Real-time treatment method and equipment of bored pile head

A technology for bored piles and treatment methods, which is applied in the direction of drilling equipment and methods, sheet pile walls, drilling equipment, etc., which can solve problems such as poor safety, low work efficiency, and large damage to main reinforcement, and achieve convenient construction and shorten the duration. Time and the effect of reducing construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

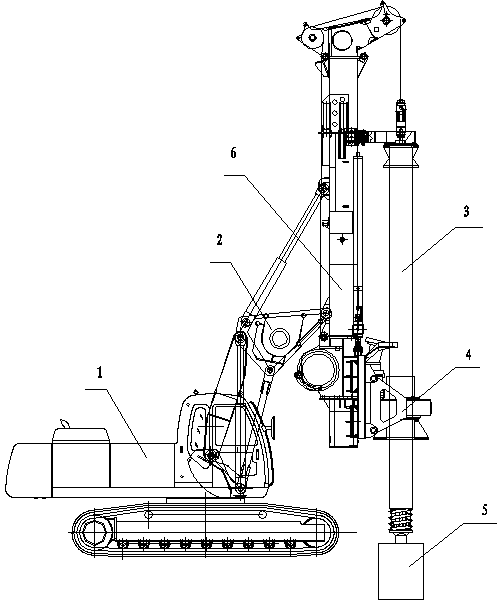

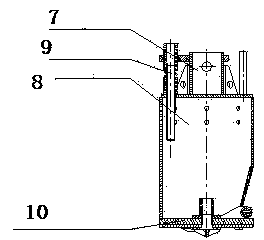

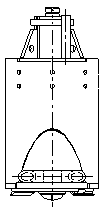

[0022] During the construction of bored piles, the concrete at the pile head will be lifted continuously during pouring. In order not to affect the quality of the pile head concrete, the underwater concrete is mostly mixed with retarder. When the concrete is poured, there is no initial setting of the concrete at the pile head, which creates the possibility for the advance treatment of our pile head concrete. The principle of the invention is to cut and break the unprepared underwater concrete by the drill bit, and put the broken concrete into the barrel by rotating the drill bit, and bring it out of the hole, so as to achieve the purpose of early treatment of the pile head.

[0023] According to the working characteristics and working environment of the pile head real-time processing drilling rig used for pile head processing for the immediate processing of bored pile heads and the working environment, the design of the tooling needs to have the ability to run without the self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com