Pile cap and method for repairing and reinforcing concrete tubular-pile pile head

A concrete pipe pile and concrete technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of unfavorable environment, physical harm, easy deformation and damage, etc., to improve the impact resistance, simple operation and good toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

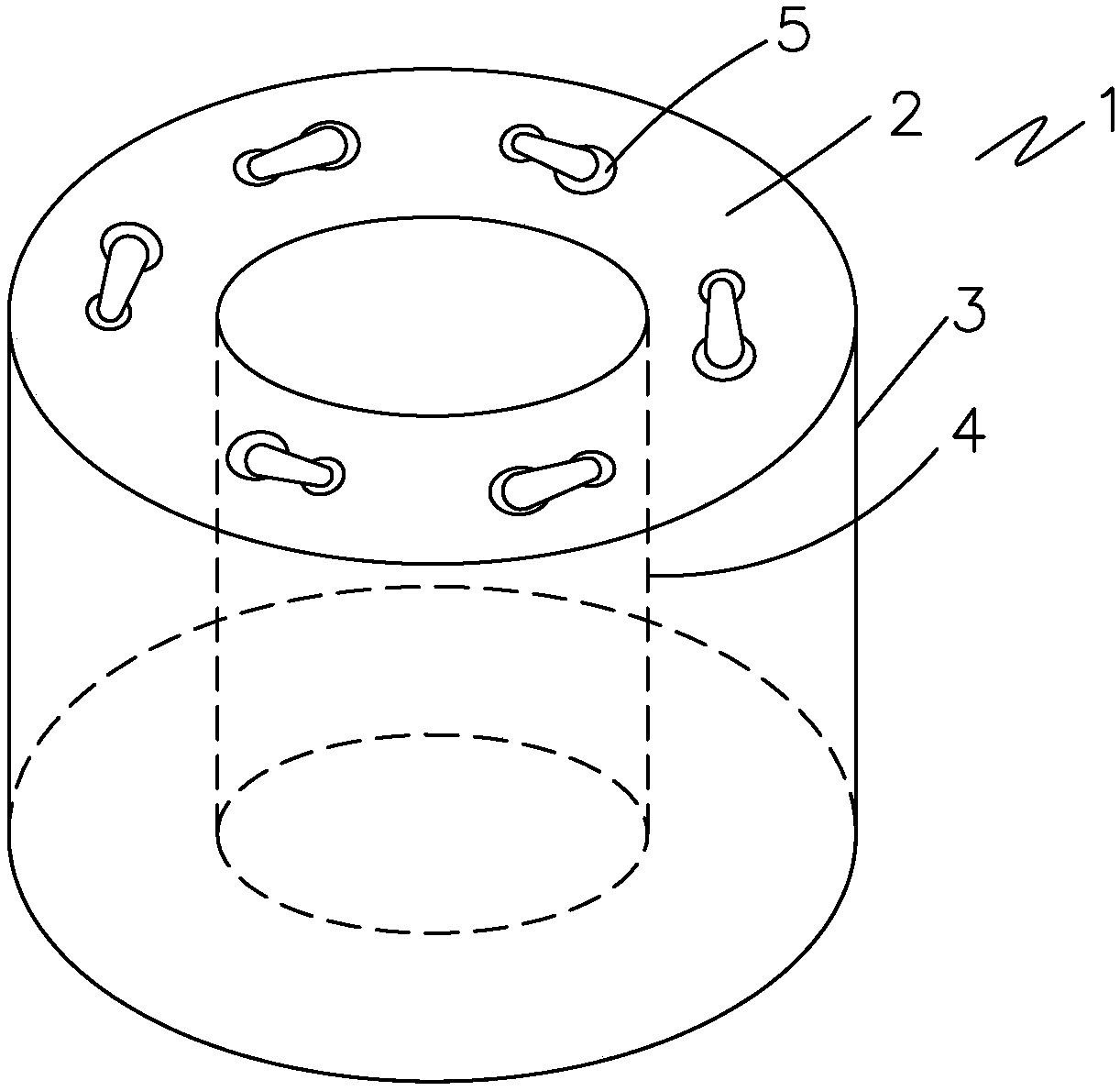

[0032] One, make a pile cap 1 with the same specifications as the pile head 6.

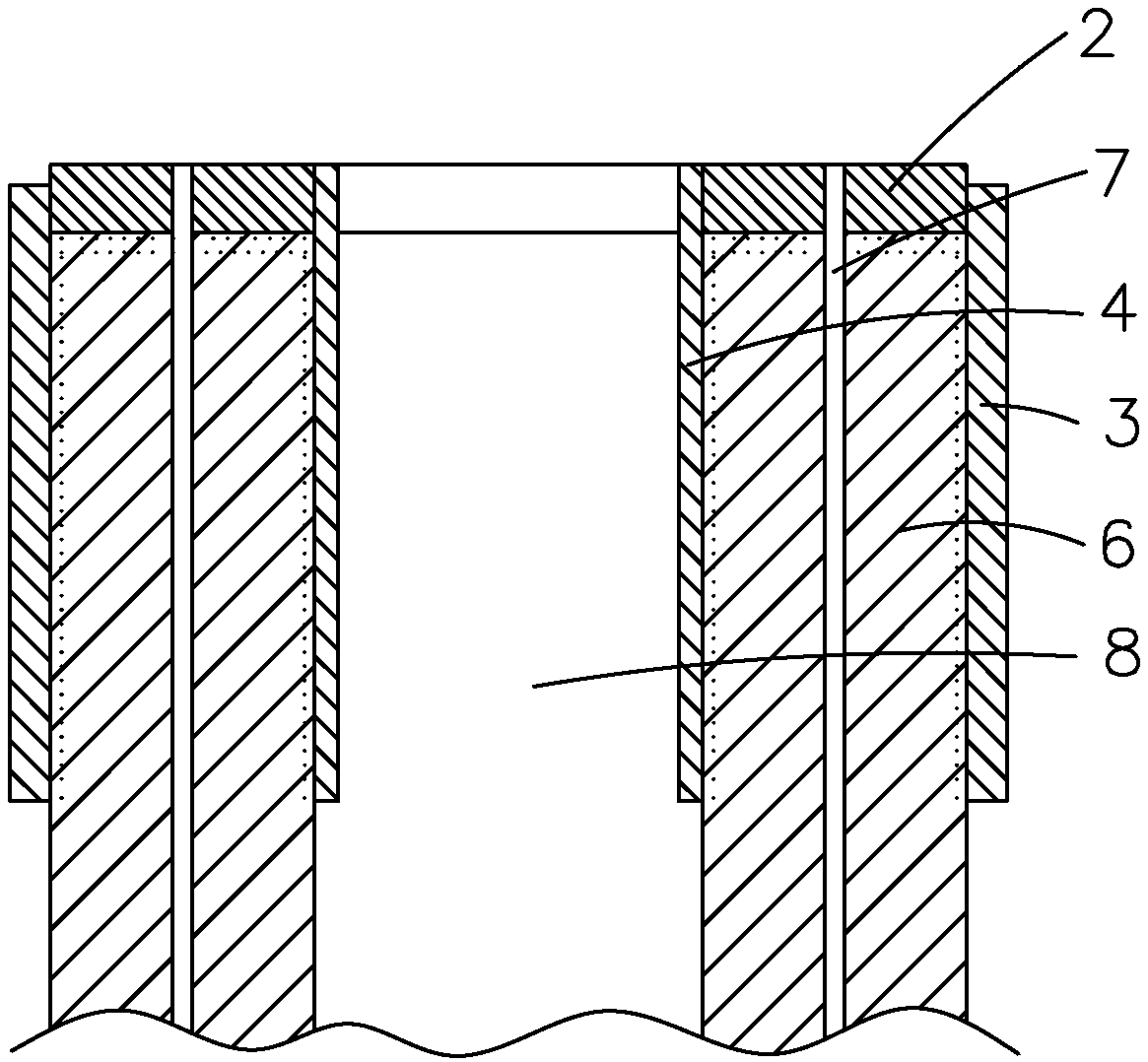

[0033] Please refer to details figure 1 and figure 2 As shown, a pile cap 1 repaired and reinforced by a concrete pipe pile head 6 includes an annular end plate 2, an outer sleeve 3, an inner sleeve 4 and a waist-shaped connection hole 5, and the outer sleeve 3 is sleeved on the The outer surface of the annular end plate 2, the inner sleeve 4 is sleeved on the inner surface of the annular end plate 2, the waist-shaped connecting hole 5 is arranged on the annular end plate 2, and the outer sleeve 3 end face is lower than ring end plate 2 end face.

[0034] When making the pile cap 1, the outer diameter of the annular end plate 2 is 2 to 5 mm larger than the outer diameter of the pipe pile to be repaired, and the inner hole diameter of the annular end plate 2 is 5 to 10 mm smaller than the cavity 8 of the pipe pile to be repaired. The end plate 2 is provided with a waist-shaped connecting hole 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com