Opposite-pulling bolt capable of shedding

A technology for pulling bolts and bolts, which is used in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Scale requirements, adverse effects of the construction process, etc., to reduce material and labor costs, facilitate subsequent construction, and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

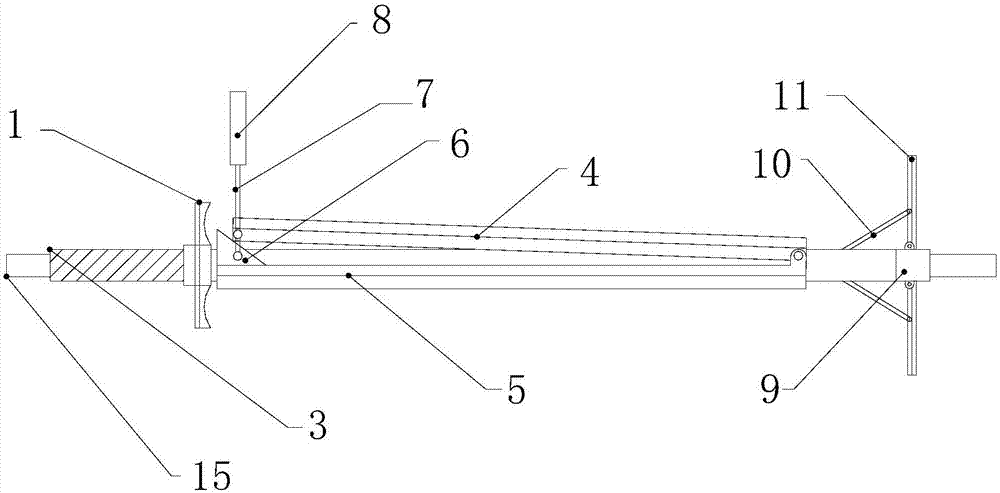

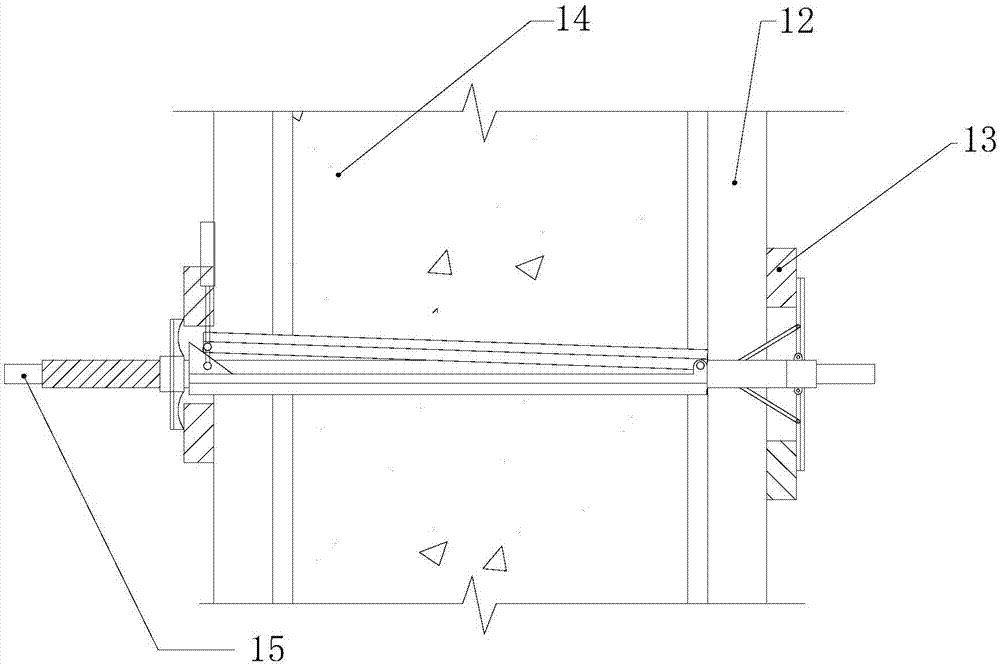

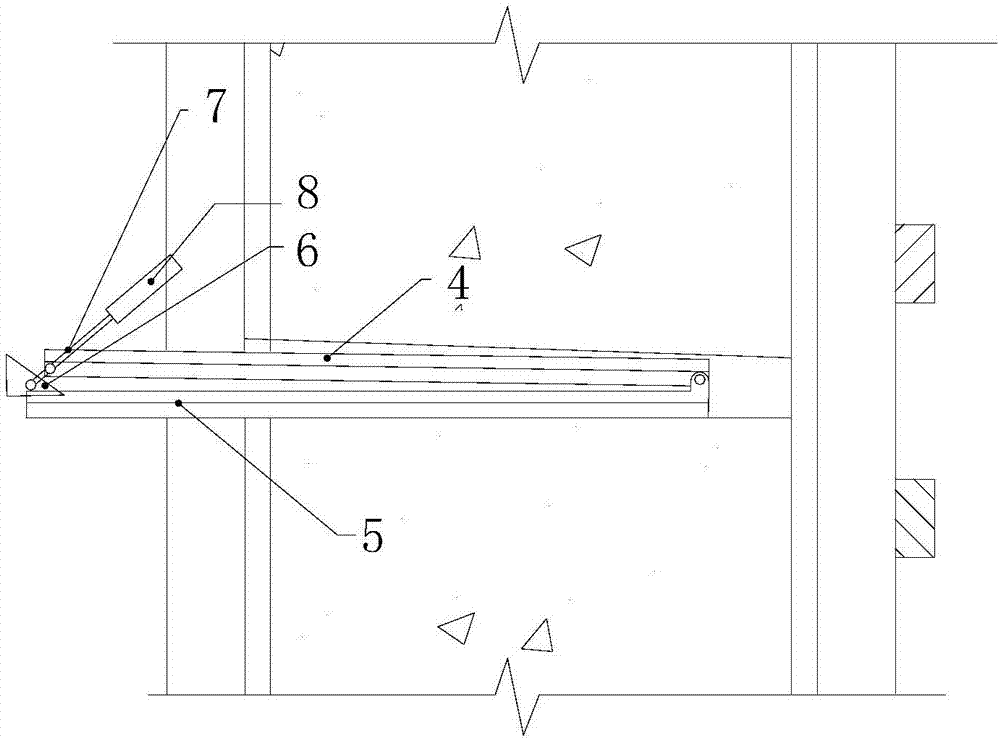

[0016] Such as figure 1 The shown detachable pull bolt 15 includes a bolt 15 and a clip 1 arranged at one end of the bolt 15, and also includes a sleeve, an outer casing 3 and a reverse bone structure, and the reverse bone structure is arranged at a position where the bolt 15 is far away from the clip. One end of the piece 1, the outer casing 3 is sleeved on the bolt 15, the bolt 15 and the outer casing 3 pass through the casing, and the two ends of the bolt 15 are exposed outside the casing for installing the clip 1 and Reverse bone structure. The sleeve comprises an upper half 4, a lower half 5, a wedge 6 and a rotating connector 7, the tail of the upper half 4 is hinged to the tail of the lower half 5, and the end of the rotating connector 7 is connected to the The wedge 6 is hinged, and the head of the upper half part 4 is hinged with the middle part of the rotating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com