A welding rod automatic production system

A technology for automatic production and welding electrodes, applied in welding equipment, welding media, welding/cutting media/materials, etc., it can solve the problems of many environmental protection treatment points, increase personnel costs, and high maintenance costs, and reduce equipment investment and maintenance costs. The effect of reducing the configuration of production personnel and the overall structure of the equipment is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

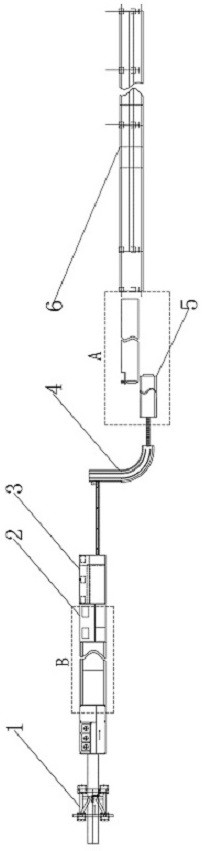

[0042] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0043] figure 1 A schematic structural diagram of an embodiment of the present invention is shown. This embodiment relates to an automatic welding rod production system for the production of welding rods. The welding rod automatic production system integrates the original segmented production as a whole to construct a The automatic production line can realize automatic production in all stages from the line entry stage to the electrode drying stage, reduce the investment of production equipment, avoid the temporary storage and turnover of materials between cutting and drawing, rotating and applying medicine, and reduce the configuration of production personnel. Reduce land space and improve production efficiency.

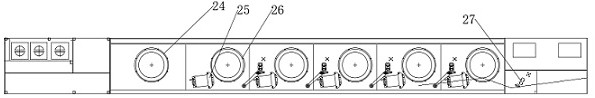

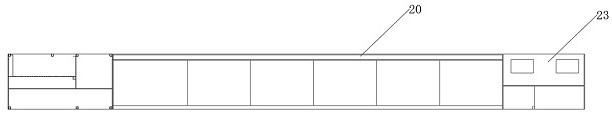

[0044] An automatic production system for welding electrodes, such as figure 1 , figure 2 and Image 6 As shown, it includes a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com