Patents

Literature

198results about How to "Facilitate subsequent construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

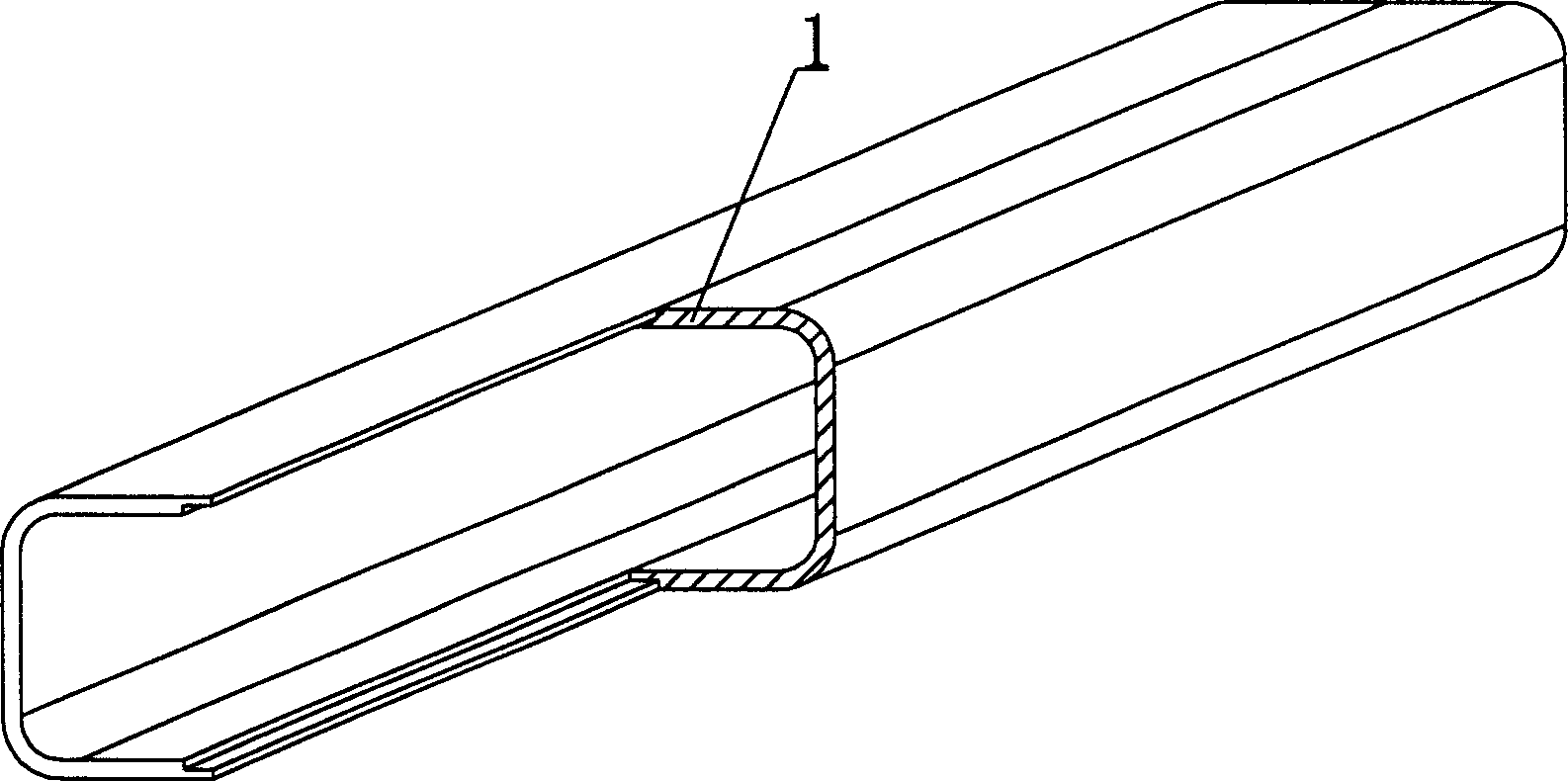

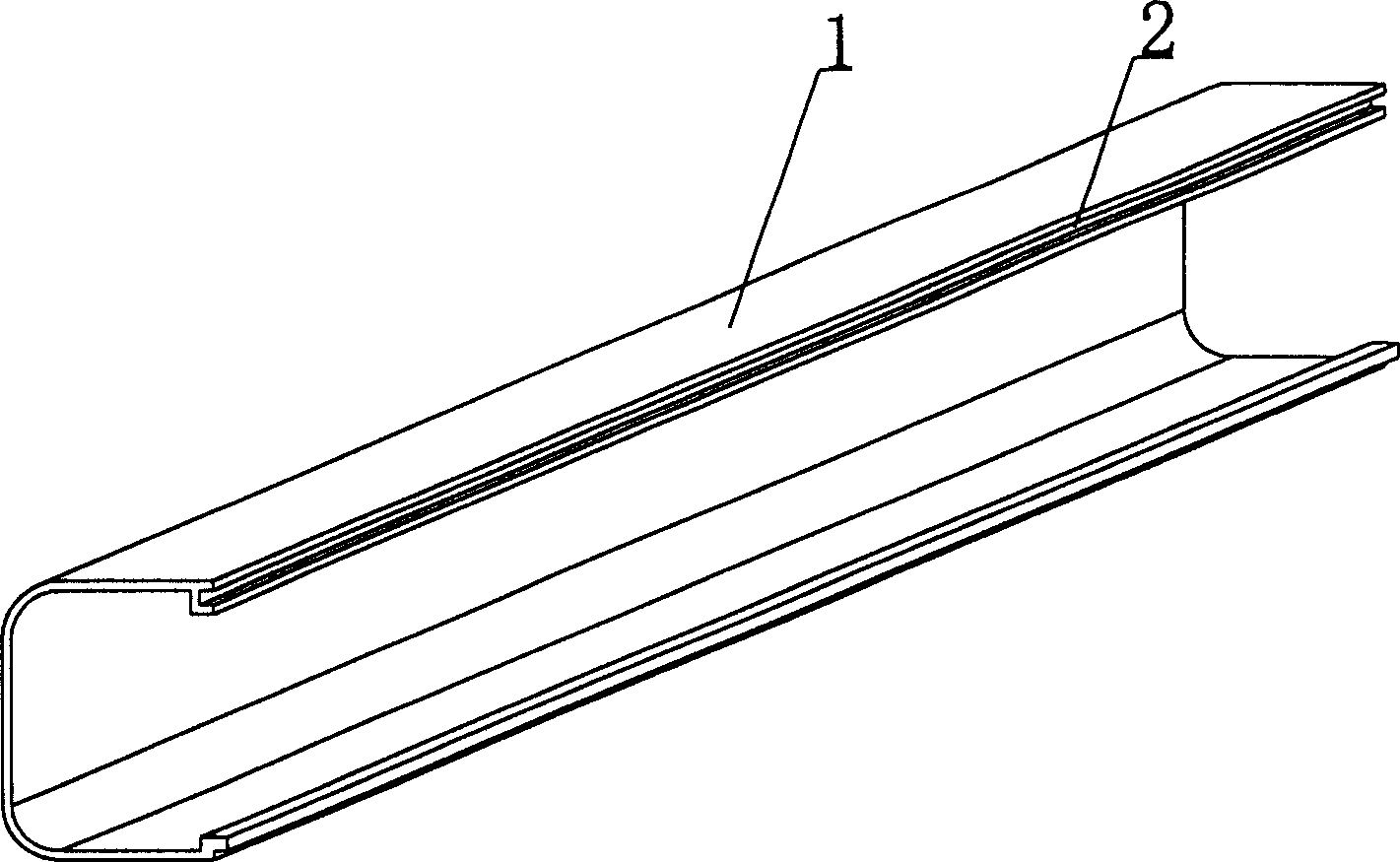

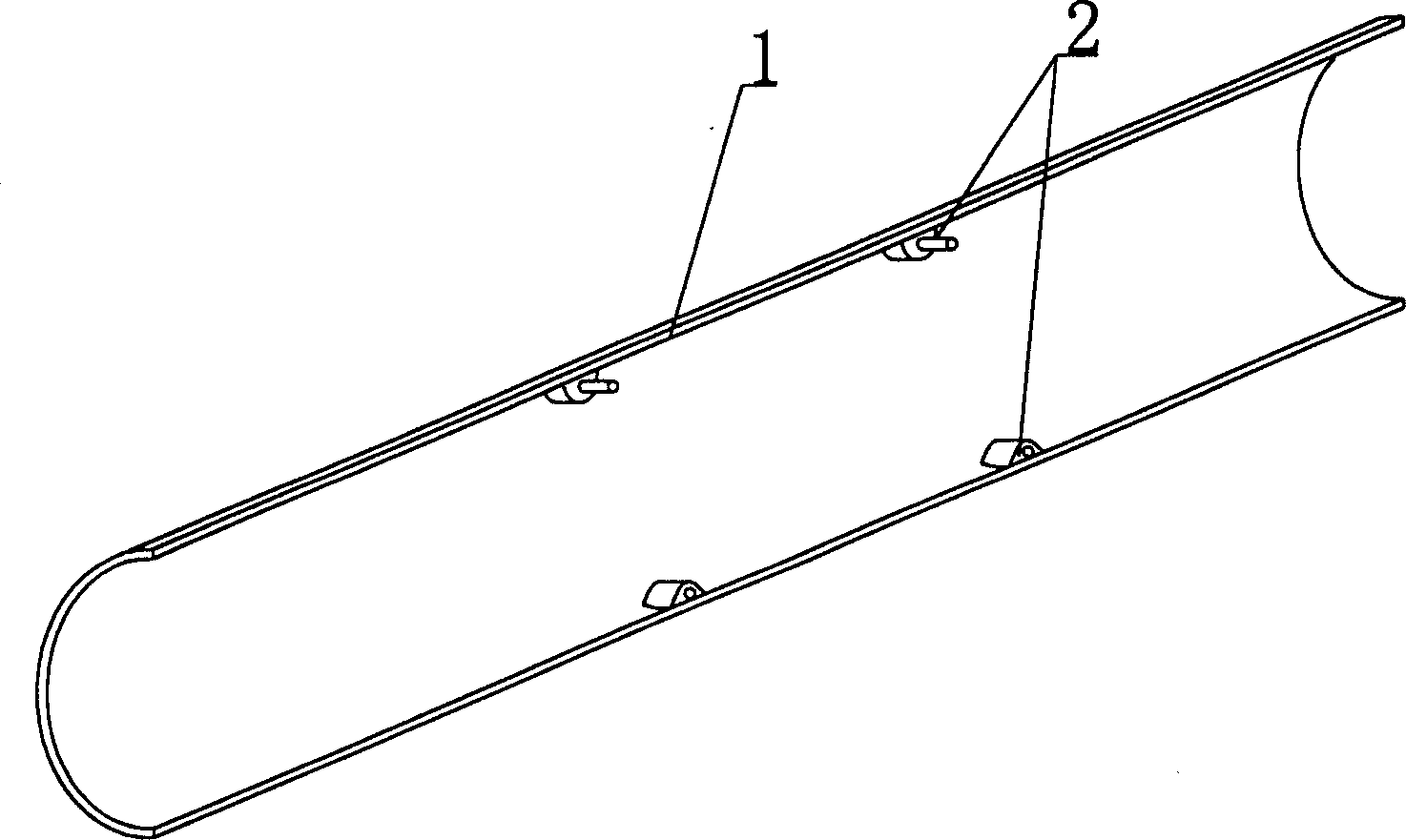

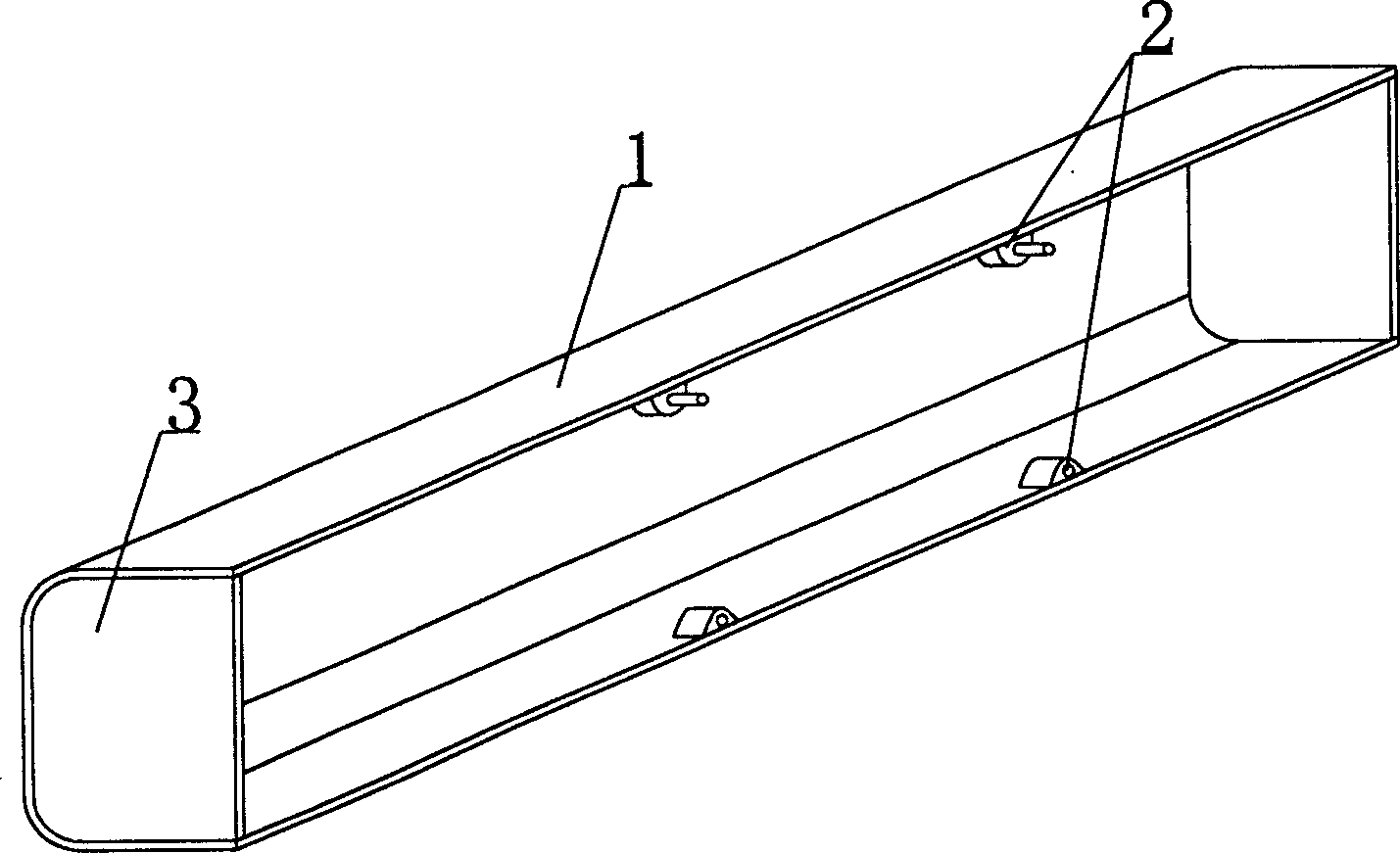

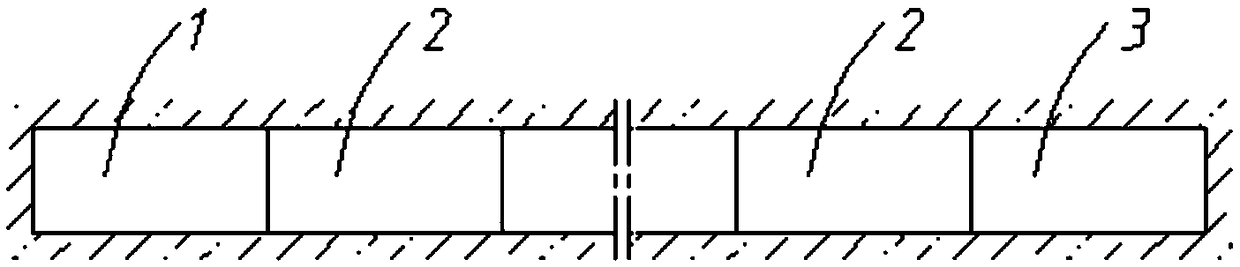

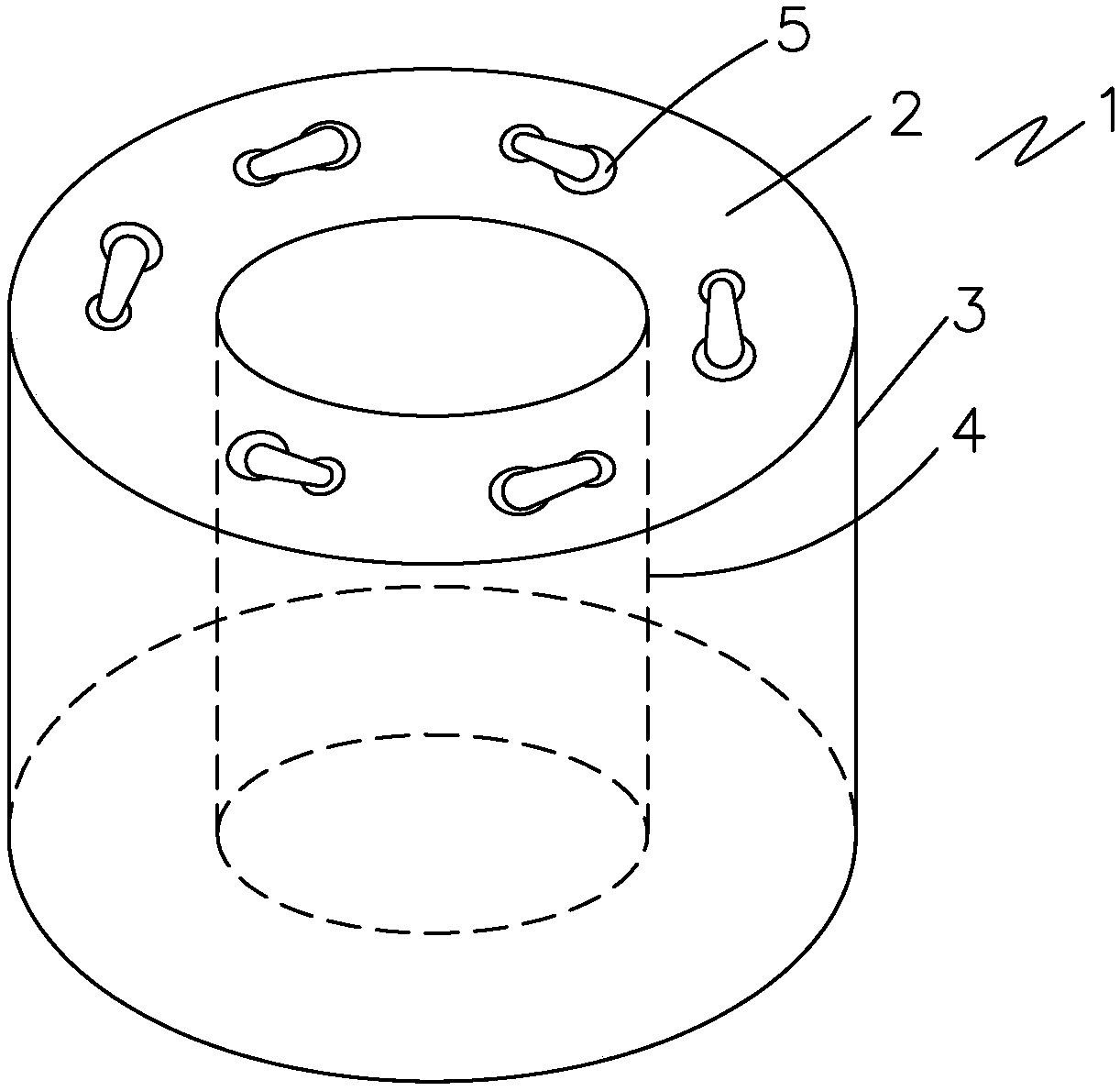

Member for cast-in-situ steel reinforced concrete

A member for in-situ casting the reinforced concrete is composed of two halves, which are fastened together to form a hollow thin-wall member used for in-situ casting hollow floor slab, roof, wall, etc. Said member is made up by die pressing. Its advantages are high strength, low cost, and convenient transportation.

Owner:湖南邱则有专利战略策划有限公司

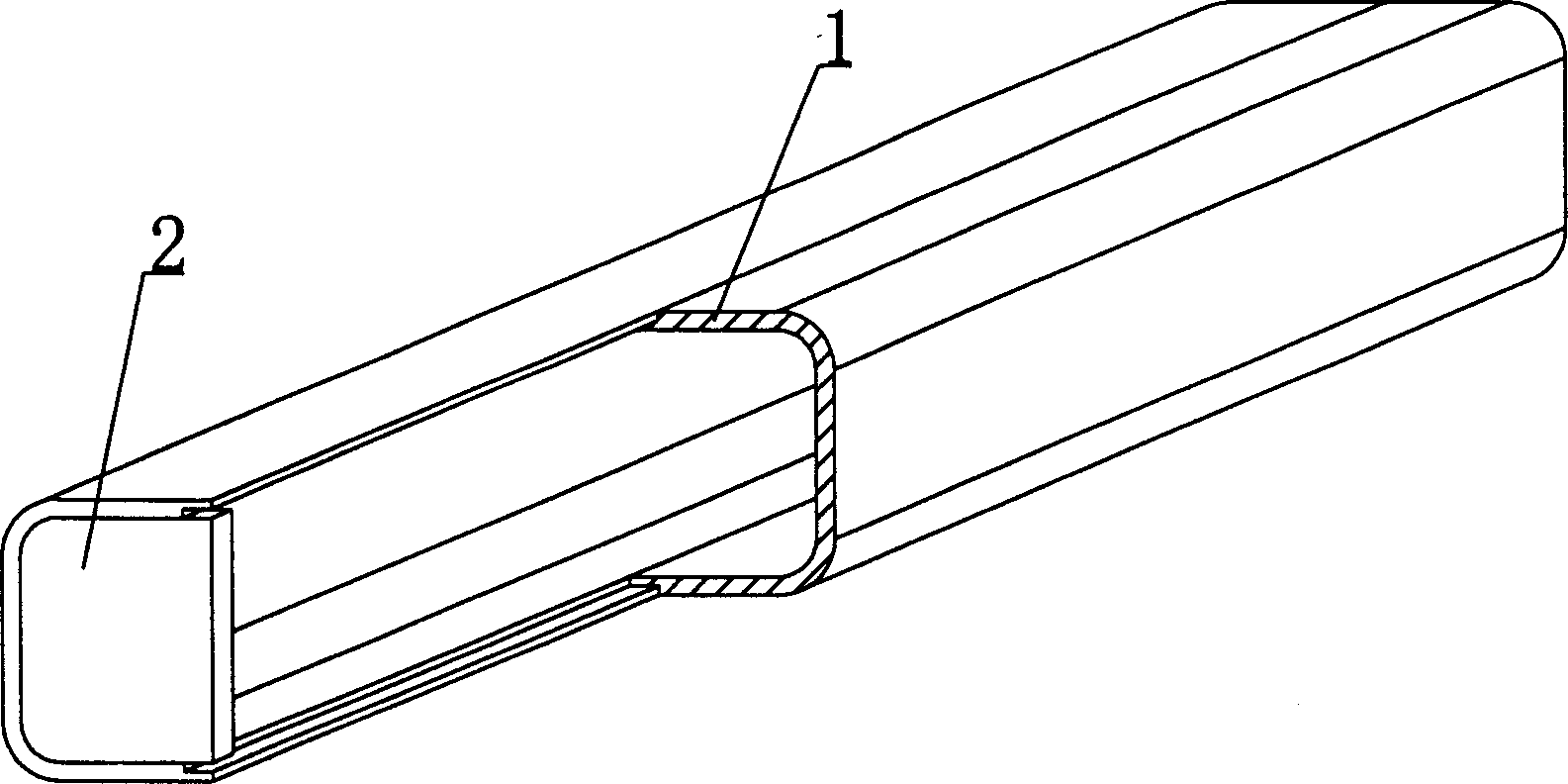

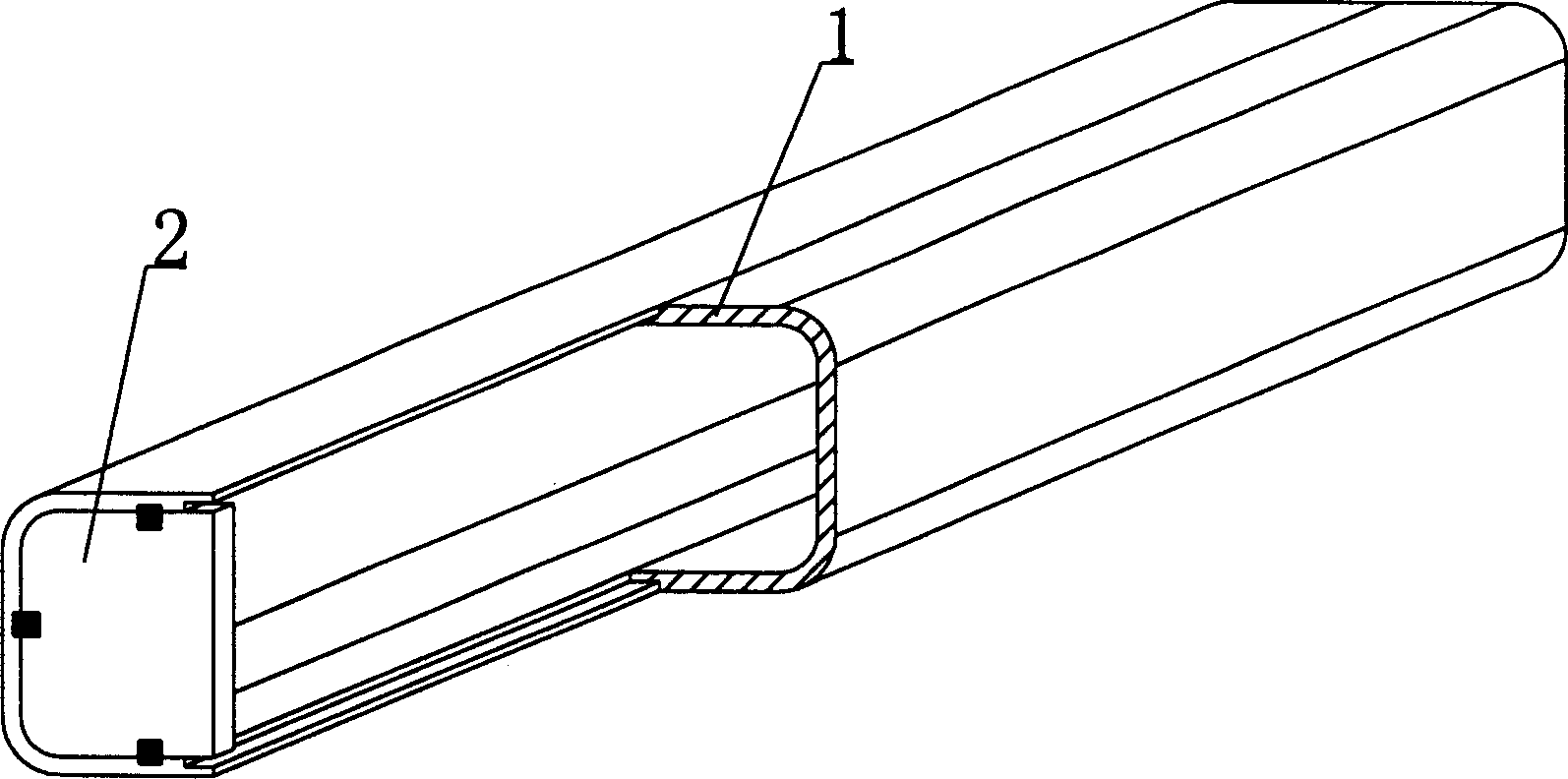

Hole constructing component for in situ cast steel bar reinforced concrete

A hole-forming member for in-situ casting the reinforced concrete is such a one used to combine a whole cavity. The connecting parts are used to combine two or more said members to form a hollow thin-wall member. Its advantages are high strength, low cost and high construction speed.

Owner:湖南邱则有专利战略策划有限公司

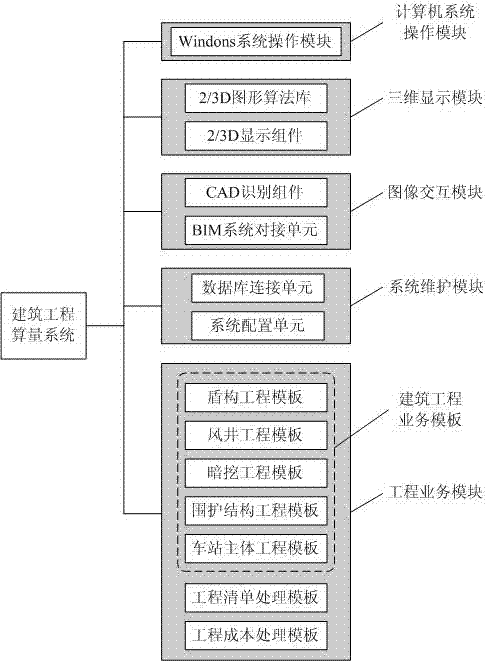

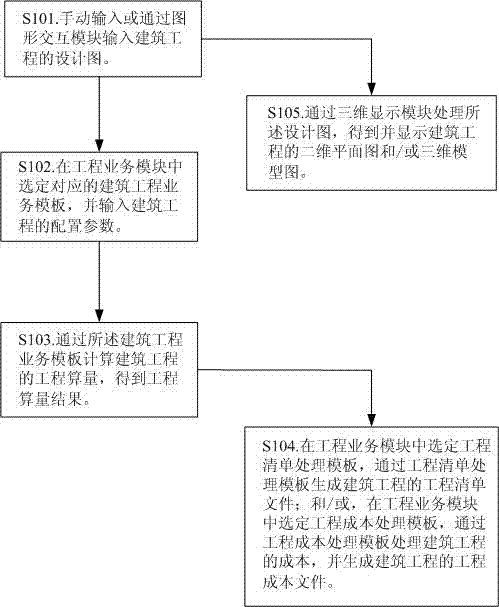

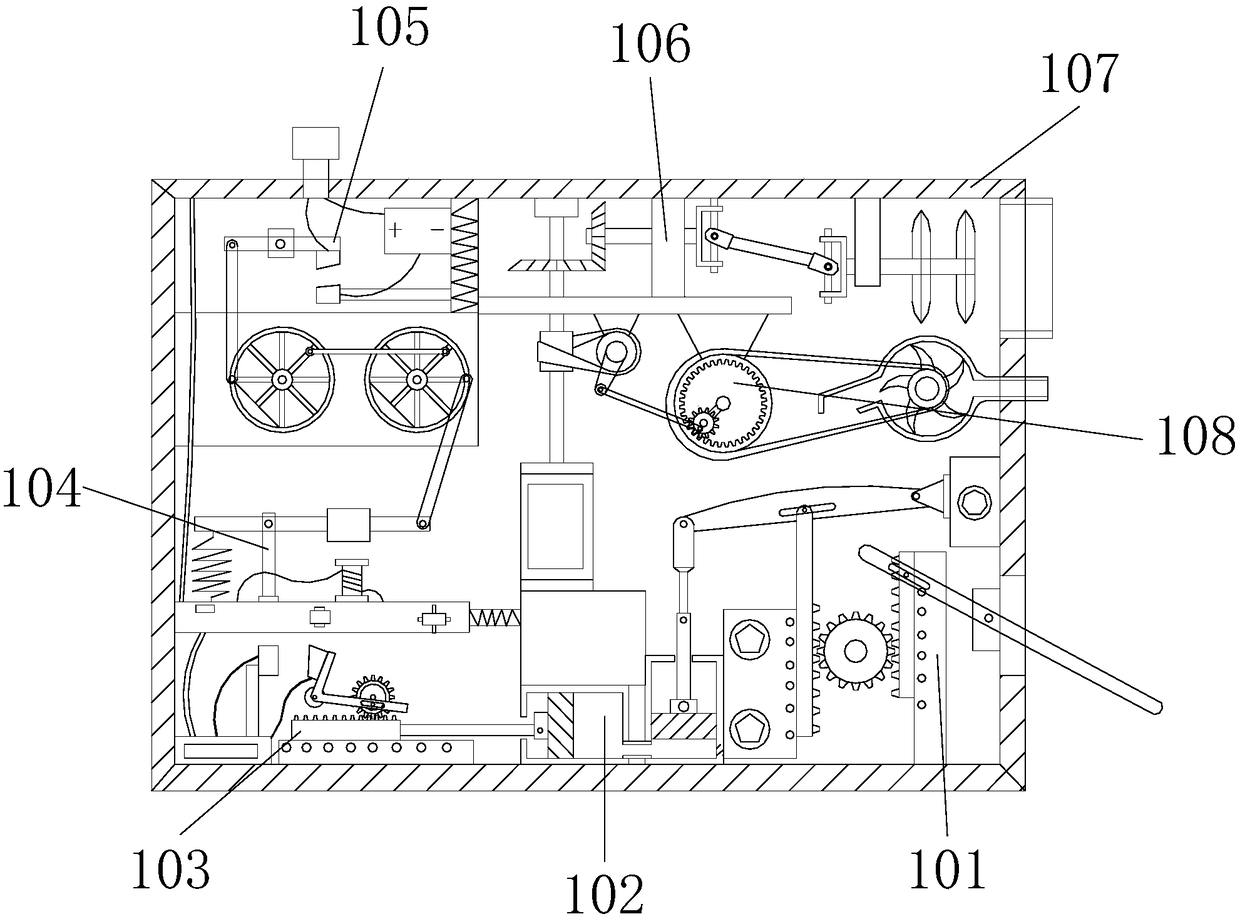

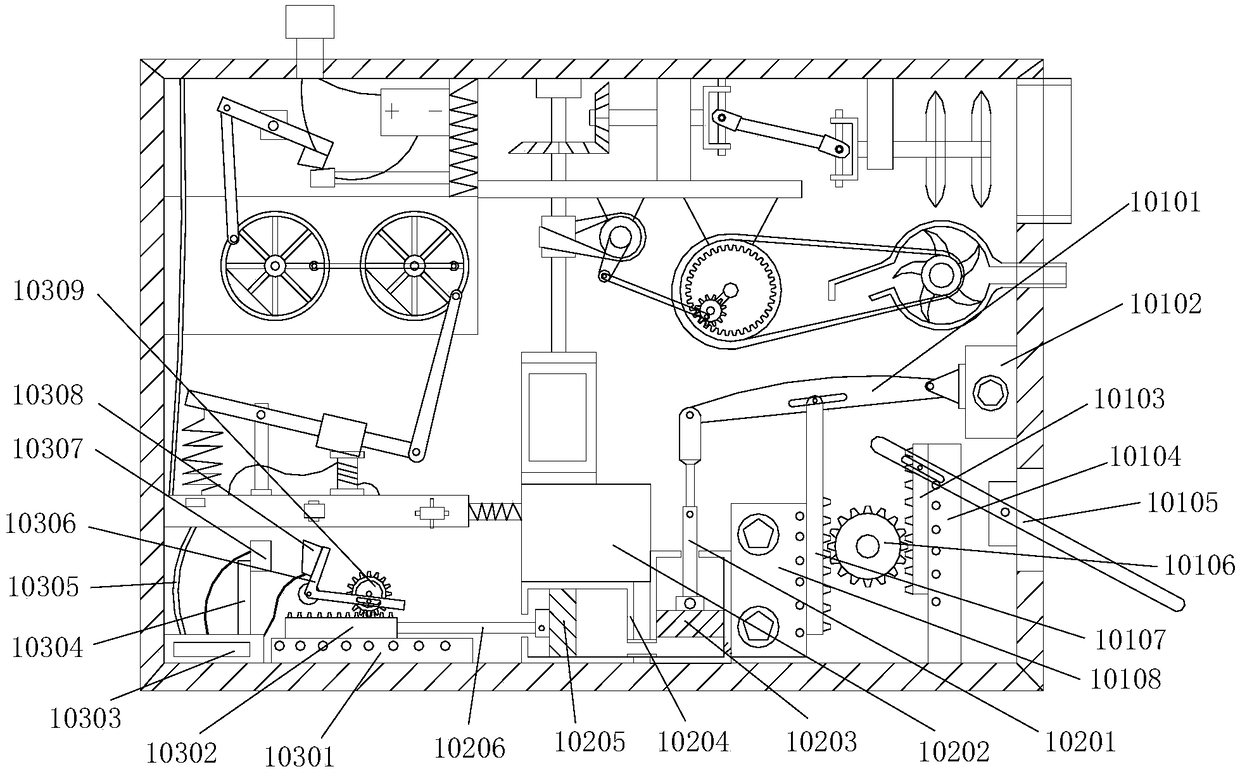

Constructional engineering budgeting system and working mechanism thereof

InactiveCN104732034AFacilitate subsequent constructionHigh degree of automationSpecial data processing applicationsGraphicsInformatization

The invention relates to the technical field of construction informatization application, and discloses a constructional engineering budgeting system and a working mechanism thereof. The constructional engineering budgeting system comprises a computer system operating module. The constructional engineering budgeting system is characterized by further comprising a system maintaining module used for maintaining system operating, a graphic interacting module used for providing a graphic interacting function, a three-dimensional displaying module used for carrying out 3D processing and / or displaying on graphs and an engineering business module used for providing at least one constructional engineering business template. According to the constructional engineering budgeting system and the working mechanism thereof, the manpower workload can be further lowered, an engineering budgeting result can be rapidly obtained, the accuracy of engineering budgeting can be assured, the automation degree of the constructional engineering budgeting system is improved, and the follow-up construction of the constructional engineering is convenient.

Owner:RANKEN RAILWAY CONSTR GROUP

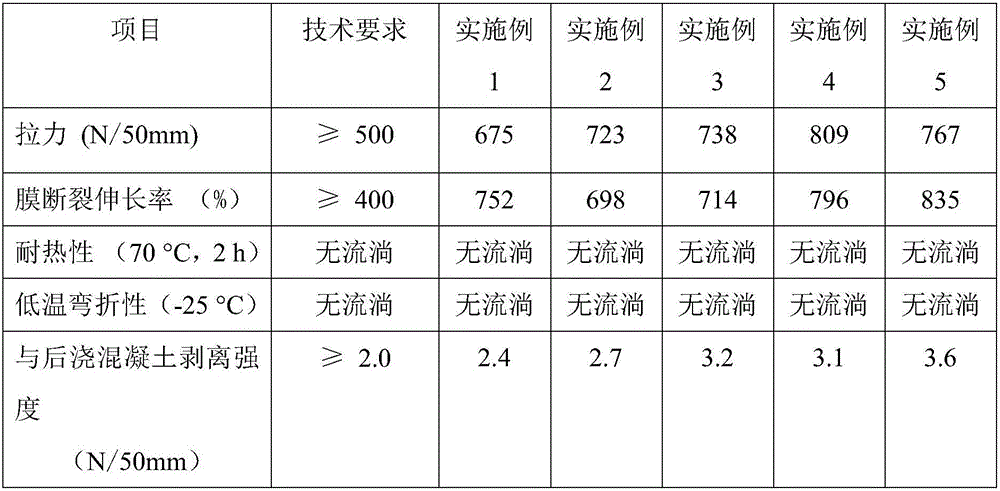

Pre-paved type polyolefin self-adhering film waterproof sheet and preparation method thereof

InactiveCN106543914AGood flexibilityModerate softnessFilm/foil adhesivesRailway tunnelEnvironmental resistance

The invention discloses a pre-paved type polyolefin self-adhering film waterproof sheet and a preparation method thereof. The pre-paved type polyolefin self-adhering film waterproof sheet is composed of two layers of structures, namely, a polyolefin waterproof sheet and a self-adhering glue layer, wherein the polyolefin sheet is prepared from the following raw materials in parts by weight: 65-85 parts of polyethylene, 10-25 parts of thermoplastic elastomer, 5-10 parts of polyethylene grafting materials, 3-8 parts of a modified tackifier, 0.2-0.6 part of titanium dioxide and 0.1-0.5 part of an antioxidant. The preparation method comprises the following steps: mixing according to the raw material ratio of the polyolefin waterproof sheet, fusing, extruding and forming the polyolefin sheet, and then compounding one self-adhering glue layer onto the sheet. The polyolefin self-adhering film waterproof sheet prepared according to the method has the advantages of excellent physical and mechanical properties, excellent waterproof property, moderate softness, excellent workability, safety, environmental protection and excellent peeling strength of self-adhering glue layer and post-poured concrete. The pre-paved type polyolefin self-adhering film waterproof sheet prepared according to the method provided by the invention can be used for waterproof purpose of railway tunnels.

Owner:广州大禹防漏技术开发有限公司

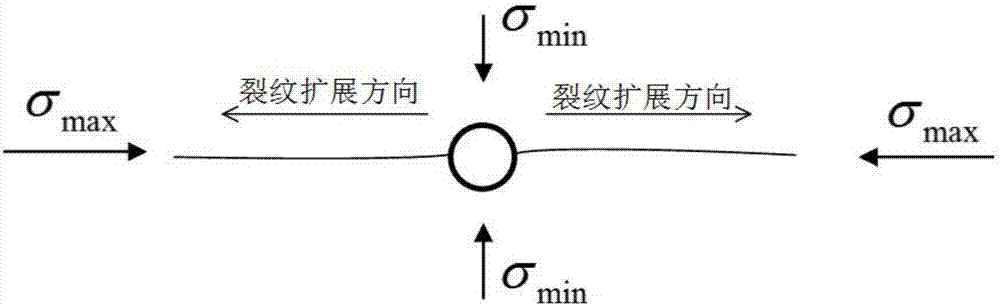

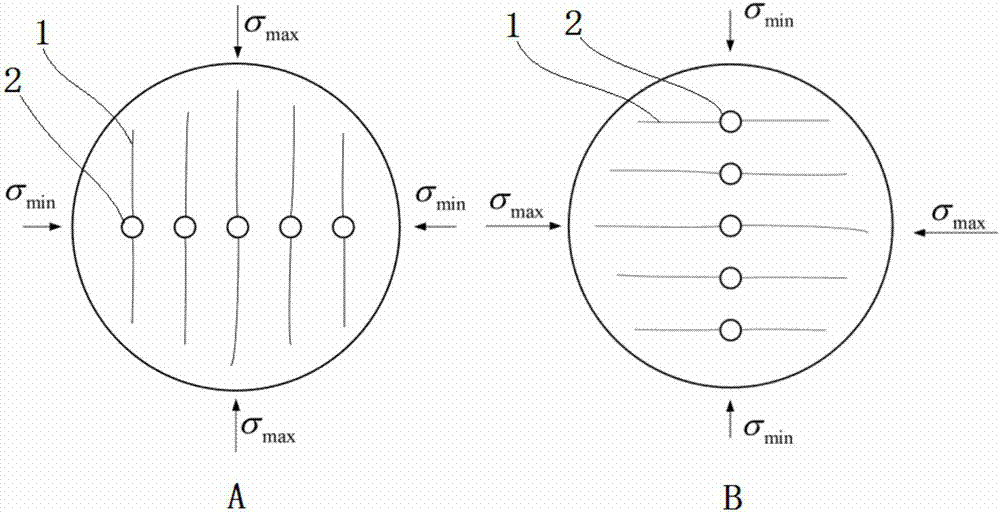

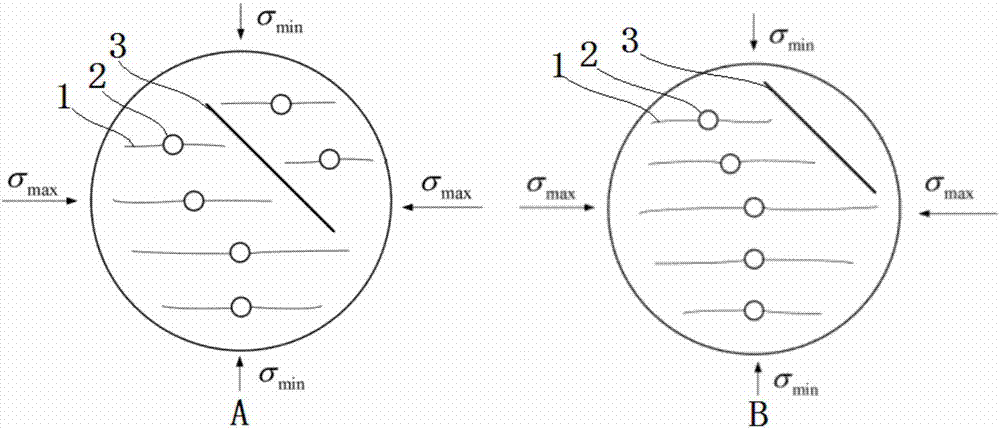

Method and system for tunneling extrahard rock by means of hydraulic fracturing technology and tunneling machine

ActiveCN107083967AAvoid turnoverEffective controlHydro energy generationTunnelsEngineeringHydraulic fracturing

The invention relates to a method and system for tunneling extrahard rock by means of a hydraulic fracturing technology and a tunneling machine. By means of the hydraulic fracturing technology, the extrahard complete rock generates cracks, and therefore the rock integrity is lowered; according to the formation condition, the drilled hole position and the fracturing sequence of a face are designed, a drill rod stretches out of a hole to perform perpendicular punching in sequence on the face, a to-be-fractured section inside the drilled hole is sealed through a packer, high-pressure water is pumped into the to-be-fractured section, the hydraulic pressure is increased continuously, after the hole wall is fractured, cracks are expanded, and pressurizing is stopped after the cracks are expanded to the preset length, the packer together with other fracturing devices is taken out, and the tunneling machine begins tunneling. According to the method and system, the integrity of the rock within the construction range is lowered, the tool abrasion during tunneling is reduced, and the tunneling efficiency is improved.

Owner:WUHAN UNIV

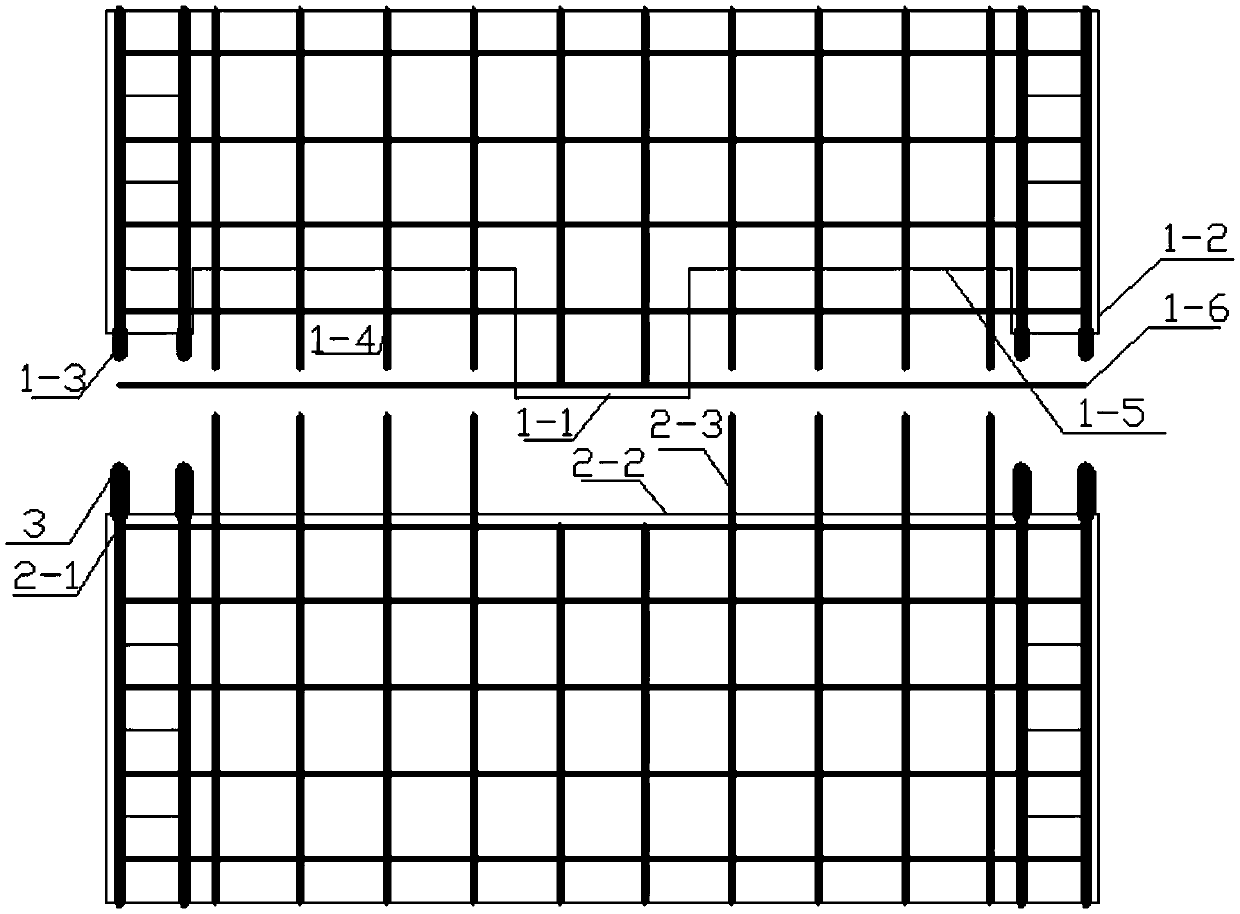

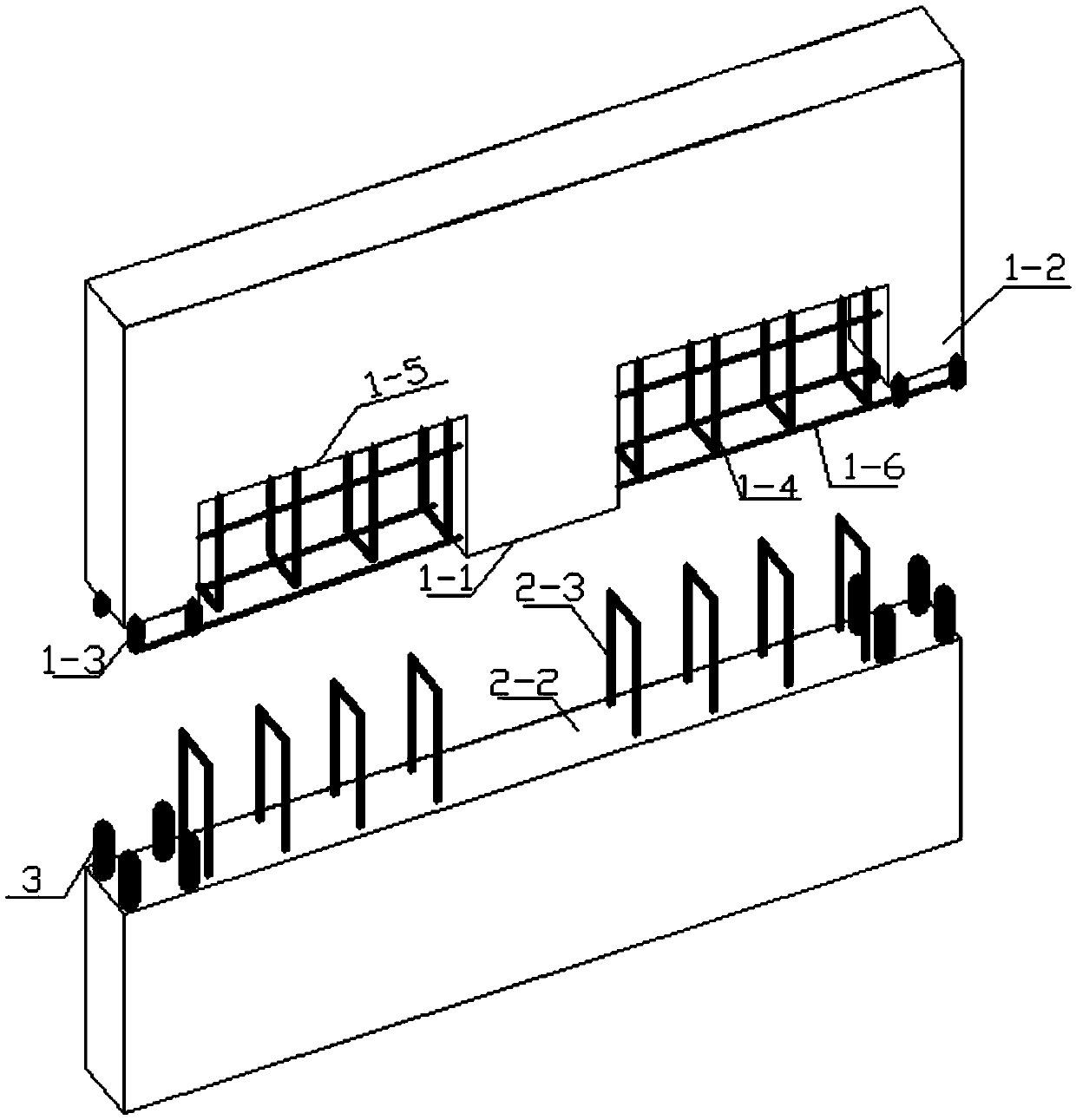

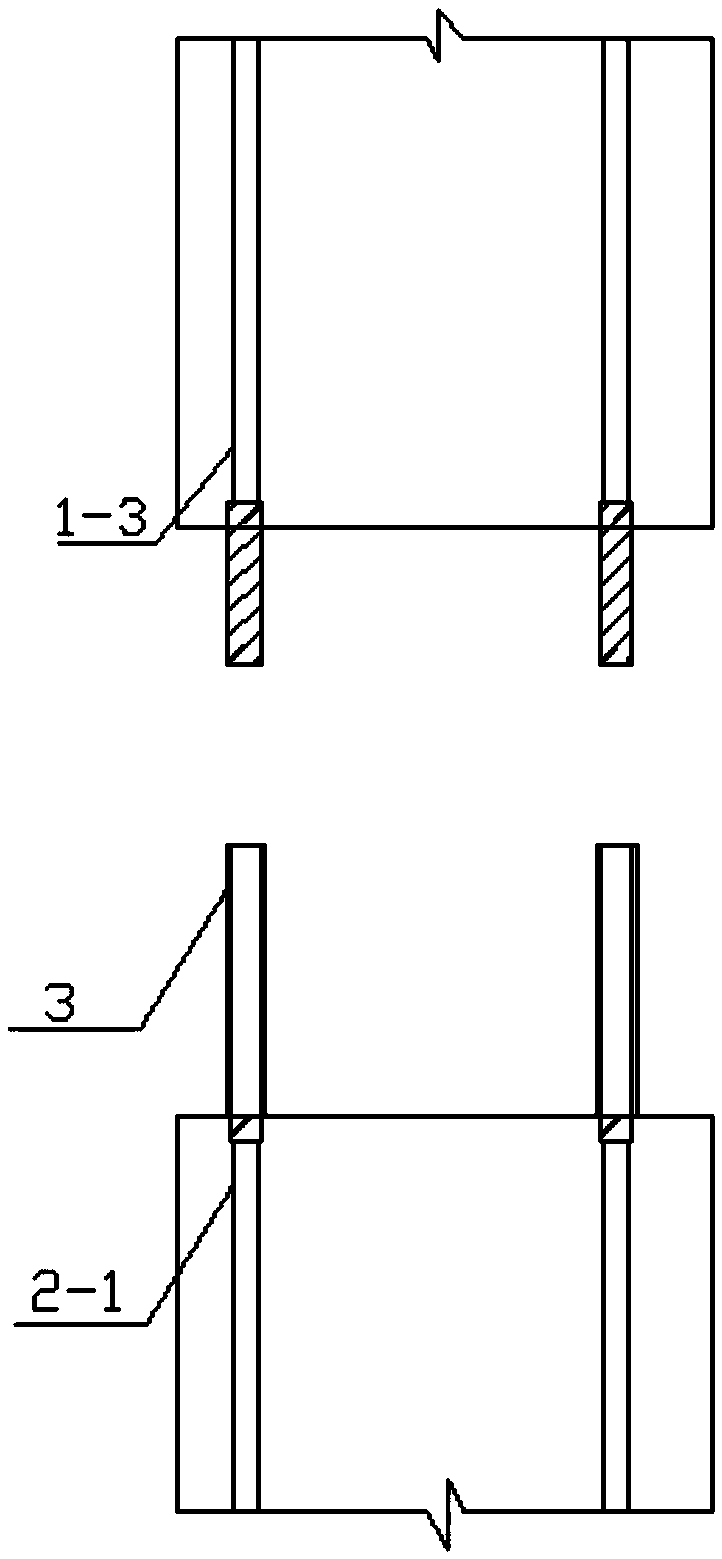

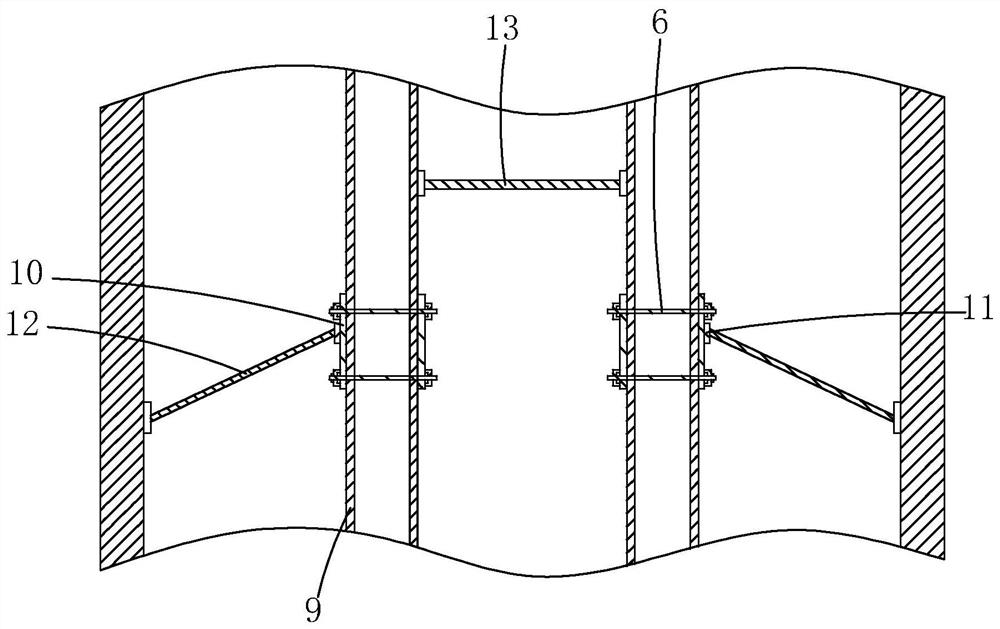

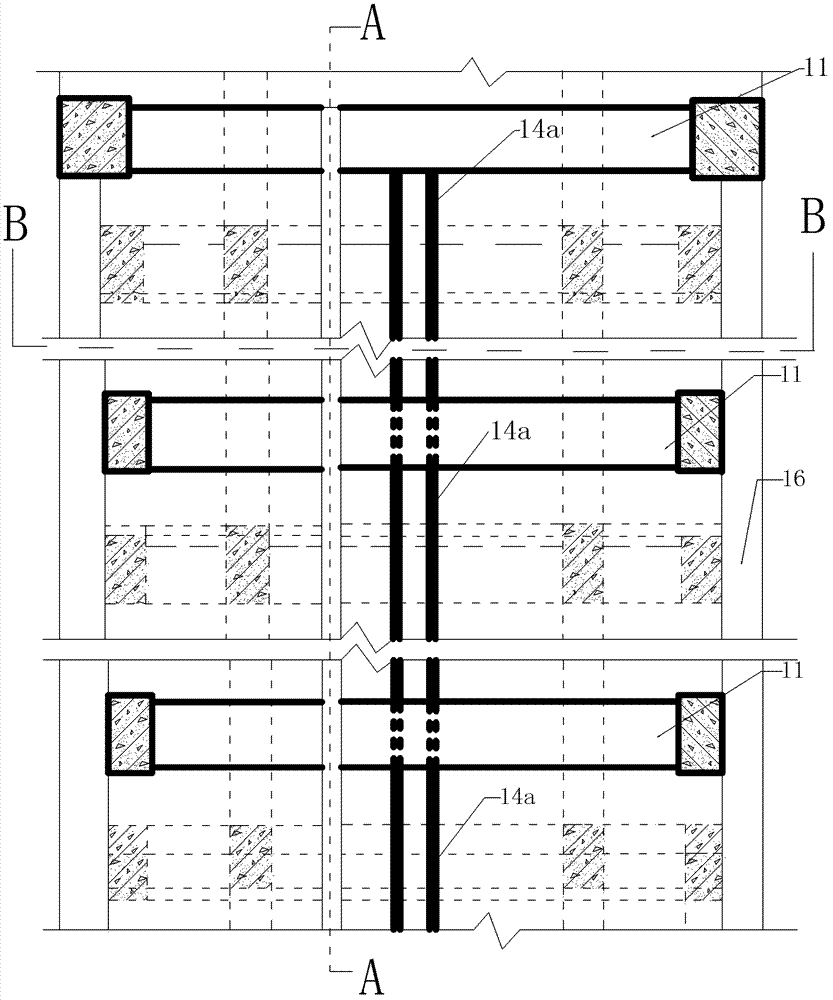

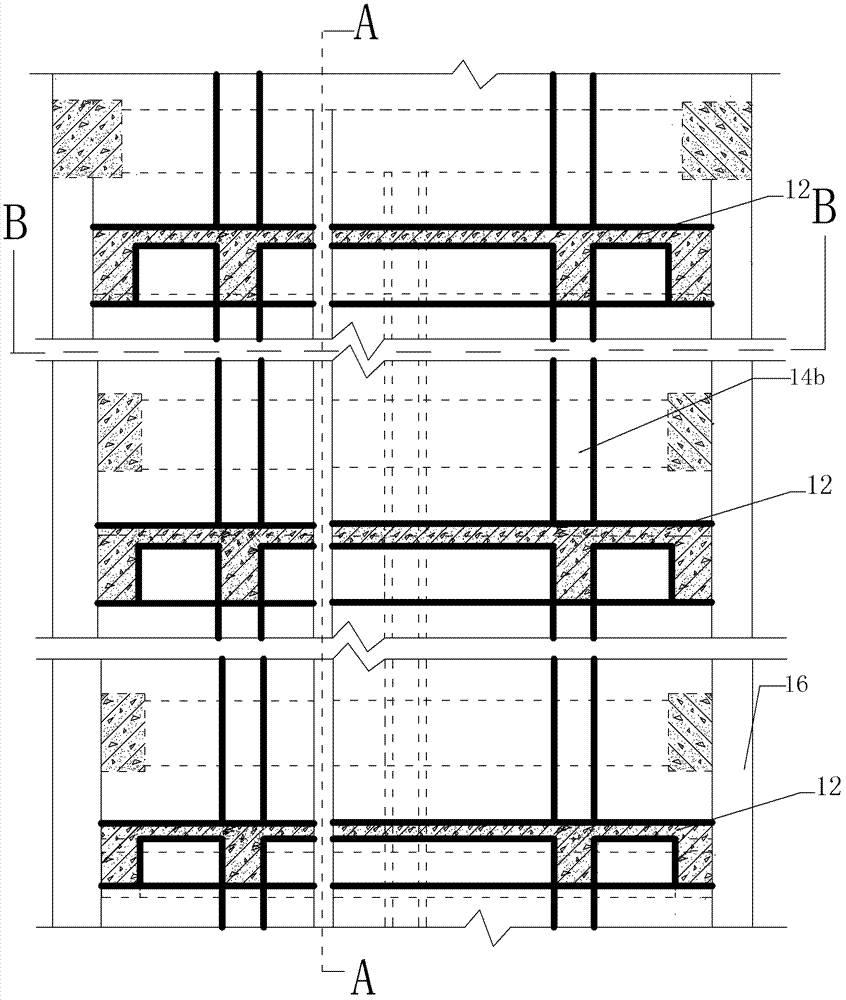

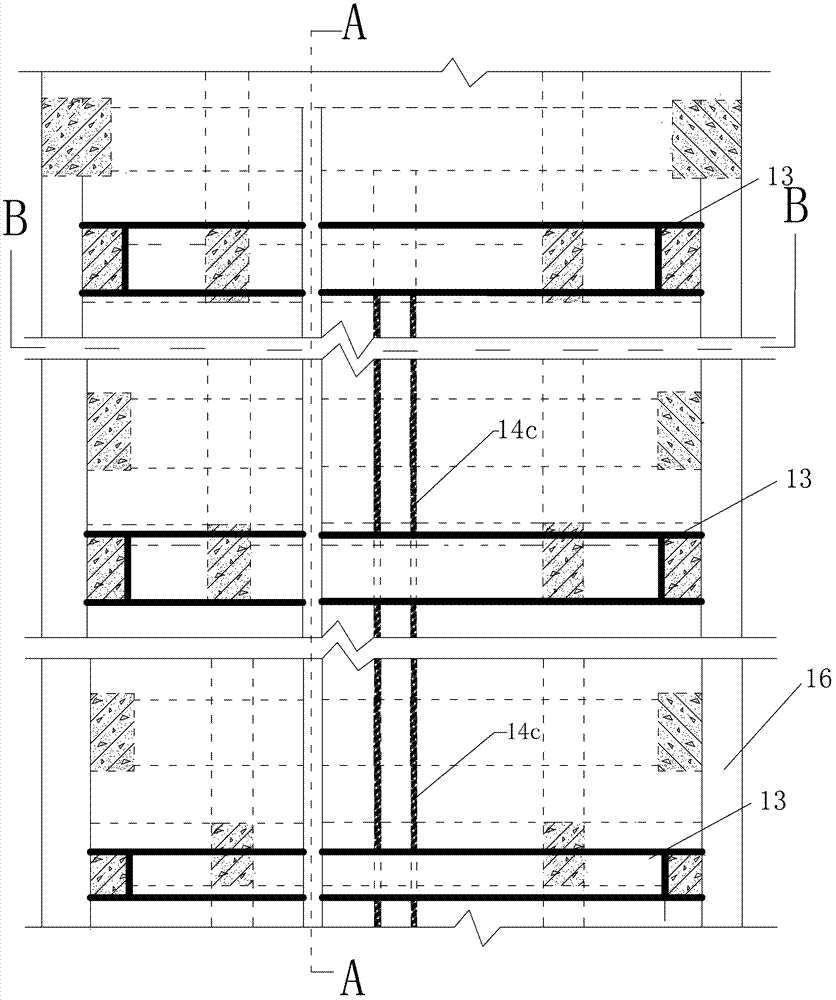

Assembled type shear wall upper-layer and lower-layer combined connection structure

The invention discloses an assembled type shear wall upper-layer and lower-layer combined connection structure which comprises an upper-layer prefabricated wall and a lower-layer prefabricated wall which are connected in a butted mode. When the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected in the butted mode, a downward-protruding supporting structure of the upper-layer prefabricated wall is supported on the lower-layer prefabricated wall, structural longitudinal ribs of an embedded column of the upper-layer prefabricated wall and structural longitudinal ribs of an embedded column of the lower-layer prefabricated wall are opposite in a one-to-one mode and are connected mechanically, the structural longitudinal ribs I of the upper-layer prefabricated wall and the structural longitudinal ribs II of the lower-layer prefabricated wall are connected in an overlapped mode, and the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected at the joint through a cast-in-place concrete structure. The combined connection way combined with the cast-in-place concrete structure is formed through mechanical connection, steel bar splicing and concrete spraying, the wall prefabrication technology is simpler, on-site construction is more convenient and rapider, and the workpiece manufacturing cost and the construction cost can be reduced.

Owner:TIANJIN UNIV

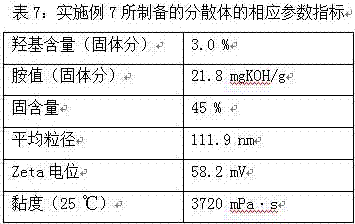

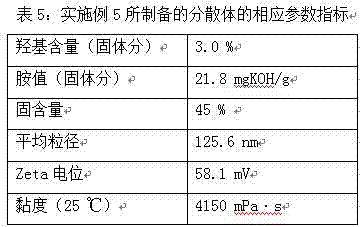

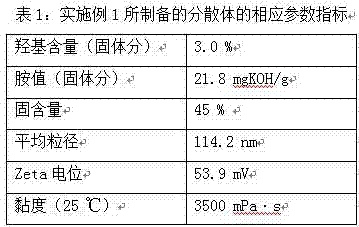

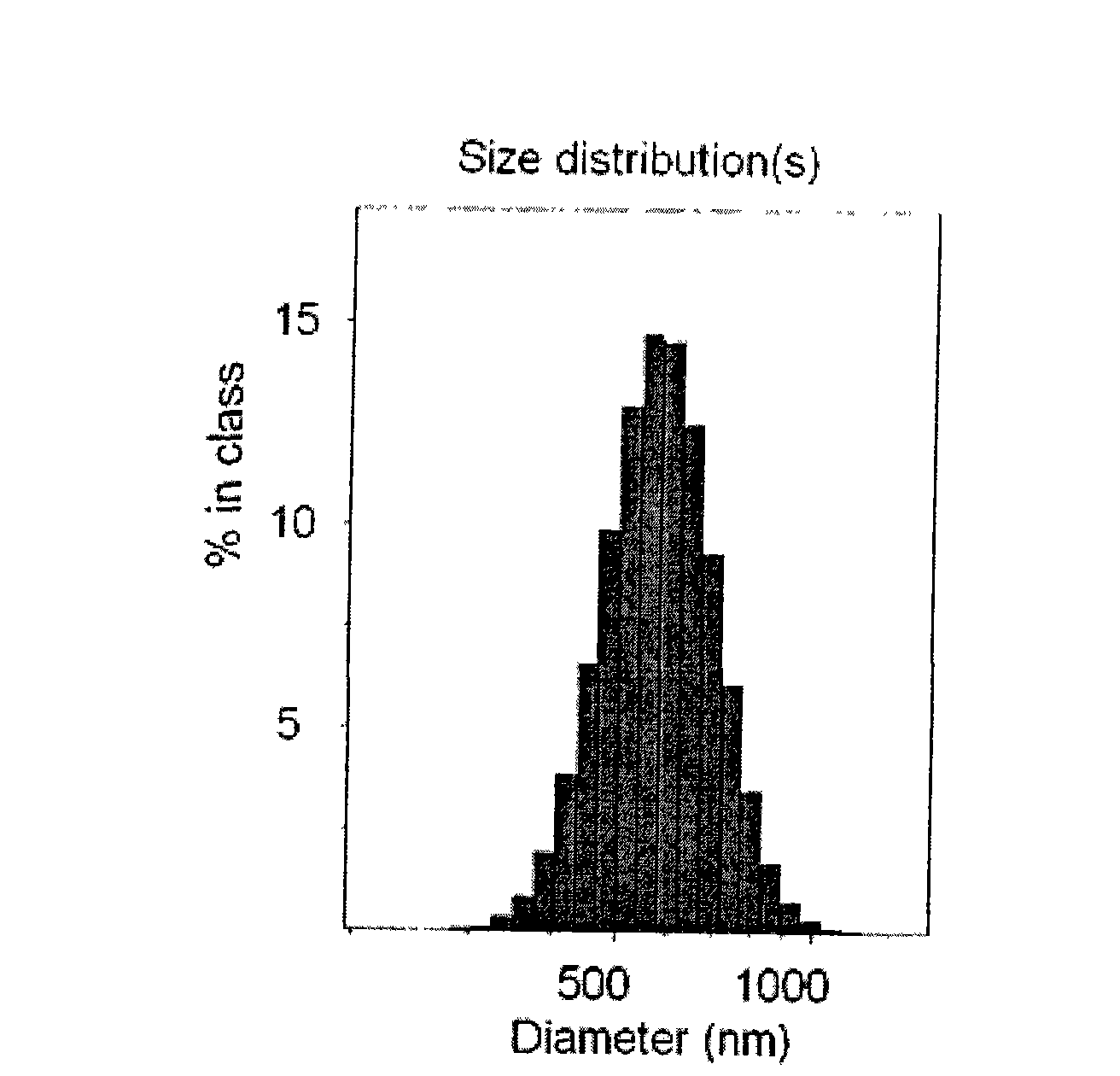

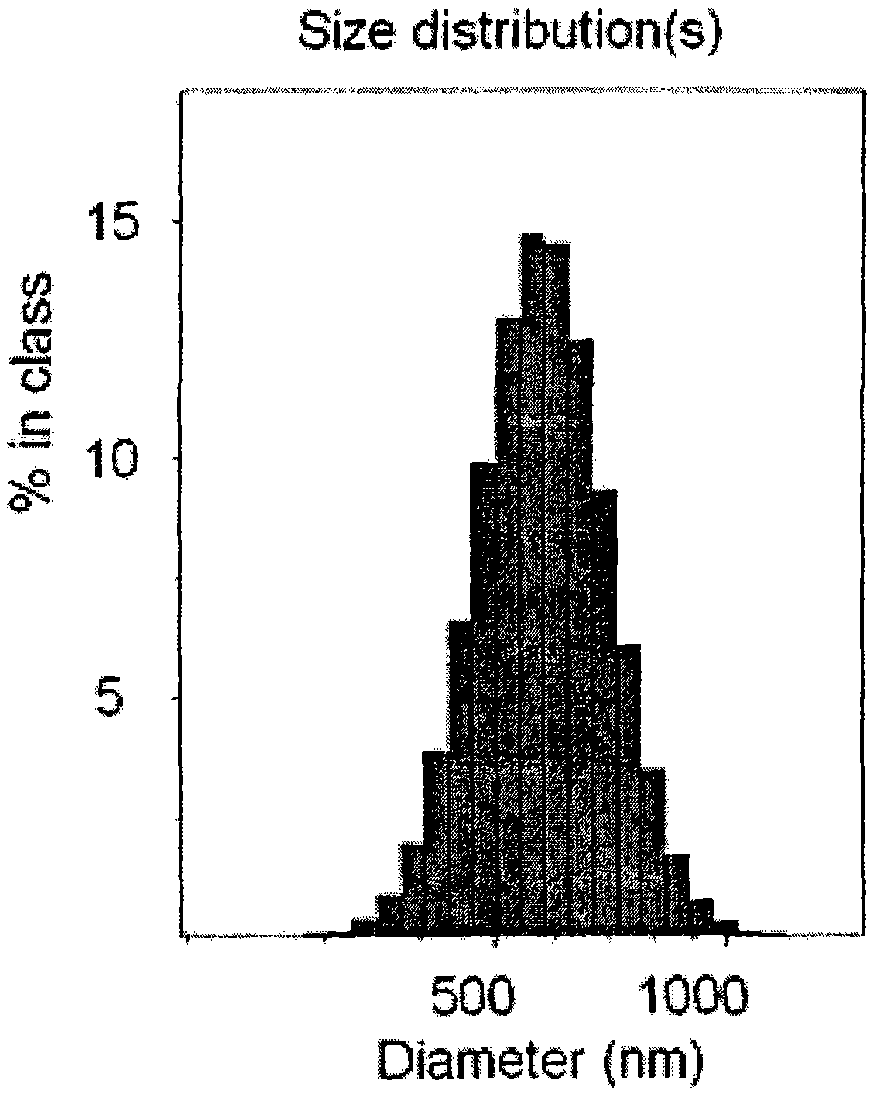

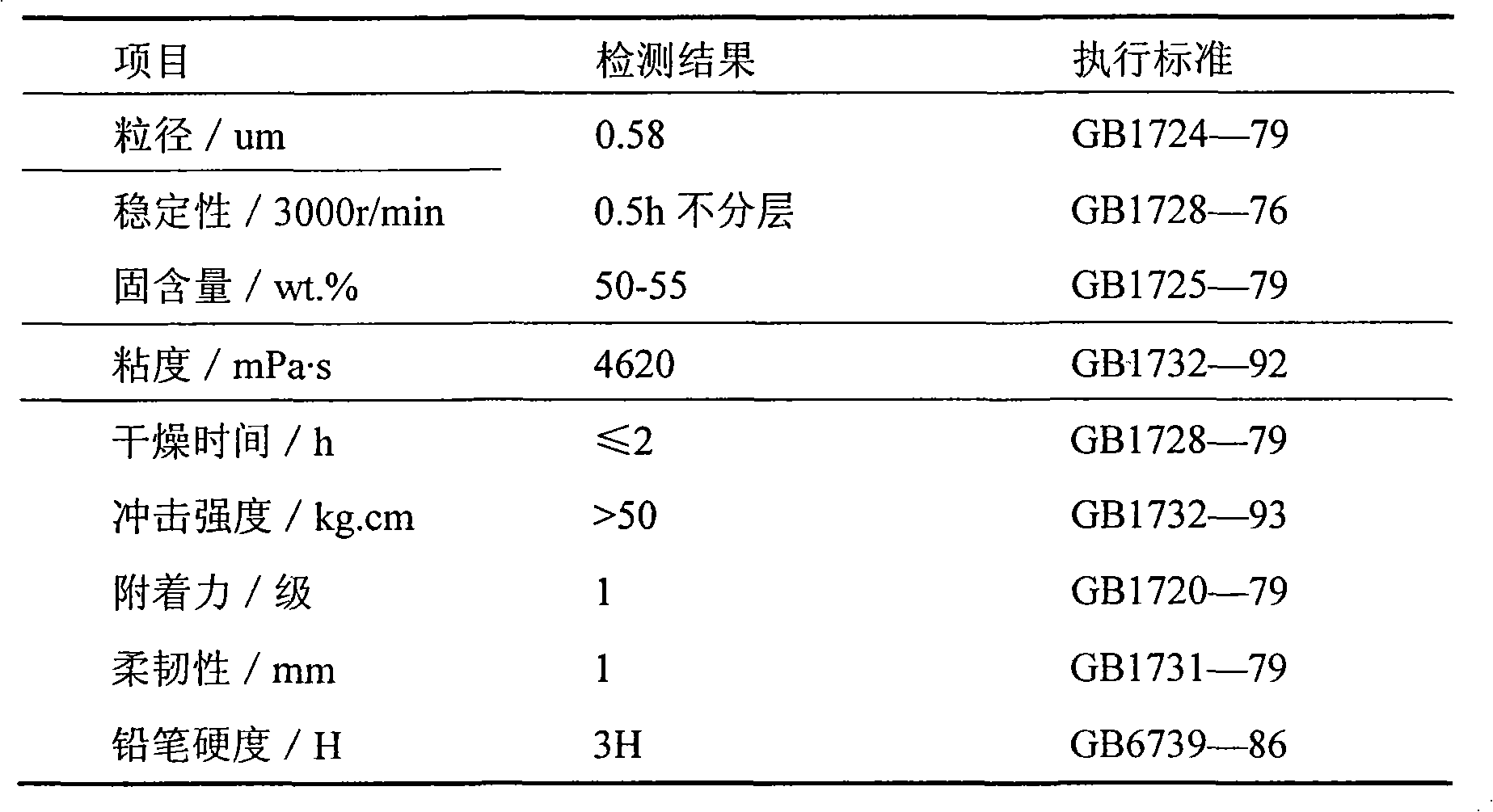

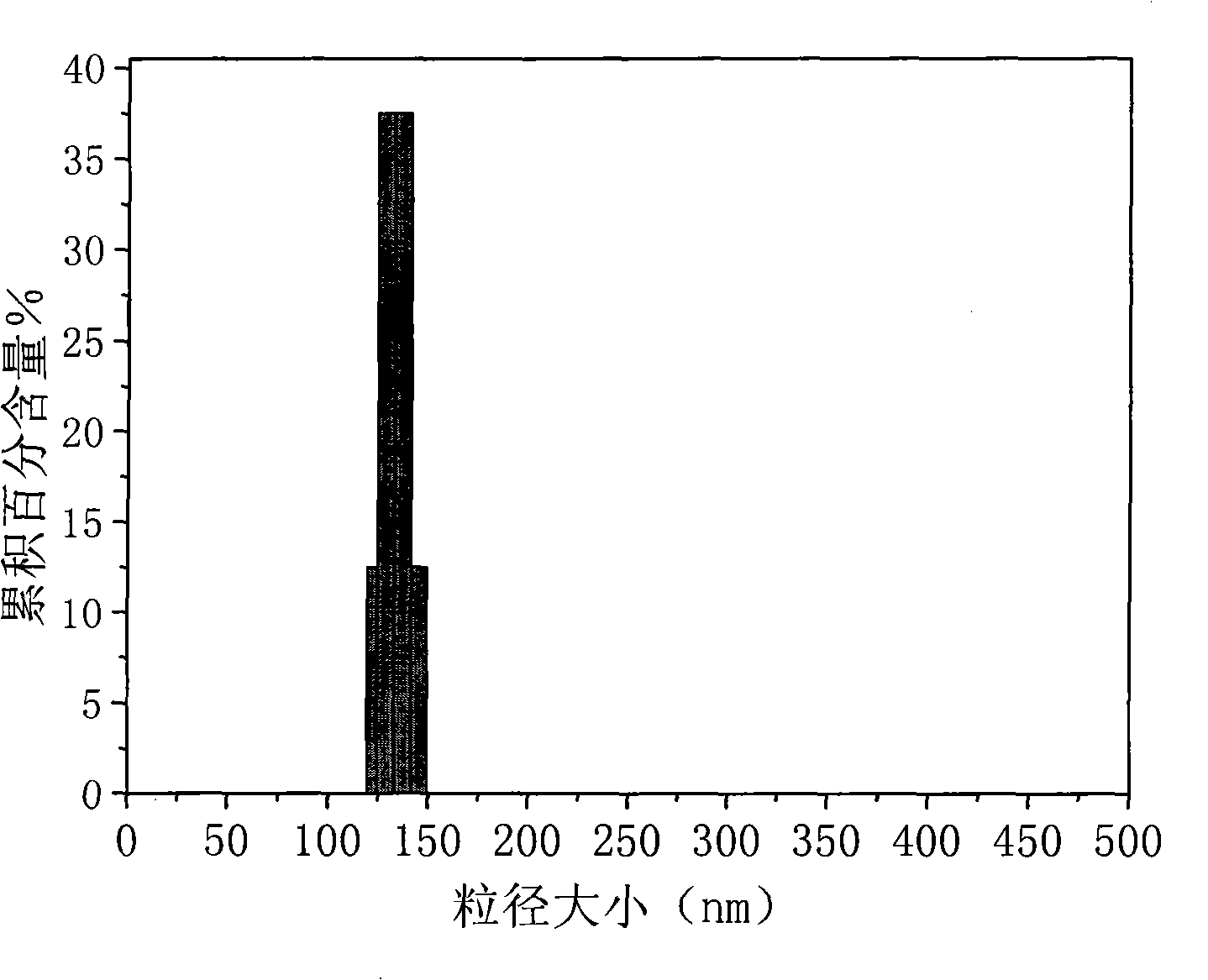

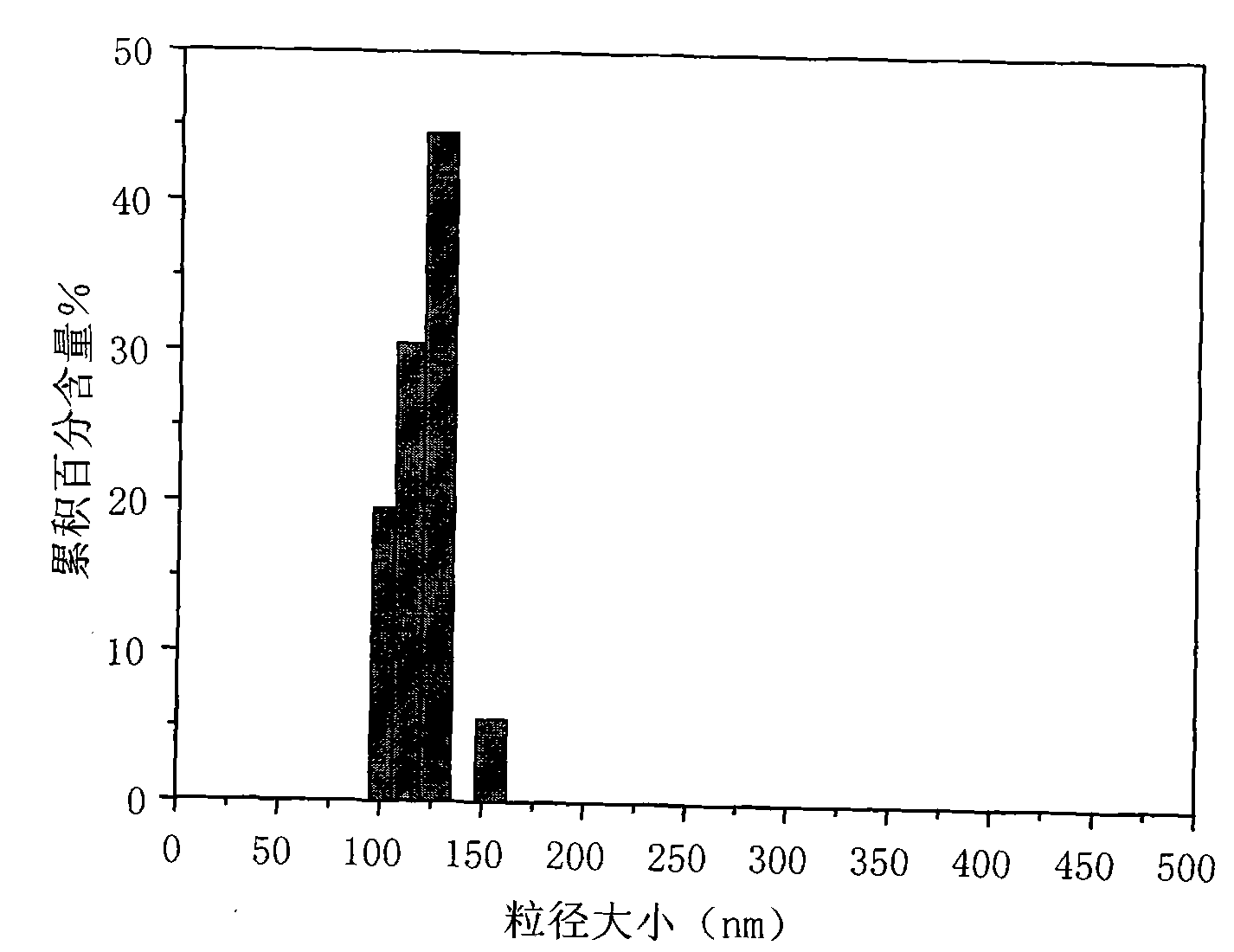

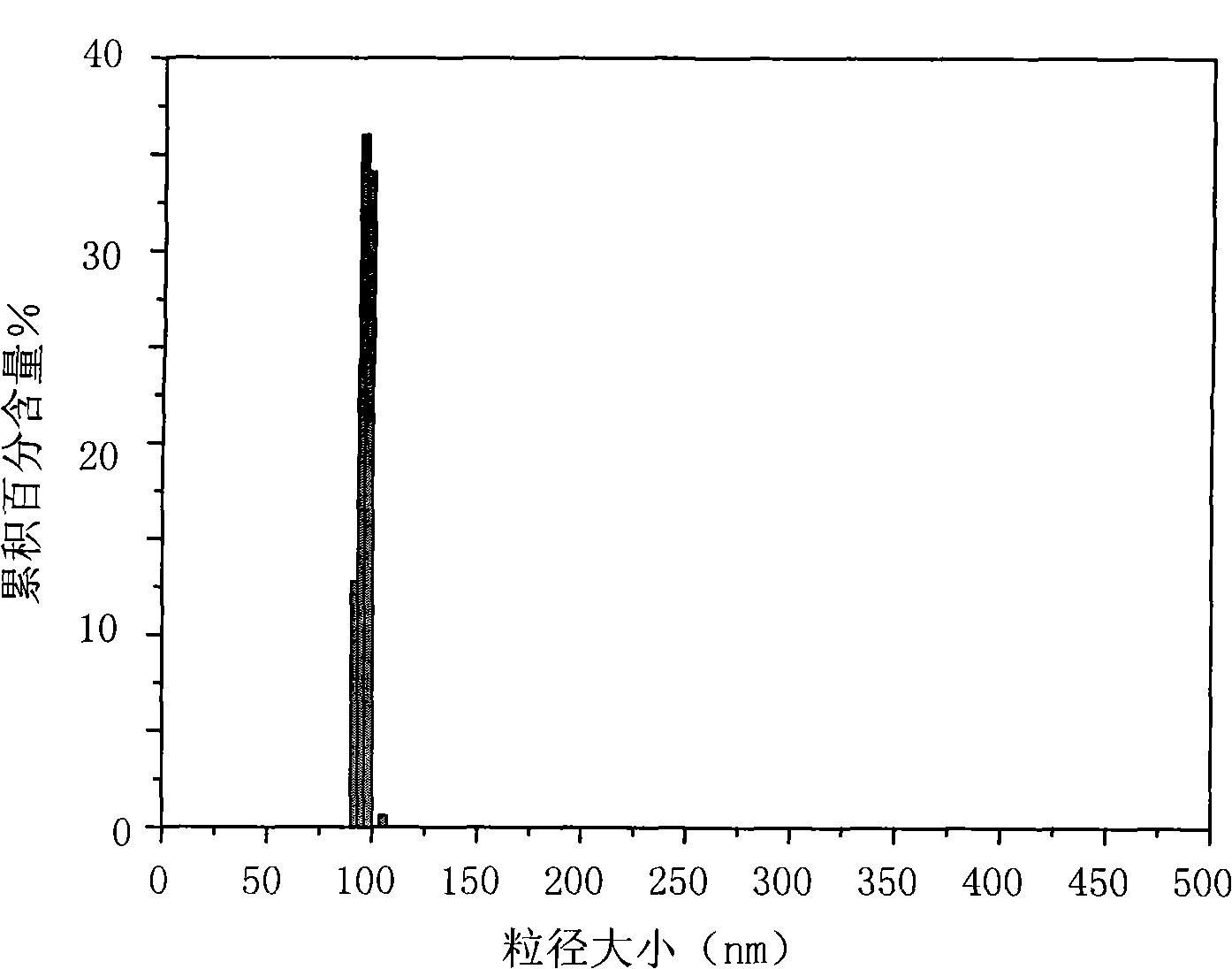

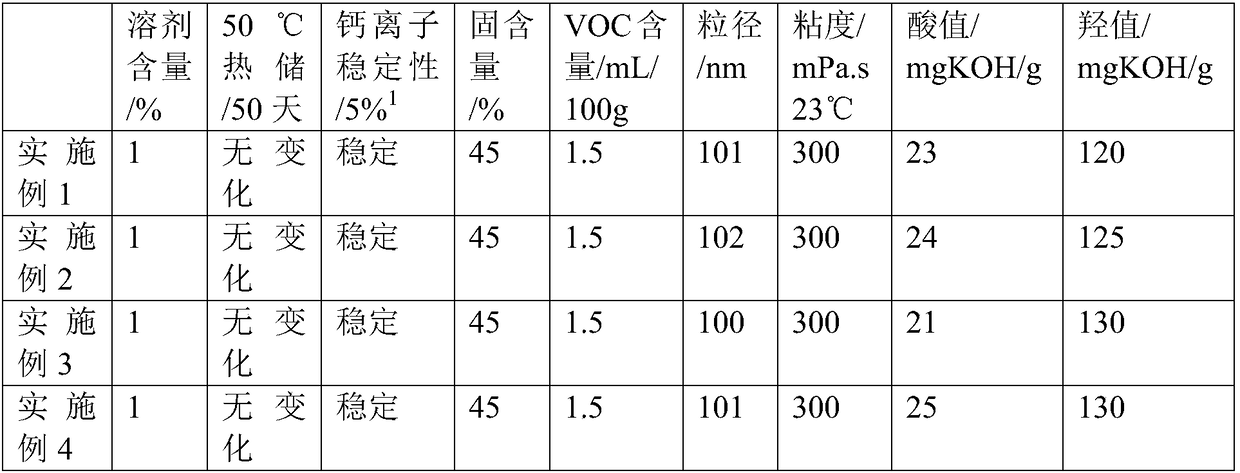

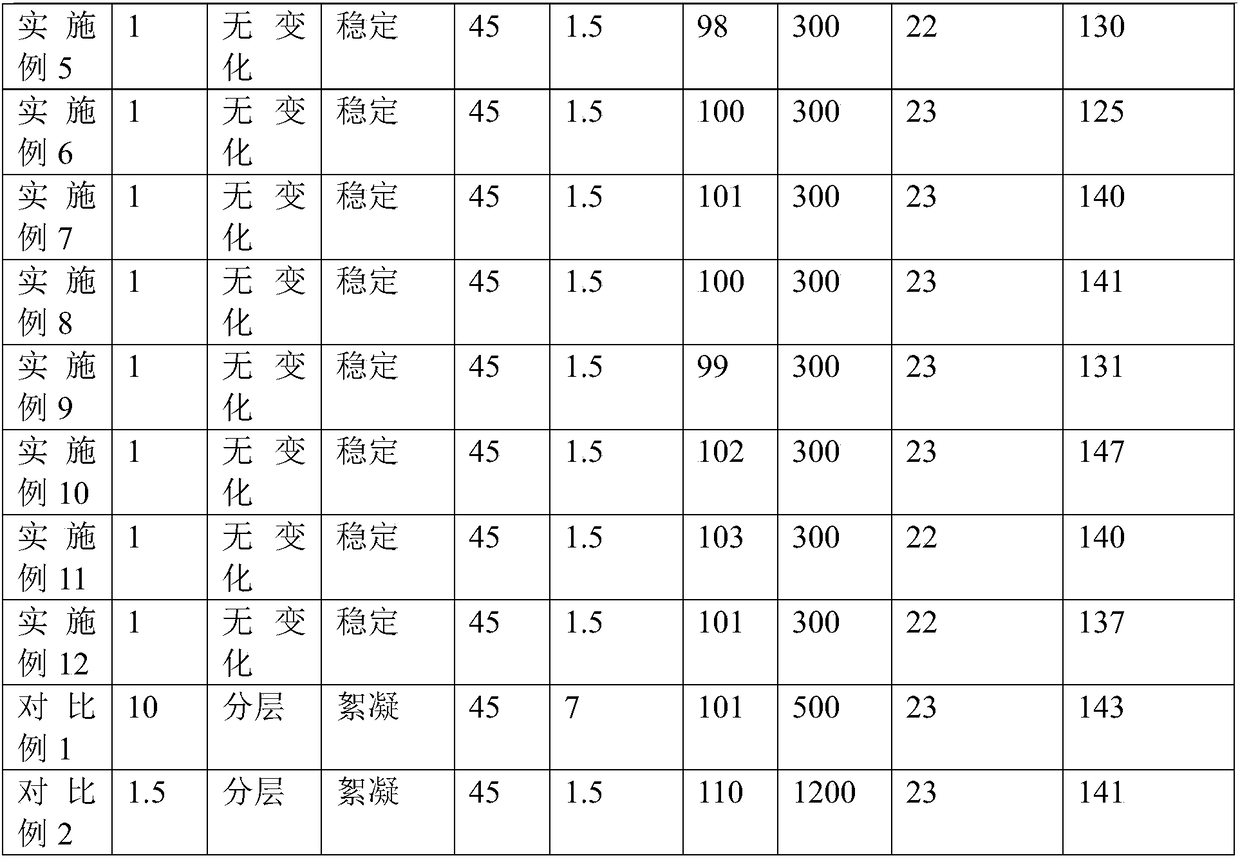

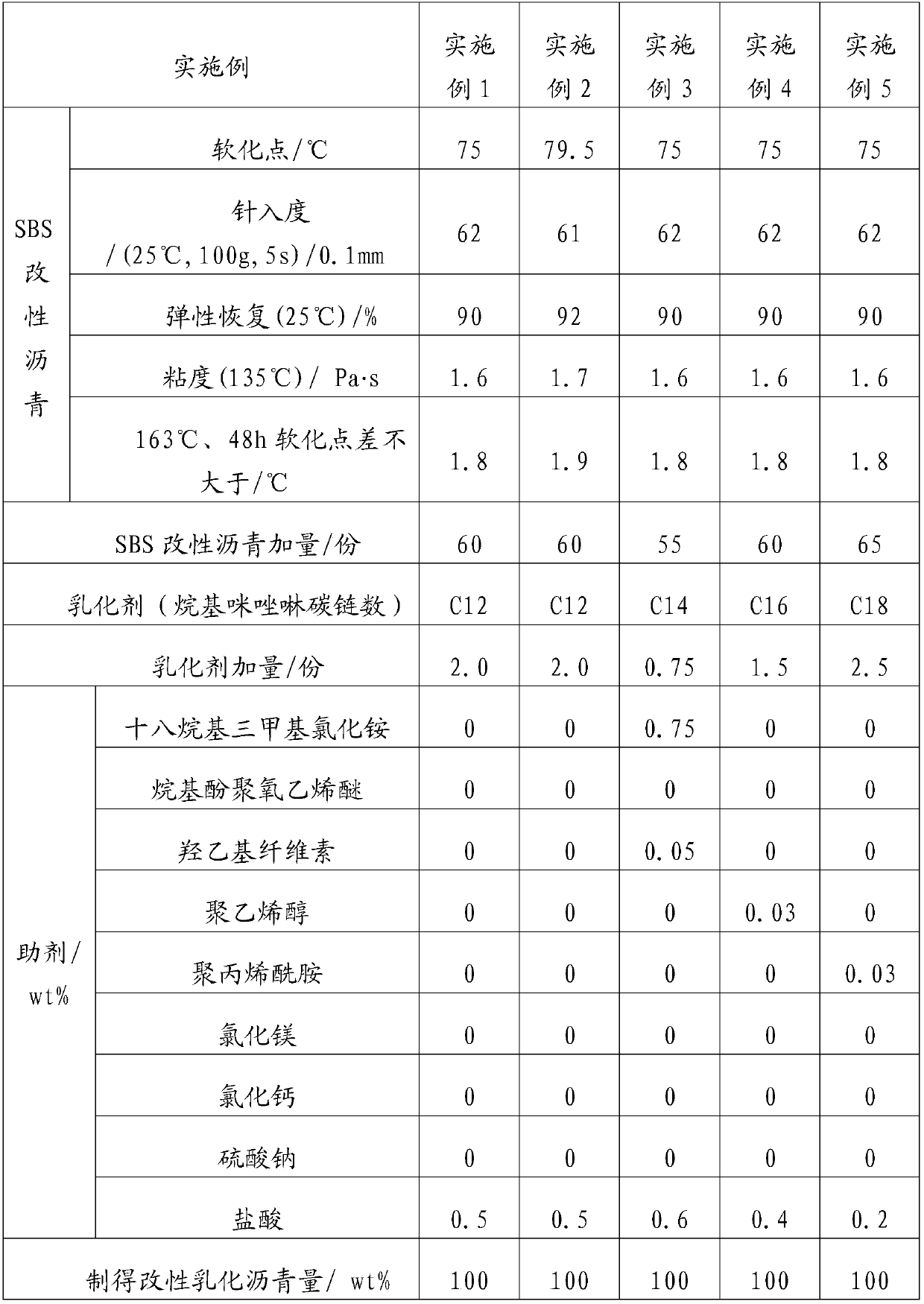

Cationic aqueous hydroxy acrylic resin secondary dispersion and preparation method thereof

InactiveCN107163192AImprove adhesionImprove anti-alkali sealingAntifouling/underwater paintsPaints with biocidesOrganic solventPolymer science

The invention relates to a cationic aqueous hydroxy acrylic resin secondary dispersion and a preparation method thereof. The dispersion comprises, by mass, 40-45% of cationic aqueous hydroxy acrylic resin, 2-9% of an organic solvent and 46-58% of deionized water. The dispersion has high adhesion, high alkali-resistant sealing property, high shielding property and high spot permeation resistance. The average size of the dispersion is small and is 90-160 nm, the particle size distribution is narrow, the polydispersity coefficient PID is 0.05-0.15, and the dispersion has good uniformity, so the improvement of the comprehensive performances of a film formed by the dispersion is benefited. The dispersion has small viscosity, so the subsequent construction of a mixture of the dispersion and a curing agent in the coating preparation process is facilitated. The dispersion has the advantages of good fluidity, high stability, no layering, settling or precipitating phenomena after standing storage at room temperature for 60 d or more, and no obvious change of the particle size, the particle size distribution and the viscosity.

Owner:SHANGHAI UNIV

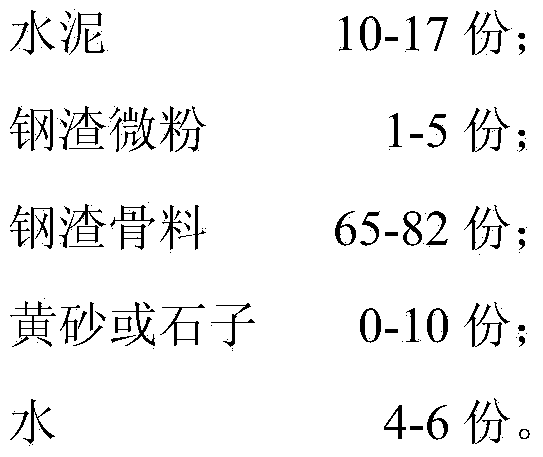

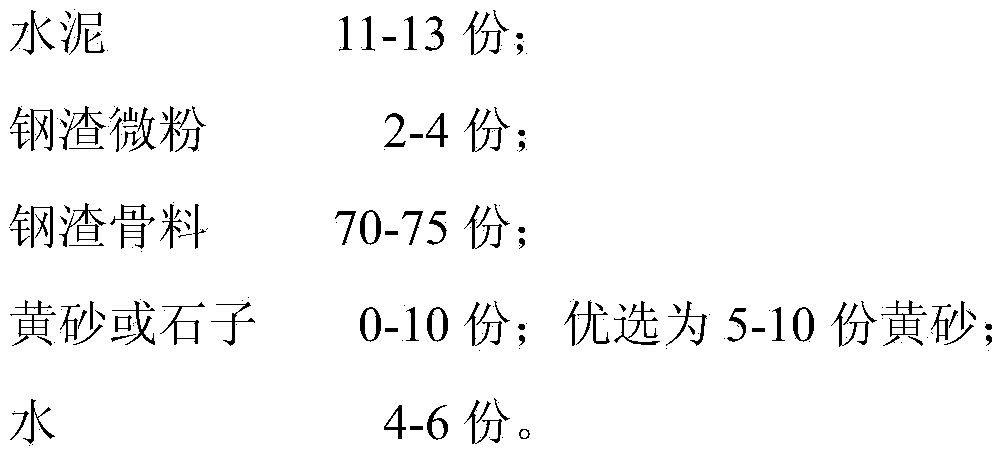

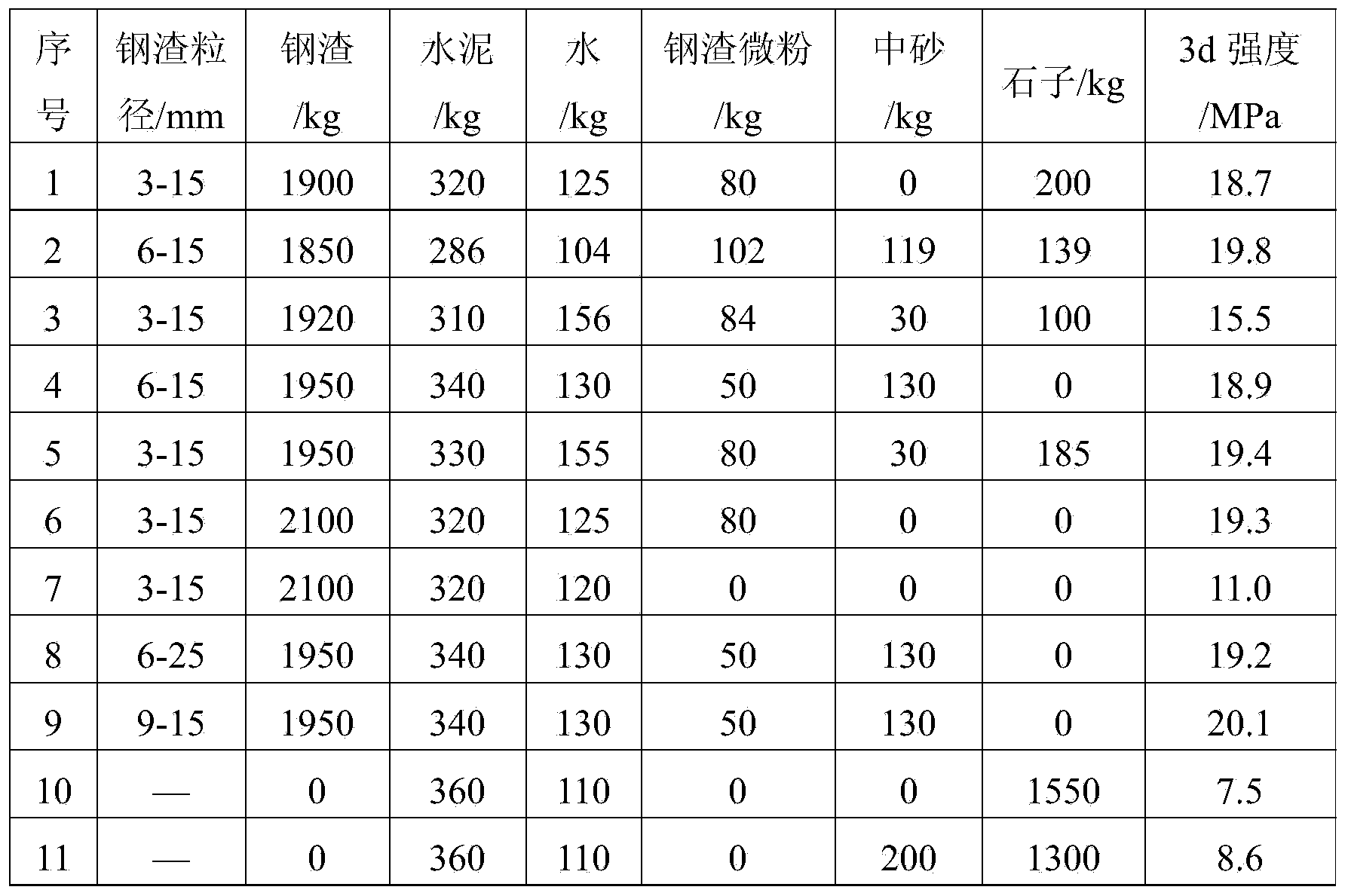

High-early-strength steel slag pervious concrete as well as preparation method and applications thereof

InactiveCN104003666AImproved early strength propertiesHigh compressive strengthSolid waste managementMetallurgical slagRoad surface

The invention relates to the field of metallurgical slag processing, and particularly relates to a high-early-strength steel slag pervious concrete as well as a preparation method and applications thereof. The invention provides a high-early-strength steel slag pervious concrete which is prepared from the following raw materials in parts by weight: 10-17 parts of cement, 1-5 parts of steel slag micro-powder, 65-82 parts of steel slag aggregates, 0-10 parts of yellow sand or gravels, and 4-6 parts of water. Compared with steel slag pervious concretes in the prior art, the concrete provided by the invention has the advantages that the early strength properties are greatly improved, and the high-early-strength steel slag pervious concrete can be put into use in a short time. According to the invention, cement, water, steel slag micro-powder and steel slag aggregates are adopted for preparing the concrete, and a small amount of yellow sand and gravels also can be added as aggregates, so that extremely high compressive strength can be formed in 3 days, thereby facilitating the follow-up construction of pervious pavement system engineering.

Owner:SHANGHAI MCC ENVIRONMENTAL ENG TECH CO LTD +1

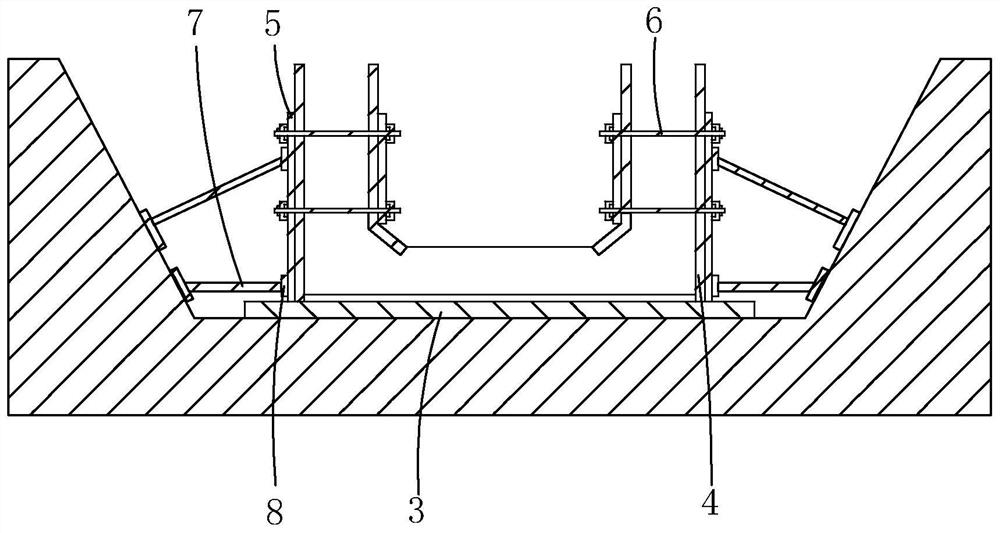

Pipe gallery construction process

InactiveCN112647537AFacilitate subsequent constructionImprove efficiencyArtificial islandsUnderwater structuresRebarWater seepage

The invention relates to the field of building construction, and particularly relates to a pipe gallery construction process. The pipe gallery construction process comprises the following process steps of S1, surveying and setting out; S2, groove excavation; S3, cushion layer construction and bottom plate waterproof construction, specifically, S31, concrete cushion layer pouring; S32, base waterproof treatment; S4, pipe gallery steel bar and concrete pouring; S5, formwork engineering; S6, concrete pouring, specifically, S61, layered pouring; S62, concrete pouring; S63, concrete curing; S7, deformation joint and construction joint treatment; S8, wall body and top plate waterproof treatment; and S9, groove backfilling. According to the pipe gallery construction process, through a concrete cushion layer, a cement mortar leveling layer, a waterproof coiled material and a waterproof coiled material, base waterproof treatment is achieved, the influence of underground water seepage on pipe gallery construction is reduced, the waterproof performance of a base is enhanced, subsequent construction of a pipe gallery is facilitated, and the overall efficiency of pipe gallery construction is improved; and meanwhile, through a concrete pouring process, holes in the concrete pouring process are reduced, and the overall strength of the pipe gallery is improved.

Owner:中交二公局萌兴工程有限公司

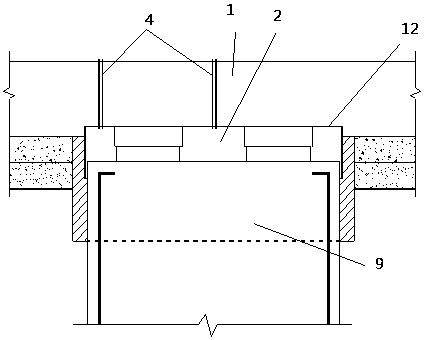

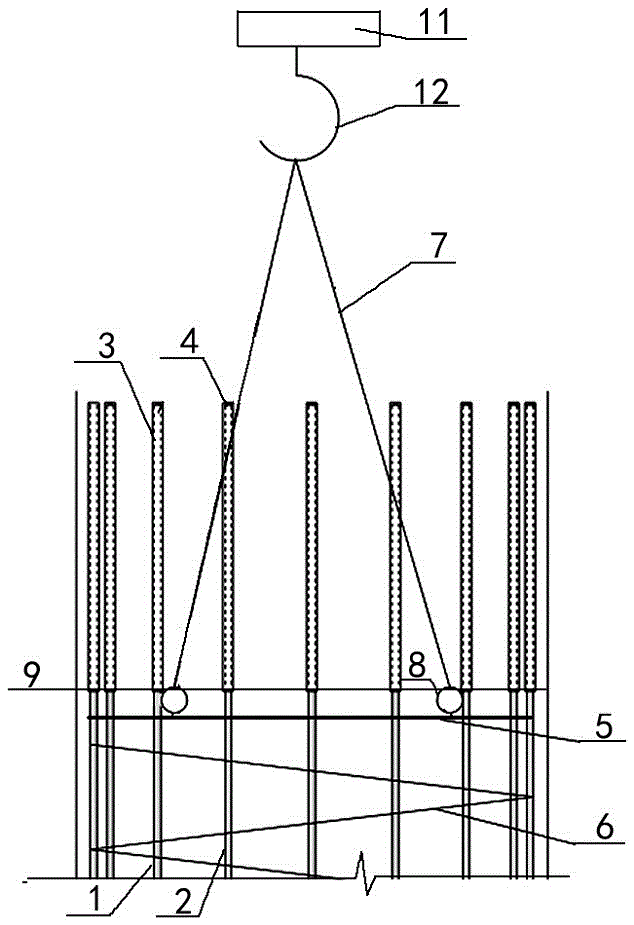

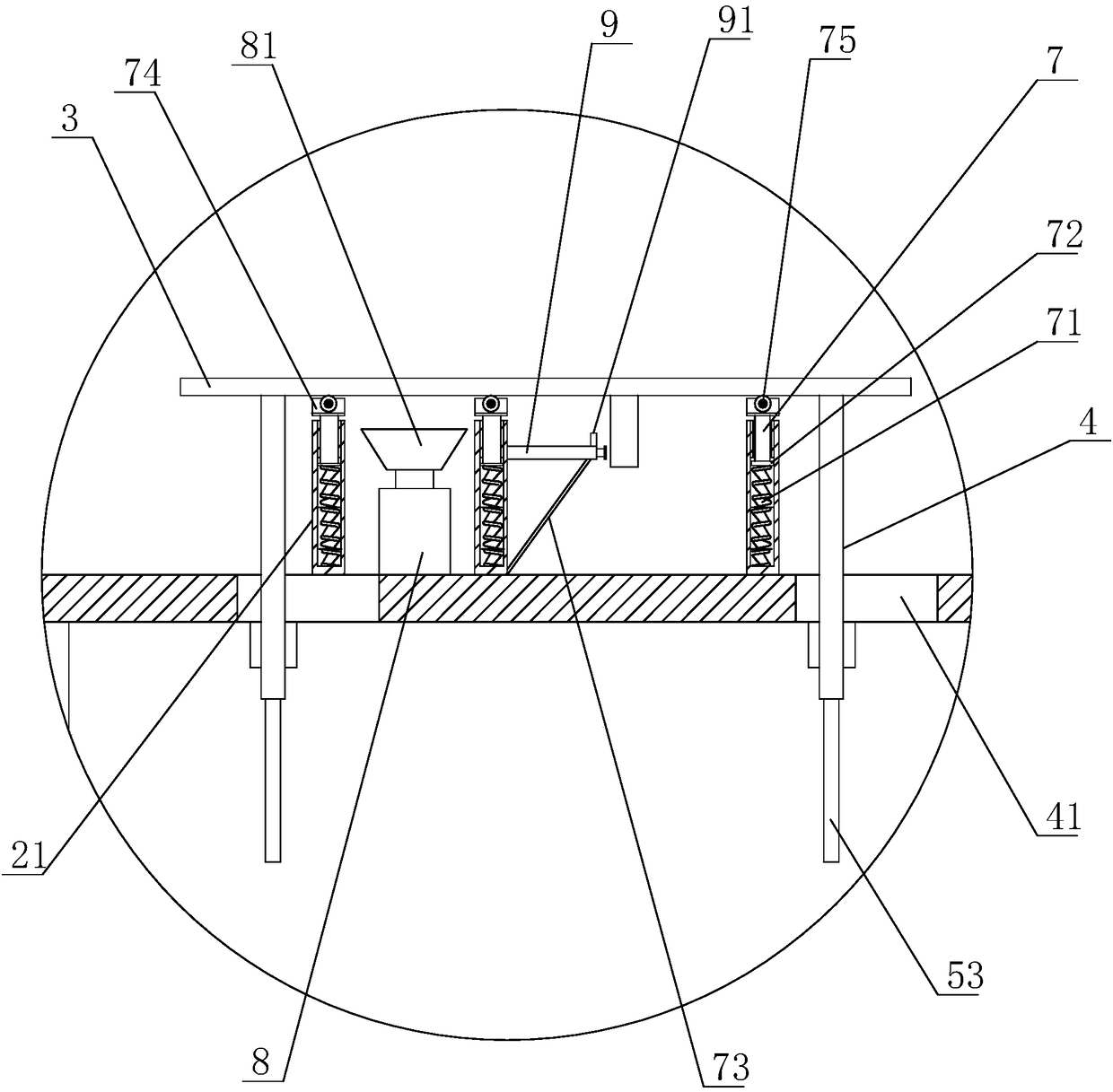

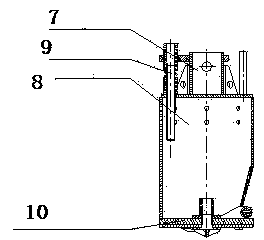

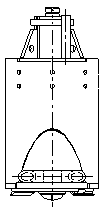

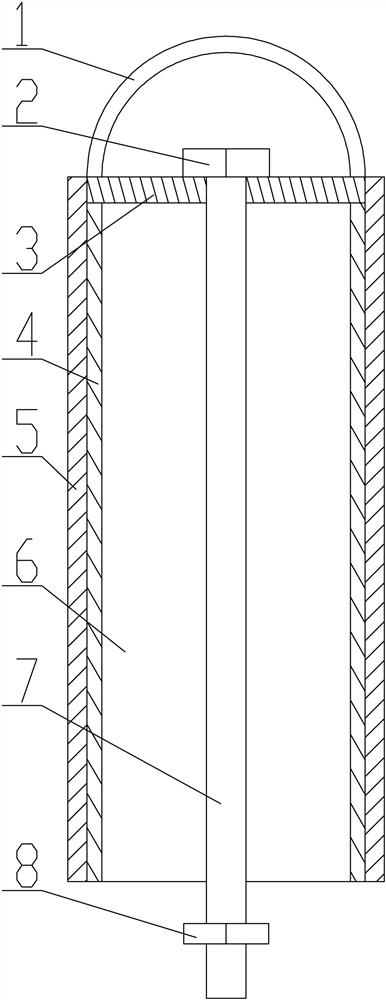

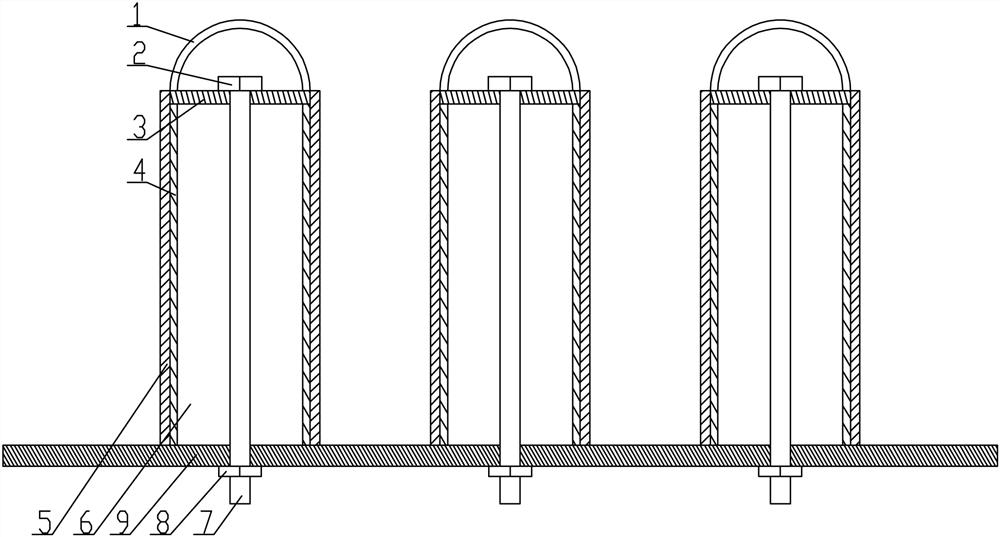

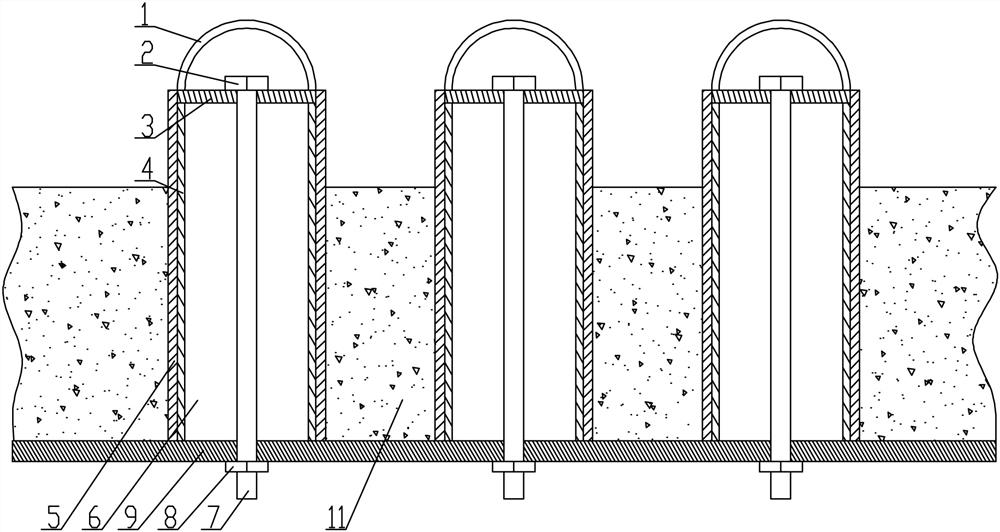

Construction device for sealing and filling headspace cavity of foundation pile of composite pile

The invention discloses a construction device for sealing and filling the headspace cavity of the foundation pile of a composite pile. When secondary pouring is carried out on the pile top, a novel grouting bottom pipe is firmly welded with a main reinforcement and is poured in a secondary pile top, and the pipe orifice is inserted in the cavity of the pile top; the novel grouting bottom pipe at the external part of the foundation pile is embedded in foundation soil shallow stratum and is led to the ground from the side face of a raft plate. Compared with the traditional grouting method, the construction device can economically and reasonably realize the grouting and sealing operation on the cavity of the pile top, ensures that the integrality of the raft plate is not destroyed and that rebar binding operation is smoothly carried out, reduces the engineering cost and improves the working efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

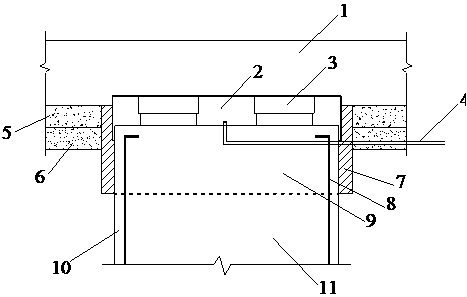

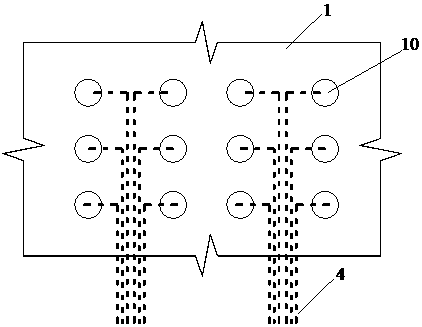

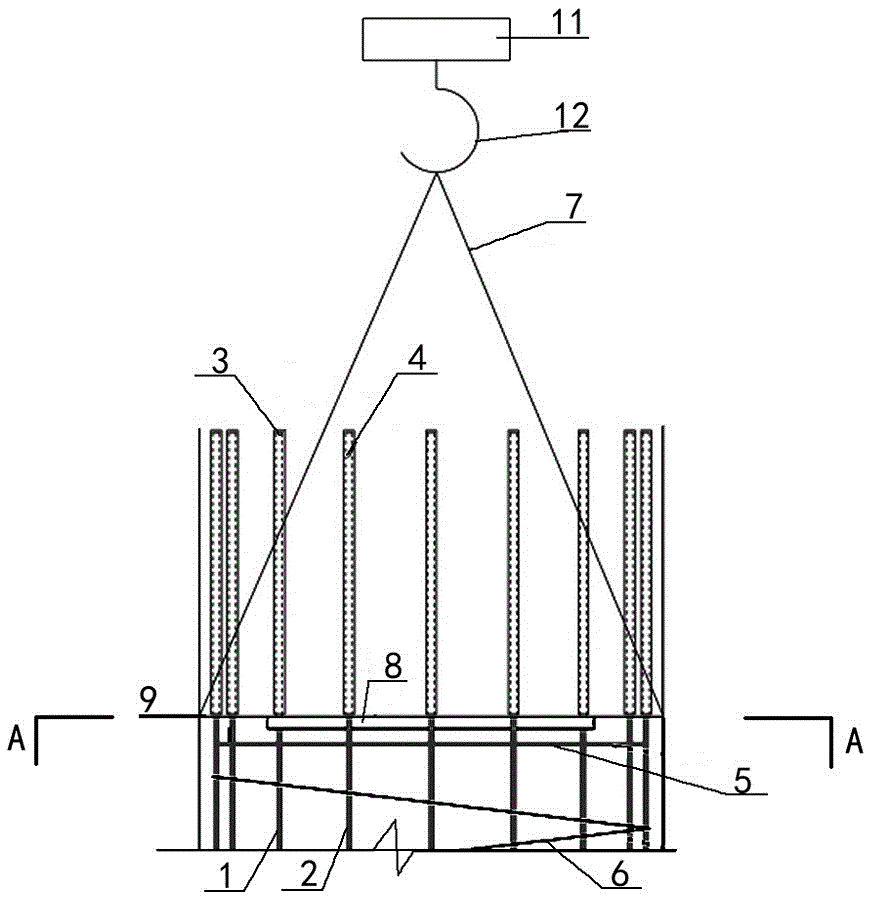

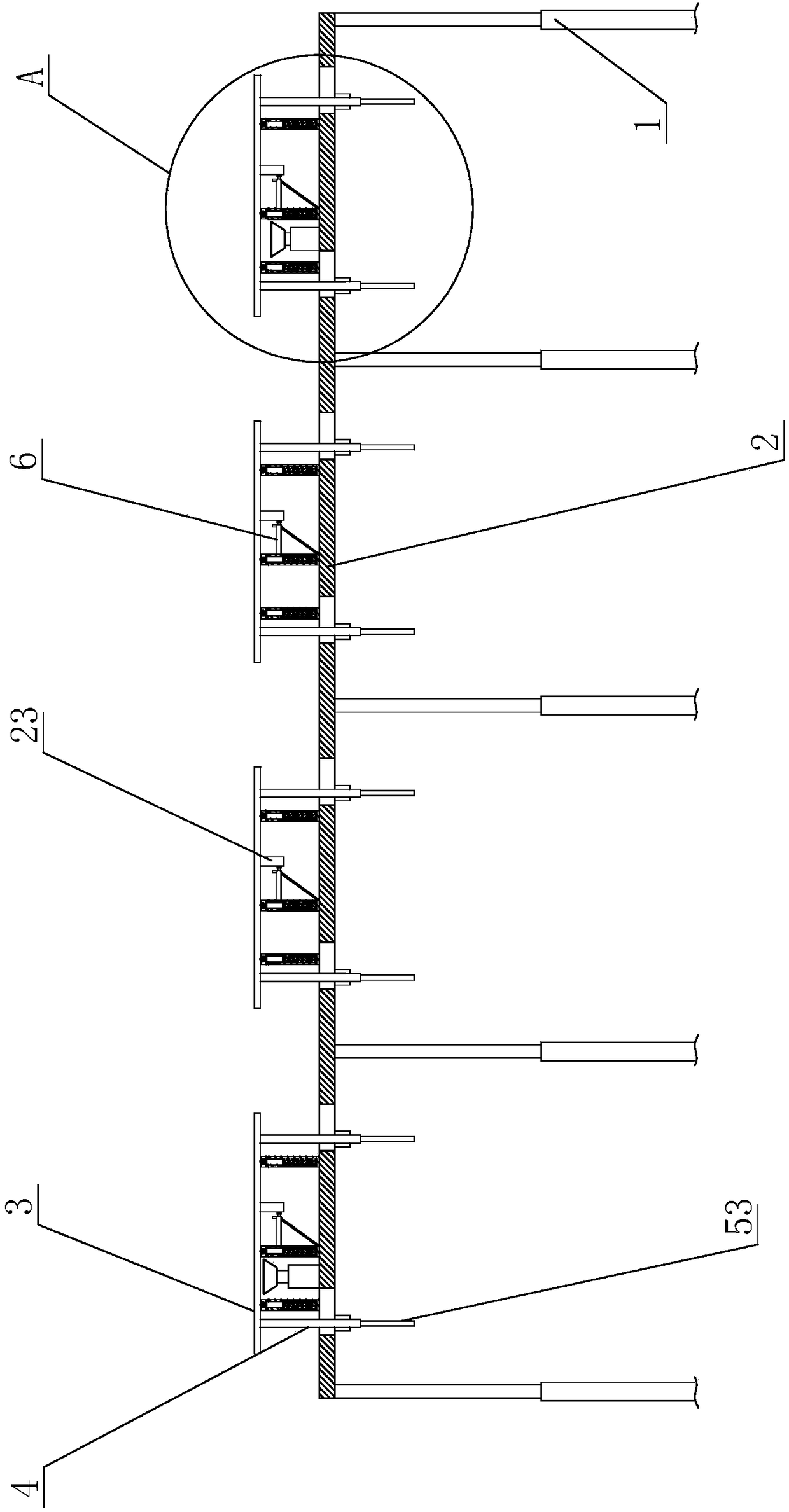

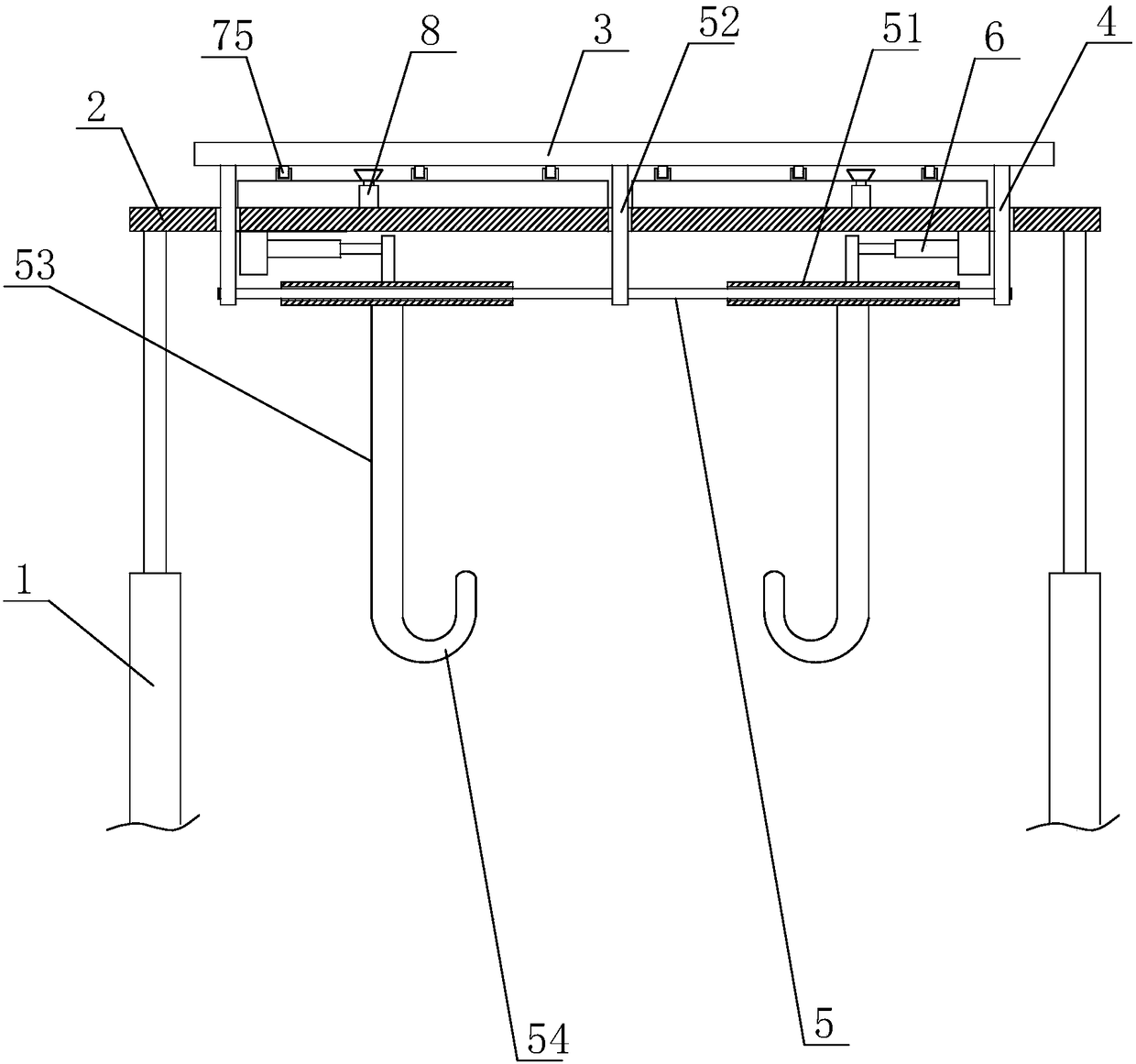

Pile foundation pile head concrete pre-stripping assembly and construction method

The invention provides a pile foundation pile head concrete pre-stripping assembly and a construction method. The assembly comprises a pre-embedded isolation component, a pre-embedded splitting component, splitting equipment and hoisting equipment. The pre-embedded isolation component comprises main reinforcement sleeves and acoustic testing pipe sleeves. The preembedded splitting component comprises a set of horizontal splitting pipes pre-embedded on a fracture surface. The splitting equipment comprises hydraulic splitting machines. The hydraulic splitting machines are inserted into the horizontal splitting pipes from the two sides to conduct splitting to form the fracture surface during breaking and stripping. The hoisting equipment comprises a lifting tool, a lifting hook and a steel wire rope. The steel wire rope penetrates through the split and broken horizontal splitting pipes and is connected with the lifting hook, so that pile head concrete is stripped off from reinforcements and acoustic testing pipes. The pile foundation pile head concrete pre-stripping assembly can be made of engineering leftover materials and is low in cost. During construction, the fracture surface is formed through the hydraulic splitting machines, and then the pile head concrete can be broken and stripped off. The process can be completed only by one person. The hydraulic splitting machines can provide smooth pile head connecting surfaces to facilitate later pile foundation detection and follow-up construction. The pile foundation pile head concrete pre-stripping assembly is easy to operate, low in technical requirement, good in breaking and stripping effect and high in efficiency.

Owner:北京城建七建设工程有限公司

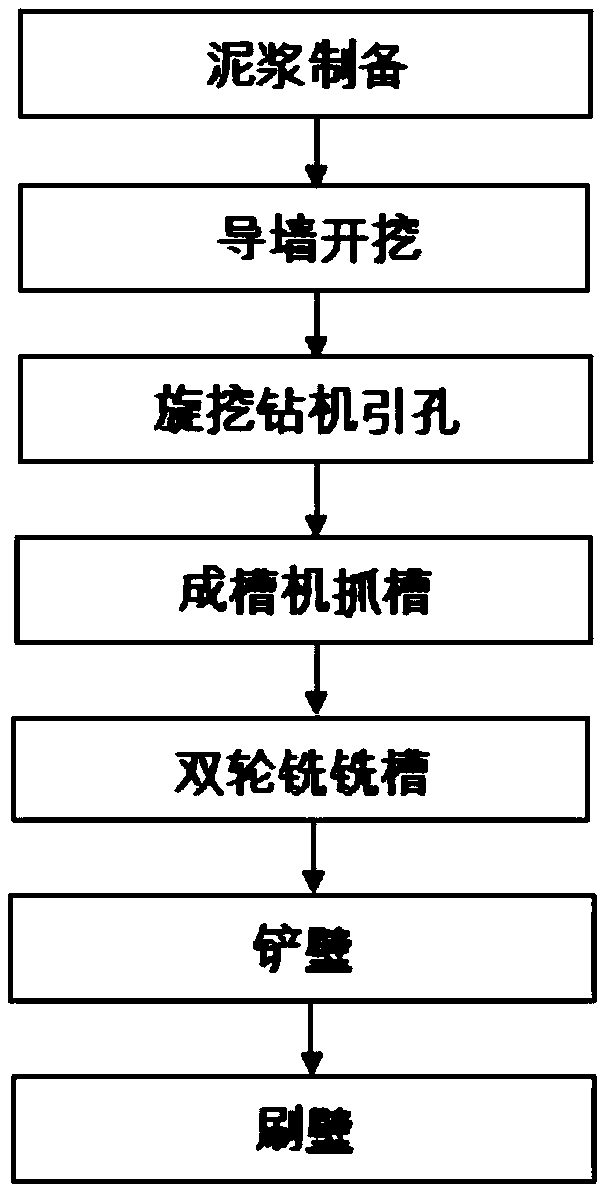

Underground diaphragm wall grooving method under complicated geological conditions

InactiveCN109138023AReduce construction costsReduce construction difficultySoil-shifting machines/dredgersSlurry wallBuilding construction

The invention relates to the field of construction, in particular to an underground diaphragm wall grooving method under complicated geological conditions. The method comprises the following steps: (1) a rotary drilling rig is used for leading holes; and the holes are as deep as underground diaphragm wall grooves; (2) after hole leading, a grooving machine is used for grabbing the grooves, and a stratum of the construction depth is judged; and (3) when the construction depth reaches an intermediary weathered sandstone layer or a weak weathered sandstone layer, the double-wheel milling is usedfor grooving construction. Through hole leading by the rotary drilling rig, groove sections form free faces, so that the construction difficulty is reduced, and the subsequent construction is convenient; the grooving machine is used for grabbing the grooves after hole leading; when the construction depth reaches the intermediary weathered sandstone layer, the double-wheel milling is used for grooving construction; and the grooving method combines respective advantages and defects of three grooving methods in the prior art, adopts the intersecting operation in the actual grooving construction to fully exert the advantages of each method, facilitates improvement of the grooving efficiency, and meanwhile, reduces the grooving construction cost.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

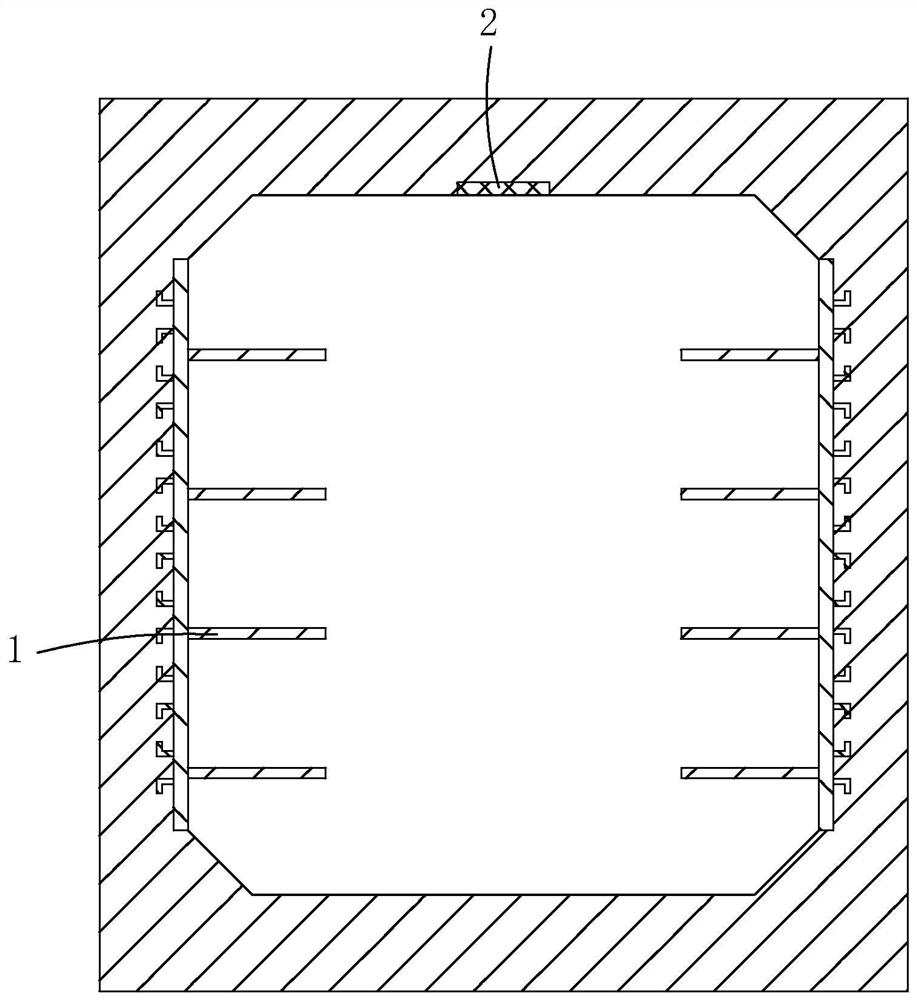

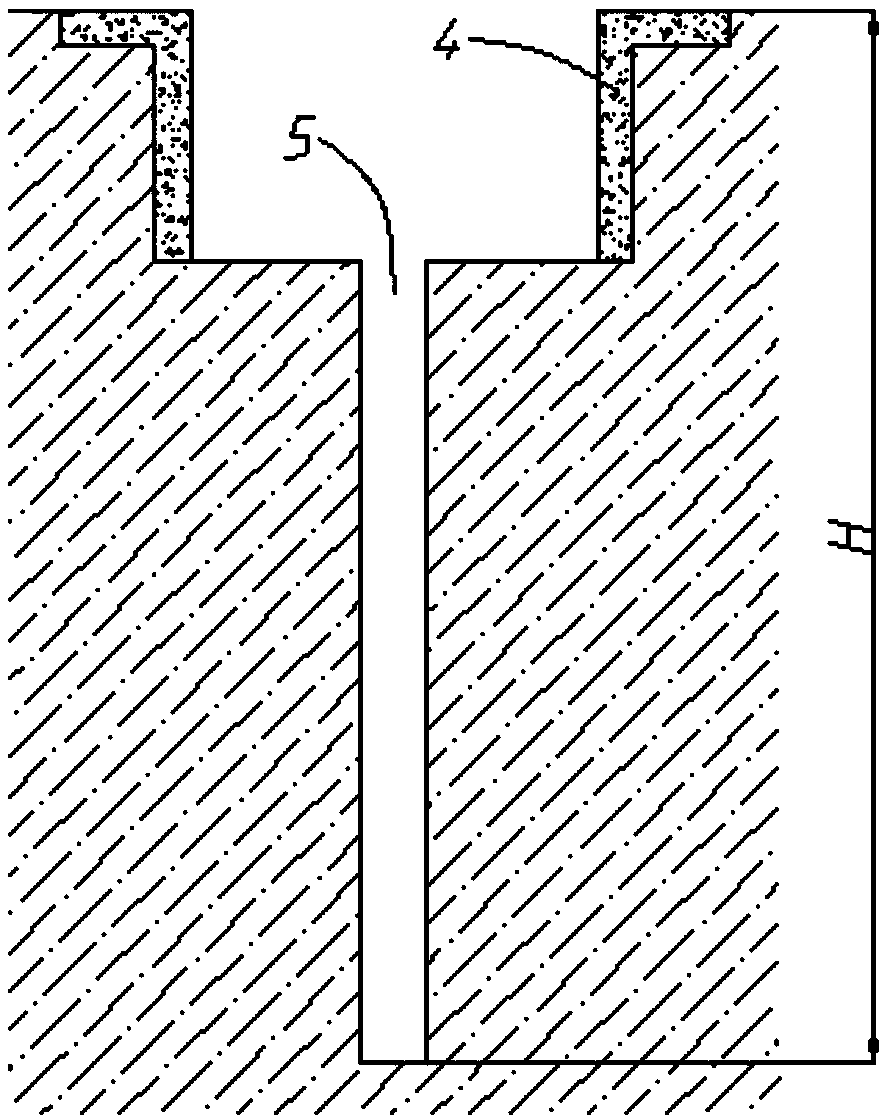

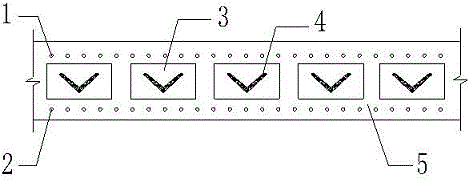

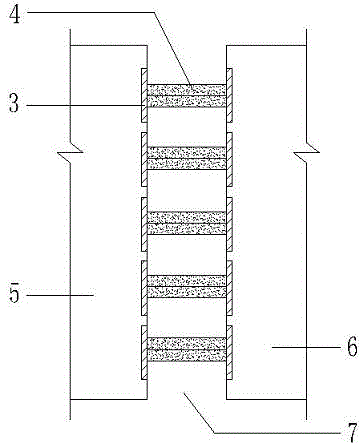

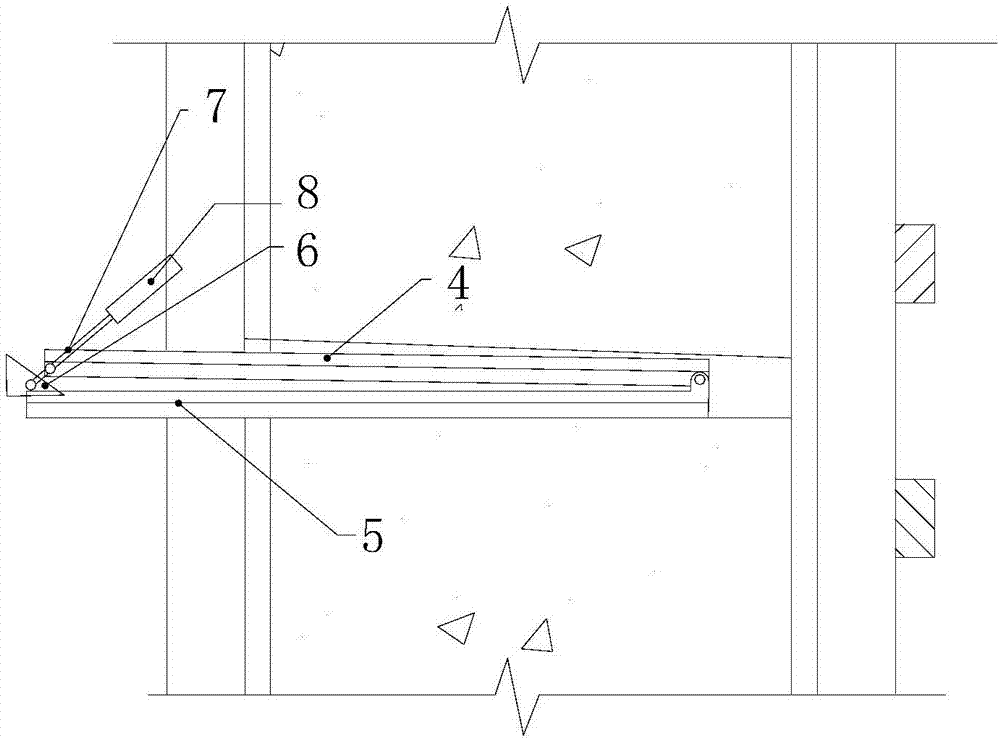

Post-cast strip replacing supporting structure used for disassembling building envelope support

ActiveCN104452825AEnsure safetyReduce displacementArtificial islandsUnderwater structuresFloor slabConstruction engineering

The invention provides a post-cast strip replacing supporting structure used for disassembling a building envelope support. The post-cast strip replacing supporting structure is composed of angle steel (4) and steel base plates (3). The steel base plates are embedded into the symmetrical positions of the middles of floors on two sides of a post-cast strip in advance. The angle steel is vertically installed between the two symmetrical steel base plates in the length direction. The angle steel and the steel base plates are connected in a welded mode before the building envelope support is disassembled. By the adoption of the replacing supporting structure, pressure generated by a building envelope in the support disassembling process can be effectively transmitted, and the safety of a body structure is ensured; moreover, when the post-cast strip is cast, the angle steel and the steel base plates do not need to be disassembled, and follow-up construction is facilitated. The replacing supporting structure is low in manufacturing cost, simple, easy to implement and wide in application range, and has high application and popularization value.

Owner:杭州福世德岩土科技有限公司

Quick-drying high-flexibility vitrified brick gum and preparation method thereof

ActiveCN113402229ASmall particle sizeSuitable glass transition temperatureSolid waste managementCellulosePolymer science

The invention belongs to the technical field of brick gum, and discloses quick-drying high-flexibility vitrified brick gum and a preparation method thereof. The vitrified brick gum comprises a liquid material component and a powder material component. On the basis of the total weight of the powder material component, the powder material component comprises the following components by weight: superfine Portland cement, aggregate, a water-retention thickening agent, an early strength agent and light calcium carbonate; and on the basis of the total weight of the liquid material component, the liquid material component comprises the following components by weight: styrene-butadiene latex, a mildew preventive, a defoaming agent, a sterilizing agent and water. The water-retention thickening agent is a mixture of a cellulose ether compound, xanthan gum and sepiolite. After being brushed, the gum can be quickly formed into a film and dried, so that the construction efficiency is improved, the bonding strength is ensured, and the gum has good flexibility.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Epoxy resin water dispersion and process for preparing the same

ActiveCN101481491BSmall particle sizeEasy to storeEpoxy resin coatingsChemical industryPolyethylene glycol

The inventive epoxy resin aqueous dispersion and preparation method thereof belong to the field of chemical industry coatings, the aqueous dispersion contains: 20-45wt.% of an epoxy resin, 2-15wt.% of bisphenol A or bisphenol F, 0.01-0.2wt.% of a catalyst, 0.1-2wt.% of double-ended carboxyl polyethylene glycol, 5-20wt.% of a reactive emulsifying agent, 3-20wt.% of a solubilizing assistant and 25-55wt.% of deionized water; the reactive emulsifying agent is synthesized at first and the epoxy resin and the bisphenol A or bisphenol F are then subjected to reactive chain extension under the actionof the catalyst triphenylphosphine, when certain epoxy equivalent value is reached, the double-ended carboxyl polyethylene glycol is subsequently added for the reaction followed by the addition of the synthesized reactive emulsifying agent for the further reaction, in the end, the water and the solubilizing assistant are added to prepare the epoxy resin aqueous dispersion via high-speed dispersion. The inventive epoxy resin aqueous dispersion is in a shape of white milk, has excellent storage stability and can be mixed directly with an aqueous curing agent without the need of the high-speed dispersion. The invention can be applied to manufacturing industrial anticorrosive coatings, floor coatings, interior / exterior wall coatings for construction, etc.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD +1

Public building interior decoration engineering sample construction method

InactiveCN102653971AGuaranteed integritySimplicity guaranteedCovering/liningsFlooringEngineeringShop drawing

The invention discloses a public building interior decoration engineering sample construction method. The method comprises the following steps of: performing integrated and detailed planning of a scheme from the aspects of dimensions of a user, indoor traffic facilities, indoor space organization, building performance simulation, indoor lighting environment, decorative modeling of wall, roof, floor, furniture, textile and plant and the like based on the design process of qualitative design first and quantitative design later of an interior decoration design scheme according to the design specification of the owner; formulating a sample unit design scheme; after determining the scheme, clearing up the sample room area, and making containment publicity sign; submitting the material sample for approval and determining the material; composing the working drawing; closing up different decoration materials; making a purchase order according to the construction progress; after the products arrive, assembling the products according to the assembly sequence of an assembly drawing; and finishing the decoration details according to a rectification scheme and protecting the finished product. The method disclosed by the invention has the advantages of complete design scheme, low comprehensive cost, simple construction environment and low safety risk.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

Method for preparing hydroxyl acrylic acid water dispersoid

InactiveCN101457005BModerate molecular weightNarrow molecular weight distributionPolyurea/polyurethane coatingsPolymer sciencePolyurethane adhesive

The invention relates to a preparation method for the hydroxyl acrylic aqueous dispersion of high performance and two-component waterborne polyurethane, which comprises four steps: synthesizing hydroxyl acrylic resin, removing a solvent, a neutralization salt forming reaction and deionization and aqueous dispersion. The hydroxyl acrylic aqueous dispersion prepared by the invention has proper molecular weight and the molecular weight is distributed much narrower, thus being beneficial for forming a uniform coating, reducing the plasticizing effect of small molecule substance to the coating, and increasing the comprehensive performance of the coating. The dispersion can be combined with an isocyanate curing agent to be used as wood coatings, corrosion protective coatings, industrial maintenance coatings, floor coatings and the like, and also can be used for preparing a two-component waterborne polyurethane adhesive, etc.

Owner:ZHEJIANG HUANDA PAINT IND GROUP +1

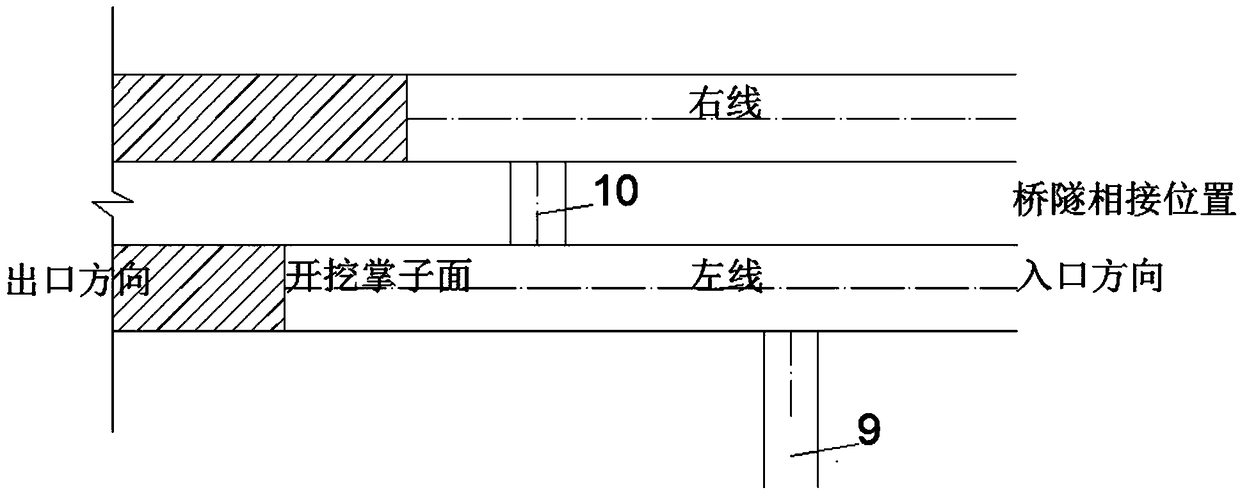

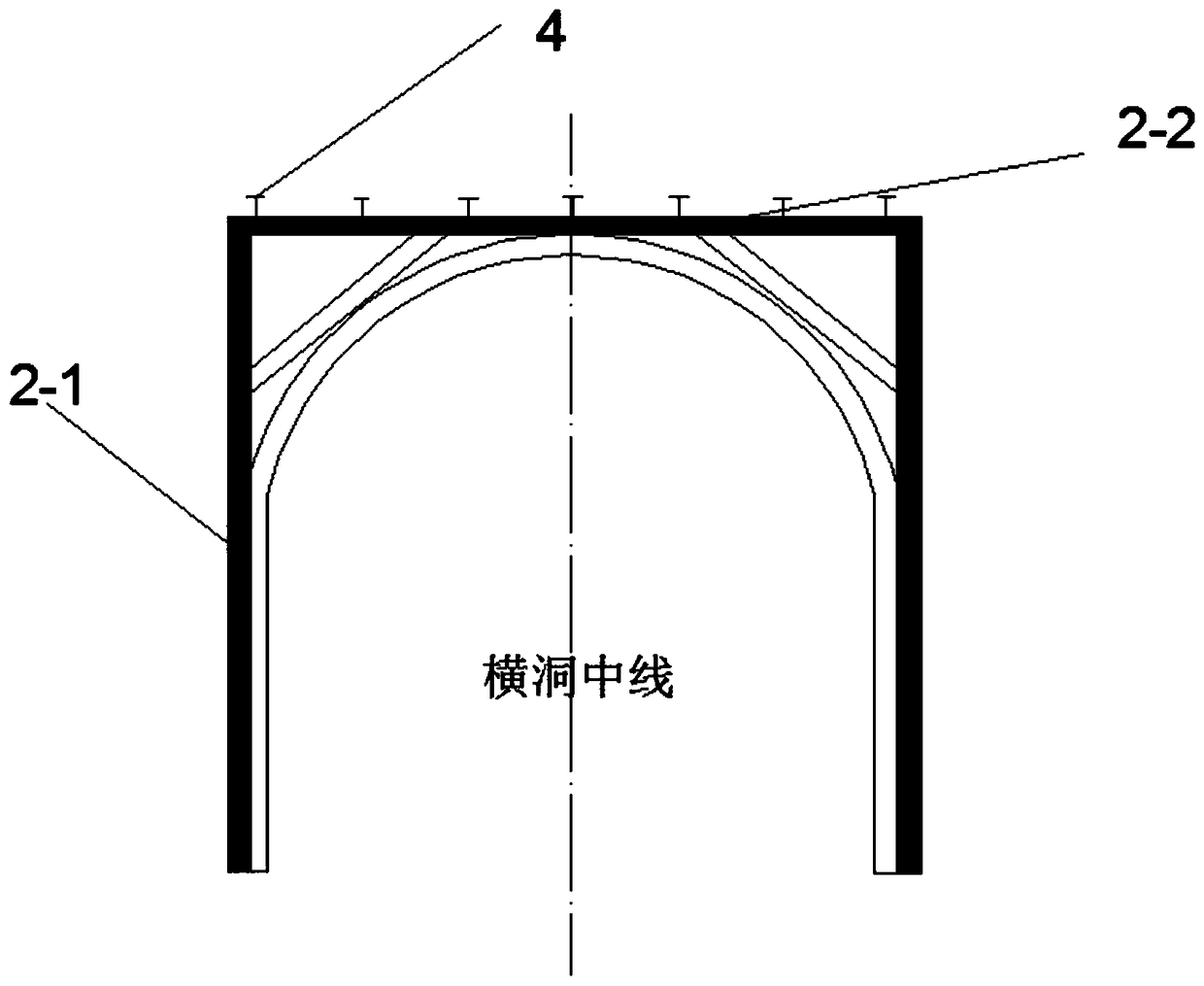

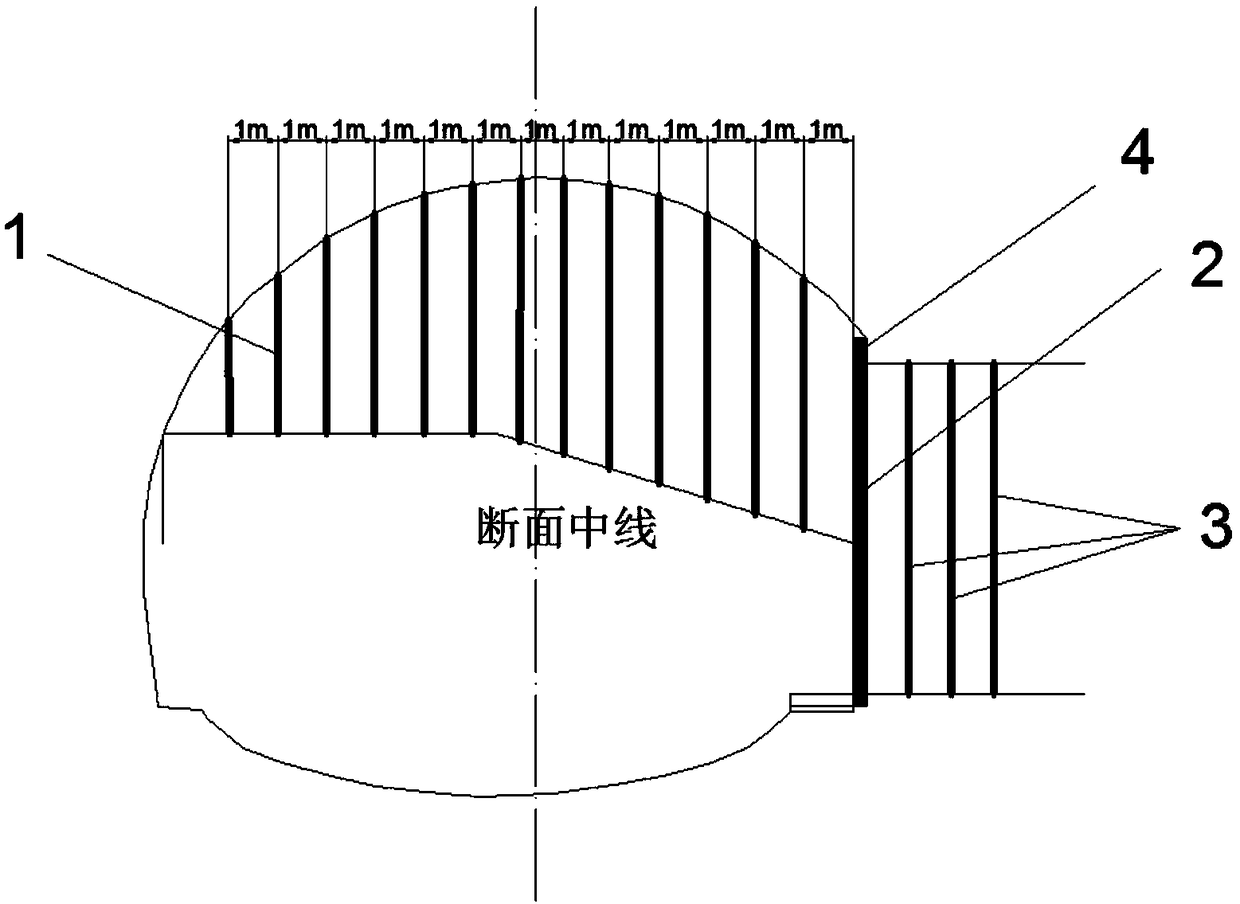

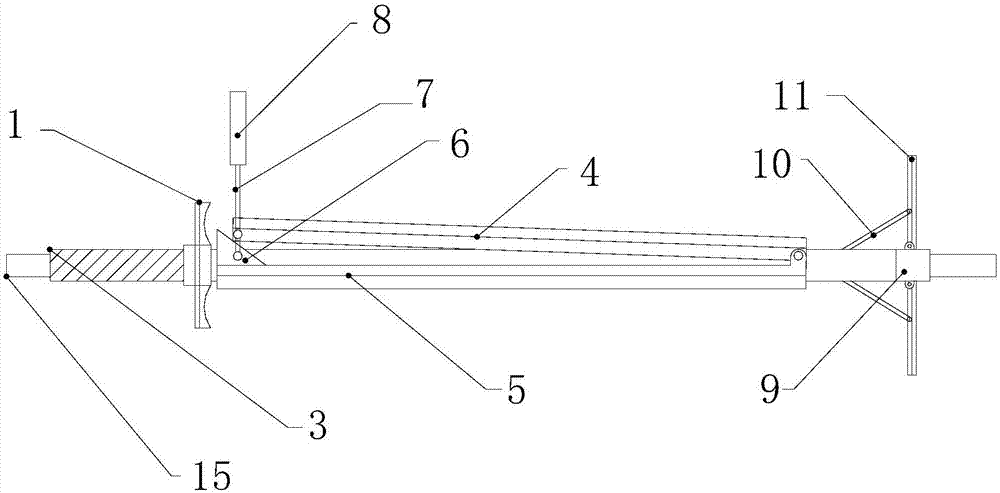

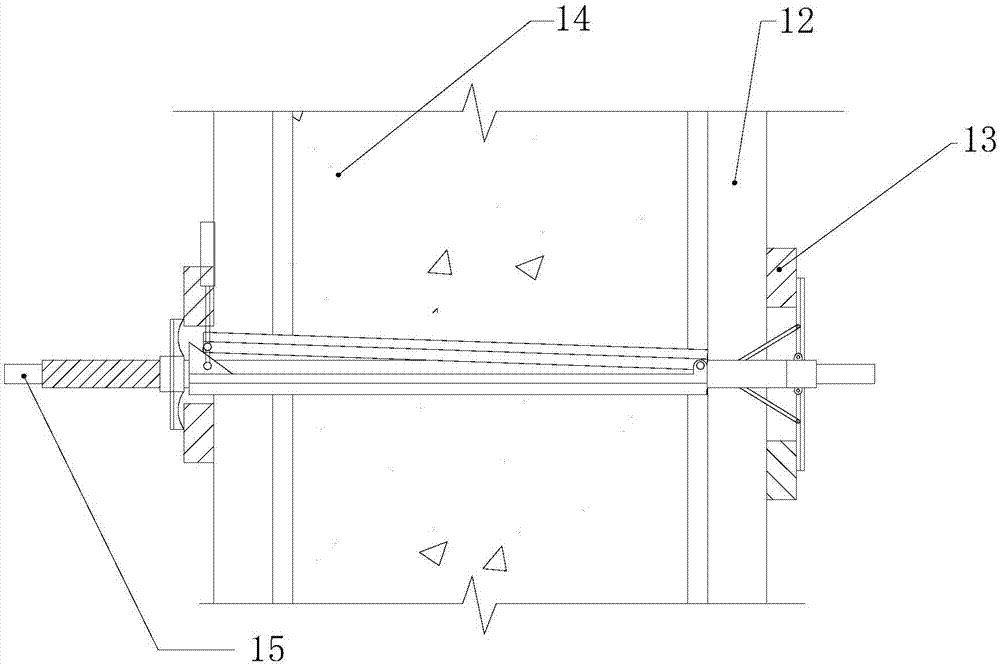

Rapid construction method for tunnel located at bridge and tunnel connected segment

InactiveCN109339800AFacilitate subsequent constructionSave construction resourcesUnderground chambersTunnel liningGuide tubePoint of entry

The invention discloses a rapid construction method for a tunnel located at a bridge and tunnel connected segment. The rapid construction method for the tunnel located at the bridge and tunnel connected segment comprises the following steps that an entrance of a construction transverse hole is selected to enter the hole; transverse hole excavation and transverse hole intersection main hole construction are carried out; left line main hole bi-directional excavation construction is carried out; vehicle travelling transverse hole construction is carried out; and right-line main hole bi-directional excavation construction is carried out. Through a mode of excavating the transverse holes to enter the main hole, then the bi-directional excavation is carried out on the main hole, hole exiting iscarried out assisted by a double-row advanced small guide pipe mode, the defects of insufficient cliff construction space in the prior art and mutual interference of a bridge and a tunnel are overcome, and the rapid construction method for the tunnel located at the bridge and tunnel connected segment has the advantages of low construction costs, short construction period, safety and reliability and high efficiency.

Owner:CHANGAN UNIV

Opposite-pulling bolt capable of shedding

ActiveCN106907004AEasy to take outEasy to assemble and disassembleAuxillary members of forms/shuttering/falseworksArchitectural engineeringLower half

The invention discloses an opposite-pulling bolt capable of shedding, particularly relates to the opposite-pulling bolt capable of shedding, and relates to the field of building construction. The opposite-pulling bolt capable of shedding comprises a bolt and a clamping piece arranged at one end of the bolt, and further comprises a casing pipe, an outer sleeve shell, and a reverse skeleton structure, the reverse skeleton structure is arranged on the end, away from the clamping piece, of the bolt, the outer sleeve shell is arranged on the bolt in a sleeving mode, and the bolt and the outer sleeve shell penetrate out of the casing pipe; the casing pipe comprises an upper half part, a lower half part, a wedge and a rotational connecting piece; the reverse skeleton structure comprises a connecting rod and a rotational clip. In the opposite-pulling bolt capable of shedding, after concrete is subjected to moulding by casting, merely one side which the clamping piece is arranged needs to be operated so that the opposite-pulling bolt can be quickly and conveniently taken out of the molded concrete for use of concrete casting next time, the opposite-pulling bolt is convenient to assemble and disassemble, thus the construction safety is guaranteed, the follow-up construction is benefited, and the material and labor cost are lowered.

Owner:CHENGDU CONSTR ENG GROUP CORP

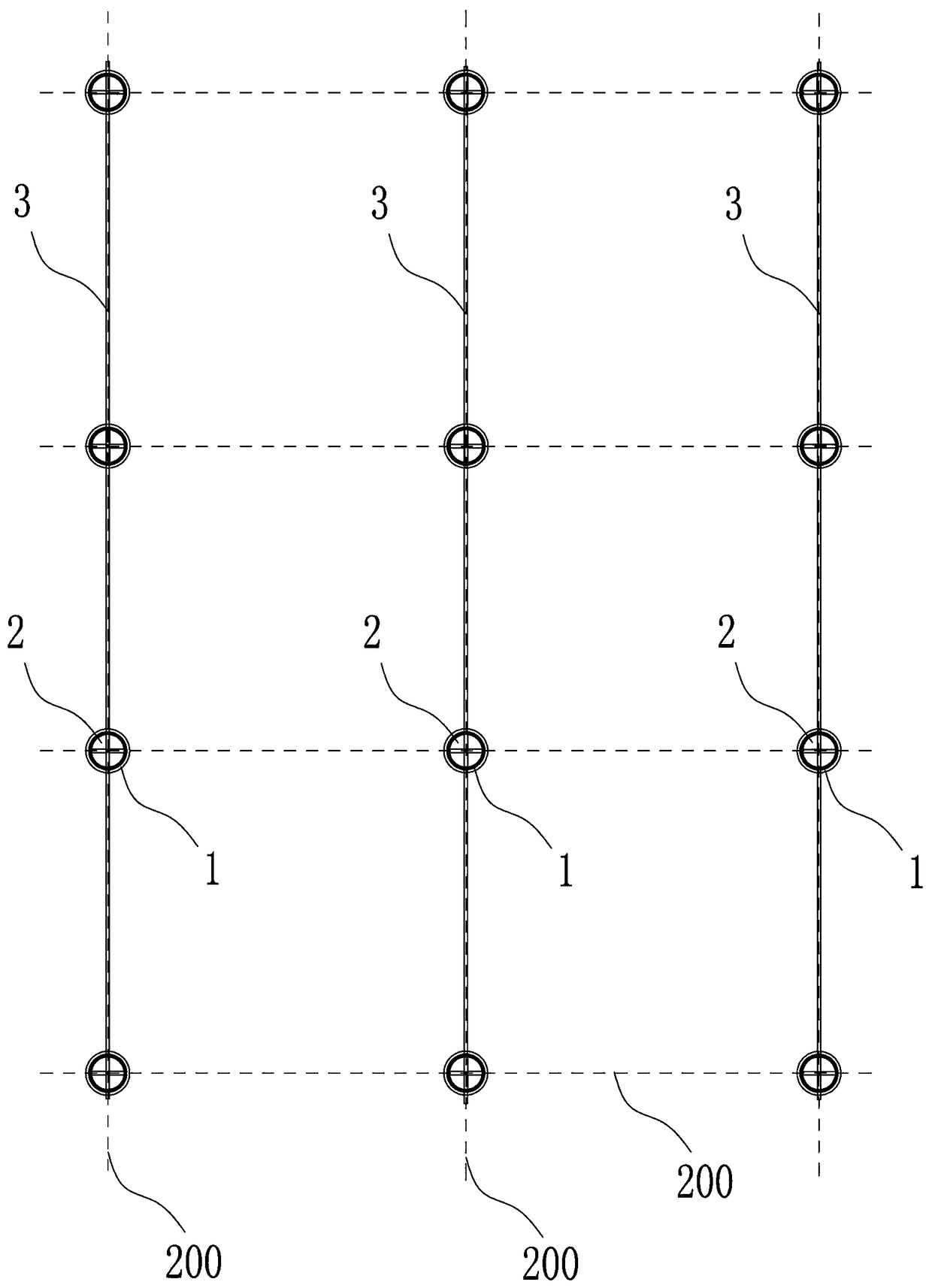

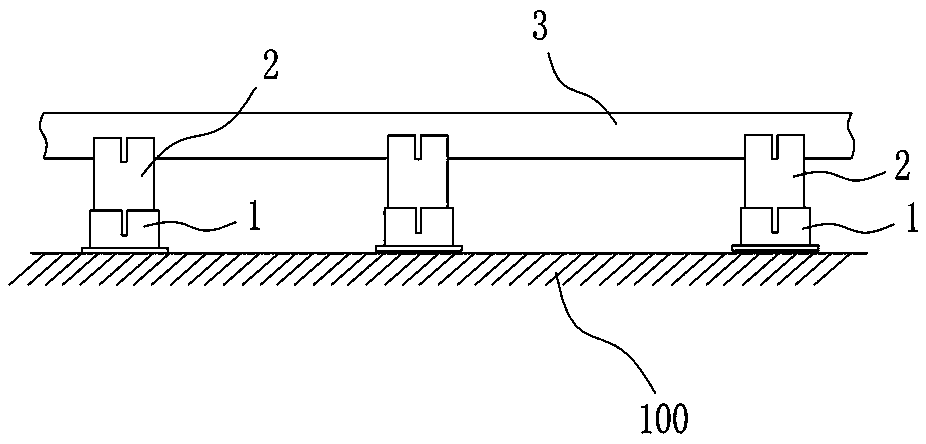

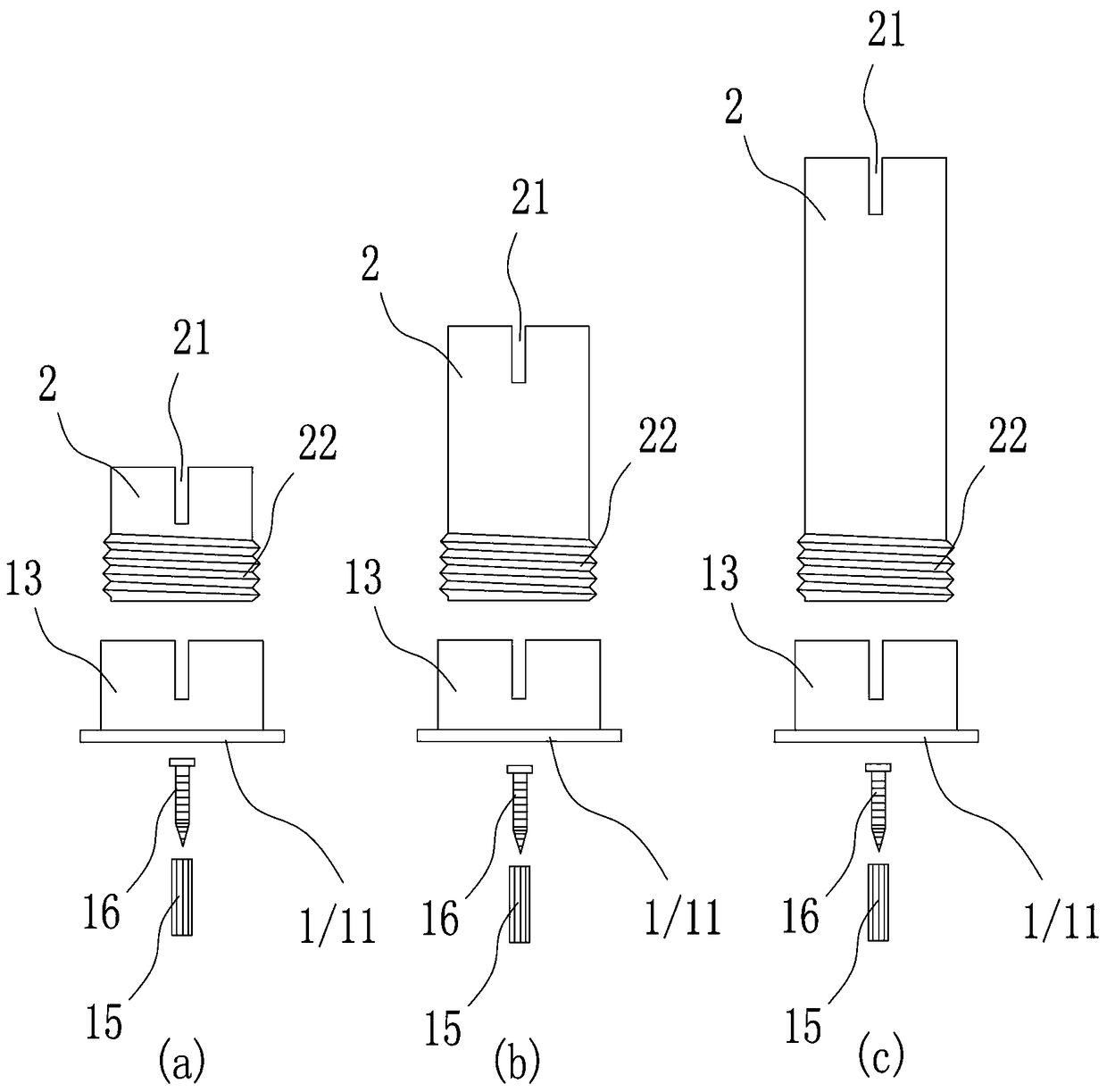

Lifting leveling guide rail and leveling process utilizing same

InactiveCN109469293ALow technical experience requiredConsistent leveling heightBuilding constructionsEngineeringMechanical engineering

The invention discloses a lifting leveling guide rail and a leveling process utilizing the lifting leveling guide rail, wherein the leveling process comprises the following steps of: striking horizontal light rays and auxiliary light rays in X and Y directions on the ground / floor by using an electronic level meter; placing and positioning a base at intervals along the auxiliary light; according tothe height distance between each base and the horizontal light above the base, the adjusting screw rod with the corresponding height specification is selected, the adjusting screw rod is screwed withthe corresponding base, and the length direction of one groove of the cross-shaped groove is ensured to be consistent with the direction of the horizontal light; a leveling guide rail is installed; pouring backfill between the leveling guide rail and the leveling guide rail; and a leveling scraper is used for leveling back and forth the filler on the leveling guide rail. According to the liftingleveling guide rail and leveling process utilizing the lifting leveling guide rail, time and labor are saved, the construction progress is fast, the requirements on operating workers are low, the thickness and the quantity of the added backfill are easy to master, the vertical leveling error is small, the empty drum rate is low, the quality is guaranteed, the substrate can be horizontal, and the subsequent construction is facilitated.

Owner:东莞市强达建材有限公司

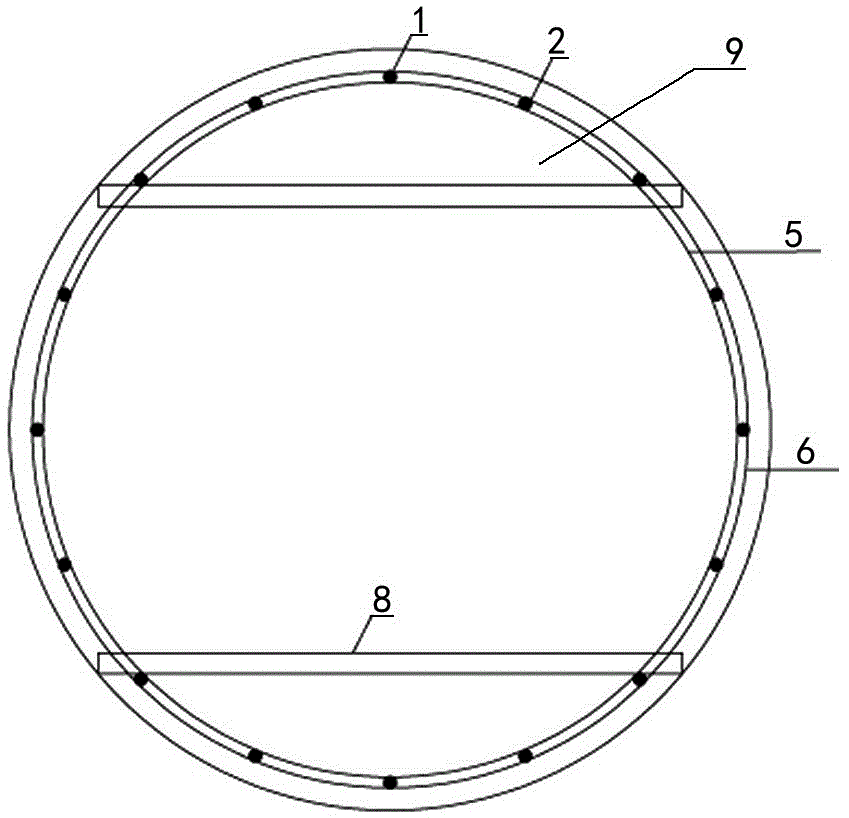

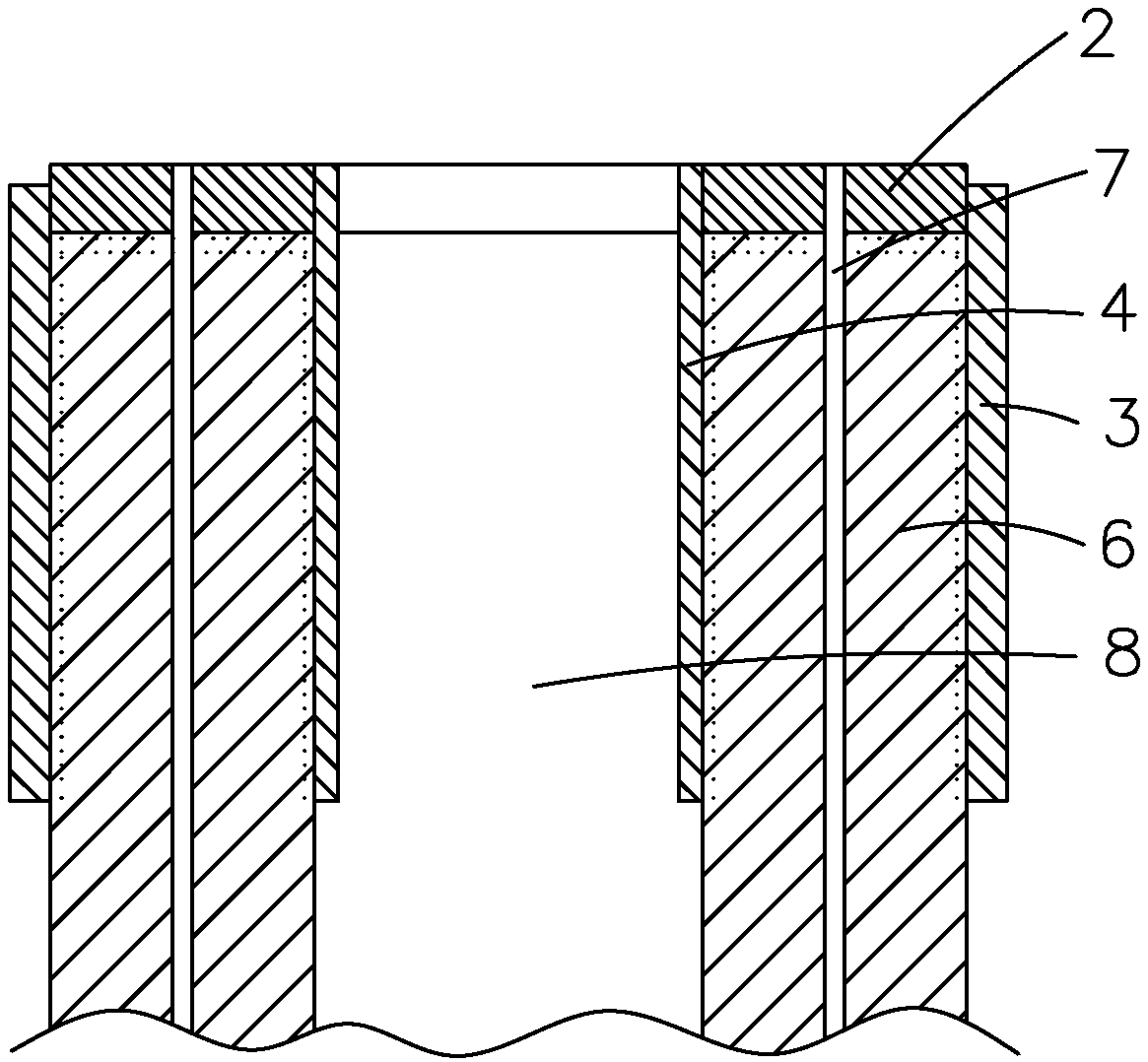

Pile cap and method for repairing and reinforcing concrete tubular-pile pile head

The invention provides a pile cap and method for repairing and reinforcing a concrete tubular-pile pile head. The pile cap for repairing and reinforcing the concrete tubular-pile pile head comprises an annular end plate, an outer sleeve, an inner sleeve and a kidney-shaped connecting hole; and the outer side face of the annular end plate is sleeved with the outer sleeve, the inner side face of theannular end plate is sleeved with the inner sleeve, and the kidney-shaped connecting hole is formed in the annular end plate. The method for repairing and reinforcing the concrete tubular-pile pile head utilizes the pile cap and comprises the steps that on the basis that an original structure of the pile head is not changed and a cavity of a tubular pile is not filled, the pile head is directly sleeved with the pile cap so that core filling of the top of the pile head or filling of a bottom cavity of the tubular pile for bottom sealing in the later project can be normally conducted. Accordingto the pile cap and method for repairing and reinforcing the concrete tubular-pile pile head, operation is easy, the working efficiency is high, and the economic loss caused by the damaged pile headcan be reduced.

Owner:FUJIAN DADI CONCRETE PILE

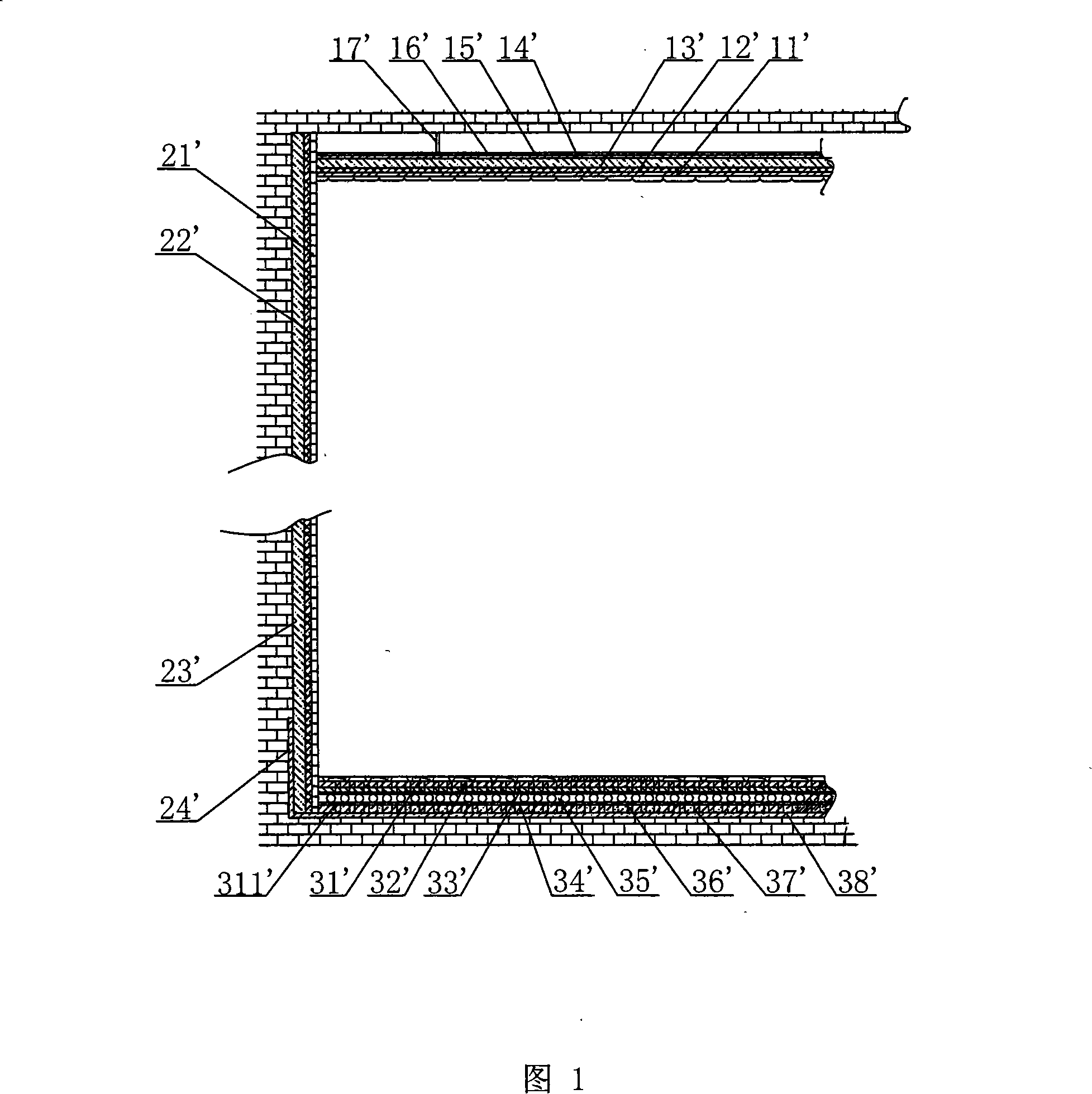

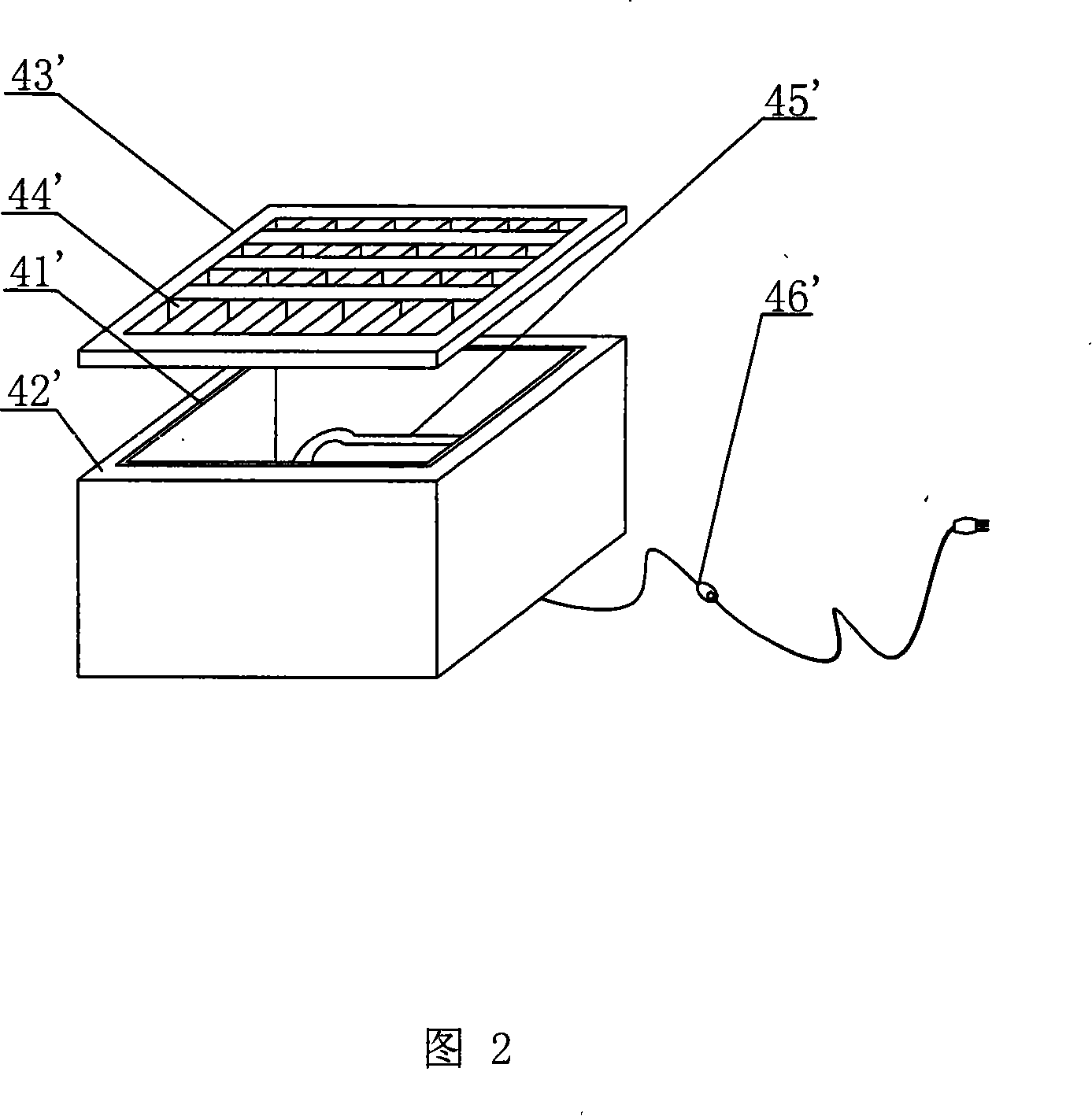

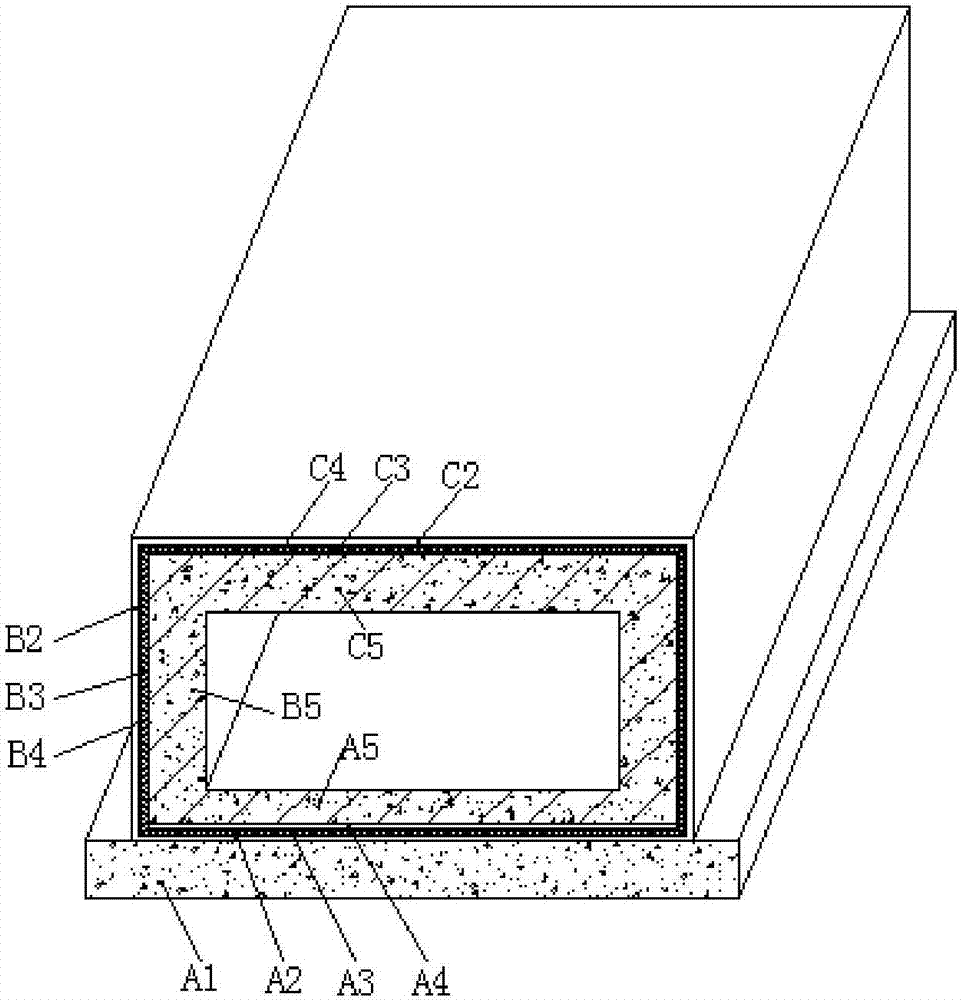

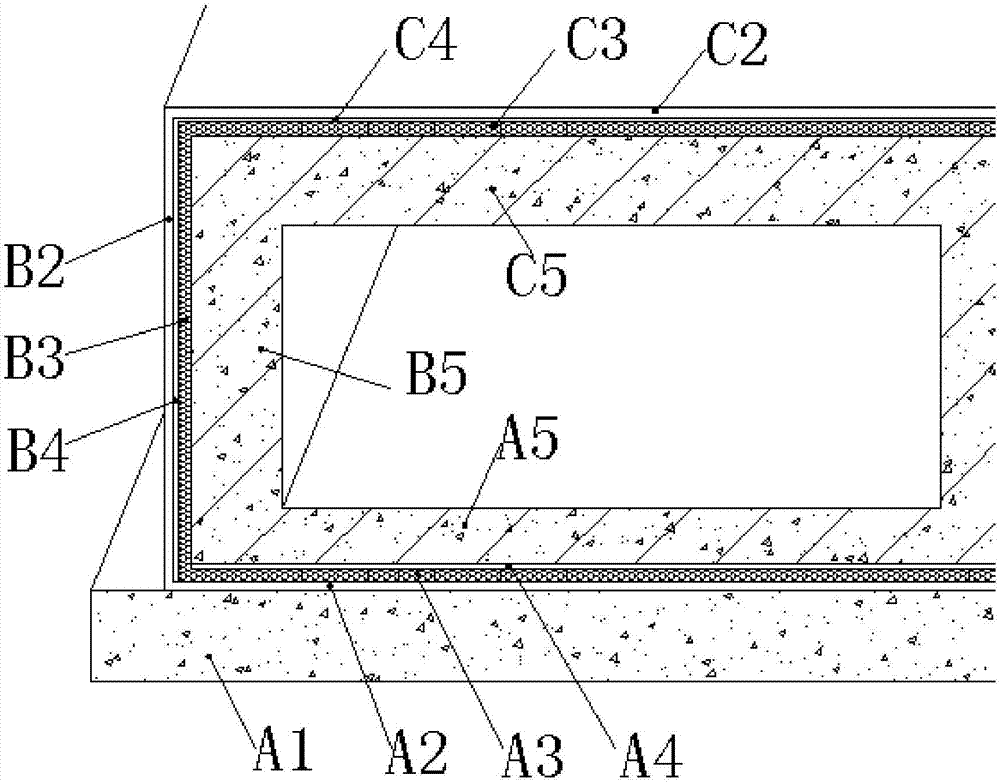

Batholith body-building bathroom

InactiveCN101215934AImprove thermal insulationMeet health needsSmall buildingsEngineeringReflective layer

A laccolite body-building bathroom comprises a building foundation structure of foundation course ground, foundation course roof, foundation course wall which are in an existing house, wherein a cement mortar layer, a supporting layer, a heat supply layer, a reflecting layer, a heat insulating layer and a waterproof layer which are distributed from the upper portion to the lower portion in turn are arranged on the foundation course ground, stone slabs which are distributed in array are arranged on the surface of the cement mortar layer. The laccolite body-building bathroom has good heat preservative and thermal insulating effects, a large amount of energy resources can be saved and simultaneously evenly heat supply to each position indoors can be realized, the bathroom accords with the requirements of human health and simultaneously enables indoor actual usable area to be larger, the bathroom is convenient to clean, install and maintain, easy to carry out subsequent construction, and will not produce impounded surface water, and the bathroom is artistic and durable. The invention can also be used as a gymnasium or a sauna bathroom or a family living room and is widely applied in a plurality of beauty shops, body-building places and private domiciles.

Owner:陈志勇

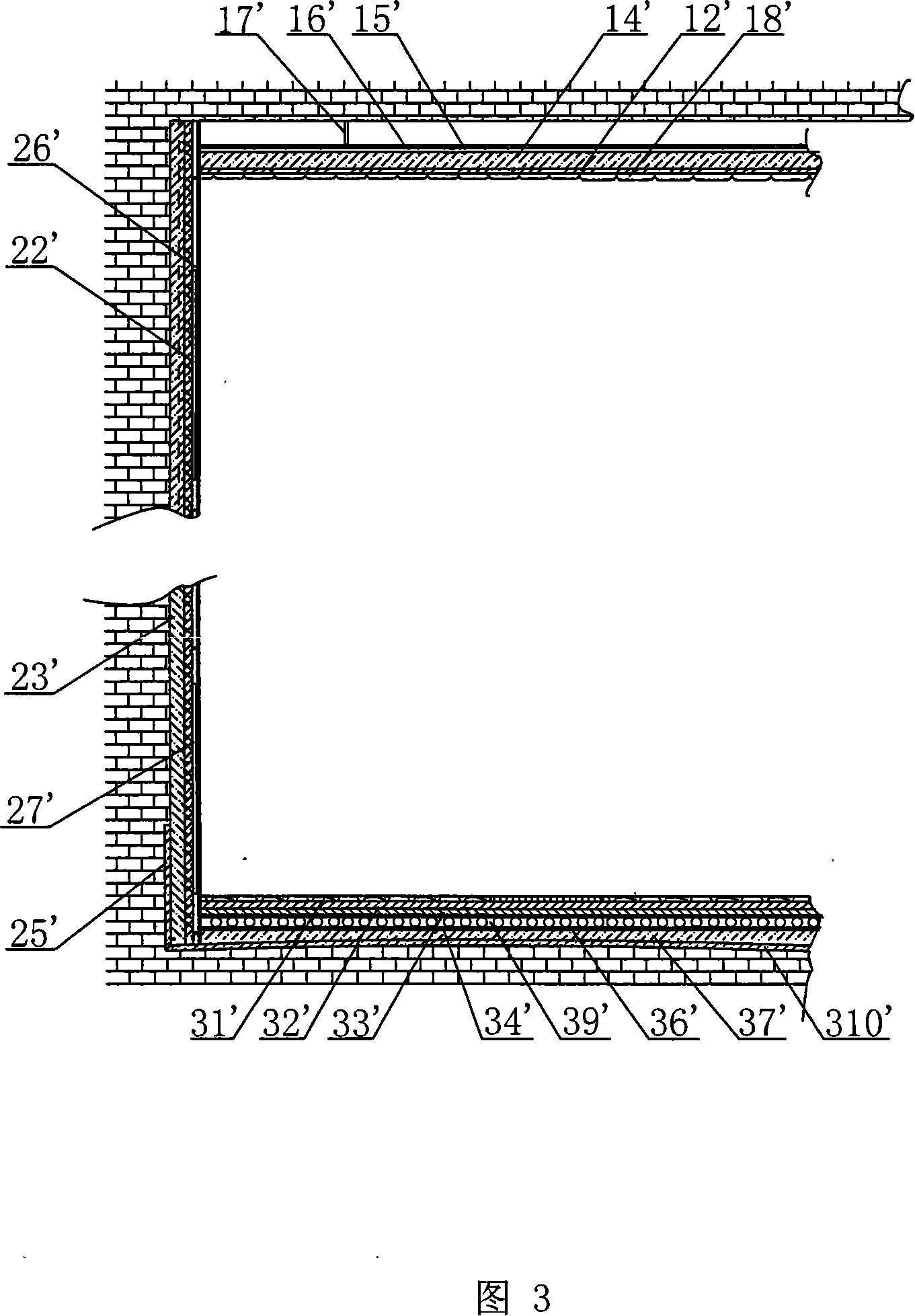

Full surrounding skin-type structure of underground waterproof engineering and construction method

PendingCN107083780AImprove performanceRealize full surroundProtective foundationStructure of the EarthEngineering

The invention relates to the technical field of waterproof construction, in particular to waterproof technologies of underground engineering such as subways, underground pipelines, tunnels, underground pipe corridors, underground garages and underground air defense facilities, and discloses a full surrounding skin-type structure of underground waterproof engineering and a construction method. The full surrounding skin-type structure of the underground waterproof engineering comprises a bottom layer, a top layer and a side face layer; the bottom layer, the top layer and the side face layer are surrounded to be whole and form a hollow structure; water-soluble non-curing coating layers and thin film reinforcing layers are arranged on the bottom layer, the top layer and the side face layer correspondingly; and the bottom water-soluble non-curing coating layer, the side face water-soluble non-curing coating layer and the top water-soluble non-curing coating layer form the integrated seamless connection full surrounding structure. According to the full surrounding skin-type structure of the underground waterproof engineering and the construction method, the defects that in the prior art, as for the underground waterproof engineering, whole failure or leakage in local joints are easy to occur are overcome.

Owner:JIANGYIN CHAMPION CHEM

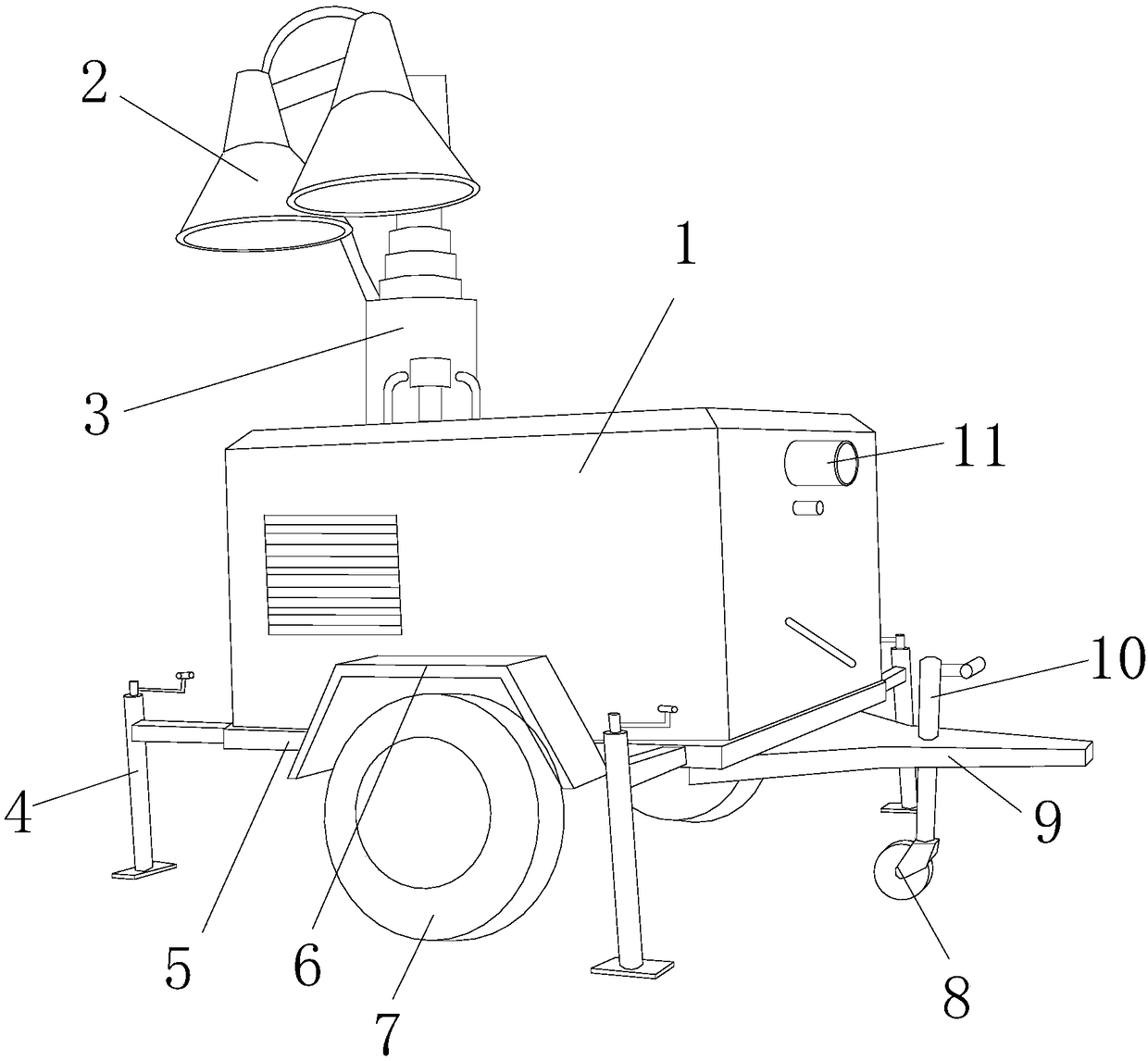

Lifting device for electric construction

InactiveCN108545674AProtection securityFacilitate subsequent constructionSafety devices for lifting equipmentsArrangements responsive to excess currentArchitectural engineeringElectric power

The invention discloses a lifting device for electric construction. The lifting device comprises an overload protecting device capable of automatically giving an alarm, an illuminating lamp, a liftingcylinder, a support rod, a base plate, a protective cover, wheels, trundles, trundle fixed plates, a direction control rod and a ventilation pipe; the lifting cylinder is welded at the left end of the upper surface of the overload protecting device capable of automatically giving an alarm; the illuminating lamp is glued to the upper end of the lifting cylinder; and the ventilation pipe is embedded in the right surface of the overload protecting device capable of automatically giving an alarm. Through arrangement of the overload protecting device capable of automatically giving an alarm, afterequipment circuits are aged, the bearing capacity on current and voltage disorder change is reduced, and the overload protecting device can protect the circuit safety to protect the equipment safety;and after the overload protecting device cuts off the equipment circuits, the alarm lamp can be timely brightened, so that workers timely know the equipment working state, the equipment safety is protected, and the workers are convenient for subsequent construction.

Owner:乐志胜

Friction sliding energy-consuming and damping device of multi-span simply supported beam

ActiveCN108342988AAvoid shakingImprove securityBridge erection/assemblyHydraulic cylinderEngineering

Owner:CHONGQING THREE GORGES UNIV

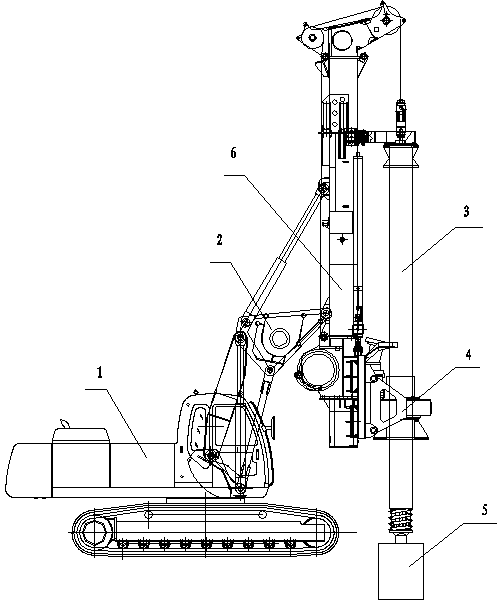

Real-time treatment method and equipment of bored pile head

InactiveCN104278676AAchieve seamless connectionFacilitate subsequent constructionBulkheads/pilesDrilling machines and methodsStructural engineeringGuide tube

Disclosed is real-time treatment method and equipment of a bored pile head. The method includes the steps of after underwater concreting for a bored pile, pulling out a guide pipe, driving the guide pipe to a position to close a pile location through a travelling and slewing system, starting a luffing device to erect a telescopic drill rod, positioning a drill rig, aligning the center of a bit with the center of a borehole position, lowering the telescopic drill rod to drive the bit to reach a layer of scum, starting a driving rotating motor to drive the bit to rotate, driving the concrete higher than the layer of scum and the pile head preset elevation into the bit, lifting up the telescopic drill rod to lift the bit out of the bored pile when the bottom of the bit reaches the preset elevation, and clearing the scum and concrete in the bit to finish real-time treatment of the pile head. The equipment comprises the travelling and slewing system and the luffing device. The real-time treatment method and equipment has the advantages that pile head concrete quality is improved, work efficiency is improved, expenditures are saved, bits of different diameters are available, adaptability is high, and deep-hole operation for great-depth pile head treatment is also available.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

Hydroxyl acrylic acid dispersion and synthetic method thereof

The invention discloses a hydroxyl acrylic acid dispersion and a synthetic method thereof, and belongs to the technical field of coatings. The hydroxyl acrylic acid dispersion comprises the followingcomponents in parts by weight: 7-25 parts of air drying type resin, 1-6 parts of an acrylic carboxyl monomer, 6-12 parts of an acrylic hydroxyl monomer, 50-70 parts of other acrylic monomers, 1-10.5 parts of an initiator, 1-3 parts of a solvent, 3-6 parts of a neutralizing agent, 1-3 parts of a drier, and 100-200 parts of deionized water. The invention also disclosed the synthetic method of the above hydroxyl acrylic acid dispersion. The hydroxyl acrylic acid dispersion disclosed by the invention has a content of the solvent of 0.5-1%, and the content is far lower than that of a similar hydroxyl acrylic acid dispersion; and the synthetic method disclosed by the invention is simple and easy to operate, and can obtain the hydroxyl acrylic acid dispersion with a low content of solvent.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

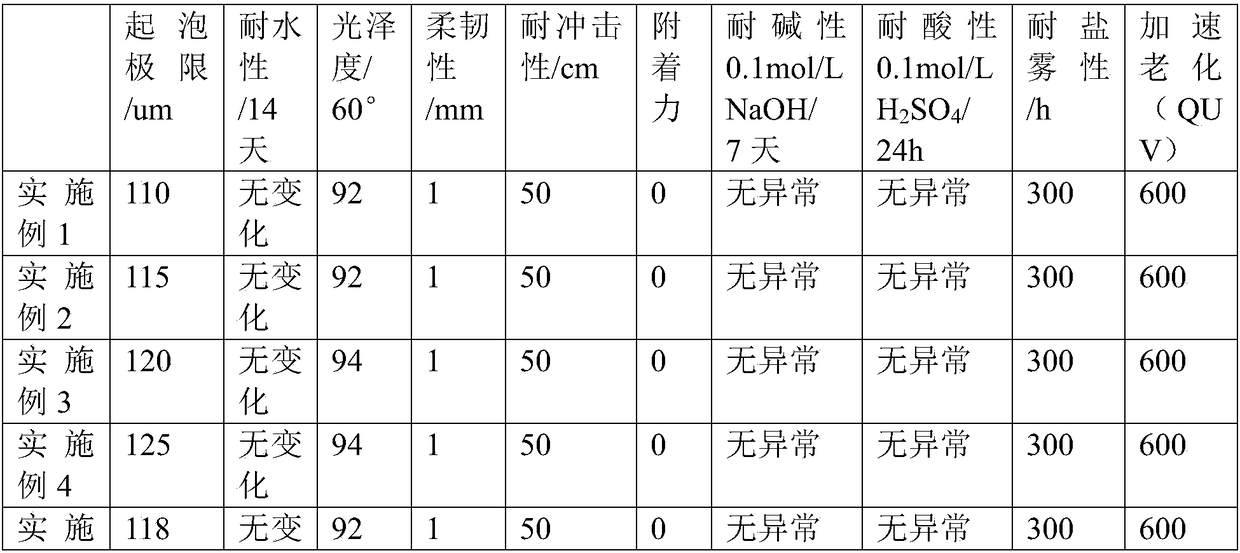

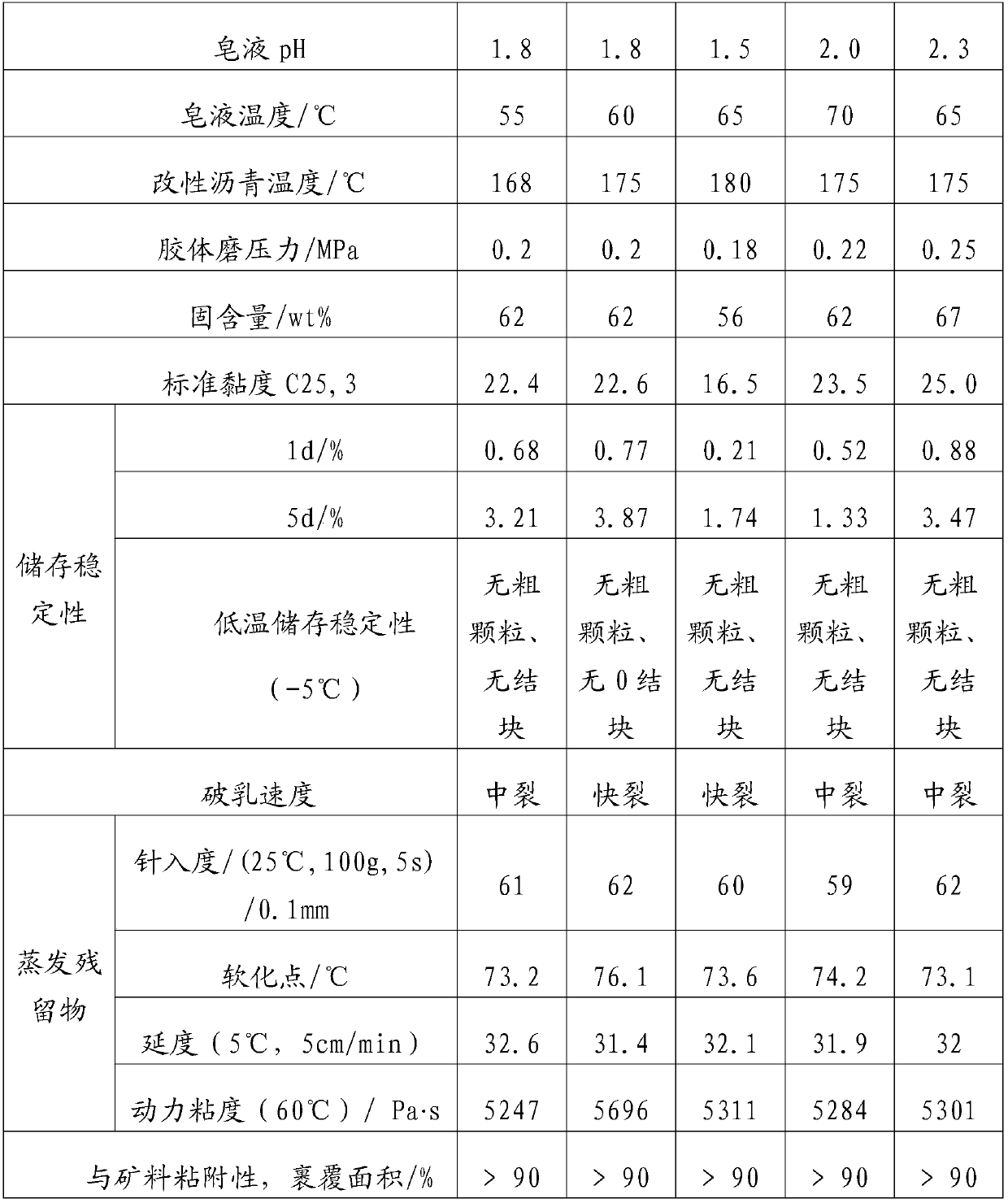

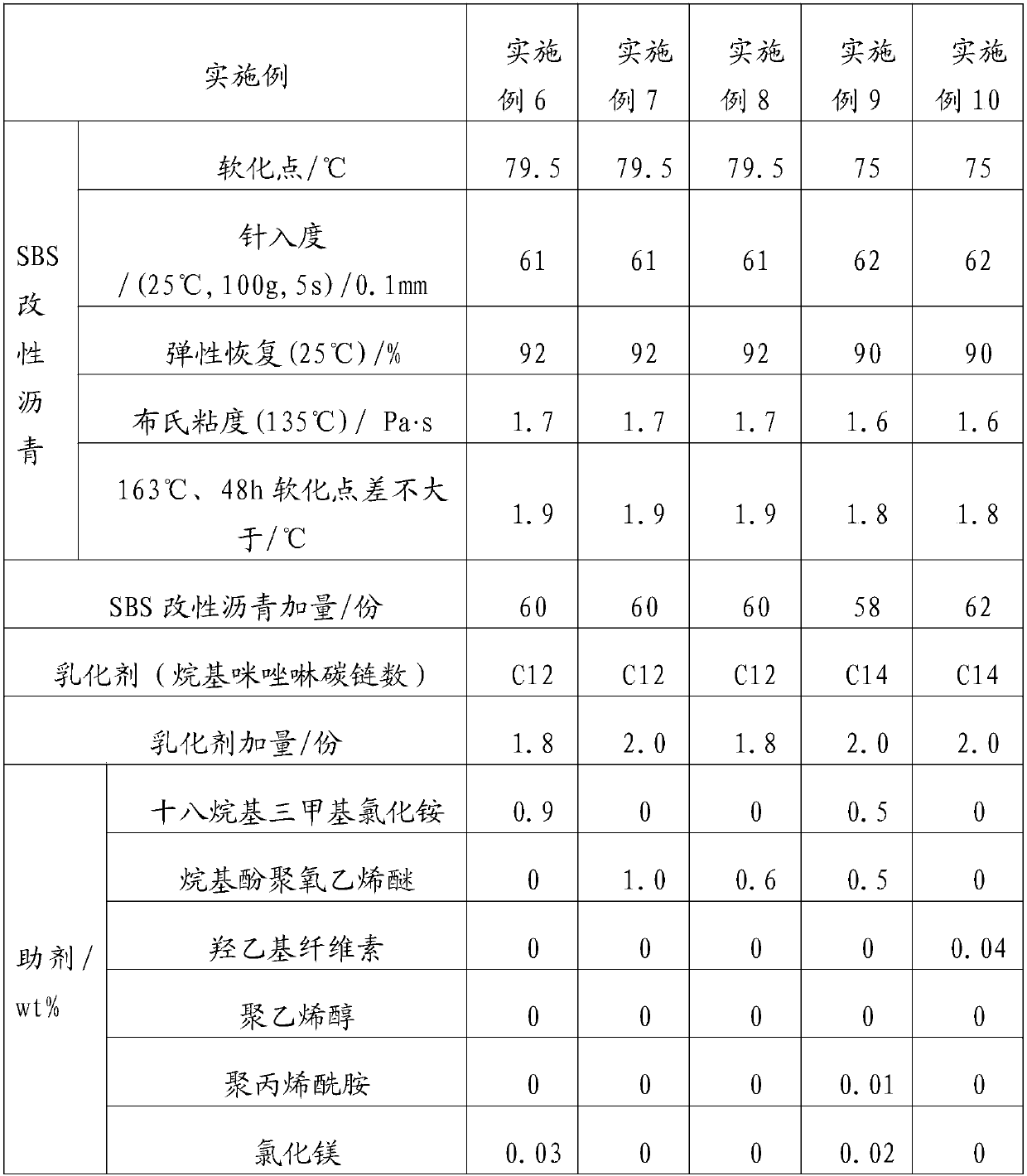

Modified emulsified asphalt and preparation method thereof

PendingCN109096781AStable storageUpper limit temperature controlBituminous material adhesivesBuilding insulationsCeiling temperatureAging resistance

The invention discloses modified emulsified asphalt and a preparation method thereof. According to the method, SBS modified asphalt heated to 168-180 DEG C and liquid soap heated to 55-70 DEG C are added to emulsifying equipment together for shear emulsification, and the modified emulsified asphalt is obtained. The method is simple and reliable; ceiling temperature of the modified asphalt and theliquid soap is controlled, energy is saved, and manufacture cost is reduced. The prepared modified emulsified asphalt is stored stably, the demulsification speed being rapid breaking or medium breaking of the emulsified asphalt is taken into consideration, so that the asphalt is easy to spray in construction, the demulsification curing time is short, and follow-up construction is not affected. Waterproofness and bonding performance of the modified emulsified asphalt when applied to a bonding layer material are obviously higher than those of the modified emulsified asphalt material in the priorart. The prepared bonding layer material can have excellent ageing resistance, bonding performance, waterproofness and high-low-temperature stability.

Owner:PETROCHINA CO LTD +1

Construction method of novel inner support of foundation trench

ActiveCN103243722AOvercome disadvantagesOvercome defectsExcavationsEnvironmental factorFinancial costs

Owner:郑鸿彰

Reusable reserved hole reserving device and construction method

InactiveCN112576031ASmall sizeNot affected by vibrationForms/shuttering/falseworksArchitectural engineeringPipe

The invention provides a reusable reserved hole reserving device and a construction method. The device comprises an inner sleeve; a top sealing cover plate used for sealing the top of the inner sleeveis fixedly installed at one end of the top of the inner sleeve; the exterior of inner sleeve is sleeved with a rubber pipe; a long screw rod is installed in the middle of the top sealing cover platein a threaded fit mode; a top hexagonal head is arranged at the top of the long screw rod; and the long screw rod is sleeved with a nut. By the adoption of a steel sleeve reserving device, after concrete pouring is completed, a steel sleeve can be smoothly pulled out from an upper portion and repeatedly used, and the steel sleeve can be used as a pipeline wall bushing after a top cover and a handle are detached in the later period, so that the positive boosting effect is achieved on on-site environmental protection and civilized construction.

Owner:CHINA NUCLEAR IND 22ND CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com