Plating device for AZO+SiN laminated protective film of solar cell

A solar cell and protective film technology, which is applied in the direction of plating, coating, and circuit of superimposed layers, can solve the problems of expensive penetrating silver paste and increasing the manufacturing cost of solar cells, so as to improve the utilization rate of sunlight and avoid The turnover of silicon wafer loading and unloading, the effect of reducing equipment cost and labor cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

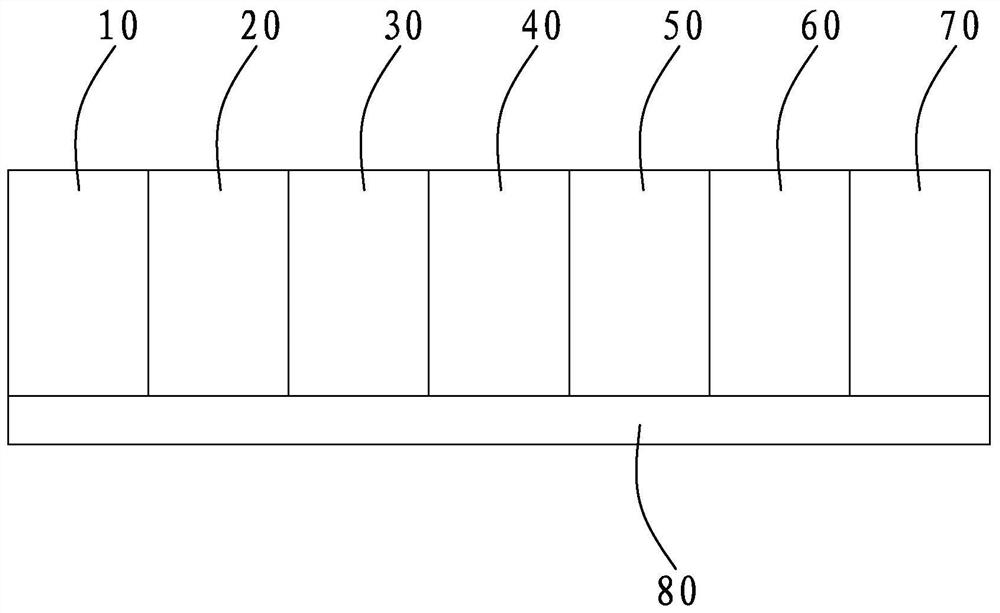

[0029] refer to figure 1 , the present invention provides a solar cell AZO+SiN laminated protective film coating equipment, including AZO coating area 30 and SiN coating area 50 sequentially arranged in the same coating chamber, between AZO coating area 30 and SiN coating area 50 There is also a transition chamber 40 between them; the feeding end of the AZO coating area 30 is provided with a loading chamber 20, and the discharging end of the SiN coating area 50 is provided with an unloading chamber 60; the feeding end of the loading chamber 20 is provided with a silicon wafer automatic feeding Mechanism 10, the discharge end of the unloading cavity 60 is provided with a silicon wafer automatic unloading mechanism 70; a carrier plate rotary mechanism 80 is also provided between the loading mechanism 10 and the unloading mechanism 70 at both ends of the plating equipment; The feeding mechanism 10, the loading chamber 20, the AZO coating area 30, the transition chamber 40, the Si...

Embodiment 2

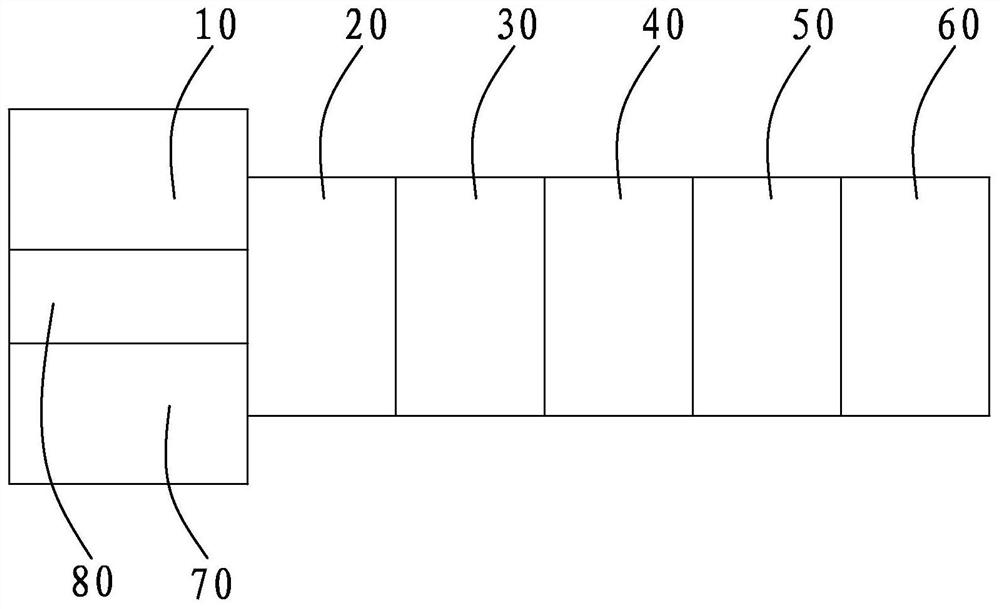

[0036] refer to figure 2 , the difference between this embodiment 2 and embodiment 1 is that the loading mechanism 10 and the unloading mechanism 70 are arranged at the same end of the plating equipment, and a carrier plate is provided between the loading mechanism 10 and the unloading mechanism 70. Institution80.

Embodiment 3

[0038] The present invention also provides a solar cell having the AZO+SiN laminated anti-reflection protective film prepared based on the above-mentioned embodiment 1 or 2.

[0039]The solar cell of the present embodiment 3 adopts AZO+SiN lamination to replace the traditional SiN layer on the surface of the passivation layer, which has the same anti-reflection and protective effect compared with the traditional SiN layer; because the doped amorphous silicon film has AZO is an aluminum-doped zinc oxide (ZnO) transparent conductive film, which has good electrical conductivity and light transmission. After the introduction of AZO, the thickness of doped amorphous silicon can be reduced. At the same time of conductivity, more light can enter the bulk silicon, thereby improving the utilization rate of sunlight and increasing the power generation; on the other hand, AZO has good conductivity and can form a good ohmic contact with silver or other metals , so that the contact resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com