Friction sliding energy-consuming and damping device of multi-span simply supported beam

A technology of shock absorption device and sliding device, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of reduced construction efficiency, excessively large gaps in prefabricated bridges, slow construction progress, etc., to prevent uneven tension, Increased safety and uniform tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

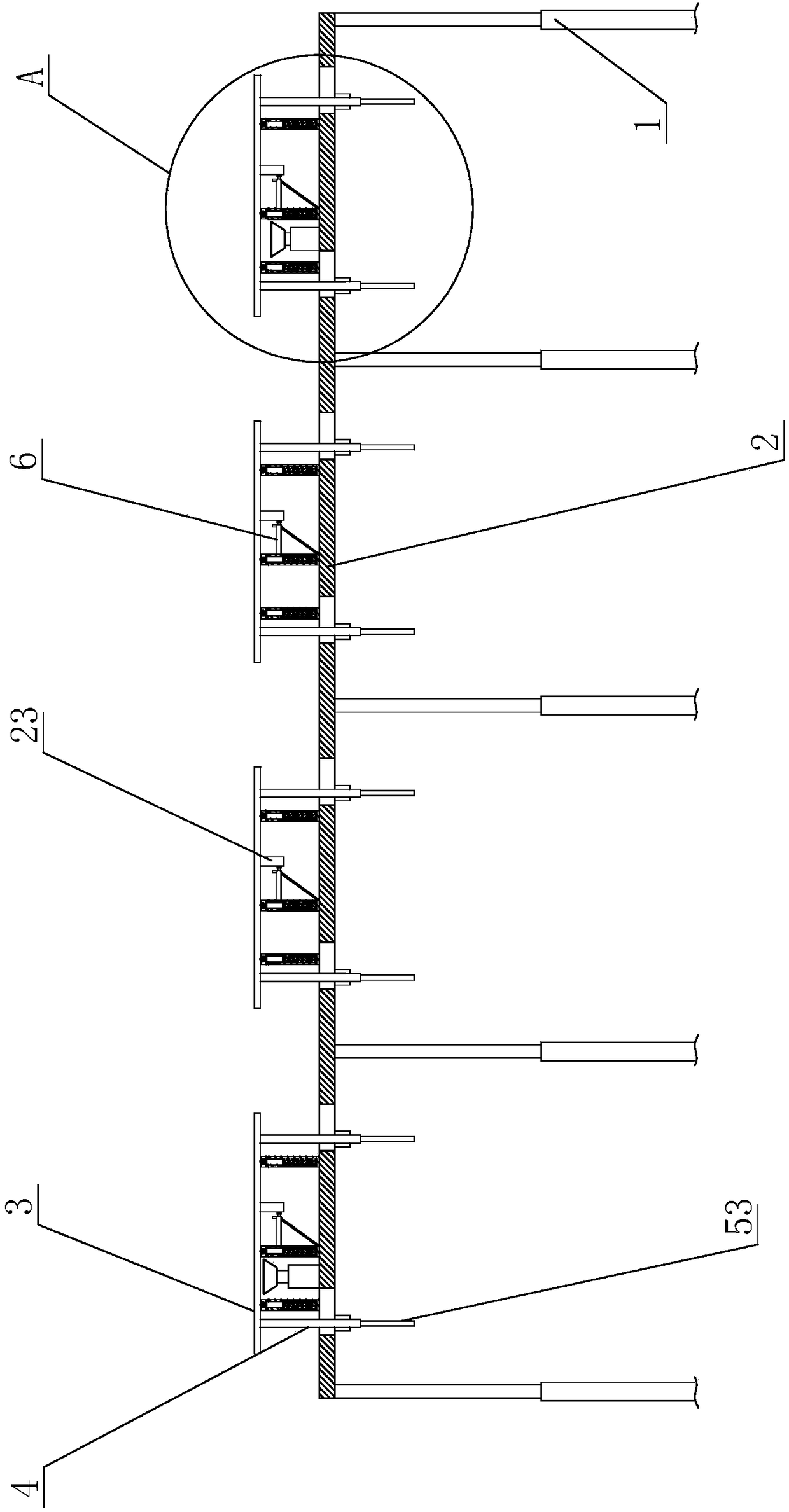

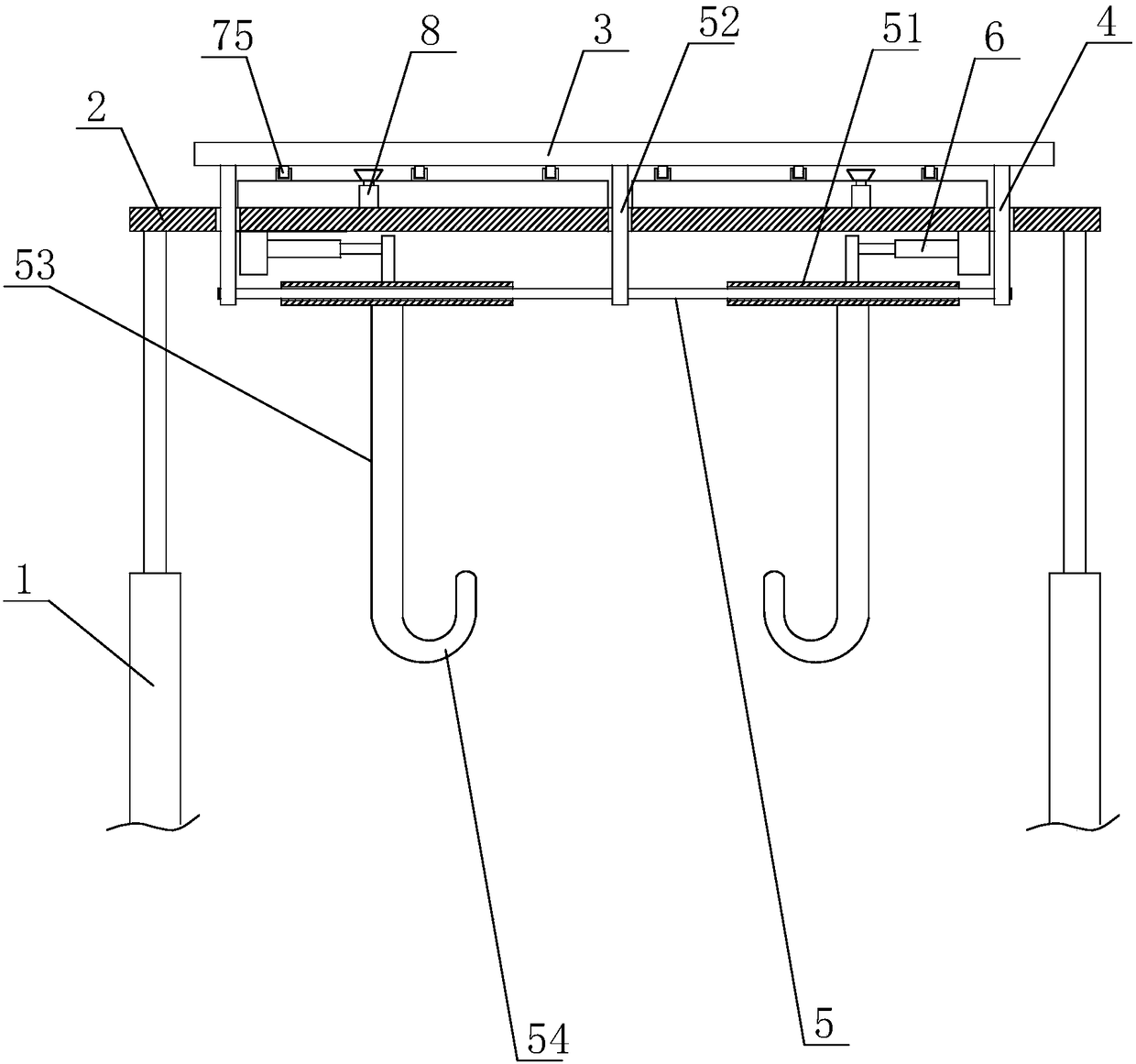

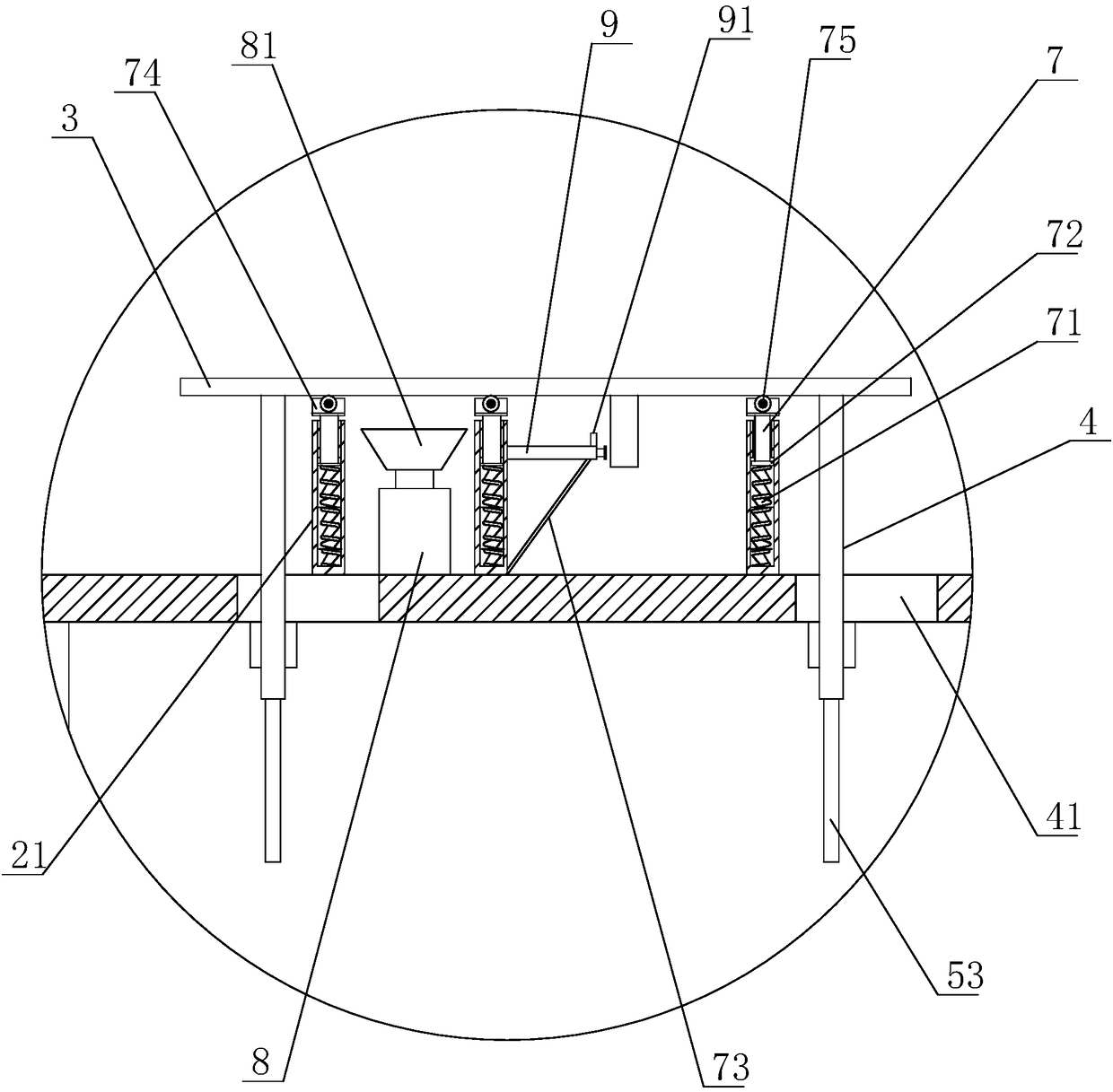

[0030] A multi-span simply supported beam frictional sliding energy dissipation damping device, including several first hydraulic cylinders 1 arranged vertically, a horizontal plate 2 is arranged at the top of the first hydraulic cylinders 1, and the first hydraulic cylinders 1 The quantity is 8-12, symmetrically distributed in the left and right ends of horizontal plate 2. Several groups of bridge sliding devices are arranged on the horizontal plate 2, and the bridge sliding device includes a top plate 3, the four corners of the top plate 3 are provided with first vertical bars 4, and the horizontal plate 2 is arranged to correspond to the first vertical bars 4. Adapt to the first chute 41, the bottom end of the first vertical rod 4 passes through the horizontal plate 2 through the first chute 41 and sets the cross bar 5, the top plate 3 is rectangular, and the short side of the top plate 3 is the same as the width of the prefabricated bridge Compatible, long side is made acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com