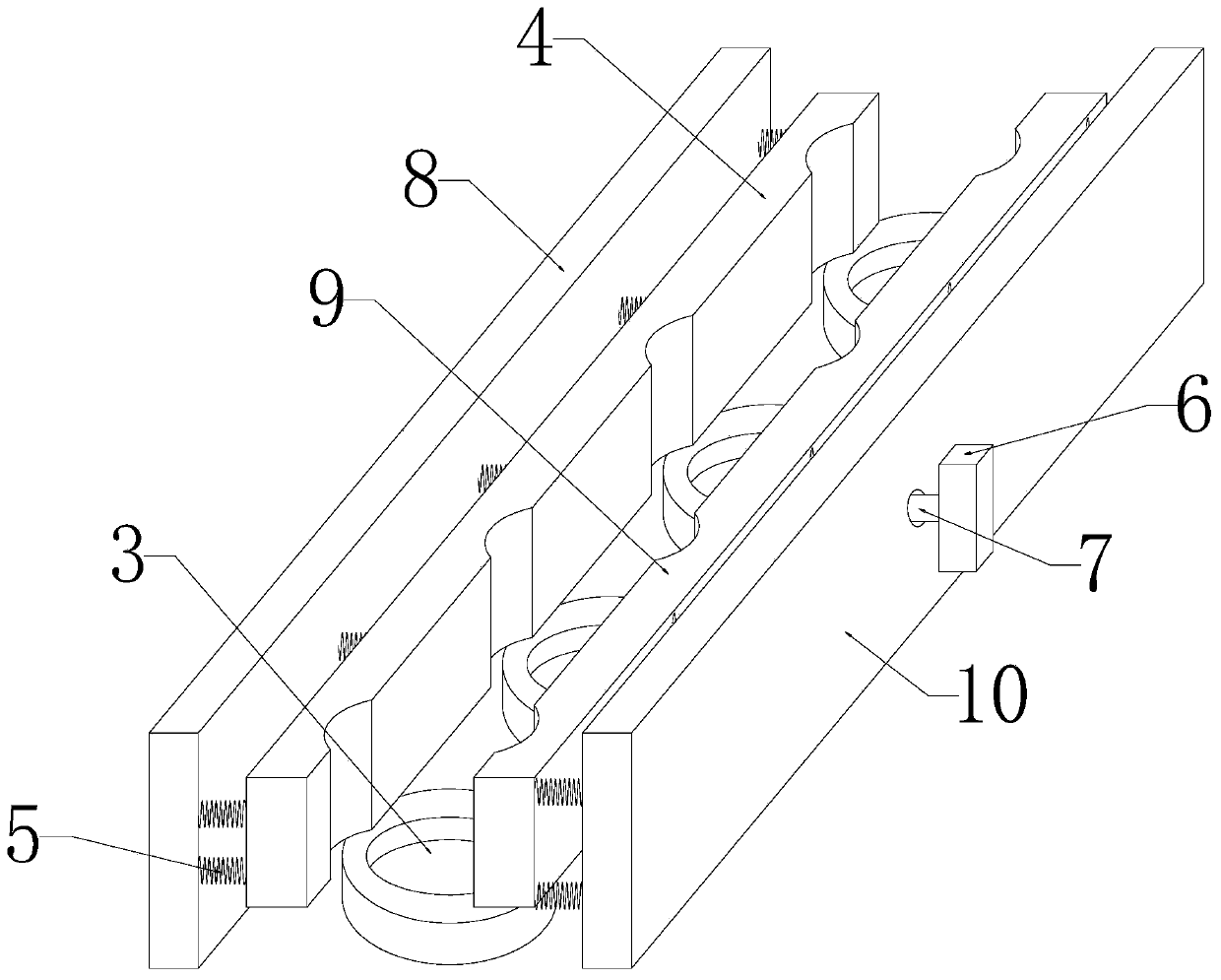

Direct injection molten iron desulphurization spray gun

The invention discloses a direct injection molten iron desulphurization spray gun for a metal particle magnesium or magnesium-based or calcium-based desulphurization agent. The direct injection molten iron desulphurization spray gun comprises a connecting flange and a gun barrel which are sequentially connected and communicated, wherein the gun barrel comprises a connecting section gun barrel and a gun body section gun barrel; the connecting section gun barrel comprises a gun core; a distributor is connected with the lower end of the gun core of the gun body section gun barrel; the distributor comprises an upper end short connecting pipe, a lower end plug platform and a plurality of through holes formed in the wall of the short connecting pipe; and each through hole is communicated with a jetting pipe, and the jetting pipes are distributed in a fire-proof pouring material liner positioned outside the side wall of the distributor. The direct injection molten iron desulphurization spray gun disclosed by the invention can be used for enhancing the jetting strength, extending the desulphurization reaction area and intensifying the gasification and dissolution of metal particle magnesium through structural design, and can be used for enhancing the adaptability on low-quality metal particle magnesium and jetting desulphurization of molten iron tanks with different sizes, extending the adaptive capacity of a process and reducing the consumption cost of the molten iron desulphurization metal particle magnesium through the improvement of desulphurization process steps.

Owner:武汉钢铁有限公司

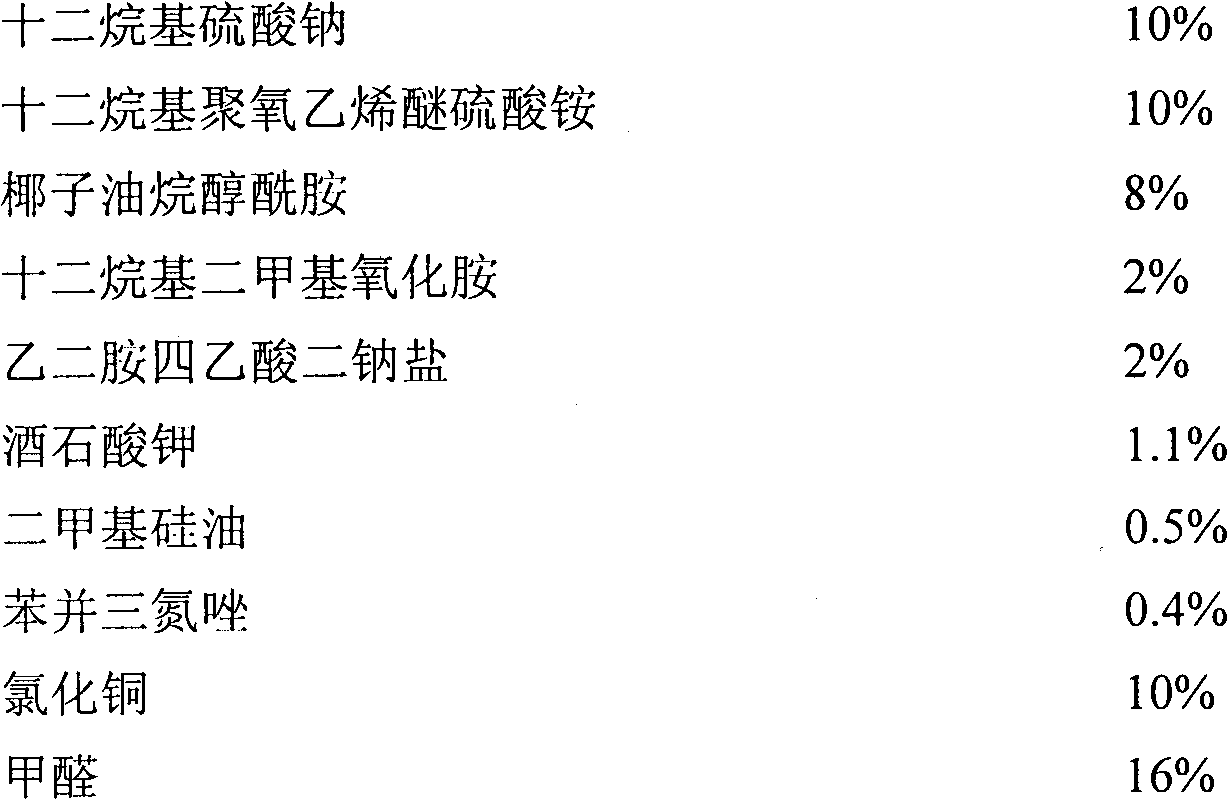

A method for preparing nanometer copper powder in a small molecule viscous medium

The invention discloses a method for preparing nano copper powder in a micromolecular viscous medium. The method comprises the steps of: by taking a surface active agent, salt, a complexing agent, an antifoaming agent, an antioxidant, cupric salt, a reducing agent and deionized water as raw materials and according to the proportion of (0.001-95 percent) : (0.001-95 percent) : (0.001-80 percent): (0.001-75 percent): (0.001-70 percent): (0.001-75 percent): (0.001-70 percent): (0.001-98 percent), preparing the micromolecular viscous medium by using the surface active agent, the salt, the complexing agent, the antifoaming agent, the antioxidant and the deionized water; adding the cupric salt and uniformly mixing; adding the reducing agent and mixing; adding the deionized water to dilute so asto reduce the degree of viscosity according to a mass ratio of 1:0.5-10 of the total quantity of all materials abovementioned to the deionized water after the reaction completes; and obtaining nano copper powder through filter-pressing, deionized water washing, acetone washing and vacuum drying. According to the method disclosed by the invention, the raw materials selected in the invention are easily available, the manufacturing technique is simple and short, the production efficiency is high, the production cost and the energy compunction are low, and powder has low possibility of agglomeration and has good dispersibility, therefore the method is suitable for large-scale production and solves the problems of easy oxidation and easy agglomeration of the nano copper powder existing in the traditional chemical preparation method.

Owner:NANJING FORESTRY UNIV

Process for producing mushroom concentrated juice

InactiveCN101991091AWithout spoiling the flavorReserve the tasteFood preparationShiitake mushroomsCentrifugal separation

The invention discloses a process for producing mushroom concentrated juice which has the advantages of convenience of production, no enzymic preparation addition, short production cycle, mushroom taste reservation and convenience of conservation. The process comprises the steps of: leaching mushroom handles or refuse parts, filtering, performing centrifugal separation, oscillation filtering and vacuum low-temperature instantaneous concentration, sterilizing the concentrated liquid, and filling, cooling and refrigerating.

Owner:FUJIAN CHANGLYU FOOD & BEVERAGE CO LTD

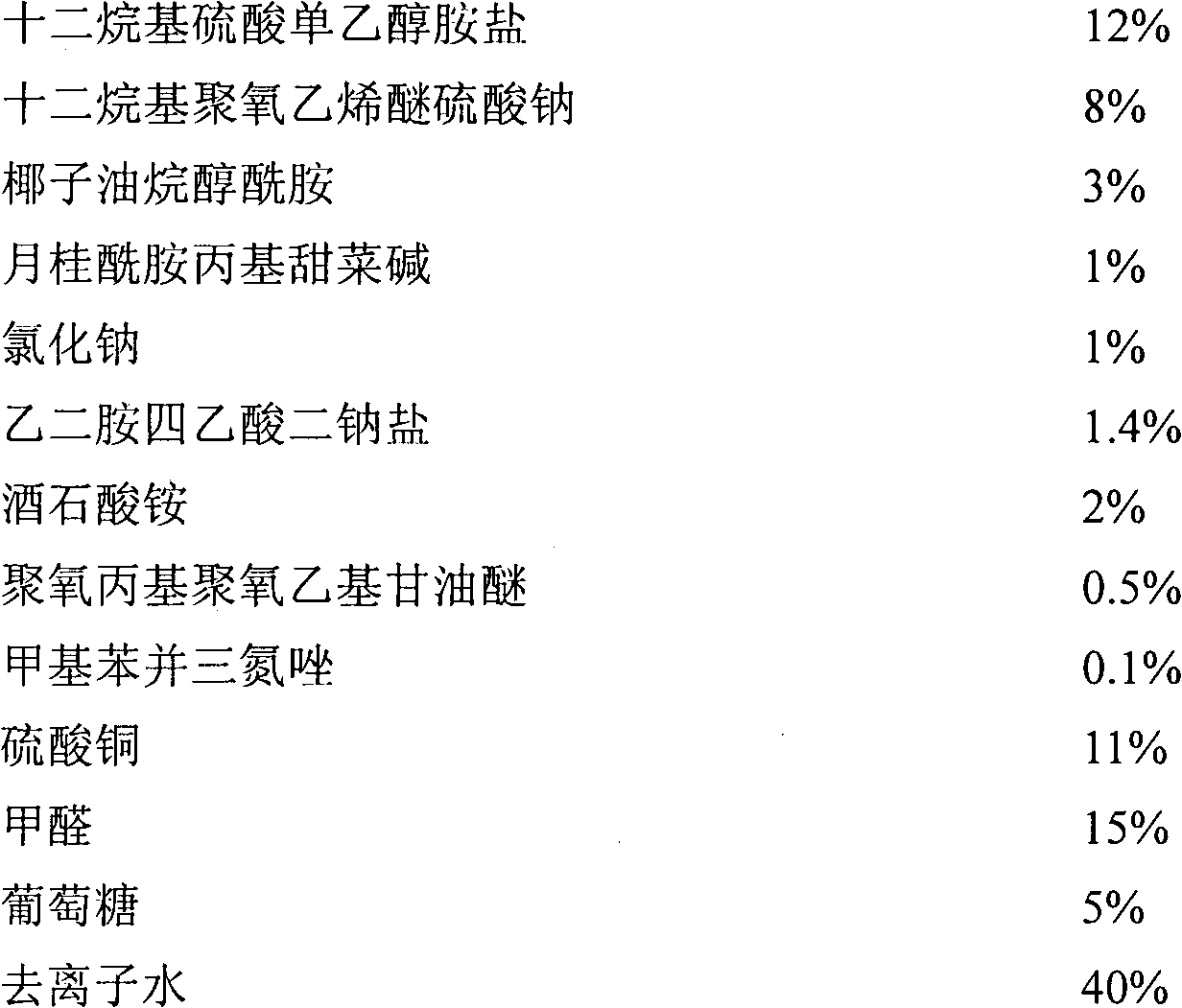

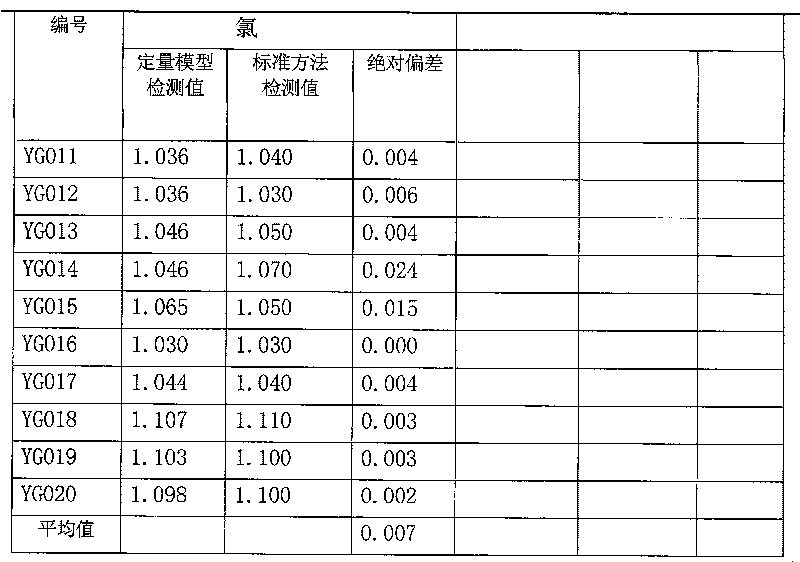

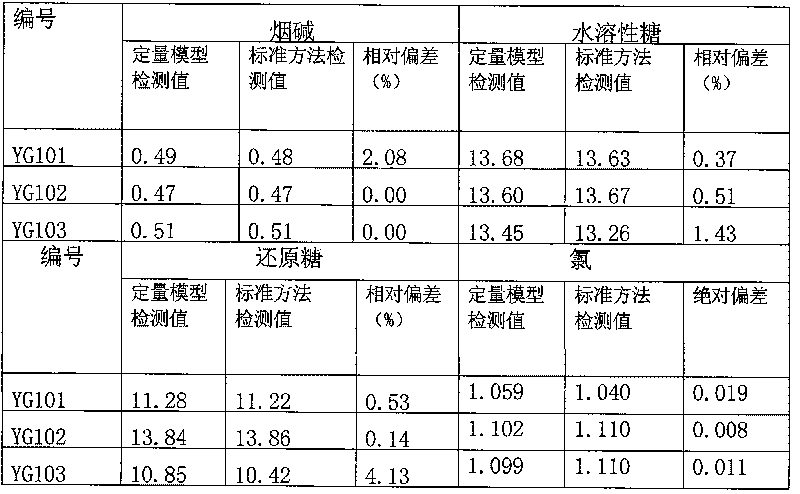

Method for detecting physical and chemical indexes of reconstituted tobacco extracting solution and tobacco extracting paste by near infrared spectrum detection paper making method

InactiveCN101710072ARapid determination of chemical compositionRapid determination of propertiesColor/spectral properties measurementsInfraredQuantitative model

The invention relates to a method for detecting physical and chemical indexes of a reconstituted tobacco extracting solution and a tobacco extracting paste by a near infrared spectrum detection paper making method, which comprises the following steps of: carrying out the detection of the physical and chemical indexes on collected samples one by one by a standard method to obtain quantitative reference data; scanning and collecting spectrums of all the samples, carrying out spectrum preprocessing for eliminating the influence of noise and baseline drift; then corresponding spectrum data to the reference data of all physical and chemical indexes obtained by the standard method one to one and establishing a quantitative model by a partial least square method and mutual verification; carrying out accuracy and reproducibility inspection and then storing the quantitative model in a computer. When the physical and chemical component content of the reconstituted tobacco extracting solution and tobacco extracting paste samples to be detected needs to be detected, the near infrared spectrum data of the samples to be detected are scanned and collected, and the physical and chemical indexes of the reconstituted tobacco extracting solution and the tobacco extracting paste in the paper making method can be detected by calling the analysis of the quantitative model. The method has rapid and accurate detection and low analyzing cost without damaging the analyzing samples and pollution.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD +1

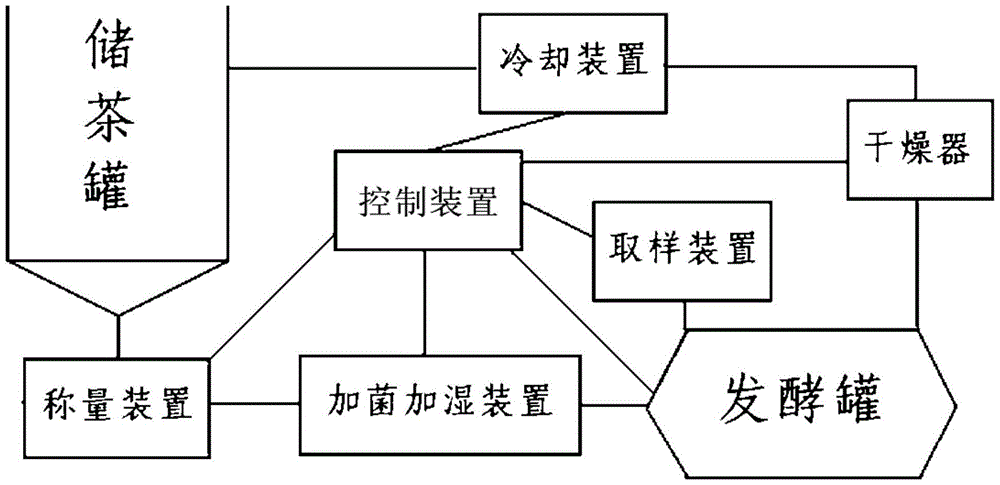

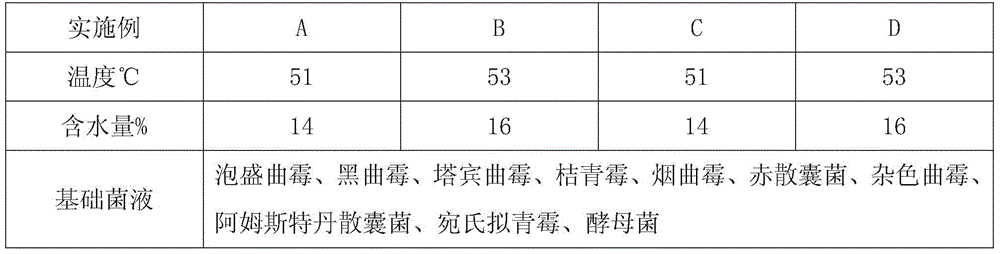

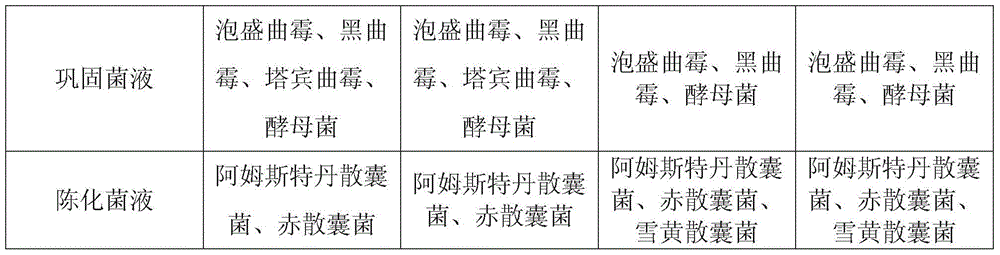

Liupao tea automatic pile fermentation technique and fermentation strain composition

ActiveCN105695339AShorten the fermentation cycleImprove filtration efficiencyFungiPre-extraction tea treatmentAutomatic controlFlavor

The invention discloses a Liupao tea automatic pile fermentation strain composition which comprises a base bacterium solution, a consolidation bacterium solution and an aging bacterium solution. The bacterium solutions contain Aspergillus awamori, Aspergillus niger, Aspergillus tubingensis, penicillium citrinum, Aspergillus fumigatus, Eurotium rubrum, Aspergillus versicolor, Eurotium amstelodami, Paecilomyces variotii, Eurotium niveoglaucum, saccharomycetes and other beneficial microorganisms. On such basis, the inventor establishes the corresponding fermentation technique and equipment; and on the premise of not changing the upstream and downstream main production techniques of the original pile fermentation, the beneficial microorganism florae are added to control the growth of harmful infectious microbes, thereby enhancing the fermentation efficiency, shortening the pile fermentation period, and keeping the special thick flavor of the traditional Liupao tea. The pile fermentation automatic control system is utilized to dynamically monitor and control the changes on temperature, humidity and florae in the whole fermentation process, thereby implementing automation, continuity and high efficiency of the production technique, and ensuring the Liupao tea product to have safe and reliable quality and high and stable quality.

Owner:GUANGXI UNIV

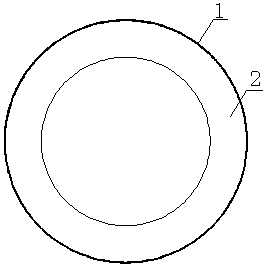

Rotary kiln applied to ferronickel reduction production technology and construction method thereof

The invention discloses a rotary kiln applied to ferronickel reduction production technology and a construction method thereof. The rotary kiln comprises a rotary kiln casing and fire-proof materials bricked in the rotary kiln casing. The rotary kiln is characterized in that a heat-resistant alloy steel cylinder with the same coaxiality as the rotary kiln casing is fixed on the surface of the fire-proof materials. According to the invention, the production efficiency for directly reducing and smelting ferronickel by the rotary kiln is improved, the production cost is reduced, formed rings in the rotary kiln can be processed effectively and timely under the condition that operation of the rotary kiln is not stopped, and the service life of the fire-proof materials used in the reduction concentration phase is prolonged.

Owner:王景军

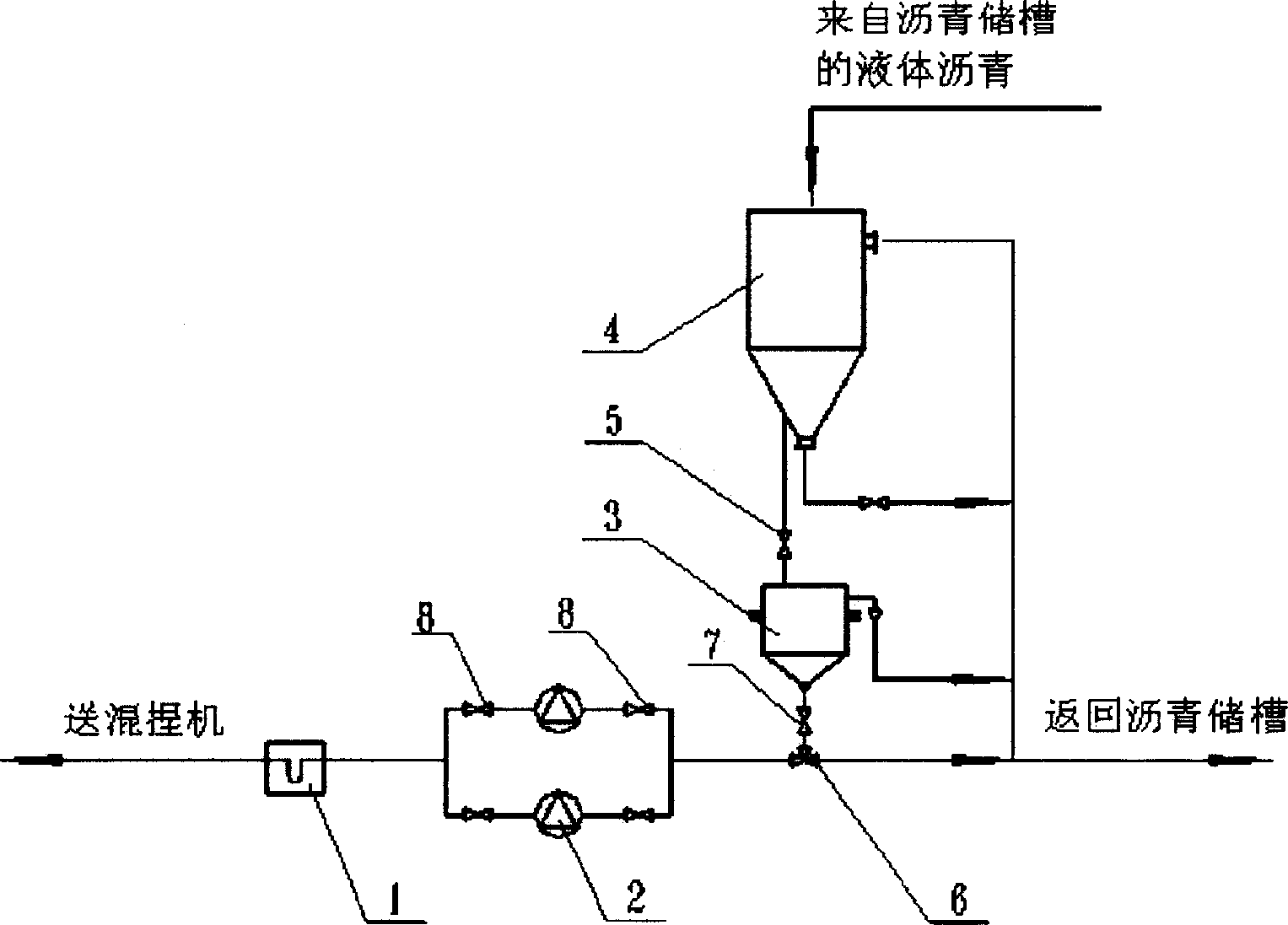

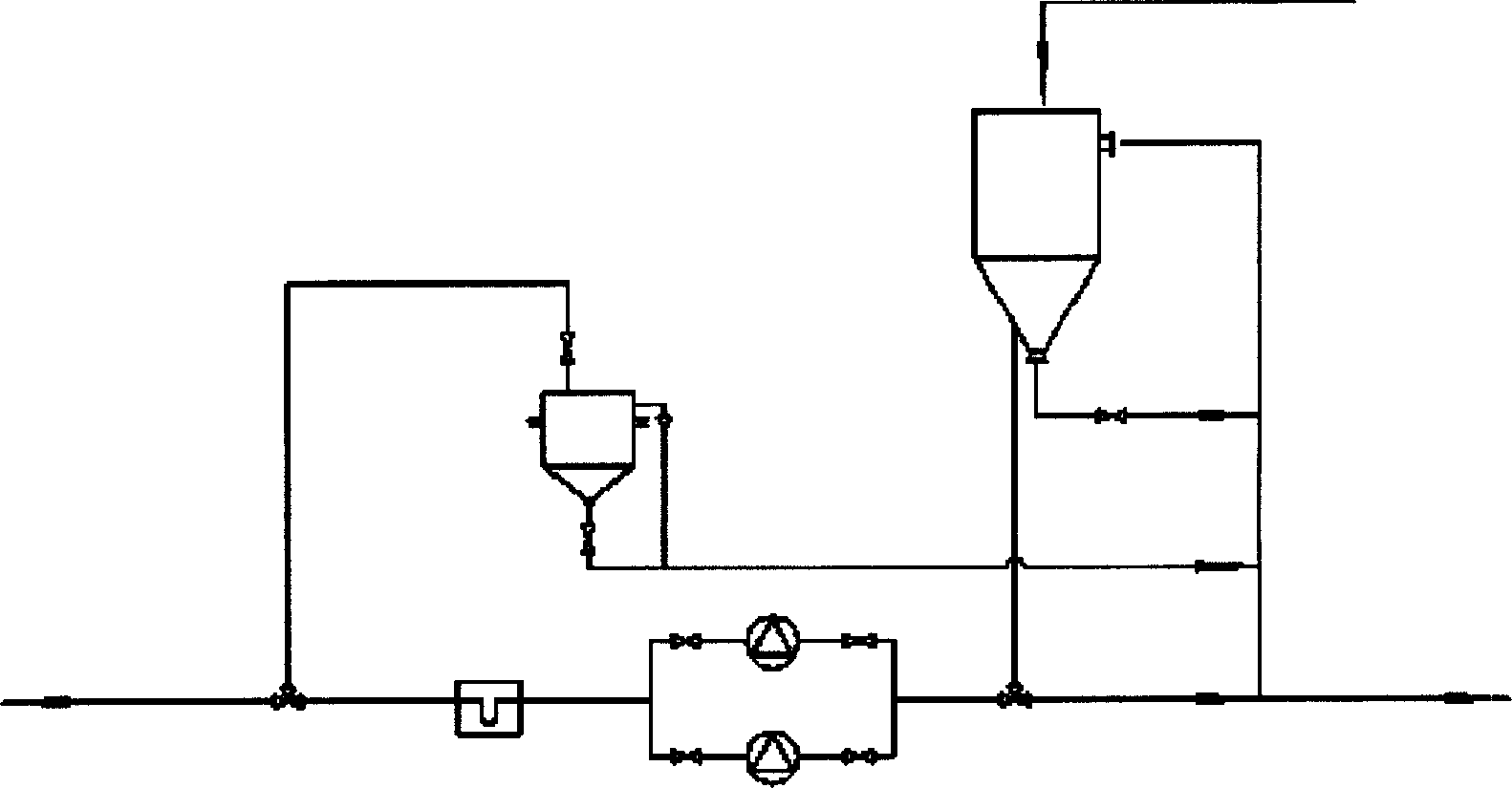

Liquid asphalt proportioning system flow and device

ActiveCN1752295AEliminate cloggingSmooth production processMixing operation control apparatusMixer accessoriesEngineeringAsphalt

A system for proportioning liquid asphalt is composed of high-position tank, check tank, two-way valve connected between outlet of high-position tank and inlet of check tank, asphalt pump, another two-way valve connected between outlet of check tank and tree-way valve connected with asphalt pum, and mass flowmeter connected to asphalt pump. Its technological flow includes such steps as comparing the flow signal from mass flowmeter with the flow setting for regulating the rotation speed of asphalt pump, and calibrating the mass flowmeter by comparing the weighing result of check tank with the result displayed by mass flowmeter.

Owner:GUIYANG AL-MG DESIGN & RES INST

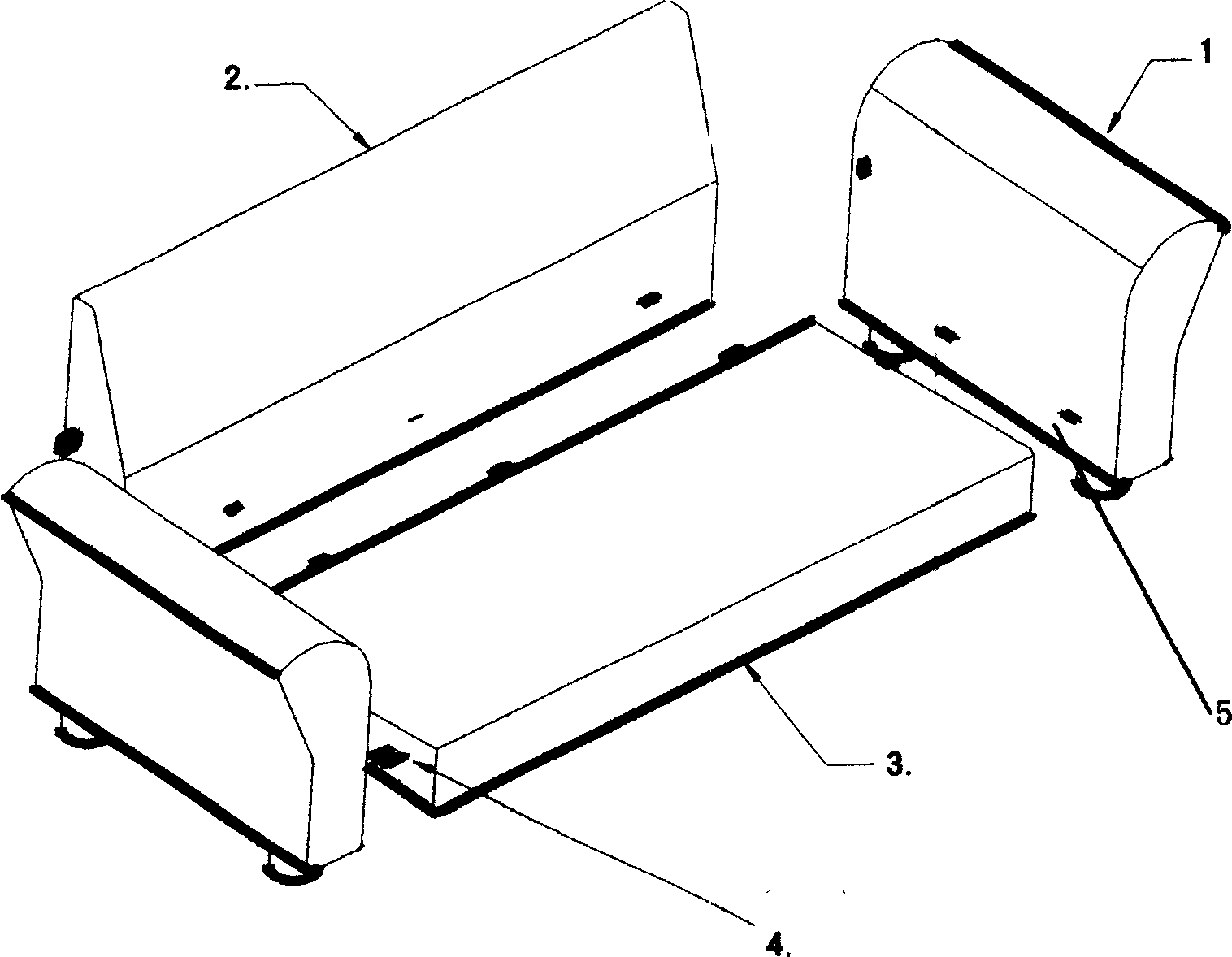

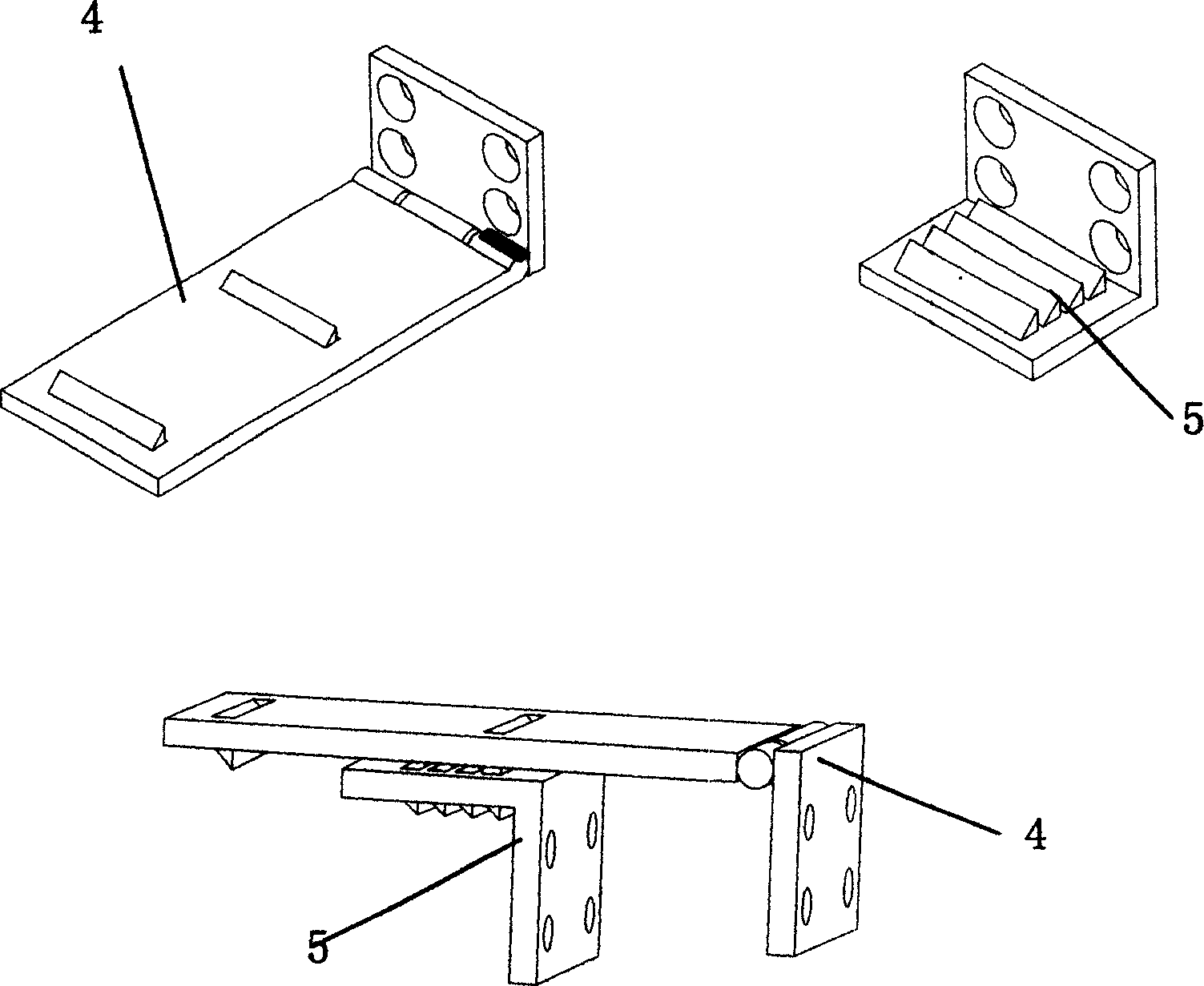

Sofa with parts interchangeable, free assembly and its production method

InactiveCN1593294AFirmly connectedSmooth production processBenchesDismountable chairsEngineeringBack support

The invention relates to an easy assembly sofa and method for making same, wherein the sofa comprises separate sofa armrests, a back support, a bottom frame and connecting pieces which facilitates easy sofa assembly. The method according to the invention has the advantages of various patterns, simple process for manufacturing and increased production efficiency.

Owner:瞿月文

Vermicelli and production method thereof

The invention relates to vermicelli which comprises the following components in parts by weight: 55-65 parts of sweet potato starch,10-14 parts of potato starch, 7-9 parts of corn starch, 1.4-1.8 parts of vermicelli opening agent and proper amount of water, wherein the vermicelli opening agent is the vermicelli opening agent containing no alum in another patent application of the applicant. The invention further discloses a production method of the vermicelli. The production method comprises the following steps of: ingredient mixing, stirring, powder processing, powder cutting, natural aging, soaking, vermicelli bulking, cleaning, dehydrating and drying, powder selecting and weight, drying, natural moisture absorbing and regaining and the like, and finally a finished product is prepared. With the production method for producing, the process flow is smooth, the aging time is short, the vermicelli bulking is easy, the production effect is improved, the labor productivity is improved, the product performance is improved, the prepared vermicelli can not stick together, can not break, can not make soup muddy, has no odor, and is glittering and translucent, the color of the vermicelli can be adjusted randomly from taupe to white according to requirements, all the minor ingredients an be purchased from the market, the vermicelli has no toxic and side effects, has production cost, and is suitable for industrialized production or small-scale production.

Owner:许兆宏

Vermicelli and its production process

InactiveCN1387785AImproved performance of the finished productNo side effectsFood preservationFood preparationParaffin waxCorn starch

The present invention provides alumless vermicelli agglutinant which includes high effective composite emulsifier, sodium carboxymethyl cellulose, sodium tripolyphosphate, tartaric acid, potassium hydrogen tartarate, sodium bicarbonate, paraffin wax, edible salt, acid denatured potato starch. The present invention also discloses alumless vermicelli including sweet potato starch, potato starch, corn starch etc. The present invention also discloses the production method of alumless vermicelli, said method can shorten ageing time, raise product performance, improve manufacturing efficiency etc.

Owner:陈朝晖

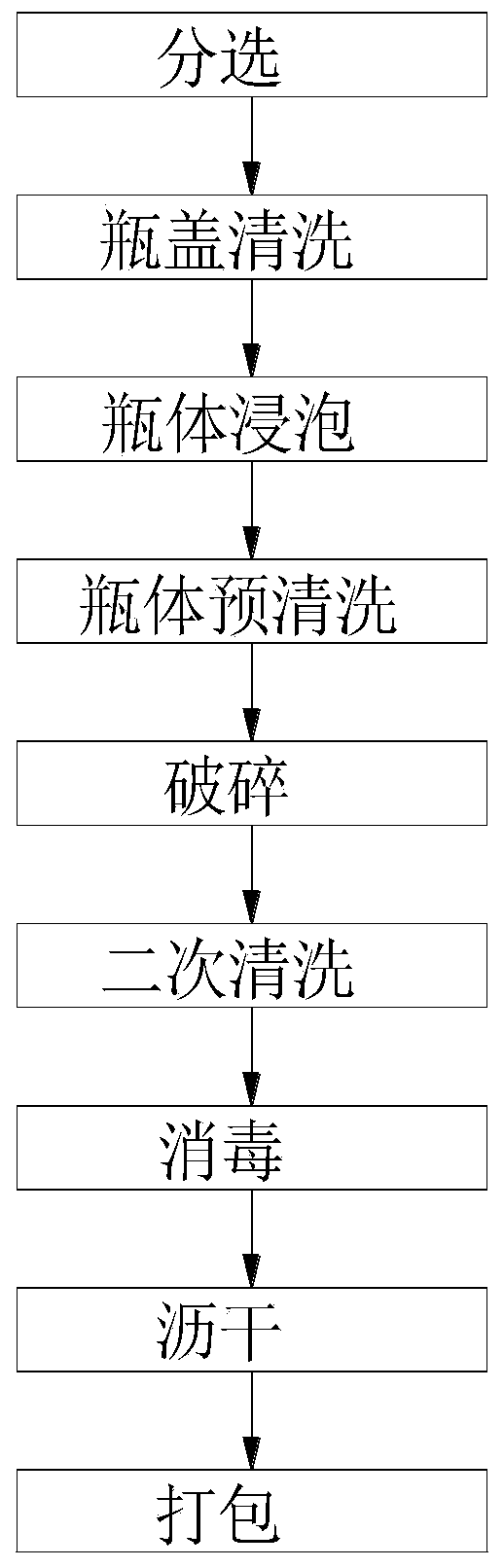

Treatment and recovery method for waste chemical reagent bottles

InactiveCN110449440AEasy to separateRealize secondary useSolid waste disposalHollow article cleaningRecovery methodResource utilization

The invention discloses a treatment and recovery method for waste chemical reagent bottles. The method comprises the following steps of carrying out sorting, cleaning bottle caps; soaking bottle bodies; pre-cleaning the bottle bodies; carrying out crushing; carrying out secondary cleaning; carrying out disinfecting; carrying out draining; and carrying out packaging. According to the treatment andrecovery method for the waste chemical reagent bottles, pollutants contained in the bottles can be fully separated, reutilization of the glass bottles is realized, by means of a method for carrying out cleaning and crushing simultaneously, no dust is generated, the method is efficient, energy-saving and free of dust pollution, meanwhile, waste gas and waste water generated in the treatment processare reasonably collected and are subjected to corresponding treatment, a production process is smooth, energy-saving, environmentally-friendly and pollution-free, the bottle bodies and the bottle caps of the waste chemical reagent bottles are treated separately, meanwhile, glass bottle caps and plastic bottle caps are treated separately, so that the glass bottle caps and the plastic bottle caps can be prevented from being abandoned, the resource utilization rate is increased, and meanwhile, cleaning is more sufficient by means of the classification treatment, so that later reutilization is facilitated.

Owner:无锡添源环保科技有限公司

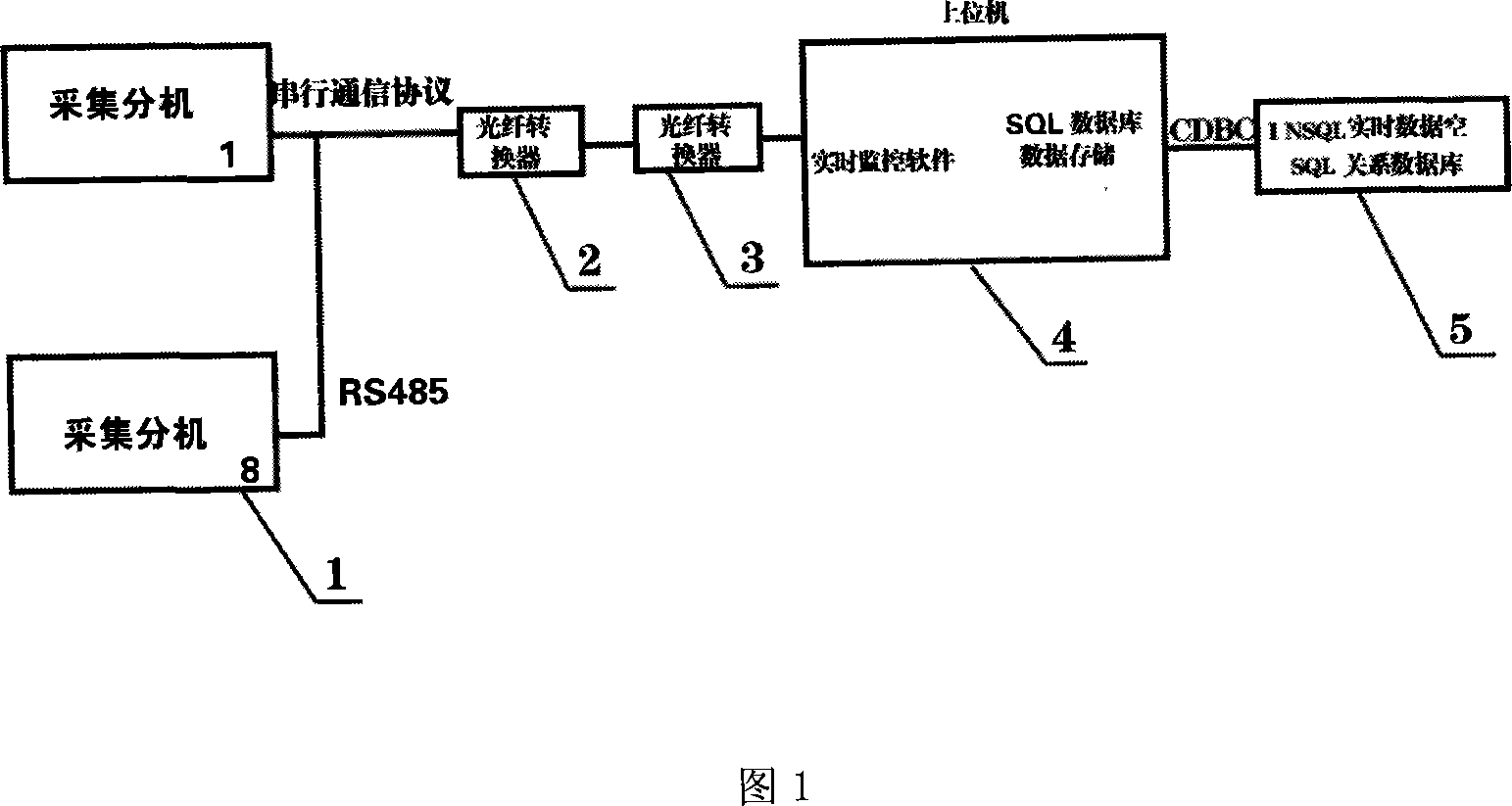

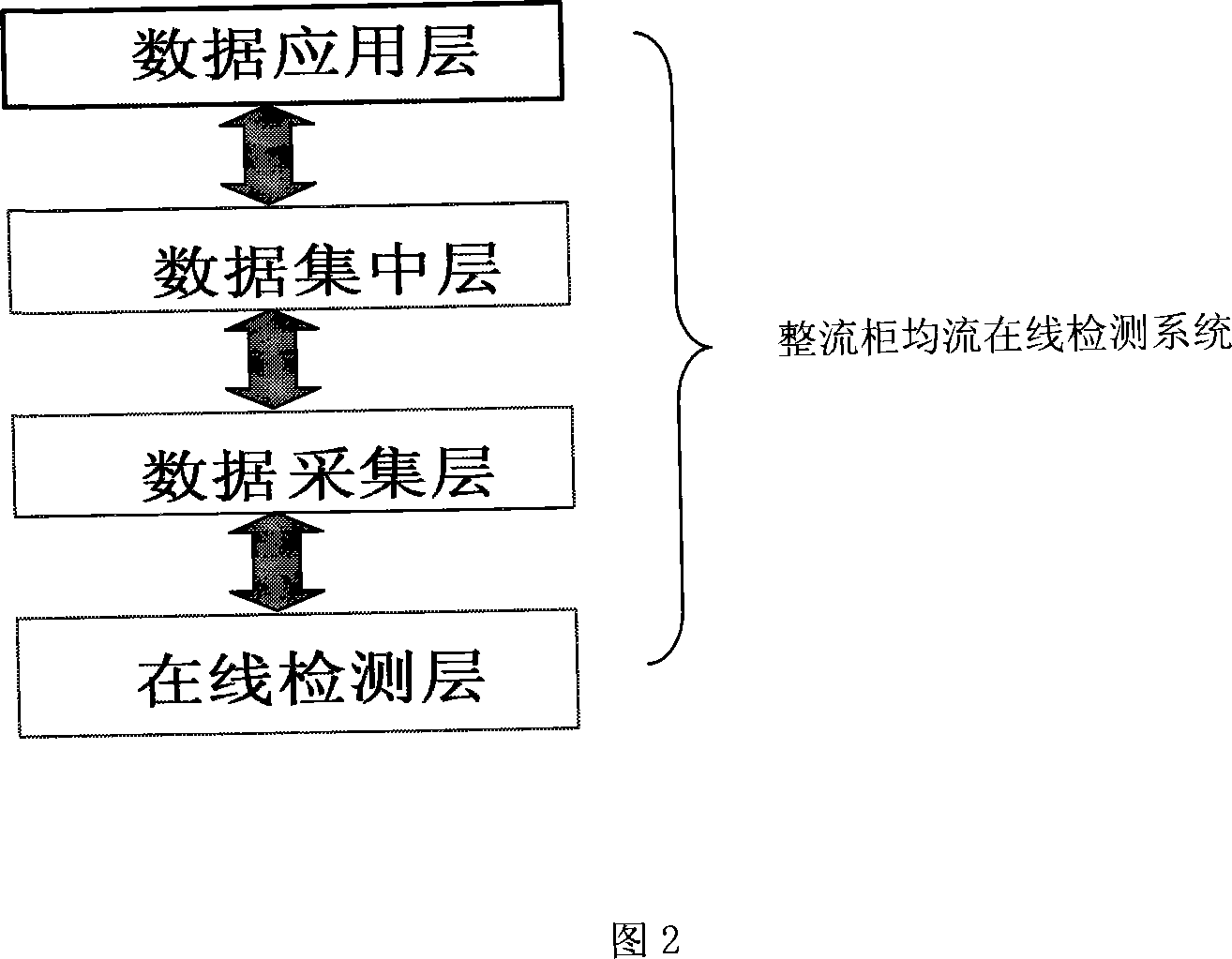

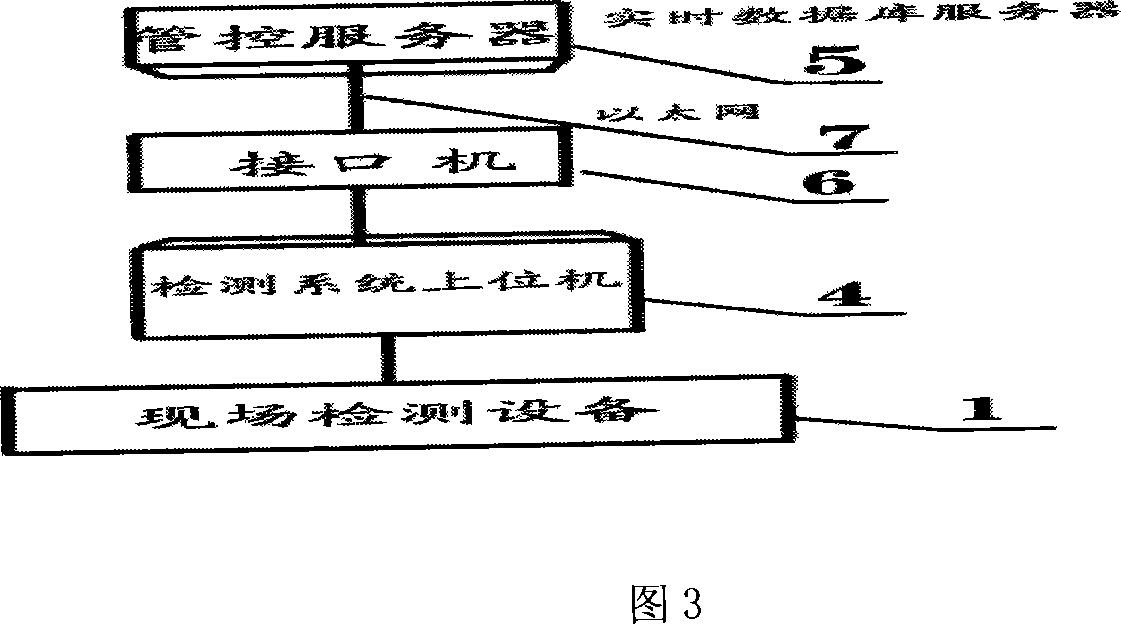

Aluminum electrolysis rectifier cabinet equal current on-line detection method

InactiveCN101078741ASafe and stable operationProvide quicklyElectric signal transmission systemsCurrent/voltage measurementAutomatic controlTransformer

The invention relates to a development and the application for on-line detecting technology for aluminum electrolysis power-supply rectifying equipment, in detail a current-sharing on-line detecting method for aluminum electrolysis rectifying cabinet. The invention comprises following procedures that on-line detection, data collection, data concentration and data application. The invention possesses following benefits. The invention realizes the integration of transformer current-sharing detection system and accomplishes management network of business management so that data share, adjusting management production resource scientifically and dynamically, in time optimizing and organizing production are realized; dynamic monitoring, dynamic analyzing and stable producing for rectifying element in transformer current-sharing cabinet are realized, producing flow is insured smooth; and modern enterprise target with enterprise information, information resource, transfer network and scientific management is realized. The on-line detecting method is suitable for automatic control system of aluminum electrolysis power supply system.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Lightweight building gypsum building block and production method thereof

InactiveCN107352933AMeet the production process requirementsSmooth production processCeramicwareCellulosePore distribution

The invention discloses a lightweight building gypsum building block and a production method thereof. The lightweight building gypsum building block is molded by mixing the following raw materials in parts by weight: 75-85 parts of phosphogypsum, 10-15 parts of fly ash, 32-45 parts of water, 0.5-1.0 parts of cellulose, and 8-10 parts of a comprehensive foaming delayed coagulant. Compared with the prior art, the gypsum solidification time is 8-12 min, the production technology requirement of the gypsum building block can be satisfied, and the smooth operation of the production technology is guaranteed. The aperture of a foaming plasterboard is 0.1-0.18 cm, the pore distribution is uniform, the enough intensity and breaking-resistant strength of the plasterboard can be guaranteed, and the surface is flat and smooth. Through multiple tests, the compressive strength of the product is 3.9-4.1 MPa, the flexural intensity is 2.0-2.1 MPa, the softening coefficient is 0.68, the unit solid weight is decreased by 20-30%, the heat conduction coefficient is between 0.086W( / m.k) and 0.13W( / m.k), sound insulation and heat insulation performances are obviously increased, through detection, the compressive strength is increased by 18.3%, and the flexural intensity is increased by 51.2%.

Owner:南充市高坪区江峰石膏有限公司

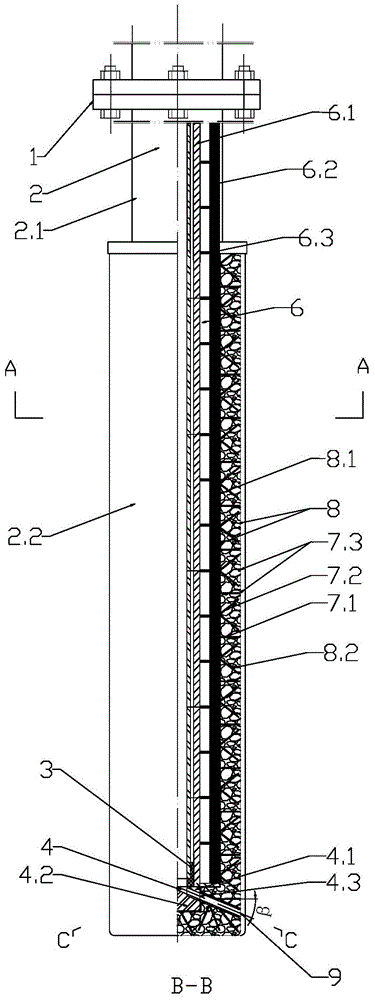

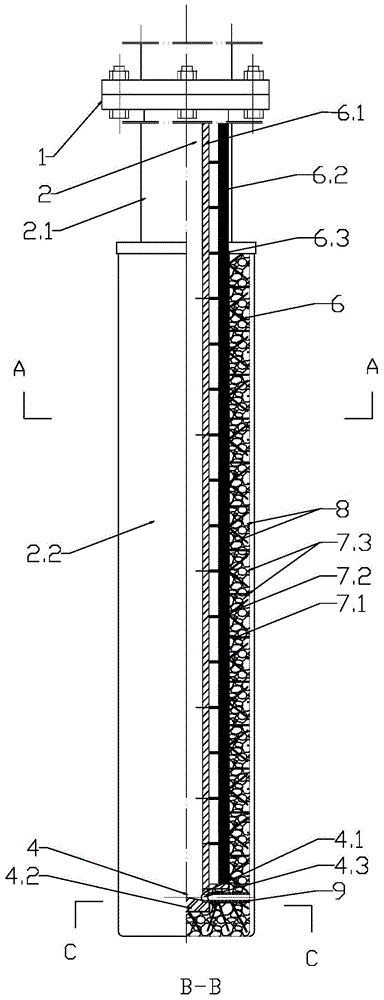

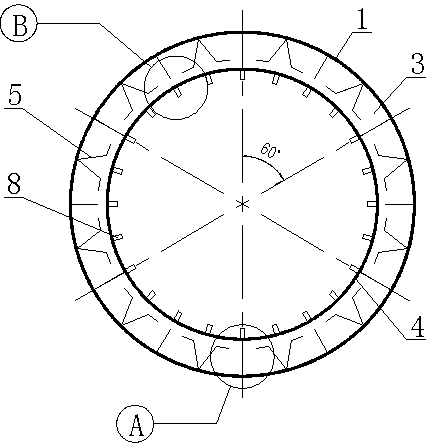

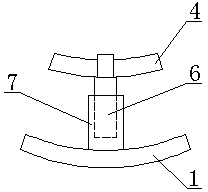

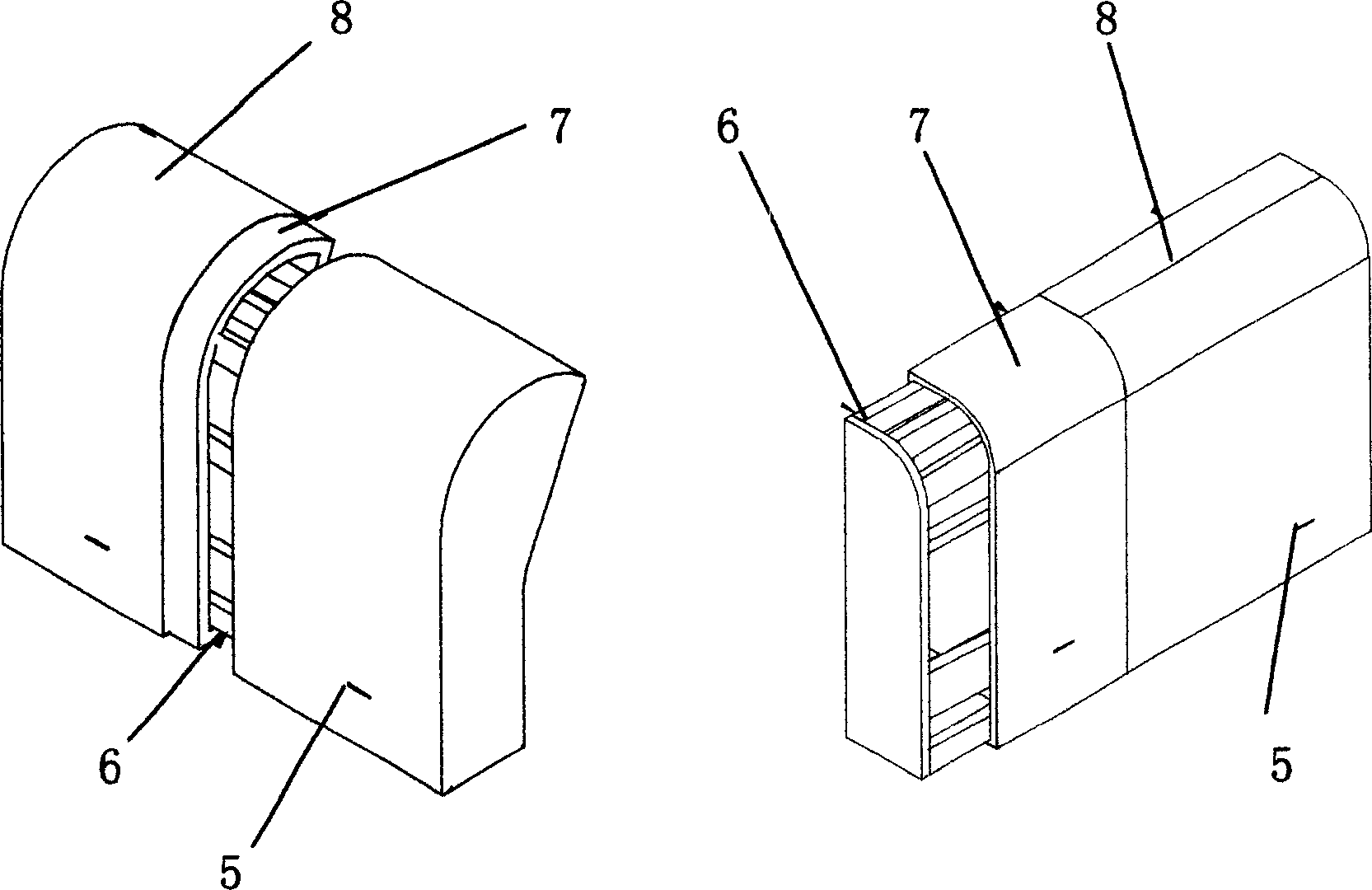

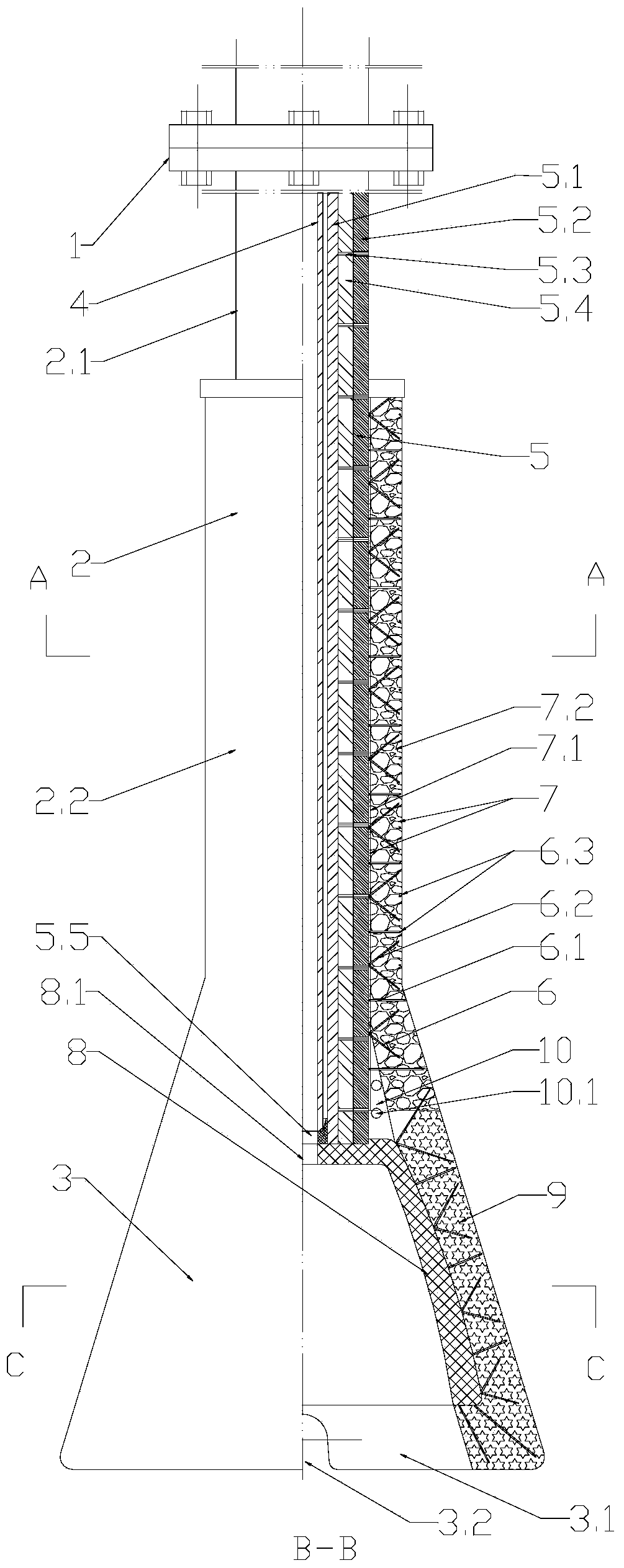

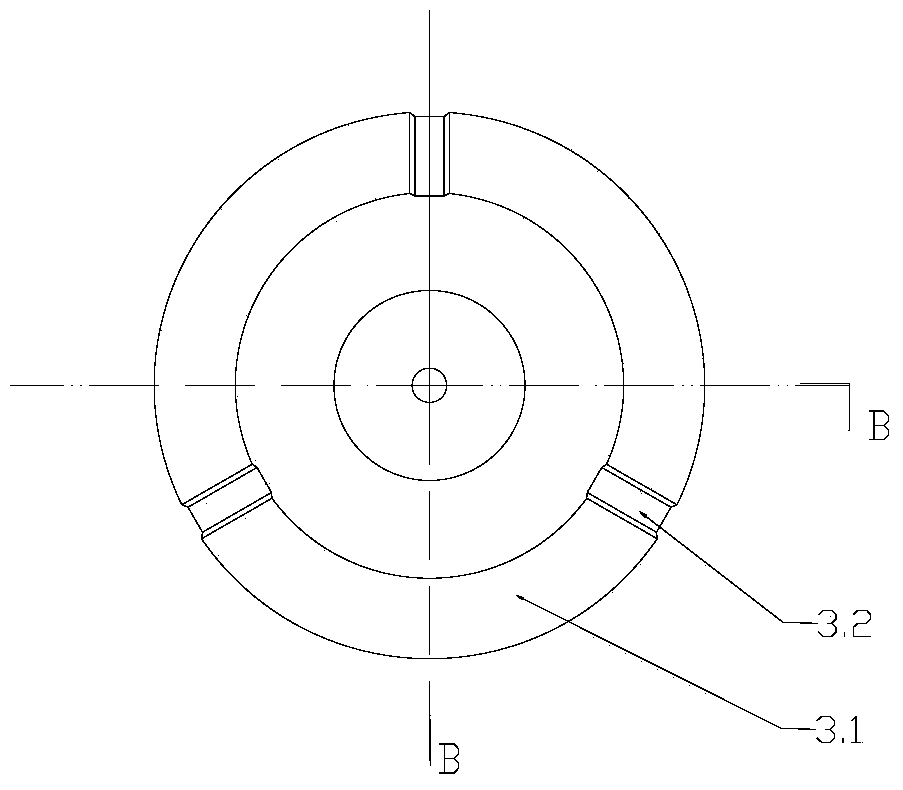

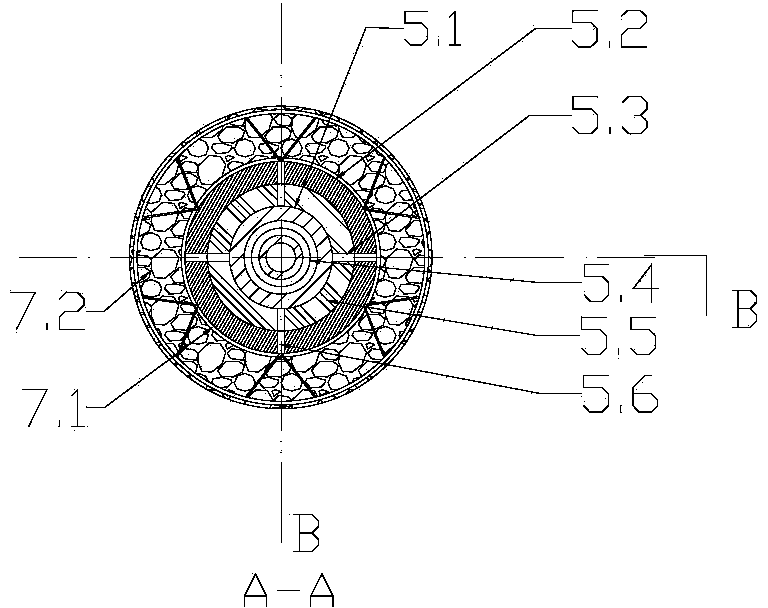

Molten iron pure spray particle magnesium desulfurization spray gun with vaporizing chamber in spearhead and preparation method of molten iron pure spray particle magnesium desulfurization spray gun

The invention discloses a molten iron pure spray particle magnesium desulfurization spray gun with a vaporizing chamber in a spearhead. The molten iron pure spray particle magnesium desulfurization spray gun comprises a connecting flange, a gun-barrel and a spearhead blowing vaporizing chamber, which are sequentially connected and communicated with each other, wherein the spearhead blowing vaporizing chamber is sequentially composed of a vaporizing chamber bell jar, an anchoring part group and a refractory castable lining from inside to outside; a bottom skirt is arranged at the lower end of the vaporizing chamber bell jar; and a plurality of air outlets are evenly formed in the bottom skirt in an emission shape. The method comprises the following steps: selecting a metal material to process and fabricate each component of the spray gun and removing rust for later use according to structural parameters of the spray gun; sequentially preparing a gun core and the vaporizing chamber bell jar; connecting the gun core and the vaporizing chamber bell jar by welding; and welding a reinforcing rib plate in a gap among the lower end of the gun core, the top of the vaporizing chamber bell jar and the refractory castable lining; and finally welding the anchoring part group, and pouring to obtain the spray gun. Compared with a conventional vaporizing chamber spray gun, the molten iron pure spray particle magnesium desulfurization spray gun disclosed by the invention has the advantages of being simple in structure, stable to blow, low in cost, efficient in desulfurization, long in service life and the like.

Owner:武汉钢铁有限公司

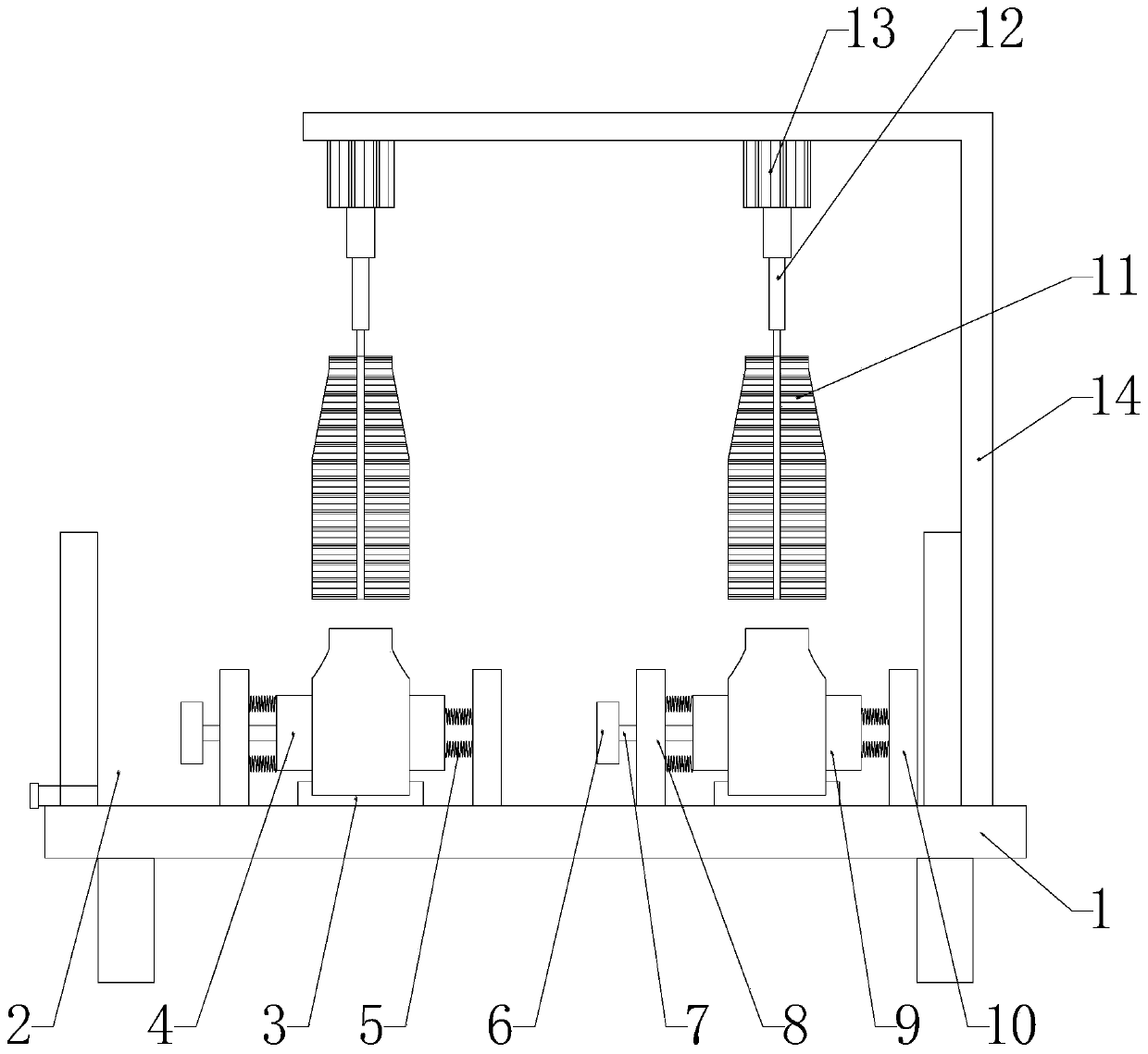

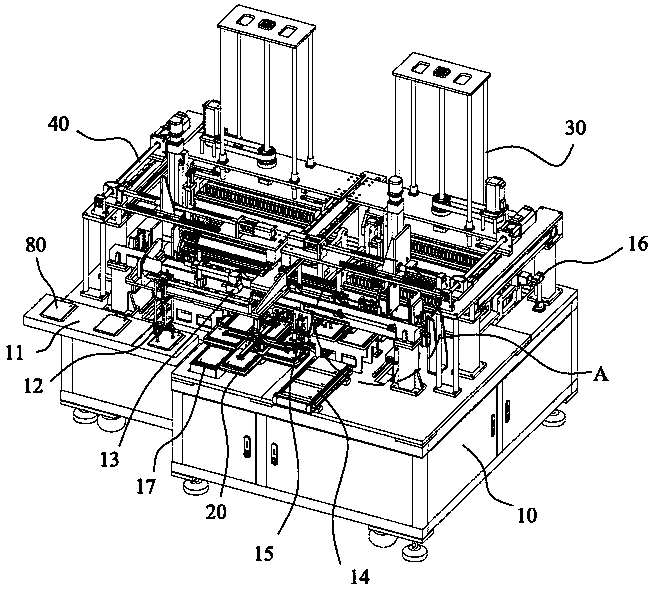

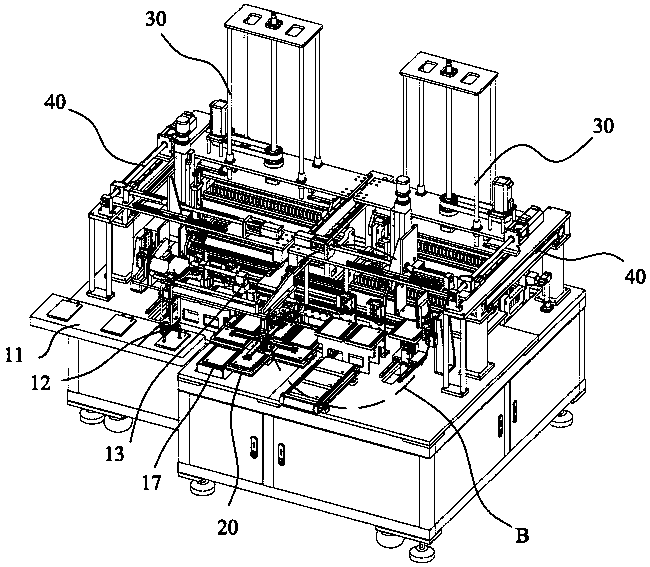

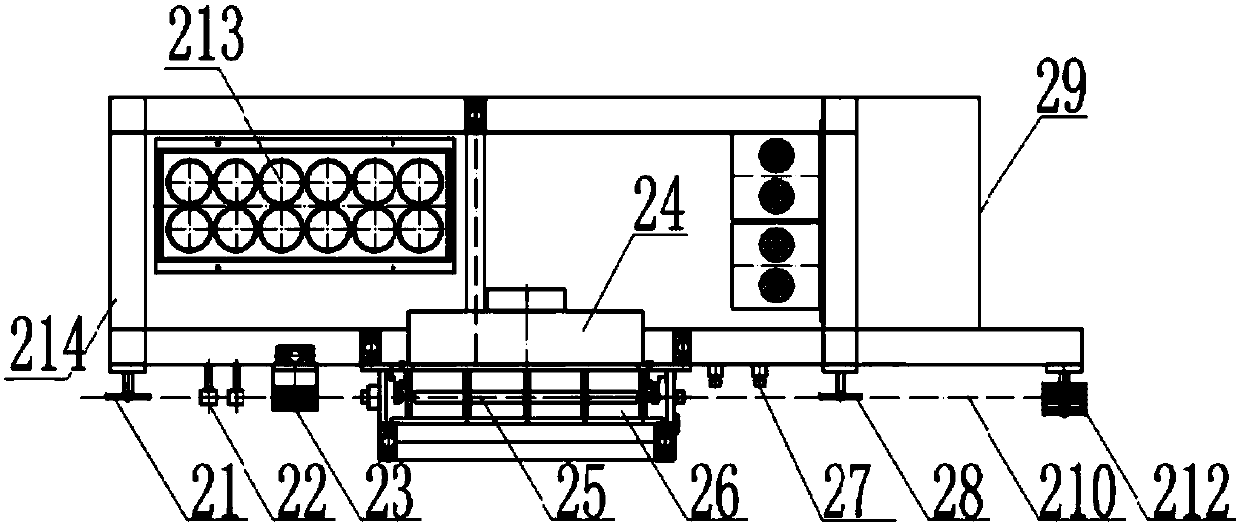

Battery automatic disk-assembling machine

PendingCN109921082ASmooth production processAutomated disk assembly process is smoothFinal product manufactureSecondary cells manufactureEngineeringElectrical and Electronics engineering

The invention discloses a battery automatic disk-assembling machine. The battery automatic disk-assembling machine comprises a rack, a rotating mechanism is arranged on the rack, a battery loading position, a battery code-scanning position, a battery blanking position, and a NG sorting position are orderly arranged along an edge of the rotating mechanism; a battery loading mechanism is arranged onthe rack at one side of the battery loading position, a battery code-scanning mechanism is arranged above the battery code-scanning position, a NG sorting mechanism is arranged on the rack at one side of the NG sorting position, a lug shaping mechanism is arranged on at least one side of the battery blanking position, a battery steering mechanism for enabling the battery to rotate along a horizontal direction is arranged at one side of each lug shaping mechanism, a battery overturning mechanism for overturning the battery in a vertical direction is arranged at one side of each battery steering mechanism, and up-down material box mechanisms are arranged by the side of the battery overturning mechanisms. The running is stable, the product consistency is improved, the one-to-one correspondence of the battery and the QR code on the material box is guaranteed, thereby guaranteeing the smooth performing of the next step of process.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

Machining method of high-precision local ultra-high current printed circuit board

InactiveCN106852033ASmooth production processIncrease order capacityMultilayer circuit manufactureCircuit graphResist

The invention discloses a method for processing a high-precision local ultra-high current printed circuit board. The printed circuit board includes a substrate and thin copper layers and thick copper layers respectively arranged on both sides of the substrate. When making outer-layer circuits, First, a layer of dry film is applied to the thick copper layer for protection, and the thin copper layer is exposed, developed, electroplated, and etched to produce a thin copper layer circuit pattern; then a layer of dry film is applied to the thin copper layer circuit pattern Protection, and the thick copper layer is made into a thick copper layer circuit pattern through exposure, development, electroplating, and etching processes. The high-precision local ultra-high-current printed circuit board processing method adopts facet-time production lines and facet-time etching and separate times to make solder resists, making it possible for yin and yang copper thick printed boards. The reform of the method makes the product quality fully meet the customer's requirements, and can meet the customer's demand for special printed boards, which increases the market's ability to receive orders and improves economic benefits.

Owner:KUNSHAN SUHANG CIRCUIT BOARD

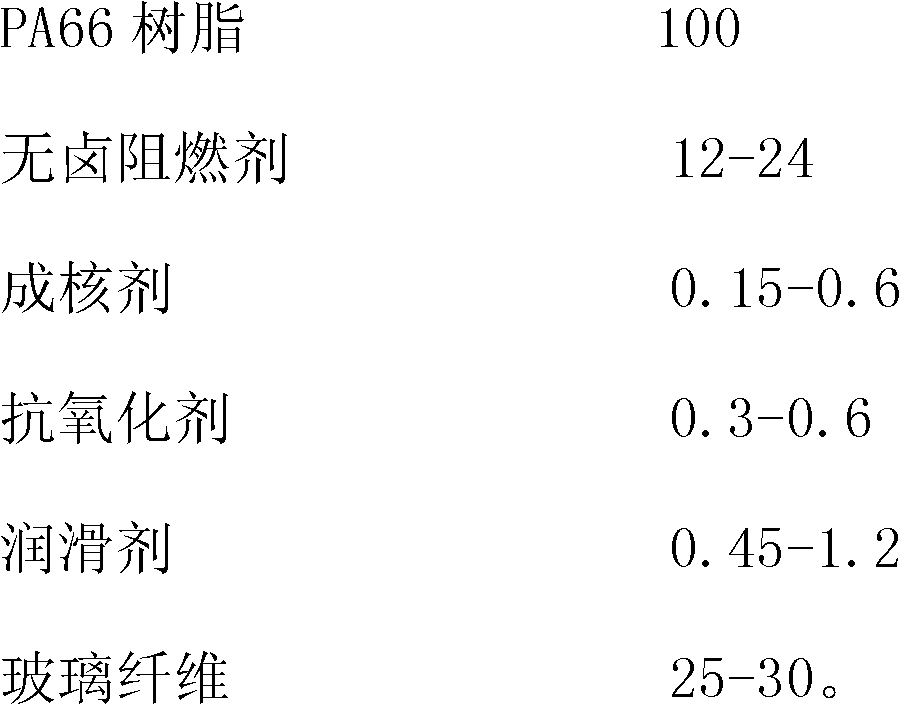

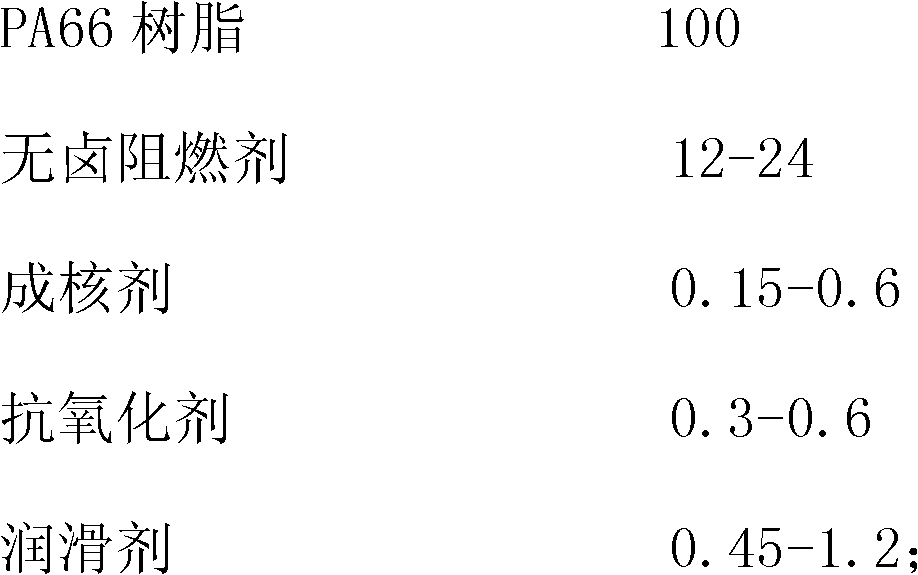

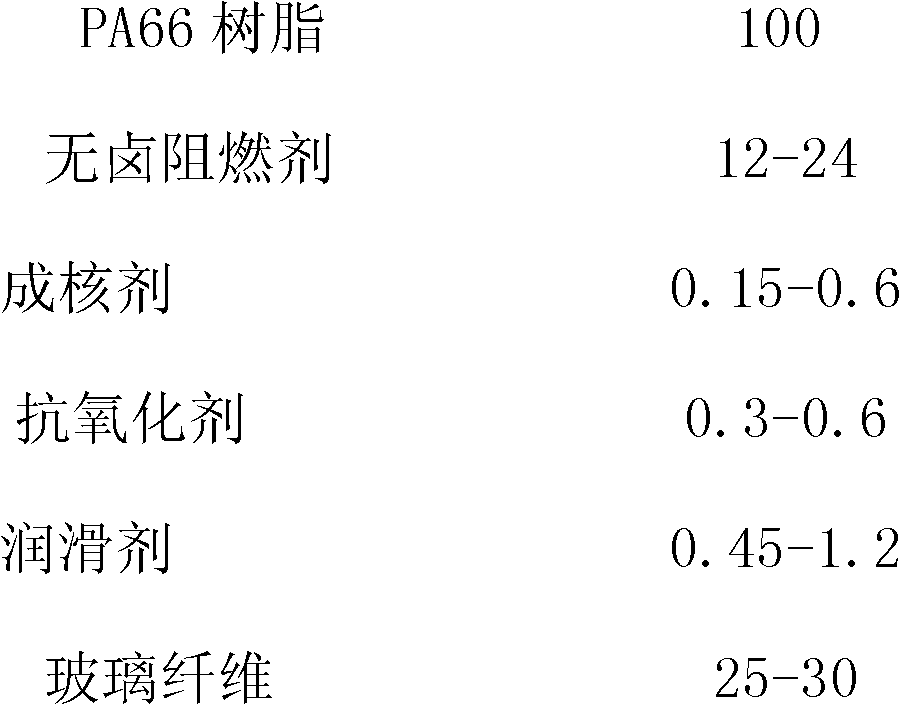

High glow-wire and fiber halogen-free flame-retardant nylon 66 material and preparation method thereof

The invention discloses a high glow-wire and fiber halogen-free flame-retardant nylon 66 material and a preparation method thereof. The high glow-wire and fiber halogen-free flame-retardant nylon 66 material comprises the following components in parts by weight: 100 parts of PA 66 resin, 12-24 parts of halogen-free fire retardant, 0.15-0.6 parts of nucleating agent, 0.3-0.6 parts of antioxidant, 0.45-1.2 parts of lubricant and 25-30 parts of glass fibre. The high glow-wire and high-performance fiber halogen-free flame-retardant nylon 66 material provided by the invention is excellent in mechanical property, halogen-free, environment friendly and flame-retardant, and the glow-wire does not inflame at 750 DEG C within 30s; and the used raw materials are wide in source and low in cost, therefore, the high glow-wire and fiber halogen-free flame-retardant nylon 66 material is very suitable for industrial production. The prepared high glow-wire and fiber halogen-free flame-retardant nylon 66 material and the preparation method thereof can be widely applied to the field of electronic appliances such as a breaker shell, a motor shell, a connector, a light touch switch and the like.

Owner:SHENZHEN KEJU NEW MATERIAL

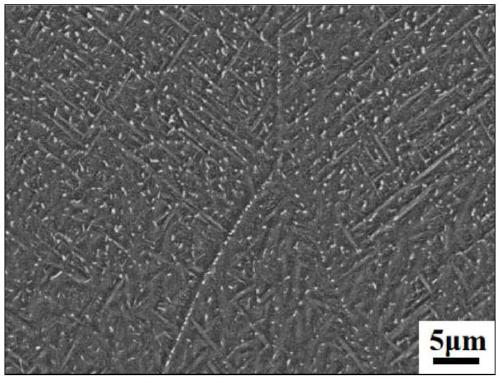

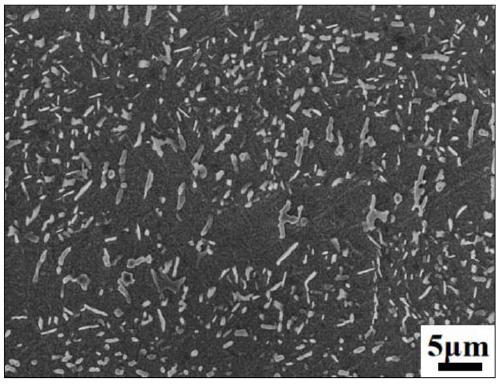

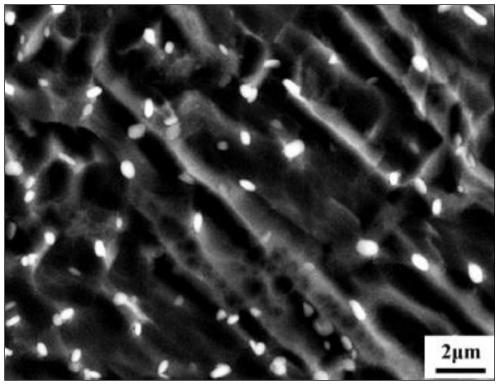

Regional control method for additive manufacturing of in-situ self-generated TiC reinforced titanium-based composite material

ActiveCN111451502APrecise control of shapePrecise content controlAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesPowder mixture

The invention discloses a regional control method for additive manufacturing of an in-situ self-generated TiC reinforced titanium-based composite material. The method comprises the following steps: I,ball-milling and drying after uniformly mixing titanium powder with nano carbon powder or uniformly mixing titanium alloy powder with nano carbon powder, spraying aerosol to uniformly mix, and dryingto obtain C / Ti composite powder; II, preparing a series of C / Ti composite powder with different nano carbon mass contents; III, separately selecting a powder mixture of one or more of one series of C / Ti composite powder with different nano carbon mass contents as a raw material, and adopting a high energy beam additive manufacturing method to prepare the in-situ self-generated TiC reinforced titanium-based composite material. Nano carbon mass content in the raw material is controlled on line by selecting the powder mixture of one or more of one series of C / Ti composite powder with different nano carbon mass contents, and different-area TiC dimension, morphology and content of the titanium-based composite material are precisely controlled, so that regional control on the in-situ self-generated TiC reinforced titanium-based composite material is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

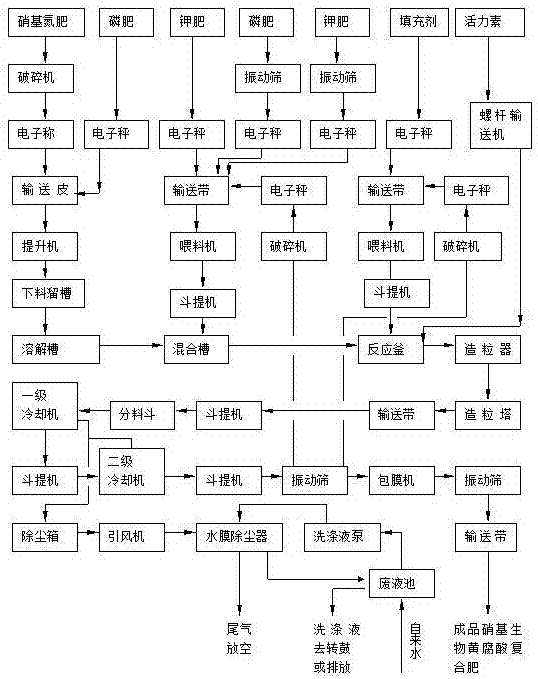

Process method for producing nitro fulvic acid compound fertilizer by virtue of high tower and compound fertilizer

InactiveCN107500921AAvoid the risk of combustion and explosionReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationPotassium

The invention provides a process method for producing a nitro fulvic acid compound fertilizer by virtue of a high tower. The compound fertilizer is prepared by virtue of a high-tower fusion-spraying granulation equipment system. The process method specifically comprises the steps of dissolving, mixing, reacting, granulating, cooling, sieving and enveloping, so as to obtain the finished nitro fulvic acid compound fertilizer. According to the process method, the problem that organic matters such as fulvic acid cannot be heavily added in the existing high-tower production process of the compound fertilizer is solved; and by utilizing novel raw materials and process, the effective content of fulvic acid in the nitro fulvic acid compound fertilizer produced by virtue of the high tower is more than or equal to 3.5%. The compound fertilizer produced by virtue of the process method contains the following components in parts by weight: 30-80 parts of a nitro-nitrogen fertilizer, 8-40 parts of a phosphate fertilizer, 0-50 parts of a potassium fertilizer and 9-25 parts of vitality elements. The compound fertilizer contains rich elements such as nitrogen, phosphorus and potassium, is capable of activating soil, can be directly absorbed and utilized by soil and can meet diversities of types, numbers and proportions of nutrients required by different crops.

Owner:YUNNAN TIANTENG CHEM IND

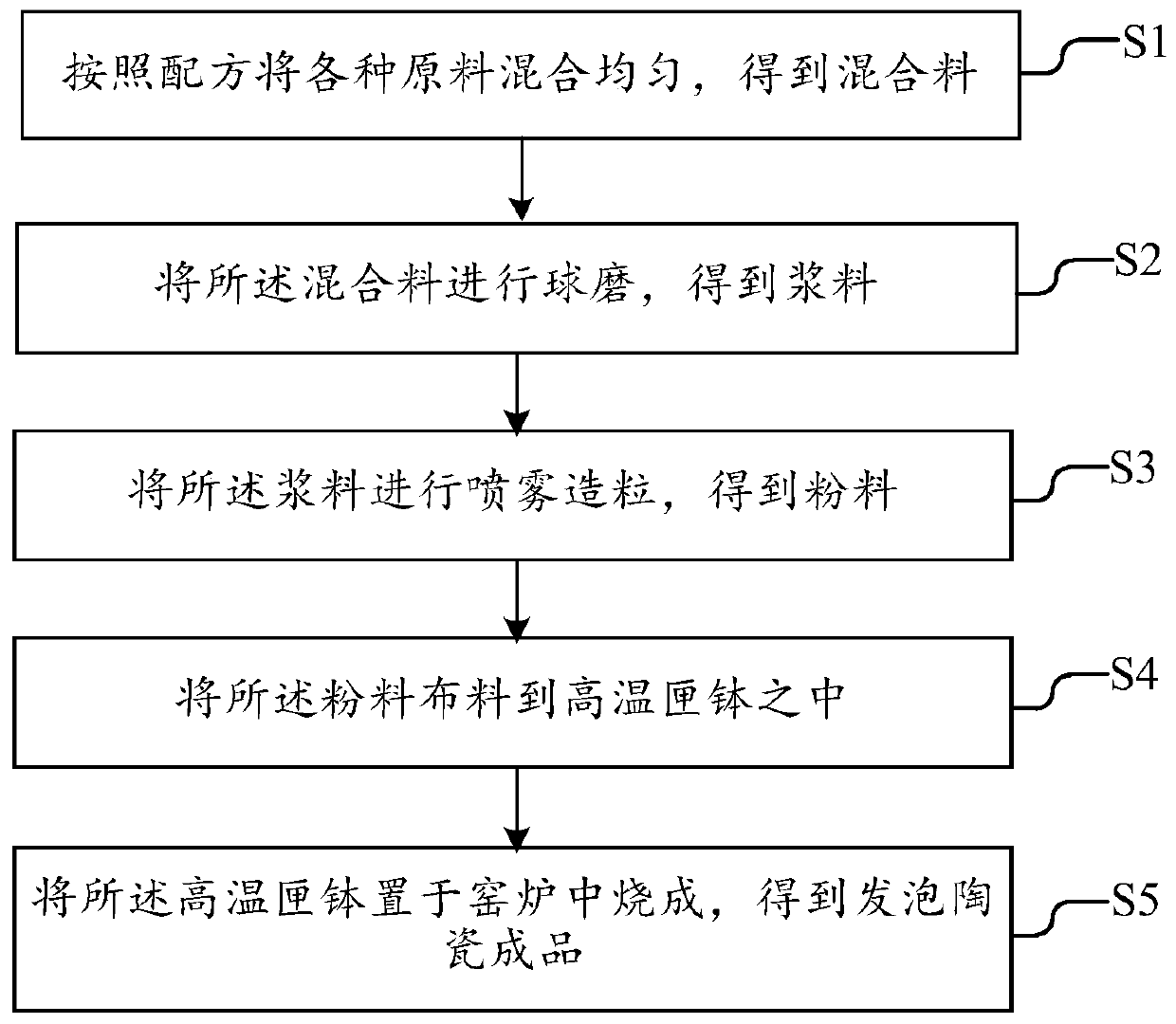

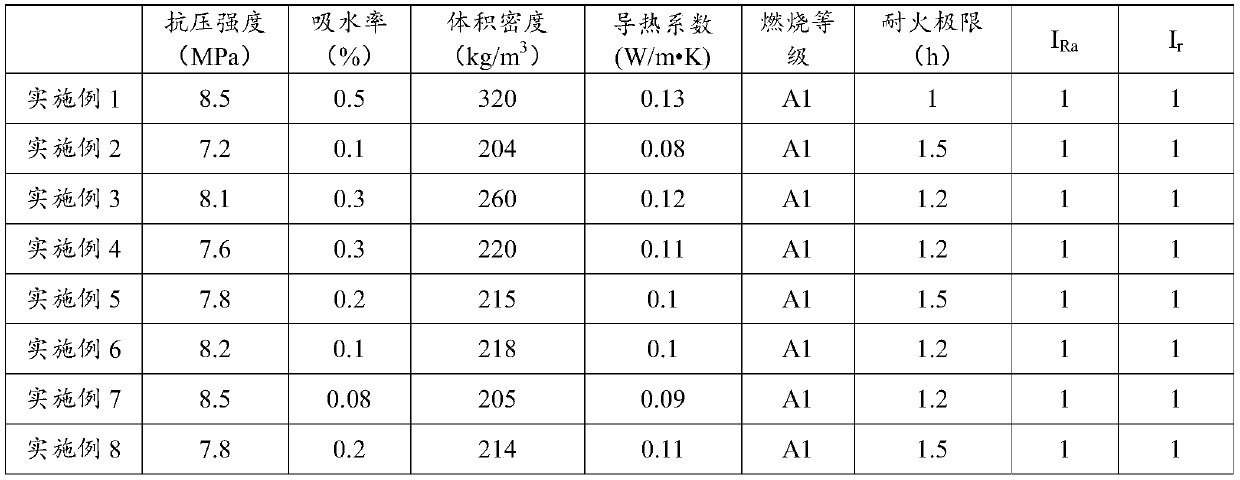

Foaming ceramic and preparation method thereof

InactiveCN110590329ARealize resourcesHigh value-added utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention discloses a foaming ceramic. The foaming ceramic is mainly prepared from the following raw materials in parts by weight: 90-95 parts of a Luoyuan red tailing, 1-9 parts of clay, 0.1-3 parts of a foaming agent and 0.1-1 part of a stabilizer; wherein the Luoyuan red tailing is mainly prepared from the following components in percentage by weight: 68-73% of SiO2, 12-15% of Al2O3, 1.2-2%of Fe2O3, 0.5-1.5% of CaO, 0.2-0.5% of MgO, 4-5.5% of K2O, 3-5% of Na2O and 0.5-3% of LOI. The invention further discloses a preparation method of the foaming ceramic. According to the foaming ceramic and the preparation method thereof, the Luoyuan red tailing is adopted as a main base material to prepare a foaming ceramic tile, and the resource utilization of the Luoyuan red tailing is effectively realized; and the prepared foaming ceramic tile has high compressive strength, low water absorption rate and low thermal conductivity.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Continuous production system of high-strength vertical corrugated paperboard

ActiveCN107364188AReasonable structureImprove work efficiencyMechanical working/deformationPaperboardIndustrial engineering

The invention discloses a continuous production system of a high-strength vertical corrugated paperboard. The continuous production system comprises an overall rack, a middle corrugated forming unit, an indentation forming unit, a vertical stacking unit, a transition conveying unit and an outer paper pasting unit, wherein the middle corrugated forming unit, the indentation forming unit, the vertical stacking unit, the transition conveying unit and the outer paper pasting unit are sequentially arranged between the side walls of the overall rack in the production line direction. The indentation forming unit comprises an indentation mechanism. The vertical stacking unit is rotationally mounted between the side walls of the overall rack and comprises a stacking section conveying mechanism. A blocking air cylinder used for blocking indented corrugated paper is arranged at the end, close to the transition conveying unit, of the stacking section conveying mechanism. The transition conveying unit comprises a transition section conveying mechanism. The outer paper pasting unit comprises an upper paper feed mechanism, a lower paper feed mechanism and an outer paper pasting section conveying mechanism. The continuous production system of the high-strength vertical corrugated paperboard is reasonable in structure set, the production process is coherent, and the production efficiency of the vertical corrugated paperboard is greatly improved.

Owner:寻乌县天源包装有限公司

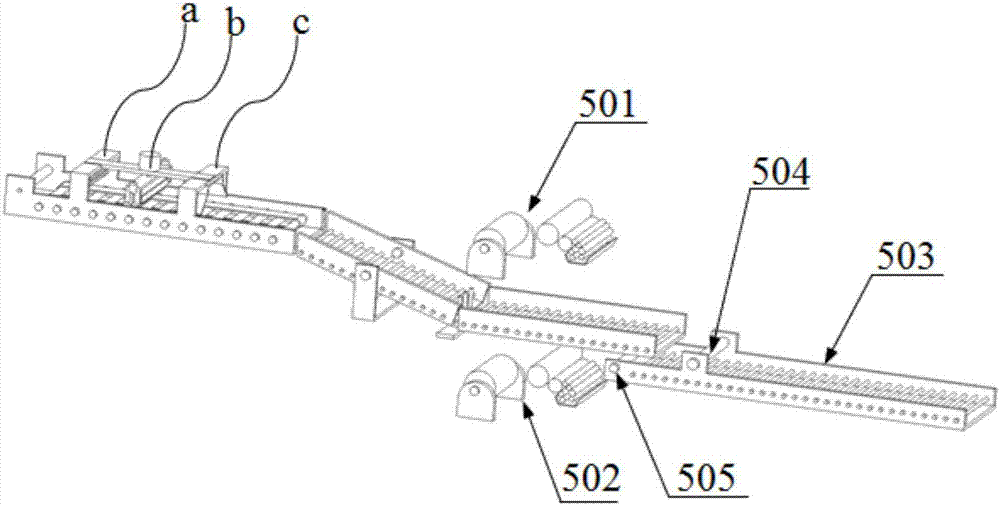

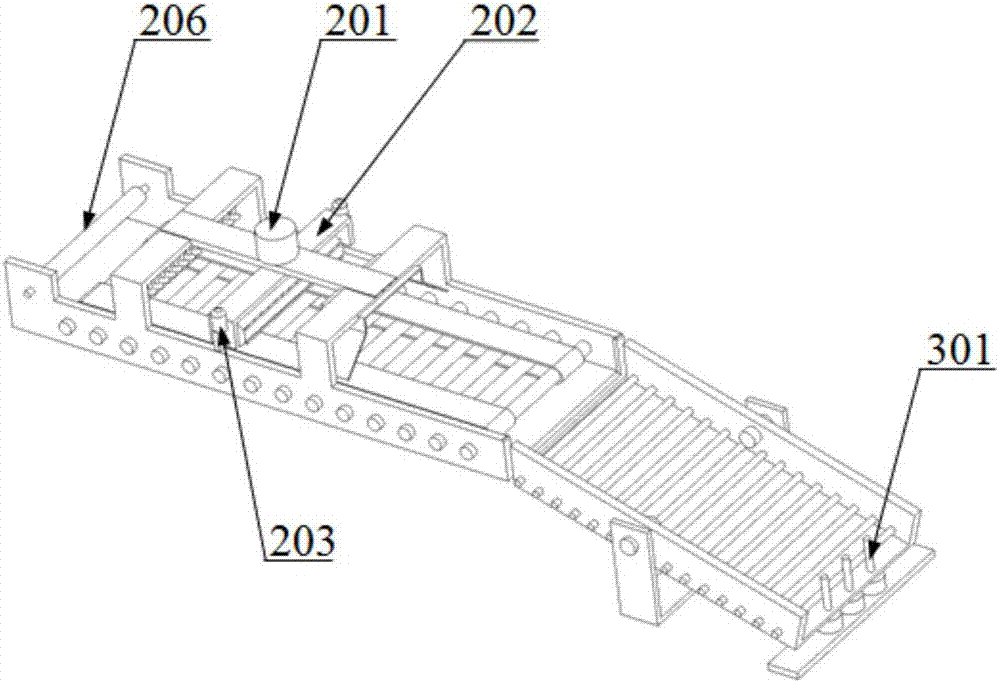

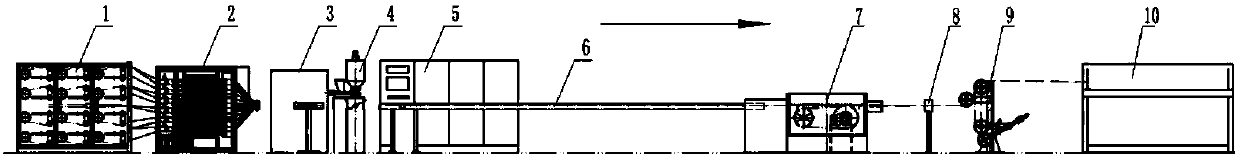

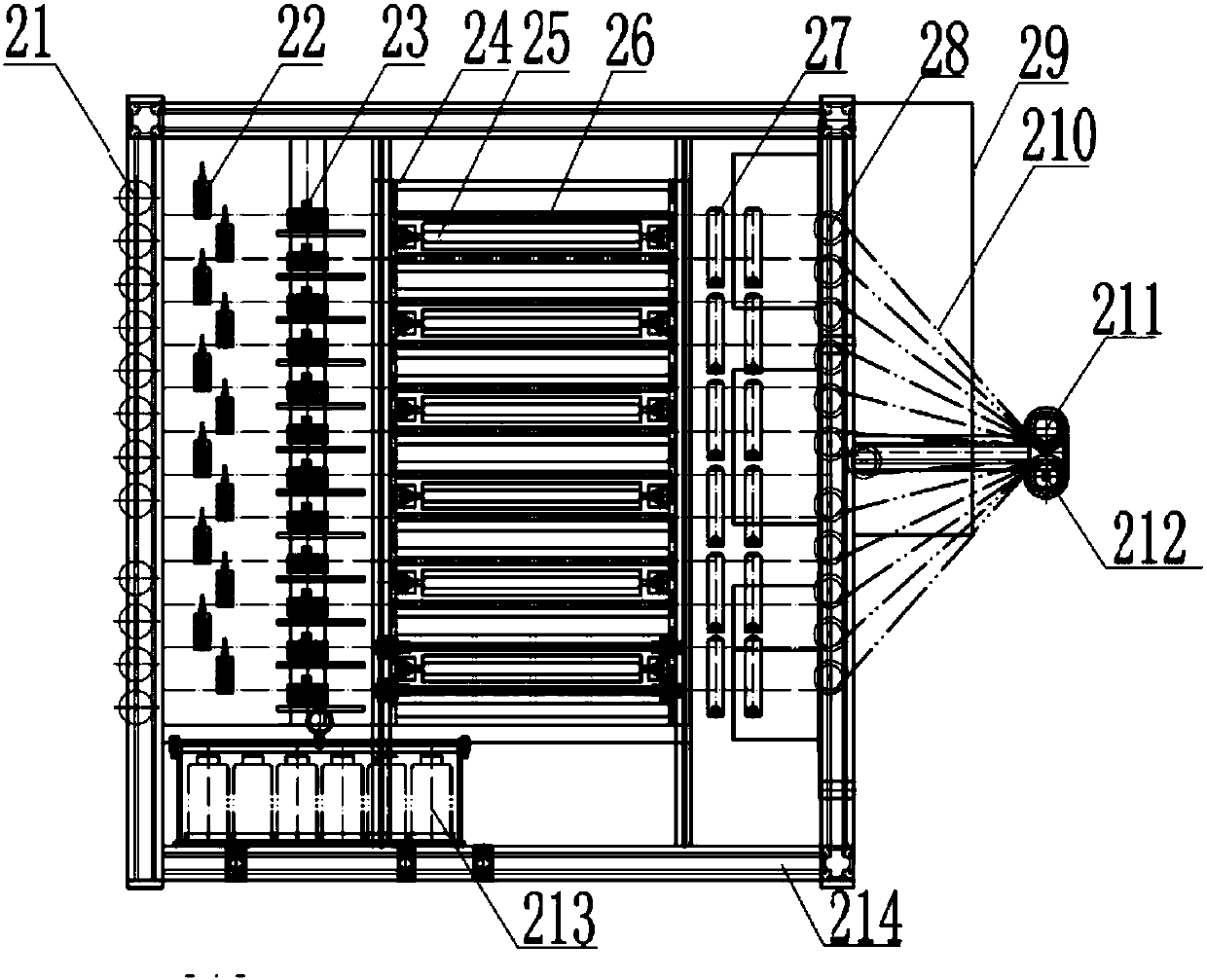

Fiber coloring and coating composite production line and production process thereof

ActiveCN107561656AIncrease productivityLow operating pressureFibre mechanical structuresFiberProcess engineering

The invention relates to a fiber coloring and coating composite production line and a production process thereof. The fiber coloring and coating composite production line comprises a fiber laying frame, a fiber coloring and curing device, a fiber paste bubble-removing and filling device, a plastic extruding machine, an electric control system, a hot water tank, a water area traction device, a diameter measuring instrument, a line collecting dance wheel and an full-automatic double-disc line collector. The fiber coloring and curing device is provided with 2n coloring and curing lines. The fiberlaying frame is provided with 2n fiber laying lines. Each coloring and curing line corresponds to a fiber laying line, and n is an integer greater than 1. The fiber coloring and coating composite production line combines two processes including the coloring and the secondary coating into a single process, thereby greatly reducing the pressure of an operator, achieving a smooth manufacturing process, and improving the production efficiency of optical cables.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

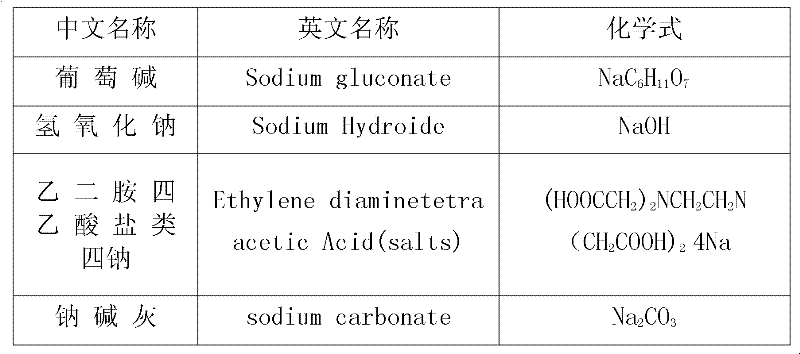

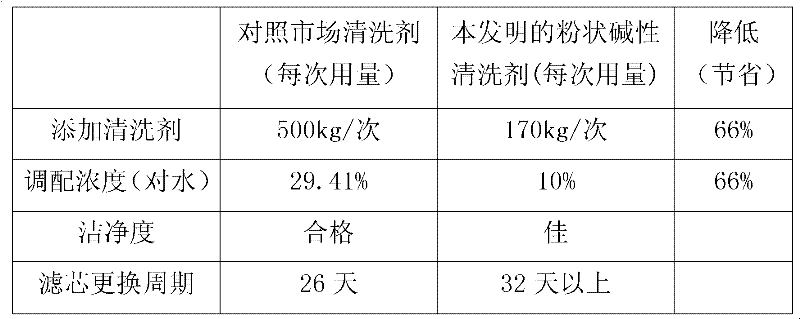

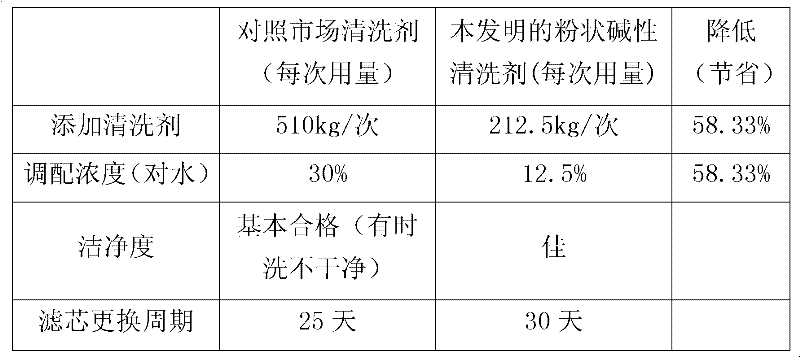

Powder alkali cleaner

InactiveCN102220187AStrongly alkalineBe carefulOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsFiberWaste processing

The invention discloses a powder alkali cleaner, comprising the following substances of: 25-35 wt% of grape alkali, 54-69 wt% of sodium hydroxide, 2-12 wt% of tetrasodium edetate, and 0-2 wt% of soda ash. The powder alkali cleaner provided by the invention is applicable to clean spinning spinnerets (PACK), parts and monomer candles of chemical fiber and terylene factories; can remove carbide, heat scale, dirt, grease stain and polymer, resist rust, and strip titanium dioxide (TiO2) on filter tubes; by using the powder alkali cleaner, two third of additive volume can be saved, the waste processing amount can also be reduced, the filter changing period of filter cores can be prolonged, the production process can be improved, and the output and quality can be greatly enhanced.

Owner:XIAMEN YIGUAN CHEM

Disposing and recycling method of waste package plastic bucket

InactiveCN108819016ARealize secondary useEasy to separatePlastic recyclingMechanical material recoveryWastewaterPlastic film

The invention discloses a disposing and recycling method of a waste package plastic bucket. The disposing and recycling method comprises the following steps of (1) removal of residual liquid in the waste package plastic bucket; (2) crushing cleaning with a crusher; (3) high-speed rubbing cleaning; (4) rinsing; (5) spin drying; (6) tag separation with a tag separator; and (7) packaging. According to the disposing and recycling method, the waste package plastic bucket is subjected to crushing cleaning, rubbing cleaning, rinsing, spin-drying and tag separation, a large number of plastic sheets are recycled, the process is simple, and energy saving and environmental friendliness are achieved. Meanwhile, generated cleaning waste water, waste gas and waste residues are reasonably disposed, and cyclic regeneration of resources is achieved.

Owner:无锡添源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com