A Method for Digitized Angle Determination of Pipeline

A fixed angle and pipeline technology, applied in applications, household appliances, tubular objects, etc., can solve the problems of unguaranteed reproducibility and consistency, poor processing stability and consistency, repeated samples, etc., to avoid turnover and repetition work, shorten the production cycle, and facilitate batch production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

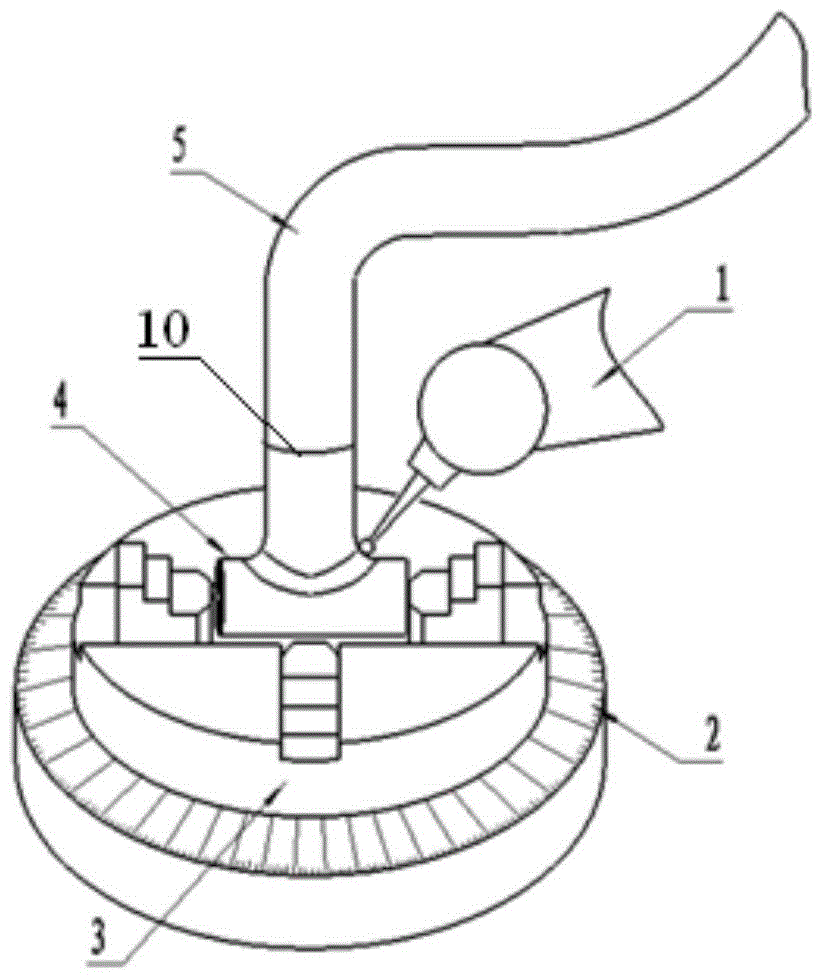

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] Assume that the conduit with the spatial angular joint is properly assembled and that the joint at the end of the pipe is a curved segment of the conduit.

[0041] 1) Use UG software to obtain auxiliary model space data:

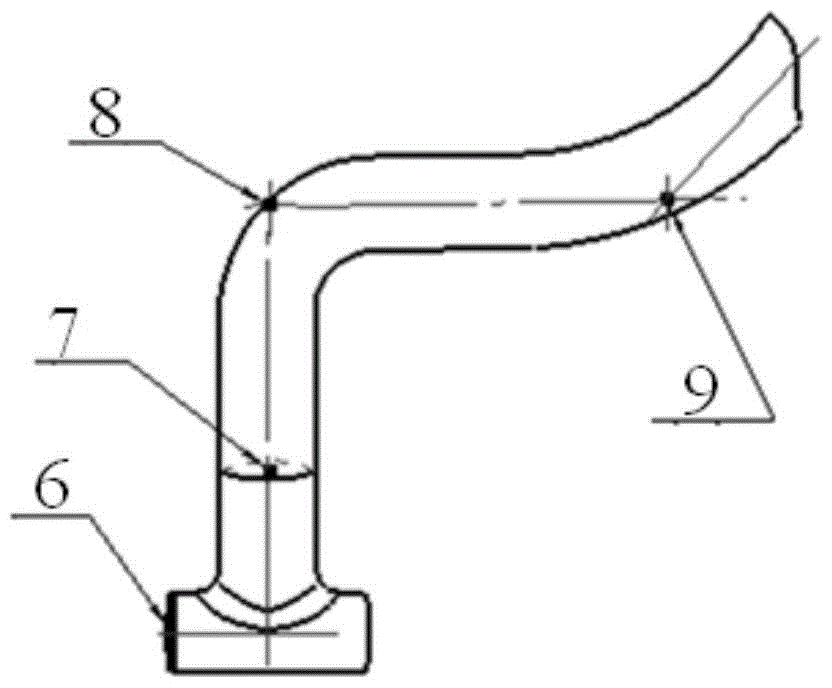

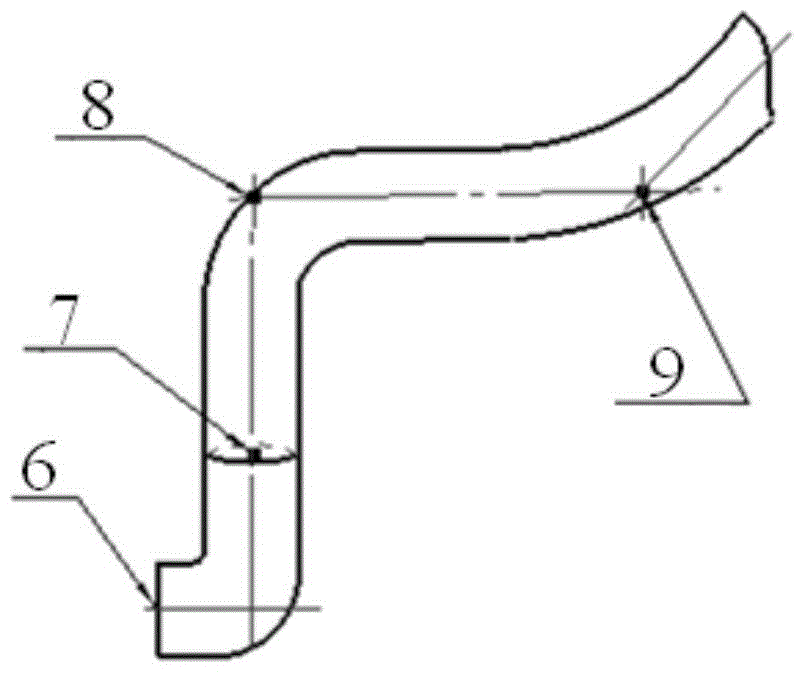

[0042] see figure 2 with image 3 , the intersection coordinates of the centerlines of each section of the pipe assembly to be processed can be captured from the UG design drawing, including the intersection coordinates at the corner of the joint and the coordinates of the center point of the joint end face. The coordinates of the intersection point 8 of the two axes of the pipe and the intersection point 9 of the two axes of the second pipe.

[0043] The principle of capturing point coordinates: Since two intersecting straight lines can determine a plane, and the purpose of capturing points this time is to determine the spatial angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com