Method and system for tunneling extrahard rock by means of hydraulic fracturing technology and tunneling machine

A tunnel boring machine and hydraulic fracturing technology, which is applied to tunnels, earthwork drilling, mining equipment, etc., can solve the problems of time-consuming, cost-increasing, low-efficiency tunnel boring machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

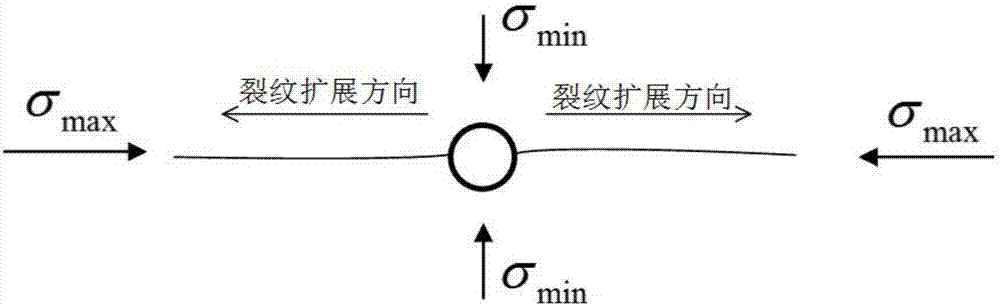

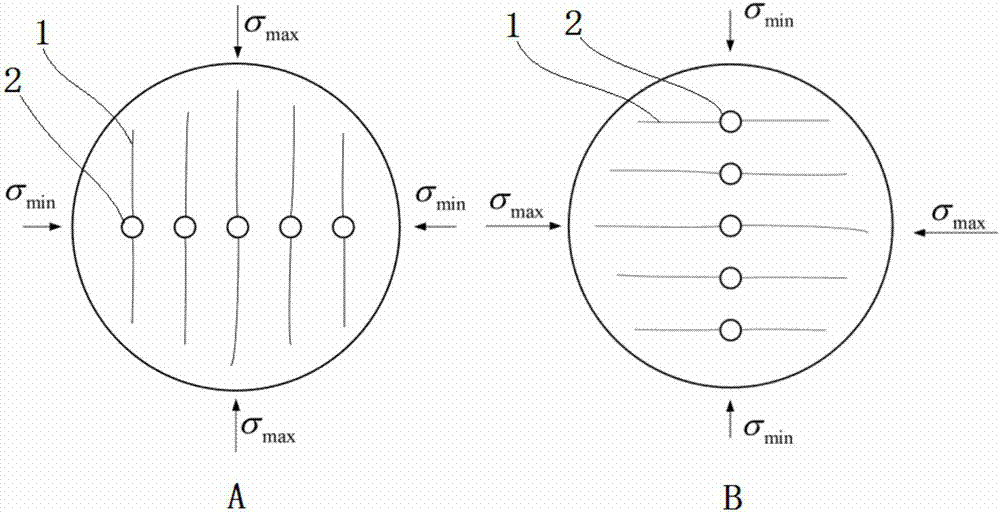

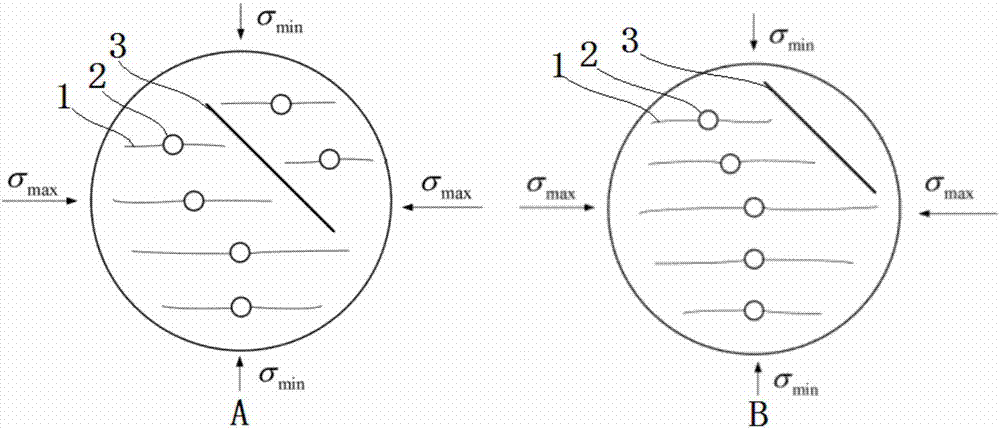

[0042]A method for assisting a tunnel boring machine in excavating extremely hard rock by using hydraulic fracturing technology, through hydraulic fracturing technology, cracks 1 are generated in the extremely hard and complete rock mass to reduce the integrity of the rock mass, including steps:

[0043] S1. Reserve holes at different positions on the cutter head surface, and set drill pipes in the holes;

[0044] S2. Design the drill hole 2 position and fracturing sequence of the face according to the formation conditions, which include stress conditions and structural surface conditions;

[0045] S3. The drill pipe extends out of the hole and drills vertically on the palm face until all drilling holes 2 are completed (the order of drilling is from top to bottom or from left to right). The depth and diameter of drilling 2 are determined according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com