Reusable reserved hole reserving device and construction method

A technology of reserved holes and sets, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of increased chisel repair work, high brittleness of PVC pipes, offset of reserved holes, etc. problem, to achieve the effect of saving labor cost, good finished product and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

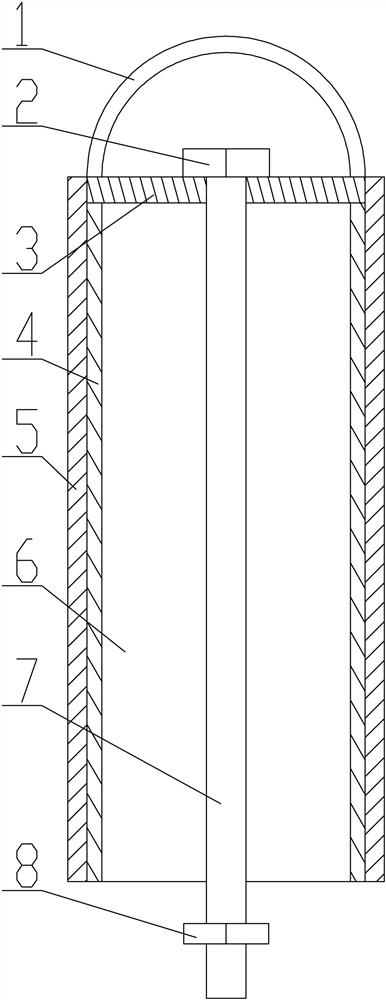

[0036] see Figure 1-5 , a reusable reserved hole reservation device, which includes an inner casing 4, one end of the top of the inner casing 4 is fixedly installed with a top cover plate 3 for sealing the top, the inner A rubber tube 5 is set on the outside of the casing 4, and a long screw 7 is mounted on the middle part of the top cover plate 3 through thread fit. The top of the long screw 7 is provided with a top hexagonal head 2, and Set has 8 nuts. The above-mentioned reserved hole reservation device can be used in the construction process of the reserved hole in the shear wall, and the construction of the reserved hole can ensure the dimensional accuracy of the reserved hole and effectively avoid the influence of concrete vibration. Flexible processing and molding, saving labor processing costs.

[0037] Further, the top cover plate 3 is fixed on the top of the inner casing 4 by means of welding or screw connection. The above-mentioned top cover plate 3 can effectiv...

Embodiment 2

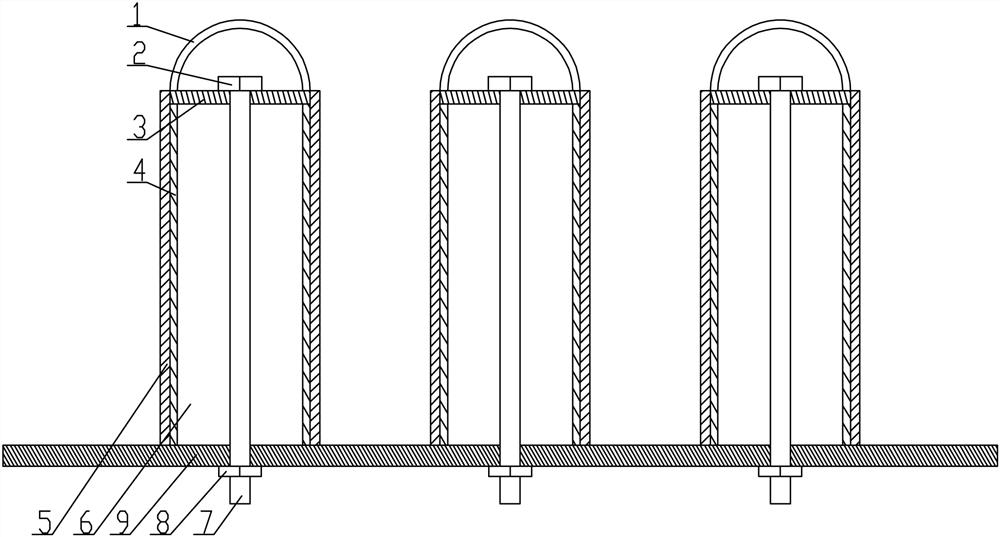

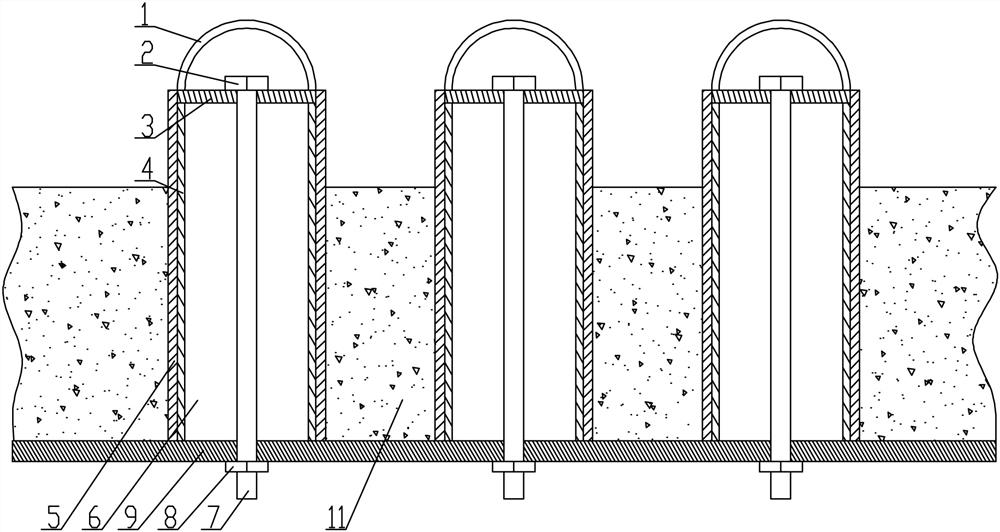

[0045] A method for constructing a reserved hole with a reusable reserved hole reservation device includes the following steps:

[0046] Step 1: Cut the rubber tube 5 of the corresponding height according to the thickness of the shear wall 11 to be poured, and select the inner casing 4 of the corresponding height;

[0047] Step 2: Position the inner sleeve 4 at the position where the hole needs to be reserved, and pass the long screw 7 through the threaded hole 10 of the top cover plate 3, and make the bottom end pass through the through hole 12 of the template 9, and then use The nut 8 locks the long screw rod 7, and then fixes the entire inner casing 4 on the template;

[0048] Step 3: Set the rubber tube 5 on the outside of the inner casing 4;

[0049] Step 4: After all the pre-embedded casings are fixed, the pouring operation is carried out, and the vibrating rod is used to vibrate, and then the concrete is vibrated;

[0050] Step 5: After the concrete reaches the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com