Treatment and recovery method for waste chemical reagent bottles

A technology for chemical reagents and recovery methods, applied in chemical instruments and methods, cleaning methods and utensils, and solid waste removal, etc., can solve problems such as threats to ecological environment safety, environmental pollution, personal injury, etc. No dust pollution, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

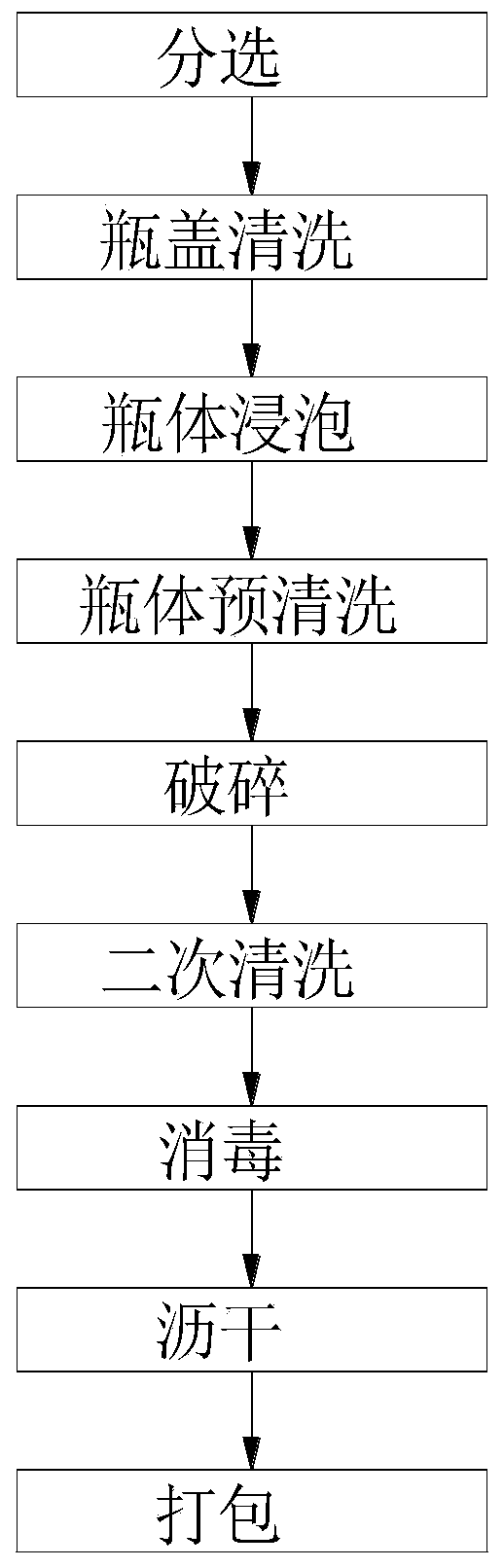

[0048] A method for disposal and recovery of waste chemical reagent bottles, comprising the following method steps:

[0049] Sorting: Remove the caps from the waste chemical reagent bottles and store them separately according to the bottle body and cap. The bottles are sorted and stored in different categories;

[0050] Bottle cap cleaning: Soak the glass bottle caps in the sorting step in lye for 30 minutes, the concentration of lye is 1%, and stir and clean with a stirrer, and the alkaline waste water generated by cleaning is treated with acid-base neutralization and pH adjustment To 6-7, use a filter to remove suspended impurities and then discharge; soak the plastic bottle caps in the sorting step in an organic solvent for 30 minutes, and use a stirrer to stir and clean them, and then put the plastic bottle caps in tap water to wash away Organic solvents on the surface of plastic bottle caps;

[0051] Bottle soaking: Fill each waste chemical reagent bottle with organic s...

Embodiment 2

[0059] A method for disposal and recovery of waste chemical reagent bottles, comprising the following method steps:

[0060] Sorting: Remove the caps from the waste chemical reagent bottles and store them separately according to the bottle body and cap. The bottles are sorted and stored in different categories;

[0061] Bottle cap cleaning: Soak the glass bottle caps in the sorting step in lye for 40 minutes, the concentration of lye is 1%, and stir and clean with a stirrer, and the alkaline waste water generated by cleaning is treated with acid-base neutralization and pH adjustment To 6-7, use a filter to remove suspended impurities and then discharge; soak the plastic bottle caps in the sorting step in an organic solvent for 40 minutes, and use a stirrer to stir and clean them, and then put the plastic bottle caps in tap water to wash away Organic solvents on the surface of plastic bottle caps;

[0062] Bottle immersion: fill each waste chemical reagent bottle with organic...

Embodiment 3

[0070] A method for disposal and recovery of waste chemical reagent bottles, comprising the following method steps:

[0071] Sorting: Remove the caps from the waste chemical reagent bottles and store them separately according to the bottle body and cap. The bottles are sorted and stored in different categories;

[0072] Bottle cap cleaning: Soak the glass bottle caps in the sorting step in lye for 50 minutes, the concentration of lye is 1%, and stir and clean with a stirrer, and the alkaline waste water generated by cleaning is treated with acid-base neutralization and pH adjustment To 6-7, use a filter to remove suspended impurities and then discharge; soak the plastic bottle caps in the sorting step in an organic solvent for 50 minutes, and use a stirrer to stir and clean them, and then put the plastic bottle caps in tap water to wash away Organic solvents on the surface of plastic bottle caps;

[0073] Bottle immersion: fill each waste chemical reagent bottle with organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com