Epoxy resin water dispersion and process for preparing the same

A technology of epoxy resin and dispersion, applied in epoxy resin coatings, coatings, etc., can solve the problems of poor stability of resin dispersion, high resin viscosity, large particle size of dispersion, etc. The effect of long and small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] (4) Preparation of the dispersion: Then add the co-solvent of the formulated amount until the reaction temperature of the system drops to 60°C; After adding, keep it for 20 minutes, then remove the epoxy water dispersion and disperse it on the disperser at a speed of 3000r / min for about 30 minutes.

[0051] Specific implementation formula:

Embodiment 1

[0053] According to 100 parts by mass, first add 92.25 parts by mass of polyethylene glycol 4000 and 7 parts by mass of epoxy resin E-44 into a 250ml four-necked bottle, adjust the temperature to 90°C, and blow in nitrogen for protection for 20 minutes. When the temperature of the system rises to 90°C, slowly add 0.75 parts by mass of triphenylphosphine dropwise, then raise the temperature of the system to 120°C within 1 hour, and then keep the system reacting for 4 hours, the color of the reaction system gradually changes from white to Pale yellow, it is a reactive emulsifier, ready for use.

[0054] According to 100 parts by mass, add 3.7 parts by mass of epoxy resin Epon8283, 7.3 parts by mass of bisphenol A, and 0.09 parts by mass of catalyst triphenylphosphine into a 500ml four-necked bottle, raise the reaction temperature to 160°C, and react for 0.5h. Stop reaction when the epoxy equivalent value is 510; then add 0.45 mass parts of double-terminal carboxyl polyethylene g...

Embodiment 2

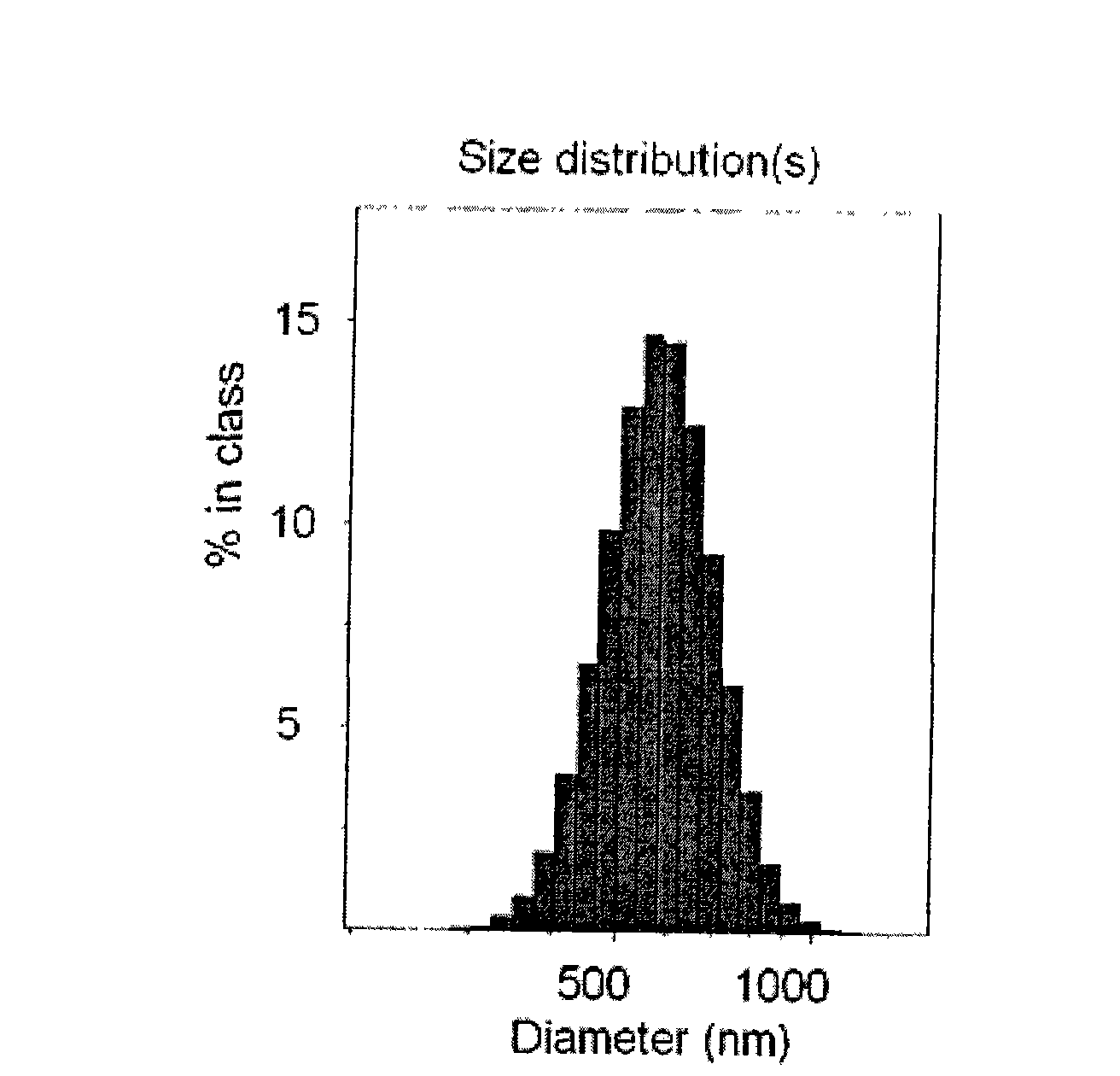

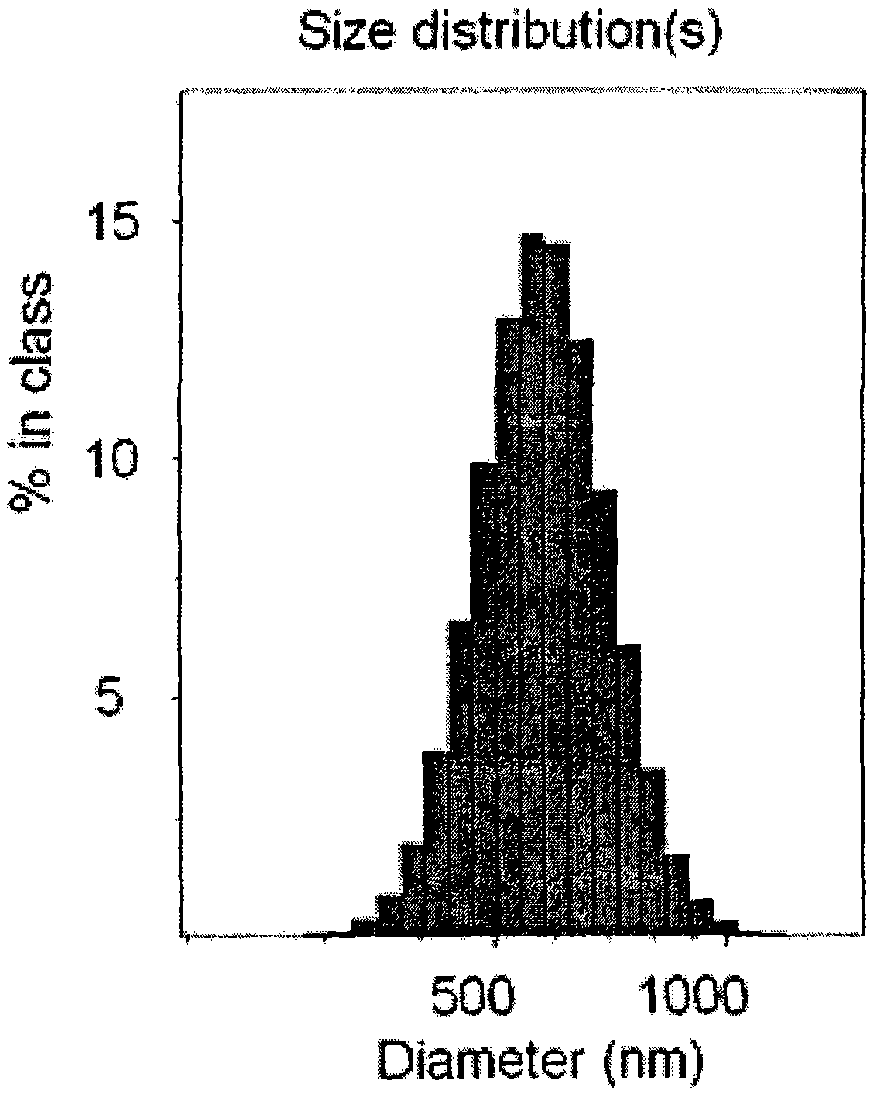

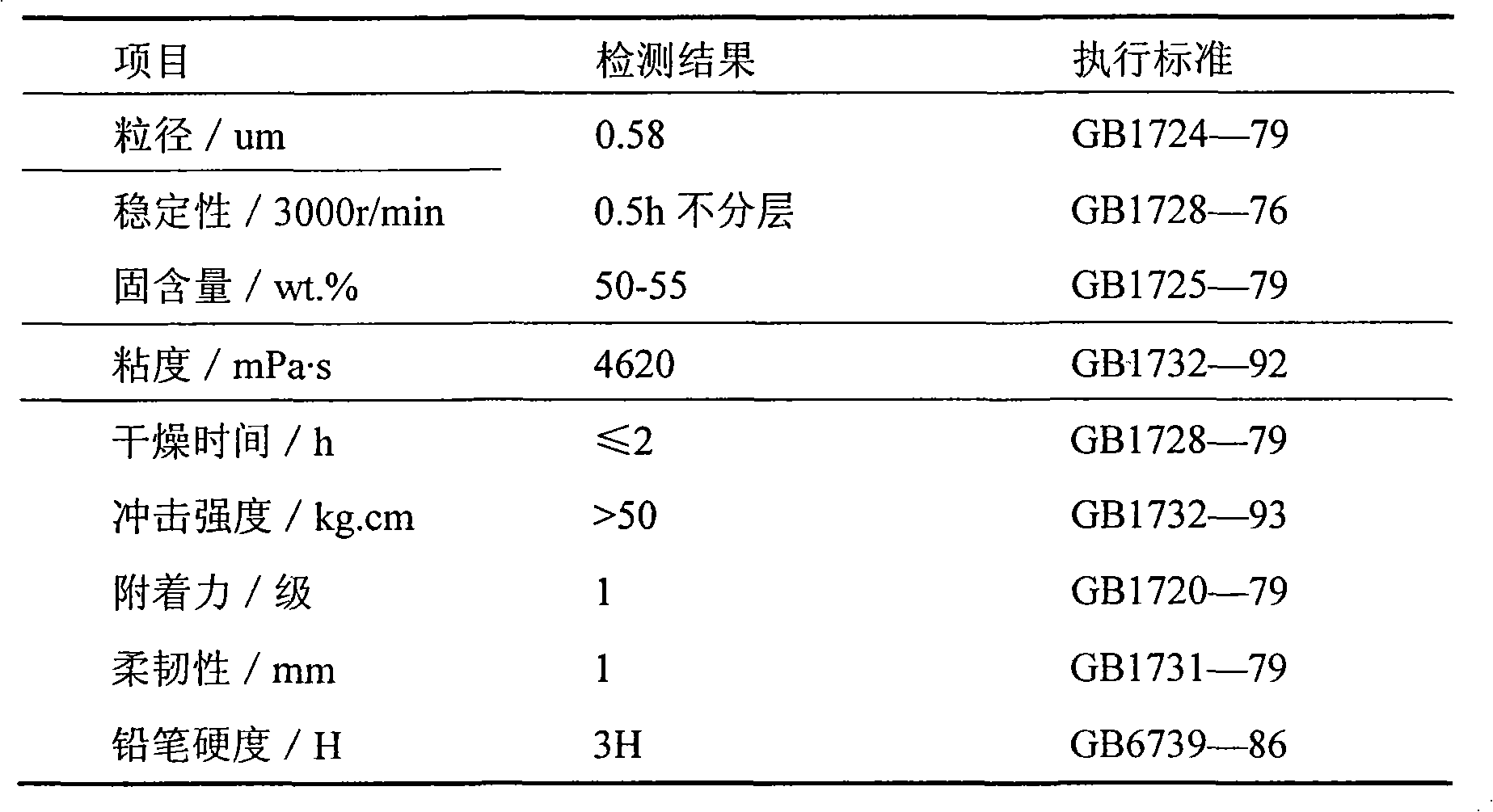

[0058] According to 100 parts by mass, 3.9 parts by mass of epoxy resin Epon828, 7.35 parts by mass of bisphenol A, and 0.09 parts by mass of catalyst triphenylphosphine were added to a 500ml four-necked bottle, and the reaction temperature was raised to 160°C for 0.5 hours. Epoxy equivalent value 510~530 stop reaction; Then add 0.90 mass parts of double-terminal carboxyl polyethylene glycol with molecular weight 1700, maintain reaction and carry out 20min, then add 12.5 mass parts of synthetic reactive epoxy emulsifier of Example 1 again, react again 20min; Add 13.57 parts by mass of co-solvent propylene glycol monobutyl ether until the reaction temperature of the system drops to 60°C; then increase the stirring speed to 3000r / min, add 31.69 parts by mass of deionized water dropwise at a speed of 5min / ml, and add 31.69 parts by mass of deionized water at a rate of 3000r / min The speed continues to disperse for about 30 minutes. The index of embodiment 2 gained epoxy aqueous di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com