Printing and stamping integrated self-service equipment and management control method

A self-service equipment, management and control technology, applied in printing devices, copying/marking methods, printing, etc., to achieve the effect of reducing physical size, achieving seamless connection, and ensuring authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

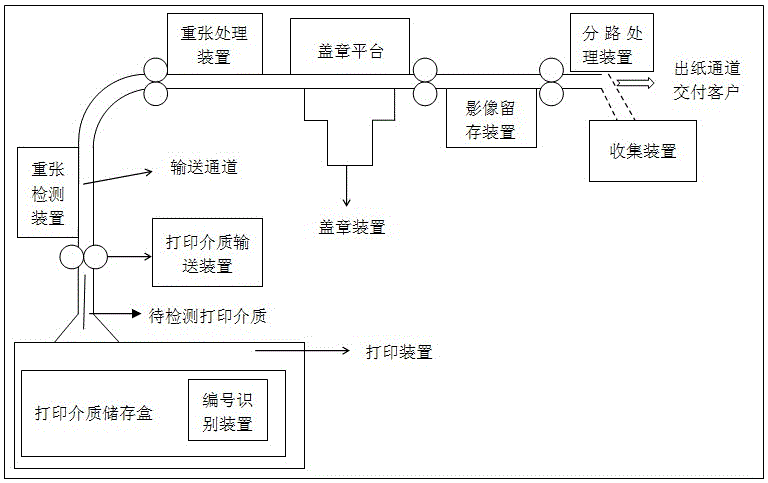

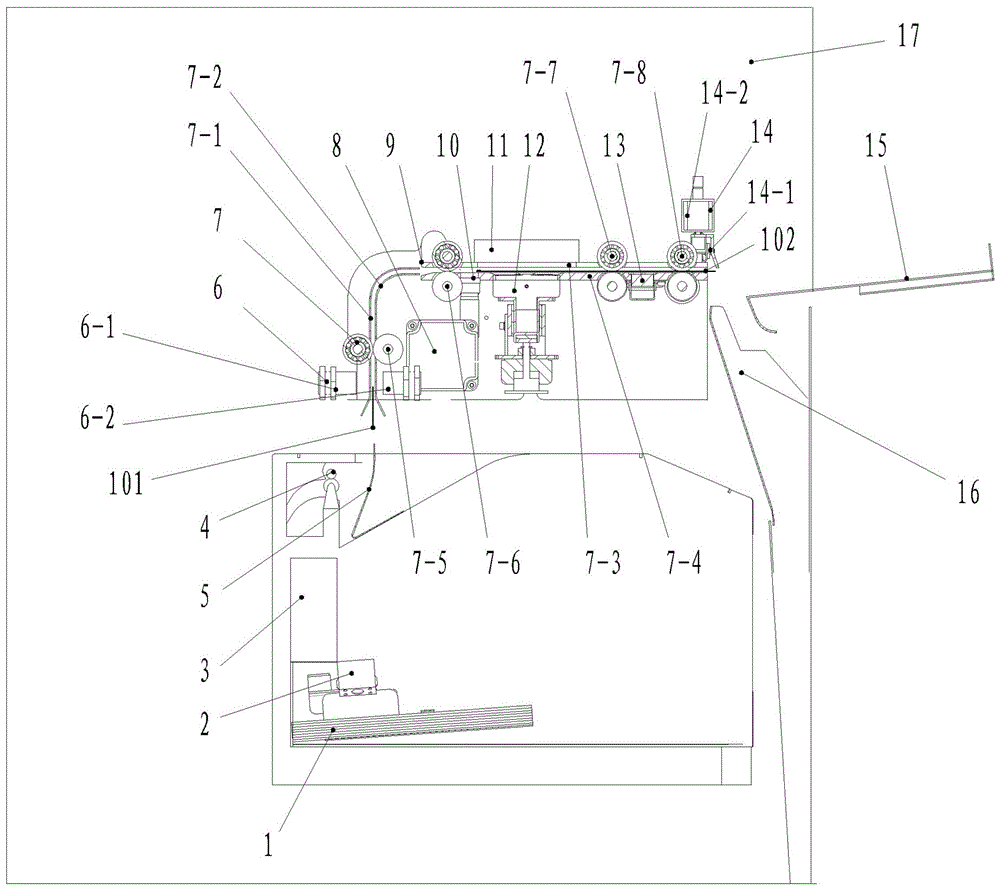

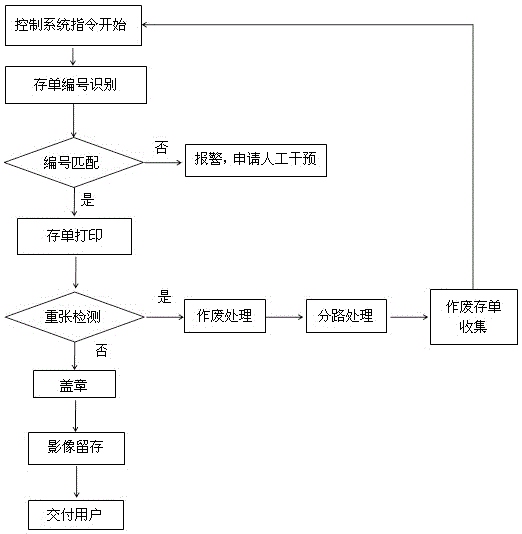

[0018] See attached figure 1 , the present invention provides a management and control method for printing and stamping integrated self-service equipment. Based on the self-service equipment with printing and stamping functions, it can detect multiple printing media and perform corresponding processing, including the following steps:

[0019] Step 1. Identify the number of the medium to be printed and match it with the data in the database of the self-service equipment control system. If the matching is successful, execute the printing operation, otherwise stop working and send an alarm signal. In this step, the identification of the printing medium number adopts OCR identification and / or two-dimensional code identification, and after the identification is completed, it is matched with the data in the database of the control system.

[0020] Step 2. Print the information on the designated area of the printing medium.

[0021] Step 3. Perform double-sheet detection on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com