3D printed wall and splicing method thereof

A 3D printing and wall technology, applied in the direction of walls, building components, buildings, etc., to achieve the effect of good stability, simple operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 3D printing is a kind of rapid prototyping technology. It is a technology based on digital model files and using bondable materials such as powdered metal or plastic to construct objects by layer-by-layer printing.

[0059] 3D printing is usually achieved by printing with 3D printers. With the development of 3D printing technology, 3D printing is also widely used in the field of construction.

[0060] The 3D printed wall is an application of 3D printing technology. In order to facilitate transportation, construction and other reasons, the wall sub-components are pre-printed by 3D printers, and then the wall components are spliced together by a splicing method.

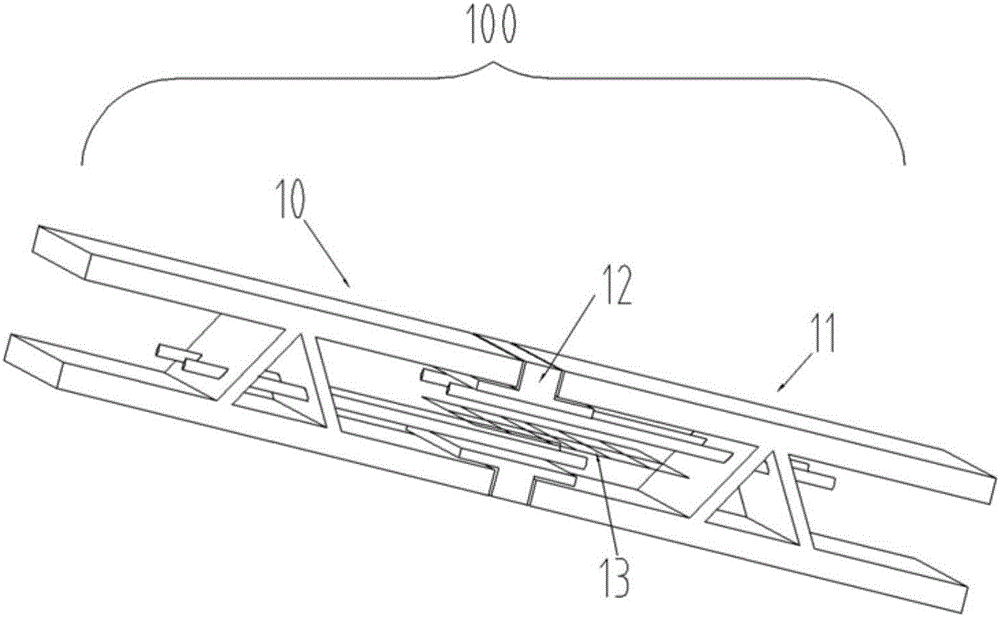

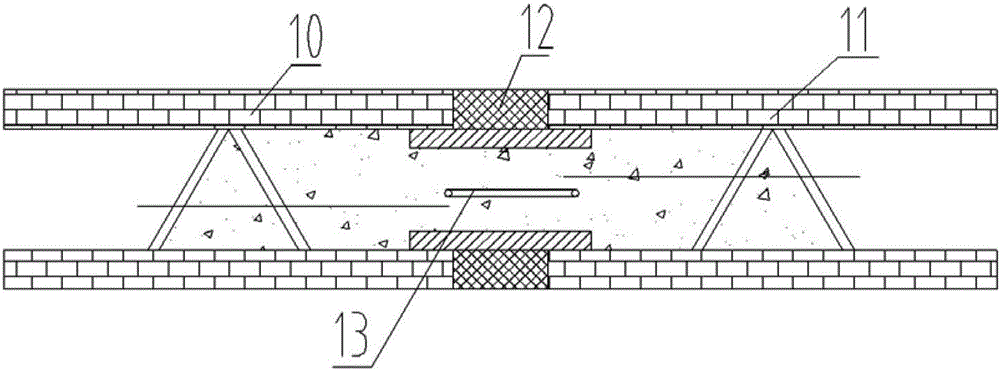

[0061] Such as figure 1 As shown, it is a schematic diagram of a 3D printed wall 100 spliced according to the method of the present invention. Combine below figure 1 The present invention will be described.

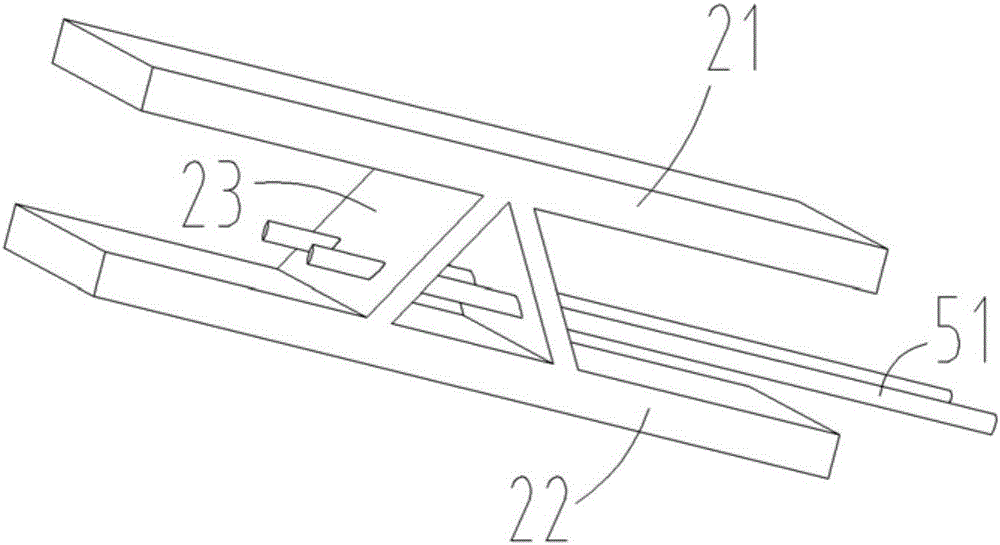

[0062] The present invention provides a 3D printed wall 100, the 3D printed wall 100 includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com