Underground diaphragm wall grooving method under complicated geological conditions

A technology of complex geological conditions and underground diaphragm wall, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high construction cost and low trough forming efficiency, so as to reduce the trough construction cost and shorten the trough forming time. , Improve the effect of slotting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

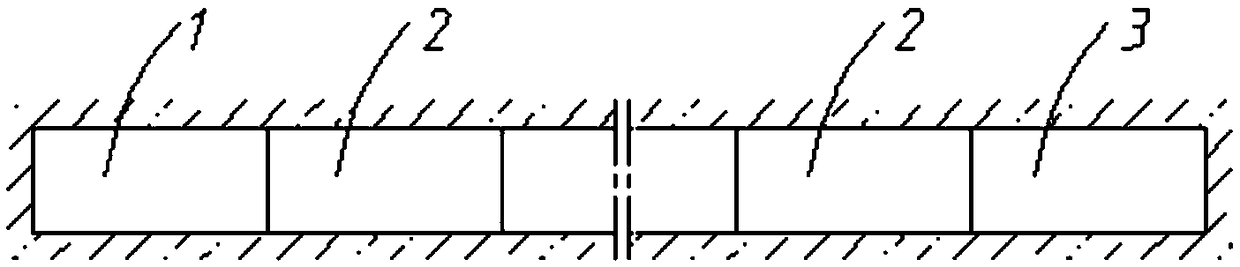

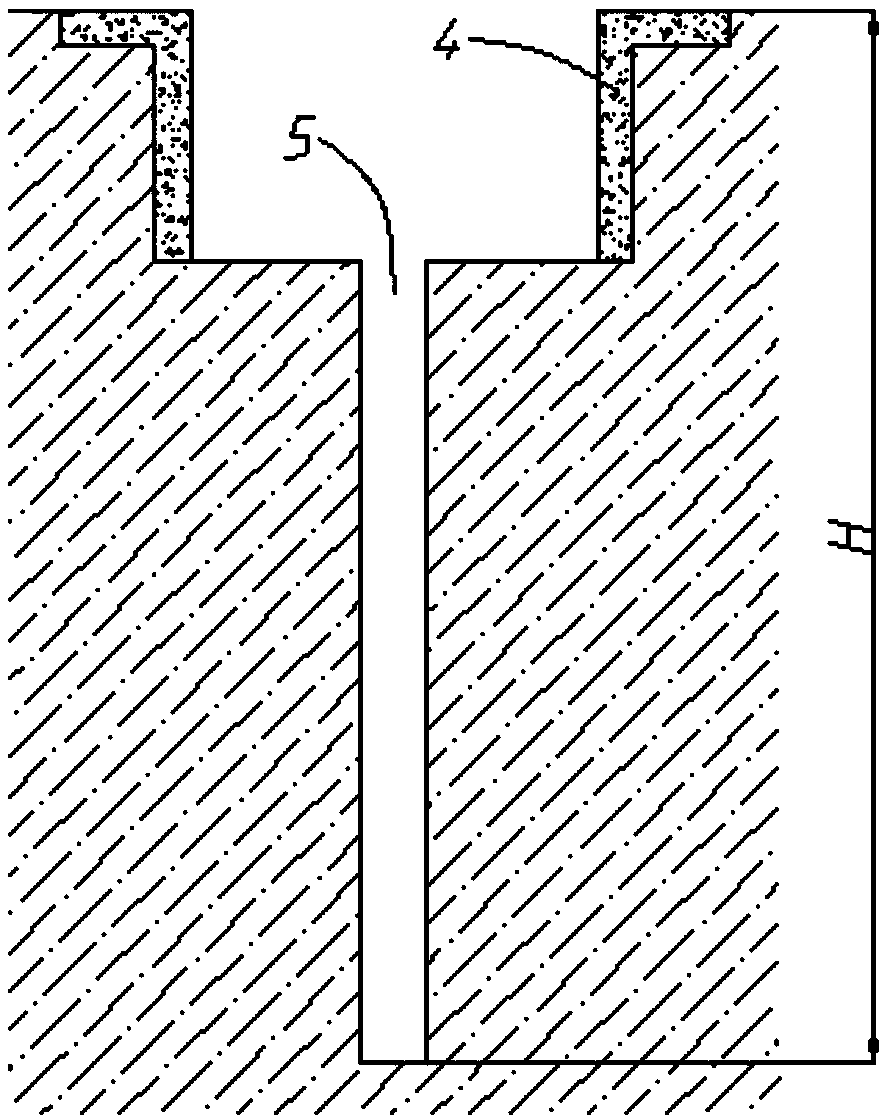

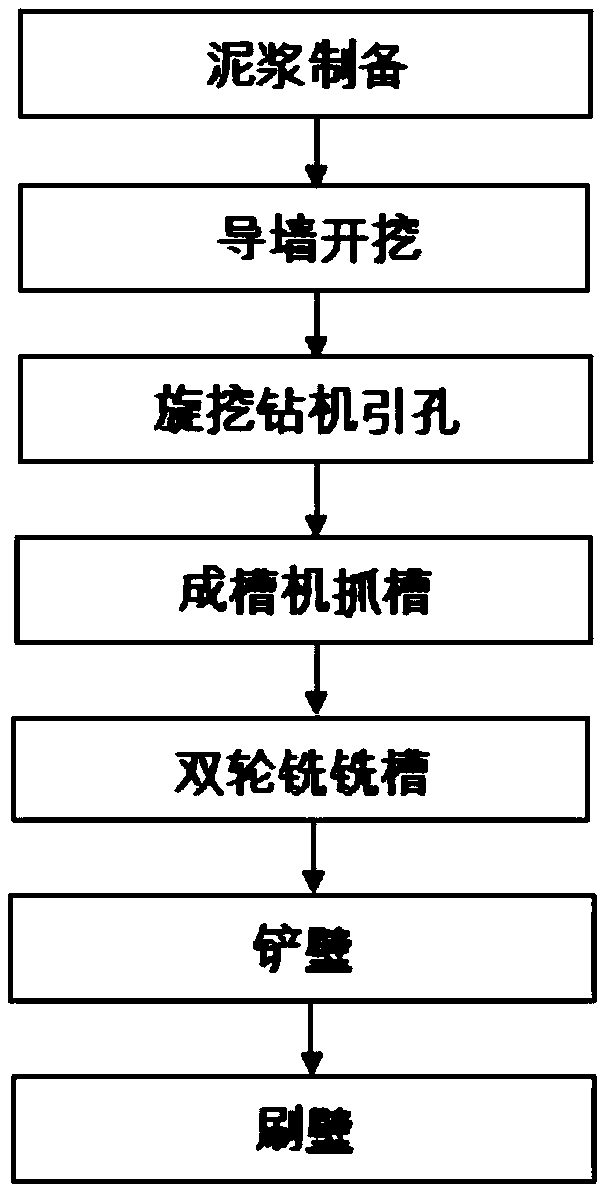

[0032] Such as Figure 1-Figure 3 As shown, the underground diaphragm wall forming groove method under complex geological conditions in this implementation includes the following steps:

[0033] a. Use a rotary drilling rig to guide the hole, and the hole depth is the same as the depth of the underground diaphragm wall groove;

[0034] b. After the lead hole is completed, use the groove forming machine to grasp the groove, and judge the construction depth and the stratum;

[0035] c. When the construction depth reaches the medium-weathered or slightly-weathered rock formation, use double-wheel milling for grooving construction.

[0036] The present invention uses a rotary drilling rig to introduce the hole to form the free surface of the groove section, which reduces the difficulty of construction and facilitates subsequent construction. During the hole introduction process, the stratum distribution of the groove section can also be clarified; after the hole introduction is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com