Patents

Literature

77results about How to "Improved performance of the finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

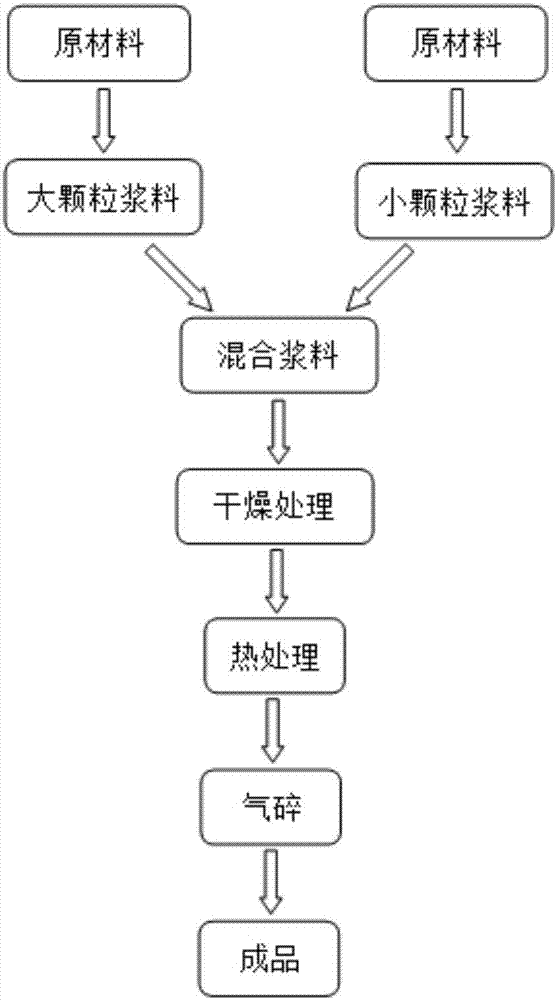

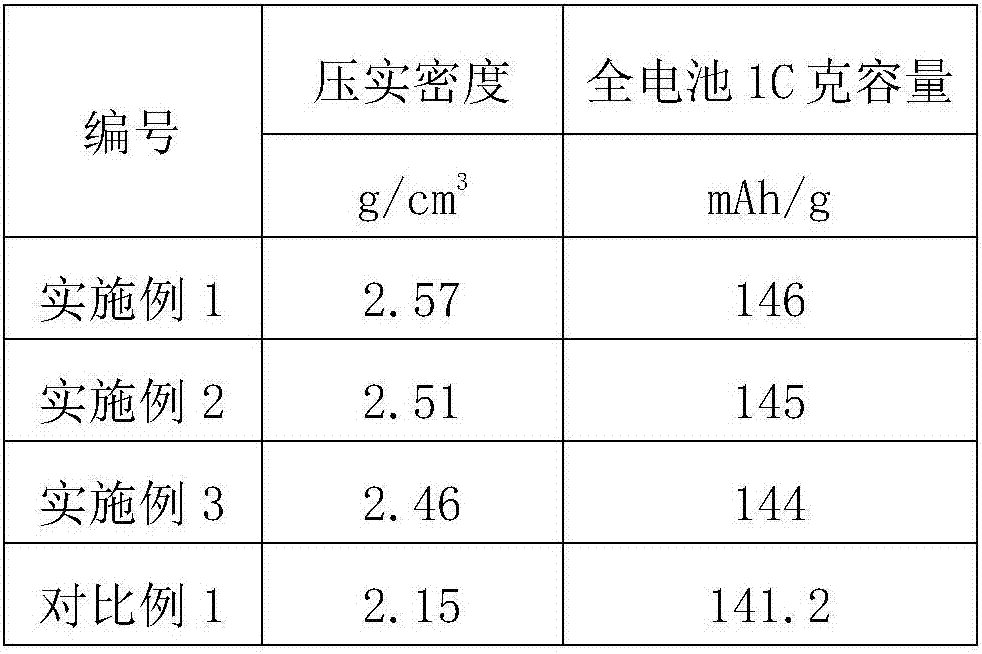

High-compaction-density lithium iron phosphate anode material and preparation method thereof

InactiveCN108011104AHigh densityThe preparation process is simpleCell electrodesSecondary cellsAutomatic controlSizing

The invention discloses a high-compaction-density lithium iron phosphate anode material and a preparation method thereof. Sizing agents of two different particles are selected, the large-particle sizing agent and the small-particle sizing agent are mixed according to a certain ratio in the grinding stage, then, drying treatment and thermal treatment are performed to obtain high-compaction-densitylithium iron phosphate, the obtained lithium iron phosphate is large in density, the preparation technological process is simple, the cost is low, the material can be applied to industrial mass production, automatic control is achieved, the finished lithium iron phosphate is good in performance, resources are saved, and the production efficiency is improved.

Owner:桑顿新能源科技(长沙)有限公司

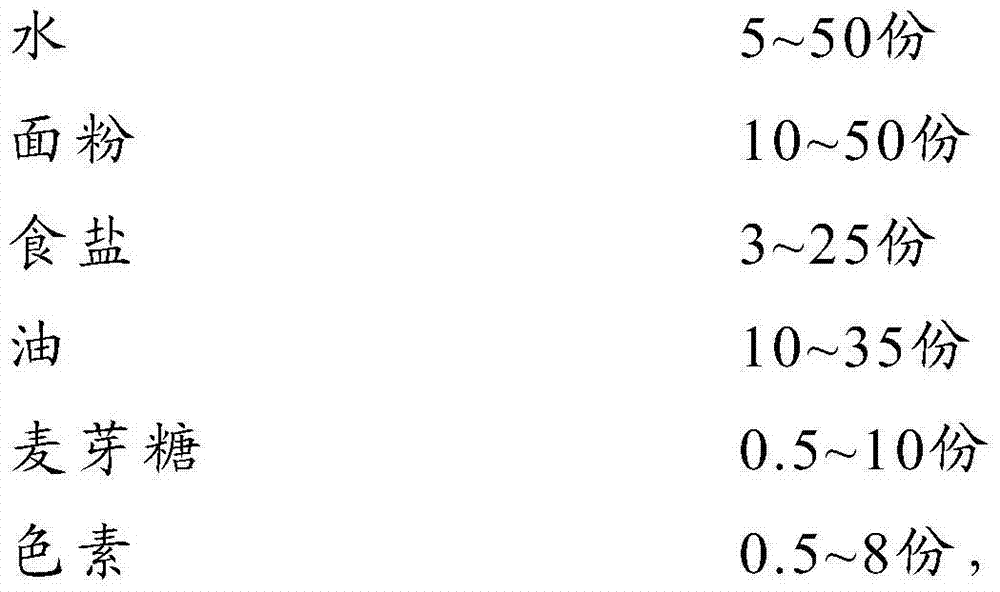

Non-toxic plasticine and preparation method thereof

The invention discloses a non-toxic plasticine and a preparation method thereof. The non-toxic plasticine is prepared from an edible flour material and water which are used as a base material, wherein the non-toxic plasticine contains collagen and nanogold sol, is excellent in elasticity, not easy to crack, environmental-friendly, non-toxic and harmless, has good moulding property and good drying resistance effect and relatively strong antibacterial action, and is suitable for being used by children. The preparation method provided by the invention is simple, convenient and easy to operate.

Owner:南京北福泉圣环保科技有限公司

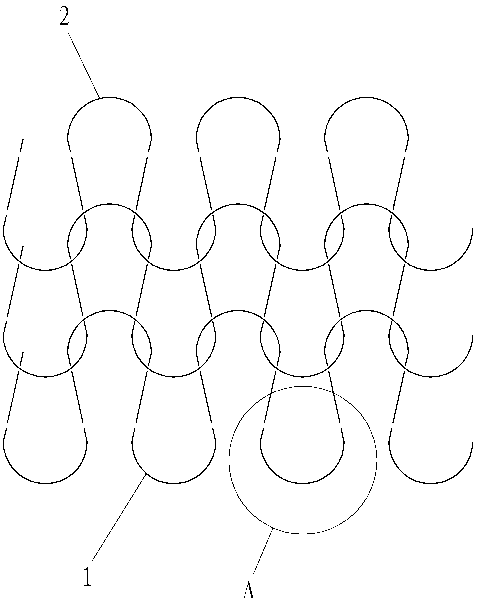

Blended yarn weaved fabric

The invention provides a blended yarn weaved fabric, comprising blending strips, wherein each blending strip is formed by wool yarns, spun silk yarns and long stapled cotton yarns; the wool yarns, the spun silk yarns and the long stapled cotton yarns are respectively formed by half-wool fibers, silk fibers and long stapled cotton fibers; and the half-wool fibers, the silk fibers and the long stapled cotton fibers are strip-shaped. According to the blended yarn weaved fabric, a stretch breaking machine is firstly used for carrying out stretch breaking on the natural wool fibers into the half-wool fibers with the length which is one half of the previous wool fibers; the length of the half-wool fibers is similar with the length of the silk fibers and the length of the long stapled cotton yarns, so that the half-wool fibers are convenient to spin and the finished-product effect is good; wools and long stapled cotton are interwoven with silks on the basis of multi-compounding to maintain the elasticity, the fluffiness and the heat preservation of the wools; and the blended yarn weaved fabric has the good glossiness of the silks and the moisture adsorption of the long stapled cotton, and the defects that the wools are itchy to wear and are easily fluff and balled up are greatly improved.

Owner:POLARGOOSE CLOTHING

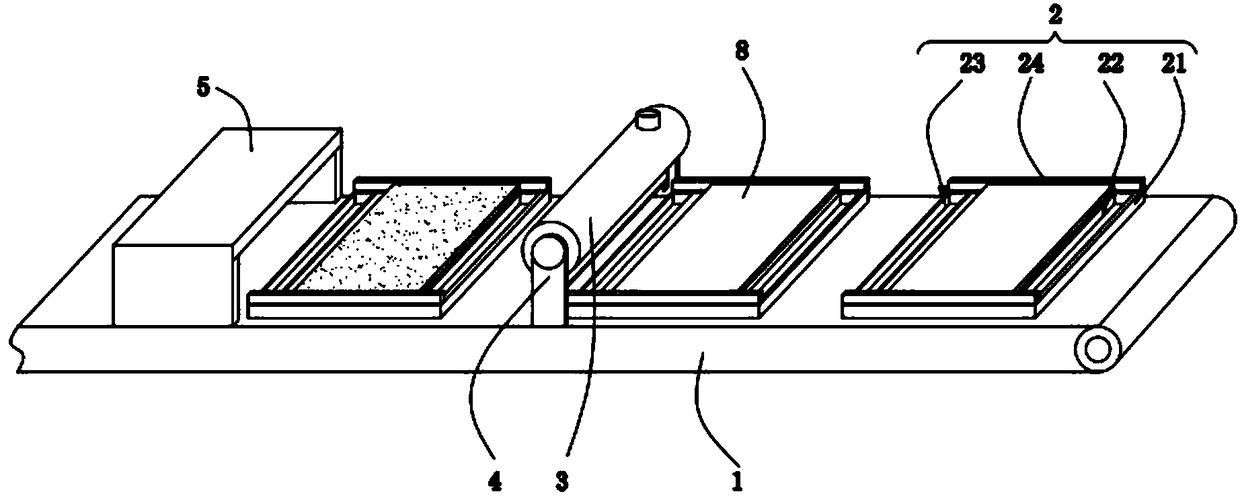

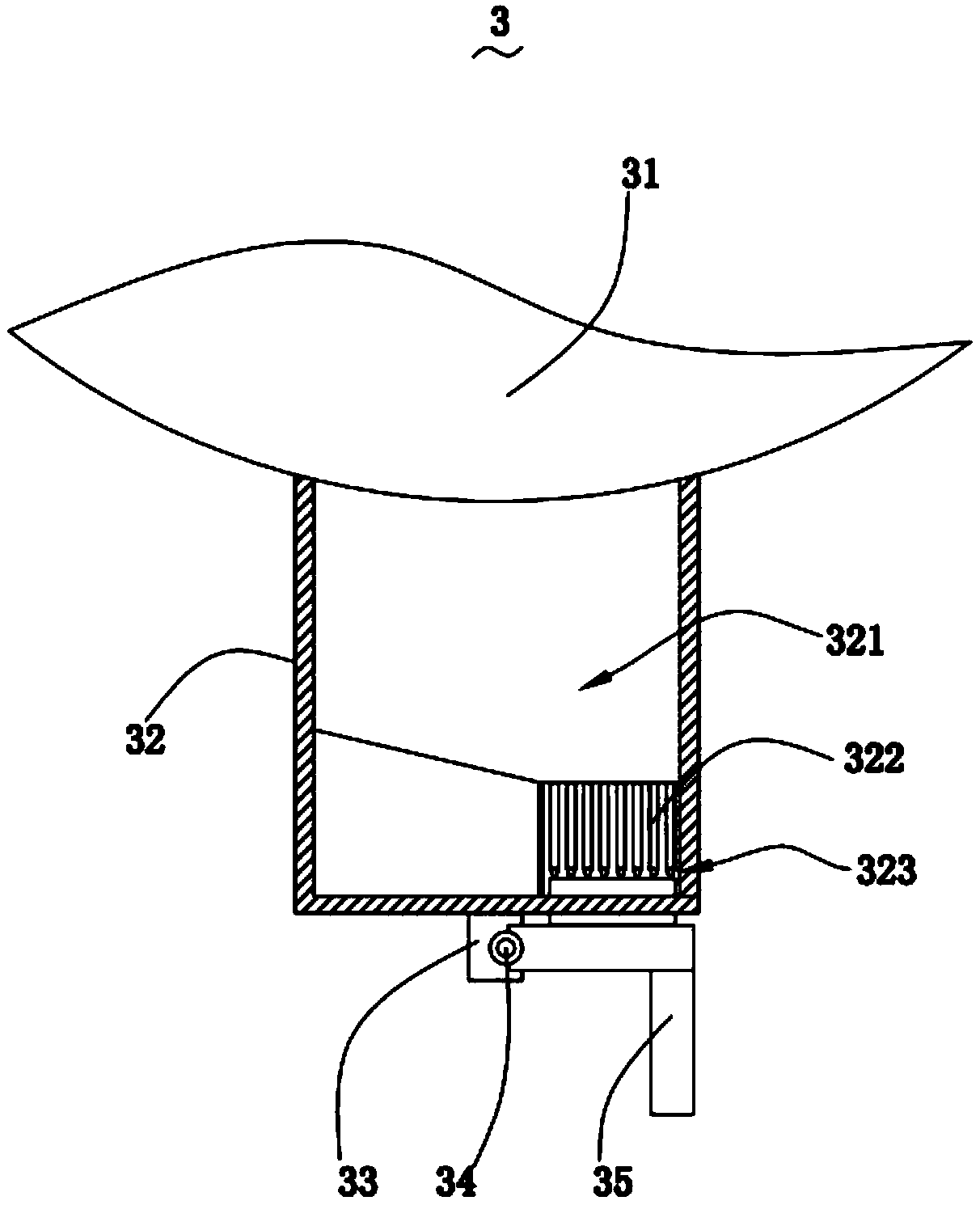

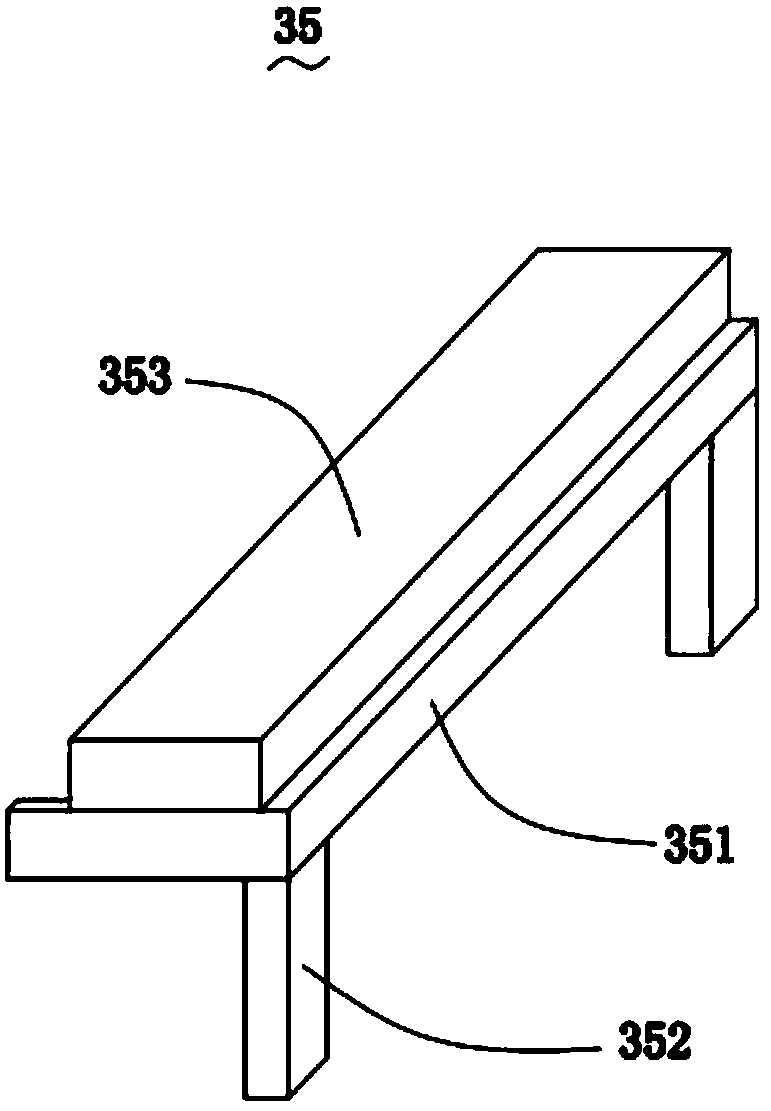

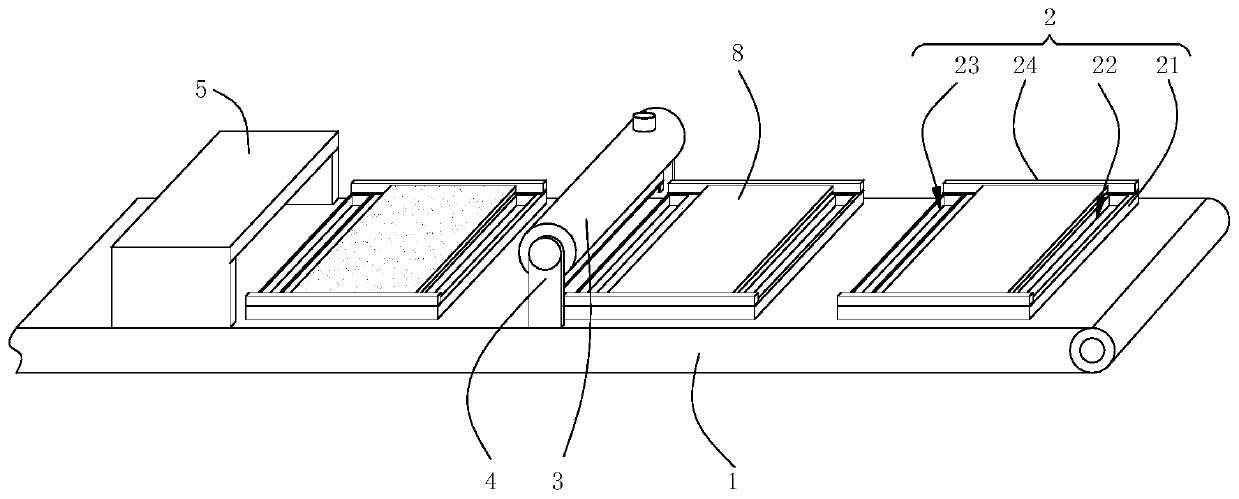

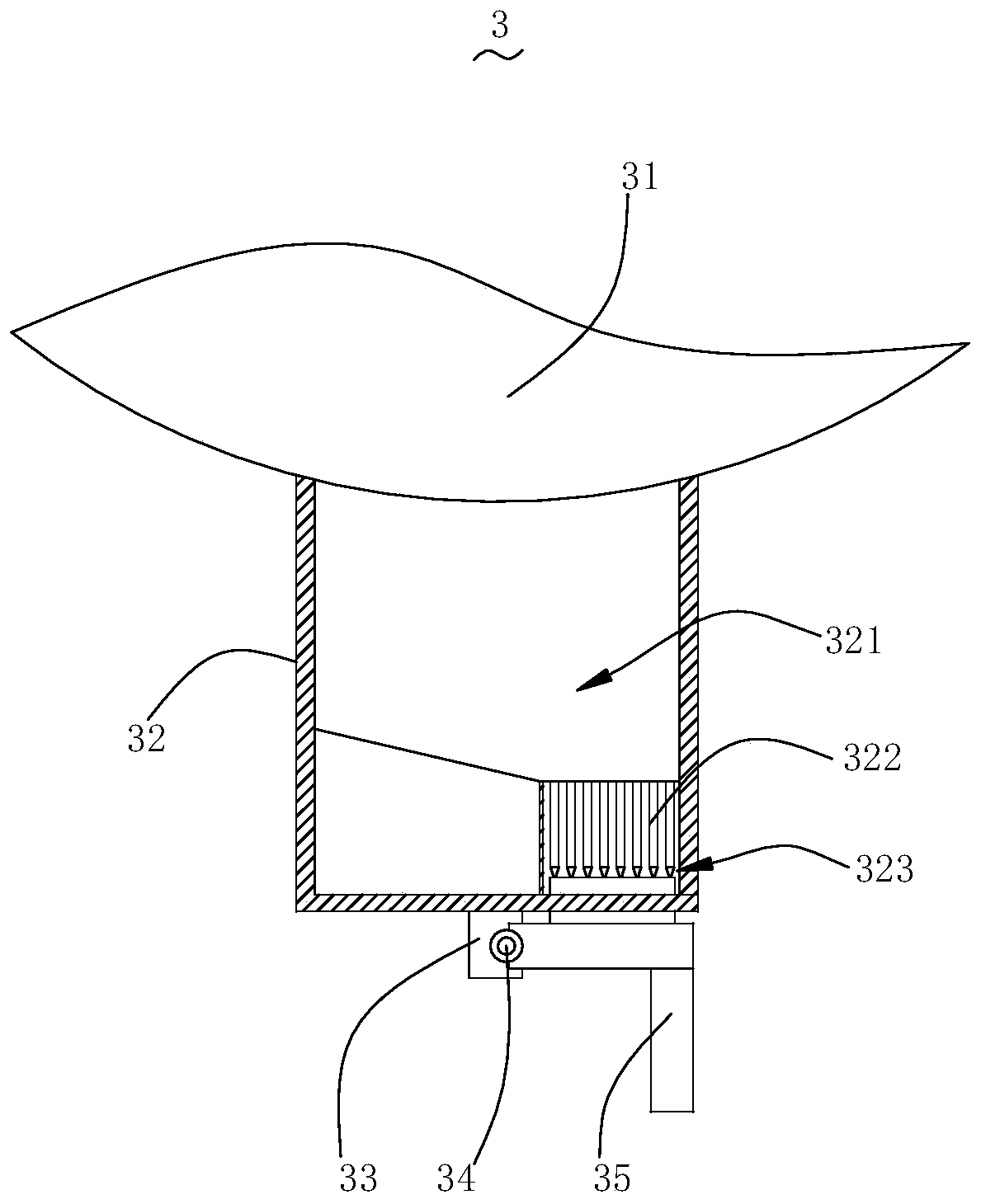

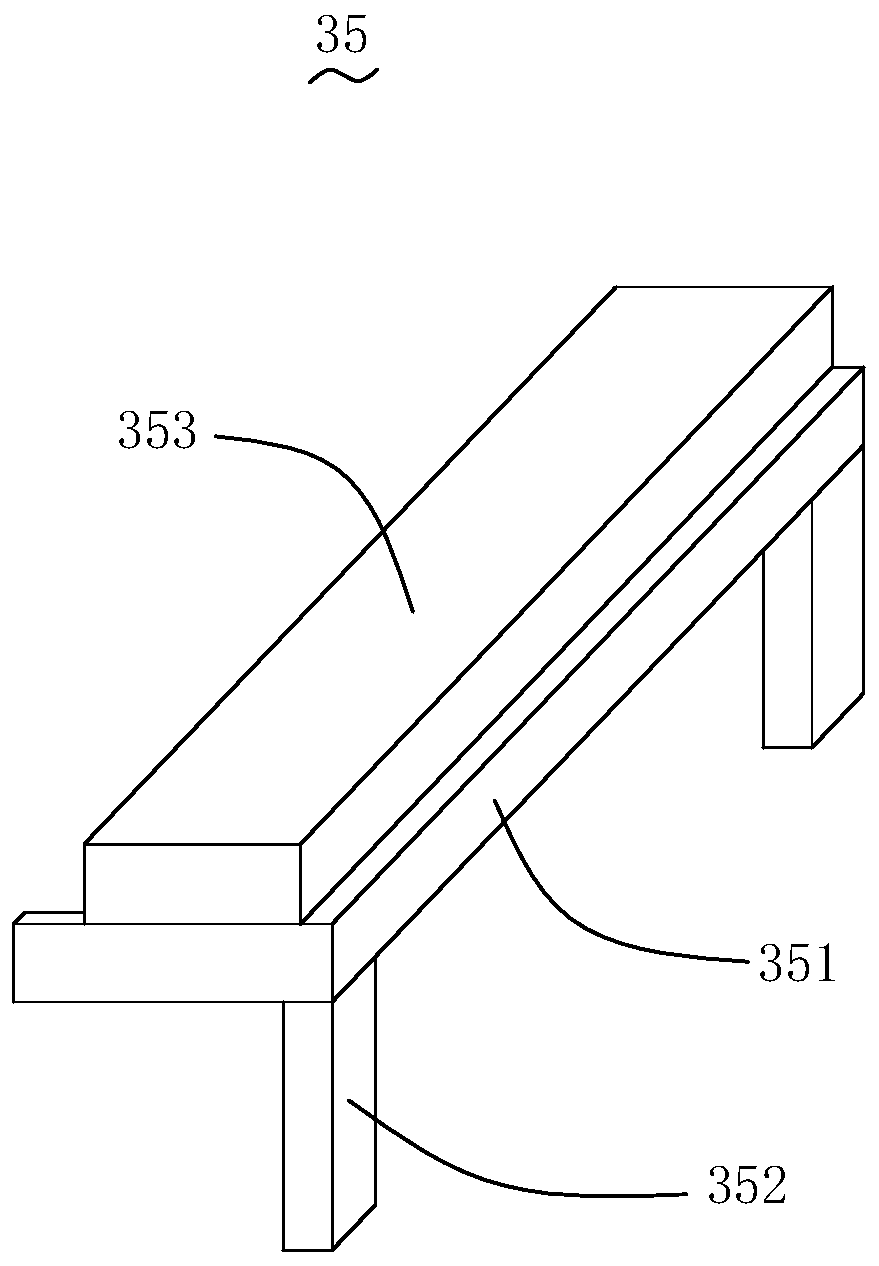

Unidirectional perspective glass manufacturing and processing equipment

InactiveCN108525945ARealize automatic film coatingNo manual operationLiquid surface applicatorsCoatingsLeveling mechanismPulp and paper industry

The invention relates to the technical field of glass processing, specifically to unidirectional perspective glass manufacturing and processing equipment. The equipment comprises a conveying belt, a material placing mechanism, a liquor drainage mechanism, a supporting plate, a processing cover, a leveling mechanism and an air drying mechanism. When the glass moves to the bottom of the liquor drainage mechanism, a plugging mechanism is opened under the push of a clamping mechanism and drainage liquor automatically. When the glass leaves the bottom of the liquor drainage mechanism, the pluggingmechanism is driven by a spring and a secondary plugging is carried out, so that automatic coating to each passing piece of glass is achieved, manual operation is not needed and automatic opening andclosing are achieved. Needle shaped liquor drainage heads in rectangular array distribution enable coating to be evenly distributed on the surface of the glass, so that the coating effect is better and the coverage is wider. The leveling mechanism scrapes the coating to a same thickness and the extending length of a scraping plate can be adjusted according to production need so that finished production is better. The collecting grooves can collect the redundant coating and waste is avoided.

Owner:夏美佳

Method for manufacturing granulated gel and coating composition having the same

ActiveCN101230141AEasy and stable to manufactureEasy to manufacture and stableCoatingsOrganic acidWater soluble polysaccharides

The invention provides a manufacturing method of granulated gel and coating composition formed of the granulated gel obtained from the manufacturing method combined with coating film forming ingredient. The granulated gel manufacturing method comprises bringing aqueous liquid compound including waterborne resin, colorant and water-soluble polysaccharide into contact with water medium containing metal compound, characterized in that organic acid metal salt serves as a component part of the metal compound.

Owner:KANSAI PAINT CO LTD

Vermicelli and its production process

InactiveCN1387785AImproved performance of the finished productNo side effectsFood preservationFood preparationParaffin waxCorn starch

The present invention provides alumless vermicelli agglutinant which includes high effective composite emulsifier, sodium carboxymethyl cellulose, sodium tripolyphosphate, tartaric acid, potassium hydrogen tartarate, sodium bicarbonate, paraffin wax, edible salt, acid denatured potato starch. The present invention also discloses alumless vermicelli including sweet potato starch, potato starch, corn starch etc. The present invention also discloses the production method of alumless vermicelli, said method can shorten ageing time, raise product performance, improve manufacturing efficiency etc.

Owner:陈朝晖

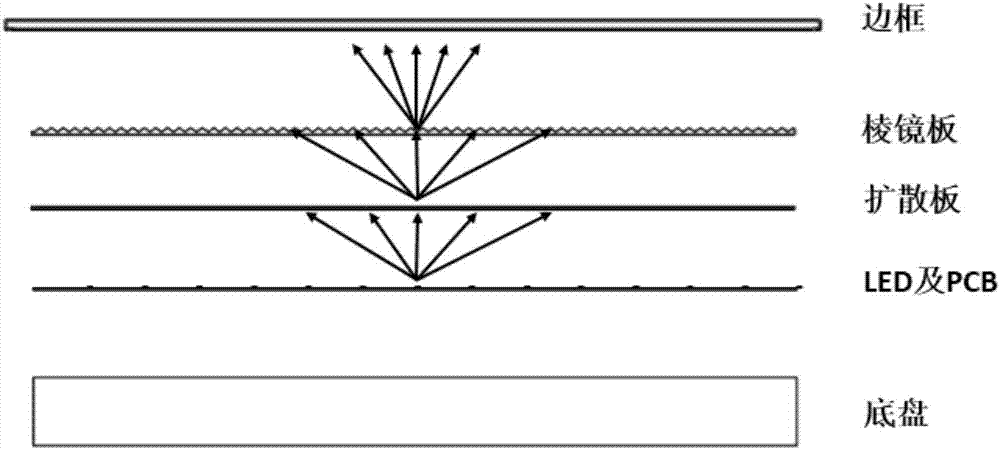

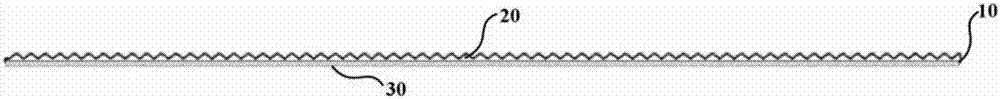

Prism diffusion plate, prism diffusion plate preparation method and lamp

The invention provides a prism diffusion plate, a prism diffusion plate preparation method and a lamp. The prism diffusion plate includes a substrate, a microprism structure layer and a diffusion layer, wherein the microprism structure layer and the diffusion layer are respectively arranged at two surfaces of the substrate. According to the prism diffusion plate provided by the invention, the anti-glare effect of a microprism structure and the light diffusion effect of a diffusion plate can be integrated on one plate, and therefore, the two kinds of functions can be simultaneously realized on the same plate, and the preparation method of the prism diffusion plate is simple, and the effects of a finished plate can be excellent. According to lamp provided with the prism diffusion plate, the cost of the diffusion plate can be decreased, and resources can be saved, the installation and fixation mode of the lamp is simpler, and the lamp will be lighter and thinner.

Owner:OPPLE LIGHTING

Vegetable powder cake and its production process

InactiveCN1403016AImproved performance of the finished productNo side effectsFood preservationFood preparationParaffin waxCorn starch

The vegetable powder cake is produced with sweet potato powder, potato powder, corn starch, powder dispersing agent, vegetable juice and vegetable powder, and its powder dispersing agent consists of carboxymethylcellulose sodium emulsifier, sodium tripolyphosphate, modified starch, sodium bicarbonate, tartaric acid, sodium bitartrate, salt and edible paraffin. The present invention also provides the production process of the vegetable powder cake. The vegetable powder cake may be well mixed with water for restoring and is delicious and tough.

Owner:SICHUAN BAI JIA FOOD CO LTD

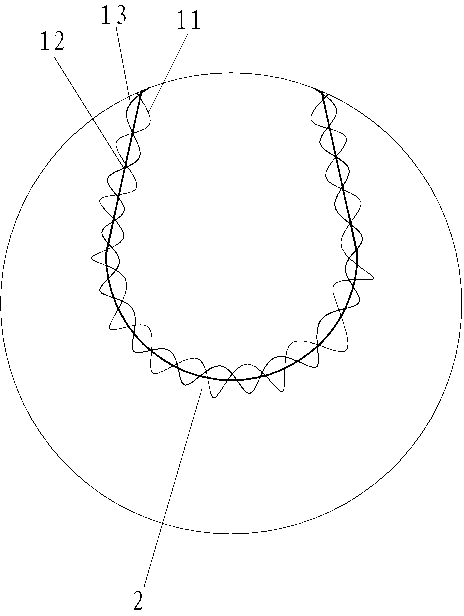

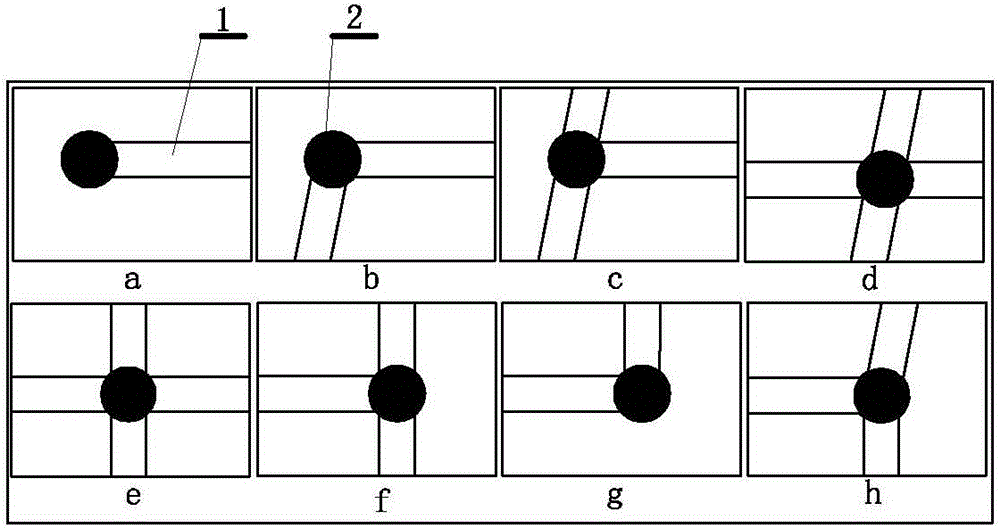

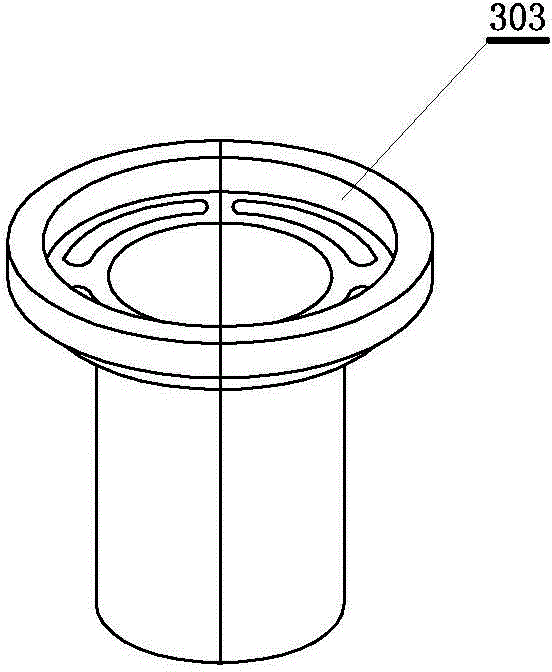

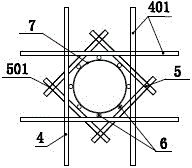

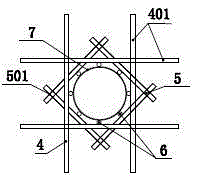

Special-shaped beam column node template and engineering template equipping method thereof

ActiveCN104563495AReduce construction costsGood deformation resistanceForms/shuttering/falseworksCollocation methodSoftware engineering

The invention discloses a special-shaped beam column node template and an engineering template equipping method thereof. The special-shaped beam column node template comprises a bottom die used for being connected with an upright column in a sealing and embracing mode, and an upper die which is fixedly connected with the bottom die, wherein an annular platform is arranged at the upper opening of the bottom die outwards at 90 degrees, a long strip arc through hole is formed in the annular platform, the upper die consists of a plurality of sections of arc templates, the plurality of sections of arc templates are regulated and spliced along the inner circumference of the bottom die to left beam connectors in different directions to form special-shaped beam column nodes, and a bolt penetrates through the through hole to be used for fixing the upper die onto the bottom die. According to the special-shaped beam column node template disclosed by the invention, by virtue of the structure, an upper template can be arranged in an arbitrary rotating mode so as to regulate the direction of a beam opening; by using the upper template formed by the arc templates with the common divisor or called modulus, the upper template can be detached and separately spliced, and the problem of non generality is solved with the combined type modulus upper template; by virtue of a matching method, the use quantity of the upper template can be proper, so that the segmented continuous construction is realized without needing to manufacture the whole template, and the construction cost is saved.

Owner:BEIJING TIANHENG CONSTR

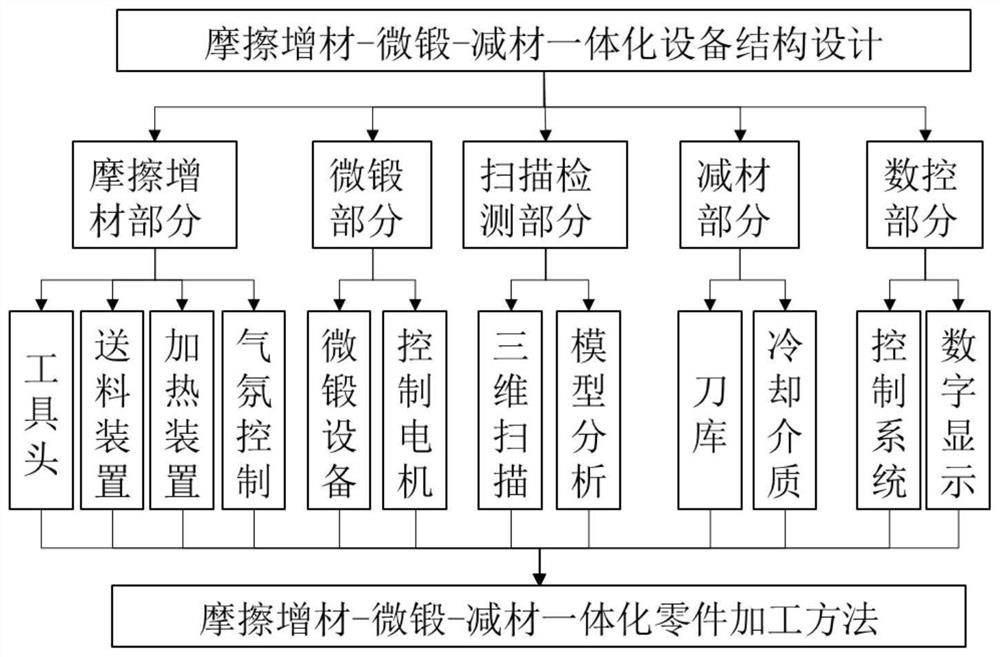

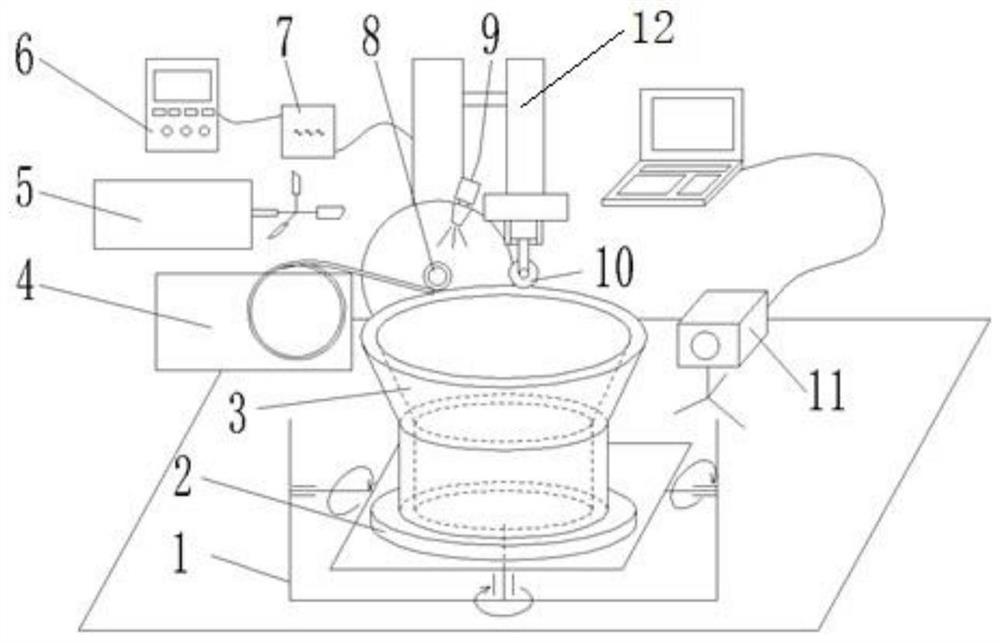

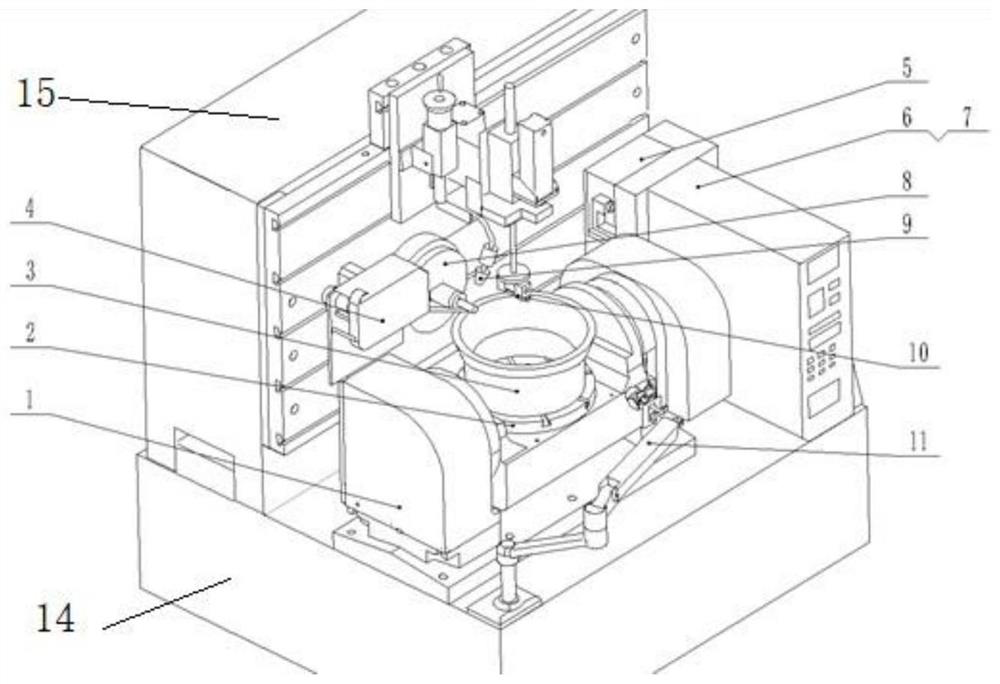

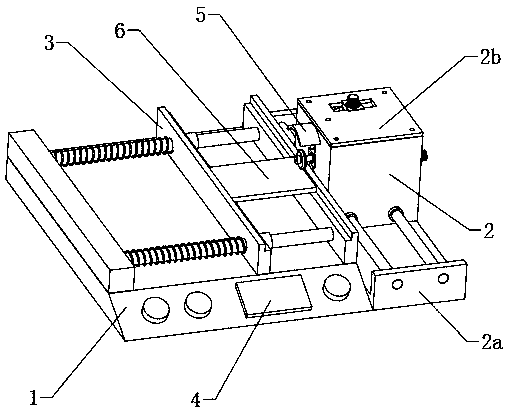

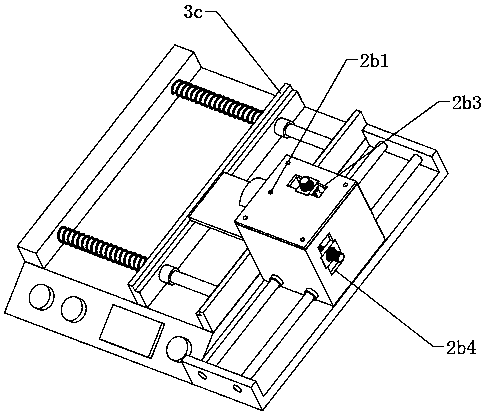

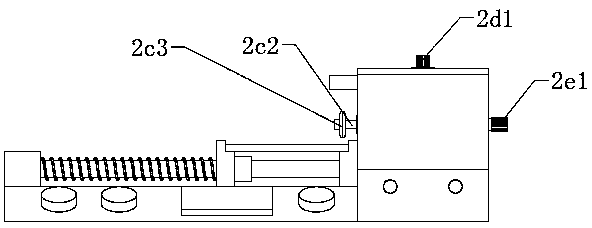

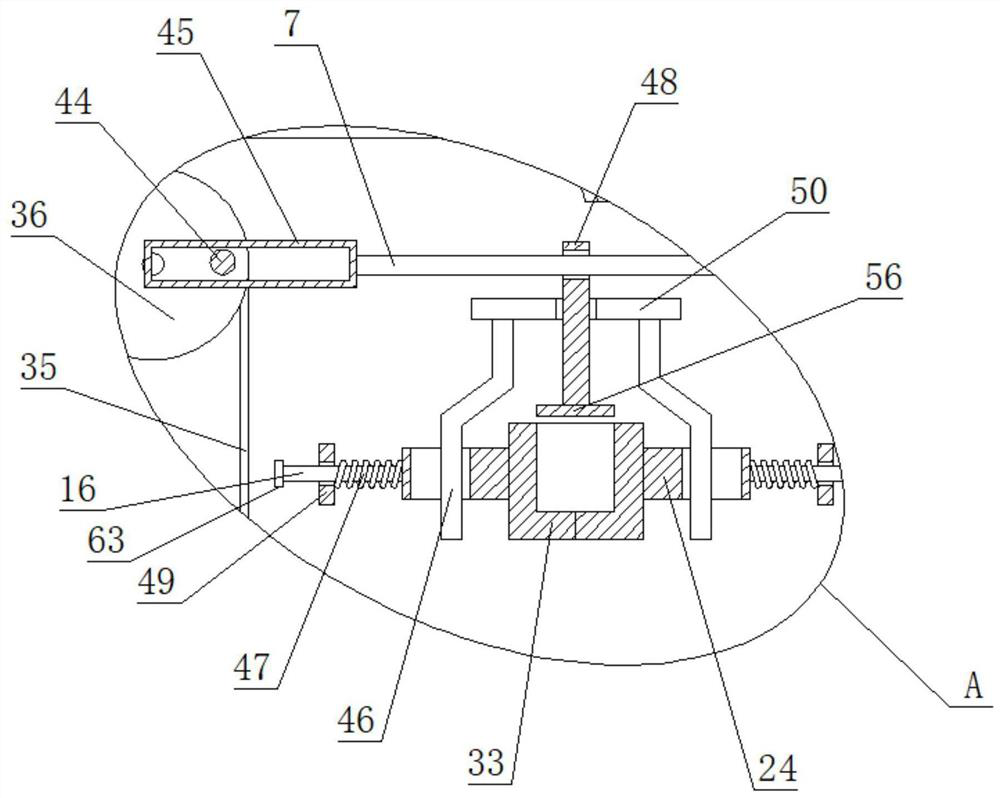

Friction material adding and reducing integrated device and machining method

PendingCN112621221AImprove performanceTightly boundOther manufacturing equipments/toolsMaintainance and safety accessoriesElectric machineryThree dimensional model

The invention relates to a friction material adding and reducing integrated device and a machining method. The friction material adding and reducing integrated device and the machining method are used for integrating the material adding process and the material reducing process of a workpiece. A friction material adding part, a micro-forging part and a material reducing part are designed as necessary structures. A material adding manufacturing part comprises a position changing machine, a rotary workbench, a rotary tool head and a feeding device and is used for solid-phase material adding manufacturing forming of a part; the micro-forging part comprises forging equipment and a motor and is used for increasing the compactness of the formed part, reducing internal defects and improving the mechanical property; a scanning detection part comprises a laser three-dimensional scanner and three-dimensional model contrastive analysis software and is used for monitoring and scanning the shape of the workpiece obtained after material adding manufacturing, comparing the workpiece with a target part for analysis and determining the area needing material reducing; the material reducing part comprises a rotary tool magazine capable of switching the machining manners of turning, milling, planing, grinding and the like and is used for precision machining of the part obtained after material adding; and a numerical control part is used for material adding-micro-forging-material reducing process control of the formed part.

Owner:BEIJING UNIV OF TECH

Preparation method of temperature-resistant wear-resistant EVA (ethylene-vinyl acetate) sole

ActiveCN107236183AImprove temperature and wear resistanceImproved performance of the finished productSolesTemperature resistanceWear resistant

The invention discloses a preparation method of a temperature-resistant wear-resistant EVA (ethylene-vinyl acetate) sole. The preparation method includes the steps: (1) raw material weighing; (2) enclosed mixing treatment; (3) open mixing treatment; (4) granulation foaming treatment. In the preparation process of the EVA sole, raw material components are reasonably selected and blended, the treatment process is optimized and improved, and finally prepared finished products have good temperature resistance, wear resistance and comprehensive characteristics and high popularizing use values.

Owner:界首市盛泽鞋业有限公司

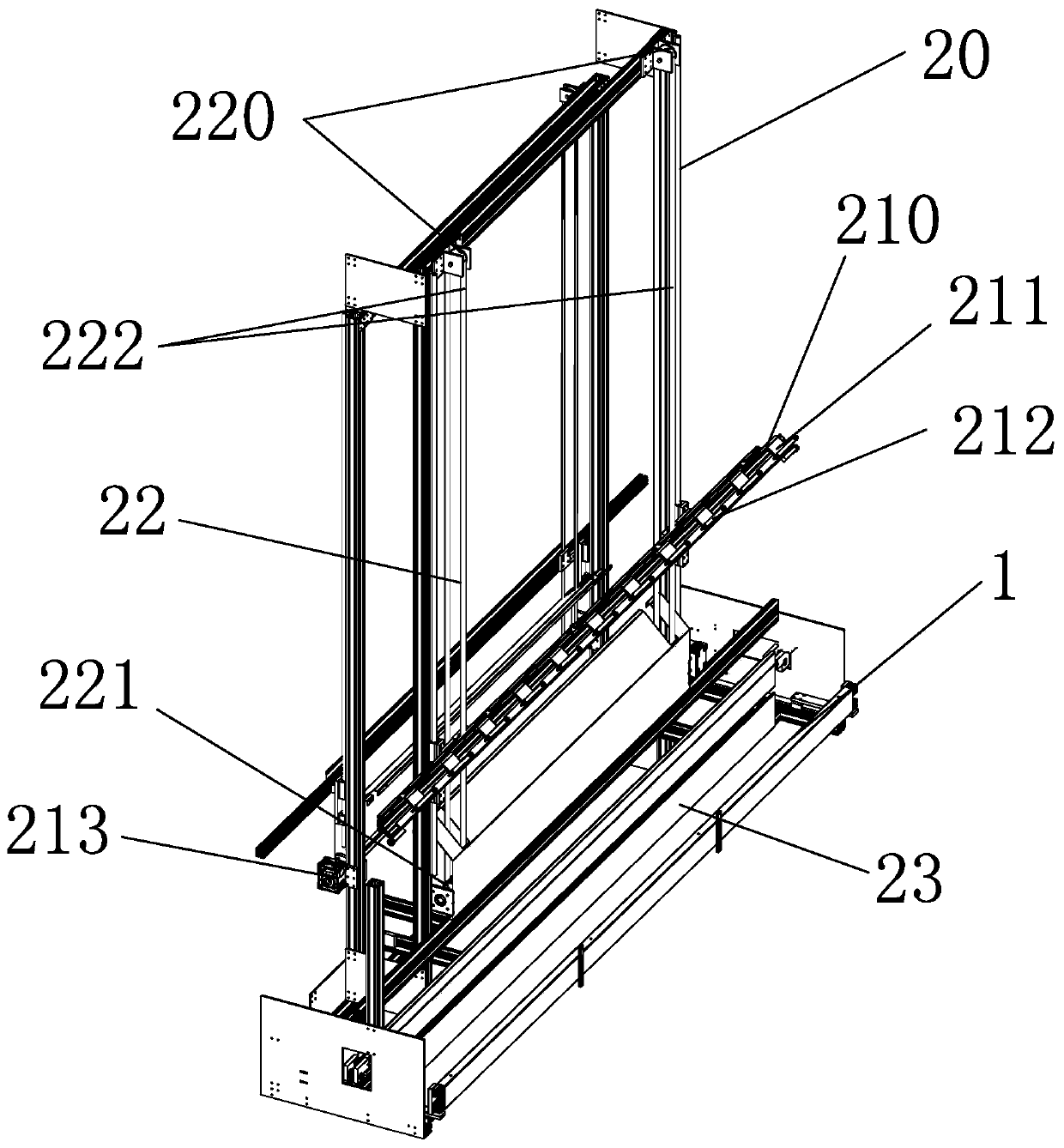

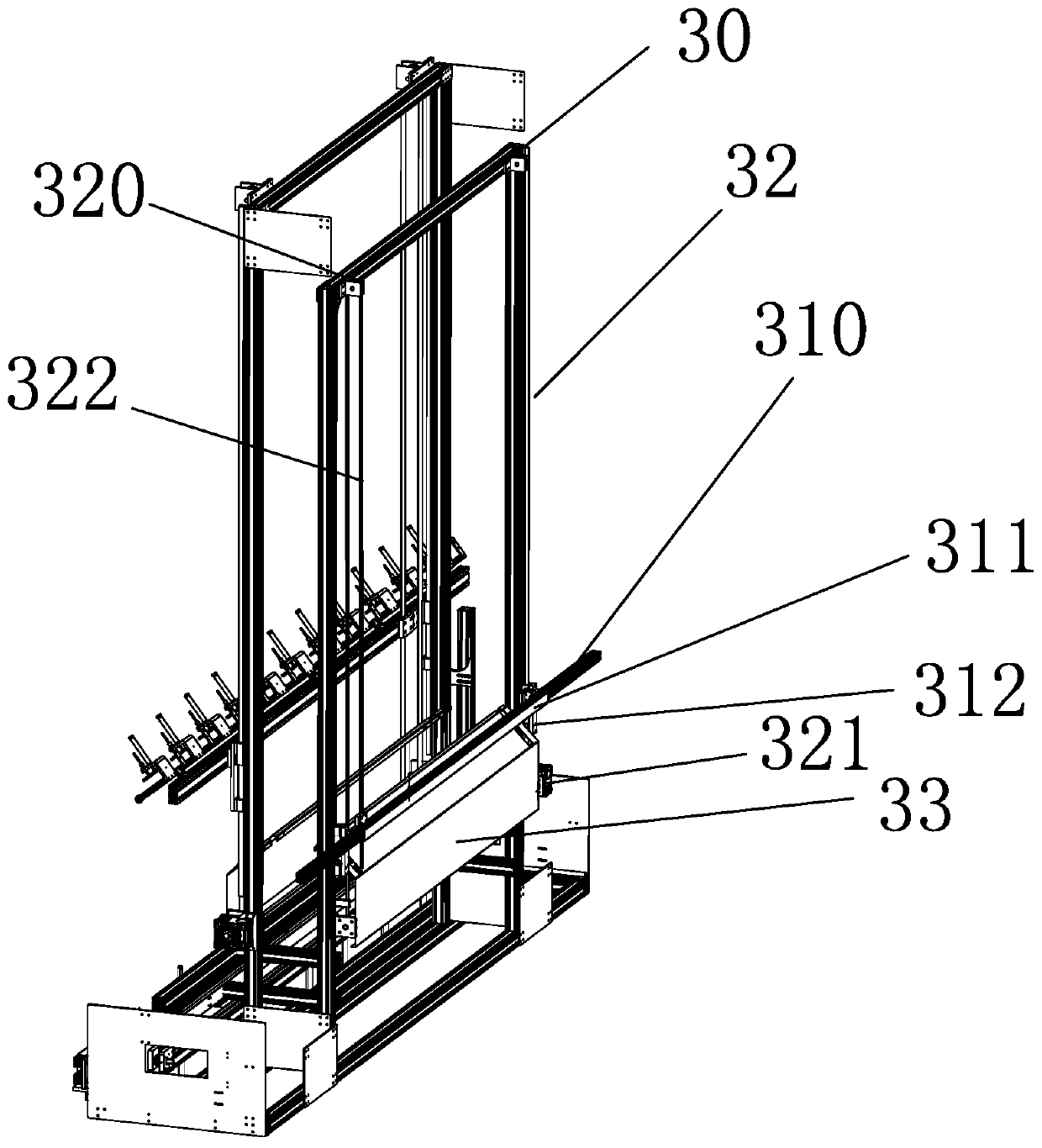

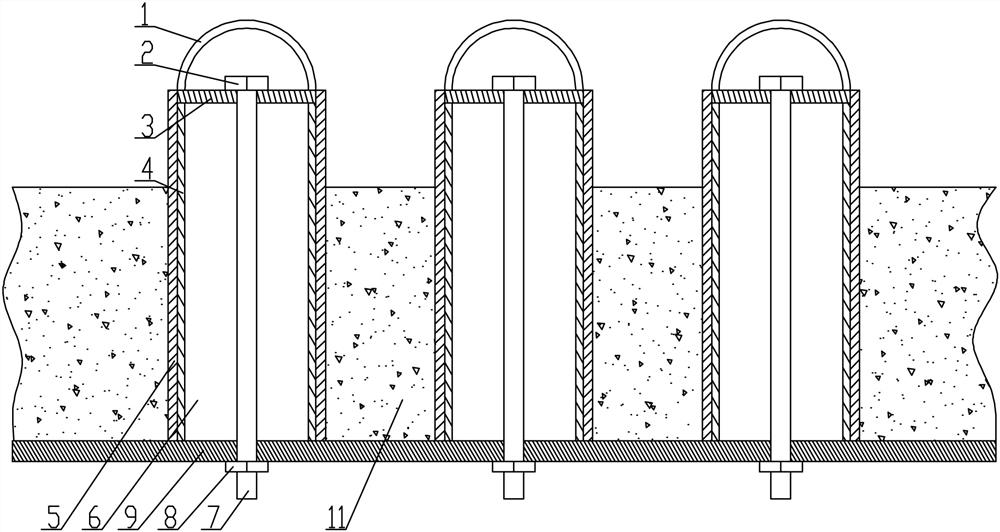

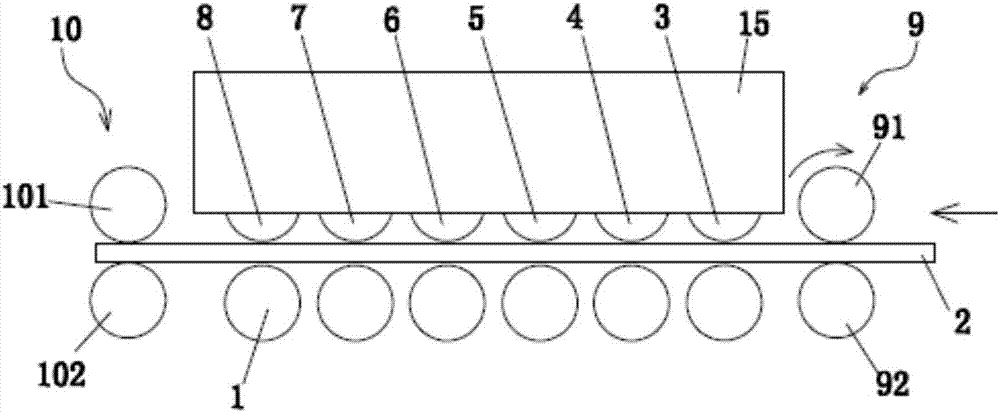

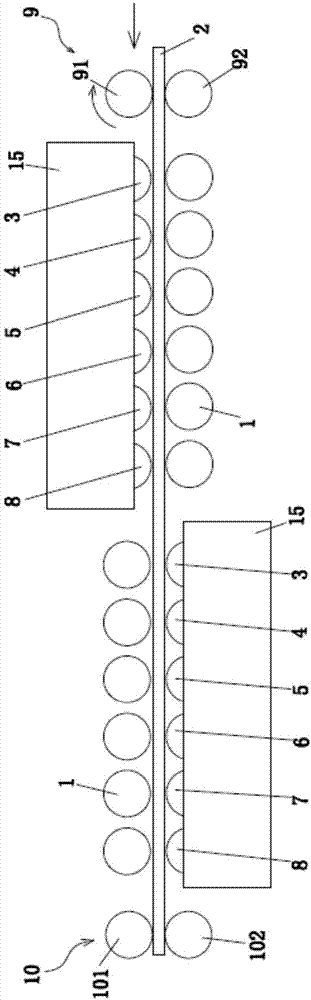

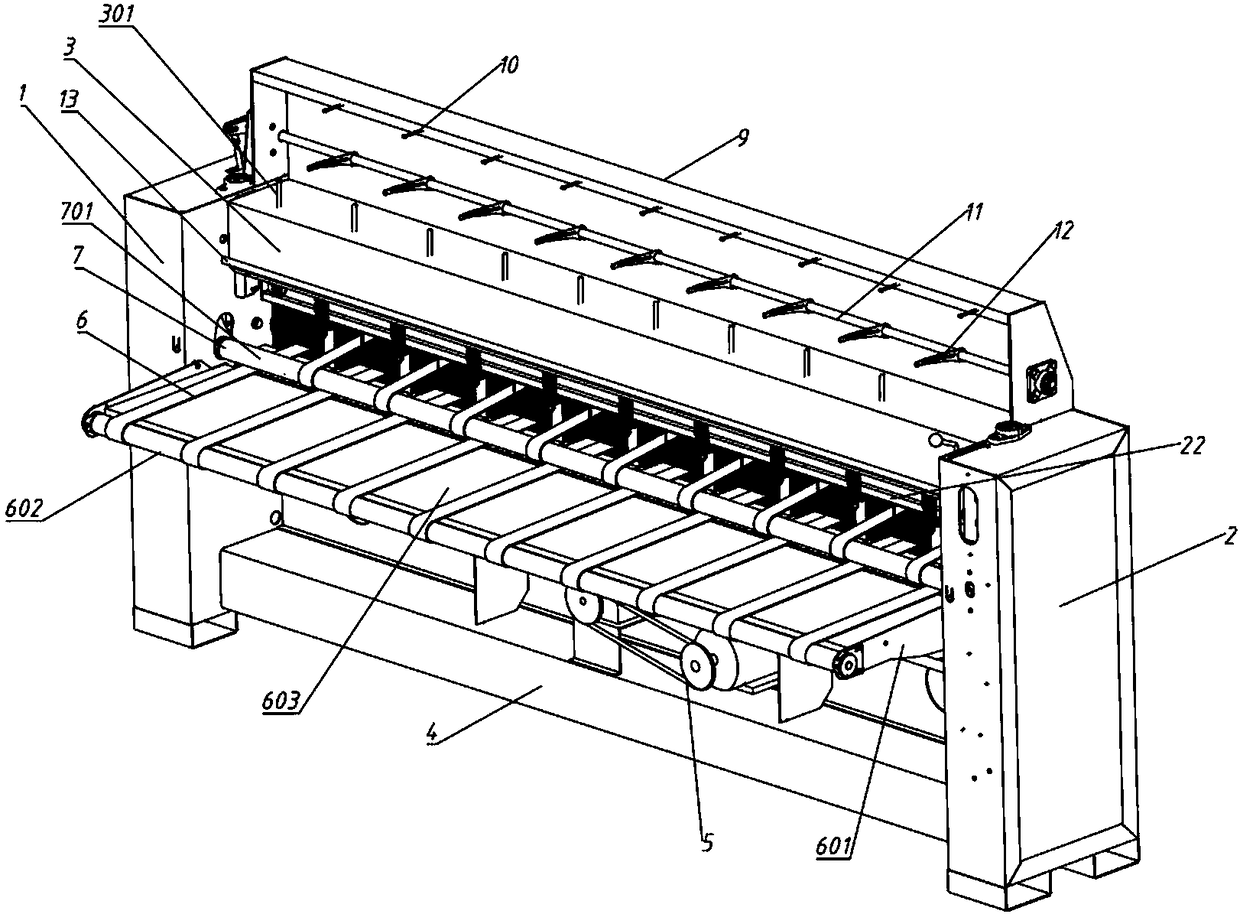

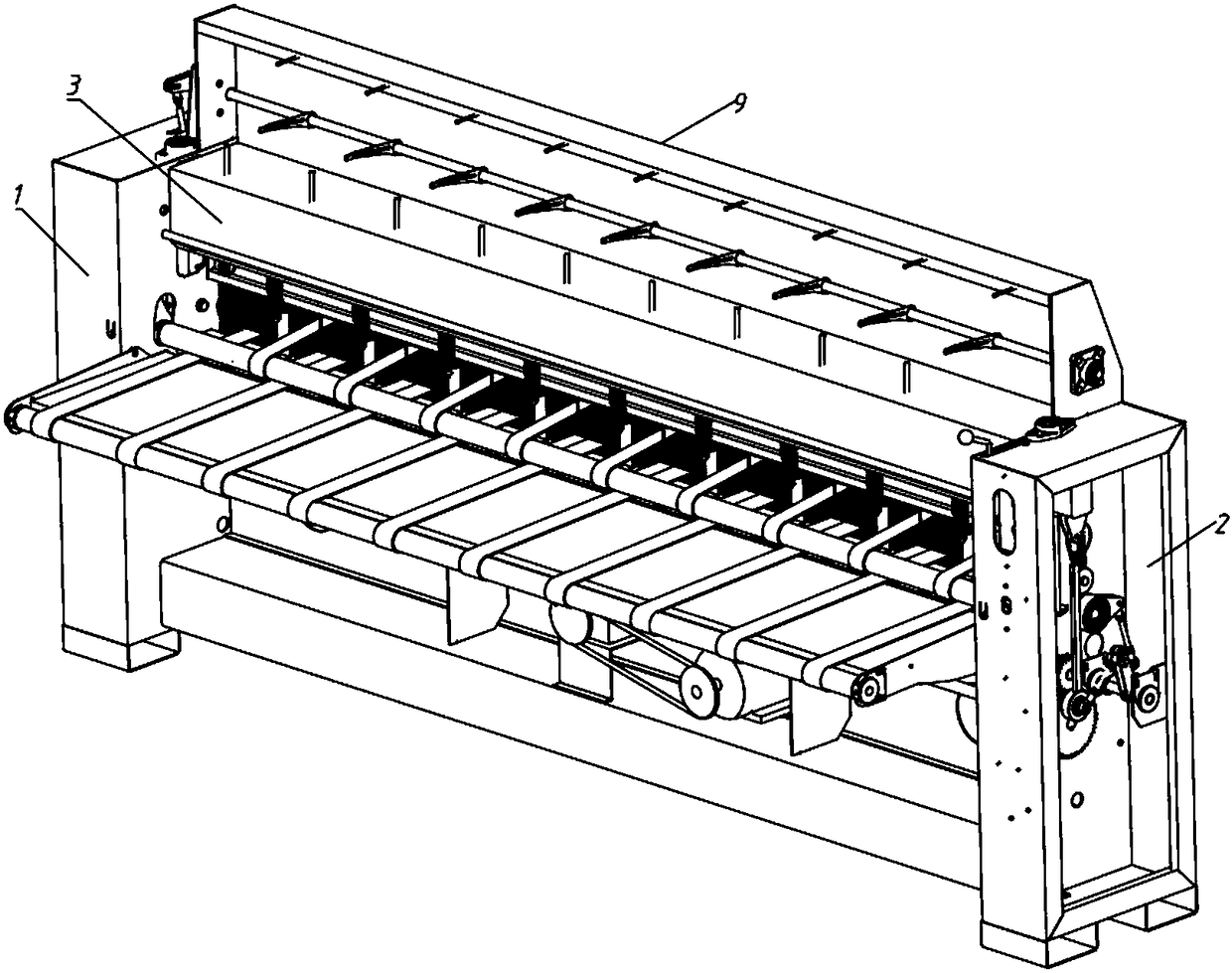

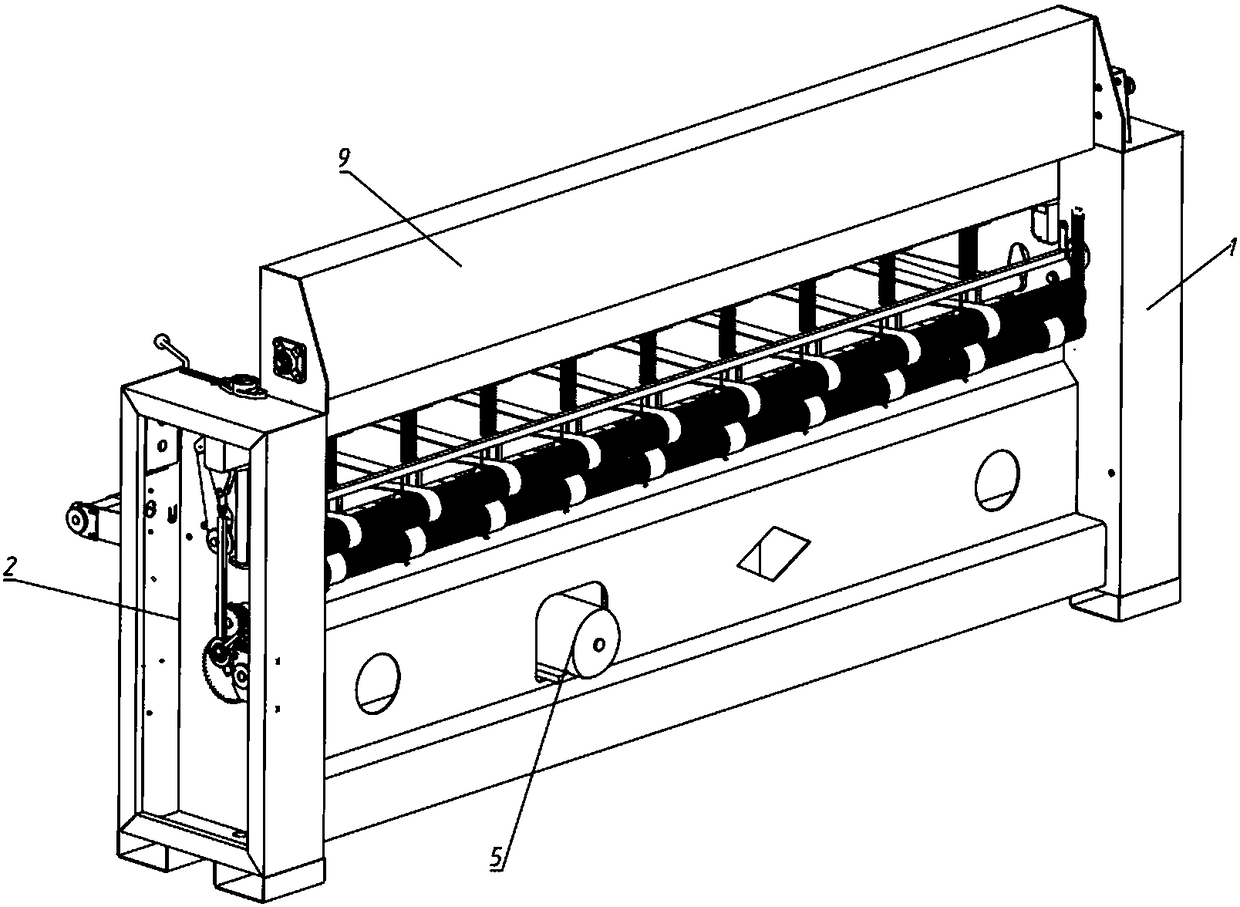

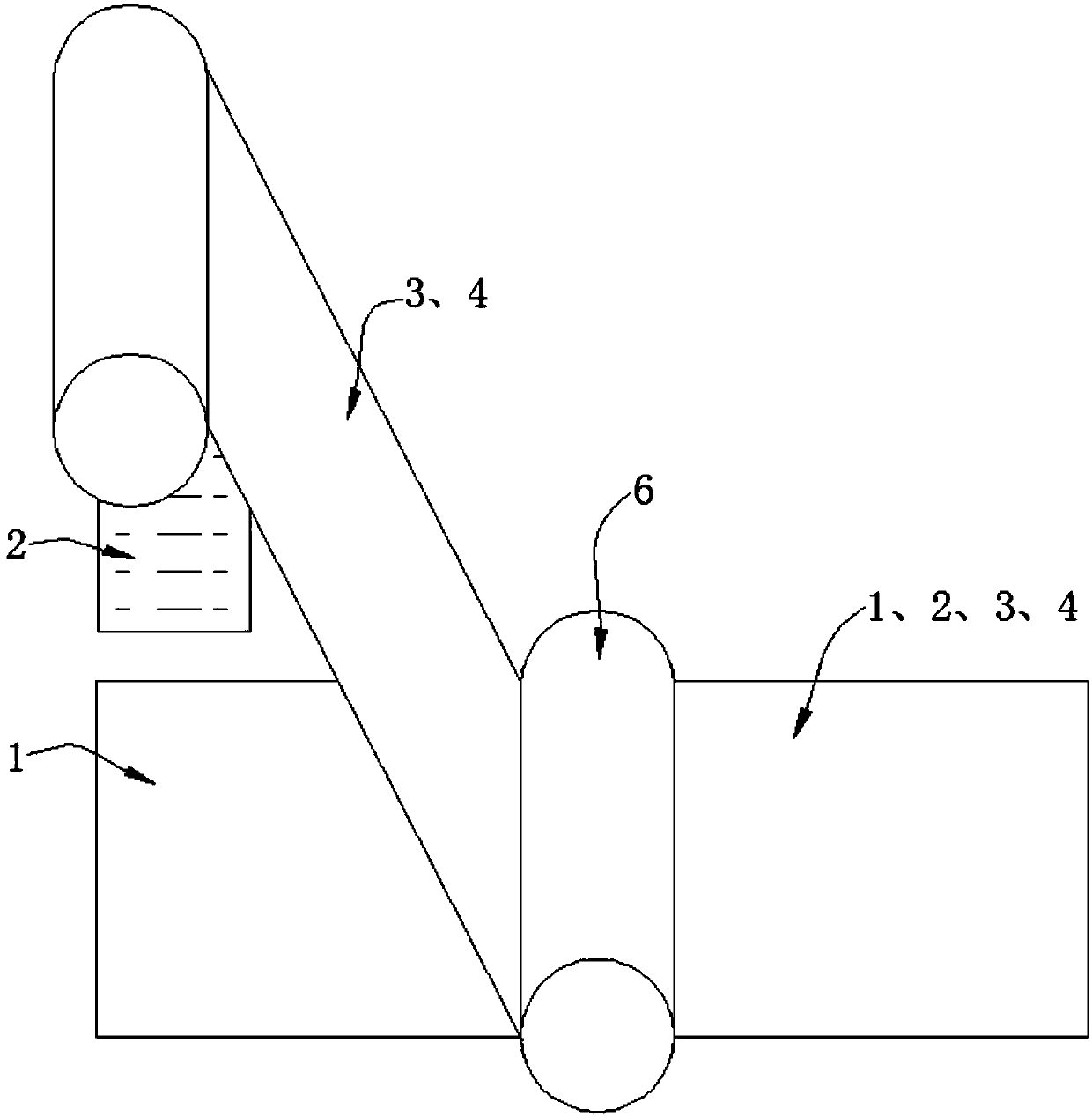

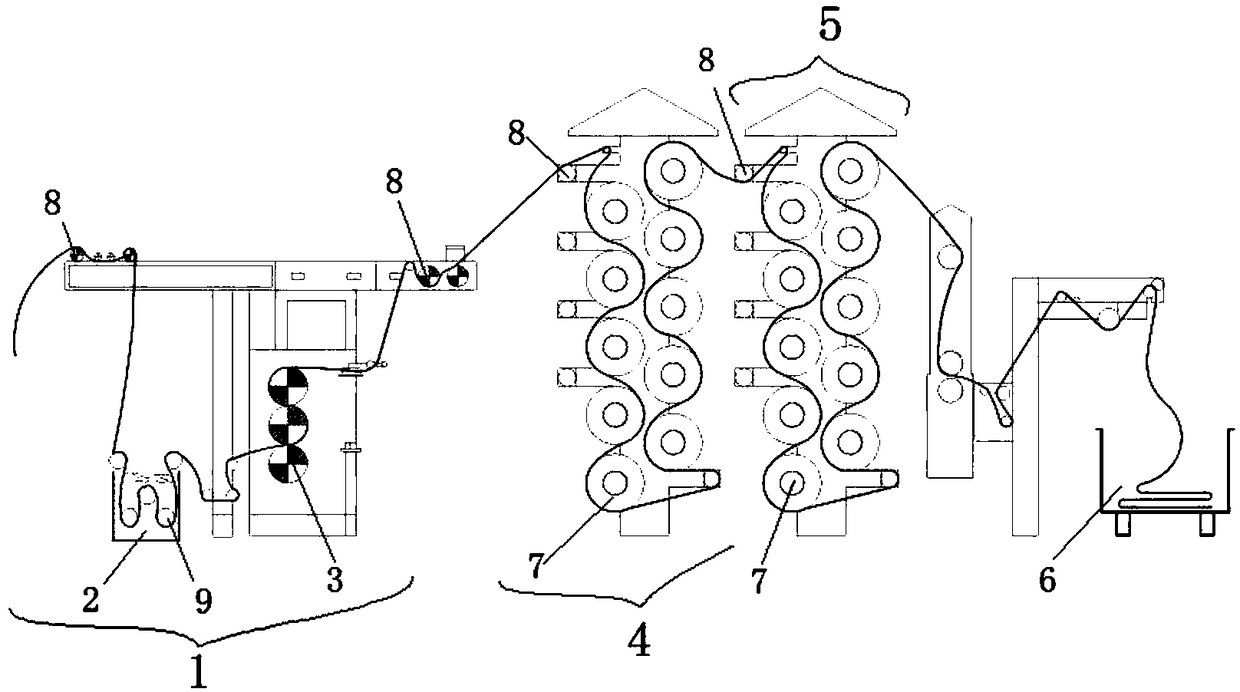

Multifunctional curtain cutting and inspection all-in-one machine and processing method thereof

PendingCN111379157AGood cropping effectImproved performance of the finished productInspecting textilesSevering textilesMachineIndustrial engineering

The invention discloses a multifunctional curtain cutting and inspection all-in-one machine and a processing method thereof, and aims to provide a multifunctional curtain cutting and inspection all-in-one machine which integrates cutting and inspection, and is simple in structure and high in practicability. According to the technical scheme, the multifunctional curtain cutting and inspection all-in-one machine is characterized in that a height fixing surface structure used for height fixing cutting is arranged on one side of a machine frame, and an inspection surface structure used for detecting the quality of a cut curtain is arranged on the other side of the machine frame. According to the multifunctional curtain cutting and inspection all-in-one machine and the processing method thereof, the height fixing surface structure and the inspection surface structure are combined, so that the height fixing cutting of the curtain and the detection of the quality of a finished product are facilitated, and the processing efficiency is improved; and the multifunctional curtain cutting and inspection all-in-one machine and the processing method thereof are suitable for the technical field ofcurtain processing equipment.

Owner:绍兴众杰屹自动化设备科技有限公司

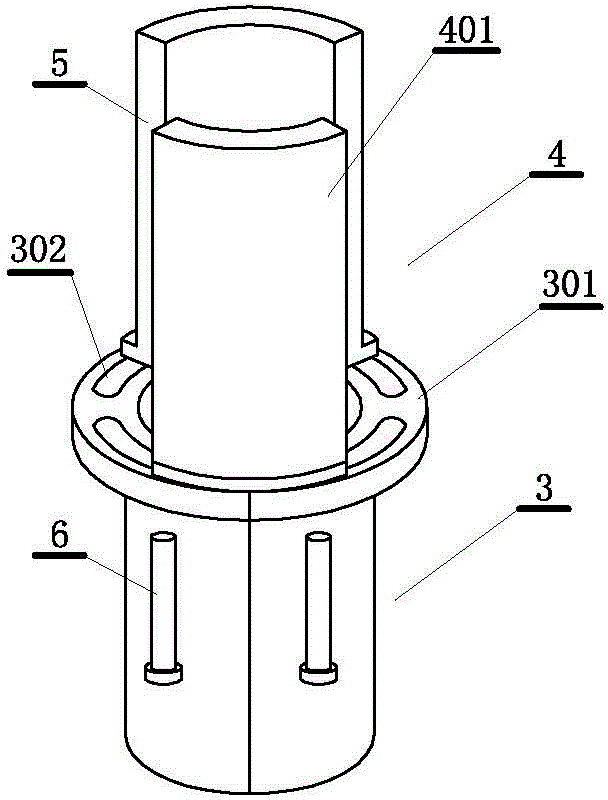

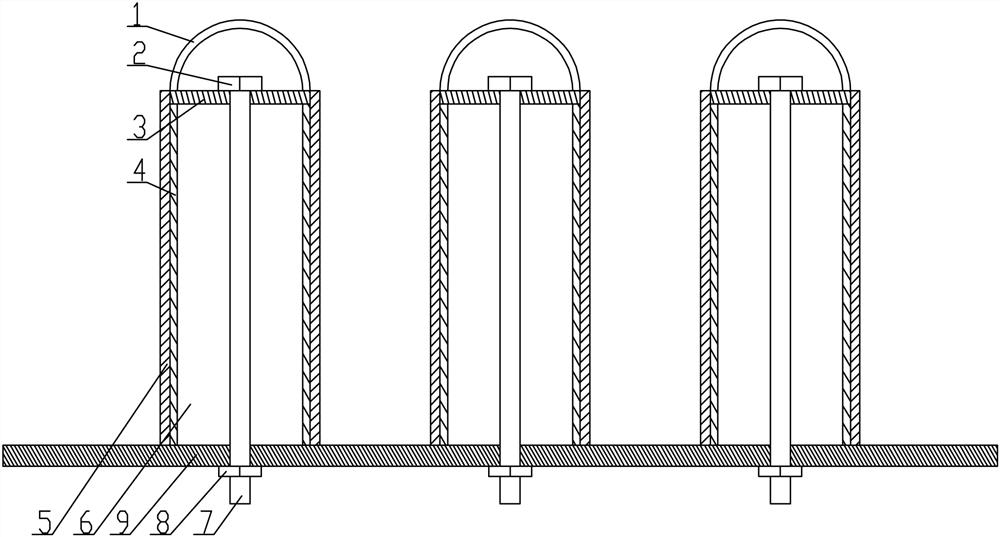

Construction method and cylinder fixing device for pouring concrete to obtain cylinders by aid of paper forms

ActiveCN104100091AFast constructionImproved performance of the finished productForms/shuttering/falseworksBuilding material handlingArchitectural engineeringPlastic film

The invention discloses a construction method and a cylinder fixing device for pouring concrete to obtain cylinders by the aid of paper forms, and belongs to the technical field of processes and devices for constructing buildings. The construction method and the cylinder fixing device have the advantages that steel forms or wooden forms in the prior art are replaced by the paper forms, the cylinders can be constructed quickly via construction procedures including structure form erecting, main reinforcement binding, paper form mounting, cylinder concrete casting and compacting, form removal and maintenance and the like, and good effects of finished concrete cylinder products can be realized owing to a construction process which is implemented by the aid of the paper forms and is favorable for construction safety, quality and progress control; the perpendicularity of the cylinders can be guaranteed owing to paper form adjusting positioners, and deformability of the cylinders can be reduced owing to the paper form adjusting positioners; plastic films wrap the surfaces of the cylinders after construction is completed and the forms are removed, accordingly, pollution on the surfaces of the cylinders can be reduced, pitted surfaces can be prevented, and the quality and the appearance of the concrete cylinders can be greatly improved.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

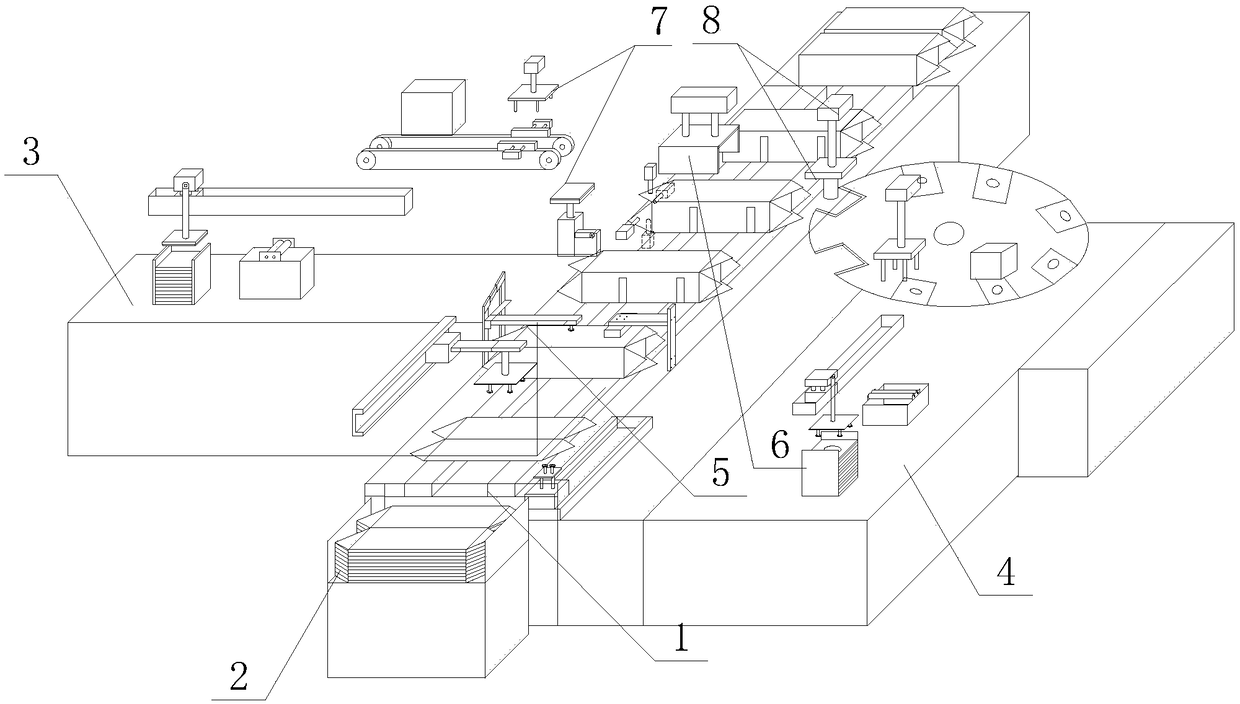

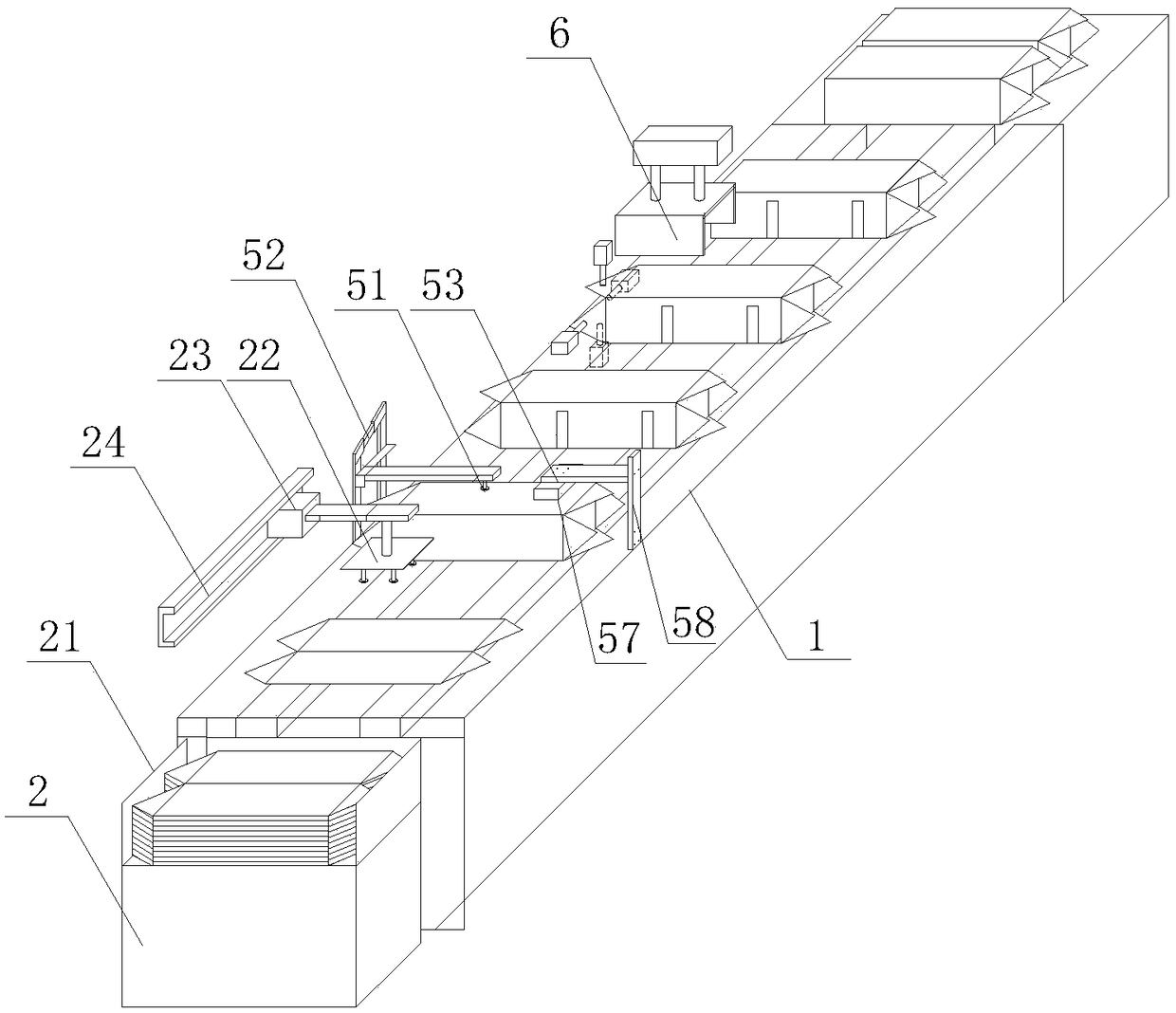

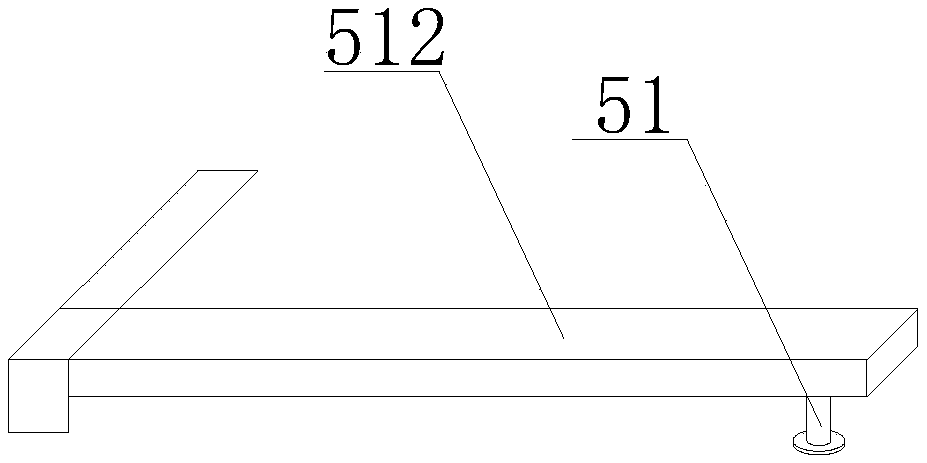

Packaging box full-automatic pasting and assembling production equipment

PendingCN108973226AShorten bonding assembly timeUnified specificationsPaper-makingBox making operationsCardboardEngineering

The invention discloses packaging box full-automatic pasting and assembling production equipment. The equipment comprises a box body conveying line, a box body paper board feeding module, a bottom sealing plate feeding module, a liner feeding module, a bottom sealing plate assembling module and a liner assembling module. A pulling-open module for unfolding paper box paper boards to form box bodiesis arranged on the front half section of the box body conveying line, a positioning module for fixing the box bodies is arranged on the rear half section of the box body conveying line, bottom sealing plates are pushed to adhere to the outer bottom faces of the positioned box bodies by the bottom sealing plate feeding module through the bottom sealing plate assembling module, and liners are pushed to adhere to the inner bottom faces of the box bodies by the liner feeding module through the liner assembling module. Compared with the prior art, the automatic mechanical equipment is adopted, thelabor input is low, the operating cost is low, the specifications of finished products are unified, the consistency of the products is greatly improved, the effect of the finished products is very good, the yield is also remarkably increased, the production period is greatly shortened, and production of large scale and industrialization is facilitated.

Owner:泸州裕同包装科技有限公司

Gel material for 3D printing of artificial cartilage as well as preparation method and application

InactiveCN108030957AAvoid influenceGood biocompatibilityAdditive manufacturing apparatusPharmaceutical delivery mechanismBiocompatibility TestingVacuum drying

The invention belongs to the technical field of 3D printing materials, and provides a gel material for 3D printing of an artificial cartilage as well as a preparation method and application. The method comprises the following steps: firstly, uniformly mixing hydroxyapatite, aluminum hydroxide, potassium trimethylsilanolate and an alginate powder, then performing vacuum drying and fine grinding, and adding glycerinum and calcium stearate for separated modulations, so as to obtain a pasty gel cartilage material; then performing 3D printing molding on the gel material, and further maintaining thegel material in water, so as to obtain a cartilage tissue. Compared with a conventional method, the method has the advantages that the prepared 3D-printed cartilage gel material is high in bonding strength, high in plasticity and excellent in material quality; a prepared cartilage finished product is high in biocompatibility and surface activity, high in strength, relatively high in precision andhigh in surface quality and has a stable effect; furthermore, the whole preparation process is simple, low in cost, relatively short in time and suitable for being popularized and used.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Glassware cutting device

InactiveCN108675623AEasy to useGreat practicabilityGlass severing apparatusNumerical controlDrive shaft

The invention relates to the field of glass cutting devices and in particular to a glassware cutting device. The glassware cutting device comprises a machine body, a cutting control device, a glassware jig and a numerical control device, wherein the cutting control device is installed beside the machine body, the glassware jig and the numerical control device are installed on the machine body, thecutting control device comprises a cutting sliding table, a cutting machine case, a cutting component, a lifting adjusting component and a transverse adjusting component, the glassware jig comprisesa first fixing clamping plate, a second fixing clamping plate and a moveable clamping plate. In use, a cutting blade is firstly fixed on a transmission shaft, an object is fixed by the glassware jig,and the lifting adjusting component and the transverse adjusting component are used for adjusting a height and a position of the cutting component, then a cutting motor is started through the numerical control device, so the transmission shaft drives the cutting blade to be rotated, the object is held by one hand of a worker, and the other hand pushes the cutting control device to be moved on thecutting sliding table, so the cutting machining is completed. The device is skillful in structure, simple in operation, and strong in practicability.

Owner:胡志会

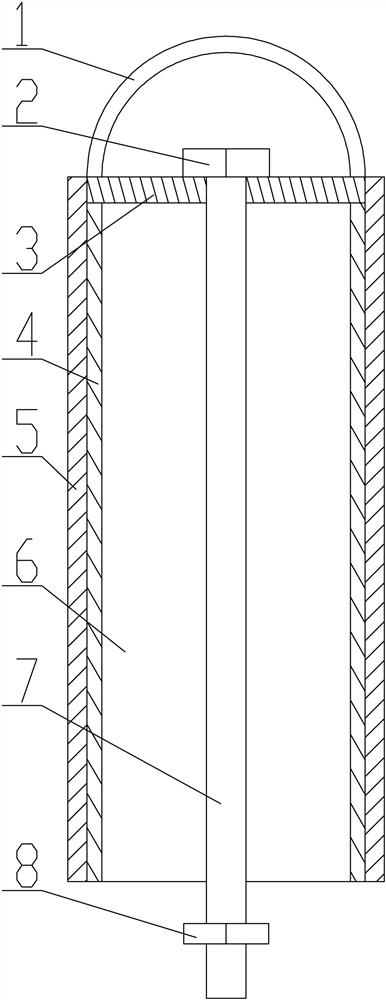

Reusable reserved hole reserving device and construction method

InactiveCN112576031ASmall sizeNot affected by vibrationForms/shuttering/falseworksArchitectural engineeringPipe

The invention provides a reusable reserved hole reserving device and a construction method. The device comprises an inner sleeve; a top sealing cover plate used for sealing the top of the inner sleeveis fixedly installed at one end of the top of the inner sleeve; the exterior of inner sleeve is sleeved with a rubber pipe; a long screw rod is installed in the middle of the top sealing cover platein a threaded fit mode; a top hexagonal head is arranged at the top of the long screw rod; and the long screw rod is sleeved with a nut. By the adoption of a steel sleeve reserving device, after concrete pouring is completed, a steel sleeve can be smoothly pulled out from an upper portion and repeatedly used, and the steel sleeve can be used as a pipeline wall bushing after a top cover and a handle are detached in the later period, so that the positive boosting effect is achieved on on-site environmental protection and civilized construction.

Owner:CHINA NUCLEAR IND 22ND CONSTR

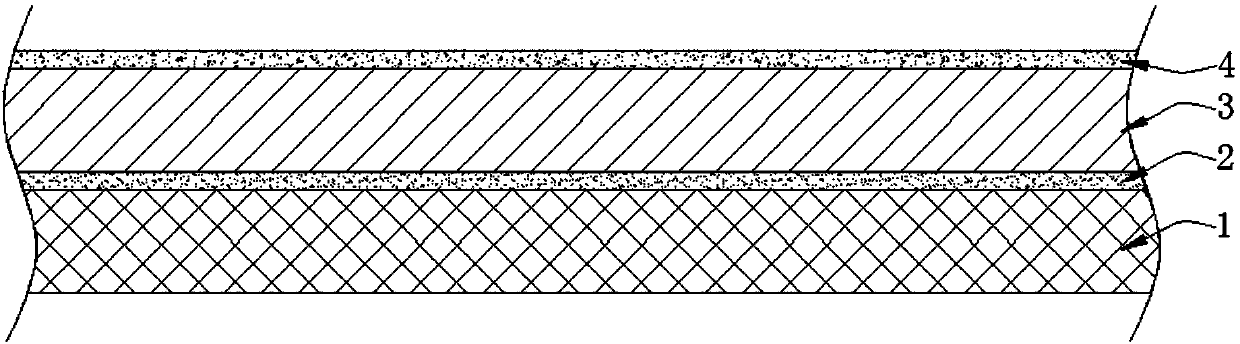

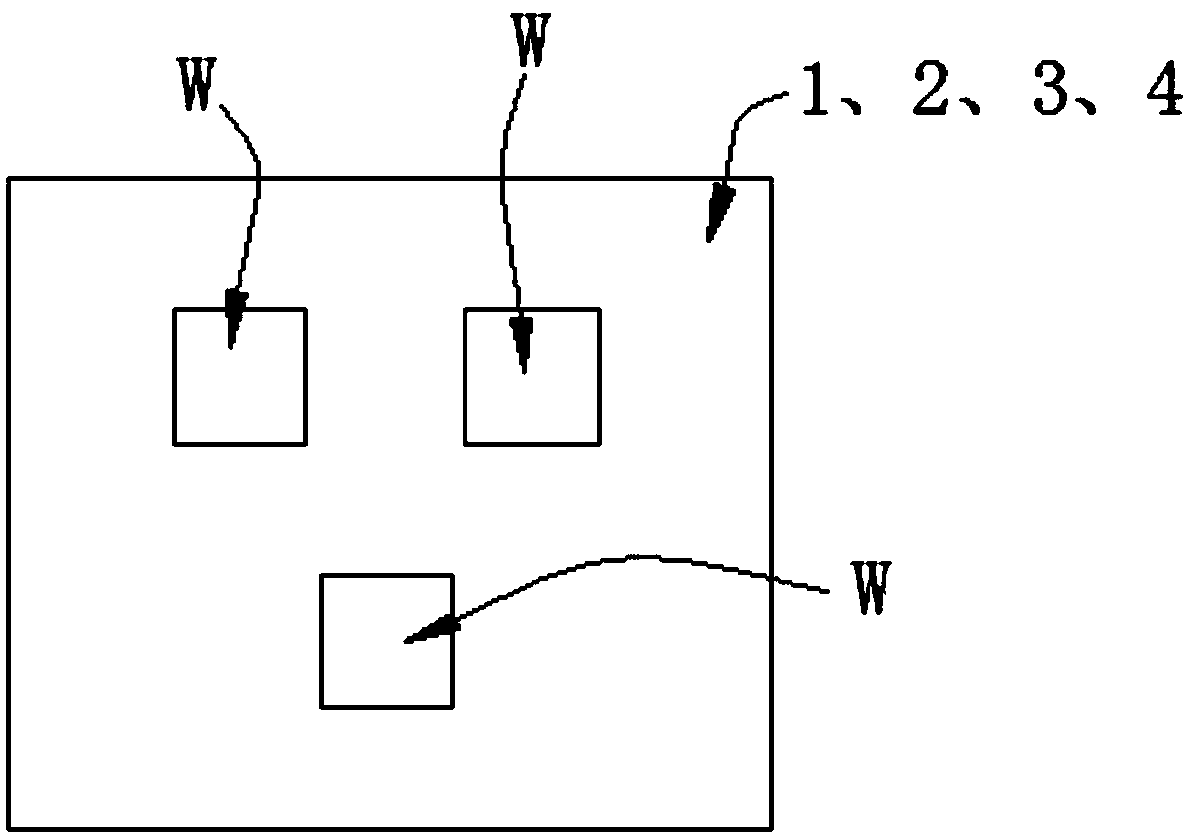

Surface treatment method and device for metal sheets

PendingCN107498410AReduce roughnessSufficient adhesionGrinding feed controlGrinding feedersCoated surfaceMetal sheet

The invention discloses a surface treatment method and device for metal sheets. Before a film coating or thermal transfer printing procedure on the metal sheets, at least one-time mechanical grinding is carried out on a to-be-coated surface of a metal sheet. The invention further discloses the surface treatment device for the metal sheets. The device comprises a traction device and at least one grinding wheel set, wherein the traction device is used for conveying the metal sheets; each grinding wheel set comprises a grinding wheel positioned on one side of a to-be-coated surface of a metal sheet and a supporting wheel positioned on one side of the other surface of the metal sheet; and each grinding wheel is opposite to the corresponding supporting wheel. By the surface treatment method and device for the metal sheets, surfaces of the metal sheets do not have color difference, oil stain or dirt; after followed-up glue coating and thermal transfer printing or film coating procedures, the thermal transfer printing layer or the film coating layer can be glued to the surface of the metal sheet well along with a gluing layer, and therefore, the quality of products is greatly improved.

Owner:广州市智铝铝业有限公司

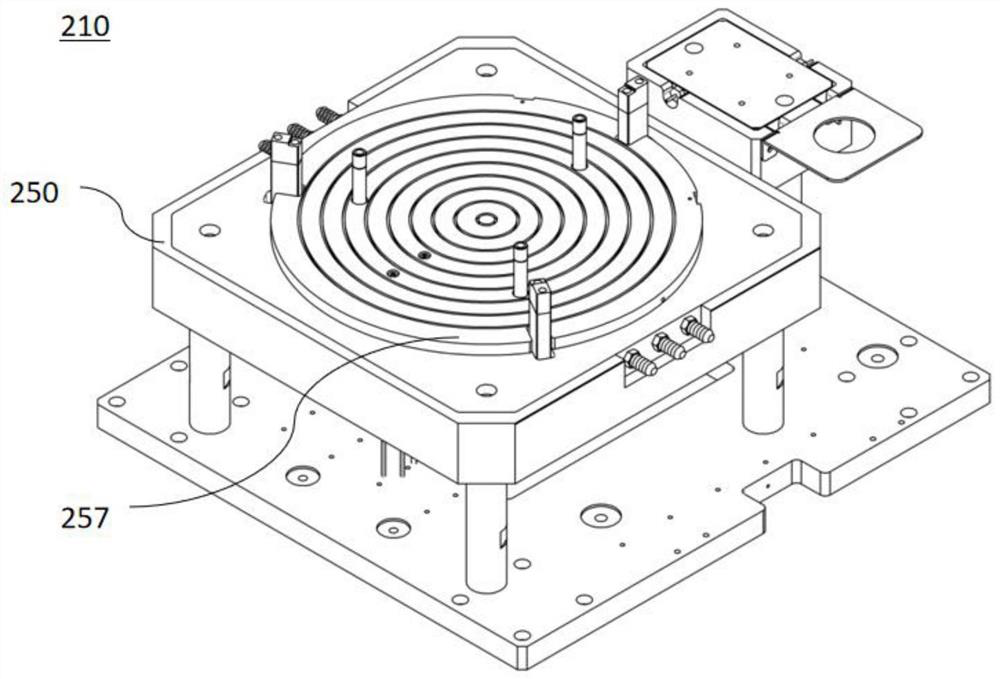

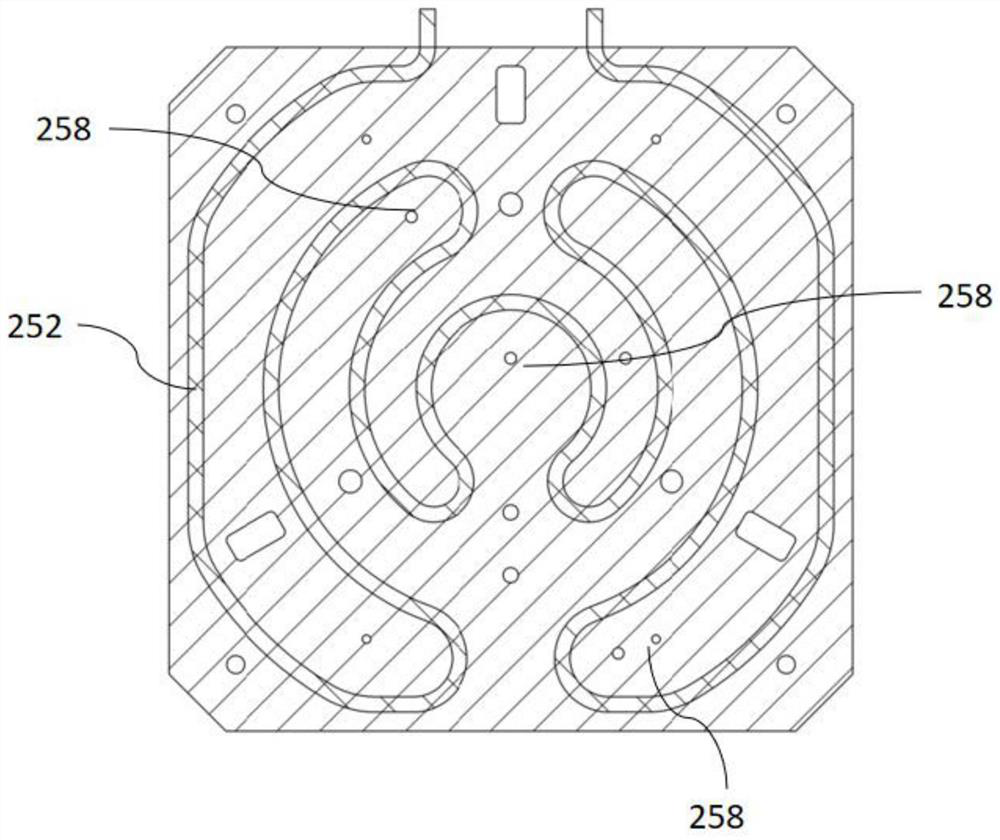

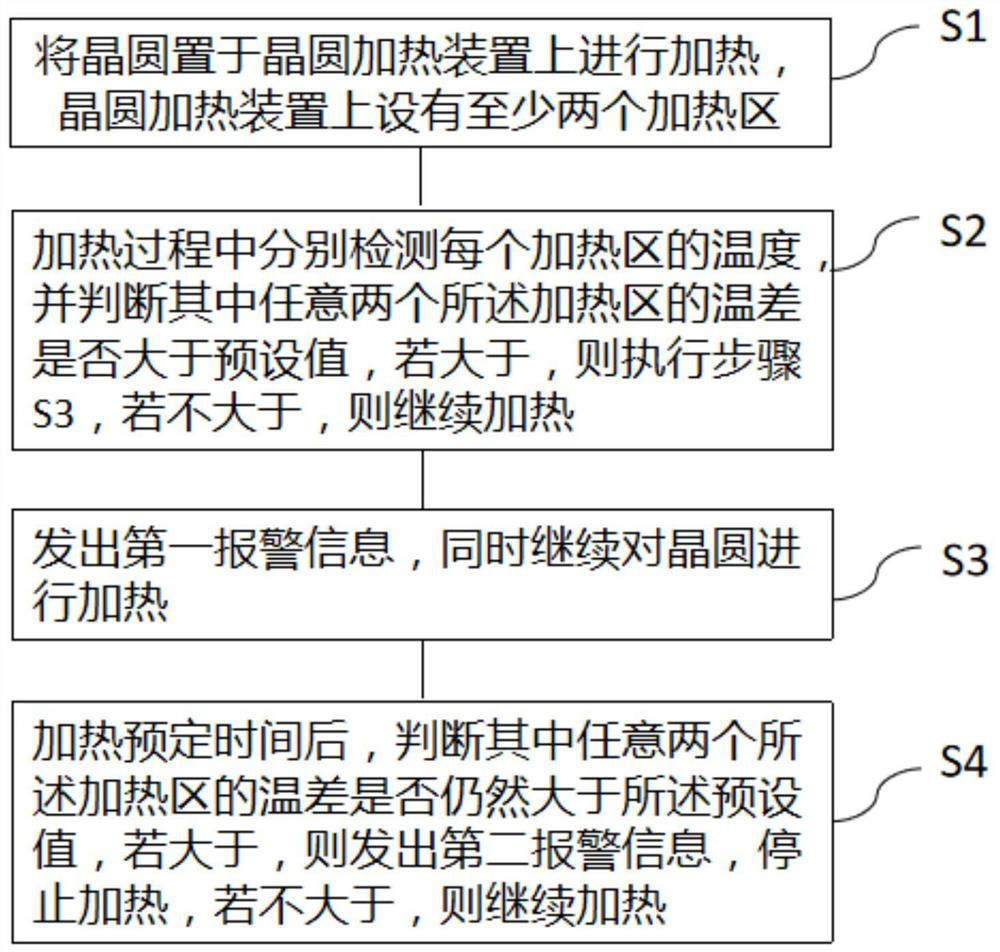

Partitioned heating wafer heating device, multi-station dispenser and wafer heating method

PendingCN111885755AEvenly heatedImprove dispensing efficiencyLiquid surface applicatorsSemiconductor/solid-state device manufacturingTemperature controlWafer

The invention discloses a partitioned heating wafer heating device, a multi-station dispenser and a wafer heating method. The partitioned heating wafer heating device comprises a heating supporting table, a heating pipe, a heating disc, at least two thermocouples and a temperature controller, and a heating cavity is defined in the heating supporting table; the heating pipe extends into the heatingcavity for heating; the heating plate is attached to the heating supporting table and located above the heating supporting table, a heating surface is formed on the upper surface of the heating plate, the heating plate receives heat of the heating pipe and transmits the heat to a wafer through the heating surface, and at least two heating areas are arranged on the heating plate; the at least twothermocouples are arranged in the at least two heating areas respectively so as to detect the temperature of each heating area; and the temperature controller is connected with the heating pipe and the thermocouples and controls the heating pipe to heat according to the temperature detected by the thermocouples. The partitioned heating wafer heating device and the wafer heating method have the advantages that the wafer is uniformly heated, and the heating process is stable.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

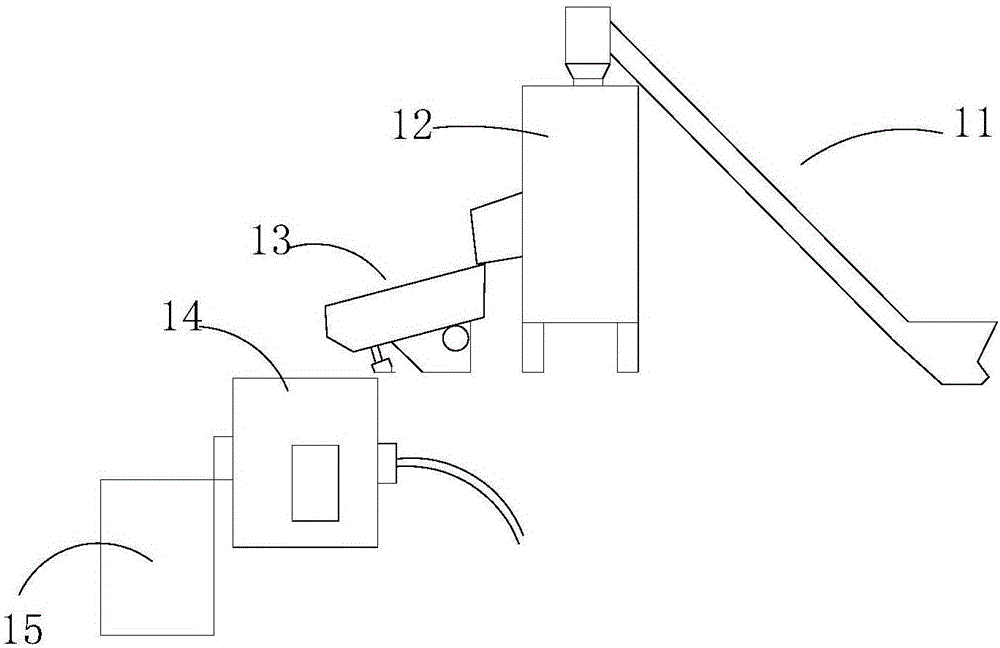

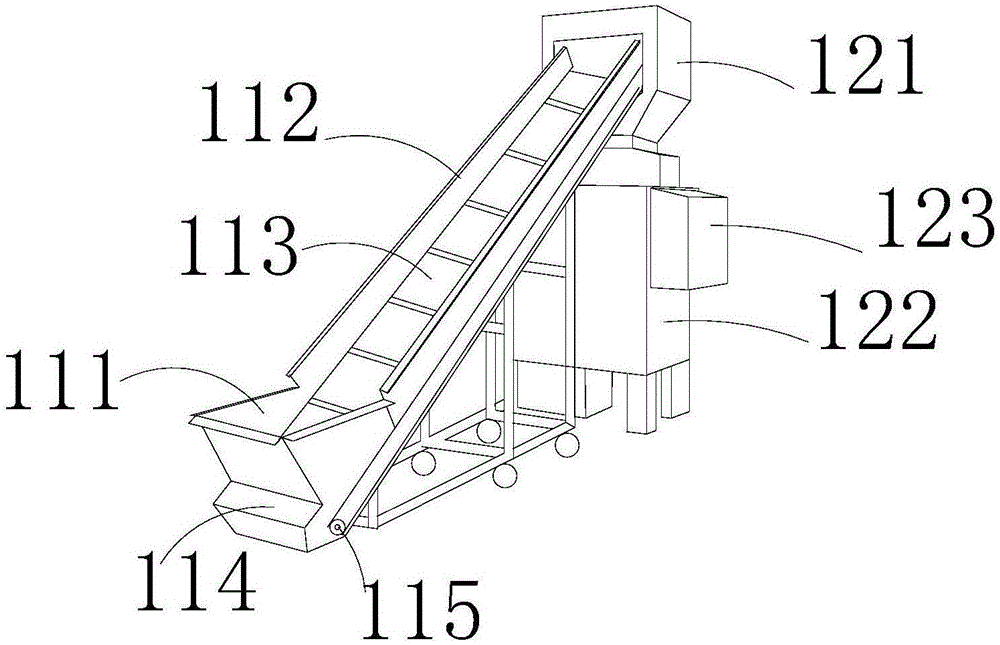

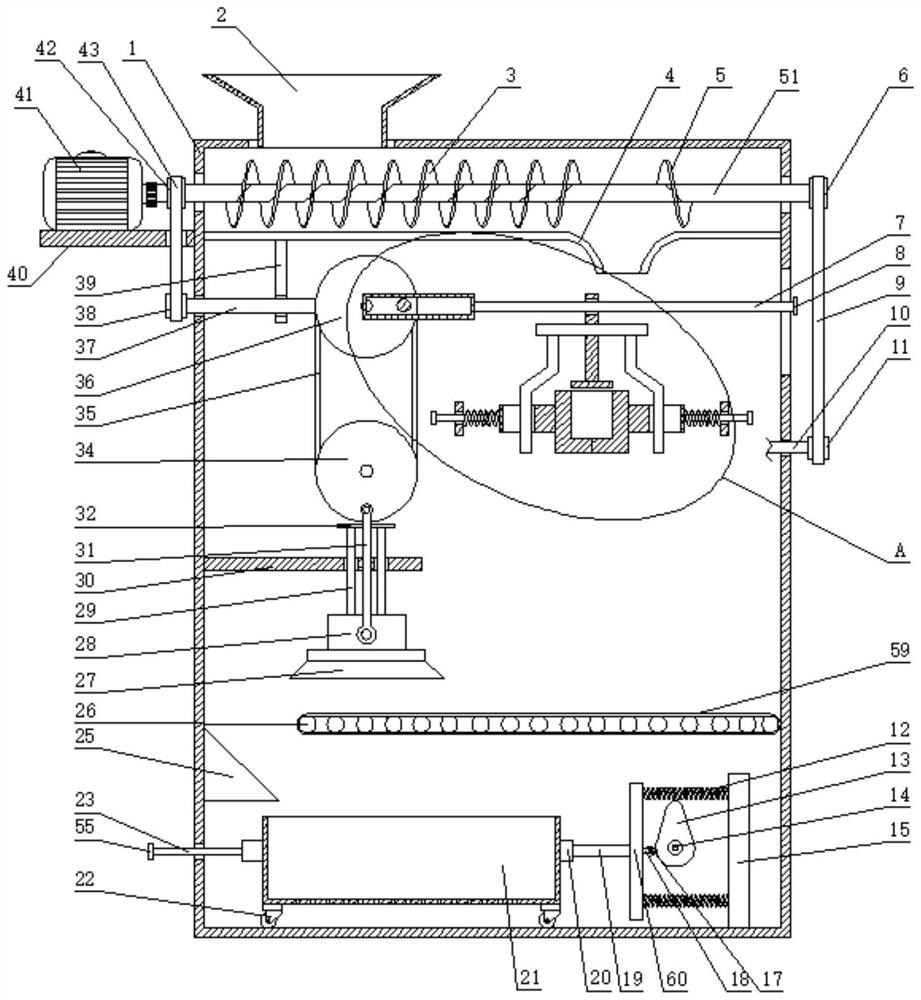

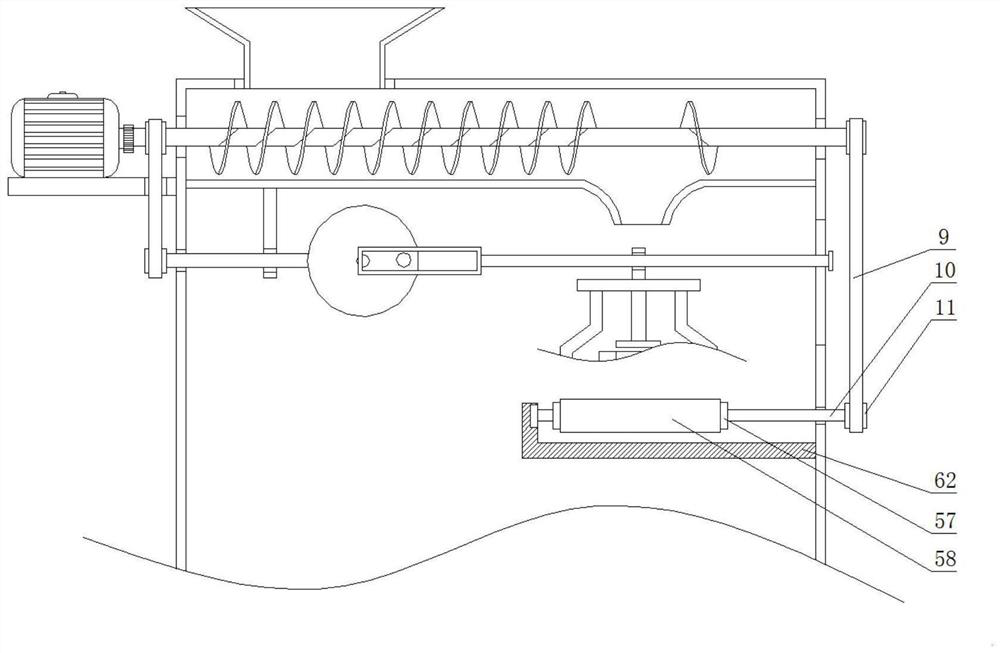

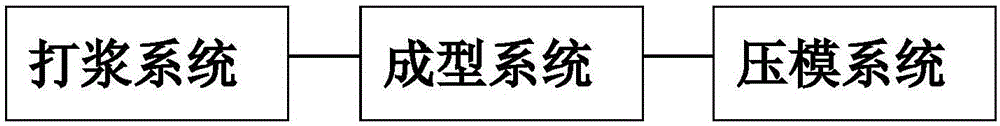

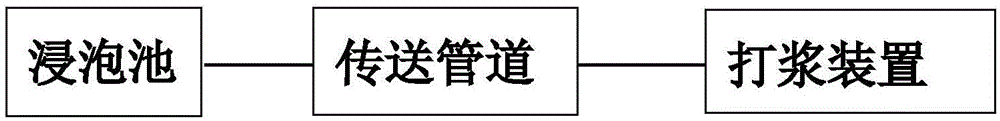

Paper mold forming system

ActiveCN106245464AQuality improvementImprove efficiencyPulp beating methodsPaper recyclingAssembly linePulp and paper industry

The invention provides a paper mold forming system. The paper mold forming system comprises a beating system, a forming system body and a mold pressing system. The discharging end of the beating system is connected with the feeding end of the forming system body, the discharging end of the forming system body is communicated with the feeding end of the mold pressing system, paper forms pulp in the beating system, the pulp flows into a pulp tank of the forming system body, paper wet blanks are manufactured in the forming system body through a wet blank mold and are conveyed into the mold pressing system through a conveying belt, and a mold pressing machine in the mold pressing system presses the paper molds into finished products with the required hardness. According to the paper mold forming system, the assembly line operation mode is formed for paper mold manufacturing through combination of the three systems, and the quality and efficiency of paper mold forming are improved. The paper mold forming system is scientific and environmentally friendly, and the productivity is improved.

Owner:东莞伦楷电声制品有限公司

PET (Polyethylene Terephthalate) sheet production method and production equipment thereof

InactiveCN113021727AImprove efficiencyGood finished productSievingScreeningPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a PET (Polyethylene Terephthalate) sheet production method and production equipment thereof. The PET sheet production equipment comprises an equipment shell, wherein a feeding hopper is inserted in the position, close to the left side, of the top of the equipment shell; two first bearings are fixedly connected to the position, close to the top, of the left side of the equipment shell; the two first bearings are arranged up and down; and a third rotating rod penetrates through an inner cavity of the first bearing located on the top. According to the PET sheet production method and the production equipment thereof provided by the invention, through mutual cooperation of all the components, the equipment can stir materials while conveying the materials, the efficiency is high, the finished product effect is good, the speed is high while a model is pressed, an automatic demolding function is achieved, materials can be trimmed and cut after demolding, cut chippings and materials can be separated through the equipment, and the rapid discharging effect is achieved, so that the labor amount and the labor cost of workers are greatly saved, and the yield and the product quality are improved.

Owner:泉州亦辉塑胶有限公司

Novel high-efficiency quilt sewing machine

ActiveCN108374241AIncrease productivityGuaranteed processing effectWork-feeding meansSewing-machine control devicesDrive shaftEngineering

The invention particularly relates to a novel high-efficiency quilt sewing machine. A quilt feeding assembly and a compression roller assembly are additionally arranged, so that guiding and pre-pressing are performed before a quilt passes through a roller, and the processing effect is guaranteed. Two groups of improved transmission assemblies are arranged on the left side and the right side, and transmission is carried out on the basis of driving of a driving assembly. A gear meshing rotation mode is adopted to drive a second shaft to rotate, and then a rotating shuttle assembly is driven to rotate and work. A T-shaped wheel or a main bearing rotates around the circle center, and a movable beam is driven to move up and down through a pull rod, so that a needle rod assembly works. While theT-shaped wheel or the main bearing rotates around the circle center, on the one hand, power is provided for moving of the roller and used for driving the quilt to move forwards, and on the other hand, the T-shaped wheel drives a take-up transmission shaft to rotate through a second connecting assembly I and a take-up rocker to provide power for work of a take-up lever. The machine is novel in structure, comprehensive in function, high in production efficiency and good in finished product effect.

Owner:安徽省萧县徽星机械制造有限公司

Window lamination method for paper

InactiveCN107599598ARealize window coatingBonded firmlyLamination ancillary operationsLaminationWork in processEngineering

The invention discloses a window lamination method for paper. The window lamination method comprises the following steps: step 1, a two-sided corona film with one side pre-coated with hot melt glue isadopted, the other side of the two-sided corona film is bonded with the surface of the paper to be subjected to window lamination, full lamination of the two-sided corona film on the paper is realized, and an early semi-finished product is obtained; step 2, windowing is performed on the early semi-finished product, that is, a window is die-cut in a predetermined position of the early semi-finished product, scraps produced in die cutting are removed, and an intermediate semi-finished product is obtained; step 3, a heat seal film provided with co-polypropylene on at least one side is adopted, hot melt glue of the intermediate semi-finished product is covered with the side, provided with co-polypropylene, of the heat seal film, the heat seal film and the intermediate semi-finished product are bonded together through hot pressing by a hot pressing roller, and a finished paper product subjected to window lamination is obtained. The window lamination method has the advantages that the process difficulty is low, the effect of the window lamination finished product is good and the production efficiency is high.

Owner:广州市恒远彩印有限公司

Environment-friendly plush fabric dyeing method and residual color paste treatment technology thereof

InactiveCN109355834AHigh uniformity of color brightnessImproved performance of the finished productHeating/cooling textile fabricsLiquid/gas/vapor removalColour fastnessDye absorption

The invention discloses an environment-friendly plush fabric dyeing method and a residual color paste treatment technology thereof. The technology comprises the following steps that 1, a white gray fabric of a plush fabric is pretreated; 2, a high-temperature dye is prepared into color paste and poured into a rolling groove of a padder; 3, the pretreated white grey cloth is guided into the rollinggroove in the padder through a cloth guide roller at the front end of the padder for quick hunger type high-permeability dye absorption to complete dyeing, and the dyed fabric and the residual colorpaste are obtained; 4, drying and primary color development are carried out; 5, drying and high-temperature color development are performed; 6, the fabric is discharged; 7, the fabric is rinsed and softened; 8, shaping is carried out; 9, post-treatment is performed; 10, a finished product is manufactured. The fabric dyed through the method is uniform in color, free of color difference, bright andgood in finished product, and the liquid rate when the padder is used for padding the gray fabric is controlled to be 35-50% so that color development can be fully achieved during color development, the color is bright, and the color fastness is quite good.

Owner:江苏康尼纺织品有限公司

Production process for perspective glass

InactiveCN110342811ARealize automatic film coatingNo manual operationGlass shaping apparatusGlass severing apparatusProduction lineMagnetic separator

The invention relates to the technical field of glass processing, and in particular relates to a production process for perspective glass. The production processing process comprises the following steps: step 1, crushing raw materials by utilizing a crushing machine; step 2, removing iron impurities in the raw materials crushed in the step 1 by utilizing a magnetic separator; step 3, putting the raw materials without the impurities obtained in the step 2 in a crucible furnace, and performing heating melting to form liquid glass; step 4, pouring the liquid glass into a molding mold, and performing cooling molding to form solid glass; step 5, putting the solid glass obtained in the step 4 in a processing production line of transparent glass, and performing coating treatment; step 6, puttingthe coated glass obtained in the step 5 in a cutting device, and performing cutting to form small-piece glass; and step 7, putting the small-piece glass obtained in the step 6 in a warehouse for storage. According to the process provided by the invention, the processing production line of the transparent glass adopted in the coating stage can realize uniform coating of a coating layer and ensure consistency and uniformity of coating, so that the quality of the glass is improved.

Owner:陈波

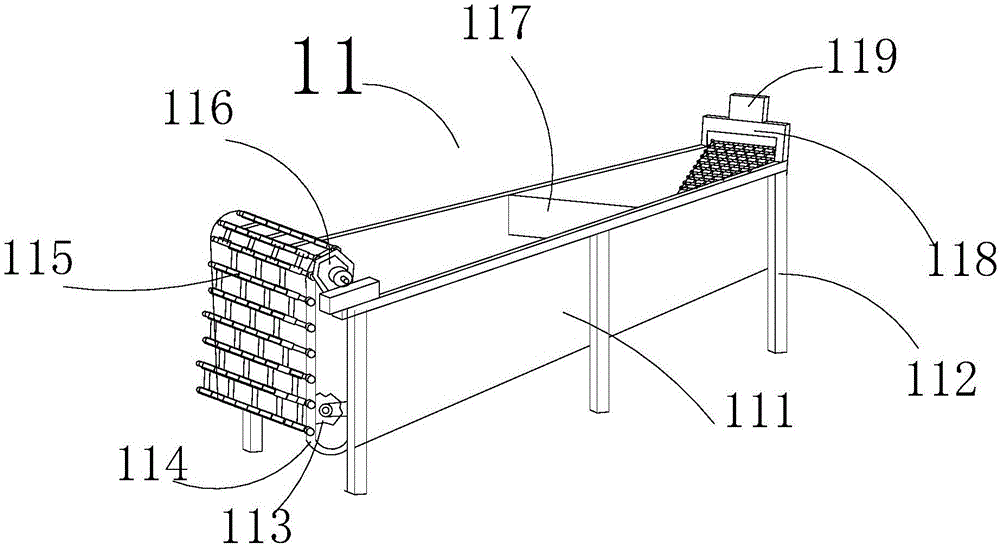

Paper form forming system

ActiveCN106283933AReduce instabilityEasy to moldPulp beating methodsPaper recyclingAssembly lineHardness

The invention provides a paper form forming system. The paper form forming system comprises a pulping system, a forming system and a form pressing system; the discharge end of the pulping system is connected with the feed end of the forming system, the discharge end of the forming system is communicated with the feed end of the form pressing system, paper forms pulp in the pulping system, the pulp flows into a pulp tank of the forming system, the forming system manufactures wet paper blanks through a wet blank mold, the wet paper blanks are conveyed into a form pressing system through a conveyor belt, and the paper forms are pressed into a finished product with the required hardness through a form press arranged in the form pressing system. According to the paper form forming system, by combining the three systems, an assembly line work mode of paper form manufacturing is formed, and the paper form forming quality and efficiency are improved. The paper form forming system is scientific and environmentally friendly, and the productivity is improved.

Owner:江门市天丰纸业有限公司

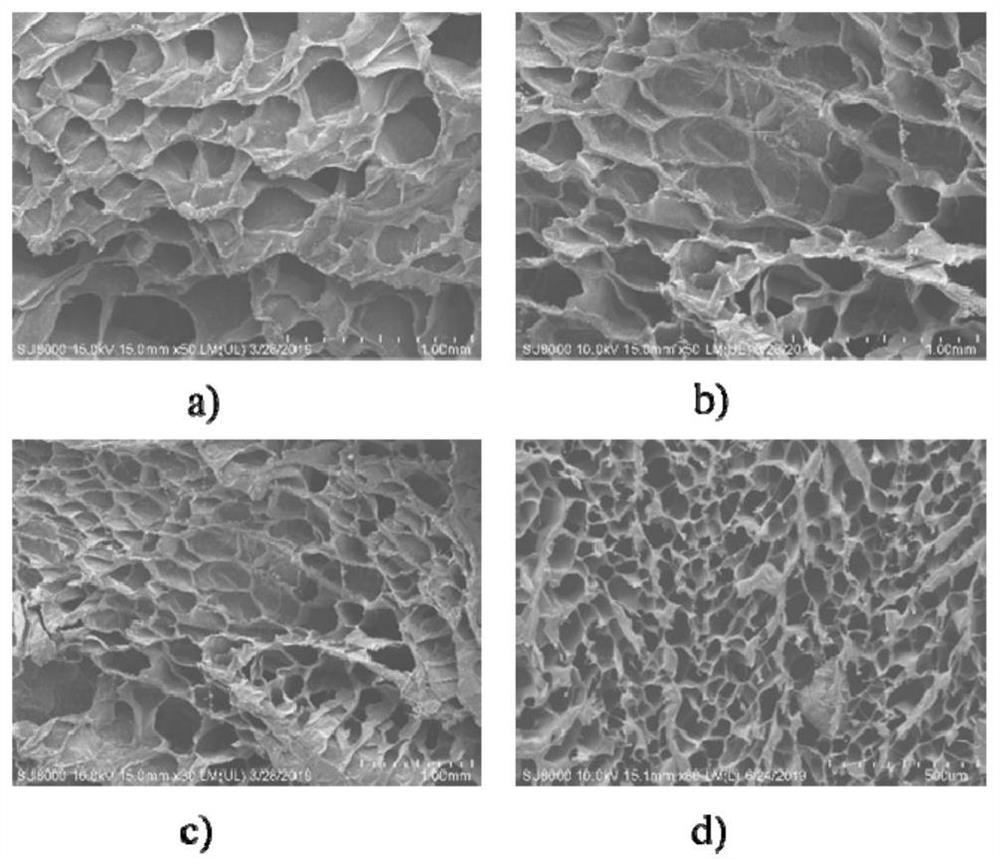

Chitosan-graphene oxide composite gel and preparation method thereof

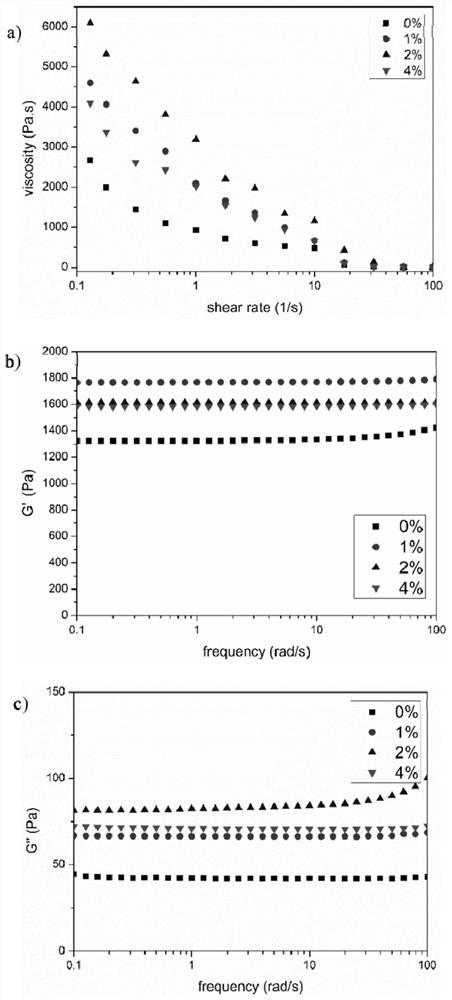

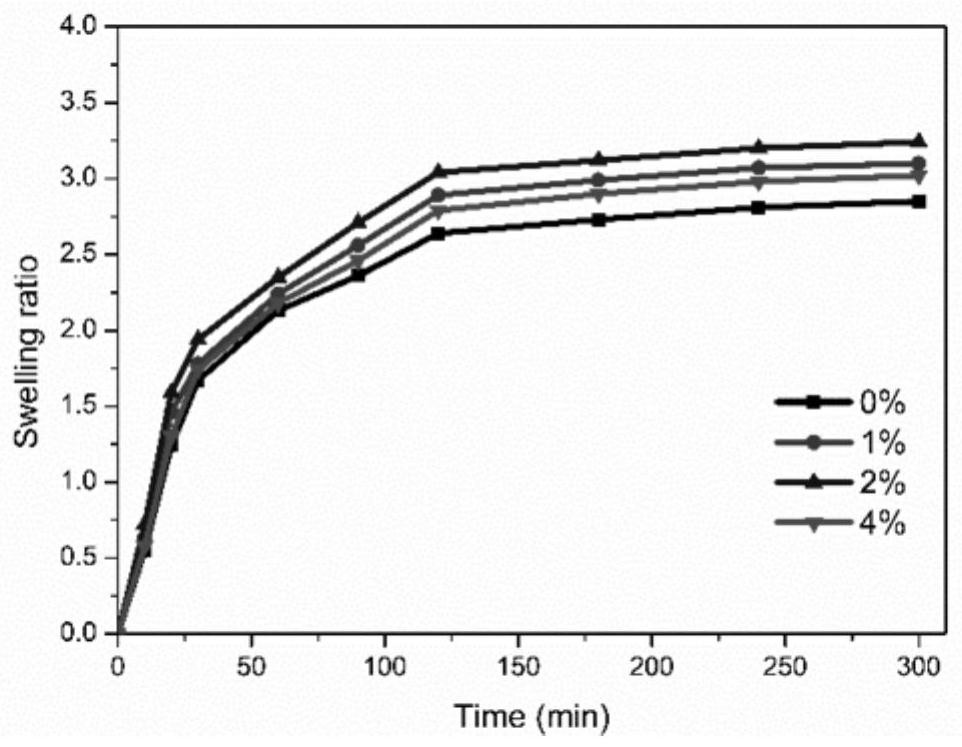

InactiveCN112704765AImprove mechanical propertiesPromote growthTissue regenerationProsthesisOxide compositeViscoelasticity

The invention discloses chitosan-graphene oxide composite gel and a preparation method thereof. The chitosan-mineralized collagen-graphene oxide composite hydrogel prepared by the invention has the characteristics of rapid gelatinization, self-healing and the like, and has biological 3D printability. After graphene oxide is added into the composite hydrogel, the mechanical property is enhanced, and the porous structure is beneficial to adhesion and growth of cells; and the biological printability is improved. The material is expected to be used as a tissue engineering scaffold material. The prepared composite hydrogel has the characteristics of shear thinning and good viscoelasticity, and a tissue engineering scaffold can be constructed through a biological 3D printing technology at 37 DEG C.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION +1

A construction method for pouring concrete cylinders with paper molds and the column fixing device used

ActiveCN104100091BFast constructionImproved performance of the finished productForms/shuttering/falseworksBuilding material handlingPlastic filmPollution

The invention discloses a construction method and a cylinder fixing device for pouring concrete to obtain cylinders by the aid of paper forms, and belongs to the technical field of processes and devices for constructing buildings. The construction method and the cylinder fixing device have the advantages that steel forms or wooden forms in the prior art are replaced by the paper forms, the cylinders can be constructed quickly via construction procedures including structure form erecting, main reinforcement binding, paper form mounting, cylinder concrete casting and compacting, form removal and maintenance and the like, and good effects of finished concrete cylinder products can be realized owing to a construction process which is implemented by the aid of the paper forms and is favorable for construction safety, quality and progress control; the perpendicularity of the cylinders can be guaranteed owing to paper form adjusting positioners, and deformability of the cylinders can be reduced owing to the paper form adjusting positioners; plastic films wrap the surfaces of the cylinders after construction is completed and the forms are removed, accordingly, pollution on the surfaces of the cylinders can be reduced, pitted surfaces can be prevented, and the quality and the appearance of the concrete cylinders can be greatly improved.

Owner:ZHEJIANG YIJIAN CONSTR GROUP

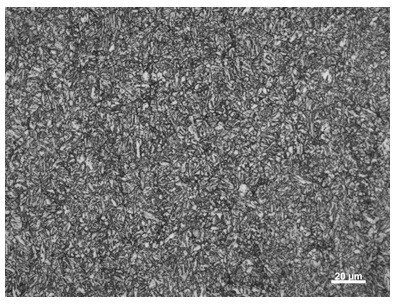

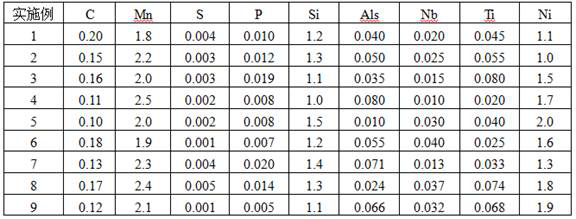

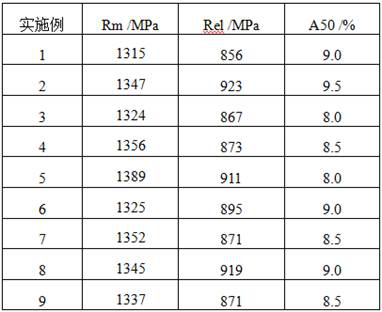

1300Mpa grade high tenacity cold-formed steel plate and production method thereof

ActiveCN112795837AImprove plasticityHigh yield strengthFurnace typesProcess efficiency improvementChemical compositionContinuous annealing

The invention relates to a 1300Mpa grade high tenacity cold-formed steel plate and a production method thereof and belongs to the technical field of metallurgy. The steel plate comprises the chemical components in percent by mass: 0.1-0.2% of C, 1.8-2.5% of Mn, less than or equal to 0.005% of S, less than or equal to 0.02% of P, 1.0-1.5% of Si, less than or equal to 0.08% of Als, 0.01-0.04% of Nb, 0.02-0.08% of Ti, 1.0-2.0% of Ni and the balance Fe and inevitable impurities. The production method comprises the following steps: steelmaking, continuous rolling, heating, rolling, pickling, continuous annealing and level pulling straightening. A temperature of a soaking zone in the continuous annealing step is 760-820 DEG C, and an insulating time is 60-225s. The yield strength of the steel plate is greater than or equal to 850 MPa, a tensile strength is greater than or equal to 1300 MPa, and a ductility A50 is greater than 8%. The steel plate has a good cold-forming property and meets a requirement on light weight steel for an automobile.

Owner:TANGSHAN IRON & STEEL GROUP +2

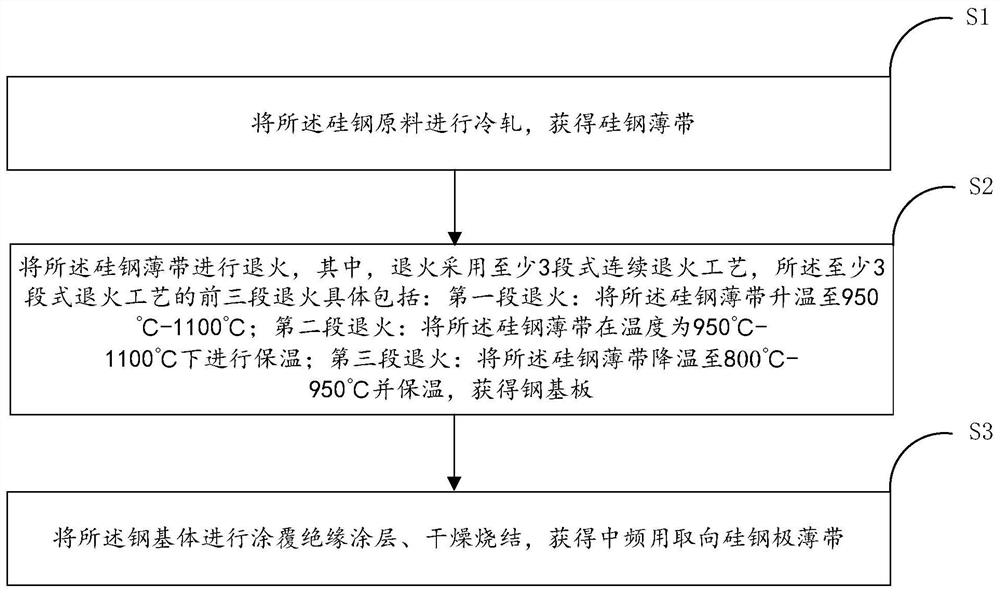

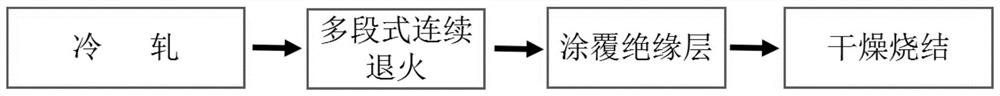

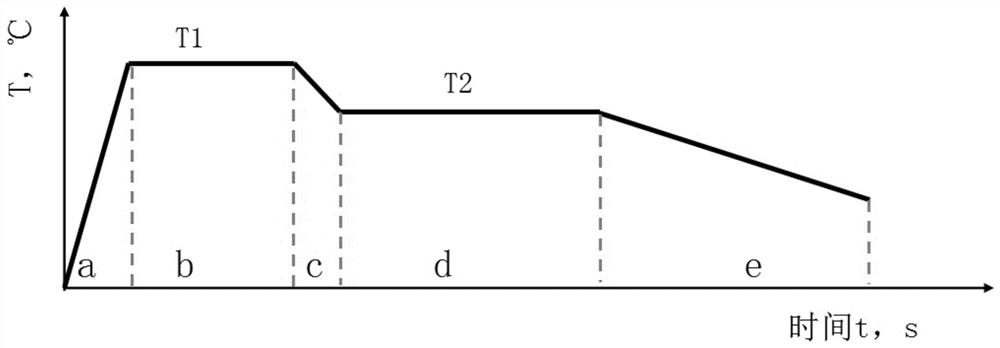

Production methods of intermediate-frequency oriented silicon steel ultra-thin strip and steel substrate of intermediate-frequency oriented silicon steel ultra-thin strip

ActiveCN113186381AImprove magnetic propertiesEasy to shapeIncreasing energy efficiencyManufacturing technologyIntermediate frequency

The invention particularly relates to production methods of an intermediate-frequency oriented silicon steel ultra-thin strip and a steel substrate of the intermediate-frequency oriented silicon steel ultra-thin strip, and belongs to the technical field of production of silicon steel ultra-thin strips. The production method of the steel substrate of the intermediate-frequency oriented silicon steel ultra-thin strip comprises the following steps: conducting cold rolling on a silicon steel raw material to obtain a silicon steel thin strip; and conducting annealing on the silicon steel thin strip to obtain the steel substrate, wherein a continuous annealing technology with at least three sections is adopted for annealing. The intermediate-frequency oriented silicon steel ultra-thin strip produced from the steel substrate produced by adopting the corresponding method has excellent magnetic performance and an excellent shape, multi-section annealing is adopted, stable finished product performance is obtained, the manufacturing technology is simple, the feasibility is high, the non-bottom-layer oriented silicon steel (silicon steel raw material) is adopted as base metal, energy is saved, environmental protection is achieved, the surface quality of a product is good, and the product can meet the use requirements under the condition of an intermediate frequency (higher than or equal to 400 Hz).

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com