Method for preparing hydroxyl acrylic acid water dispersoid

A hydroxyacrylic acid and dispersion technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficulty in achieving the performance of solvent-based two-component polyurethane coatings, poor water resistance of coating films, and large particle size of dispersions. Effects of low solvent content, long pot life and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

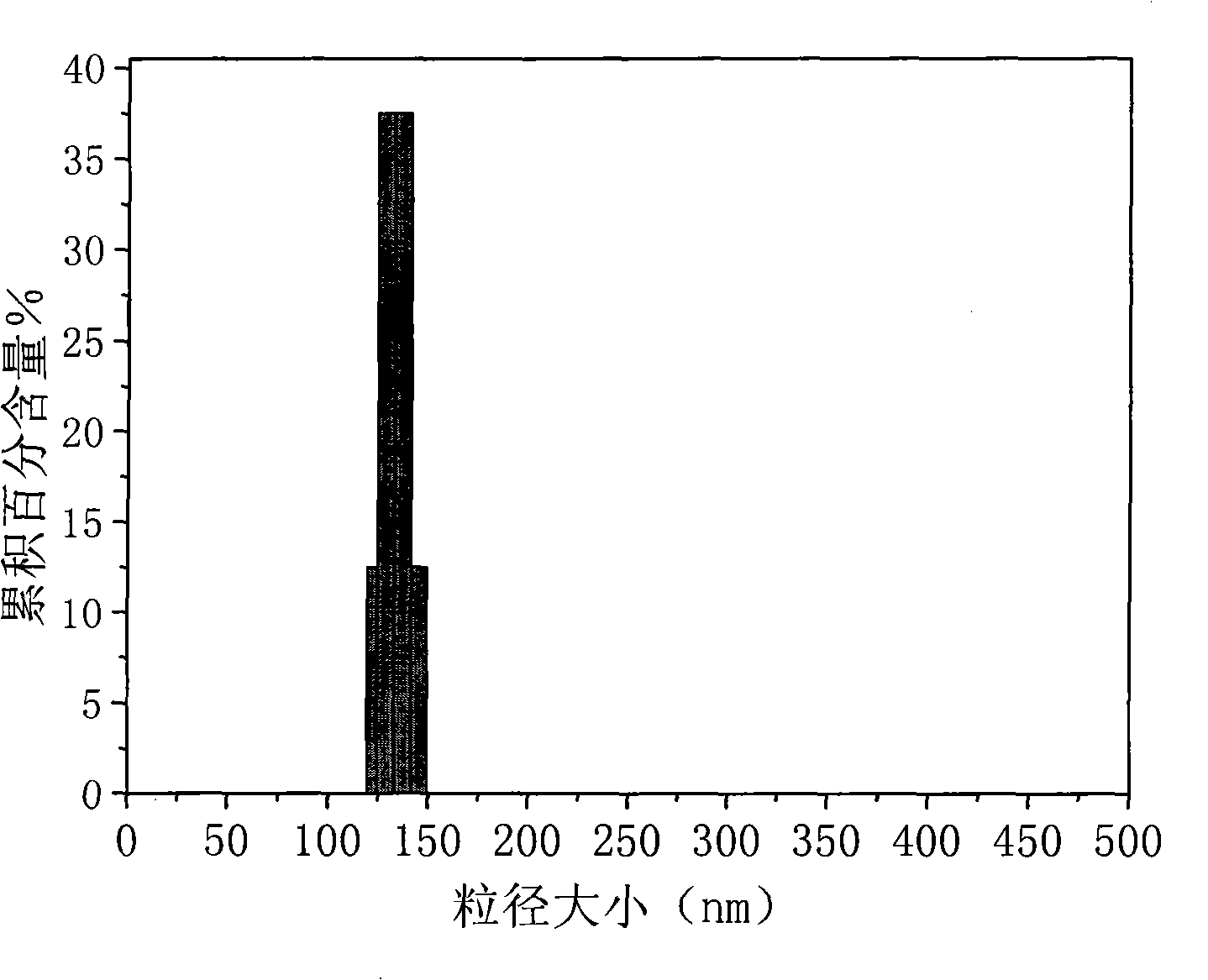

[0041]Firstly, 90 g of propylene glycol methyl ether acetate and 20 g of glycidyl tert-carbonate were added to a reaction kettle equipped with a condensing device and a stirring rod, and the temperature was raised to a reflux temperature of 140° C. while feeding nitrogen. After constant temperature, start to drop the mixed solution composed of non-functional (meth)acrylate, hydroxyl-containing (meth)acrylate, (meth)acrylic acid, vinyl monomer, partial initiator and chain regulator (20 g of methyl methacrylate, 10 g of styrene, 10 g of butyl acrylate, 30 g of hydroxypropyl acrylate, 15 g of acrylic acid, 1 g of dodecyl mercaptan, 4 g of t-amyl peroxyacetate). Control the dropping speed, add the monomer mixture within 2 to 3 hours, keep it for 0.5 to 1 hour, then add a mixed solution of 0.5g initiator and 5g propylene glycol methyl ether acetate, keep warm for 2 to 3 hours, and measure the hydroxyl The conversion rate of the acrylate resin reaches over 98%, and then the temperat...

Embodiment 2

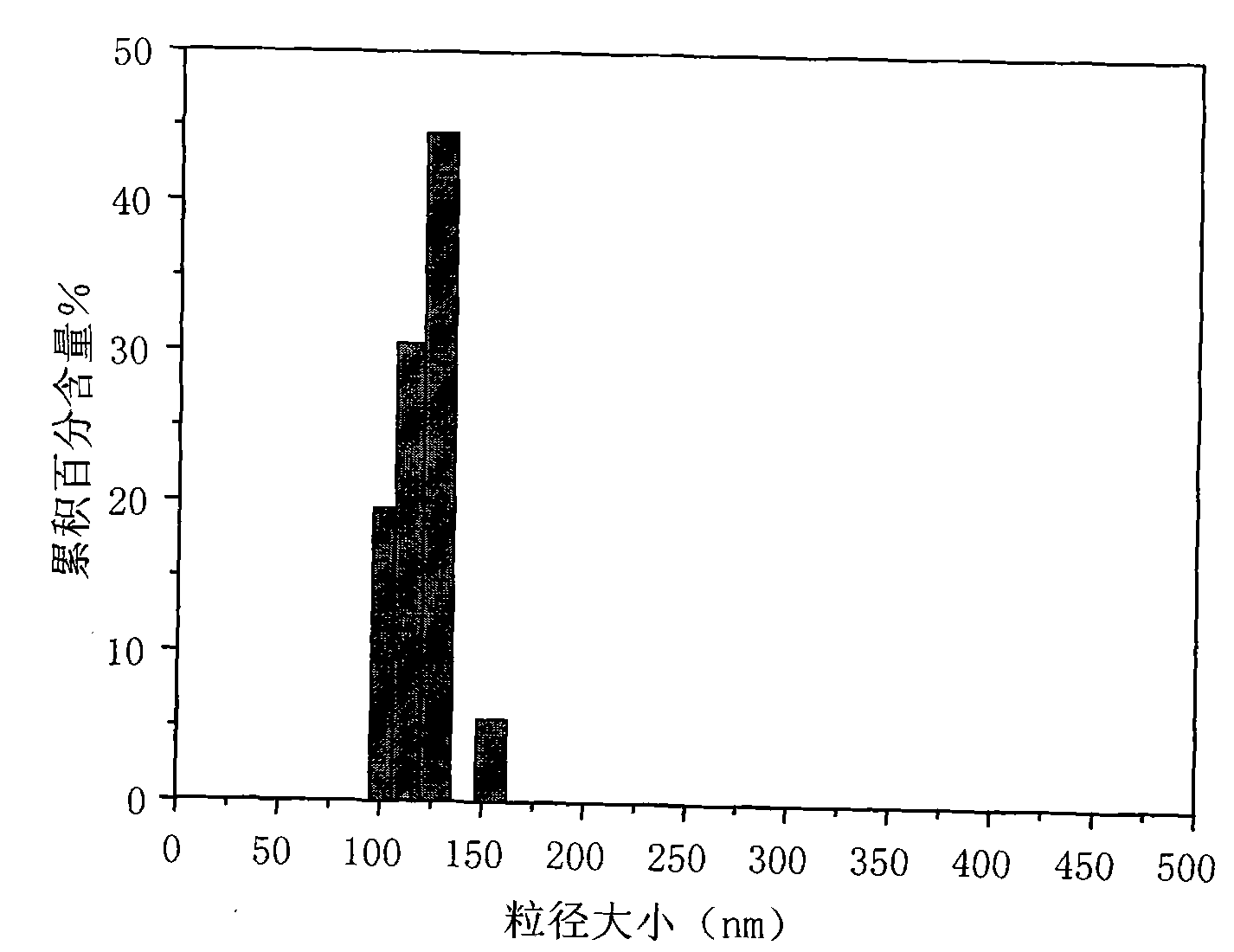

[0049] First put 24g of glycidyl tert-carbonate and 80g of propylene glycol methyl ether acetate into a reaction kettle with a condensing device and a stirring rod, and raise the temperature to 140° C. while blowing nitrogen. After constant temperature, start to drop the mixed solution composed of non-functional (meth)acrylate, hydroxyl-containing (meth)acrylate, (meth)acrylic acid, vinyl monomer, partial initiator and chain regulator (30g methyl methacrylate, 10g styrene, 6g butyl acrylate, 10g hydroxypropyl acrylate, 14g hydroxyethyl methacrylate, 12g acrylic acid, 1g dodecyl mercaptan, 3g tert-amyl peroxyacetate) . The monomer mixture is dropped within 2 to 3 hours, and kept for 0.5 to 1 hour, then a mixed solution of 0.3g of initiator and 4g of propylene glycol methyl ether acetate is added, and the temperature is continued for 2 to 3 hours to measure the hydroxyacrylate resin. The conversion rate reaches over 98%, and then the temperature is lowered to 80° C., and part o...

Embodiment 3

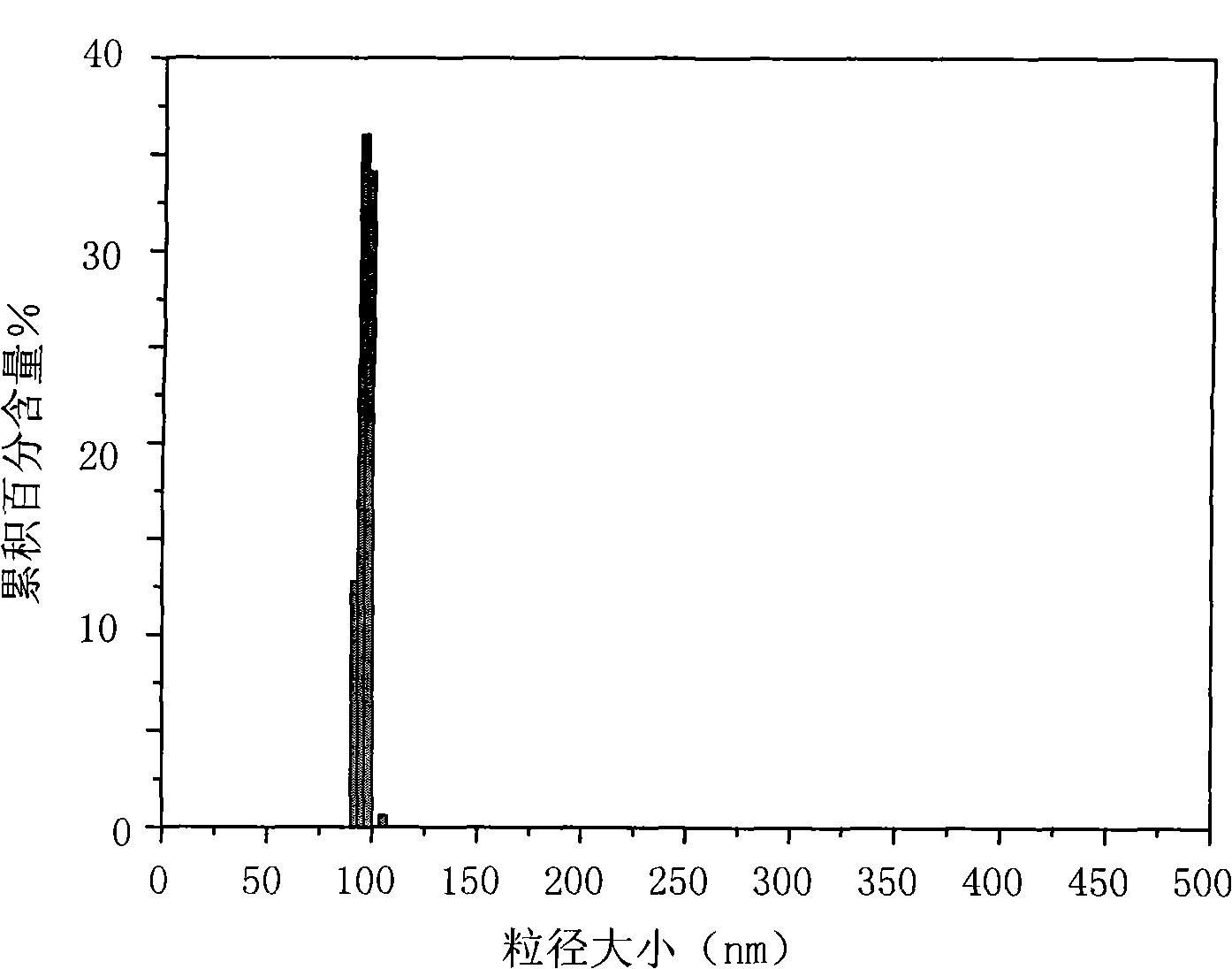

[0054] First, 86g of propylene glycol methyl ether acetate and 20g of glycidyl tert-carbonate were added to a reaction kettle equipped with a condensing device and a stirring rod, and the temperature was raised to 130°C while blowing nitrogen. After constant temperature, start to drop the mixed solution composed of non-functional (meth)acrylate, hydroxyl-containing (meth)acrylate, (meth)acrylic acid, vinyl monomer, partial initiator and chain regulator (Methyl methacrylate 22g, styrene 10g, butyl acrylate 10g, hydroxyethyl methacrylate 32g, methacrylic acid 12g, dodecyl mercaptan 1g, tert-amyl peroxyacetate 3g. Monomer mixture After dropping within 2 to 3 hours, keep it for 0.5 to 1 hour, then add a mixed solution of 0.3g initiator and 5g propylene glycol methyl ether acetate, and continue to keep warm for 2 to 3 hours, and the conversion rate of hydroxyacrylate resin is determined to reach 98%. % above, then lower the temperature to 90°C, evaporate part of the solvent in vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com