Glass fiber reinforced PBT (Poly Butylenes Terephthalate)/PP (Polypropylene) alloy material and preparation method thereof

A technology of alloy material and PBT resin, applied in the field of glass fiber reinforced PBT/PP alloy material and its preparation, can solve the problems of low notched impact performance of PBT, high production cost, poor dimensional stability of PP, etc. The effect of high efficiency and large market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

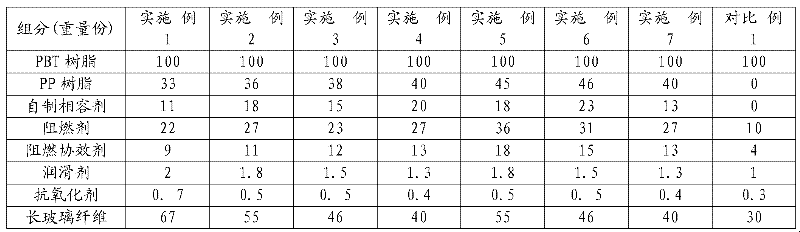

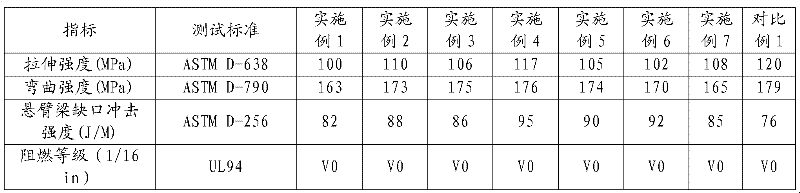

[0052] The preparation method of embodiment 1 to 7 of the present invention is as follows:

[0053] First, weigh the raw materials according to the composition ratio in Table 1, then dry the PBT resin at 120°C for 2-3 hours, and control the moisture content below 0.05%; dry the PP resin at 75-80°C for 2-3 hours, control The moisture content is below 0.05%; put the dried PBT resin PP resin, self-made compatibilizer, flame retardant, flame retardant synergist, 1 part lubricant, 1 part antioxidant in a mixing bucket and stir for 10 minutes. Then it is extruded and granulated by a twin-screw extruder, and long glass fibers are added in the middle section of the extruder. The processing temperature is 190-200℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, 200-210℃ in the fifth zone, 190-200℃ in the sixth zone, and 210℃ in the seventh zone. -220°C, the conveying time of the mixture in the extruder is 1-2 minutes.

[0054] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com