Hydroxyl acrylic acid dispersion and synthetic method thereof

A technology of hydroxyacrylic acid and dispersion, applied in the field of coatings, can solve the problems of restricting the development of hydroxyacrylic acid dispersion, unstable and poor stability of hydroxyacrylic acid dispersion, and achieve the effects of moderate molecular weight, narrow molecular weight distribution and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

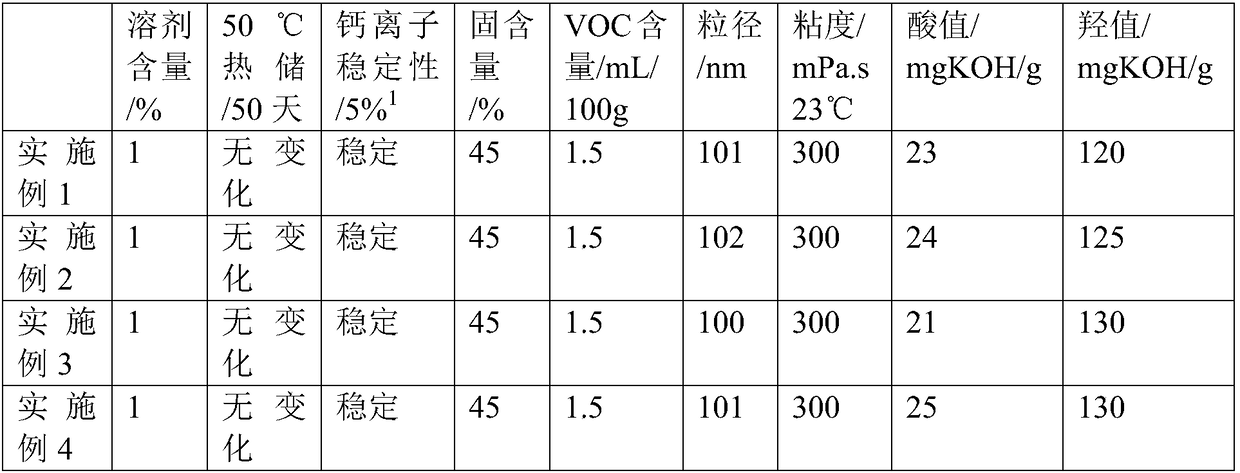

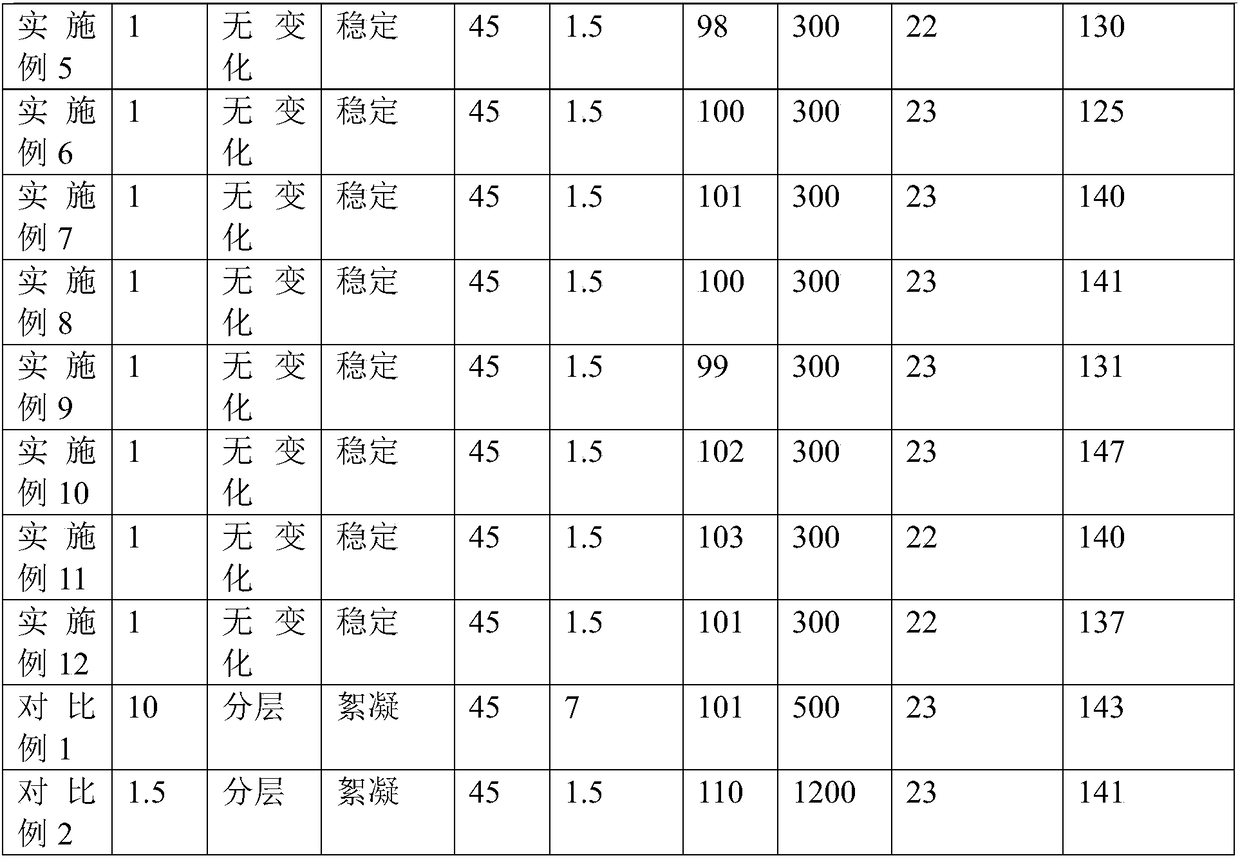

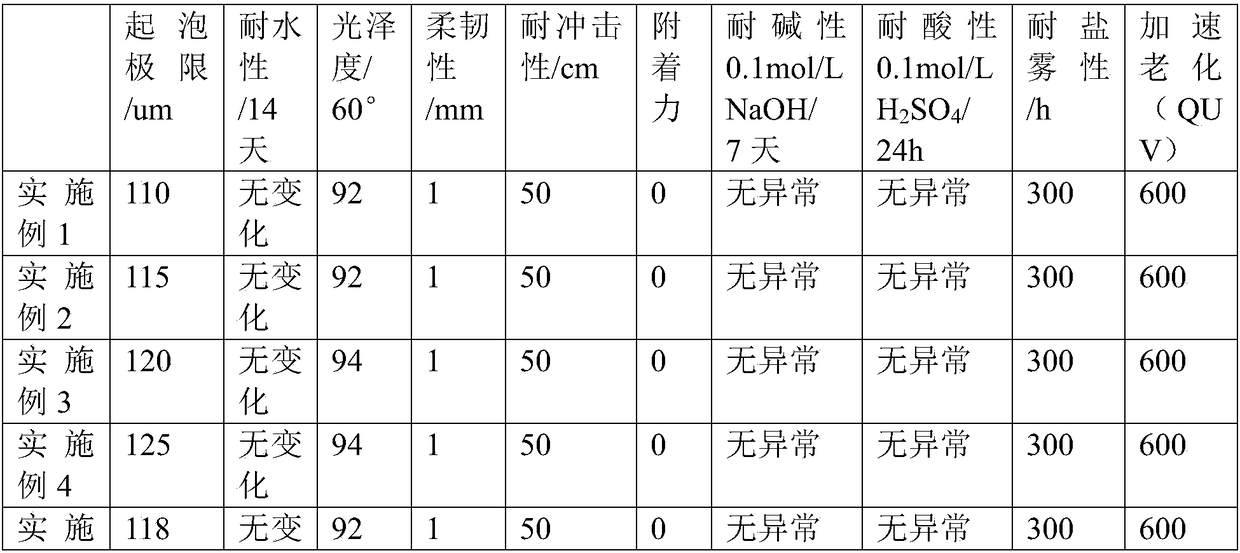

Examples

Embodiment 1

[0030] 10 parts of air-drying resin and 2 parts of ethylene glycol butyl ether were added to the reaction vessel, heated to 115°C to dissolve, 3 parts of acrylic acid, 20 parts of butyl acrylate, 10 parts of hydroxyethyl methacrylate, methyl methacrylate 22 parts of ester, 22 parts of styrene, and 3 parts of tert-butyl peroxybenzoate were mixed evenly, and added dropwise to the reaction vessel for 3-4 hours. , and the final reaction was incubated for 1 h. The temperature was lowered to 80° C., 4 parts of neutralizing agent N,N-dimethylethanolamine were added, 2 parts of drier were dispersed in 140 parts of water, and then cooled to room temperature to obtain a hydroxyacrylic acid dispersion.

[0031] The air-drying resin used in this example is prepared by the following method:

[0032] The four-hole flask was equipped with nitrogen, mechanical stirring, thermocouple, and reflux condenser respectively. 878 parts of linseed oil were added to the flask, the temperature was rais...

Embodiment 2

[0034] 10 parts of air-drying resin and 2 parts of ethylene glycol butyl ether were added to the reaction vessel, heated to 115°C to dissolve, 3 parts of acrylic acid, 20 parts of butyl acrylate, 10 parts of hydroxyethyl methacrylate, methyl methacrylate 22 parts of ester, 22 parts of styrene, and 3 parts of tert-butyl peroxybenzoate were mixed evenly, and added dropwise to the reaction vessel for 3-4 hours. , and the final reaction was incubated for 1 h. The temperature was lowered to 80° C., 4 parts of a neutralizing agent dimethylethanolamine was added, and 2 parts of a drier was dispersed in 140 parts of water, and cooled to room temperature to obtain a hydroxyacrylic acid dispersion.

[0035] The air-drying resin used in this example is prepared by the following method:

[0036] The four-hole flask was equipped with nitrogen, mechanical stirring, thermocouple, and reflux condenser respectively. 878 parts of linseed oil were added to the flask, the temperature was raised ...

Embodiment 3

[0038] A hydroxyacrylic acid dispersion, in parts by weight, comprising 7 parts of air-drying resin, 1 part of acrylic acid, 6 parts of hydroxyethyl methacrylate, 25 parts of isobornyl methacrylate, 25 parts of styrene, peroxide 9 parts of benzoic acid, 2 parts of ethylene glycol butyl ether, 4 parts of triethylamine, 2 parts of drier, and 100 parts of deionized water. The air-drying resin includes polyethylene glycol lauryl ether, triglyceride, and cinnamic acid.

[0039] Prepared by:

[0040] A. Add air-drying resin and solvent, stir to dissolve and heat up to 110°C;

[0041] B. Add 8 parts of the mixture of acrylic carboxyl monomer, acrylic hydroxyl monomer, other acrylic monomers and initiator at a uniform speed for 3h. After dropping, add 0.5 part of initiator and continue the reaction for 1h;

[0042] C. Cool down to 80°C, add neutralizer and drier, and disperse in deionized water to obtain a low-solvent hydroxyacrylic acid dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com