Aluminum electrolysis rectifier cabinet equal current on-line detection method

A detection method and technology of rectifier cabinets, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve problems affecting normal production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

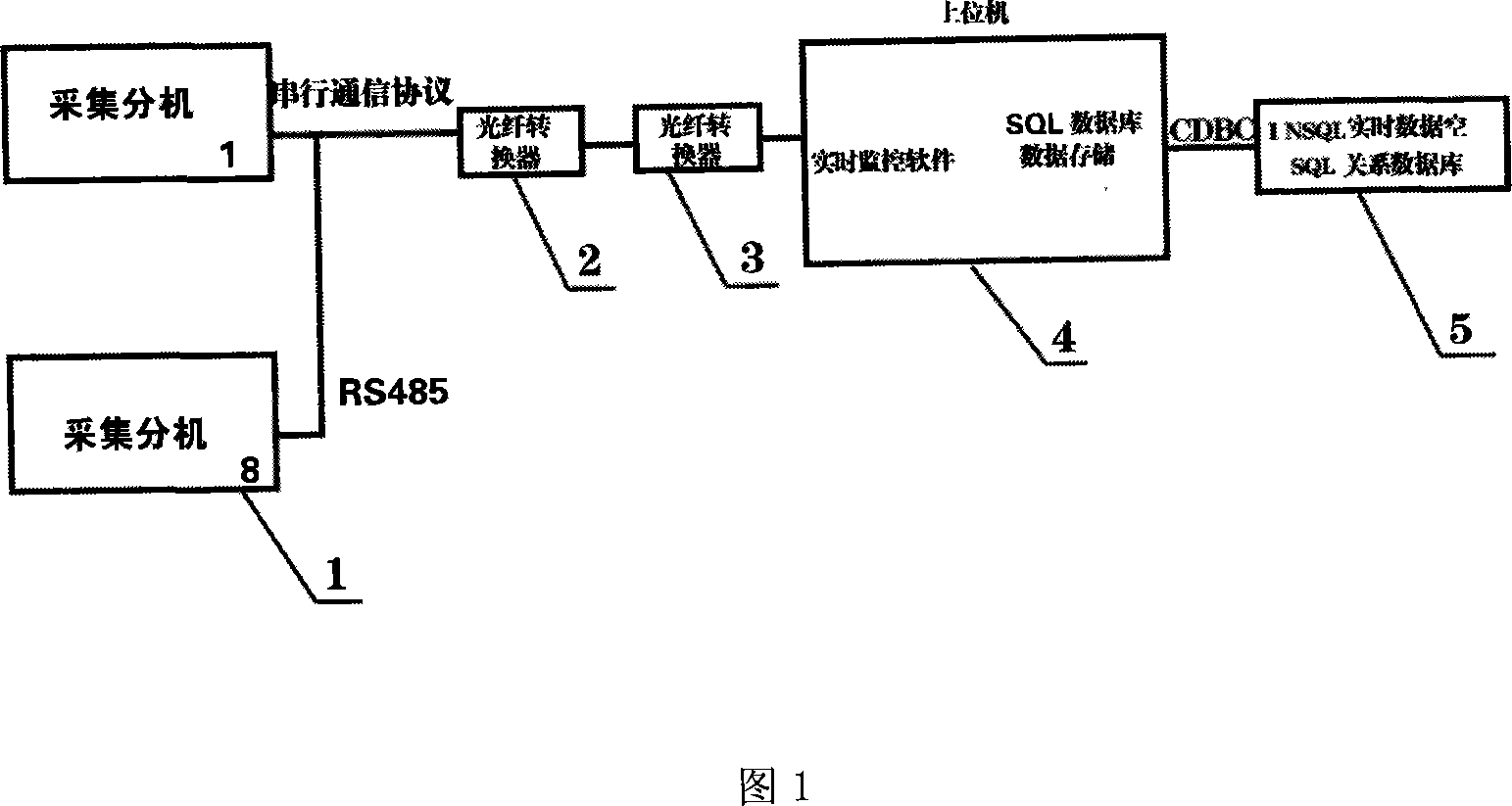

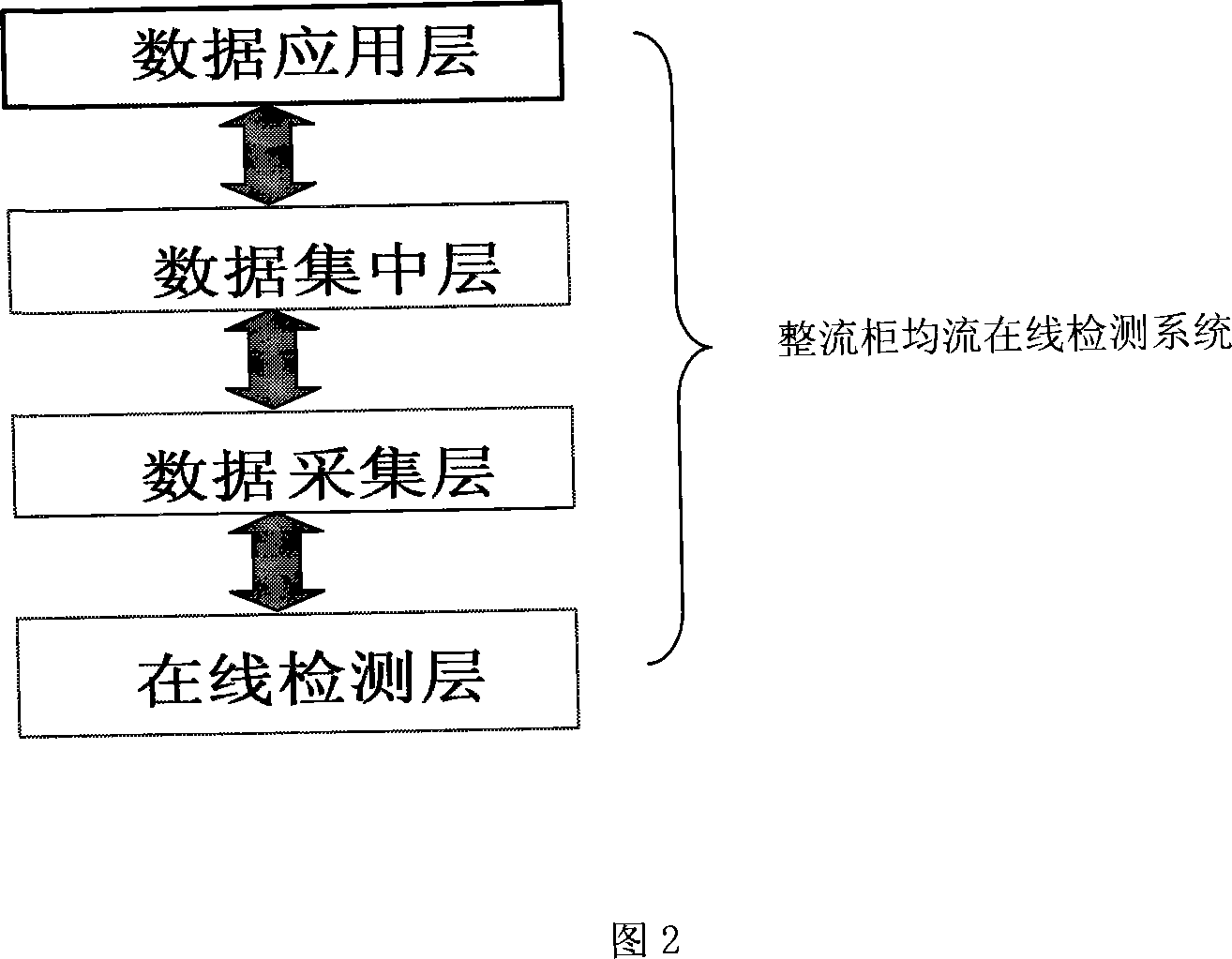

[0025] The rectifier cabinet current equalization online detection method is an overall solution that integrates on-site data detection, data collection, data concentration, and data processing; it can realize the collection, concentration, and processing of data from scattered rectifier cabinets in the whole plant; it is a safe production of power supply The basis of process centralized dynamic monitoring; it is a bridge for information exchange between production process and operation management, providing guarantee for the real-time, comprehensive and efficient operation and management of enterprises; it is the basis of production process analysis; it is the basis of scientific decision-making of enterprises.

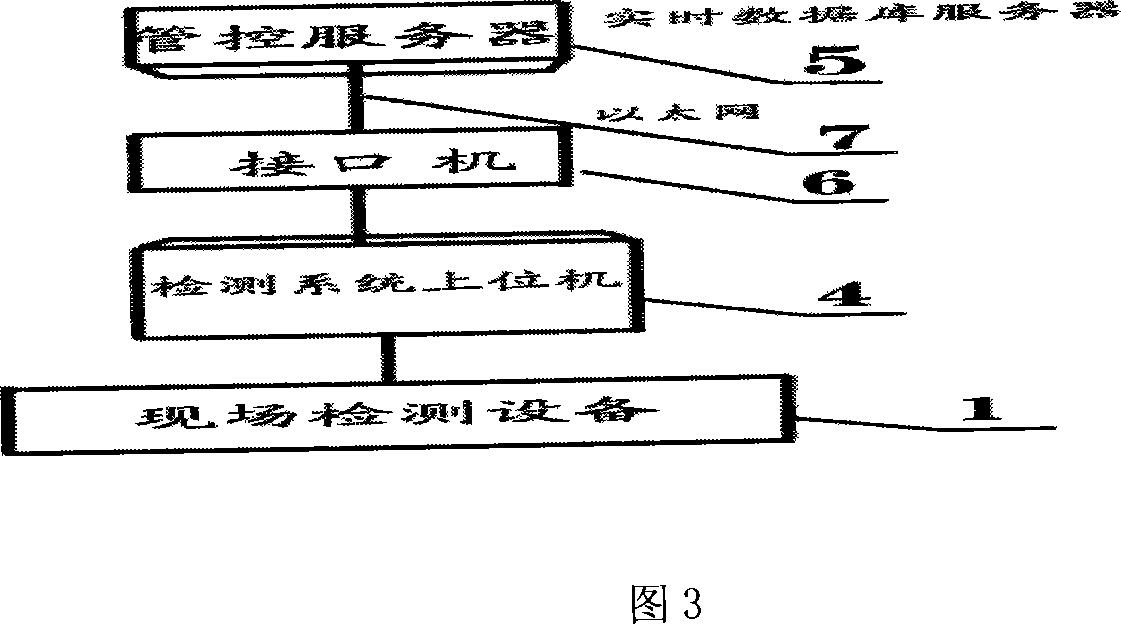

[0026] The architecture of the rectifier cabinet current equalization online detection system can be divided into two parts: the storage application of real-time data and the storage application of production management data:

[0027] Adopt the combination of B / S stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com