Powder alkali cleaner

A cleaning agent and alkaline technology, which is applied in the field of cleaning polymeric filter elements and spinning spinnerets in chemical fiber polyester factories, to achieve the effects of prolonging the replacement cycle, improving output and quality, and improving the smooth production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

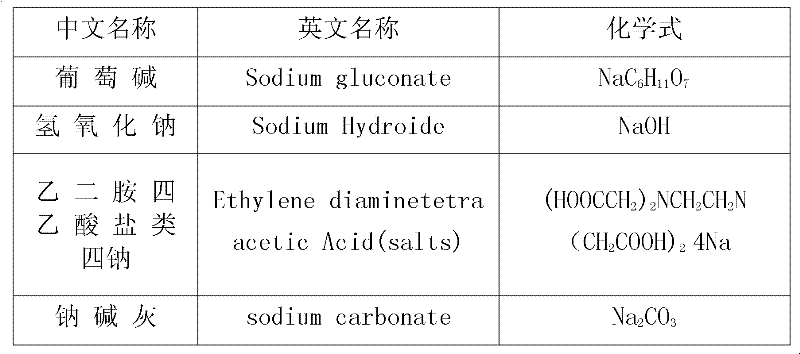

[0033] Weigh 87.2kg of grapevine, 205.8kg of sodium hydroxide, 10.5kg of tetrasodium ethylenediaminetetraacetate, and 0.1kg of sodium soda ash, mix and stir these raw materials evenly with a circular mixer, filter, screen and pass the inspection, and pack them in bags .

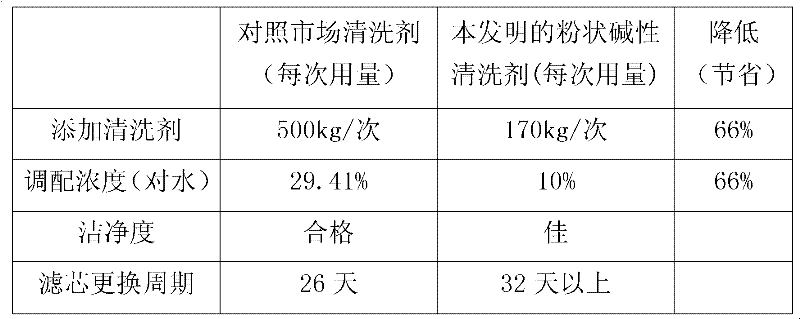

[0034] Apply powdery alkaline cleaning agent of the present invention in Jiangsu Jiangyin Sanfangxiang Group Co., Ltd. to carry out filter element cleaning test, test for 2 months, and carry out comparative test. The test results are as follows:

[0035] (2 tons of boiling tank, add water 1700kg)

[0036]

Embodiment 2

[0038] Weigh 143.5kg of grapevine, 341.8kg of sodium hydroxide, and 17.5kg of tetrasodium ethylenediaminetetraacetate salts, mix and stir these raw materials evenly through a circular mixer, filter, screen and pass the inspection, and pack them in separate bags.

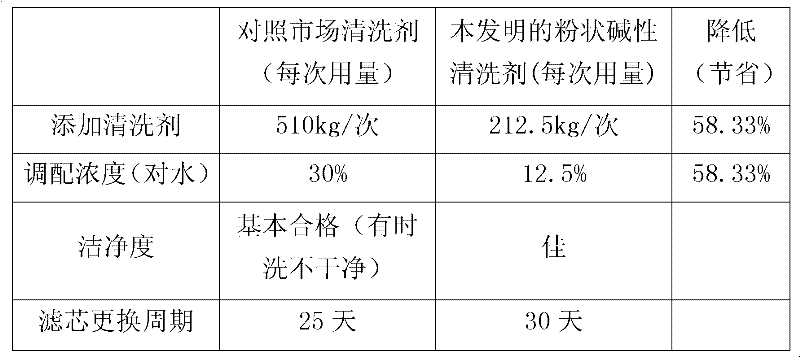

[0039] Apply powdery alkaline cleaning agent of the present invention to carry out filter core and spinneret cleaning agent in Fujian Paihong Group Polyfiber Science and Technology Industry Co., Ltd. (production fine denier fiber). The test works well after 3 months of use. The test results are as follows:

[0040] (2 tons of boiling tank, add water 1700kg)

[0041]

Embodiment example 3

[0043] Weigh 57.2kg of grapevine, 137kg of sodium hydroxide, 7.5kg of tetrasodium edetate salts, and 0.3kg of soda ash. These raw materials are mixed and stirred evenly by a circular mixer, filtered and screened to pass the inspection, and packed in separate bags.

[0044] Apply powdery alkaline cleaning agent of the present invention to carry out filter element cleaning in Zhejiang Far East Group Far East New Polyester Co., Ltd. The test works well after 2 months of use. The test results are as follows:

[0045] (2 tons of boiling tank, add water 1700kg)

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com