Full surrounding skin-type structure of underground waterproof engineering and construction method

An underground waterproof and fully enclosed technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve problems such as difficult construction, weak waterproofing, and short base plates, and achieve the effect of ensuring health, saving labor, and preventing hanging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

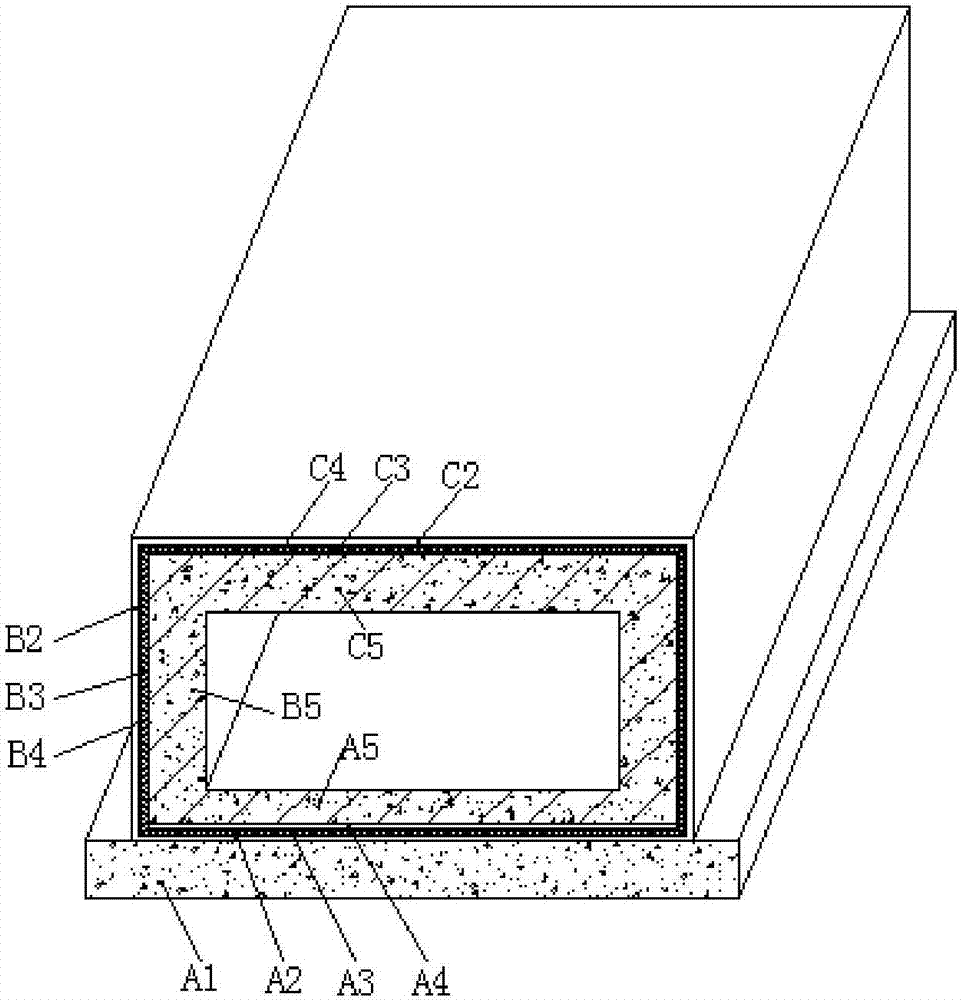

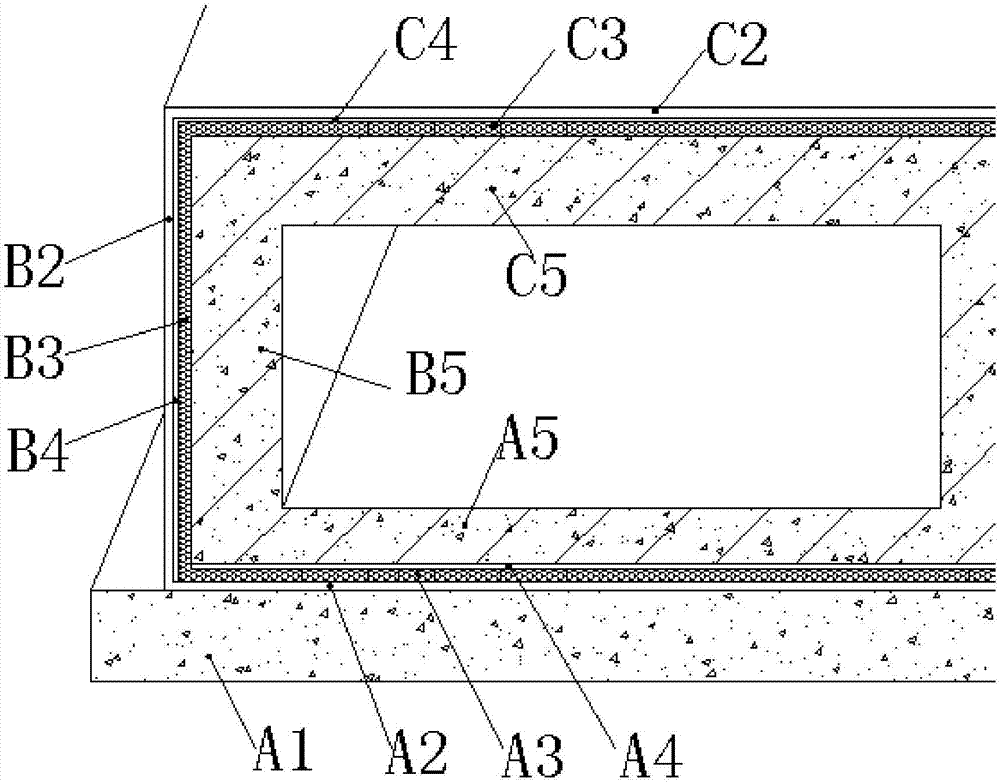

[0047] Such as Figures 1 to 2It is a fully-enclosed skin-type structure for underground waterproofing projects, including a bottom layer, a top layer, and a side layer. The bottom layer, top layer, and side layers are integrated to form a hollow structure. The bottom layer is the bottom concrete cushion layer A1 from bottom to top. , the bottom rubber asphalt waterproof coating layer A2, the bottom water-based non-curing coating layer A3, the bottom film reinforcement layer A4, the bottom concrete base layer A5; the side layer includes the side concrete base layer B5, outside the side concrete base layer B5 The side water-based non-curing coating layer B3, the side film reinforcement layer B4, and the side waterproof layer B2 are successively provided, and the side waterproof layer B2 is a rubber asphalt waterproof coating layer or a waterproof coiled material layer; the top layer includes a top concrete base layer C5, On the outside of the top concrete base layer C5, a top w...

Embodiment 2

[0055] The construction method of the fully enclosed skin formula structure of the underground waterproofing project in embodiment 1 is as follows:

[0056] Step 1, ground floor construction, which includes:

[0057] Step 1-1. After the construction of the concrete cushion of the underground project is completed, under the condition of no clear water, use mechanized spraying, and the construction is a 2mm thick rubber asphalt waterproof coating;

[0058] Step 1-2. After the construction of the rubber asphalt waterproof coating is completed (it can also be followed by simultaneous construction), use mechanized spraying to construct a 2mm thick water-based non-curing coating;

[0059] Steps 1-3, laying non-woven fabrics synchronously during the construction of water-based non-curing coatings;

[0060] Steps 1-4. After laying the non-woven fabric, directly bind the steel bars on the upper spring line, support the formwork, and carry out concrete pouring.

[0061] Step 2, side c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com