Patents

Literature

499 results about "Solar cell fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

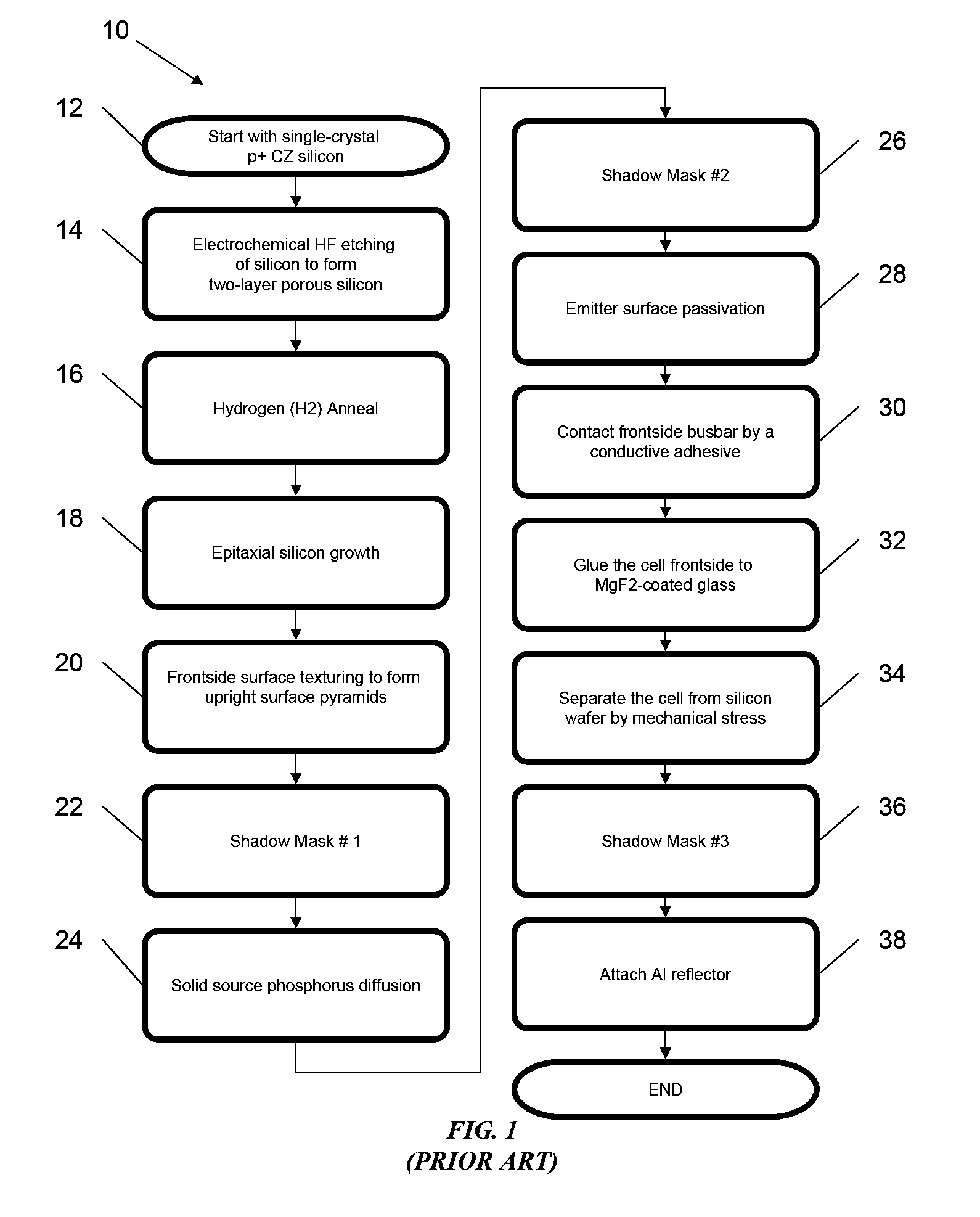

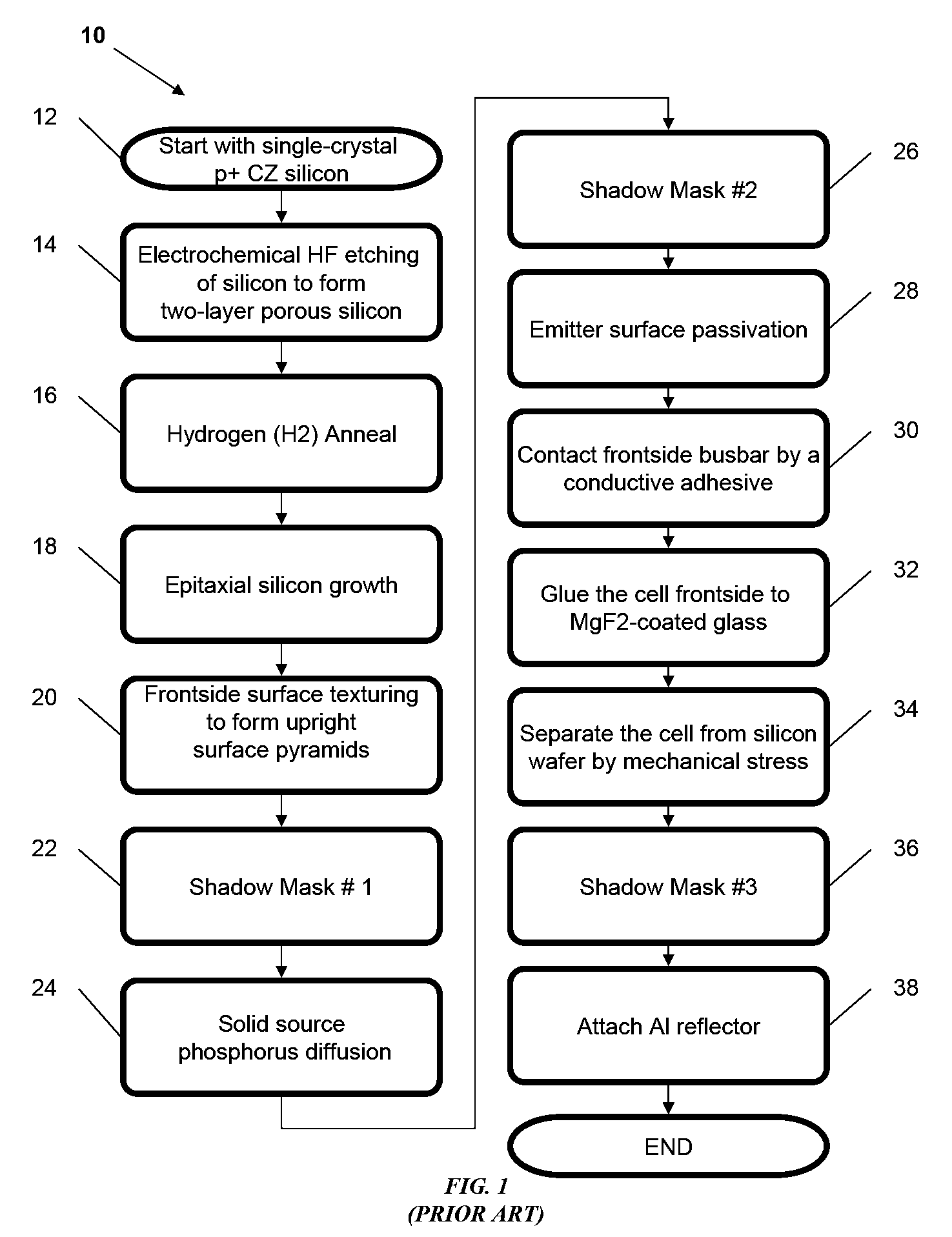

FABRICATION OF SOLAR CELLS The first practical photovoltaic cell was developed in 1954 at Bell Laboratories .They used a diffused silicon p–n junction that reached 6% efficiency, compared to the selenium cells. Most practical solar cells are silicon based, because it is cheap and abundant material.

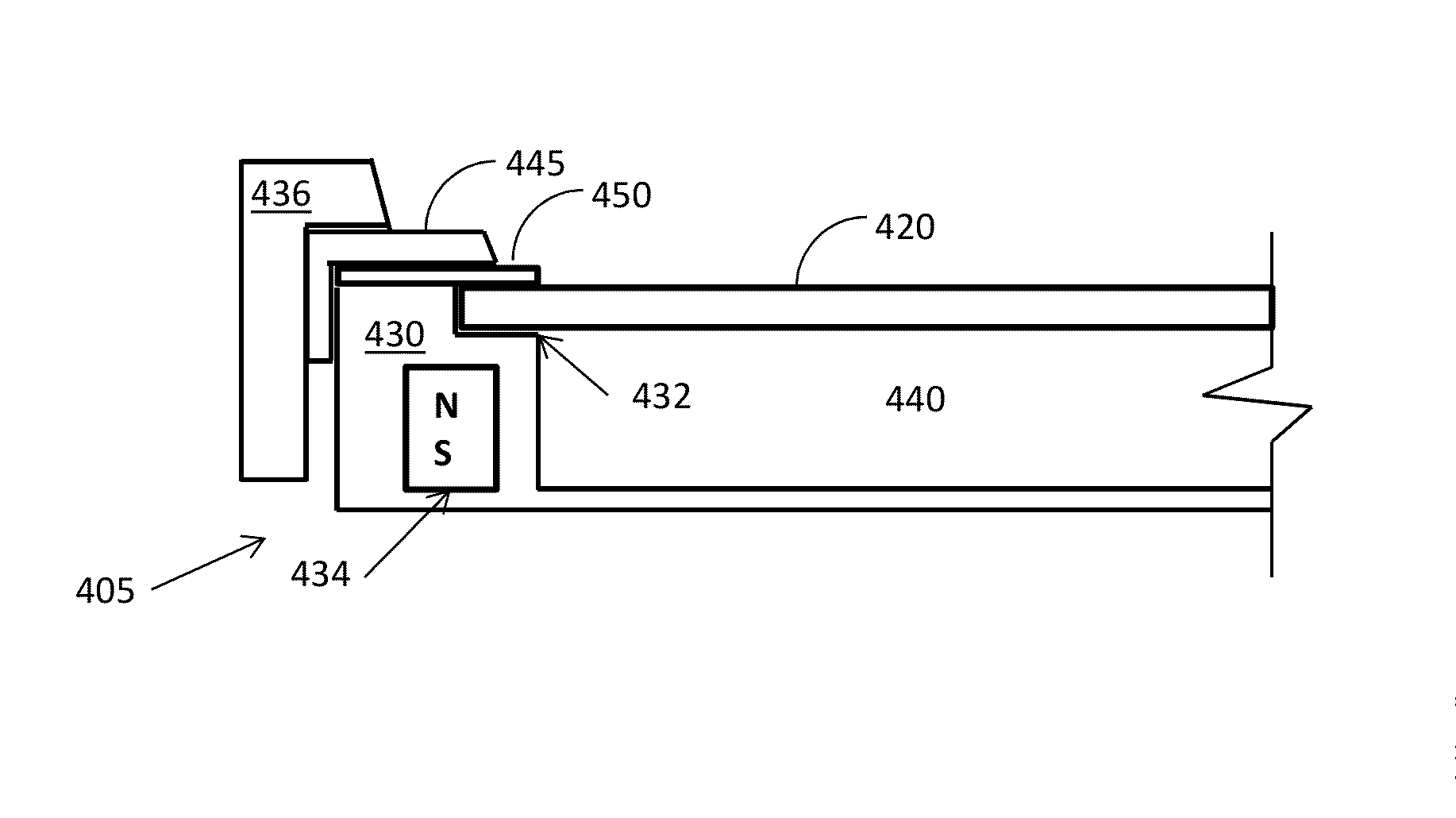

Dual-mask arrangement for solar cell fabrication

ActiveUS20130276978A1Easy and fast unloadingAvoid depositionLiquid surface applicatorsVacuum evaporation coatingSolar cell fabricationSolar energy

An arrangement for supporting substrates during processing, having a wafer carrier with a susceptor for supporting the substrate and confining the substrate to predetermined position. An inner mask is configured for placing on top of the substrate, the inner mask having an opening pattern to mask unprocessed parts of the substrate, but expose remaining parts of the substrate for processing. An outer mask is configured for placing on top of the inner mask, the outer mask having an opening that exposes the part of the inner mask having the opening pattern, but cover the periphery of the inner mask.

Owner:INTEVAC

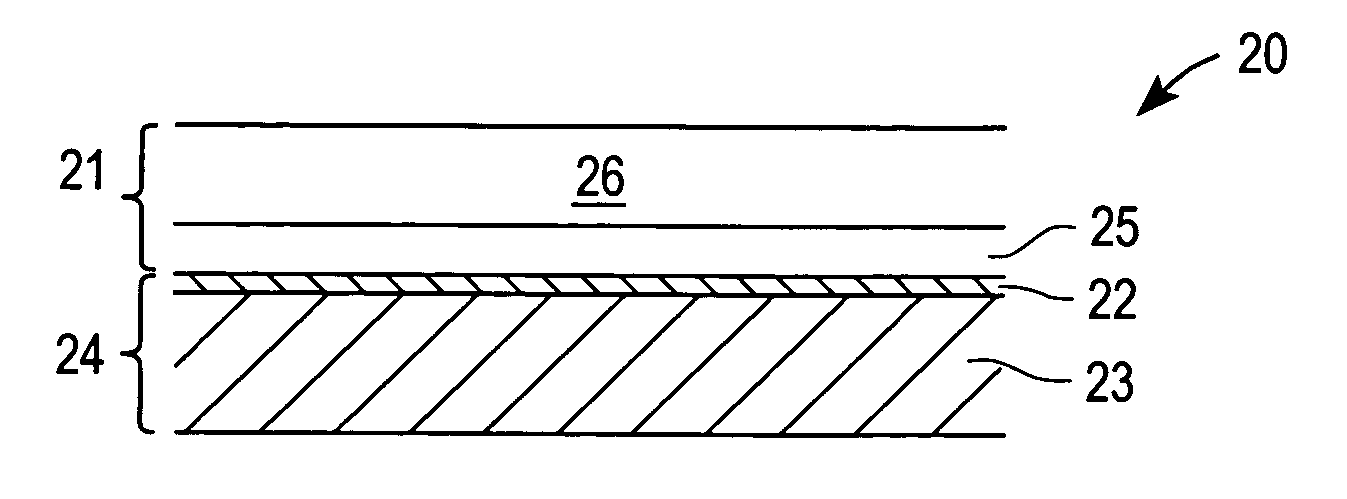

Use of doped silicon dioxide in the fabrication of solar cells

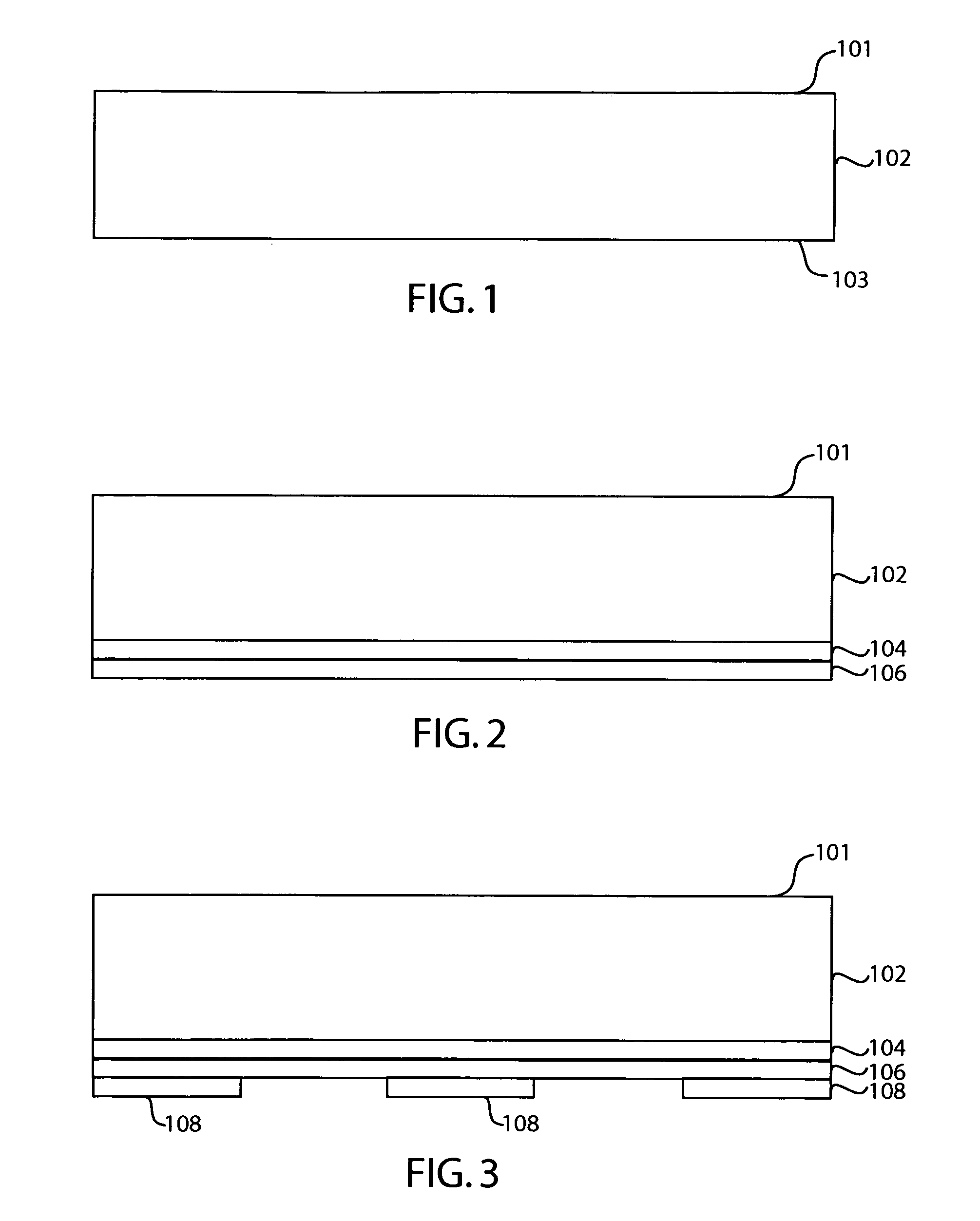

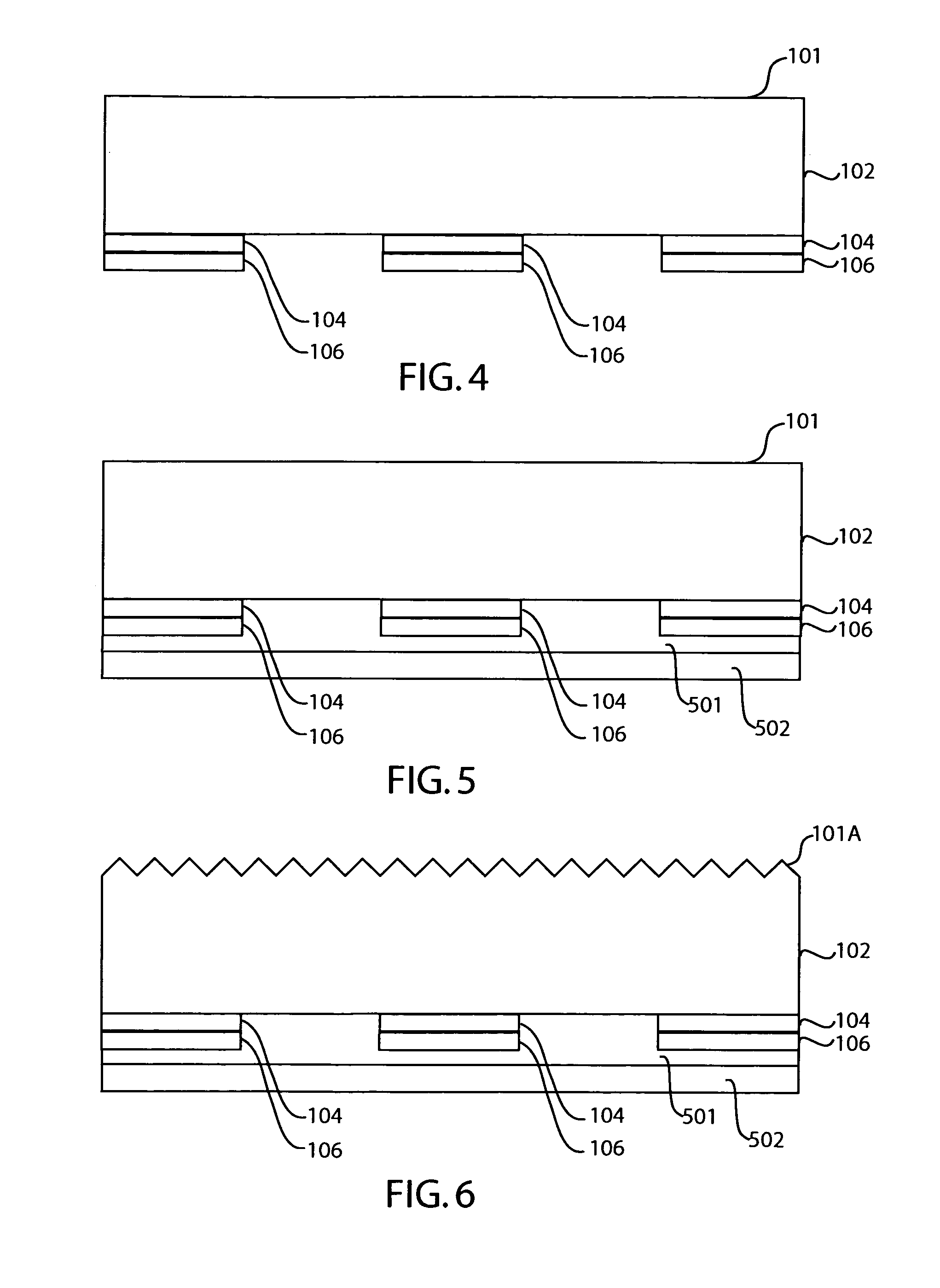

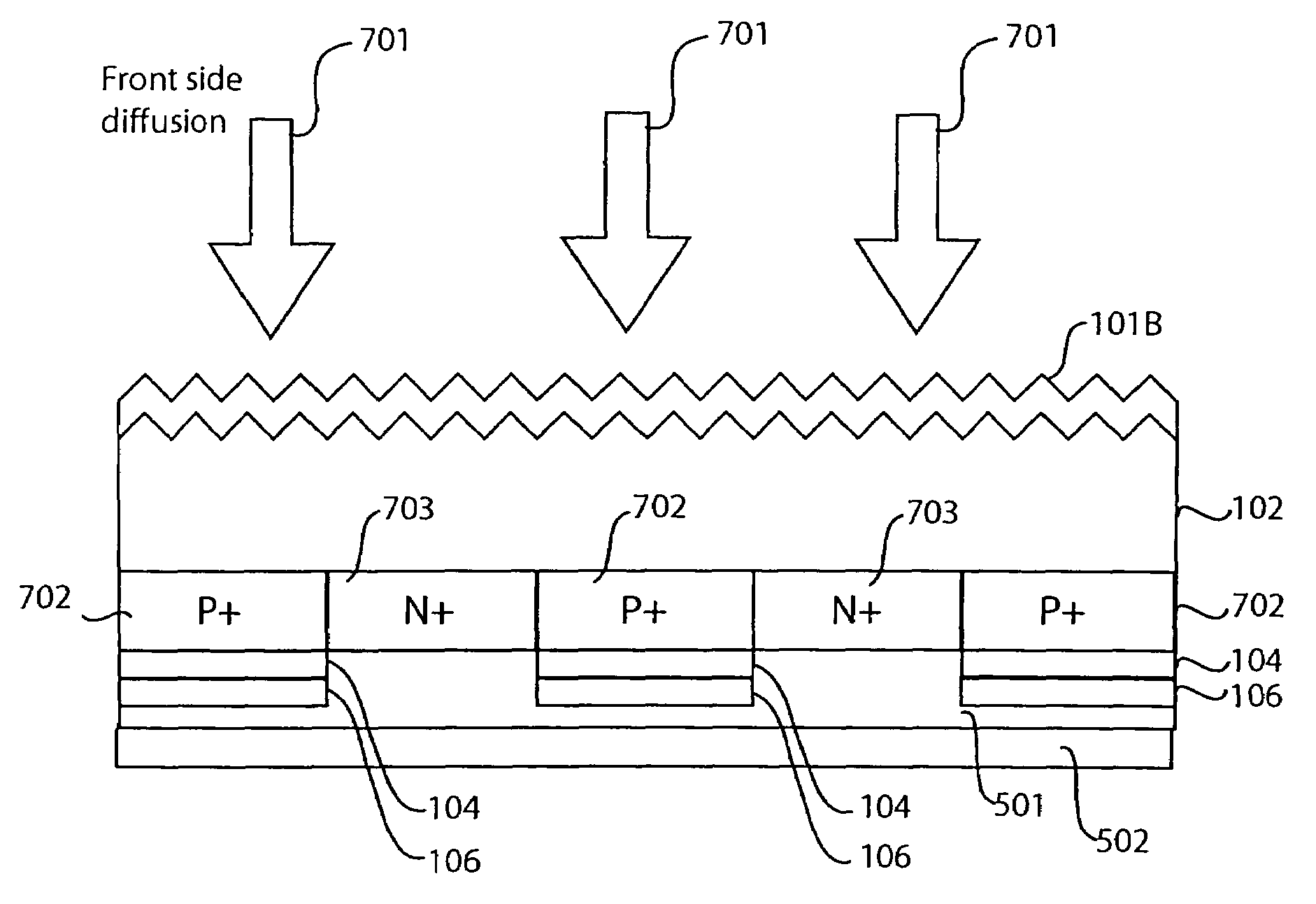

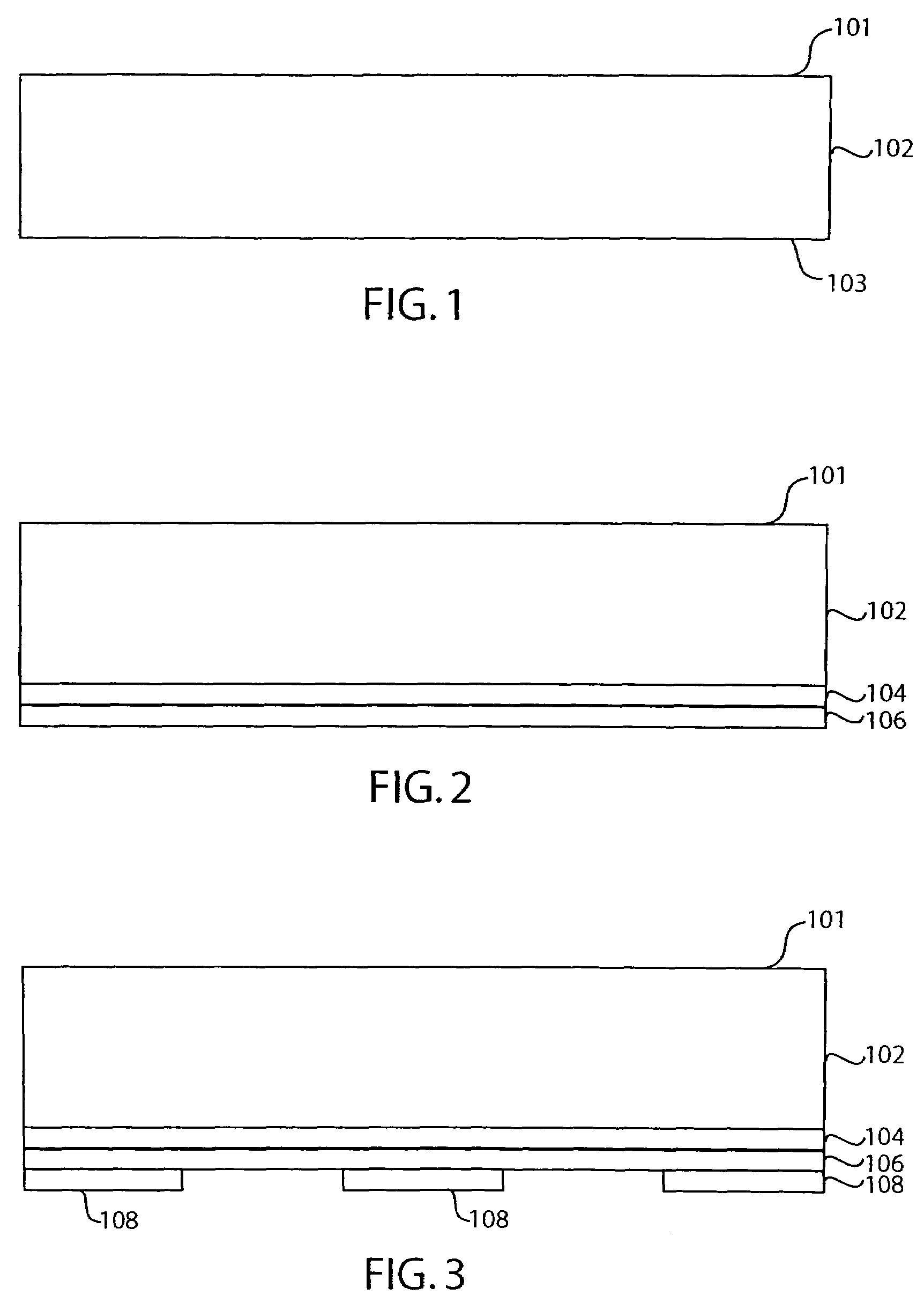

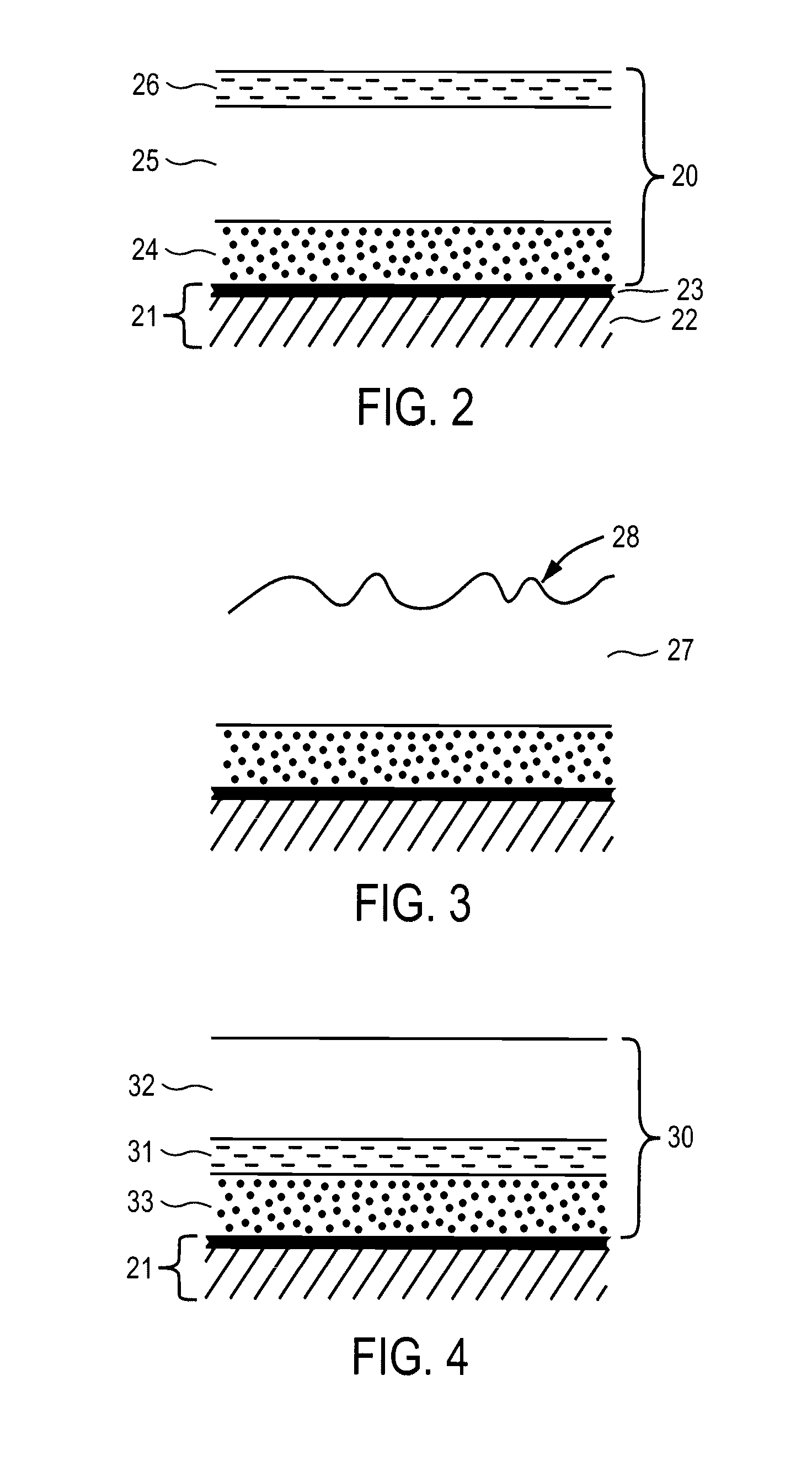

In one embodiment, a method of forming doped regions in a substrate of a back side contact solar cell includes the steps of depositing a first doped oxide layer on a back side of a substrate, depositing a first undoped oxide layer over the first doped oxide layer, diffusing a first dopant from the first doped oxide layer into the substrate to form a first doped region in the substrate, and diffusing a second dopant into the substrate by way of a front side of the substrate, wherein the diffusion of the first dopant and the second dopant into the substrate are performed in-situ. The method may further include the steps of patterning the first doped and undoped oxide layers to expose portions of the back side of the substrate and depositing a second doped and undoped oxide layers on the back side of the substrate.

Owner:MAXEON SOLAR PTE LTD +1

Use of doped silicon dioxide in the fabrication of solar cells

In one embodiment, a method of forming doped regions in a substrate of a back side contact solar cell includes the steps of depositing a first doped oxide layer on a back side of a substrate, depositing a first undoped oxide layer over the first doped oxide layer, diffusing a first dopant from the first doped oxide layer into the substrate to form a first doped region in the substrate, and diffusing a second dopant into the substrate by way of a front side of the substrate, wherein the diffusion of the first dopant and the second dopant into the substrate are performed in-situ. The method may further include the steps of patterning the first doped and undoped oxide layers to expose portions of the back side of the substrate and depositing a second doped and undoped oxide layers on the back side of the substrate.

Owner:MAXEON SOLAR PTE LTD

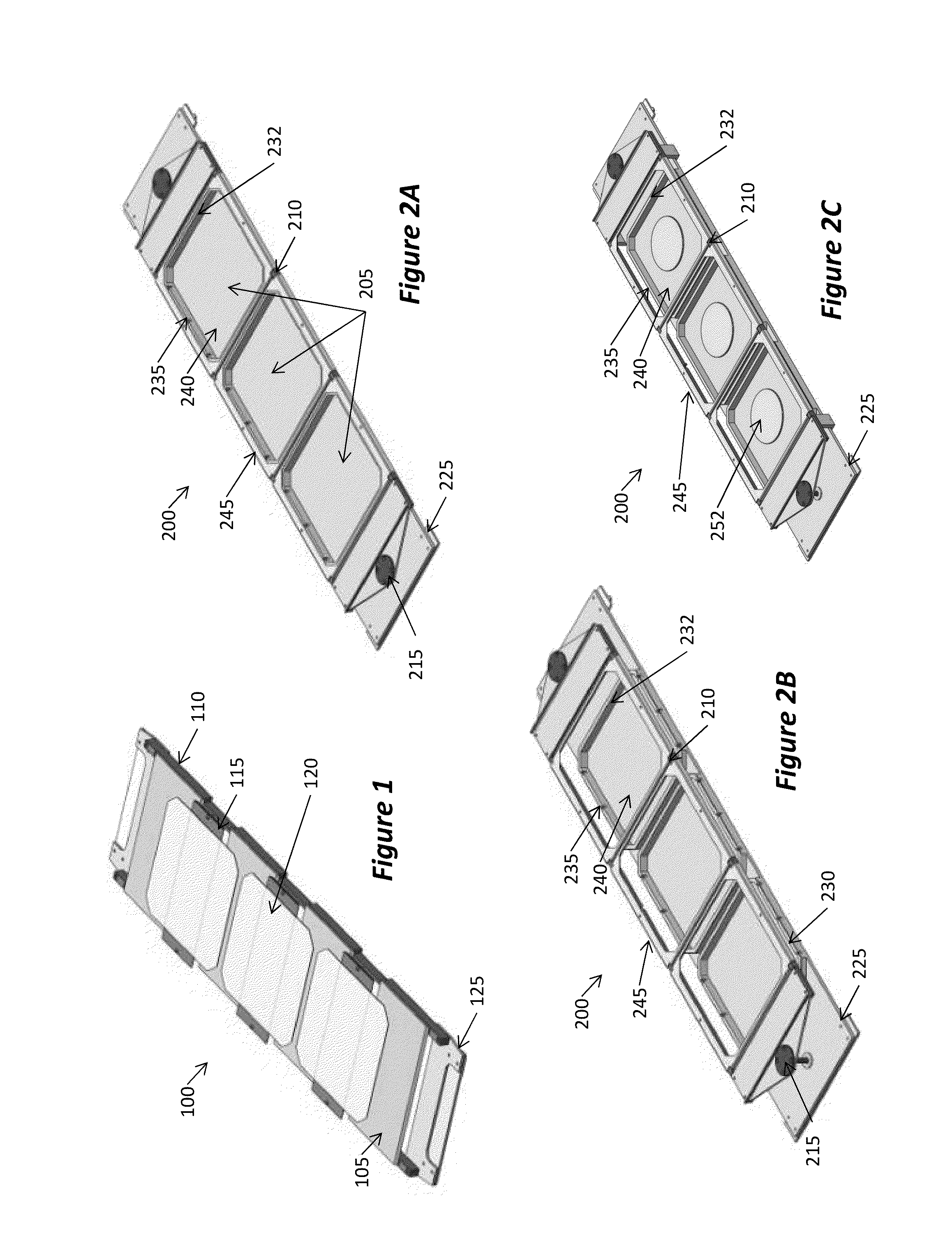

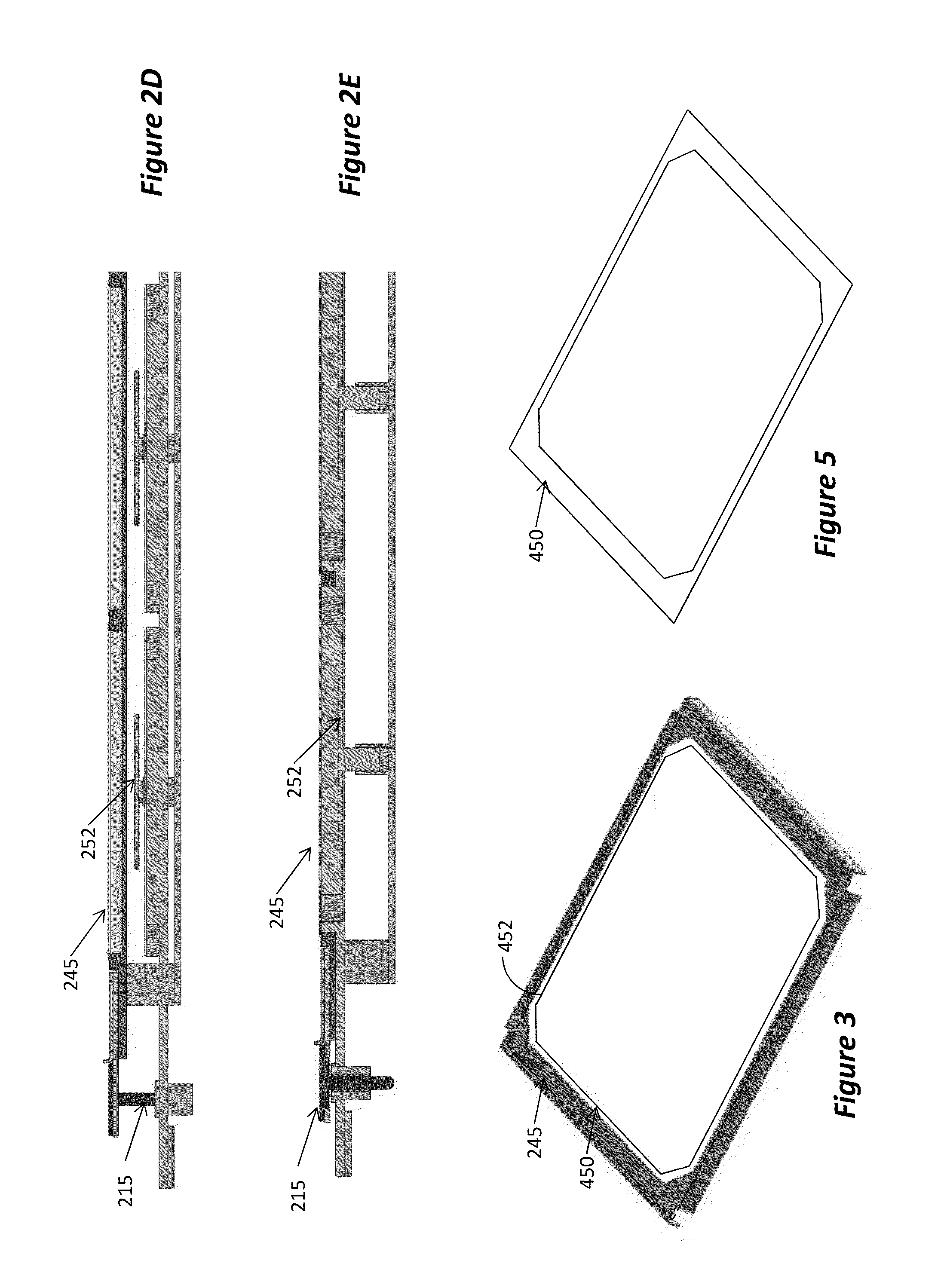

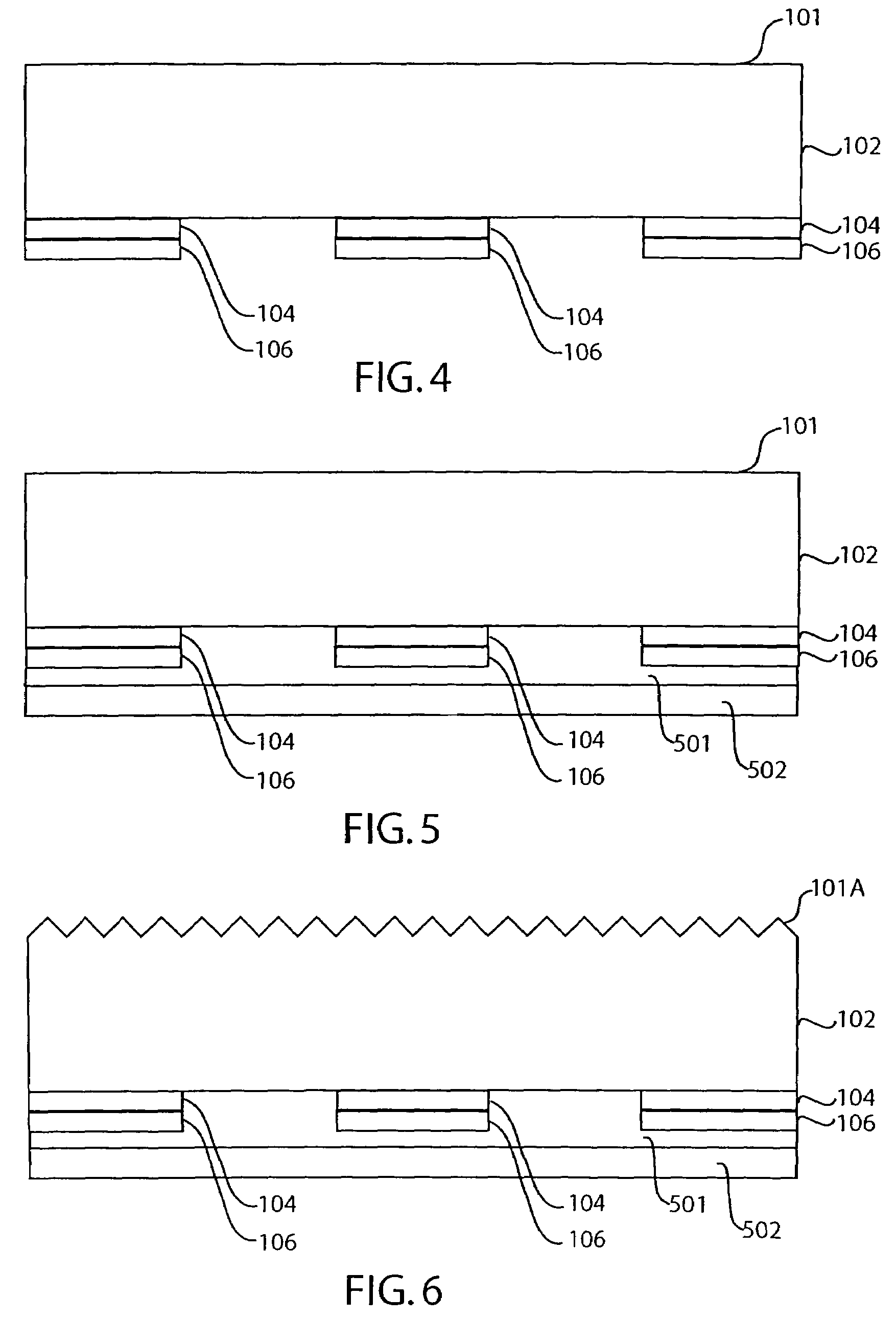

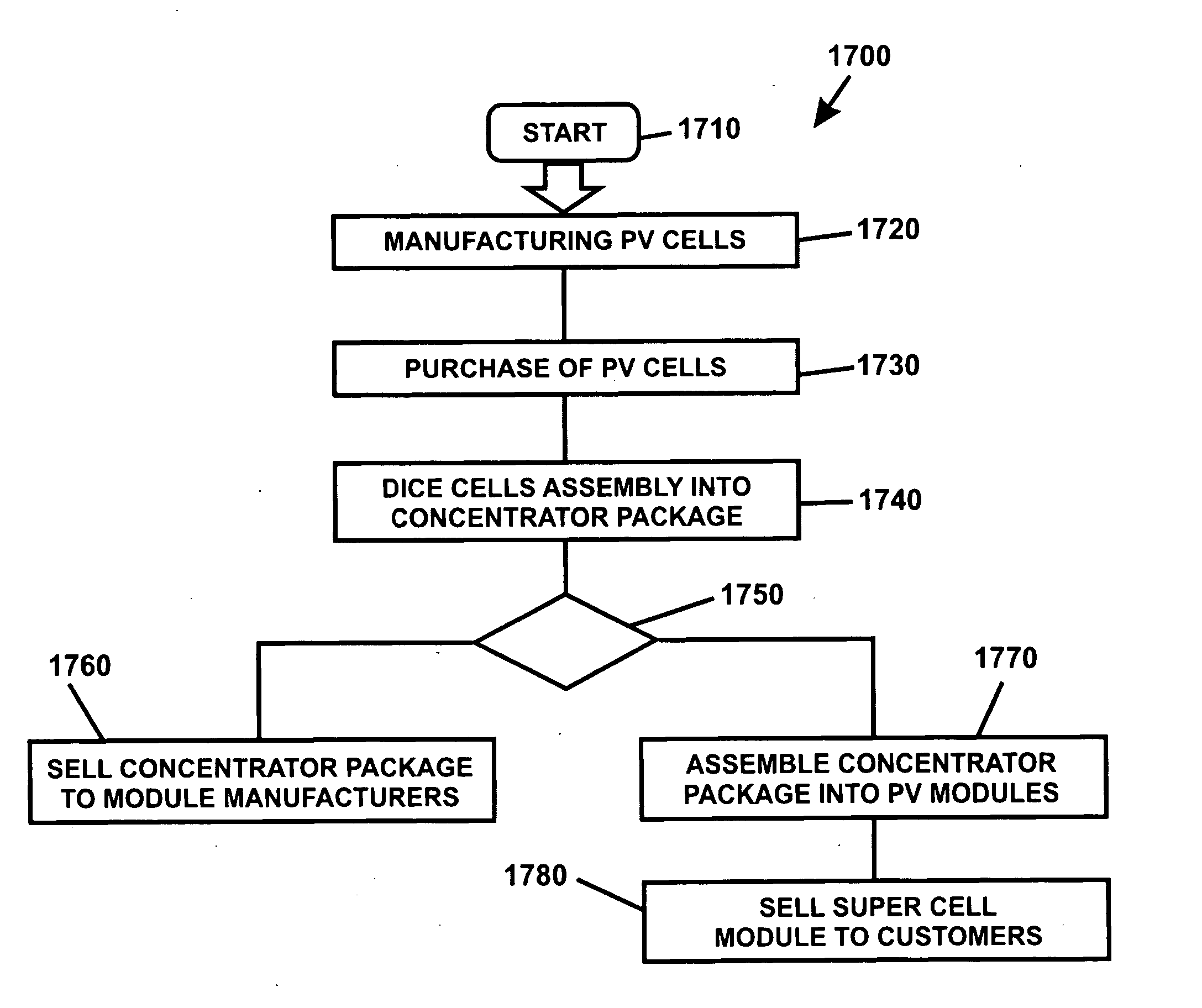

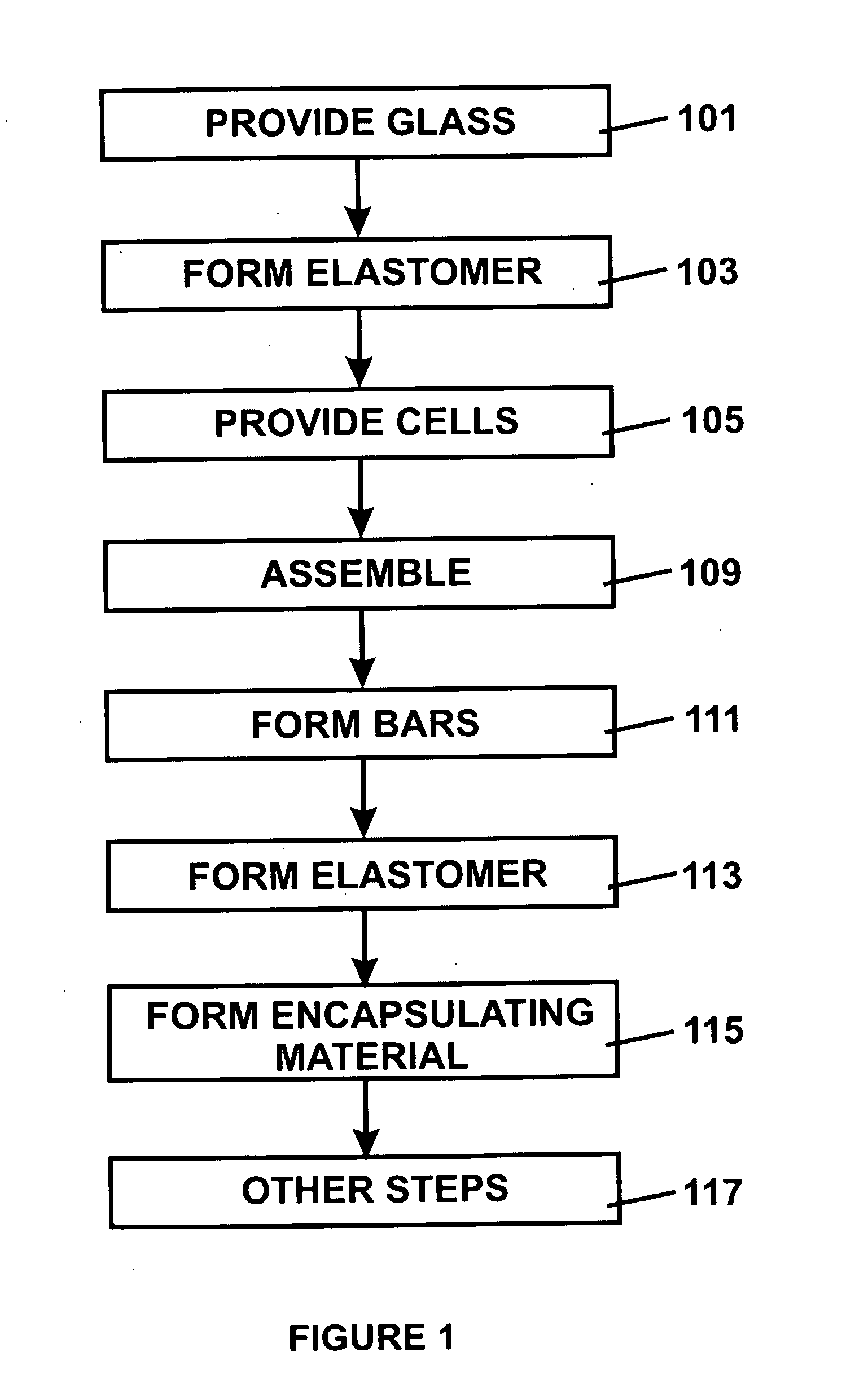

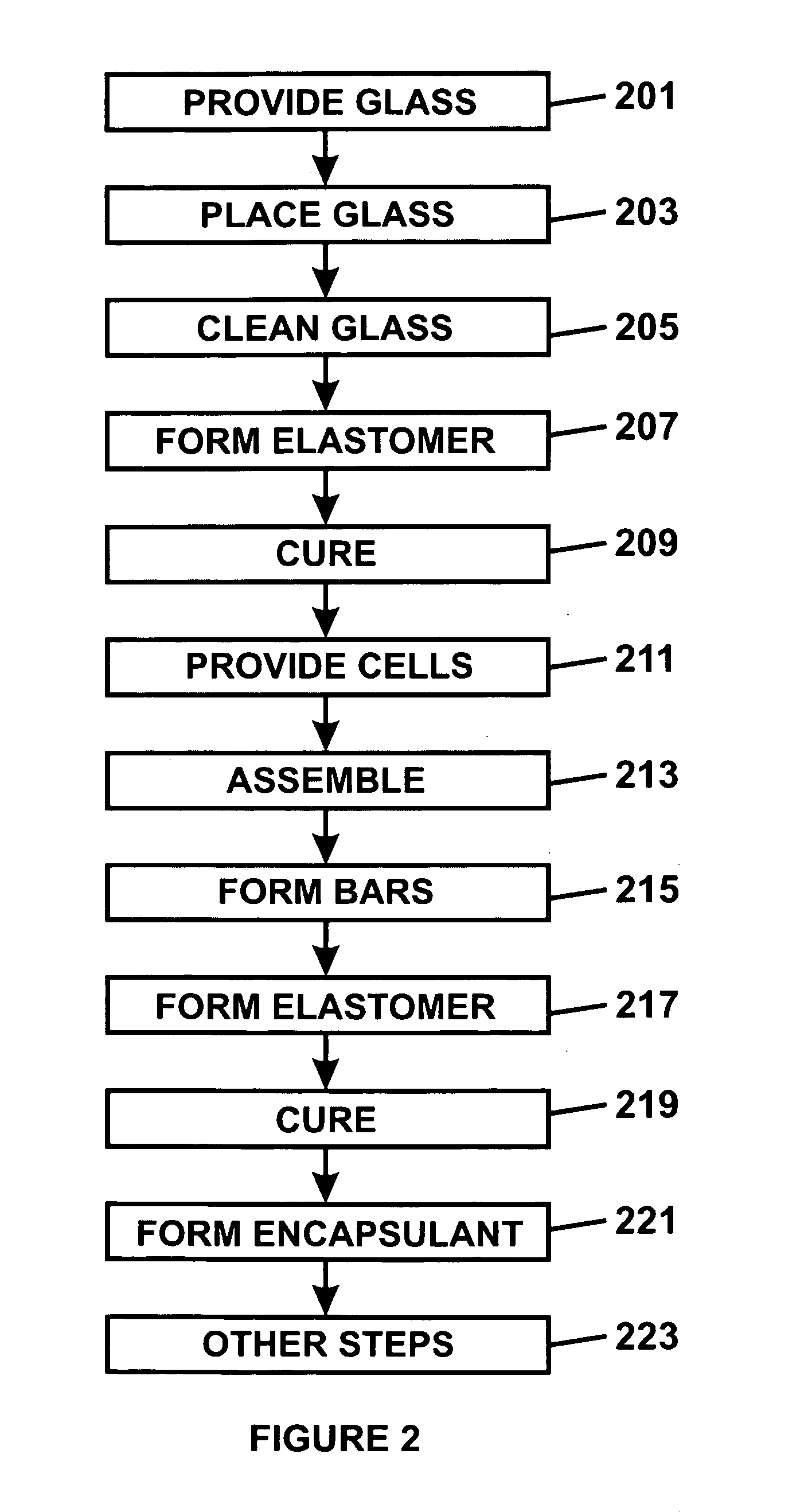

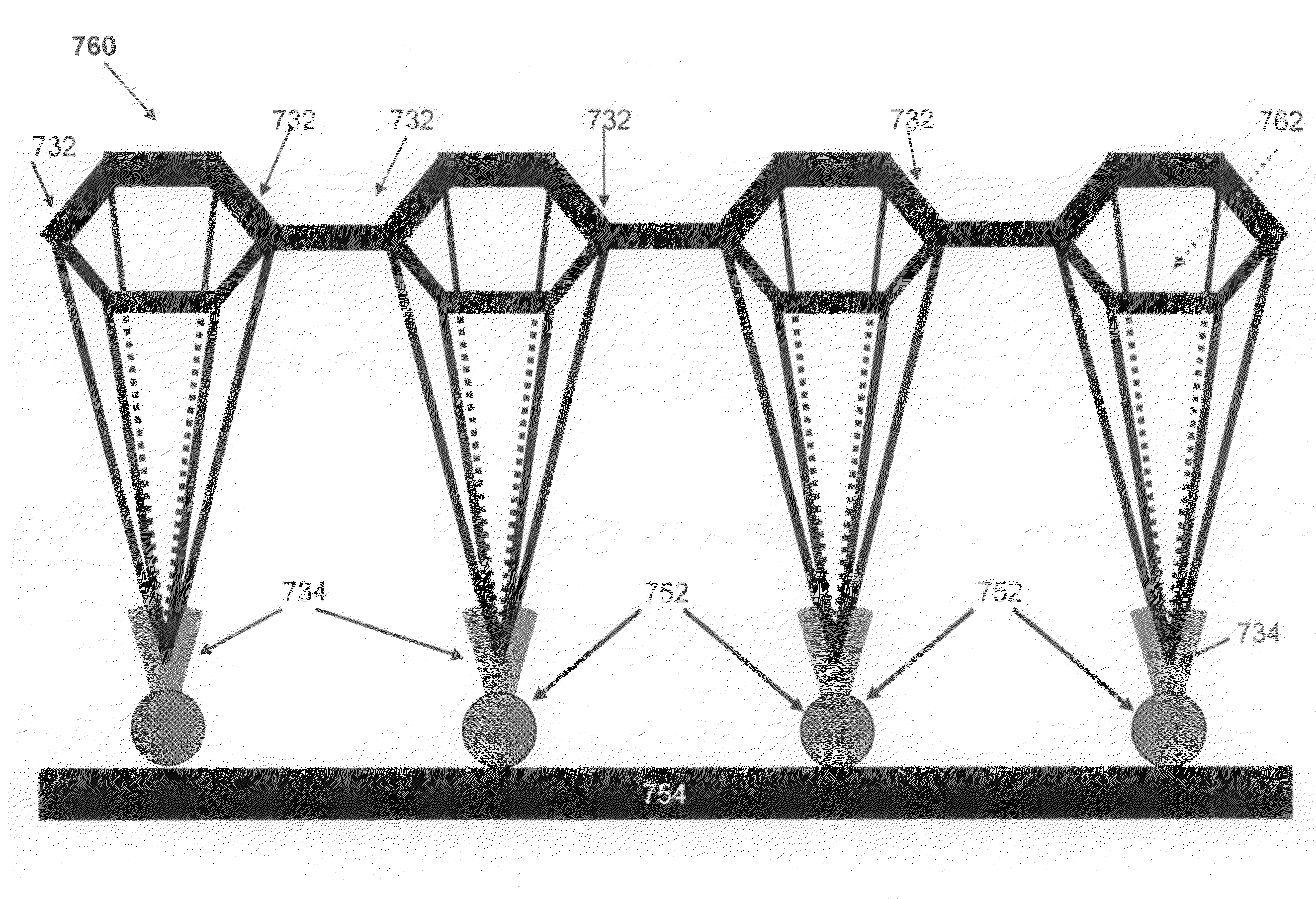

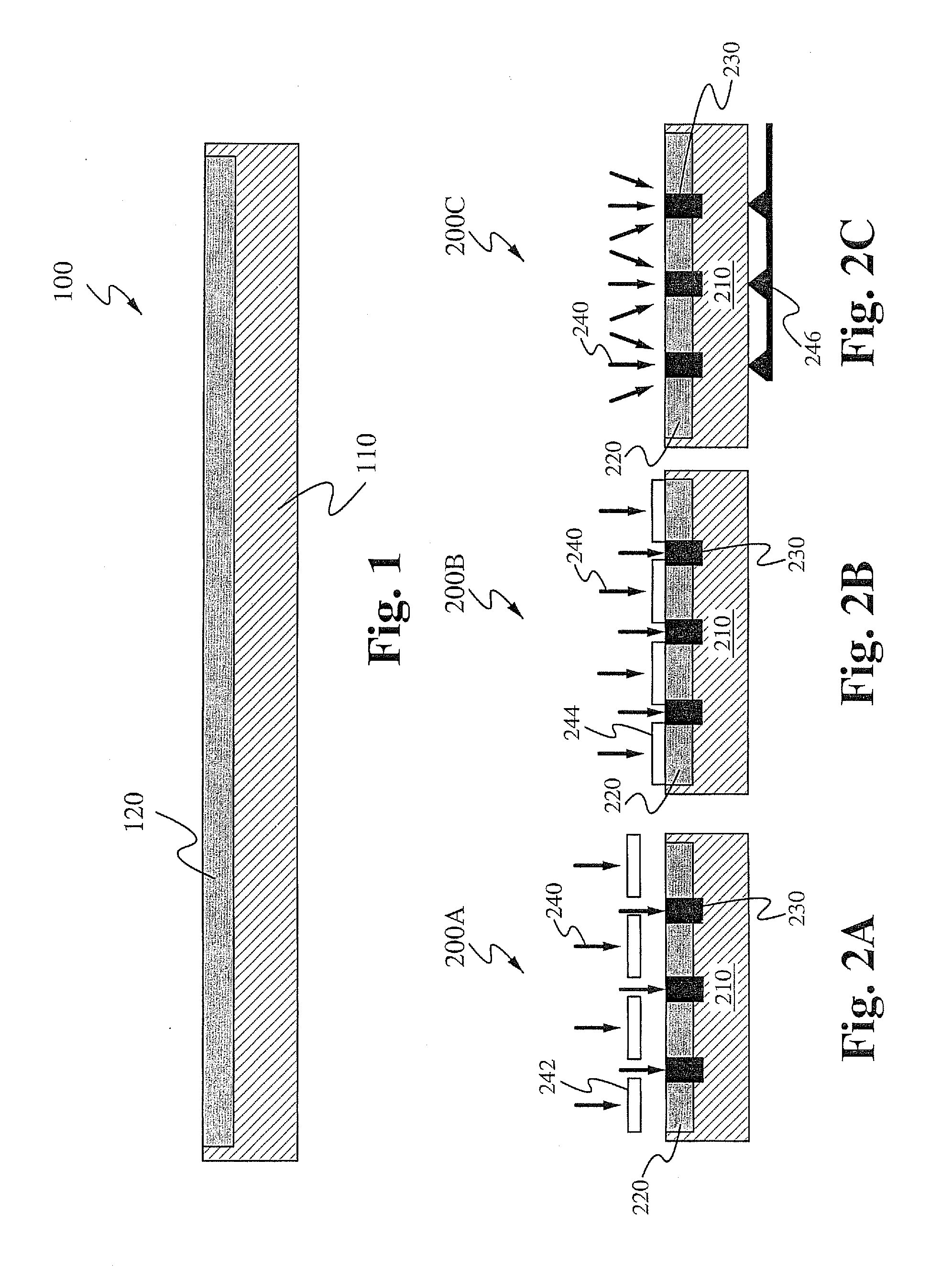

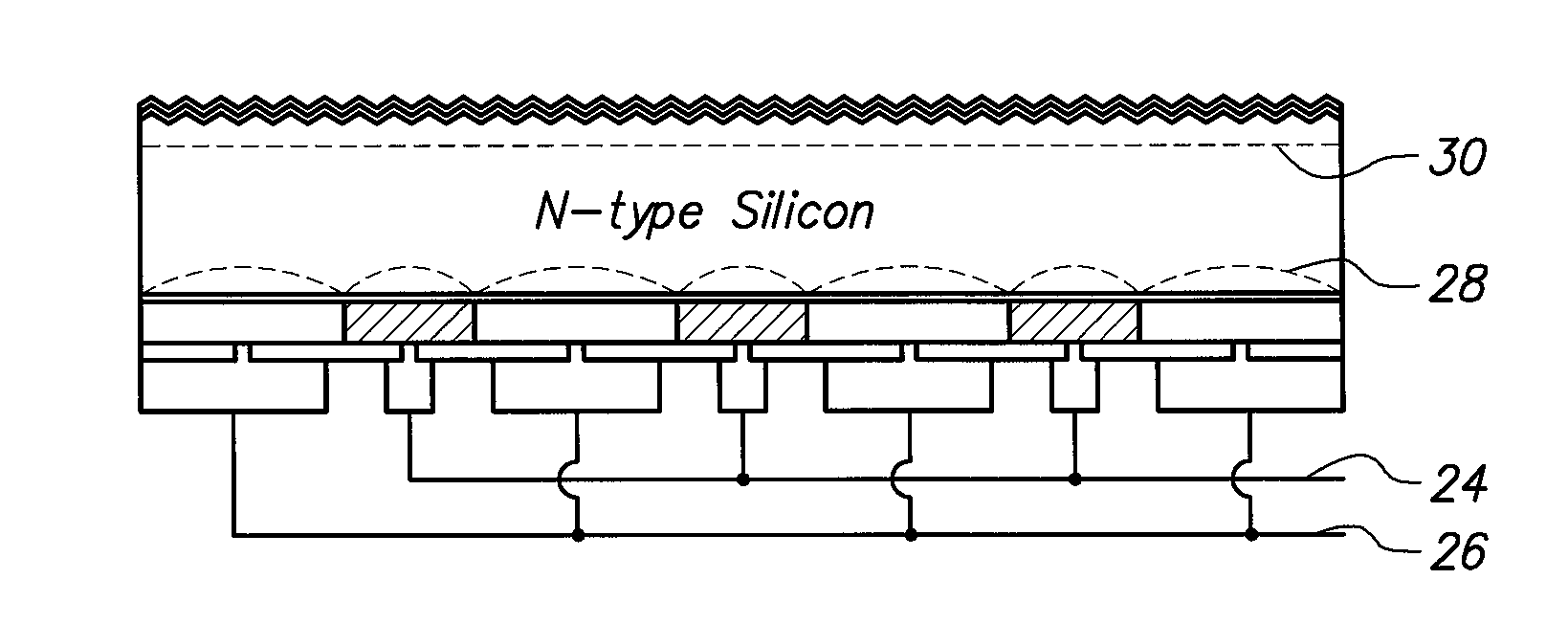

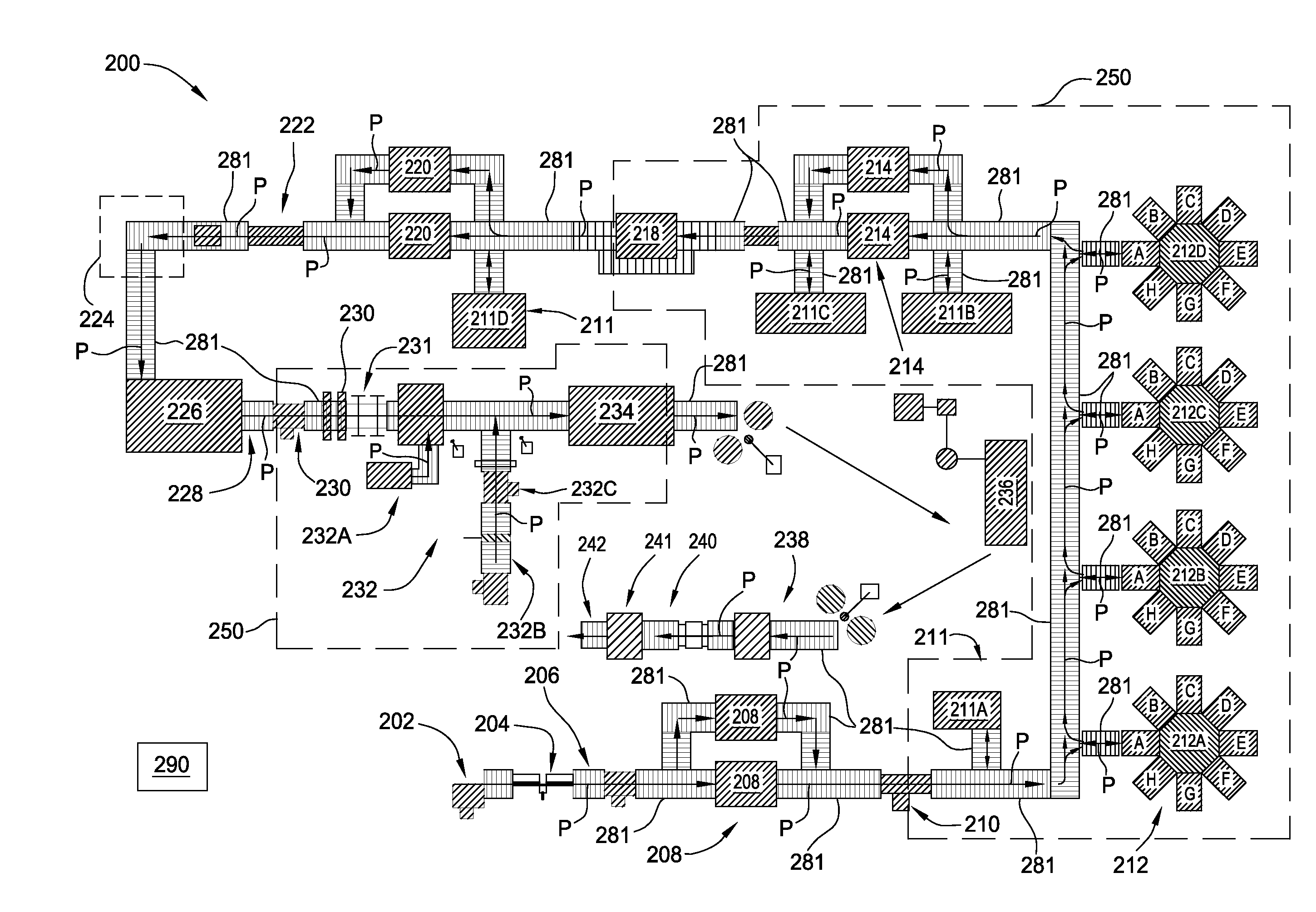

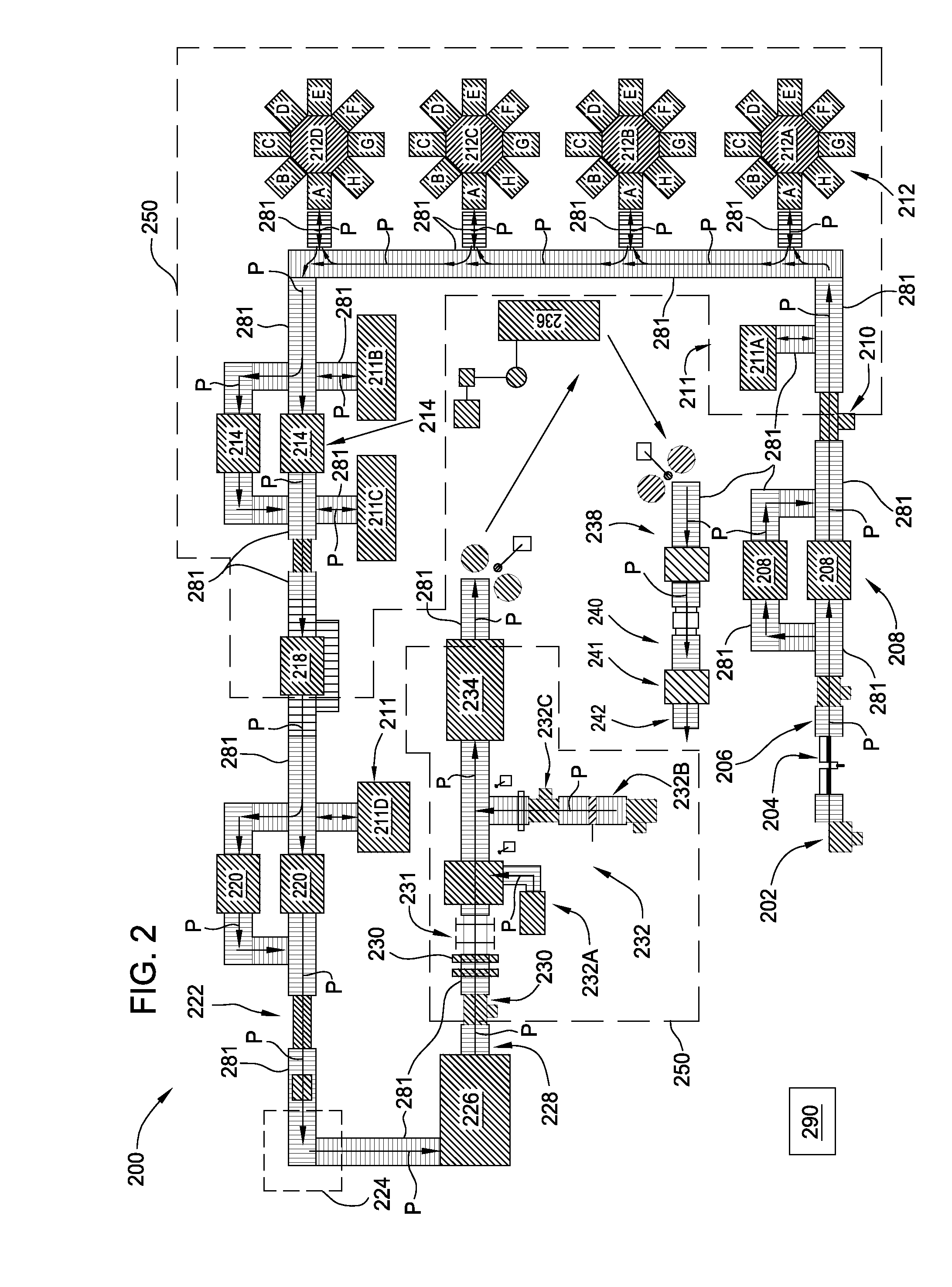

Method and system for manufacturing solar panels using an integrated solar cell using a plurality of photovoltaic regions

InactiveUS20060235717A1Easily use processLight weightData processing applicationsPV power plantsEngineeringPhotodiode

A method and system for manufacturing solar panels using an integrated solar cell using a plurality of photovoltaic regions. The method includes purchasing a first photovoltaic solar cell from a first entity for a first value. The method includes dicing the photovoltaic solar cell into a plurality of photovoltaic regions that may be characterized as a photodiodes. The method includes assembling a second photovoltaic solar cell. The second photovoltaic solar cell includes a first substrate member including a first substrate surface, one or more photovoltaic regions spatially disposed overlying the first substrate surface. One or more concentrator elements are respectively coupled to the one or more photovoltaic regions. An encapsulating material is provided between each of the photovoltaic regions and each of the concentrator elements. The method includes transferring the second photovoltaic solar cell to a second entity for a second value that is less than 79% of the first value.

Owner:SOLARIA CORP

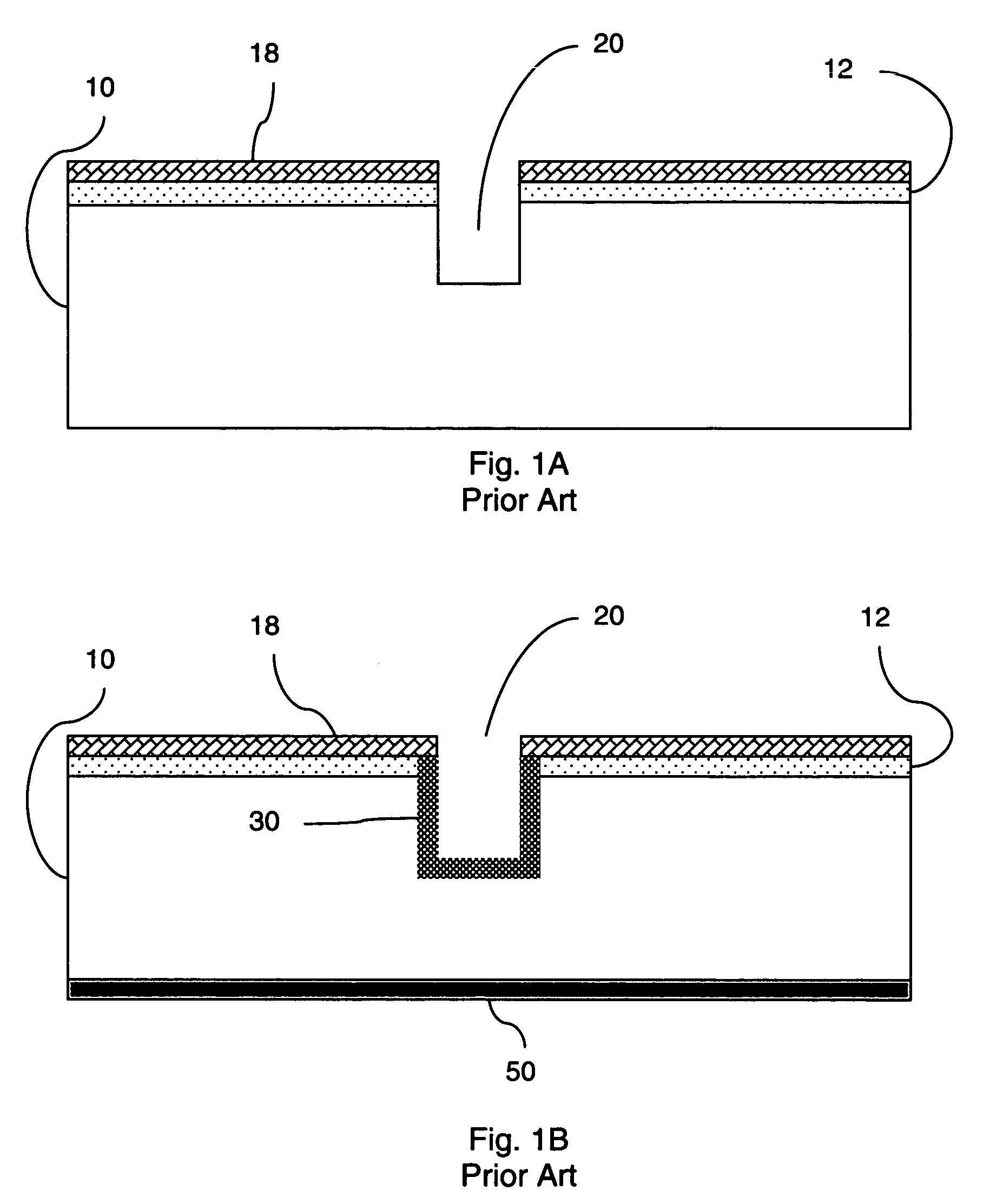

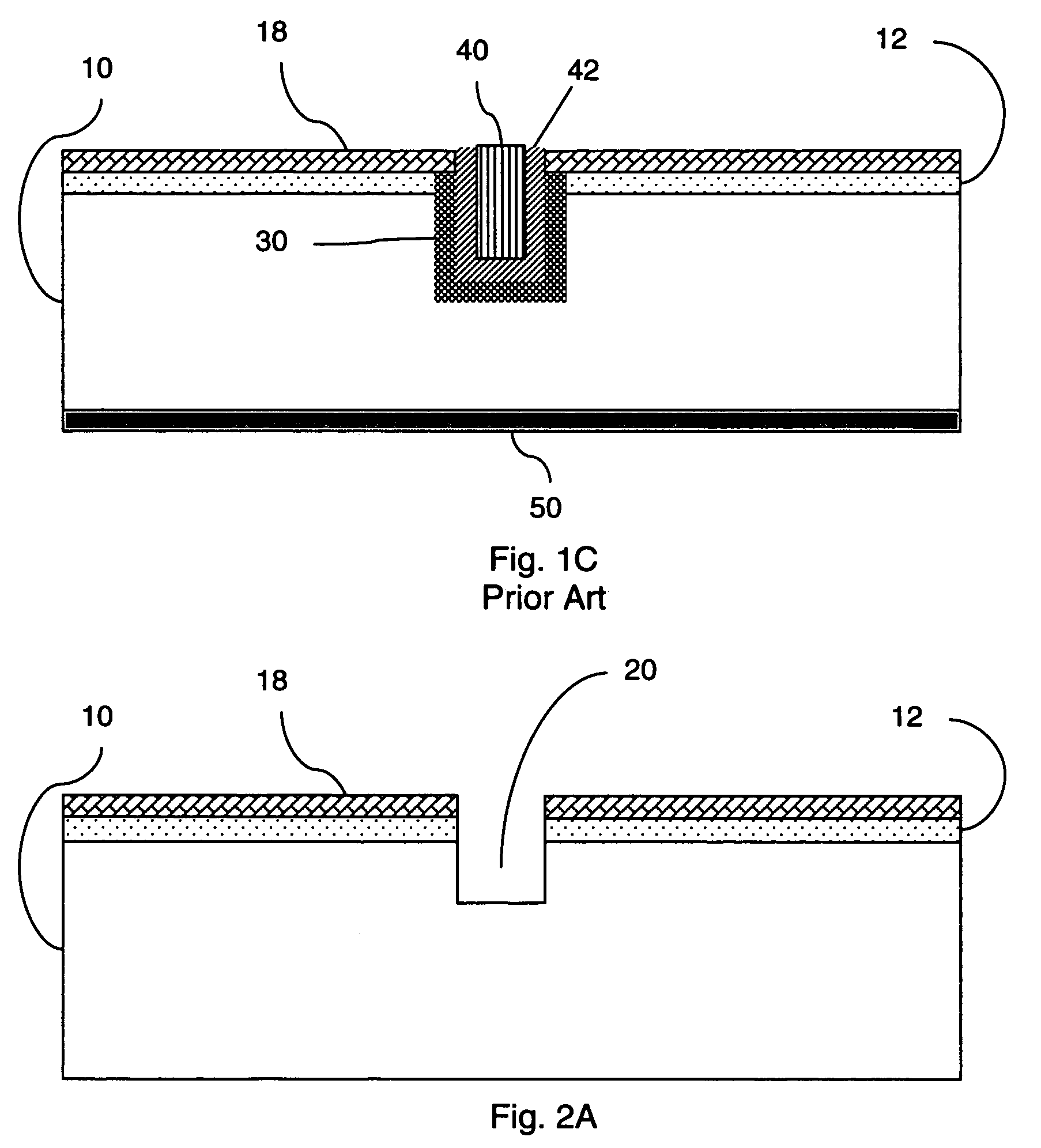

Hybrid heterojunction solar cell fabrication using a doping layer mask

InactiveUS20100015756A1Prevent substantial etching of back surfaceFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionSolar cell

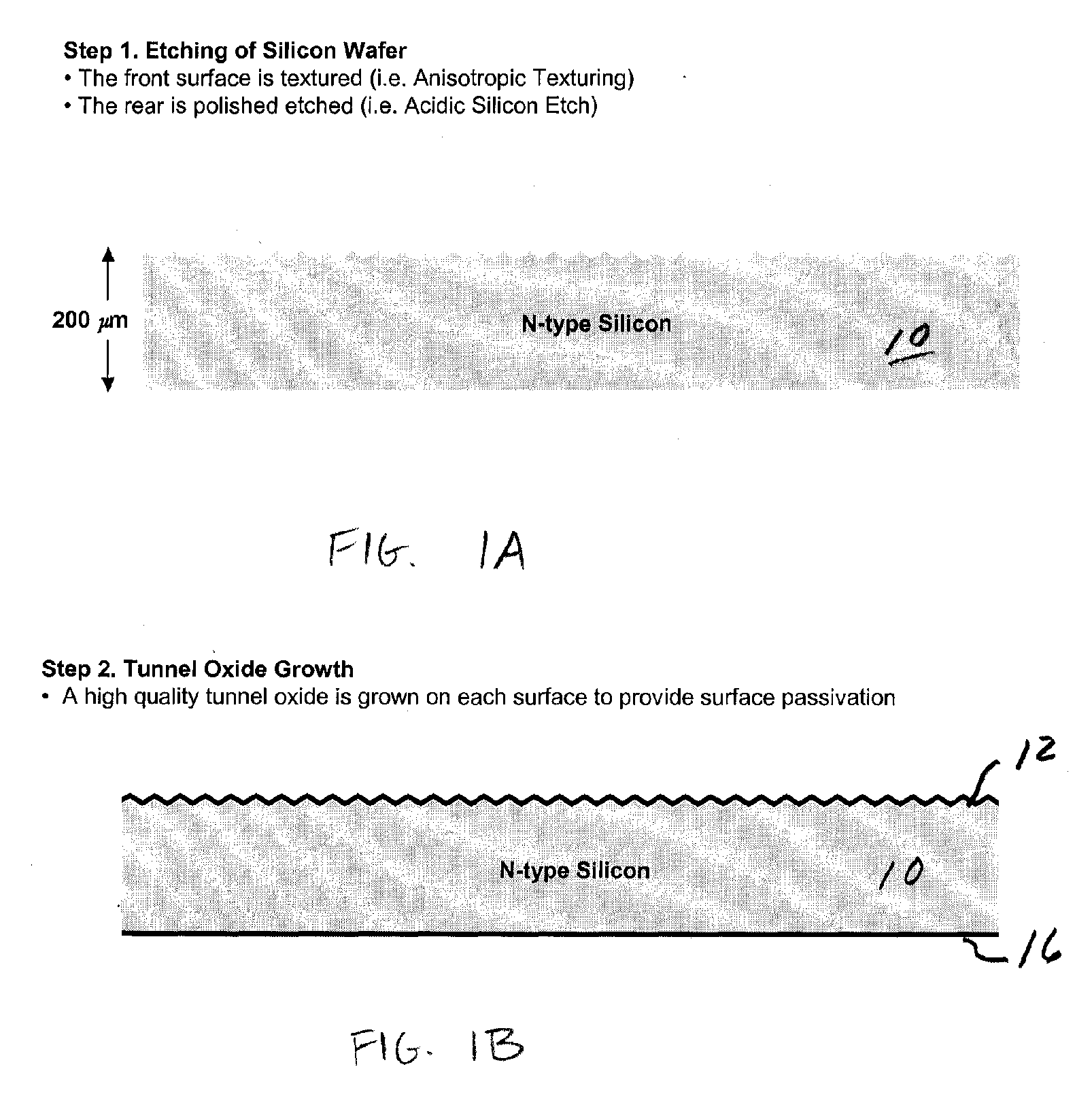

Embodiments of the invention contemplate the formation of a high efficiency solar cell using a novel processing sequence to form a solar cell device. In one embodiment, the methods include forming a doping layer on a back surface of a substrate, heating the doping layer and substrate to cause the doping layer diffuse into the back surface of the substrate, texturing a front surface of the substrate after heating the doping layer and the substrate, forming a dielectric layer on the back surface of the substrate, removing portions of the dielectric layer from the back surface to from a plurality of exposed regions of the substrate, and depositing a metal layer over the back surface of the substrate, wherein the metal layer is in electrical communication with at least one of the plurality of exposed regions on the substrate, and at least one of the exposed regions has dopant atoms provided from the doping layer.

Owner:APPLIED MATERIALS INC

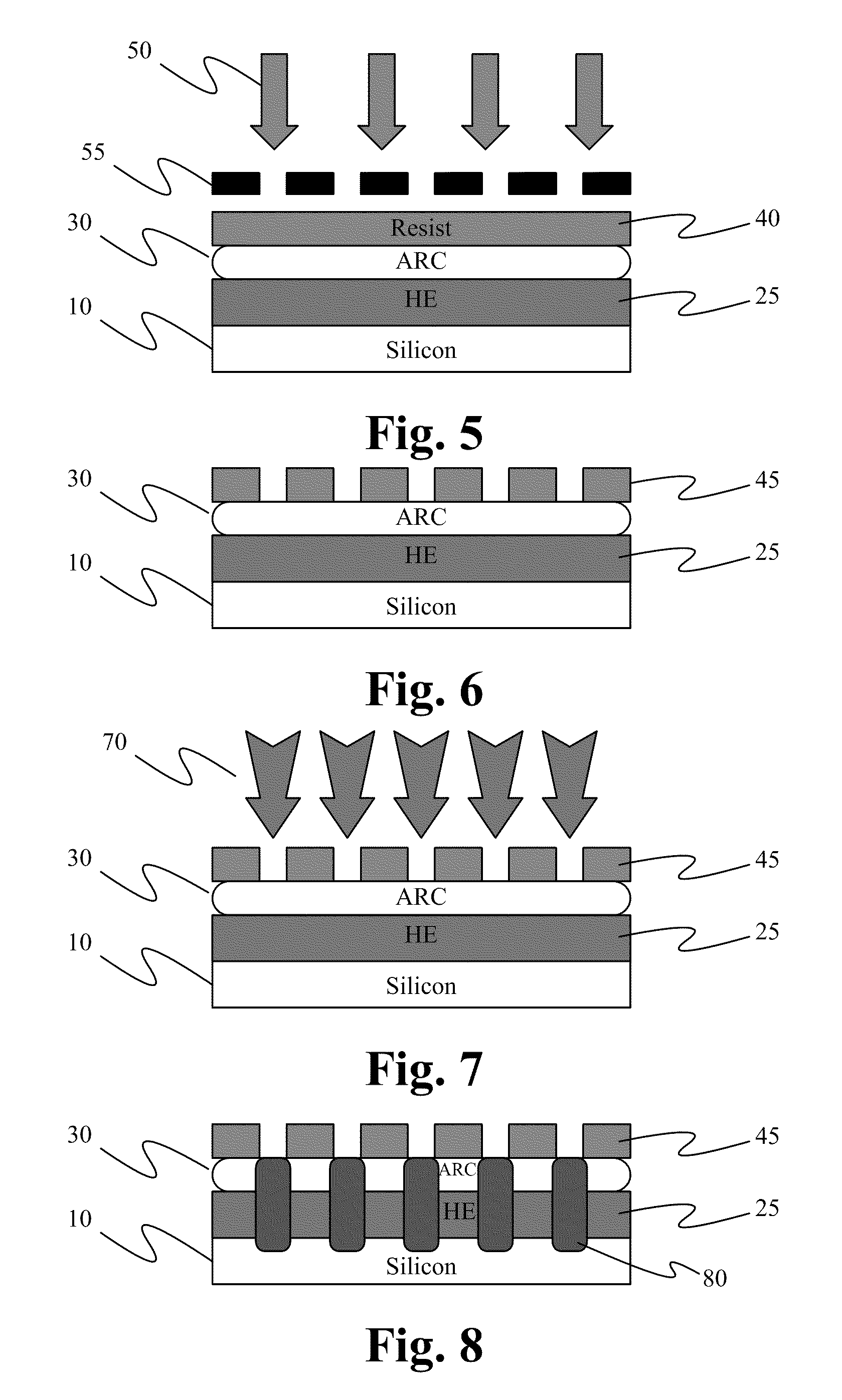

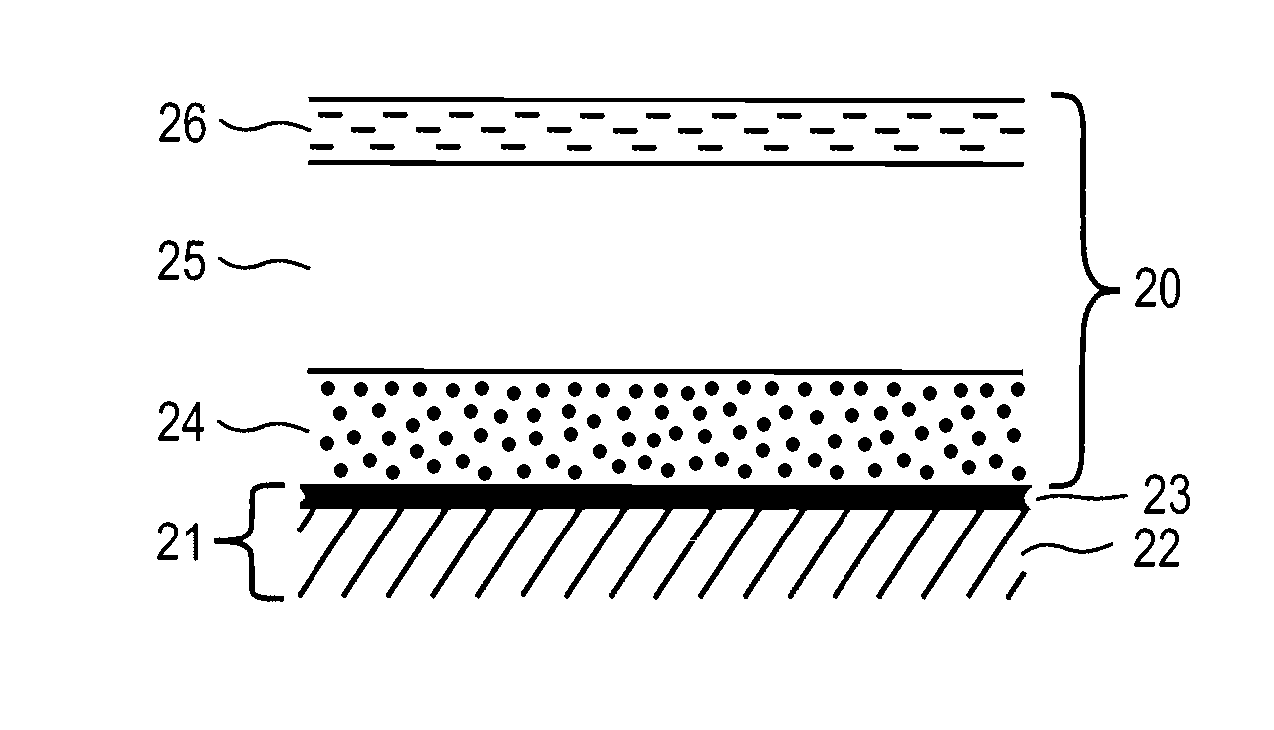

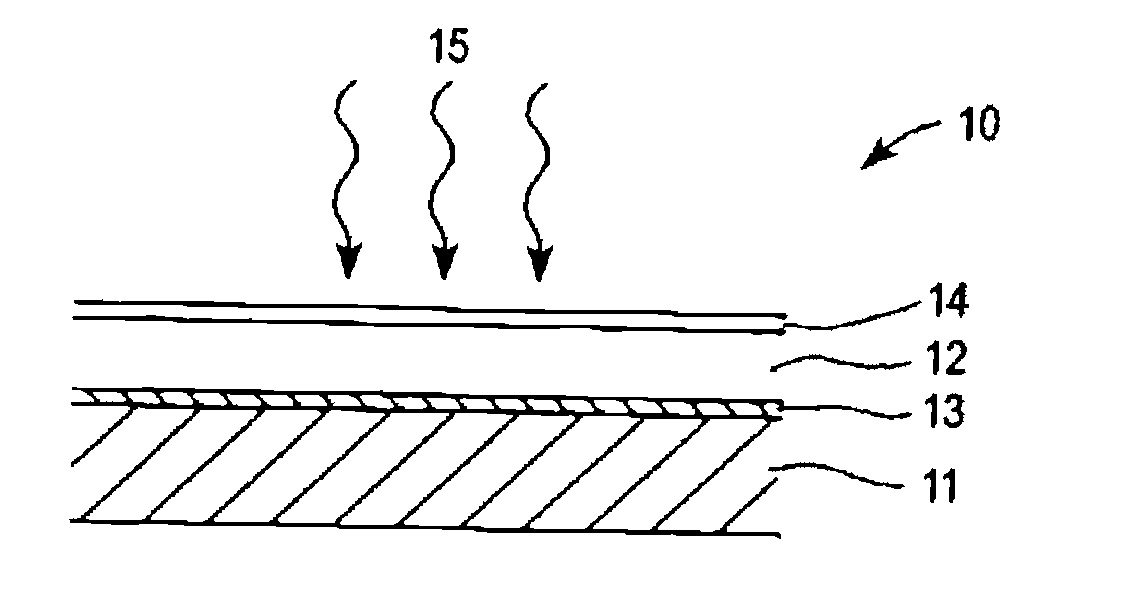

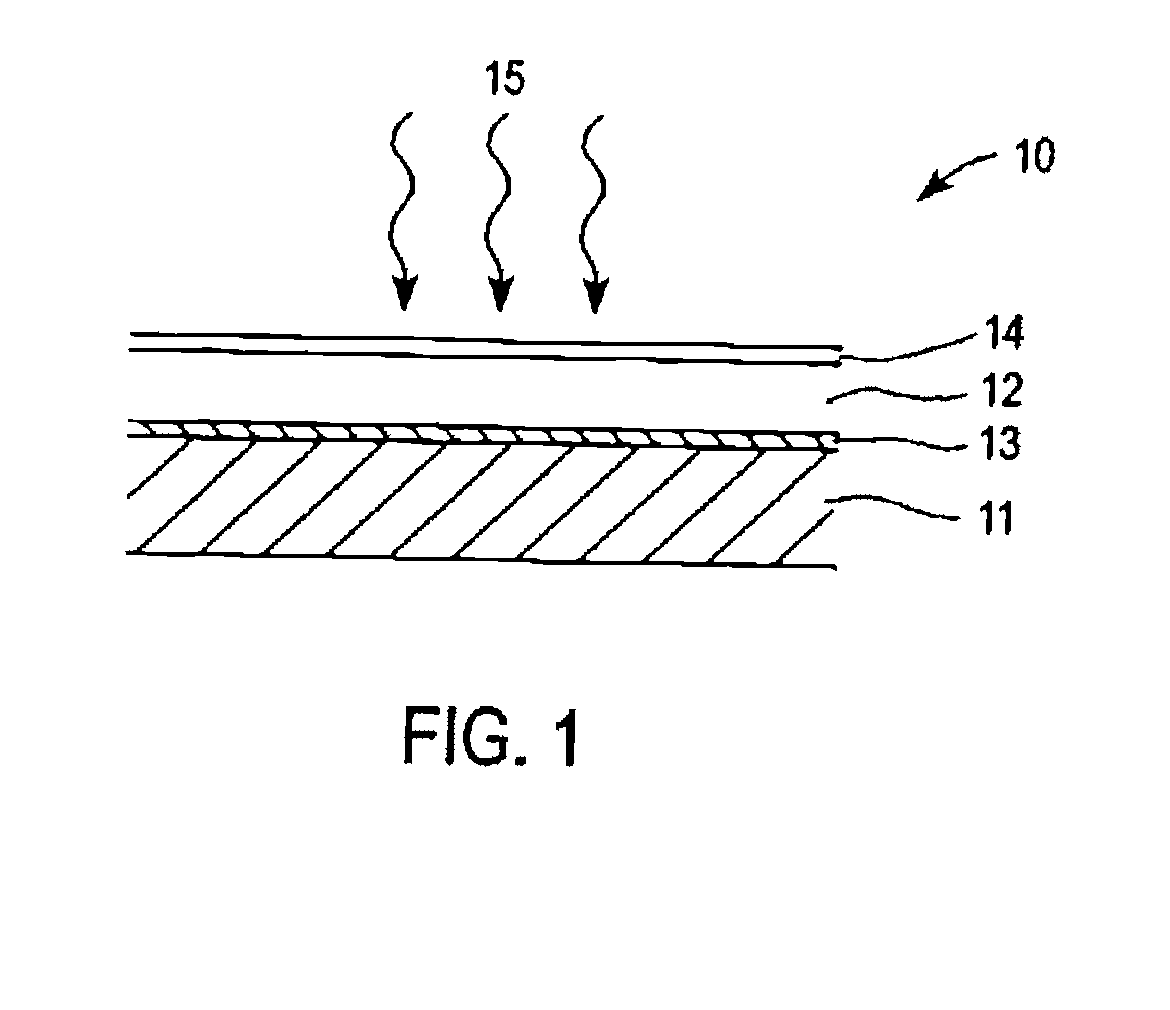

Thin film solar cell

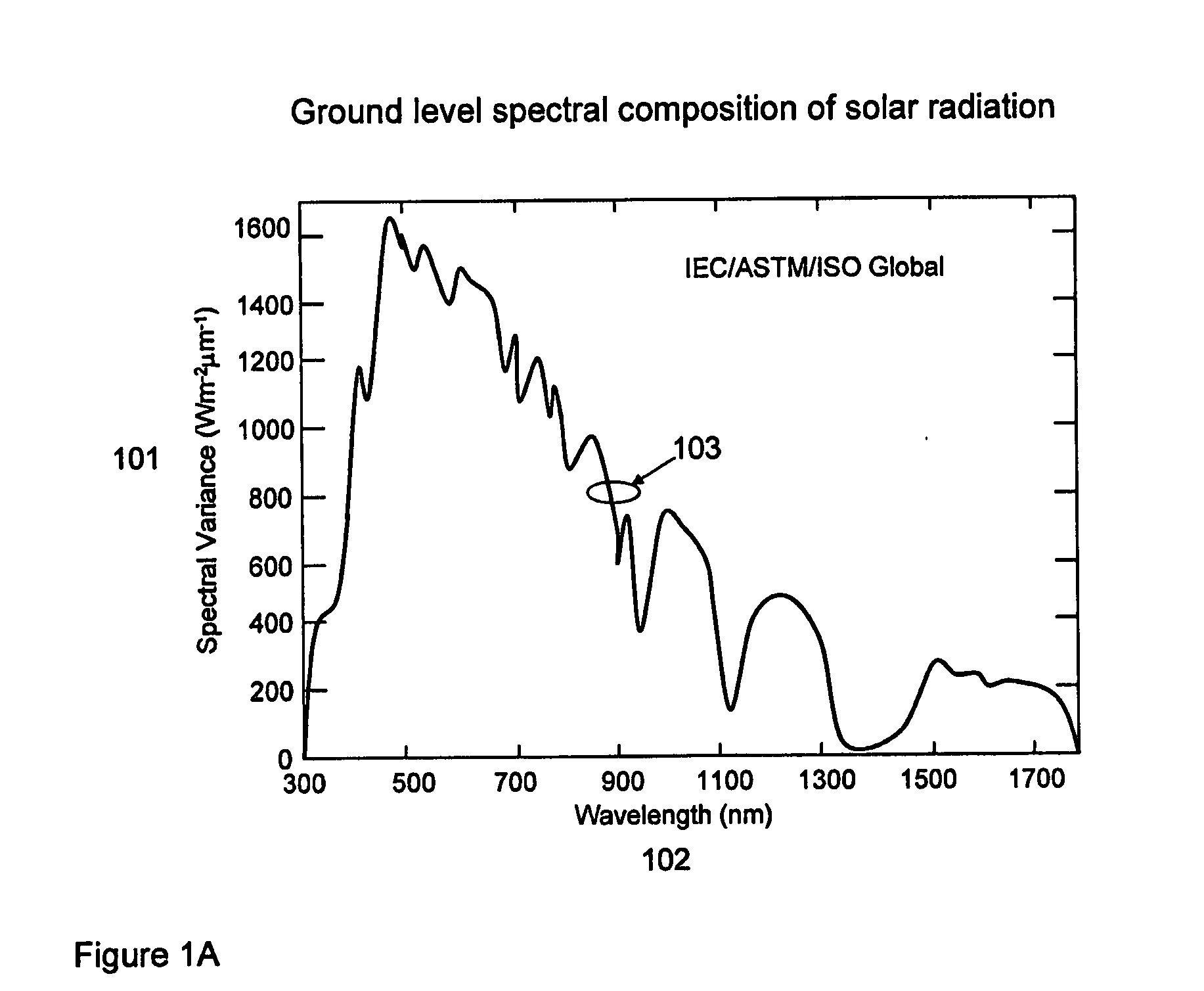

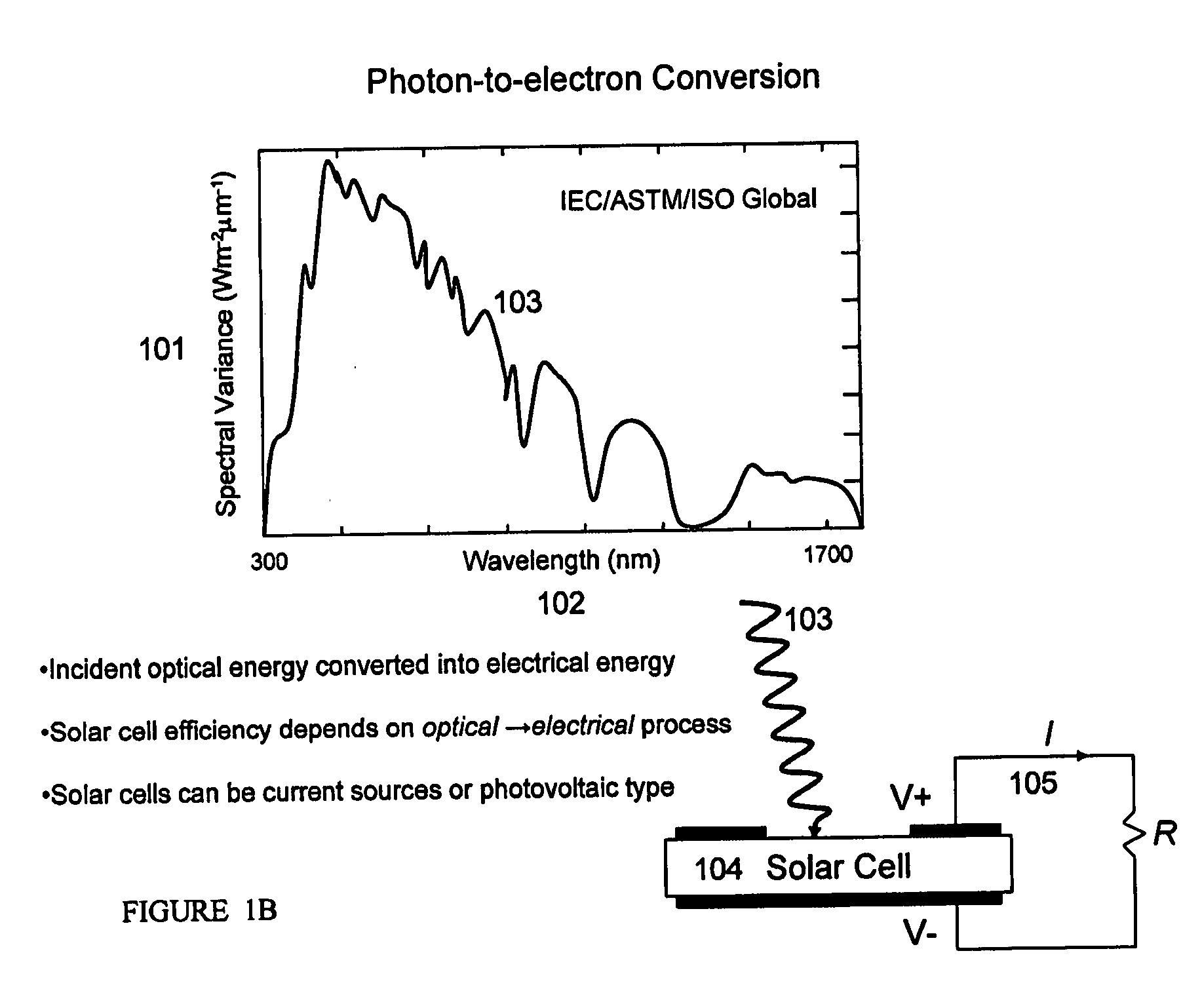

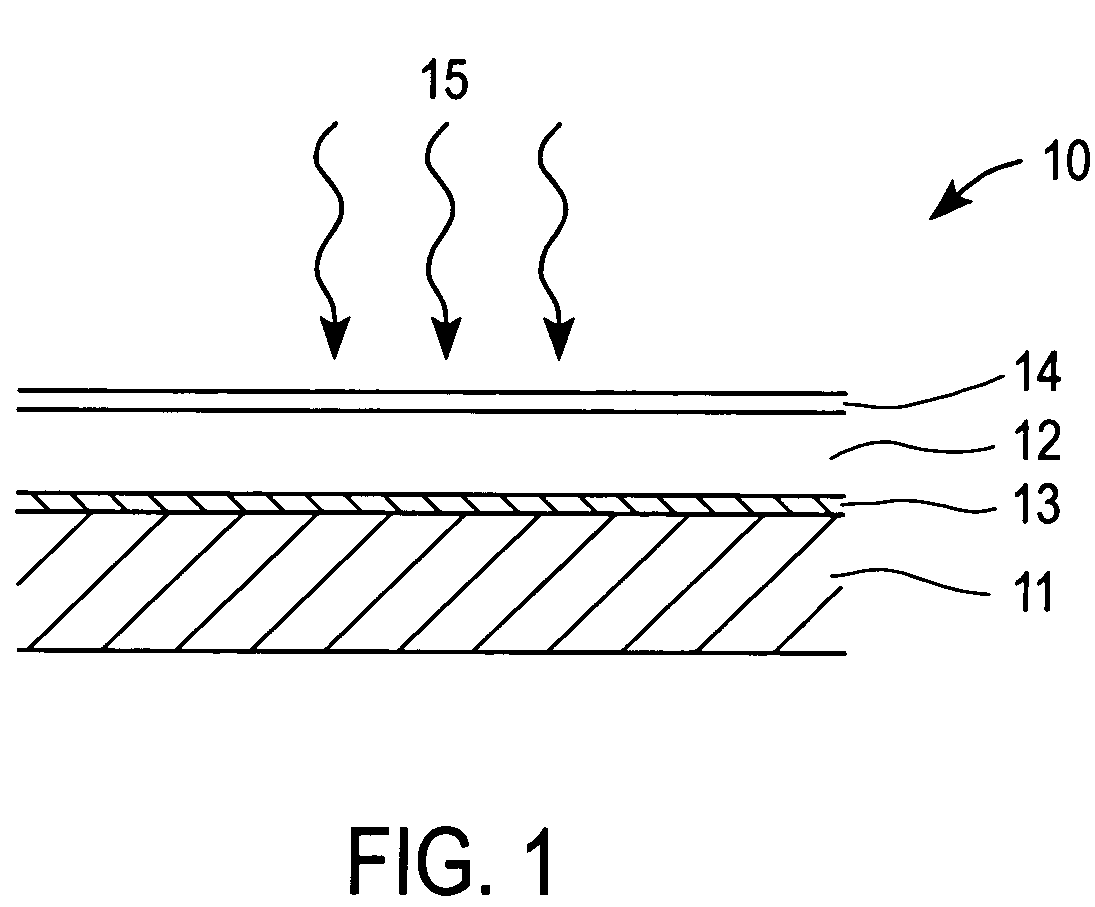

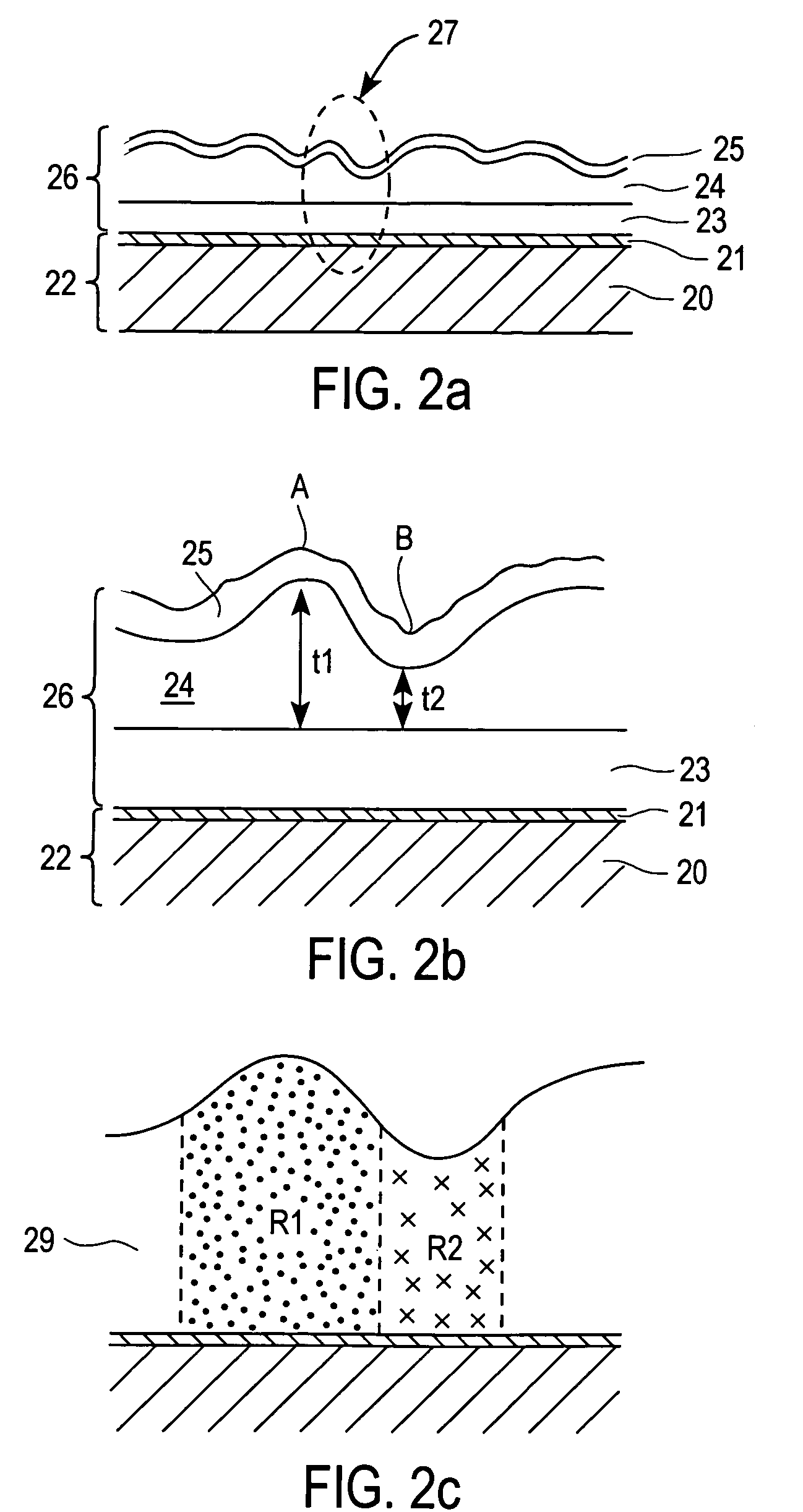

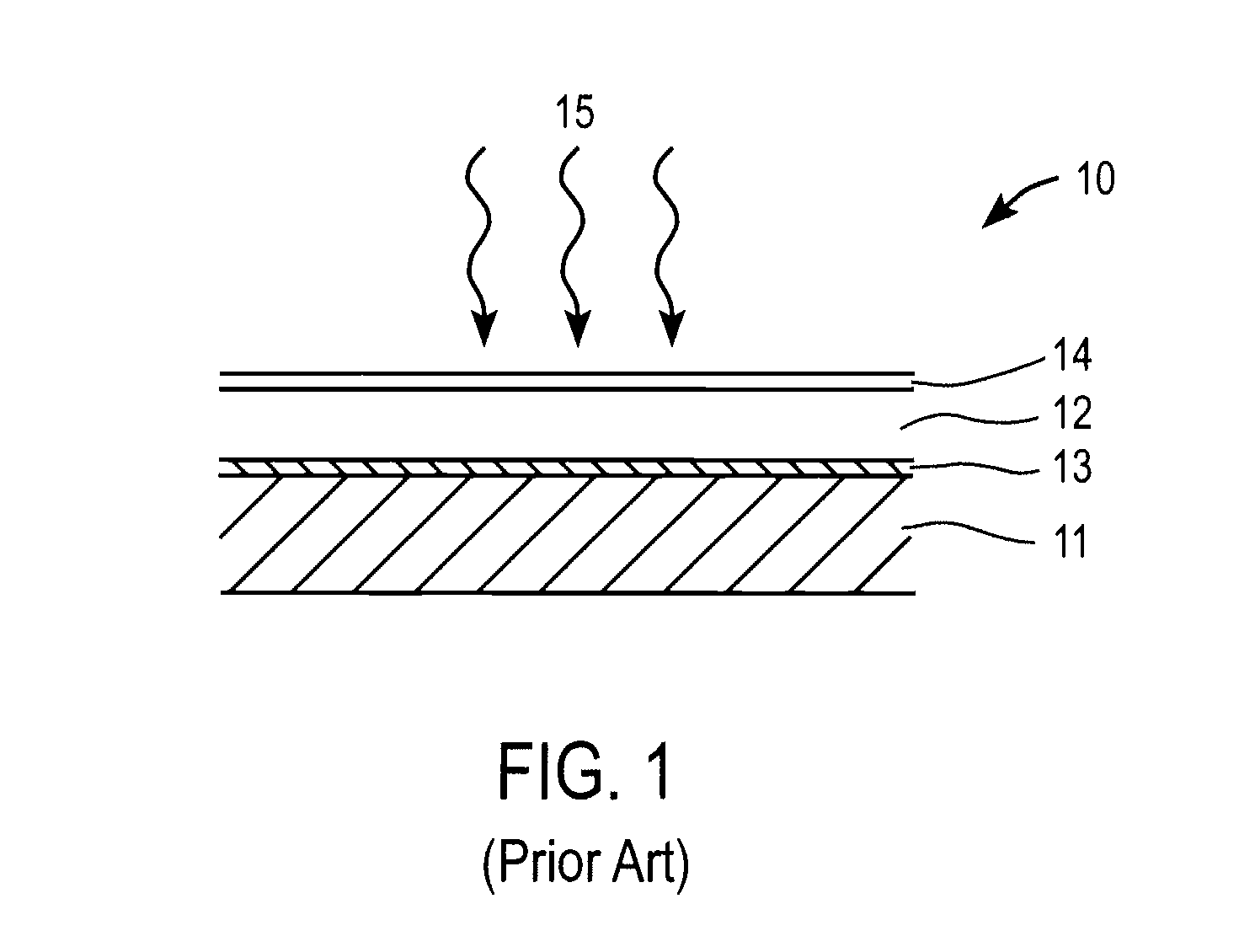

InactiveUS20080078444A1Good choiceImprovement factorPhotovoltaic energy generationSemiconductor devicesHigh energyUltraviolet

Optimal structures for high efficiency thin film silicon solar energy conversion devices and systems are disclosed. Thin film silicon active layer photoelectron conversion structures using ion implantation are disclosed. Thin film semiconductor devices optimized for exploiting the high energy and ultraviolet portion of the solar spectrum at the earths surface are also disclosed. Solar cell fabrication using high oxygen concentration single crystal silicon substrates formed using in preference the CZ method are used advantageously. Furthermore, the present invention discloses optical coatings for advantageous coupling of solar radiation into thin film solar cell devices via the use of rare-earth metal oxide (REOx), rare-earth metal oxynitride (REOxNy) and rare-earth metal oxy-phosphide (REOxPy) glasses and or crystalline material. The rare-earth metal is chosen from the group commonly known in the periodic table of elements as the lanthanide series.

Owner:IQE

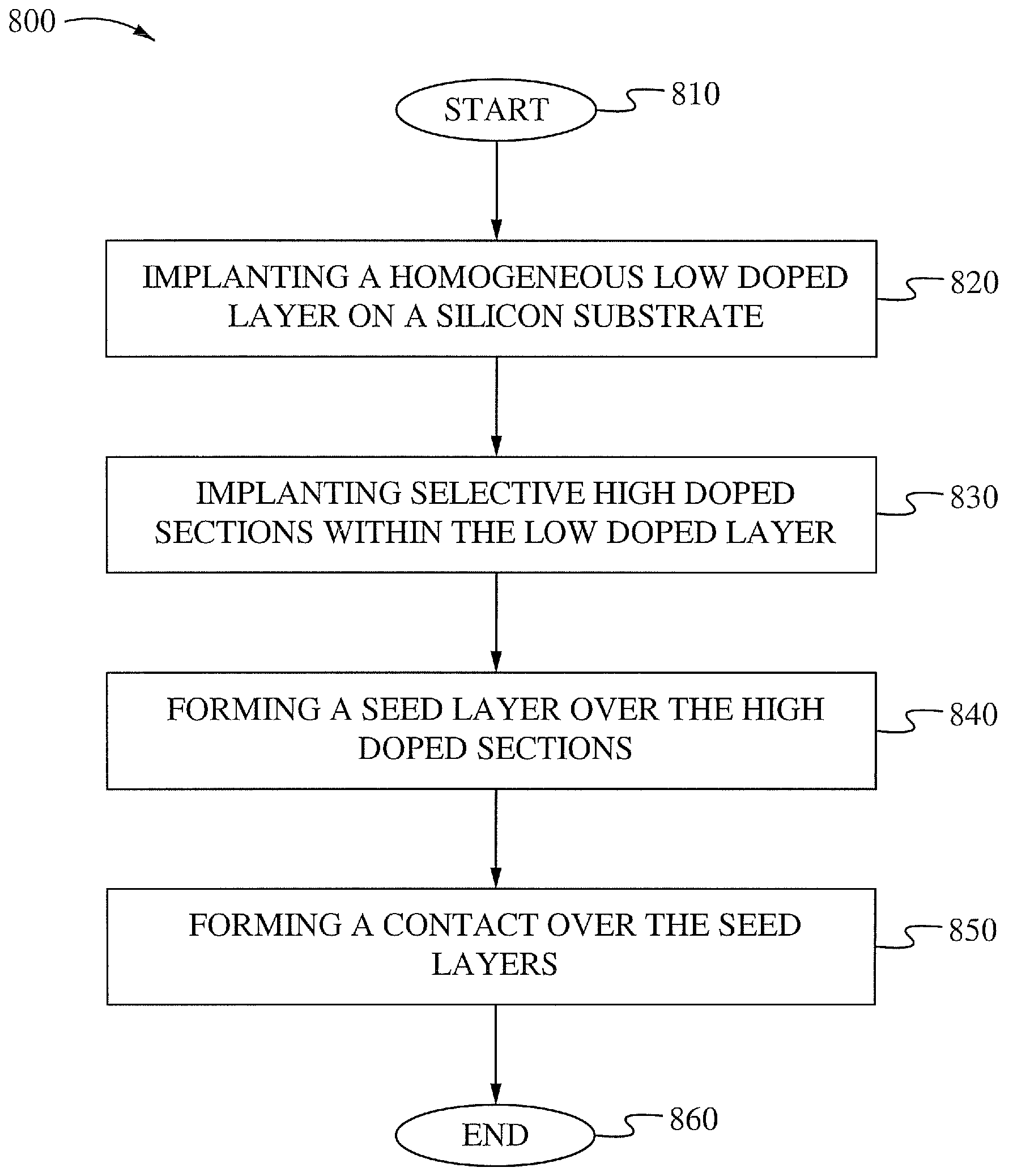

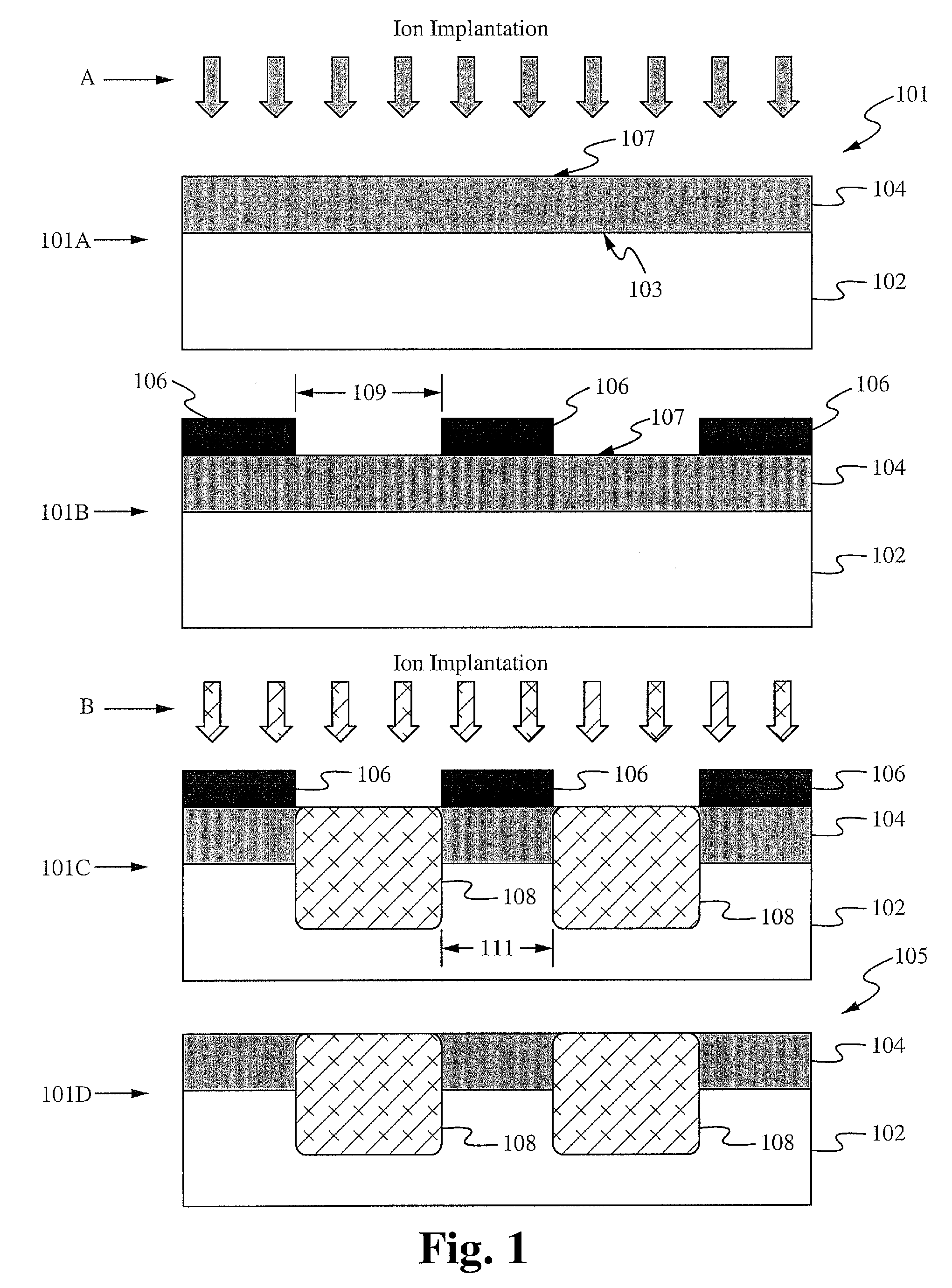

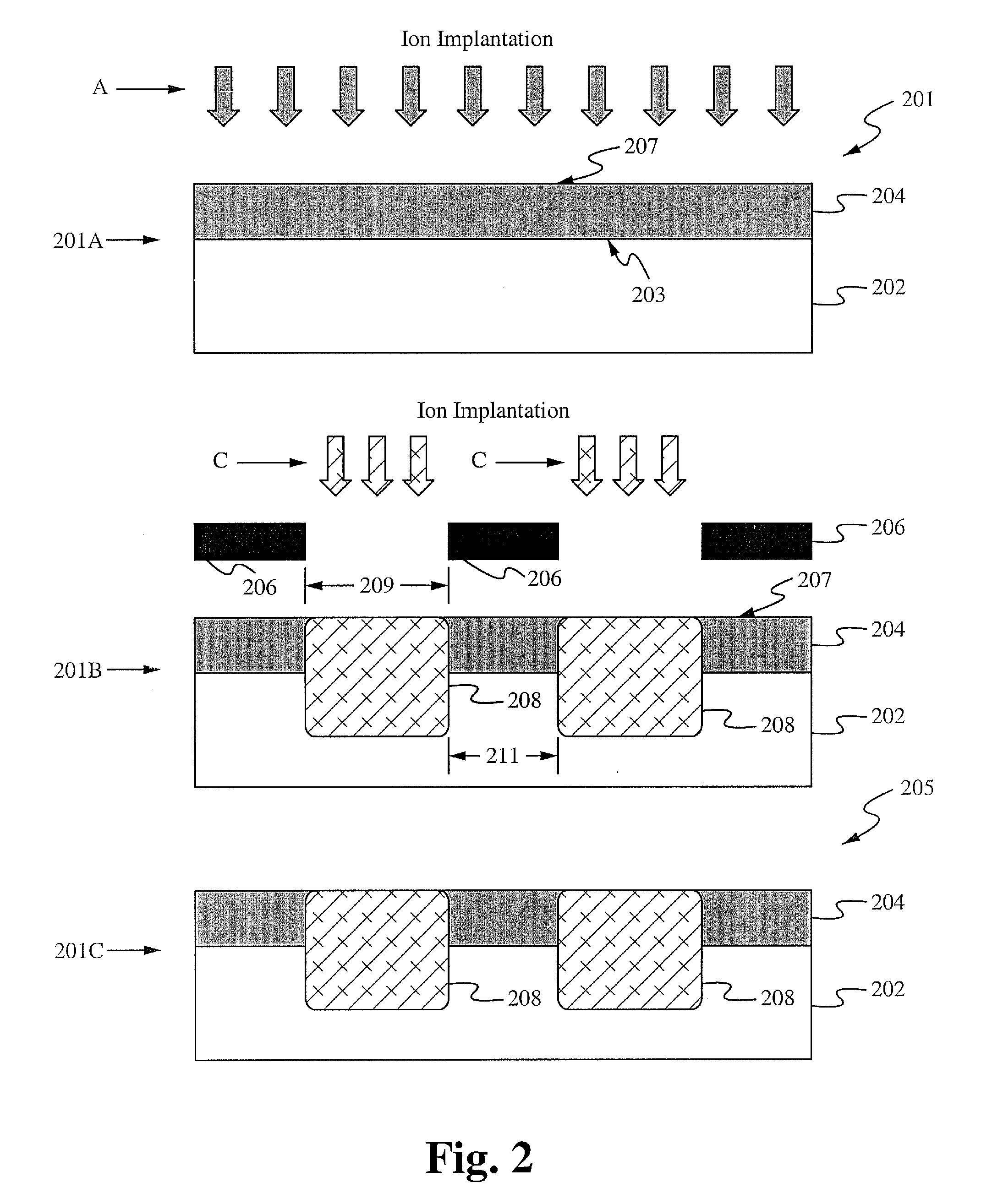

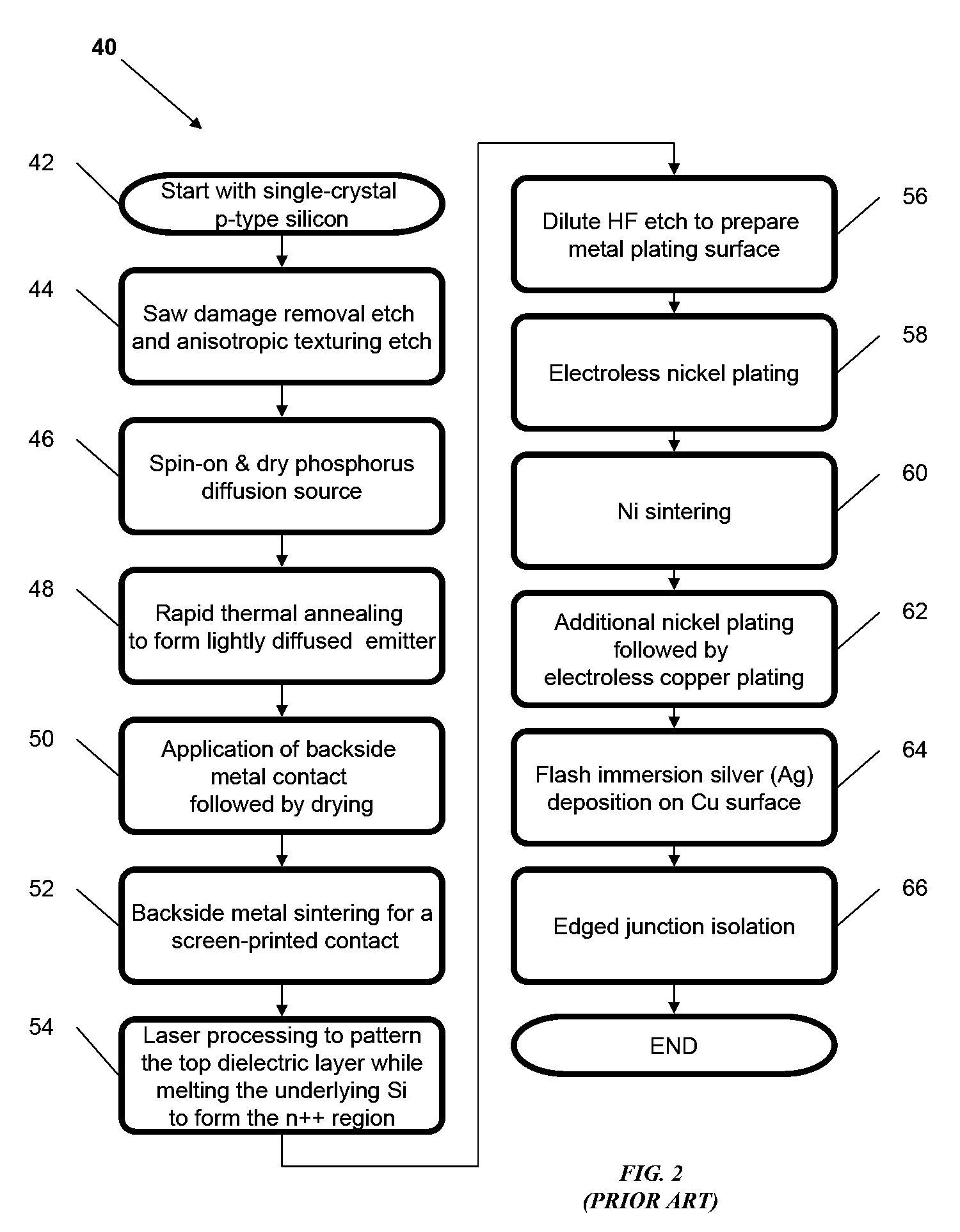

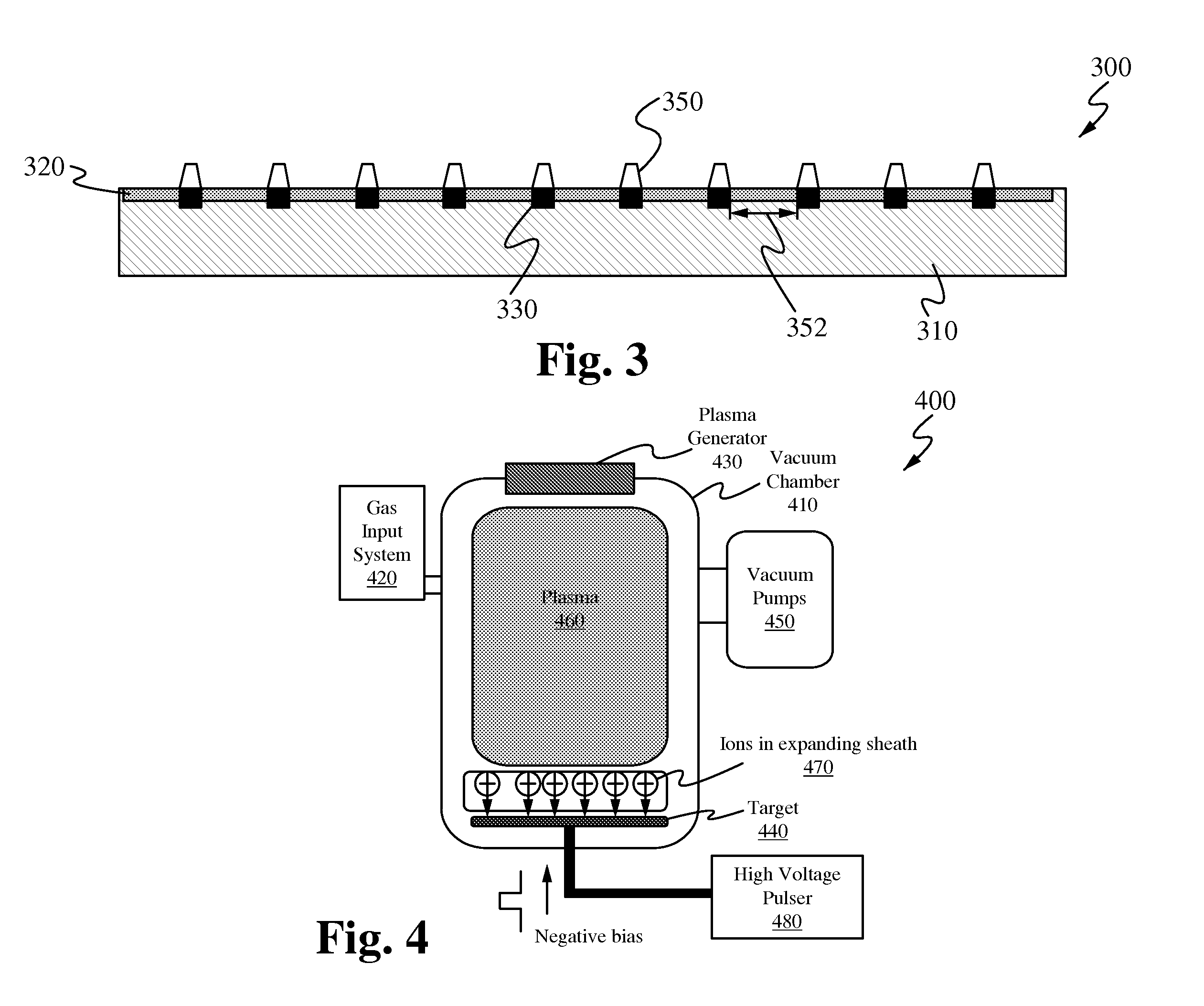

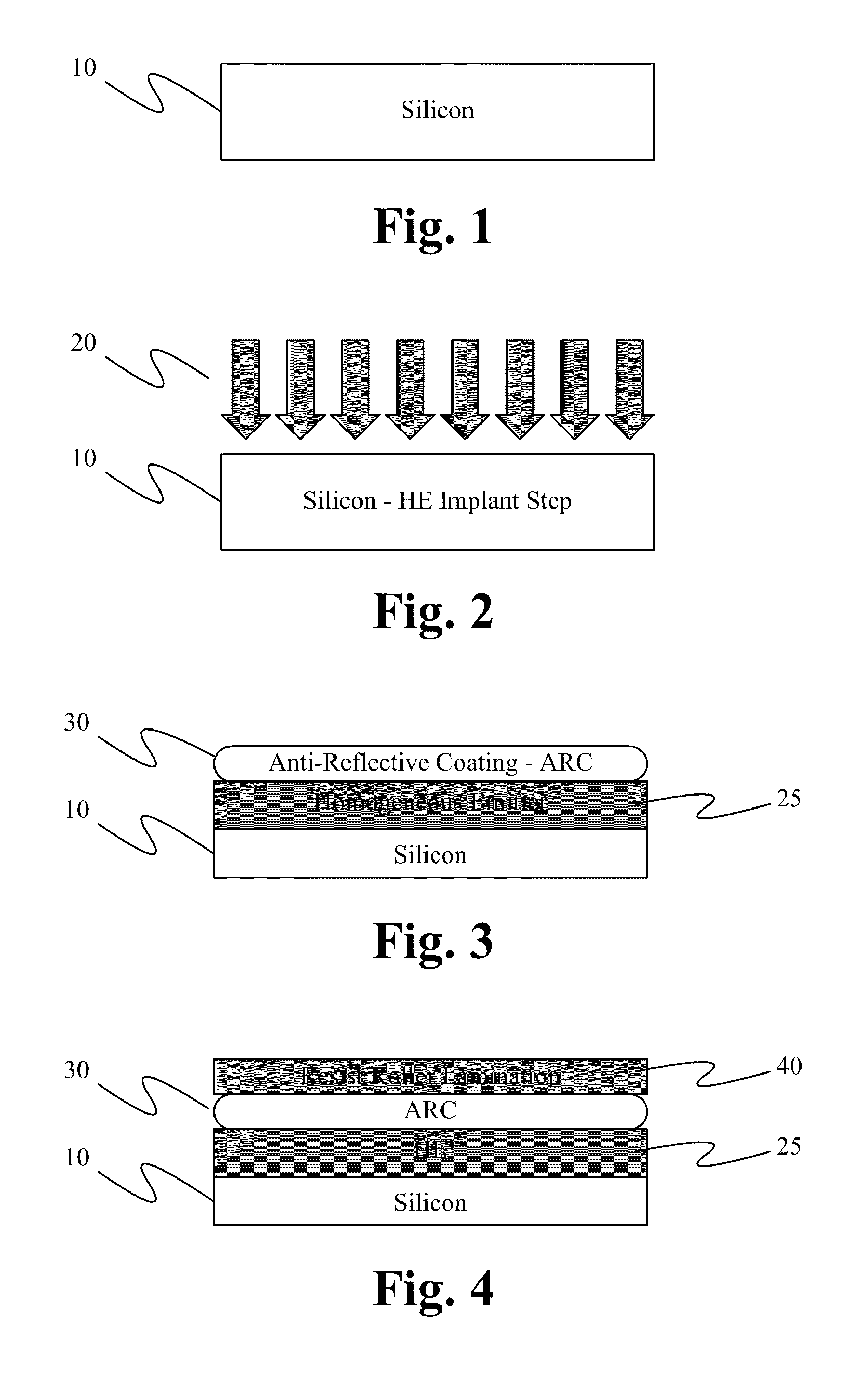

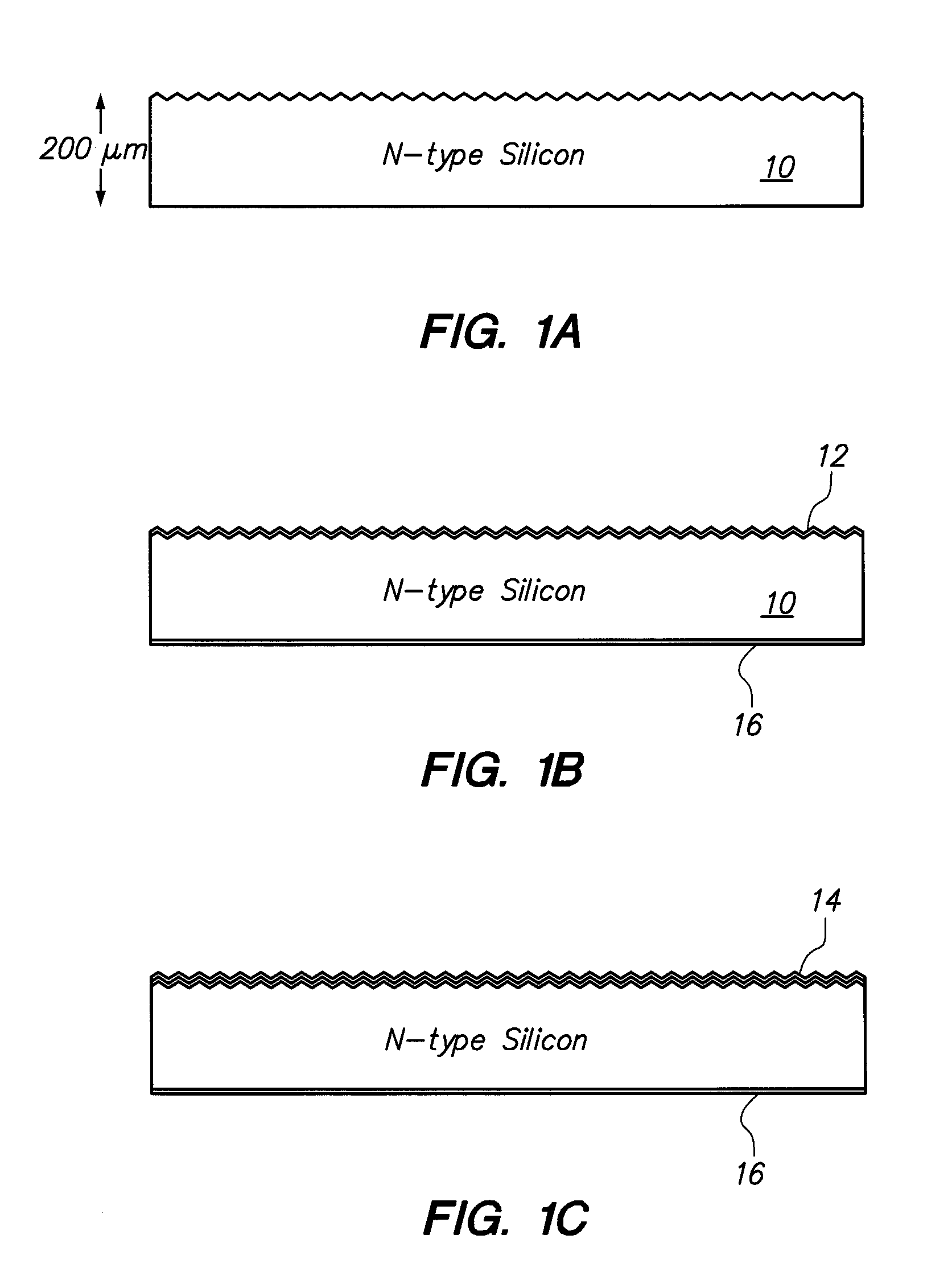

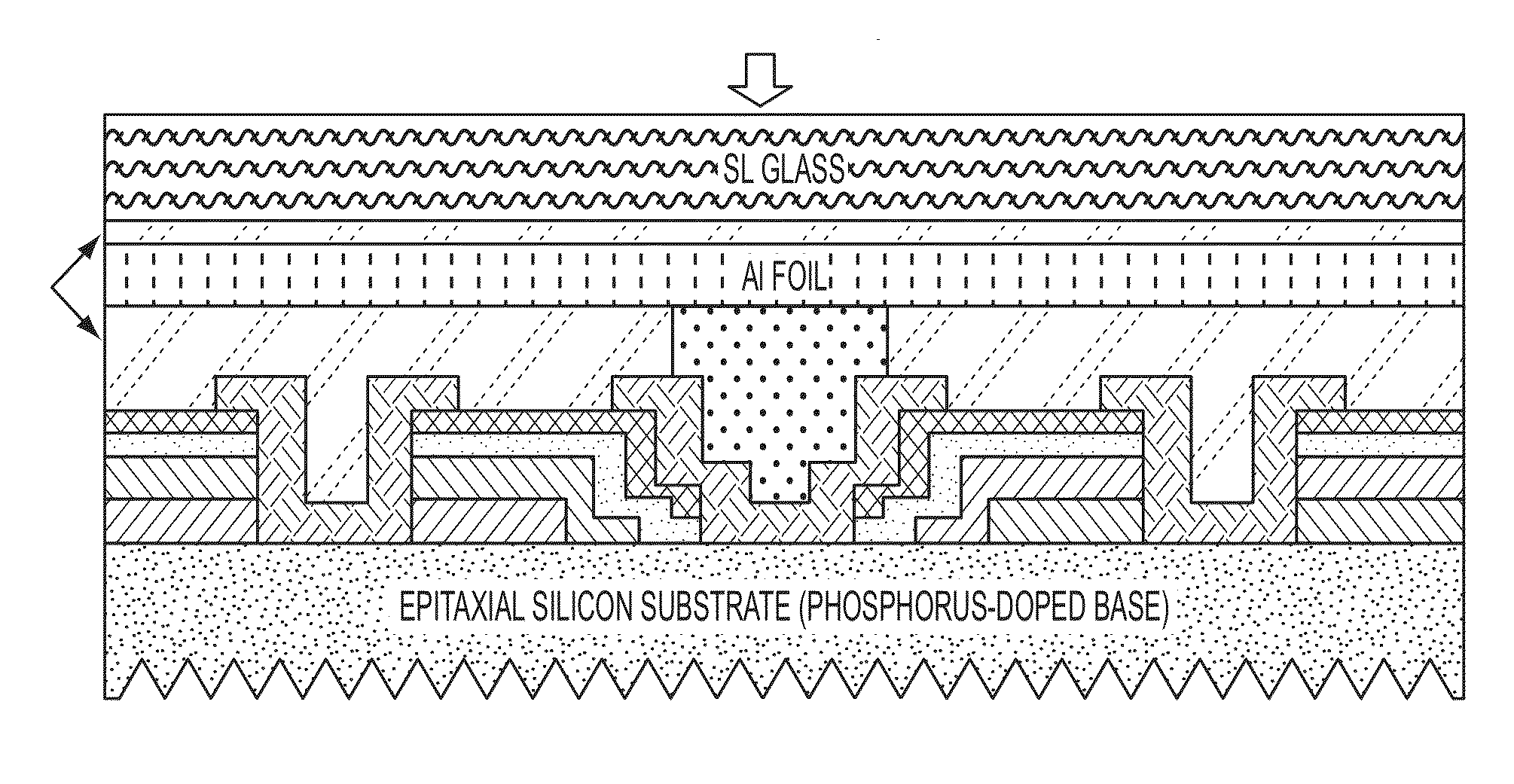

Solar cell fabrication using implantation

InactiveUS20090308439A1Low temperature annealingLower temperature annealingFinal product manufactureSemiconductor/solid-state device manufacturingAnti-reflective coatingDopant

A solar cell device and method of making are provided. The device includes a silicon substrate including a preexisting dopant. A homogeneous lightly doped region is formed on a surface of the silicon substrate to form a junction between the preexisting dopant and the lightly doped region. A heavily doped region is selectively implanted on the surface of the silicon substrate. A seed layer is formed over the heavily doped region. A metal contact is formed over the seed layer. The device can include an anti-reflective coating. In one embodiment, the heavily doped region forms a parabolic shape. The heavily doped regions can each be a width on the silicon substrate a distance in the range 50 to 200 microns. Also, the heavily doped regions can be laterally spaced on the silicon substrate a distance in the range 1 to 3 mm from each other. The seed layer can be a silicide. The silicon substrate can include fiducial markers configured for aligning the placement of the heavily doped regions during an ion implantation process.

Owner:INTEVAC

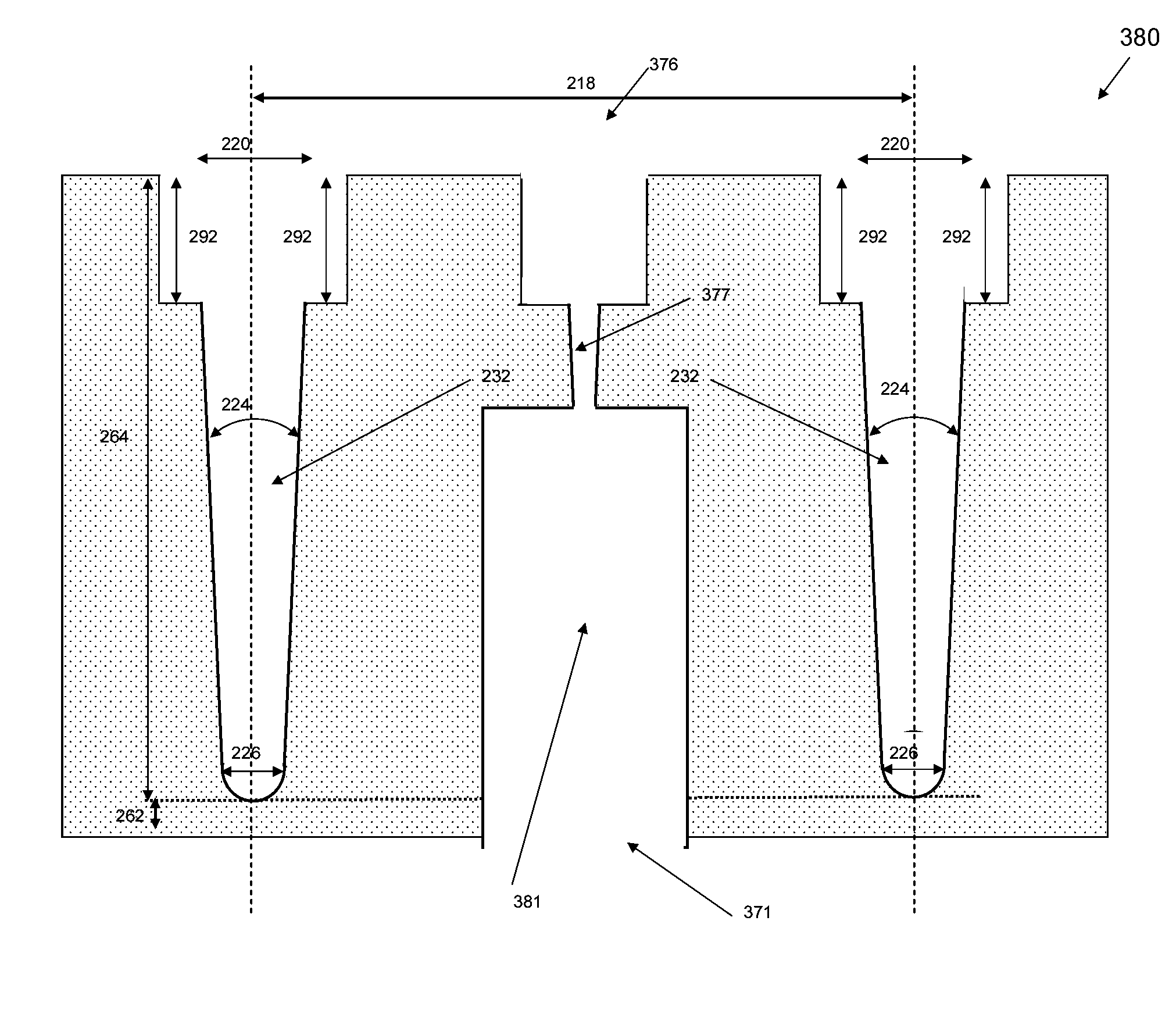

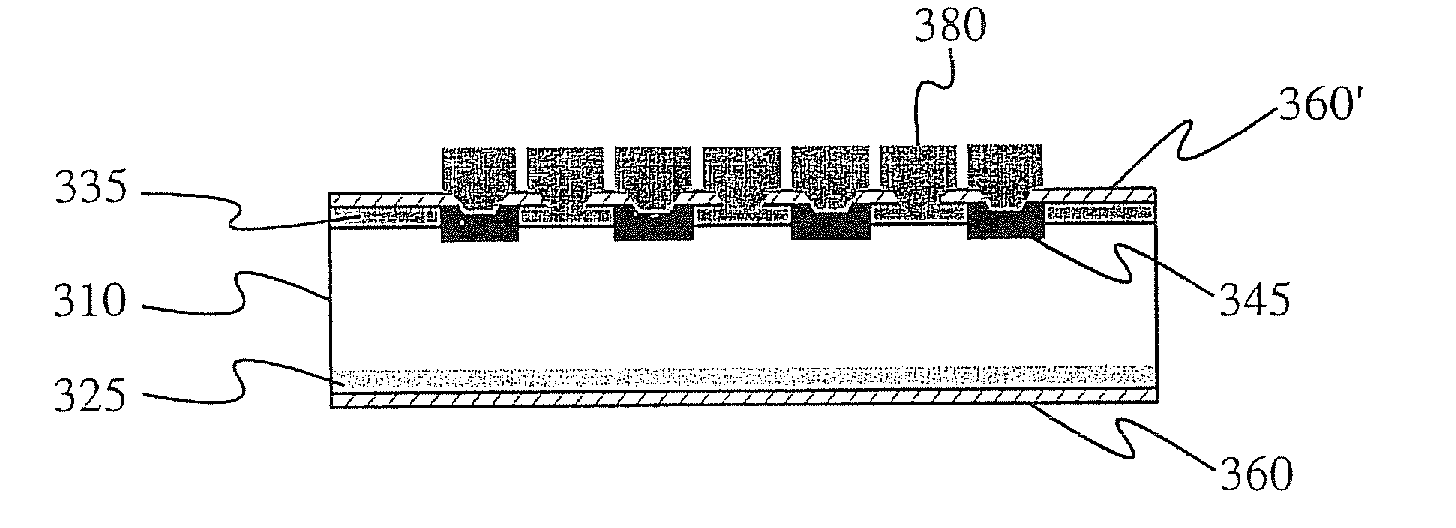

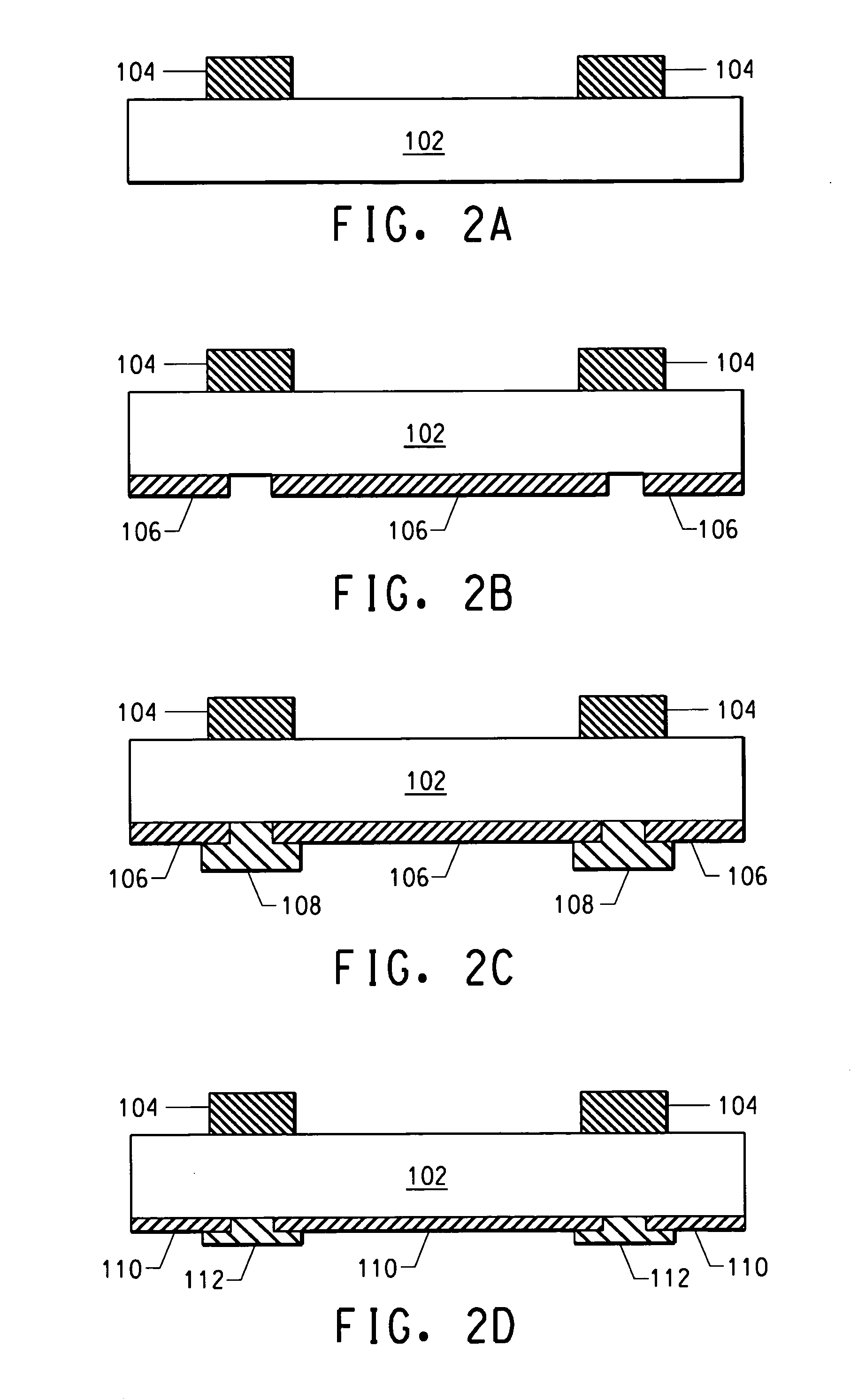

Template for three-dimensional thin-film solar cell manufacturing and methods of use

InactiveUS20080157283A1Reduce disadvantagesReduce problemsThermoelectric device with peltier/seeback effectSemiconductor/solid-state device manufacturingEngineeringSolar cell fabrication

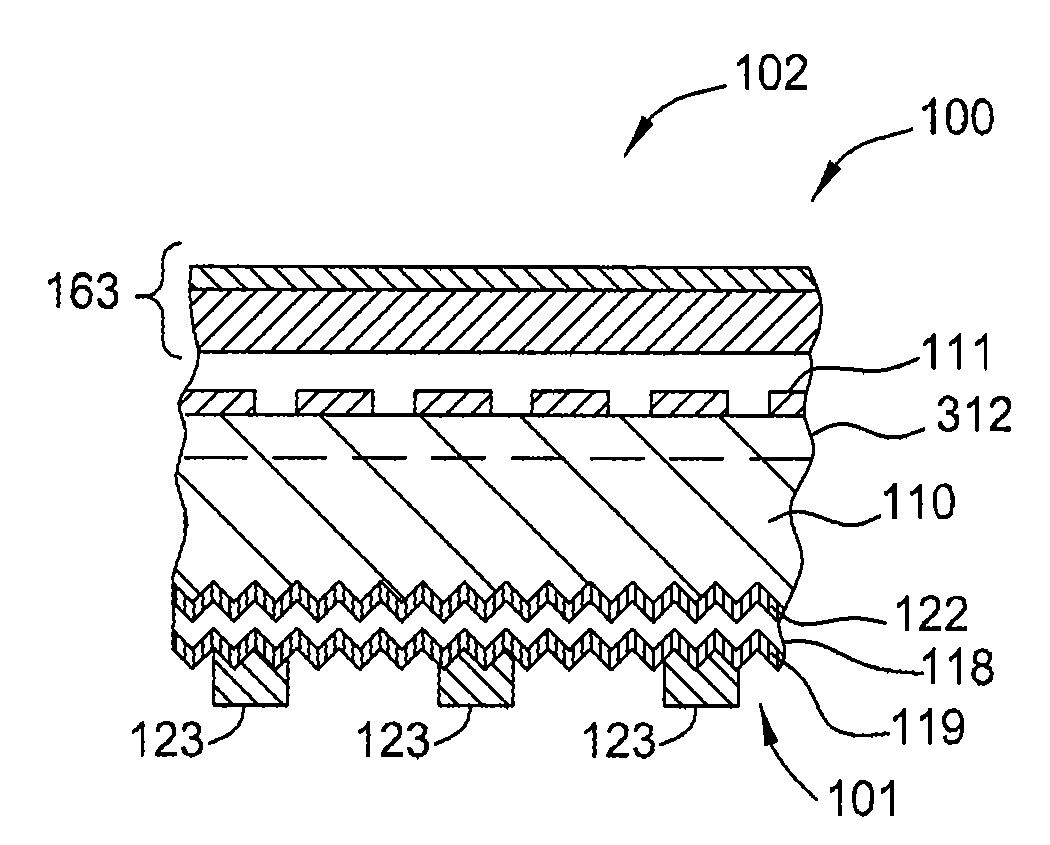

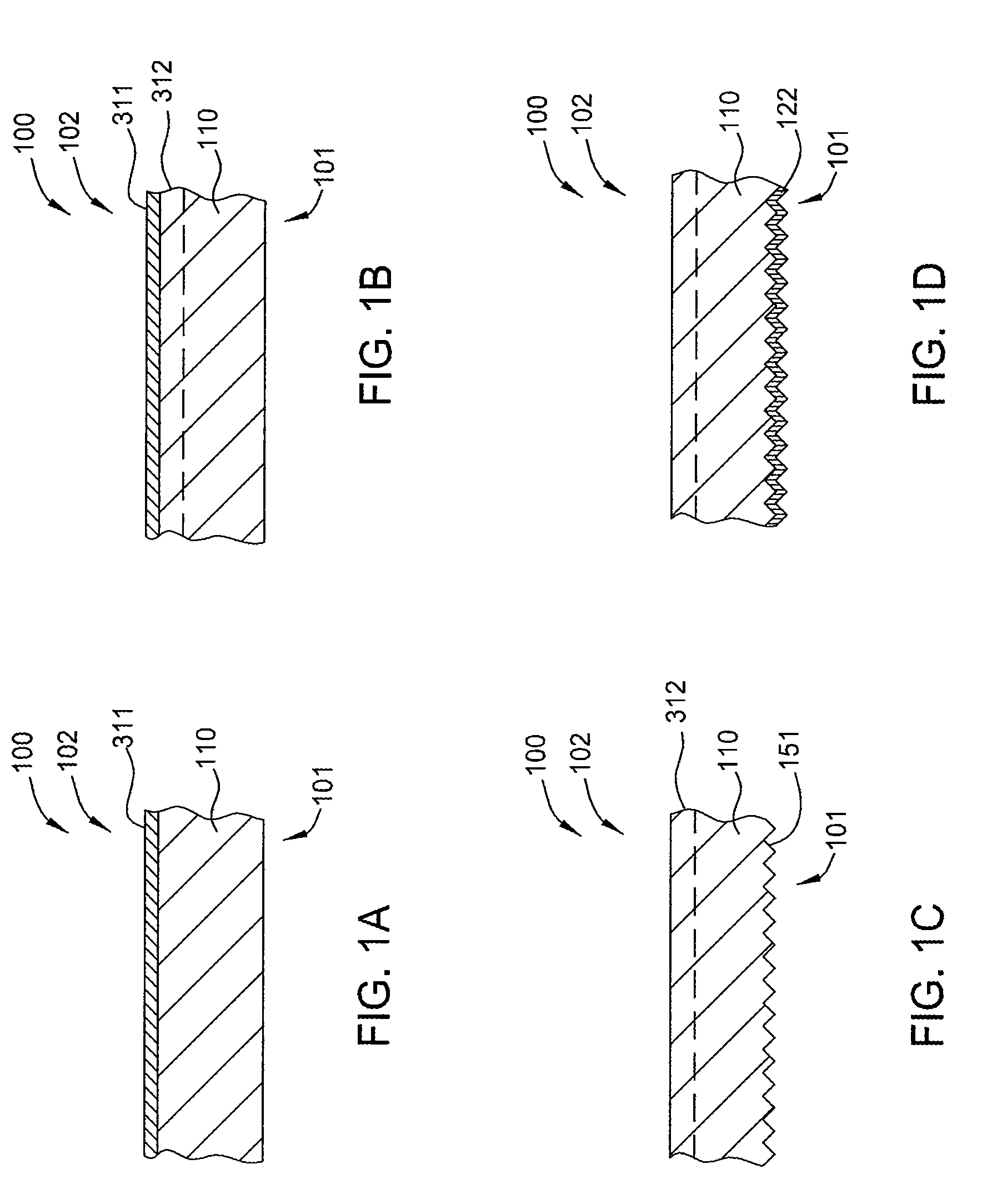

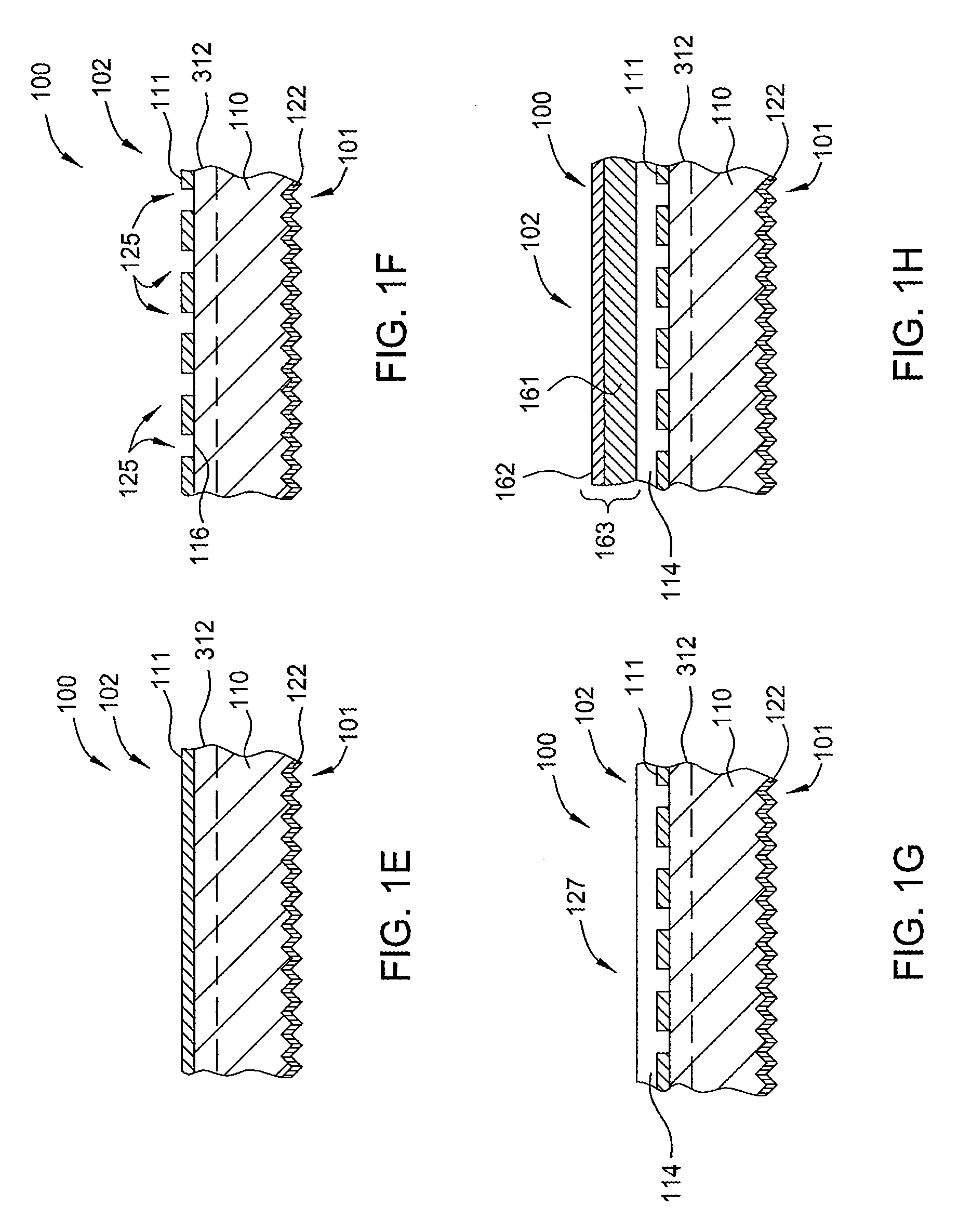

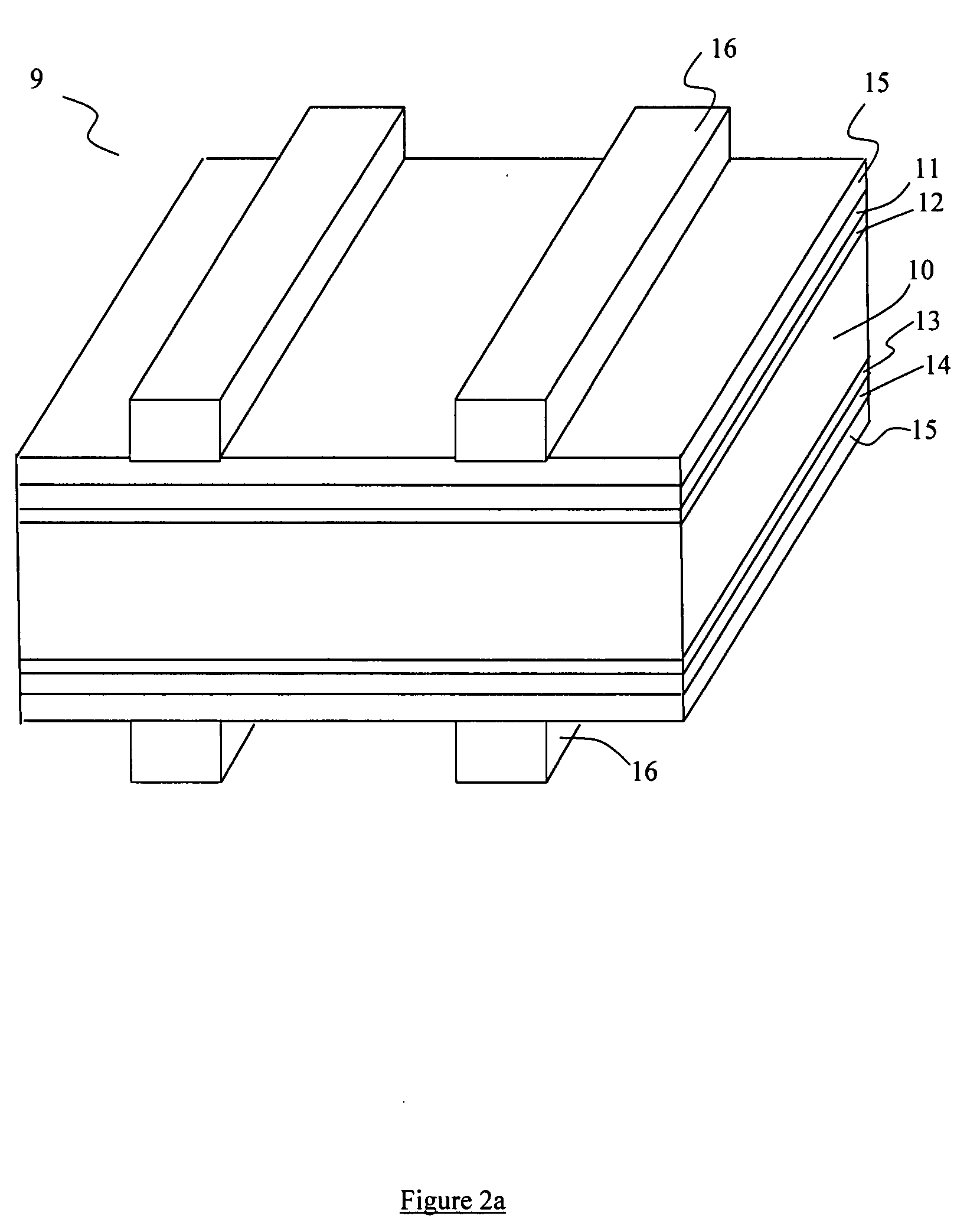

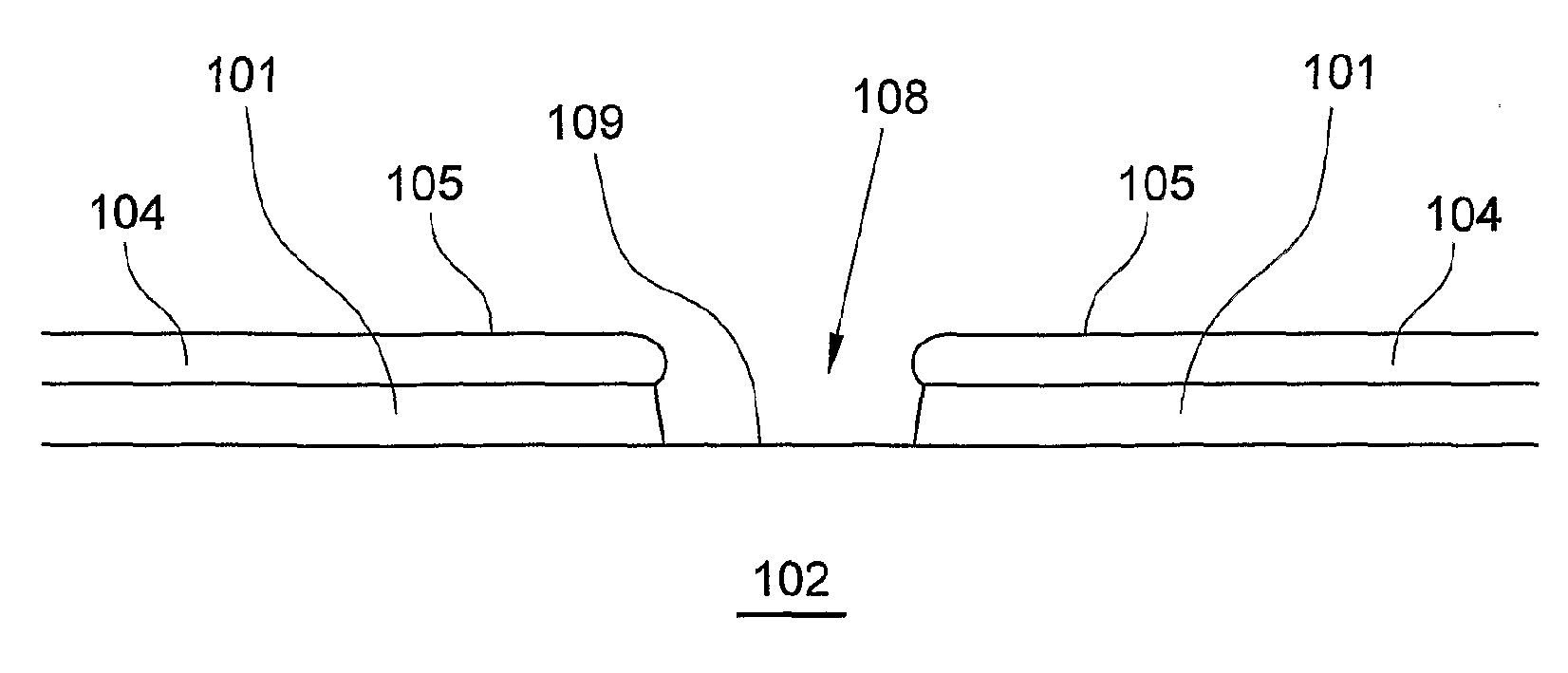

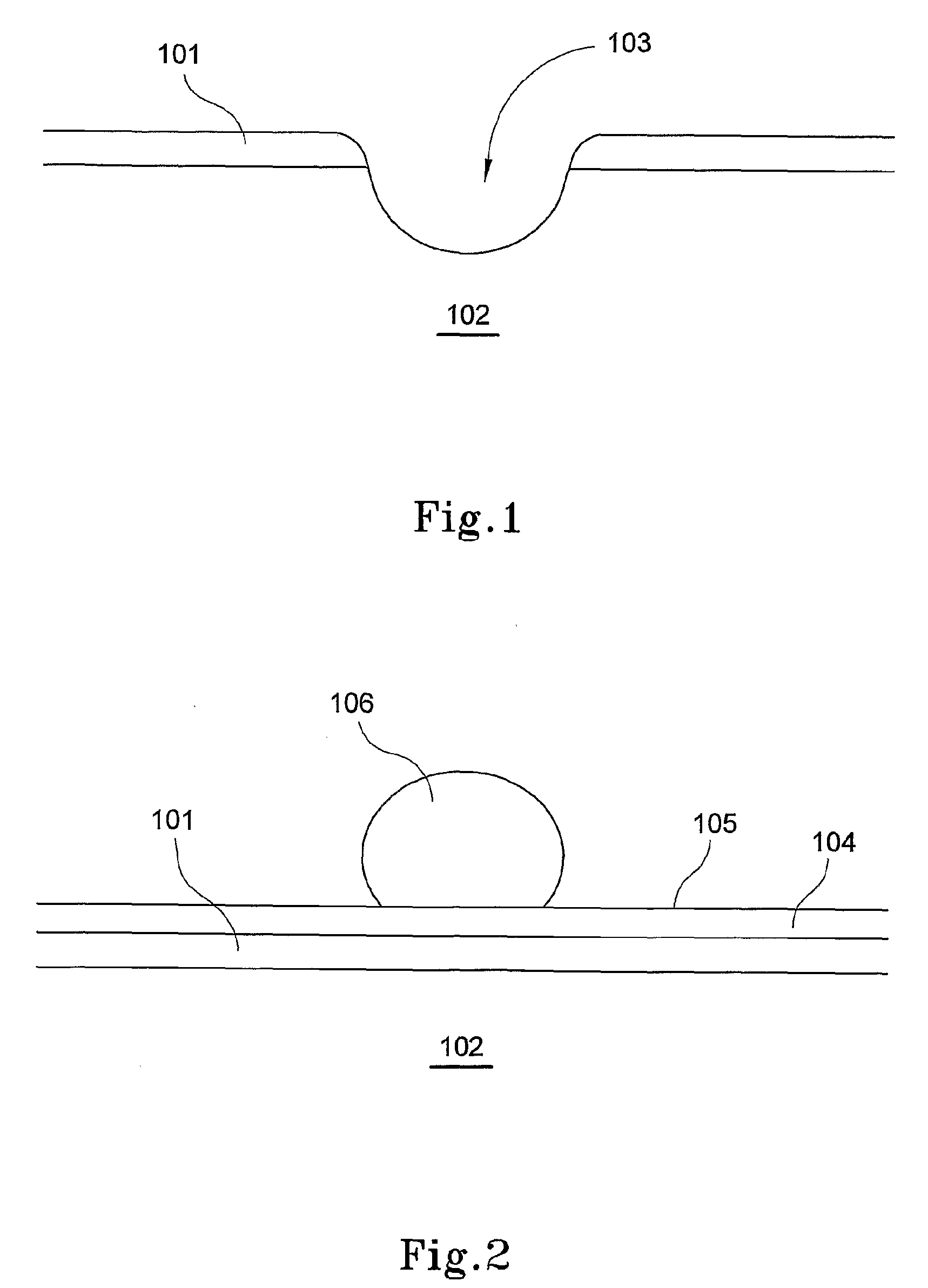

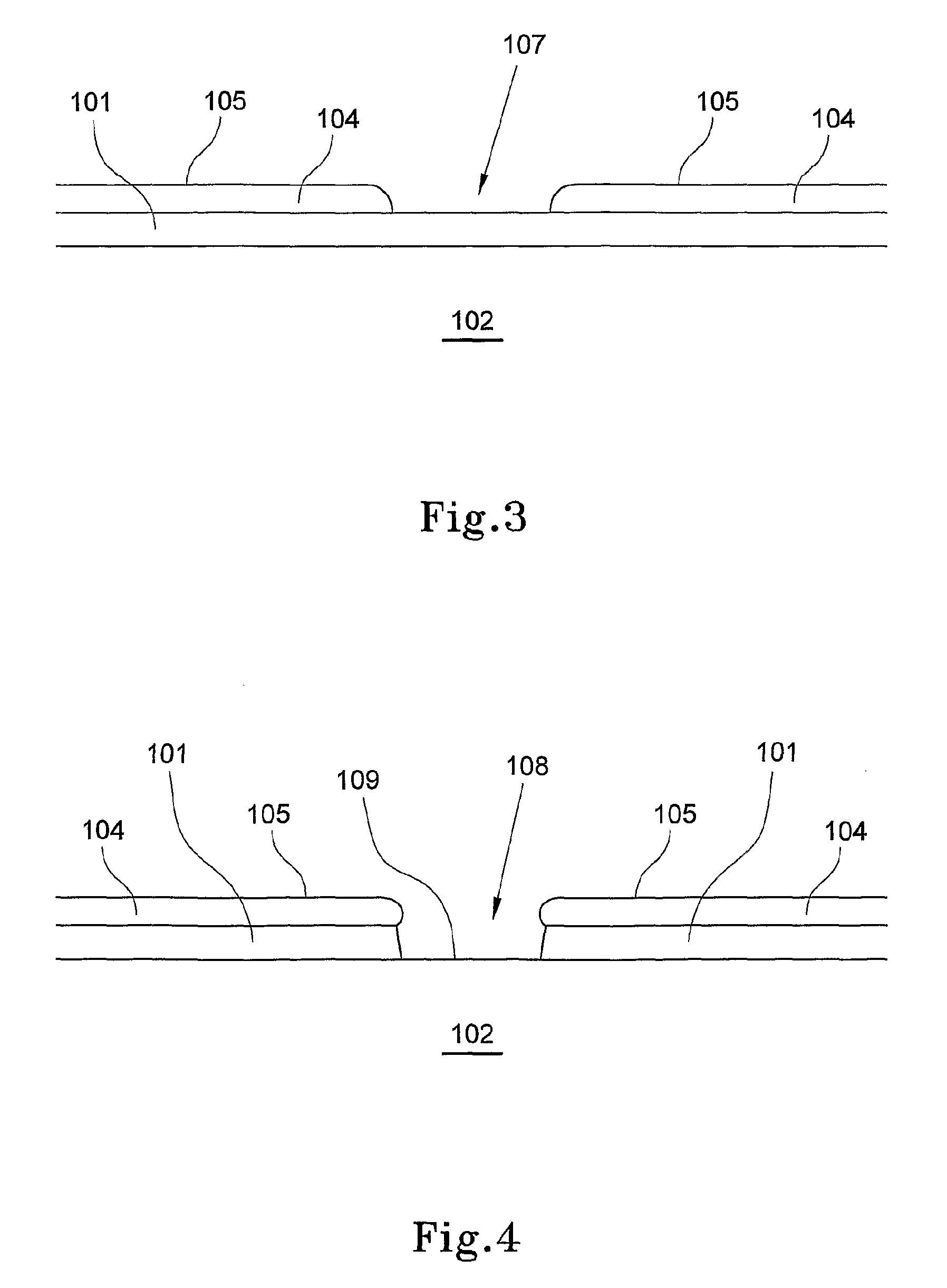

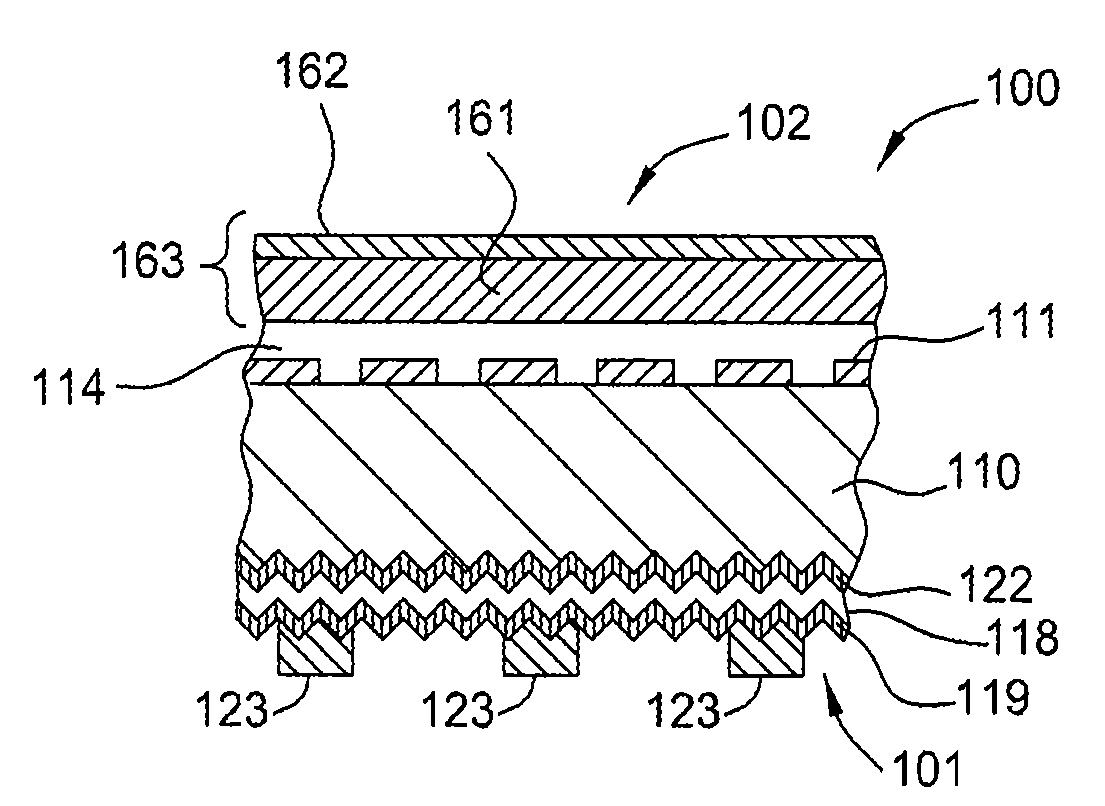

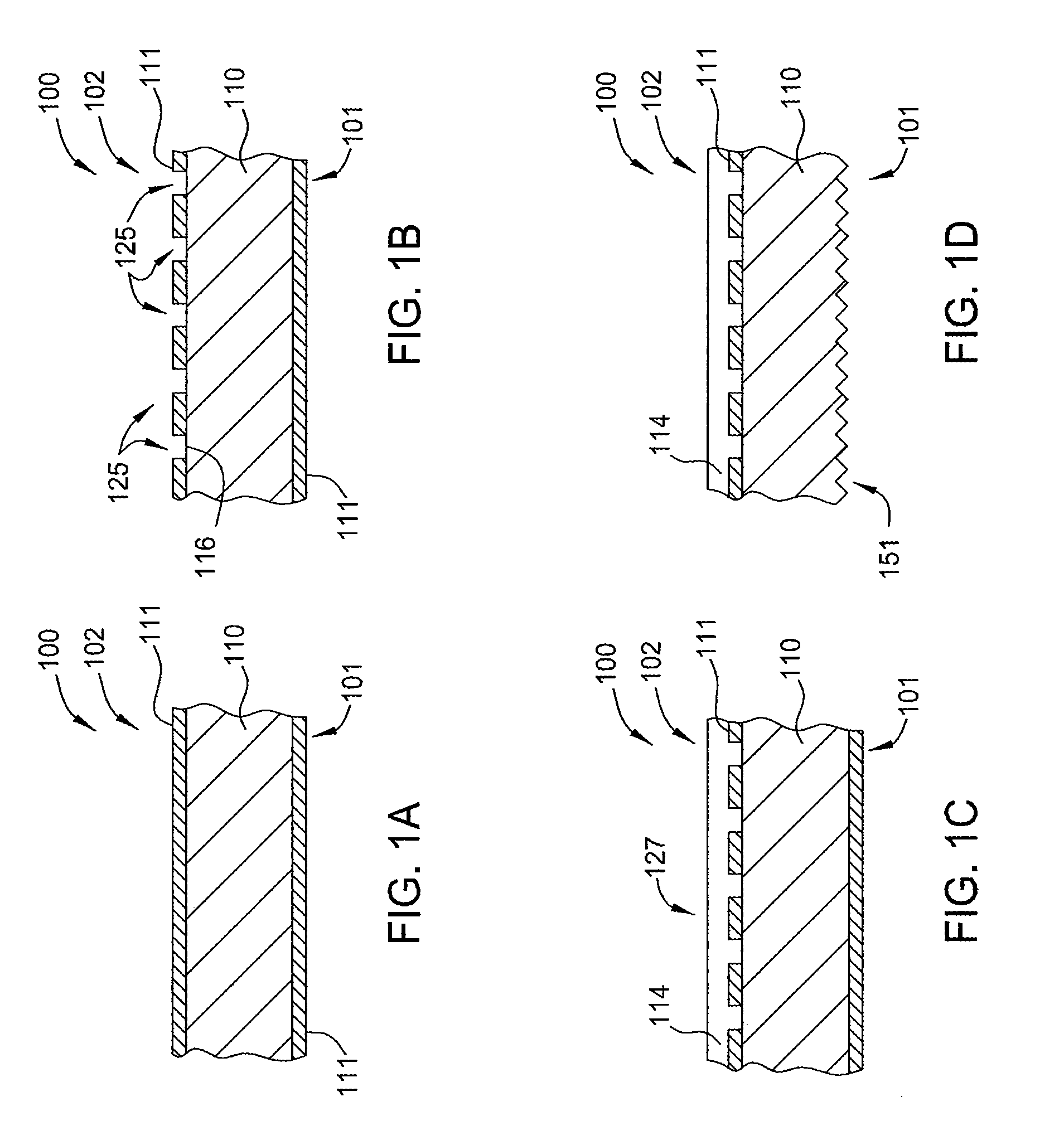

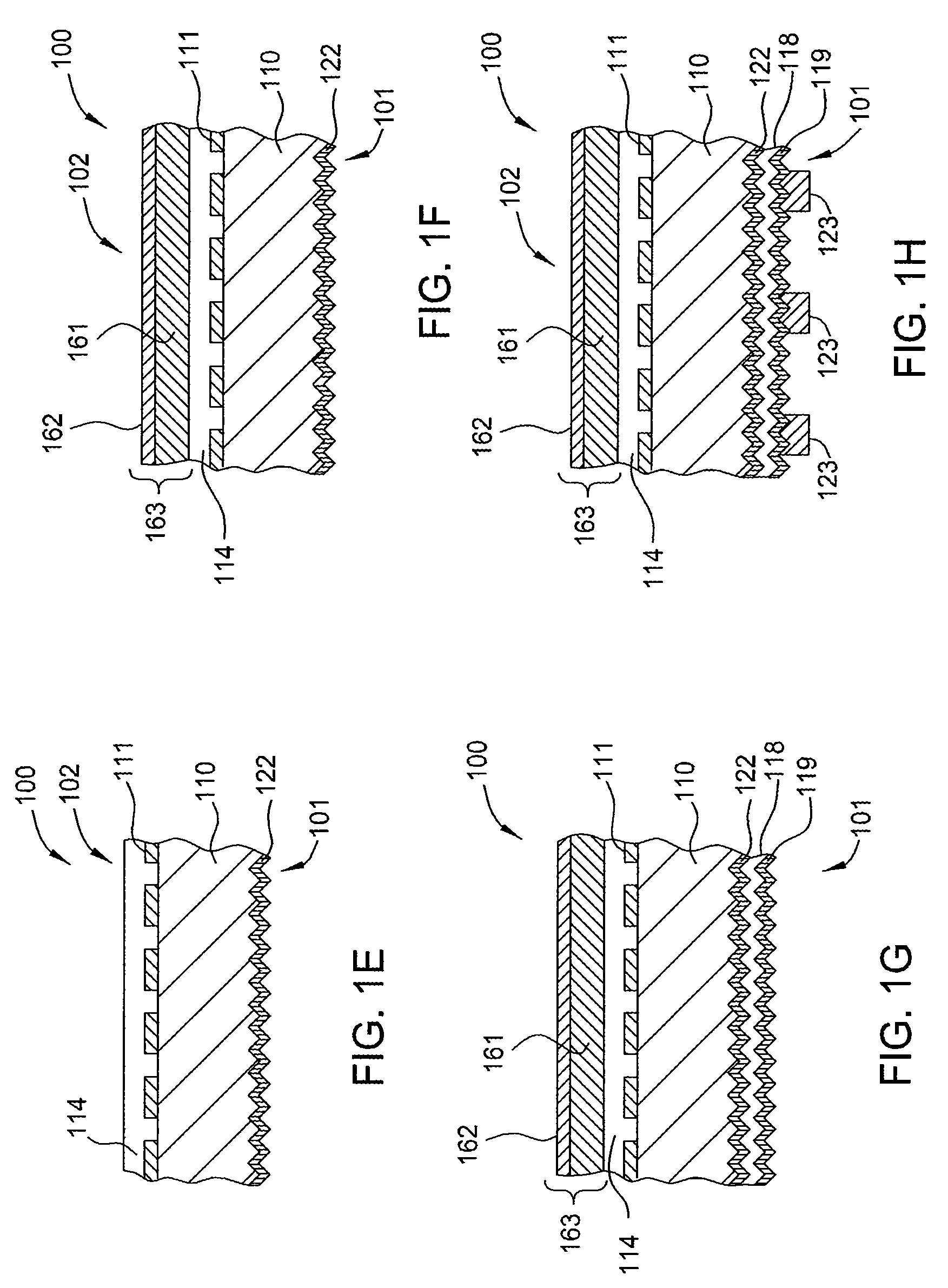

A template 100 for three-dimensional thin-film solar cell substrate formation for use in three-dimensional thin-film solar cells. The template 100 comprises a substrate which comprises a plurality of posts 102 and a plurality of trenches 104 between said plurality of posts 102. The template 100 forms an environment for three-dimensional thin-film solar cell substrate formation.

Owner:BEAMREACH SOLAR INC

Template for pyramidal three-dimensional thin-film solar cell manufacturing and methods of use

InactiveUS20090107545A1Reduce disadvantagesReduce problemsFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell fabrication

A template 120 for pyramidal three-dimensional thin-film solar cell substrate formation for use in pyramidal three-dimensional thin-film solar cells. The template 120 comprises a substrate which comprises a plurality of pyramid trenches 122 between a plurality of posts 123. The template 120 forms an environment for pyramidal three-dimensional thin-film solar cell substrate formation.

Owner:BEAMREACH SOLAR INC

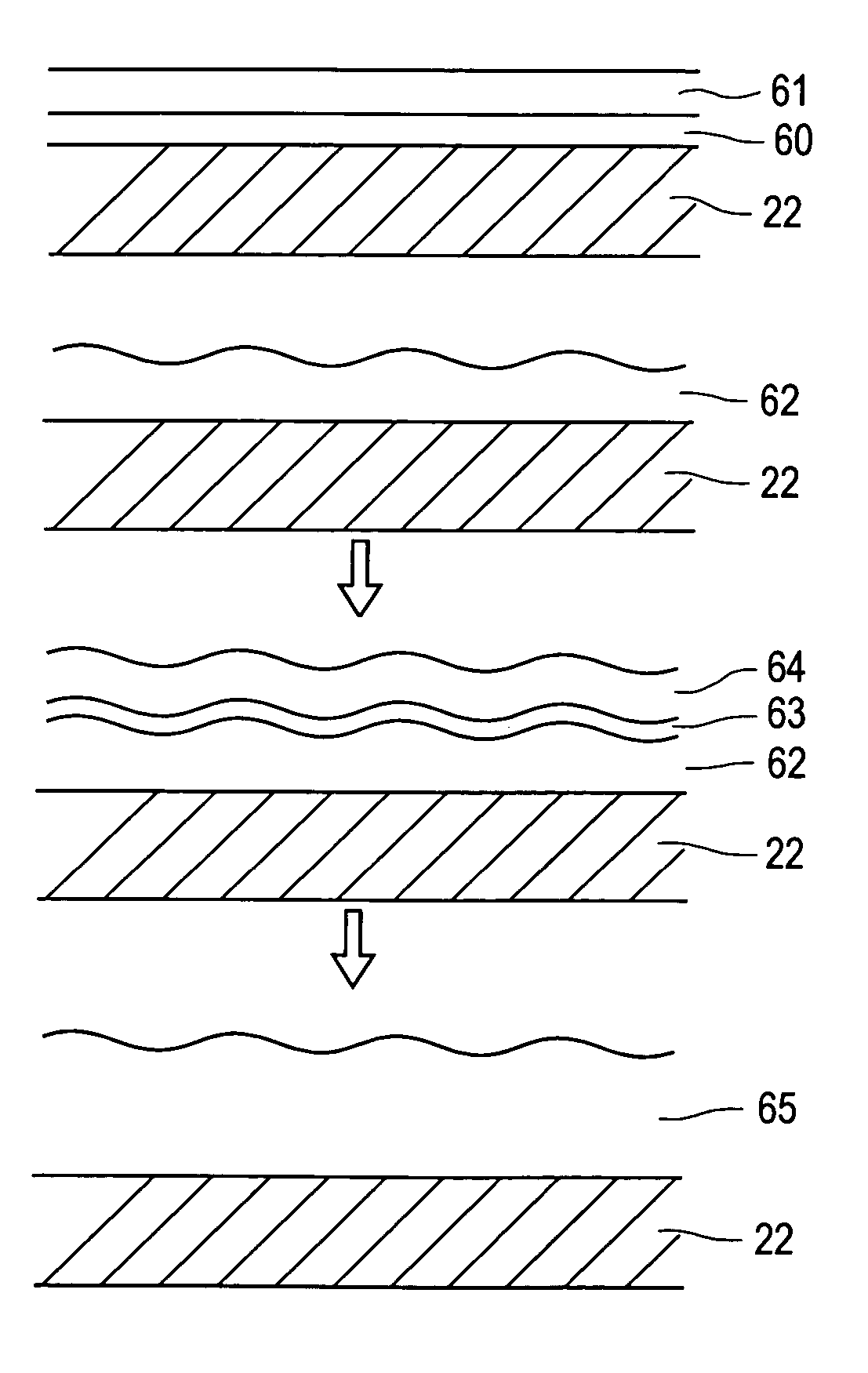

Technique and apparatus for depositing thin layers of semiconductors for solar cell fabrication

InactiveUS20050202589A1Rough surface cutObtain microscale compositional uniformitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationThin layerCompound (substance)

The present invention advantageously provides for, in different embodiments, low-cost deposition techniques to form high-quality, dense, well-adhering Group IBIIIAVIA compound thin films with macro-scale as well as micro-scale compositional uniformities. In one embodiment, there is provided a method of growing a Group IBIIIAVIA semiconductor layer on a base, and includes the steps of depositing on the base a film of Group IB material and at least one layer of Group IIIA material, intermixing the film of Group IB material and the at least one layer of Group IIIA material to form an intermixed layer, and forming over the intermixed layer a metallic film comprising at least one of a Group IIIA material sub-layer and a Group IB material sub-layer. Other embodiments are also described.

Owner:SOLOPOWER

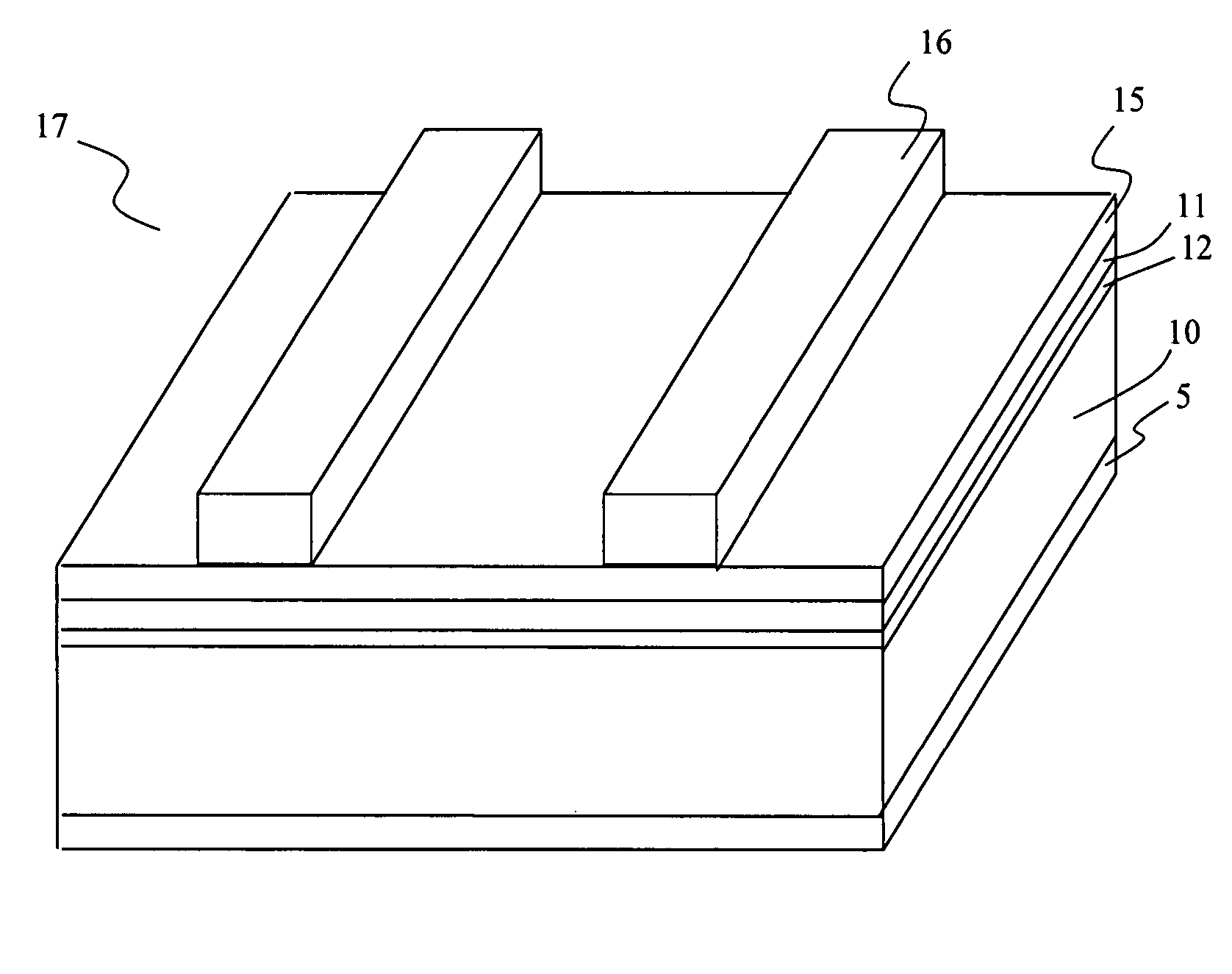

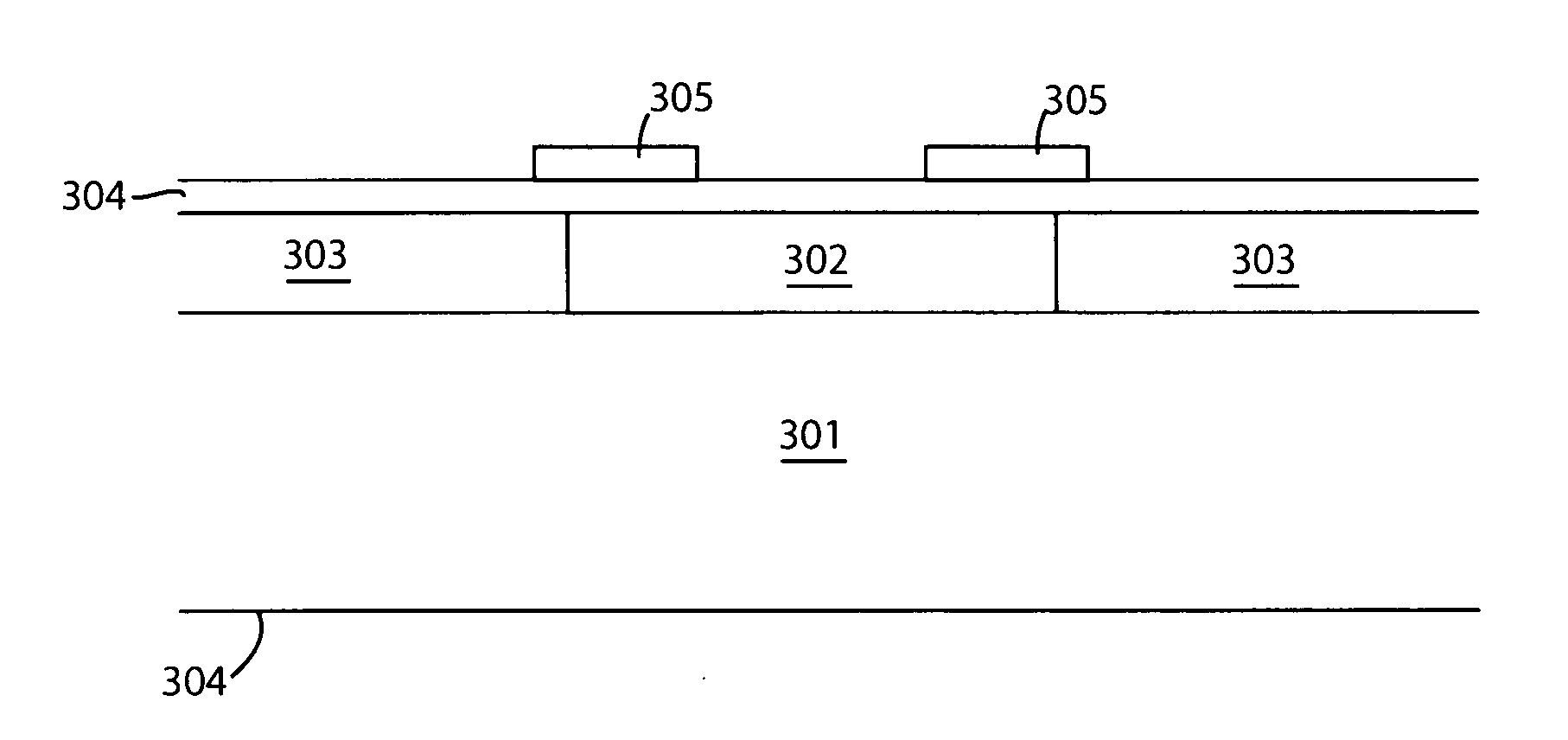

Solar cell having polymer heterojunction contacts

ActiveUS20070151599A1Reduce degradationIncrease in costSolid-state devicesPhotovoltaic energy generationHeterojunctionEngineering

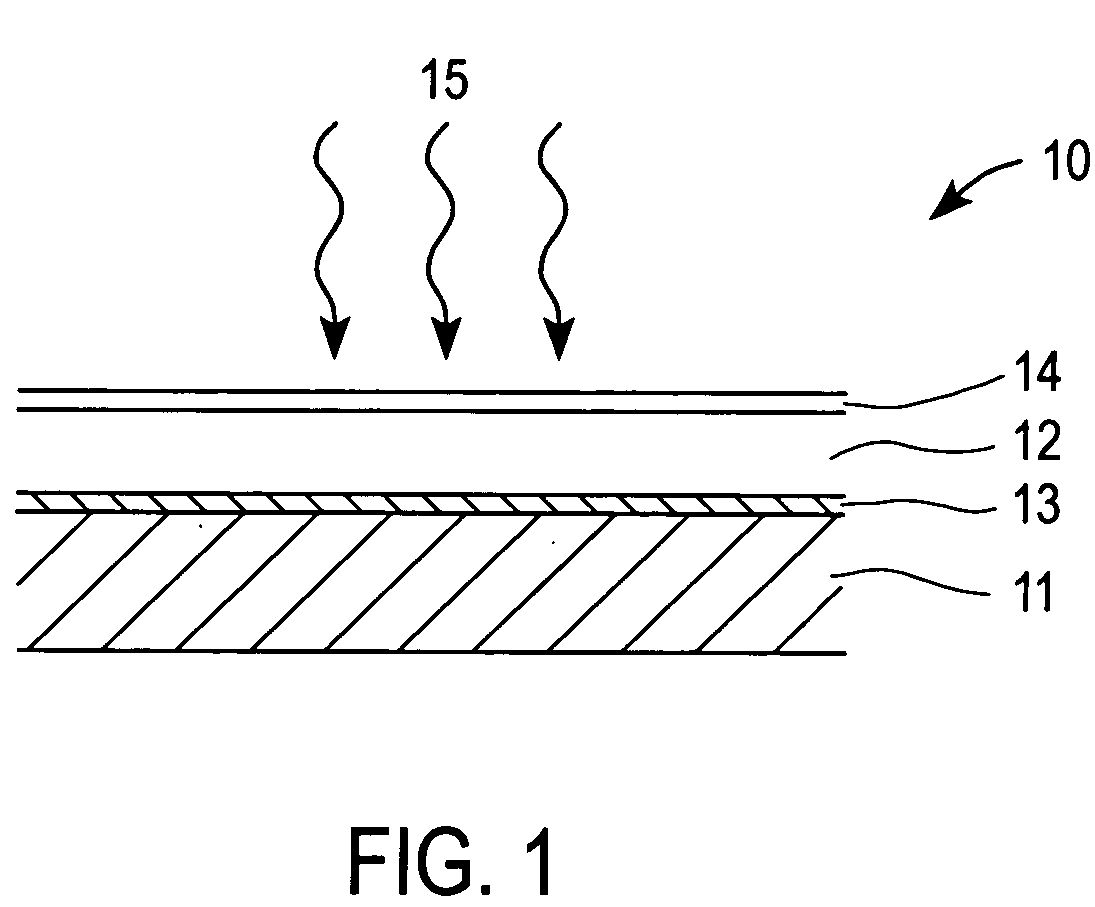

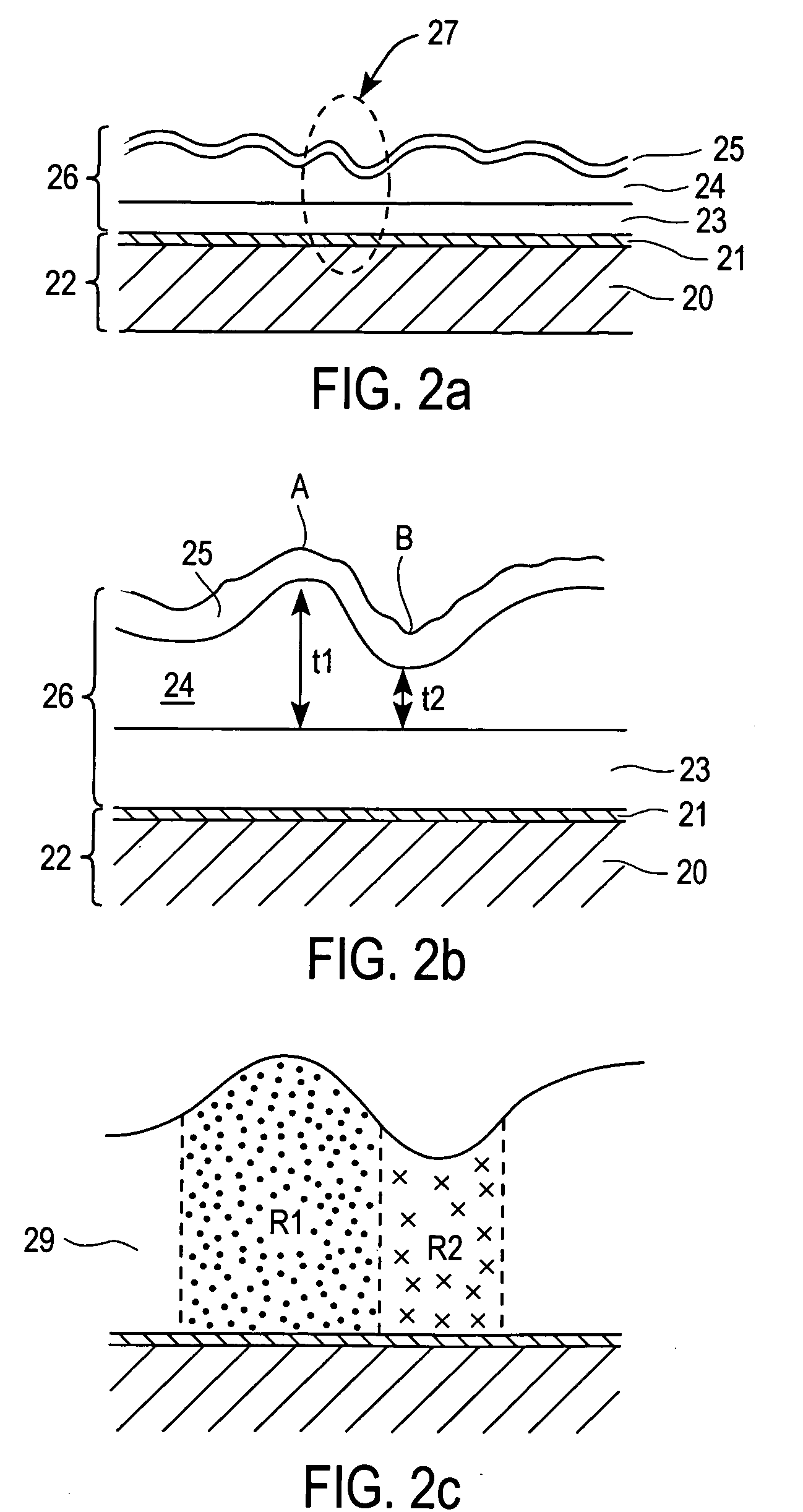

A solar cell having backside contacts is economically fabricated through use of acceptor and donor polymers which are inkjet printed in interleaved patterns on the back surface as the carrier accepting electrodes of the solar cell. The polymers can be placed on a tunnel oxide on the surface of a semiconductor substrate, or the polymers can be in direct contact with the semiconductor substrate. Electrical patterns interconnecting the acceptor and donor polymer patterns can also be formed by inkjet printing a seed layer and then electroplating the seed layer. Advantageously, high temperature processing is not required in the process as is required in conventional solar cell fabrication using dopant implants into the semiconductor substrate. In alternative embodiments, doped contacts are diffused in the top surface and a polymer contact is formed over the back surface.

Owner:MAXEON SOLAR PTE LTD

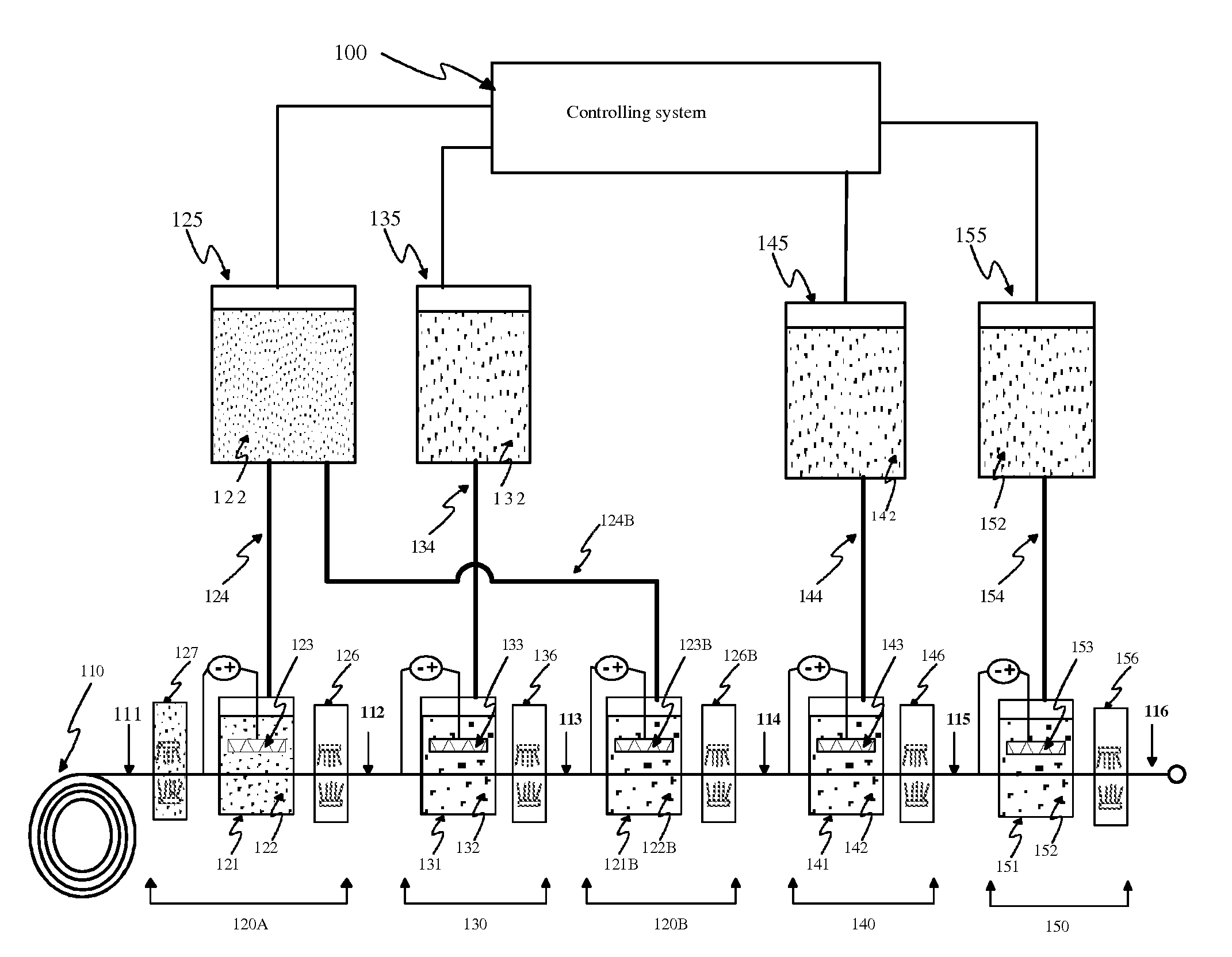

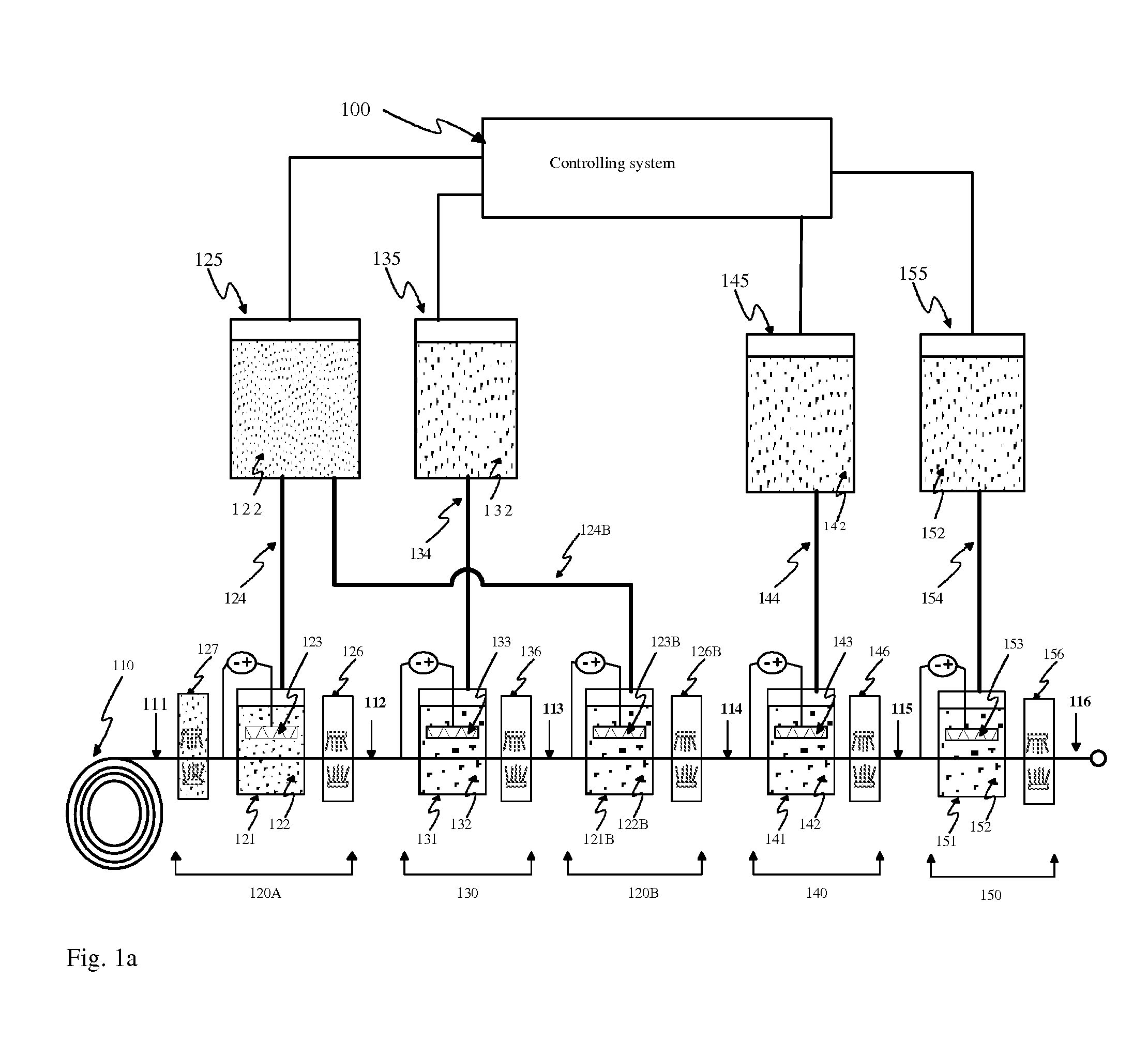

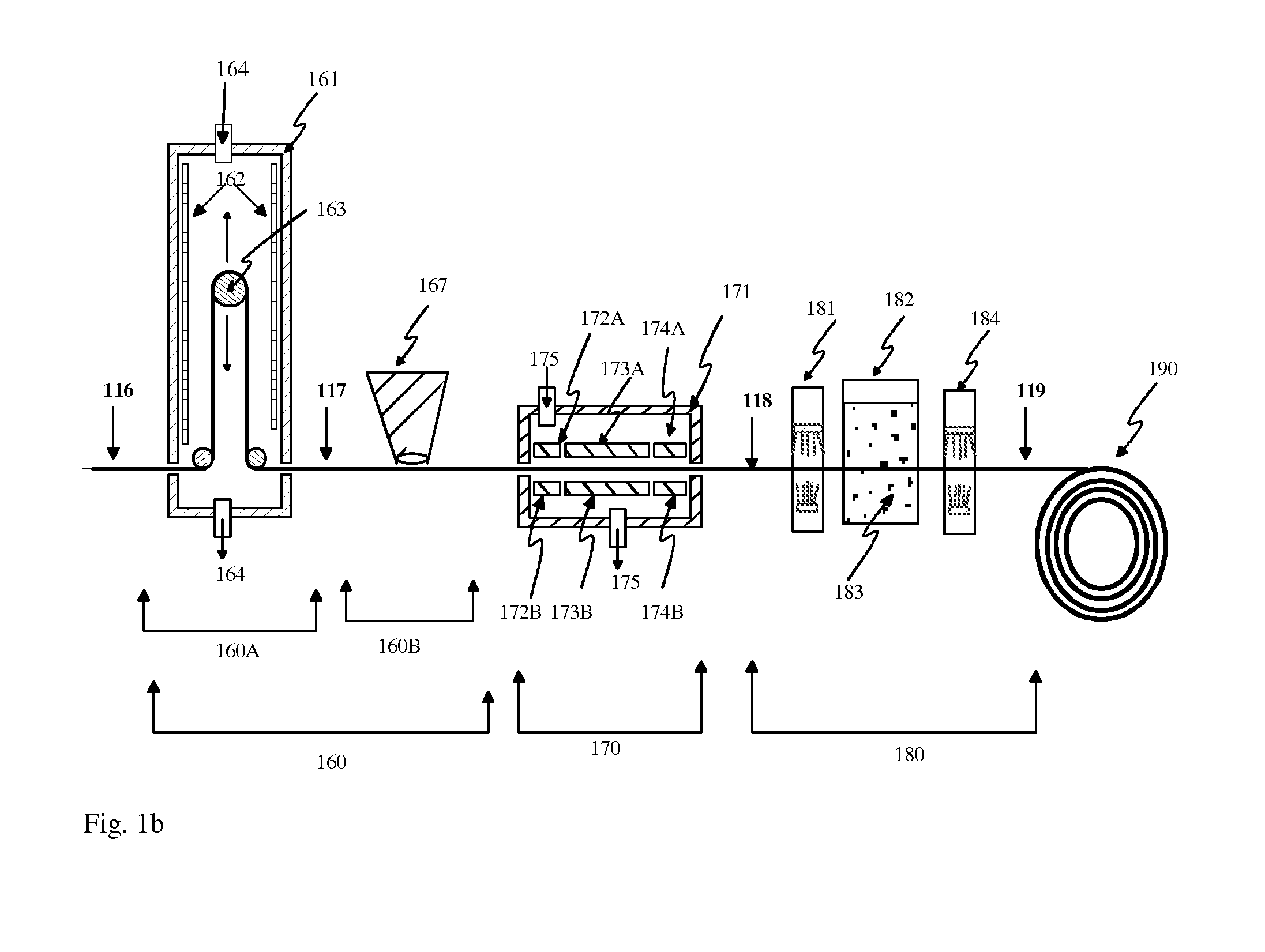

Methods for fabricating thin film solar cells

The present invention relates to CIGS solar cell fabrication. The invention discloses a method for fabricating CIGS thin film solar cells using a roll-to-roll system. The invention discloses method to fabricate semiconductor thin film Cu(InGa)(SeS)2 by sequentially electroplating a stack comprising of copper, indium, gallium, and selenium elements or their alloys followed by selenization at a temperature between 450 C and 700 C.

Owner:SOLTRIUM TECH LTD SHENZHEN

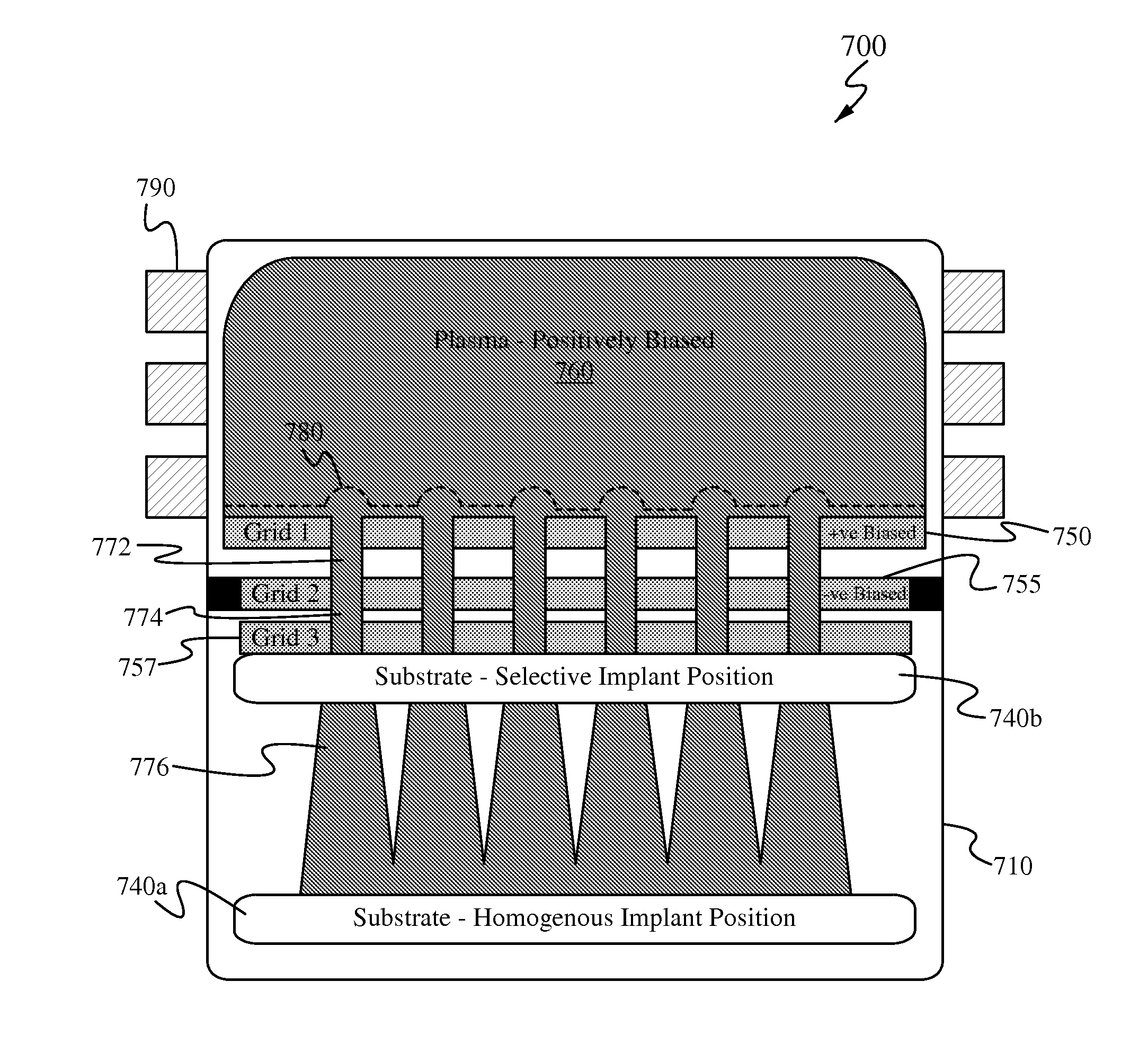

Plasma grid implant system for use in solar cell fabrications

ActiveUS20100323508A1Increase pressureReduce pressureElectric discharge tubesFinal product manufactureComputational physicsSolar cell

A method of ion implantation comprising: providing a plasma within a plasma region of a chamber; positively biasing a first grid plate, wherein the first grid plate comprises a plurality of apertures; negatively biasing a second grid plate, wherein the second grid plate comprises a plurality of apertures; flowing ions from the plasma in the plasma region through the apertures in the positively-biased first grid plate; flowing at least a portion of the ions that flowed through the apertures in the positively-biased first grid plate through the apertures in the negatively-biased second grid plate; and implanting a substrate with at least a portion of the ions that flowed through the apertures in the negatively-biased second grid plate.

Owner:INTEVAC

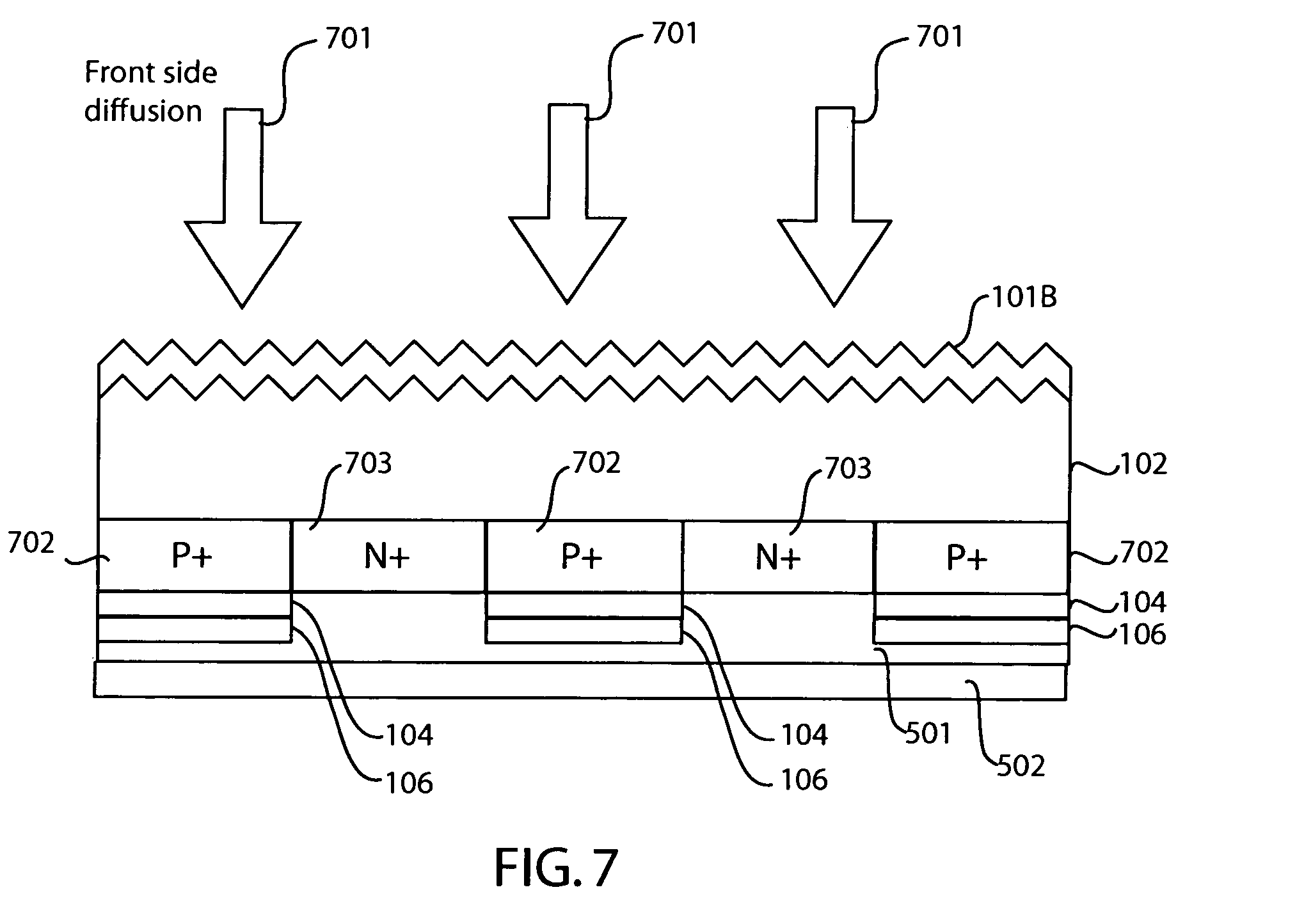

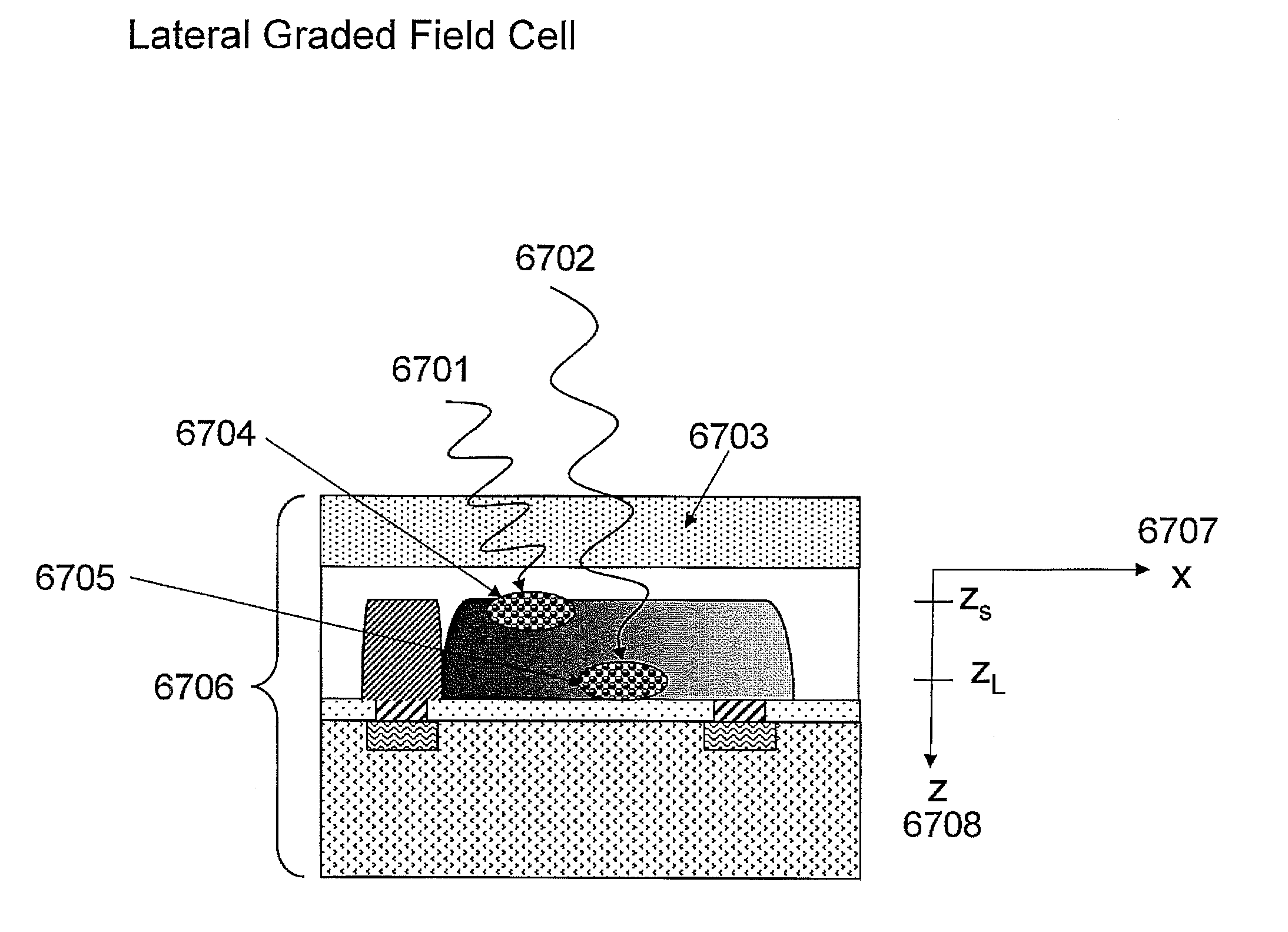

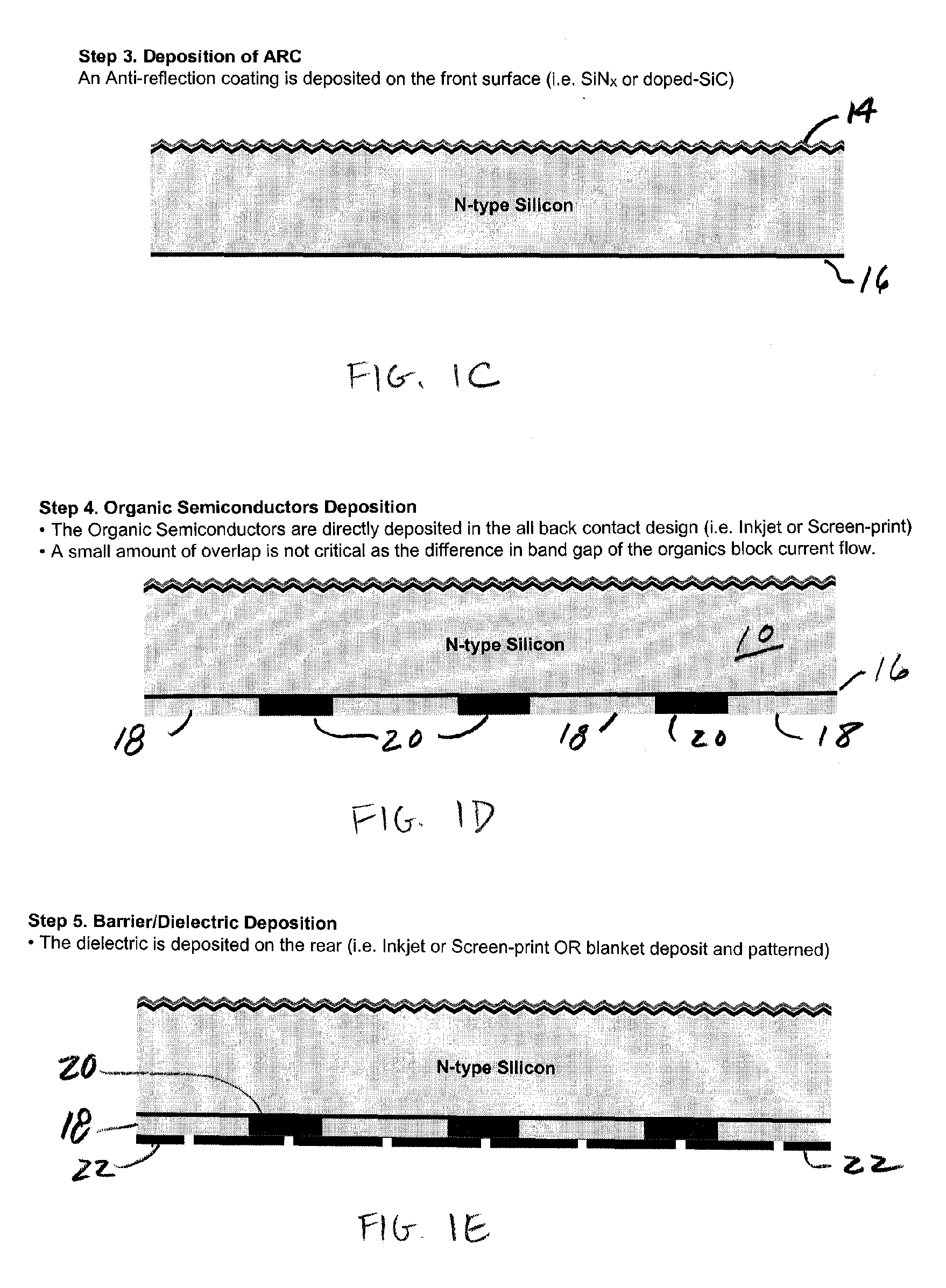

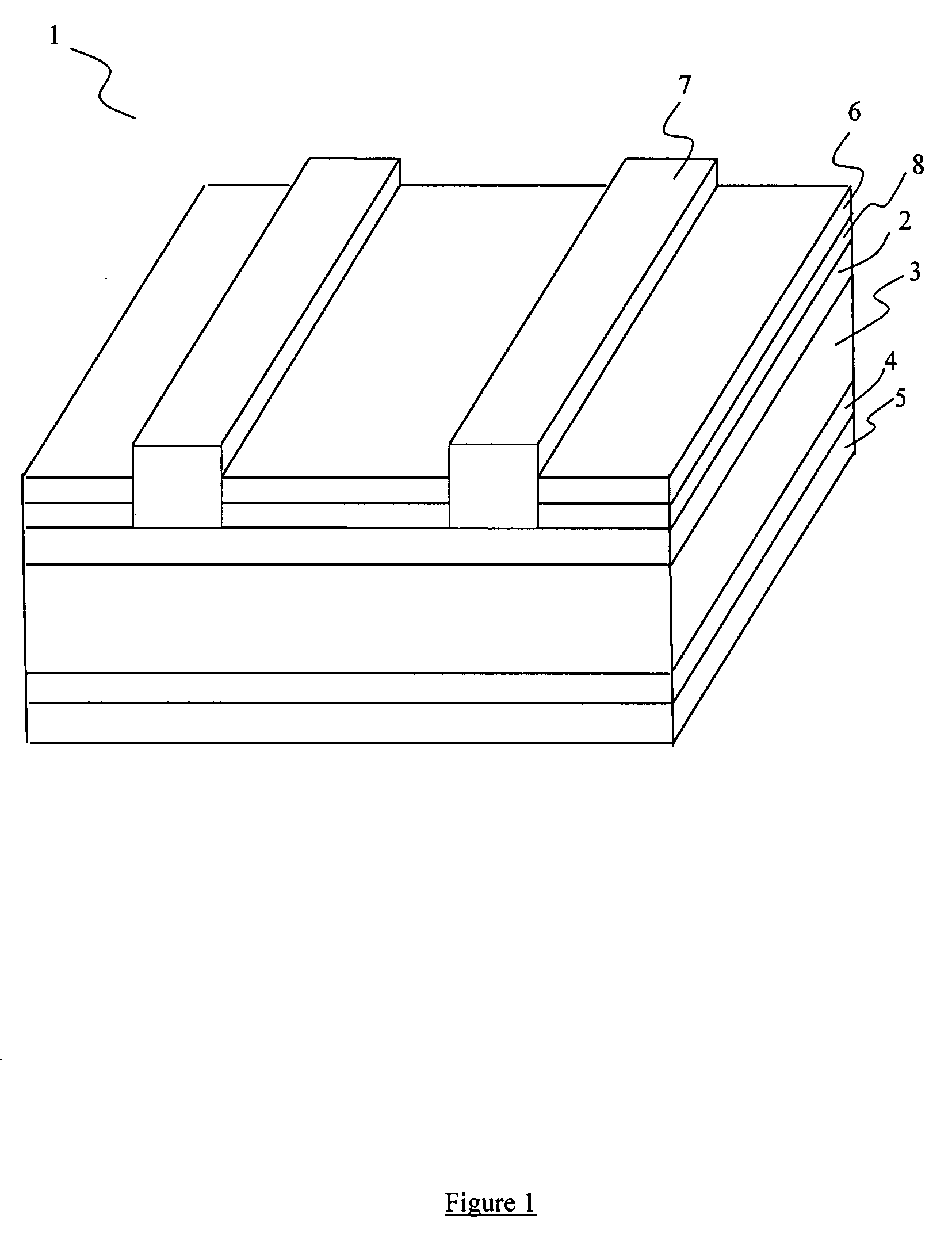

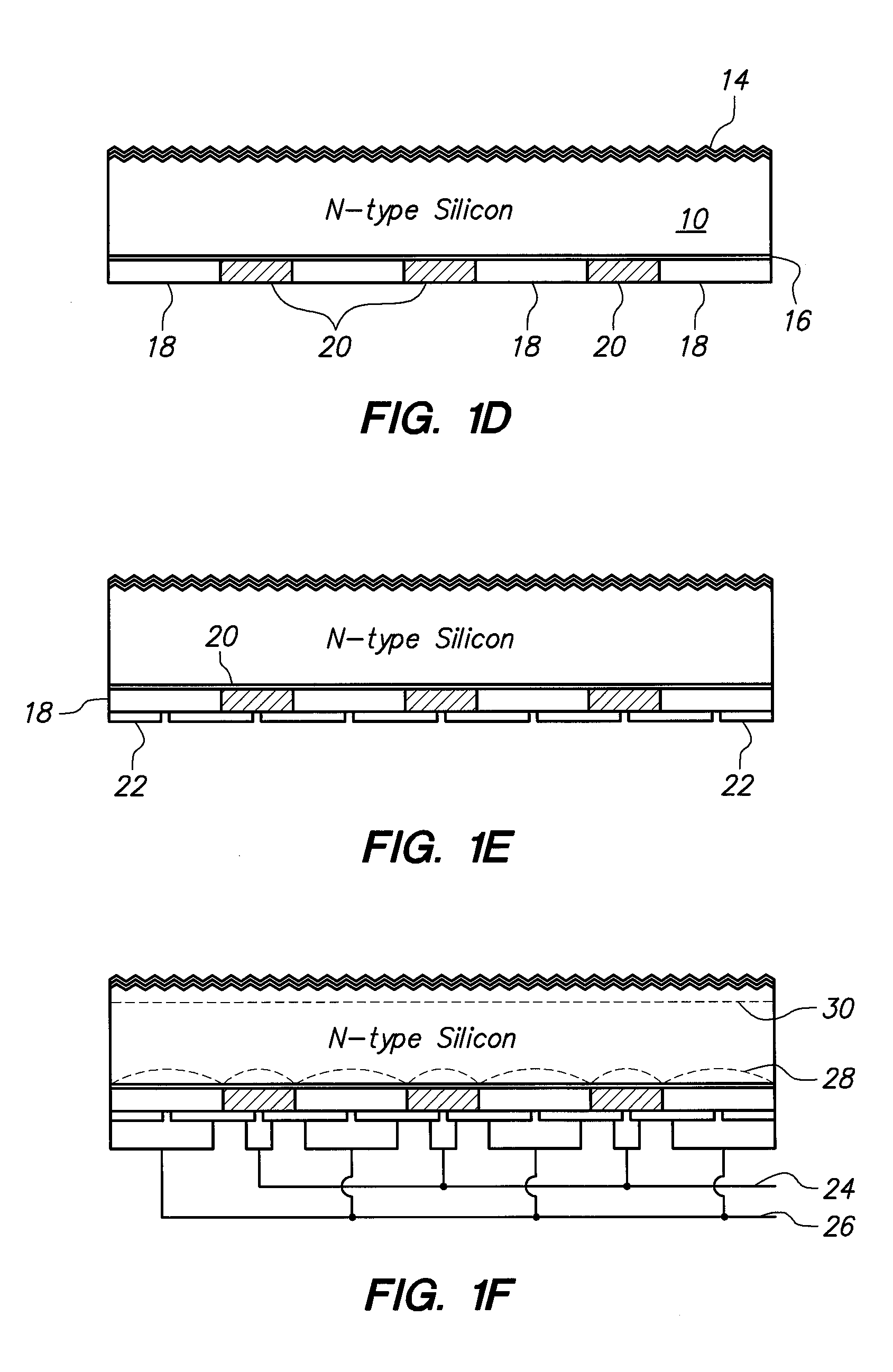

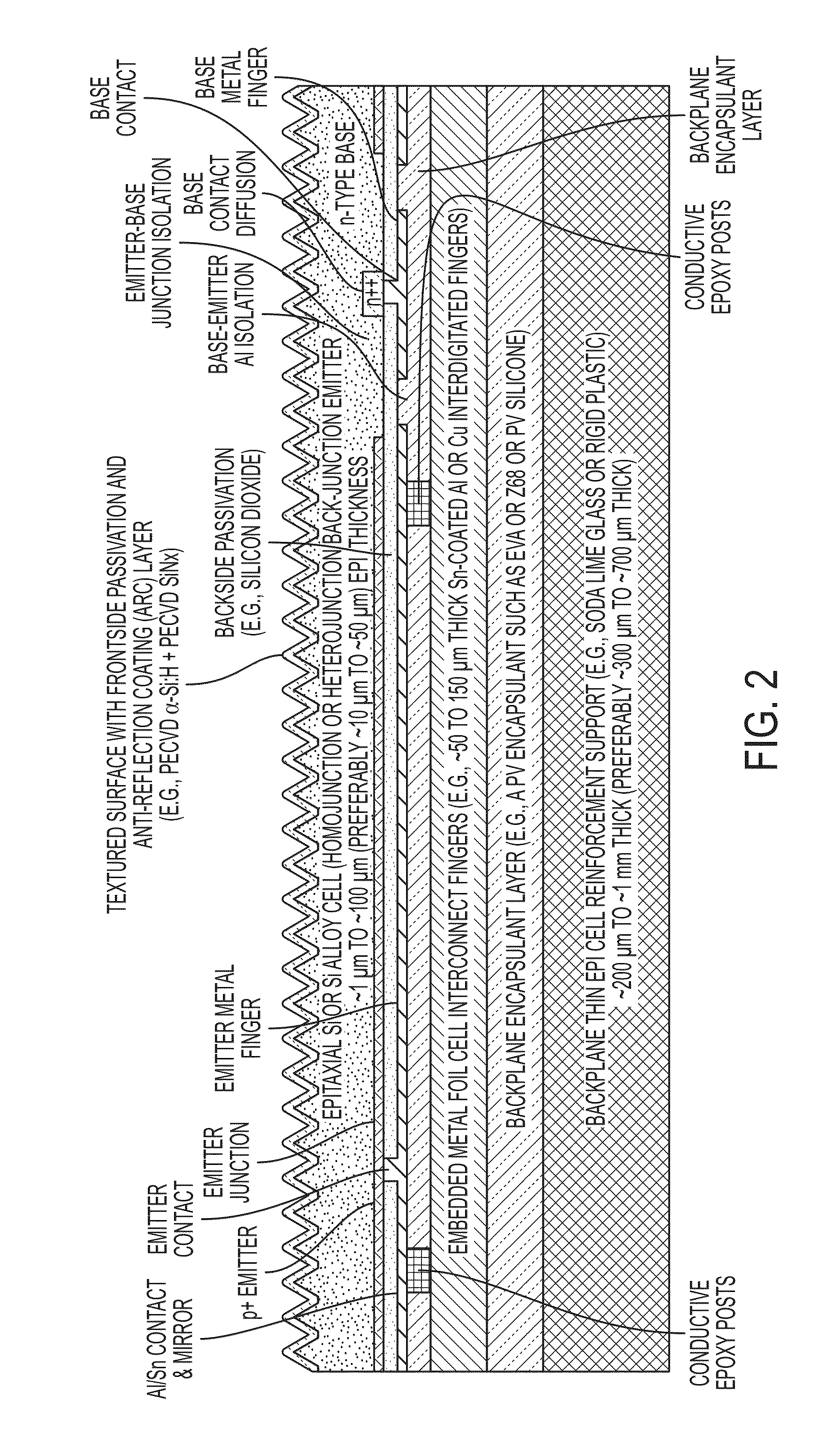

Advanced high efficientcy crystalline solar cell fabrication method

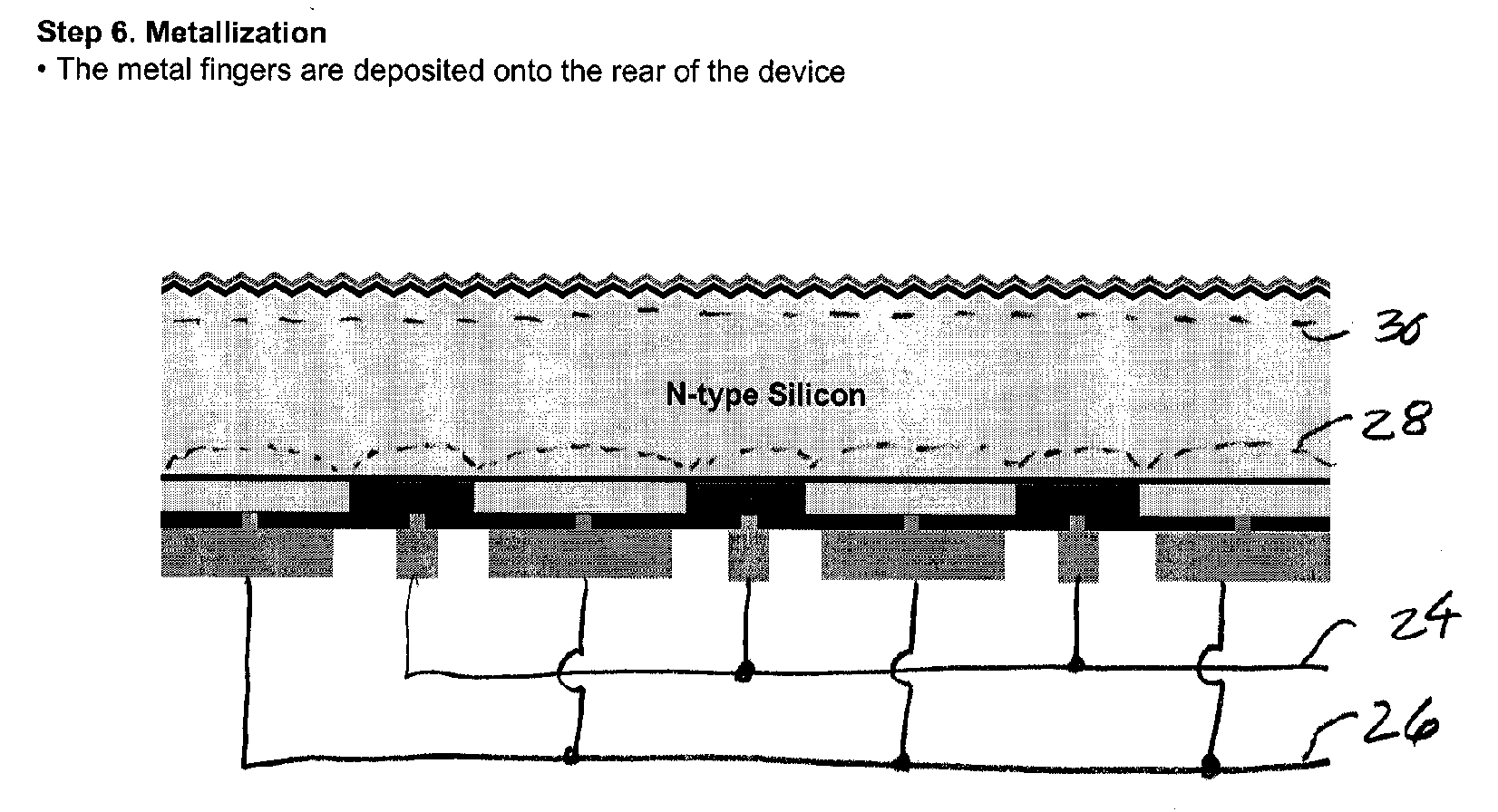

InactiveUS20110162703A1Improve efficiencyEliminate front surface shadingFinal product manufactureSemiconductor/solid-state device manufacturingDopantContact layer

A method of fabricating a solar cell comprising: providing a semiconducting wafer having a front surface, a back surface, and a background doped region; performing a set of ion implantations of dopant into the semiconducting wafer to form a back alternatingly-doped region extending from the back surface of the semiconducting wafer to a location between the back surface and the front surface, wherein the back doped region comprises laterally alternating first back doped regions and second back doped regions, and wherein the first back doped regions comprise a different charge type than the second back doped regions and the background doped region; and disposing a back metal contact layer onto the back surface of the semiconducting wafer, wherein the back metal contact layer is aligned over the first and second back doped regions and is configured to conduct electrical charge from the first and second back doped regions.

Owner:INTEVAC

Low-temperature doping processes for silicon wafer devices

InactiveUS20080000521A1Quality improvementImprove concentrationPolycrystalline material growthFinal product manufactureGas phaseSystem configuration

A low temperature method and system configuration for depositing a doped silicon layer on a silicon substrate of a selected grade. The silicon substrate for functioning as a light absorber and the doped silicon layer for functioning as an emitter. The method comprises the acts of: positioning the silicon substrate in a chamber suitable for chemical vapour deposition of the doped silicon layer on the silicon substrate, an external surface of the silicon substrate suitable for promoting crystalline film growth; using a plurality of process parameters for adjusting growth of the doped silicon layer, the plurality of process parameters including a first process parameter of a process temperature for inhibiting diffusion of dopant atoms into the external surface of the silicon substrate, and a second process parameter of a hydrogen dilution level for providing excess hydrogen atoms to affect a layer crystallinity of the atomic structure of the doped silicon layer; exposing the external surface of the silicon substrate in the chamber to a vapour at appropriate ambient chemical vapour deposition conditions, the vapour including silicon atoms, dopant atoms and the excess hydrogen atoms, the atoms for use in growing the doped silicon layer; and originating growth of the doped silicon layer on the external surface to form an interface between the doped silicon layer and the silicon substrate, such that the doped silicon layer includes first atomic structural regions having a higher quality of the layer crystallinity next to the interface with adjacent second atomic structural regions having a lower quality of the layer crystallinity with increasing concentrations of crystal defects for increasing thickness of the doped silicon layer from the interface. The resultant silicon substrate and doped layer (or thin film) can be used in solar cell manufacturing.

Owner:SIVOTHTHAMAN SIVA +1

Buried-contact solar cells with self-doping contacts

InactiveUS7335555B2Less expensiveMinimum obscurationFinal product manufactureSemiconductor/solid-state device manufacturingSolar cellSolar cell fabrication

Owner:APPLIED MATERIALS INC

Solar cell having polymer heterojunction contacts

ActiveUS7718888B2Reduce degradationIncrease in costPV power plantsSolid-state devicesHeterojunctionEngineering

A solar cell having backside contacts is economically fabricated through use of acceptor and donor polymers which are inkjet printed in interleaved patterns on the back surface as the carrier accepting electrodes of the solar cell. The polymers can be placed on a tunnel oxide on the surface of a semiconductor substrate, or the polymers can be in direct contact with the semiconductor substrate. Electrical patterns interconnecting the acceptor and donor polymer patterns can also be formed by inkjet printing a seed layer and then electroplating the seed layer. Advantageously, high temperature processing is not required in the process as is required in conventional solar cell fabrication using dopant implants into the semiconductor substrate. In alternative embodiments, doped contacts are diffused in the top surface and a polymer contact is formed over the back surface.

Owner:MAXEON SOLAR PTE LTD

Technique and apparatus for depositing thin layers of semiconductors for solar cell fabrication

InactiveUS7374963B2Obtain microscale compositional uniformityRough surface cutSemiconductor/solid-state device manufacturingPhotovoltaic energy generationThin layerSemiconductor

The present invention advantageously provides for, in different embodiments, low-cost deposition techniques to form high-quality, dense, well-adhering Group IBIIIAVIA compound thin films with macro-scale as well as micro-scale compositional uniformities. In one embodiment, there is provided a method of growing a Group IBIIIAVIA semiconductor layer on a base, and includes the steps of depositing on the base a film of Group IB material and at least one layer of Group IIIA material, intermixing the film of Group IB material and the at least one layer of Group IIIA material to form an intermixed layer, and forming over the intermixed layer a metallic film comprising at least one of a Group IIIA material sub-layer and a Group IB material sub-layer. Other embodiments are also described.

Owner:SOLOPOWER

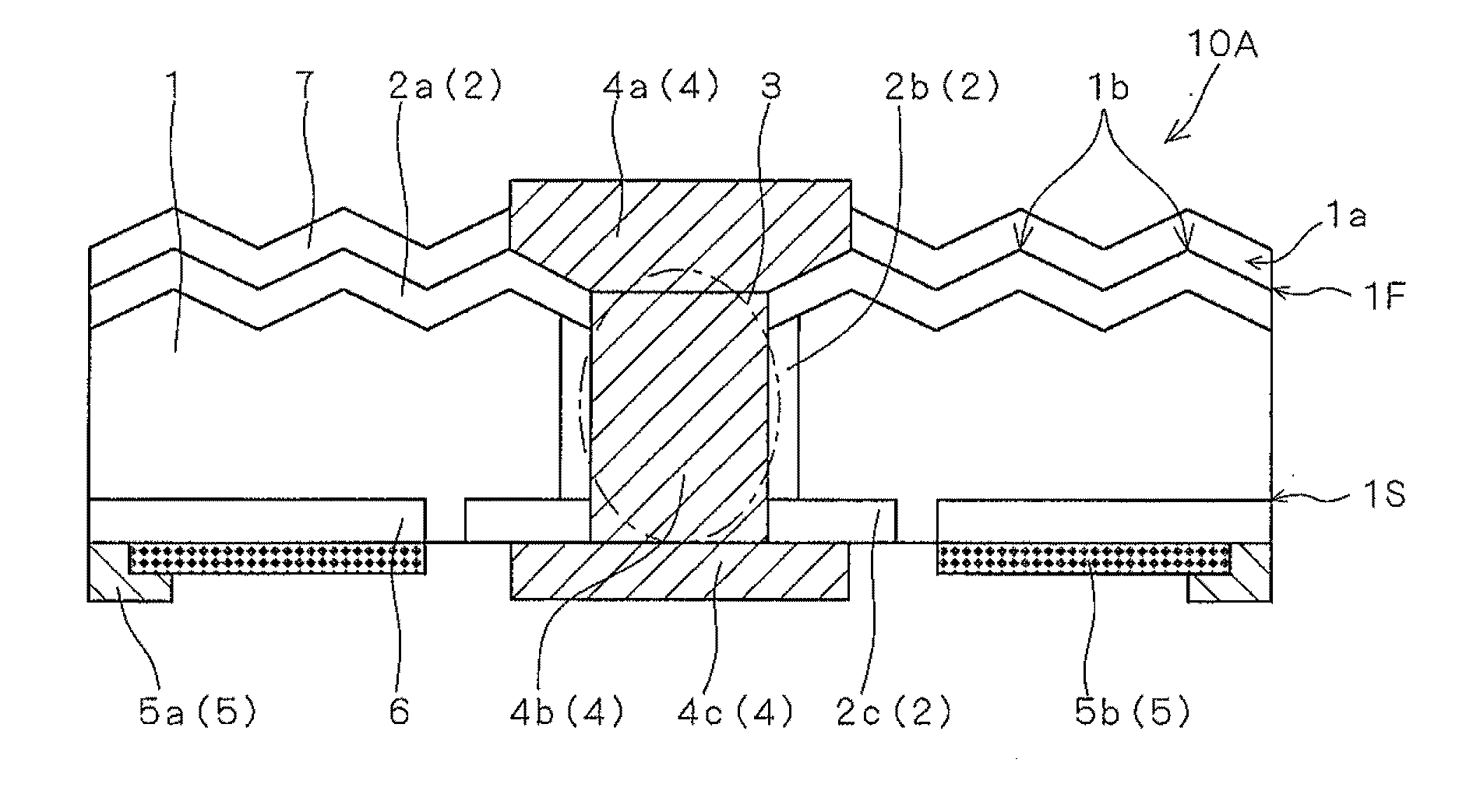

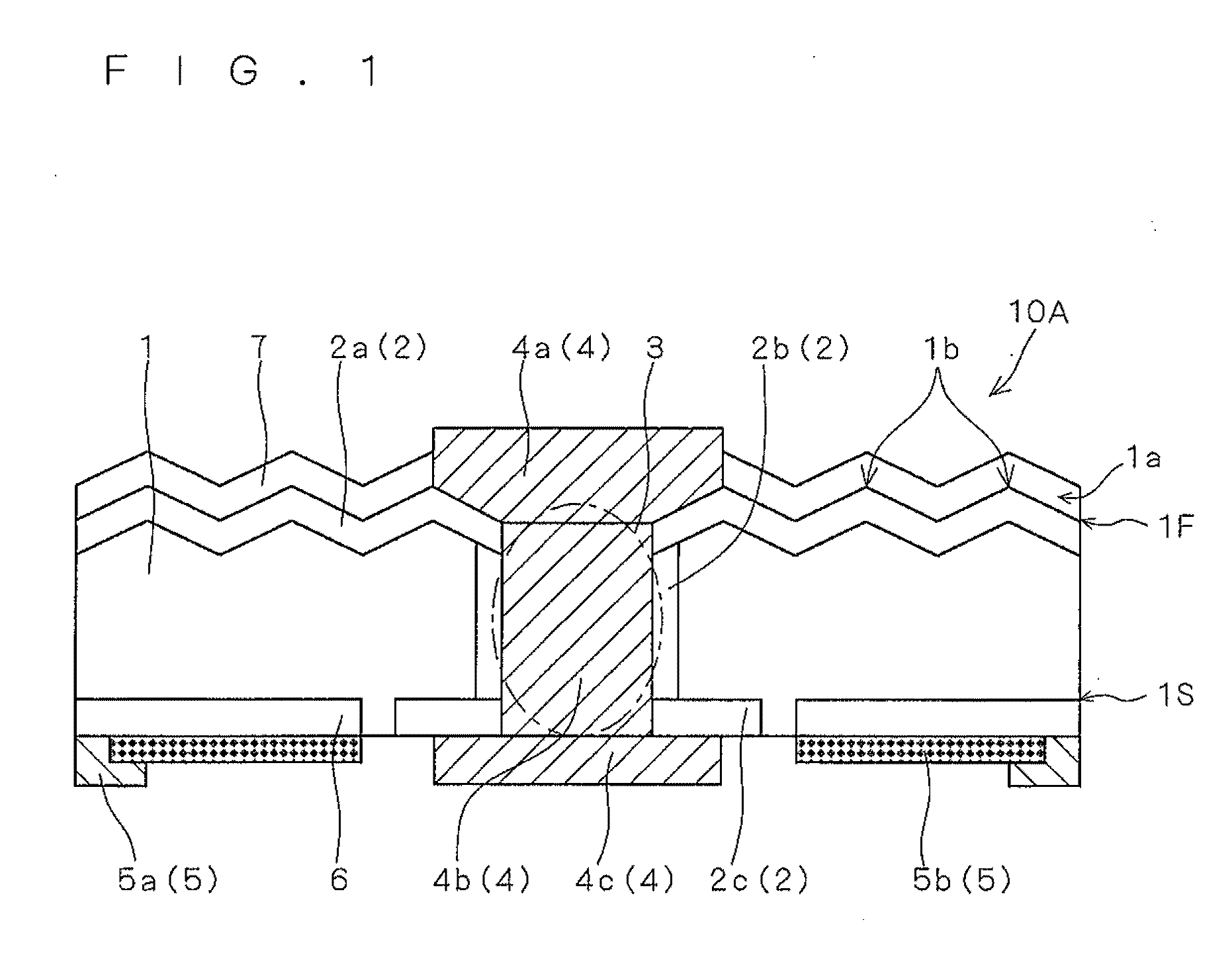

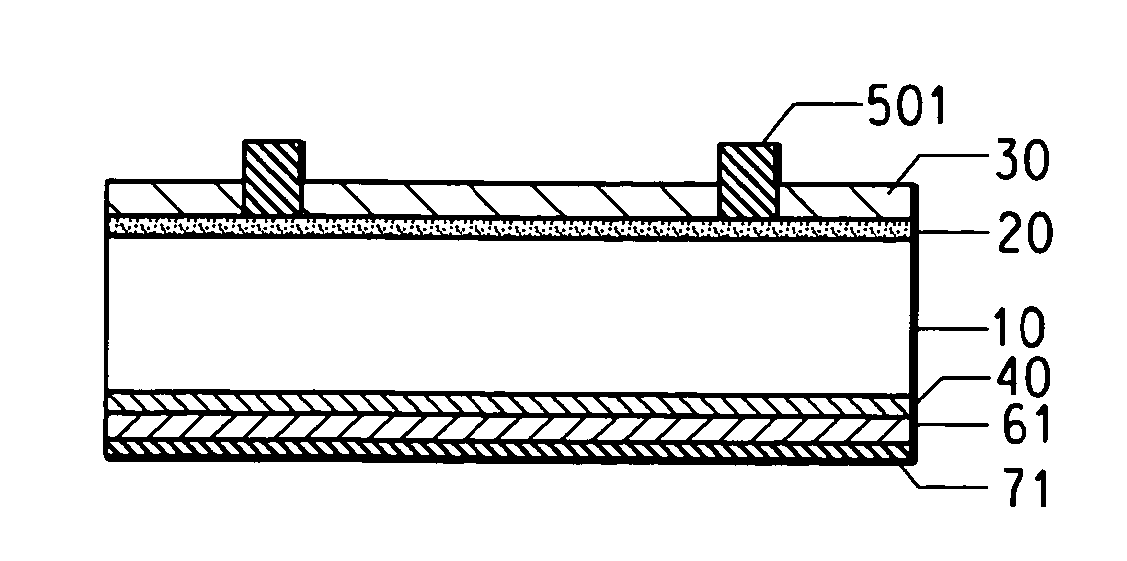

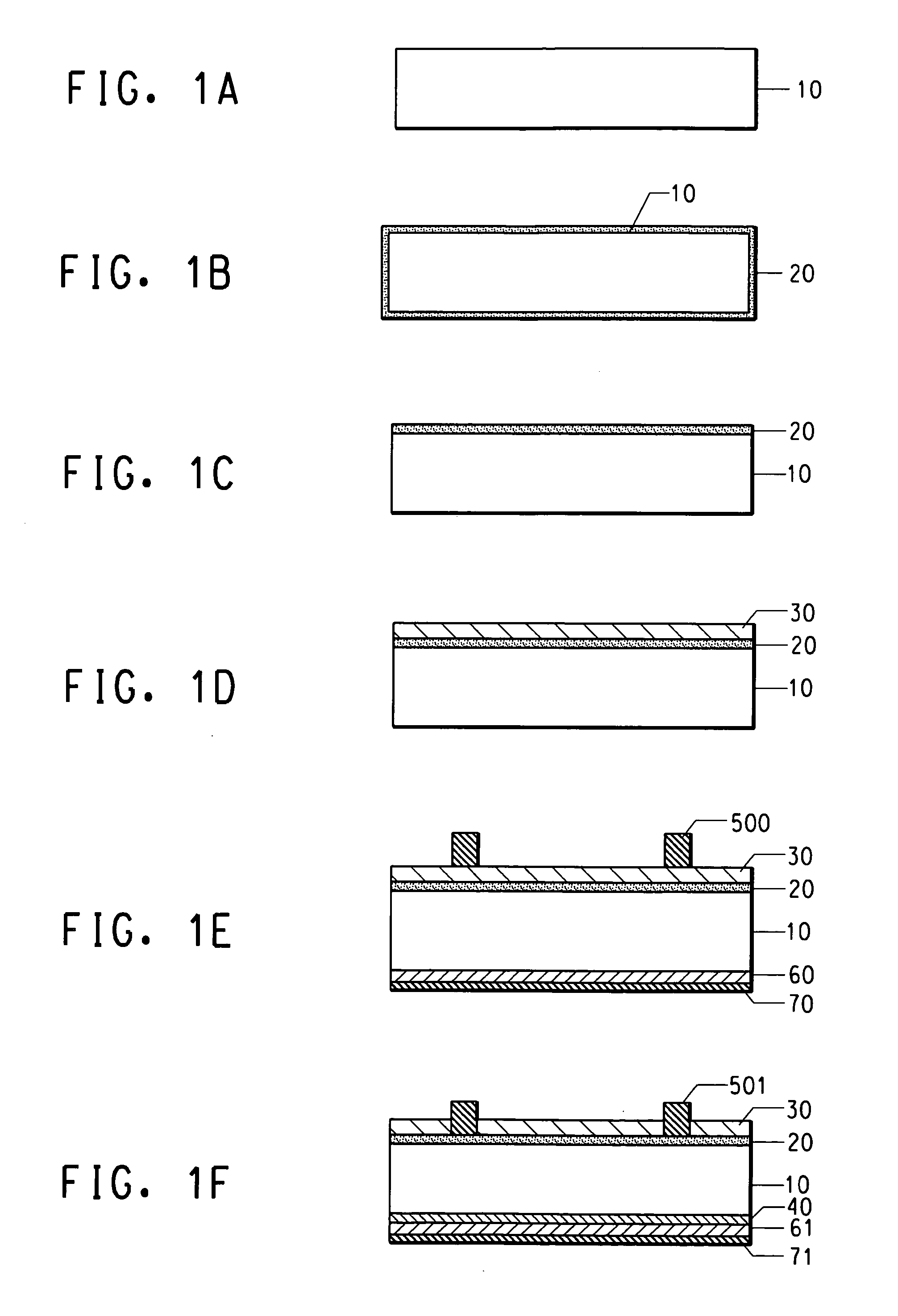

Solar Cell and Solar Cell Manufacturing Method

ActiveUS20100275987A1Reduce corrosionLower resistanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

A solar cell with a simple configuration and high efficiency, and a manufacturing method therefor are provided. A solar cell of the present invention includes a semiconductor substrate that has a first surface receiving sunlight and a second surface on the back side of the first surface and that includes a through hole passing through between the first surface and the second surface; and a first electrode that includes a main electrode portion containing a glass component and formed on the first surface of the semiconductor substrate and a conducting portion electrically connected to the main electrode portion, formed in the through hole of the semiconductor substrate, and having a lower glass-component content than the main electrode portion.

Owner:KYOCERA CORP

Aluminum thick film compositions(s), electrode(s), semiconductor device(s) and methods of making thereof

InactiveUS20070079868A1Significant bow reduction tendencyDusting tendency is decreasedConductive materialNon-conductive material with dispersed conductive materialElectrical conductorDevice material

The present invention is directed to a thick film conductor composition comprised of (a) aluminum-containing powder; (b) amorphous silicon dioxide (c) and one or more optional glass frit compositions; dispersed in (d) organic medium. The amorphous silicon dioxide contributes to significant bow reduction tendency for solar cells thinner than 270 microns and larger than five inches square without significant effect on reducing the electrical performance of the fired solar cell. In addition and as preferred by solar cell manufacturers, the addition of glass frit reduces the dusting tendency of the aluminum thick film composition.

Owner:EI DU PONT DE NEMOURS & CO

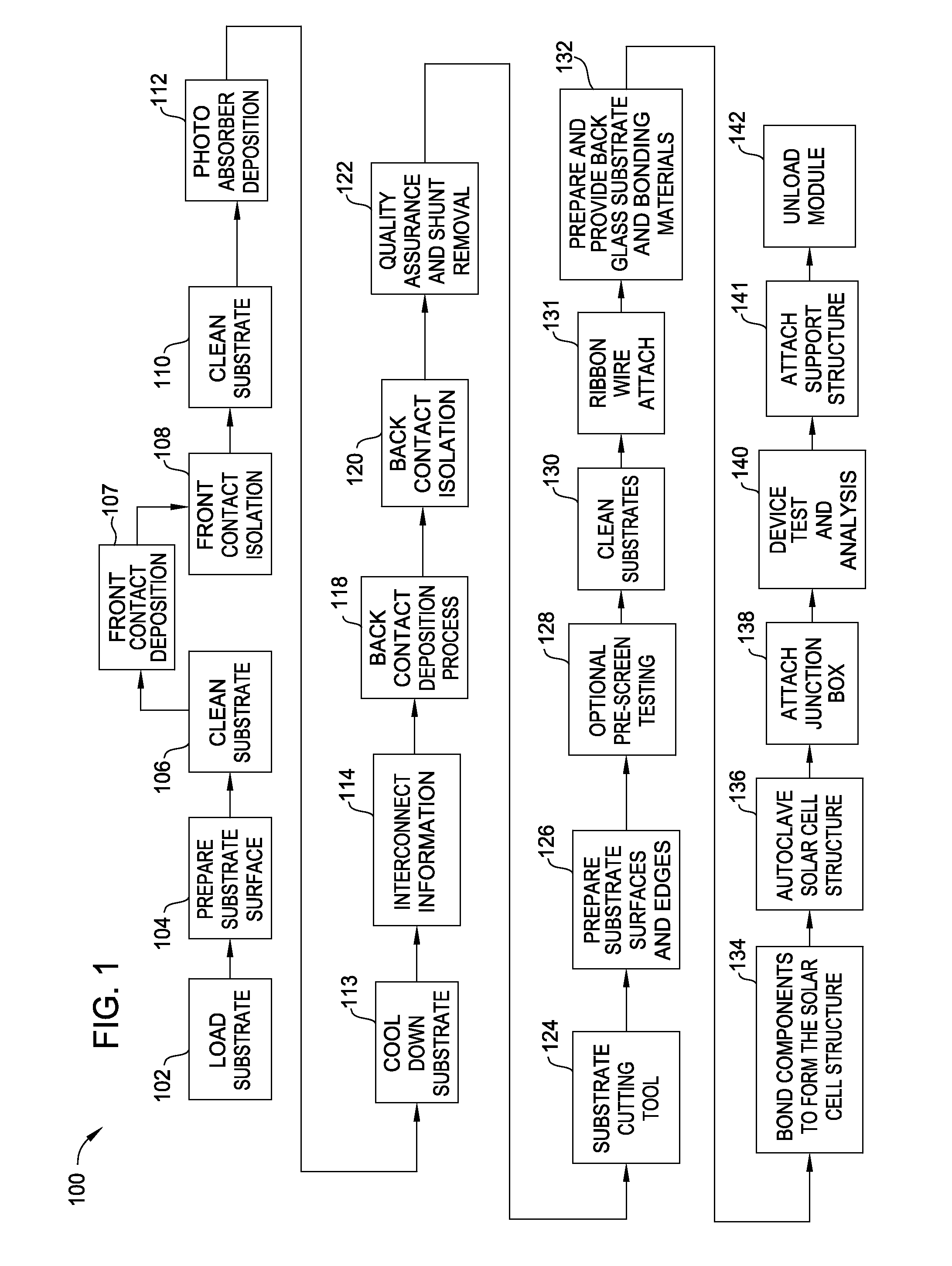

Photovoltaic cell reference module for solar testing

The present invention generally includes an apparatus and method of forming a reference module device that is able to deliver a repeatable and desirable amount of power that does not degrade or change over time. The reference module can be used to help test and calibrate various testing equipment used in the production of a photovoltaic device that may be formed in a solar cell fab. The solar cell fab is generally an arrangement of processing modules and automation equipment that is used to form solar cell devices.

Owner:APPLIED MATERIALS INC

Precursor Containing Copper Indium And Gallium For Selenide (Sulfide) Compound Formation

InactiveUS20070166964A1Easy to useSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSolar cell

The present invention relates to systems and methods for preparing metallic precursor thin films for the growth of semiconductor compounds to be used for radiation detector and solar cell fabrication. In one aspect, there is provided a method of efficiently using expensive materials necessary for the making of solar cells.

Owner:SOLOPOWER

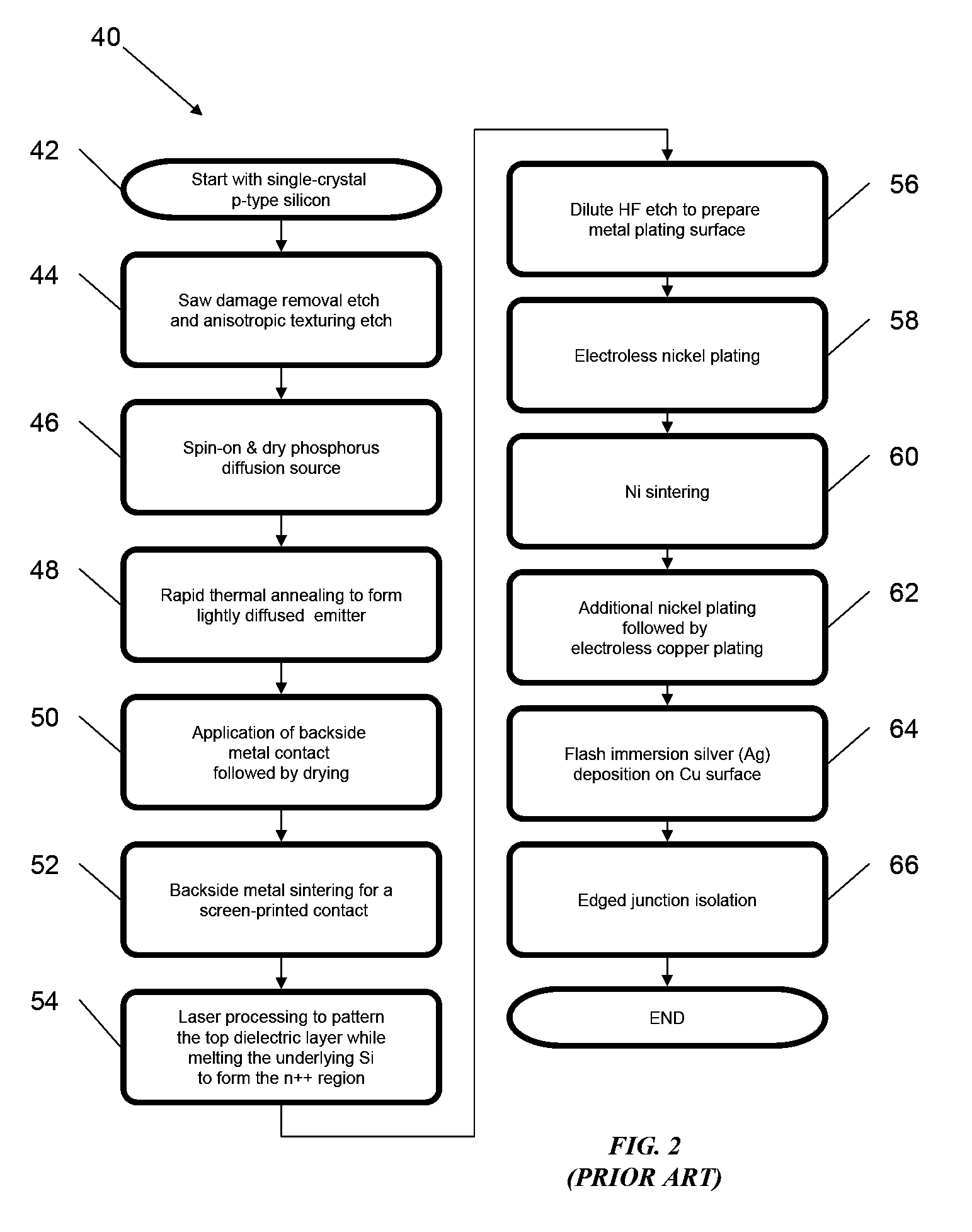

High efficiency solar cell fabrication

InactiveUS20090008787A1Small droplet sizeIncrease etch rateLiquid surface applicatorsSemiconductor/solid-state device detailsSemiconductor materialsEngineering

A method of forming a contact structure and a contact structure so formed is described. The structure contacts an underlying layer of a semiconductor junction, wherein the junction comprises the underlying layer of a semiconductor material and is separated from an overlying layer of semiconductor material by creating an undercut region to shade subsequent metal formation. Various steps are performed using inkjet printing techniques.

Owner:NEWSOUTH INNOVATIONS PTY LTD

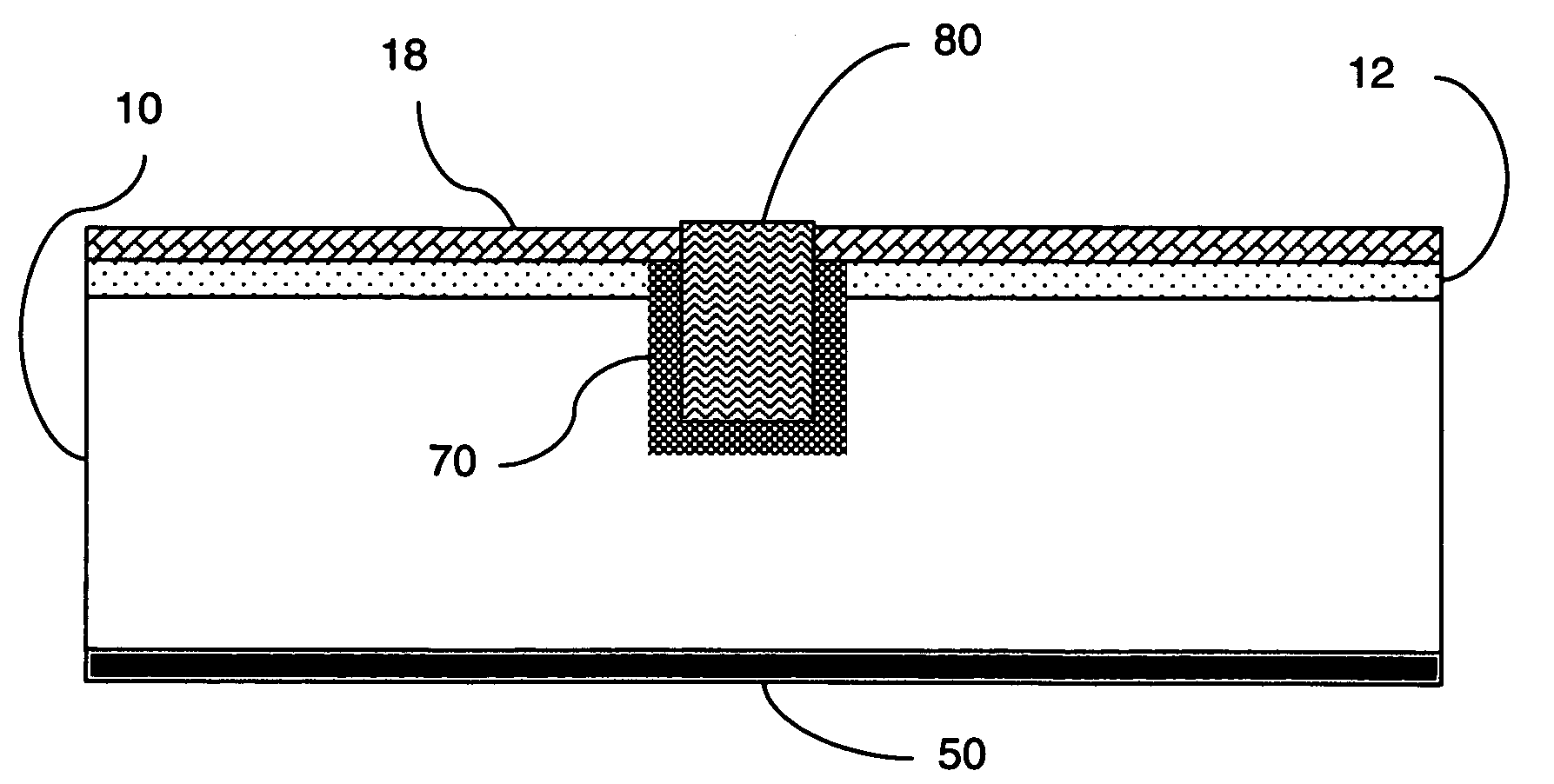

Hybrid heterojunction solar cell fabrication using a metal layer mask

Embodiments of the invention contemplate the formation of a high efficiency solar cell using a novel processing sequence to form a solar cell device. In one embodiment, the methods include the use of various etching and patterning processes that are used to define active regions of the device and regions where the device and / or contact structure is to be located on a surface of a solar cell substrate. The method generally includes the steps of forming one or more layers on a backside of a solar cell substrate to prevent attack of the backside surface of the substrate, and provide a stable supporting surface, when the front side regions of a solar cell are formed. In one embodiment, the one or more layers are a metalized backside contact structure that is formed on the backside of the solar cell substrate. In another embodiment, the one or more layers are a chemical resistant dielectric layer that is formed over the backside of the solar cell substrate.

Owner:APPLIED MATERIALS INC

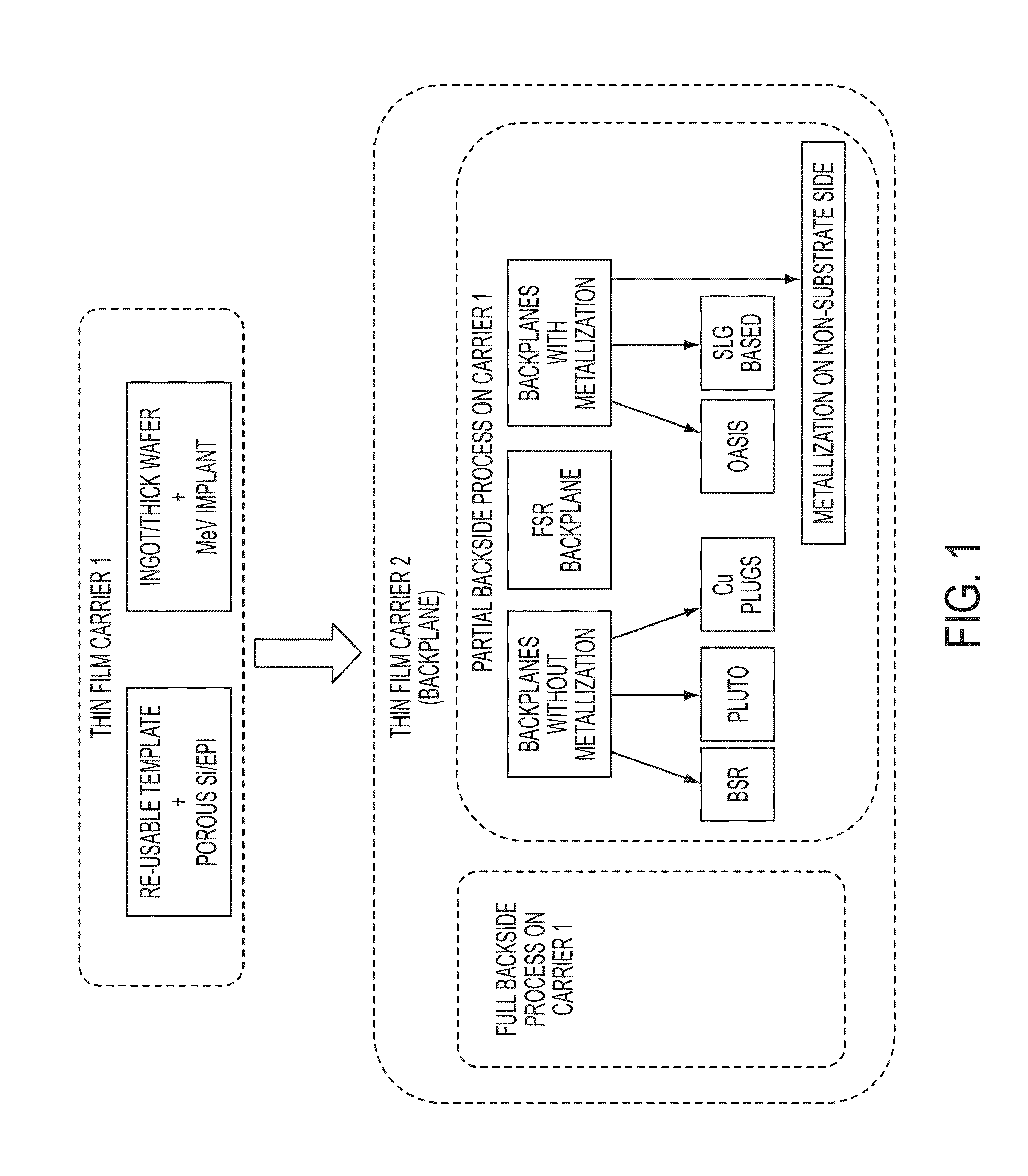

Fabrication methods for back contact solar cells

InactiveUS20150171230A1Reduce and eliminate disadvantageReduce and eliminate and problemSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringSolar cell

Owner:BEAMREACH SOLAR INC

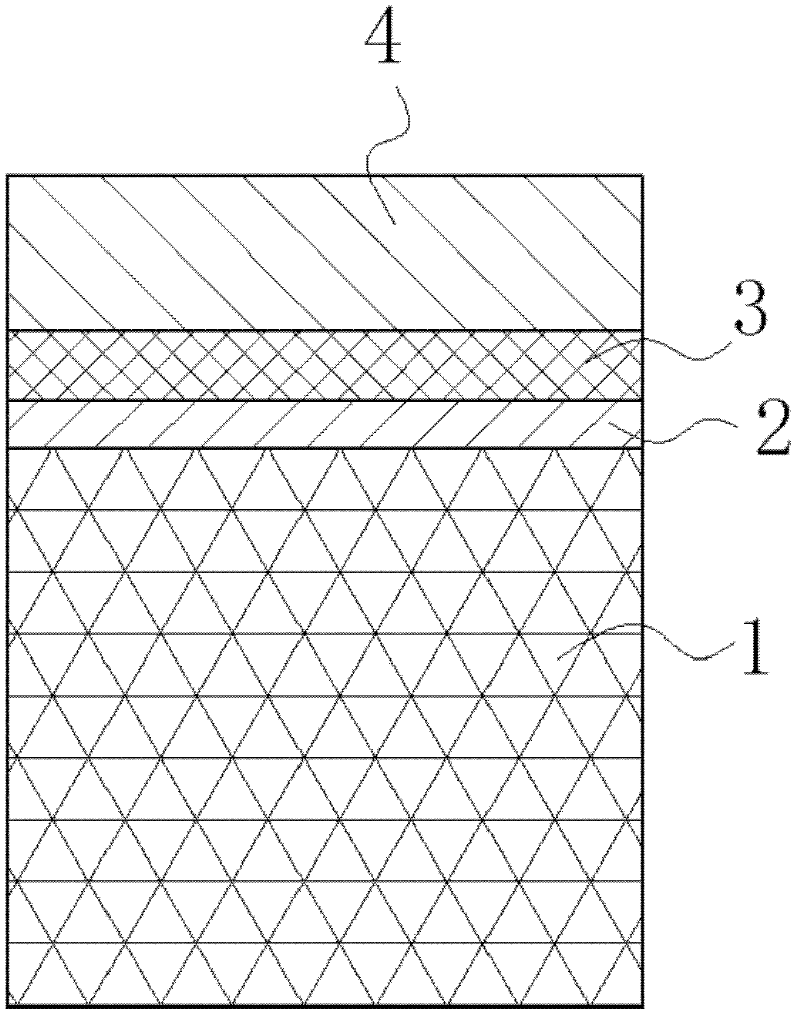

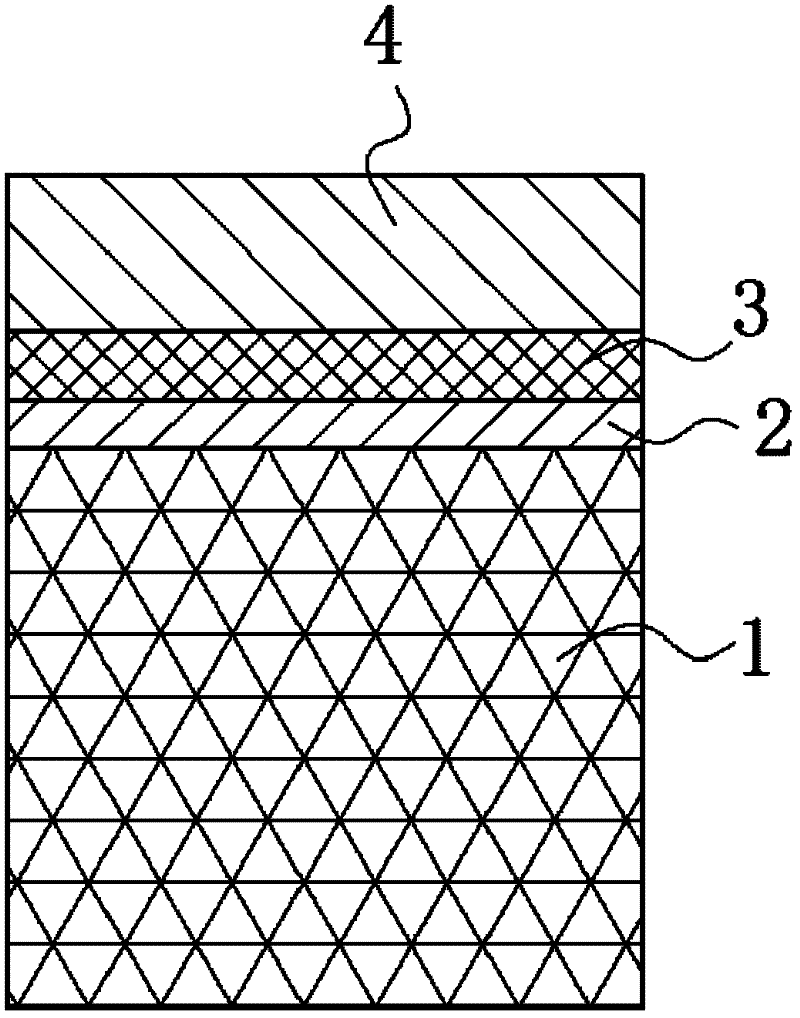

Multilayer silicon nitride antireflection film of crystalline silicon solar cell and preparation method of multilayer silicon nitride antireflection film

InactiveCN102339872AImprove conversion efficiencyImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingCrystalline siliconSemiconductor

The invention discloses a multilayer silicon nitride antireflection film of a crystalline silicon solar cell and a preparation method of the multilayer silicon nitride antireflection film, belonging to the technical field of manufacturing of semiconductor crystalline silicon and solar cells. The multilayer silicon nitride antireflection film comprises at least three silicon nitride films which are deposited on a silicon substrate, the refraction indexes of all the silicon nitride films are sequentially reduced from bottom to top, and the thicknesses of all the silicon nitride films are sequentially increased from bottom to top. According to the invention, the passivation effect of a coating film is effectively improved, the antireflection effect of the antireflection film is improved, thepassivation effect of the antireflection film is enhanced, and the photoelectric conversion efficiency of the solar cell is increased.

Owner:湖南红太阳新能源科技有限公司

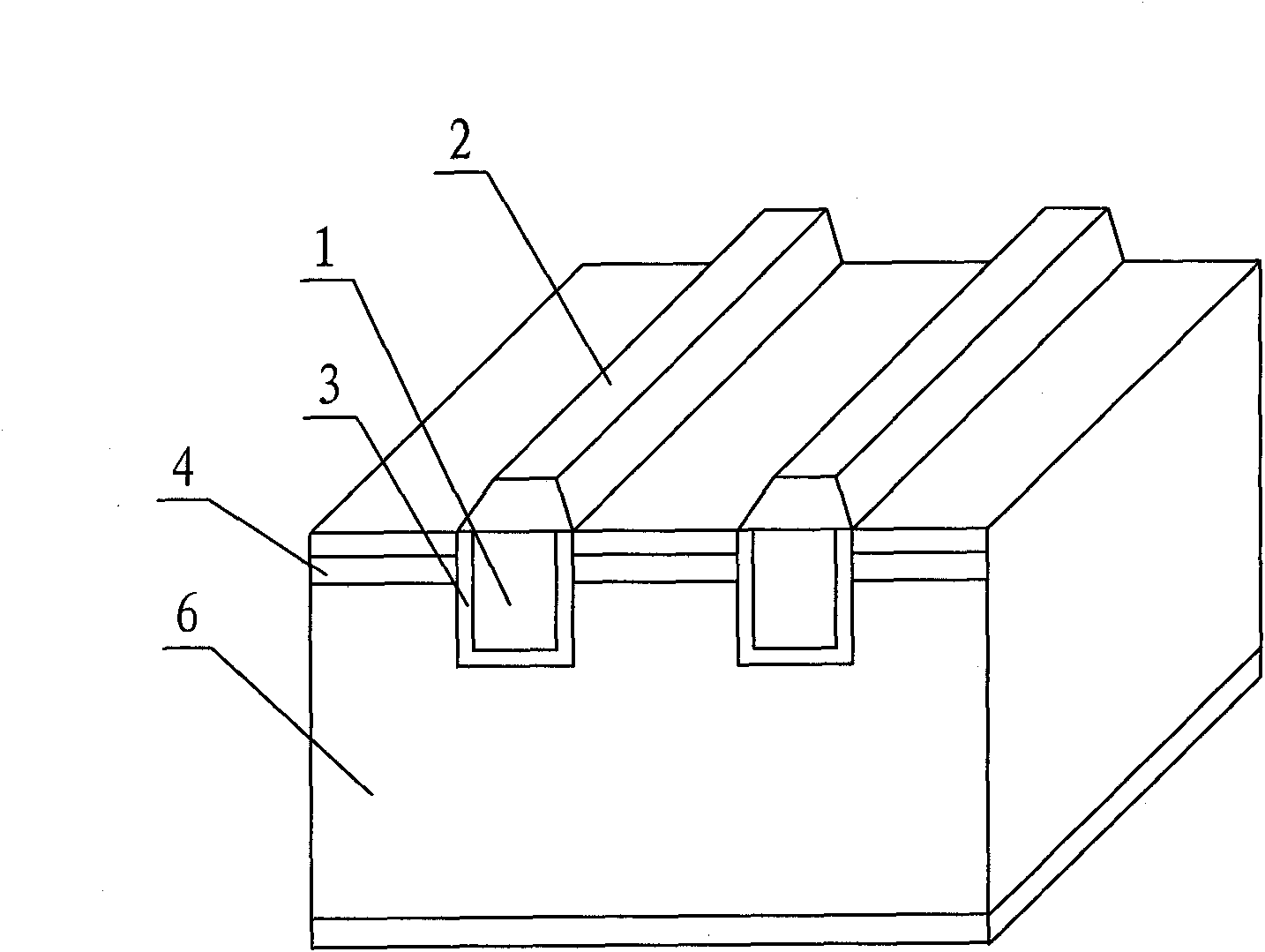

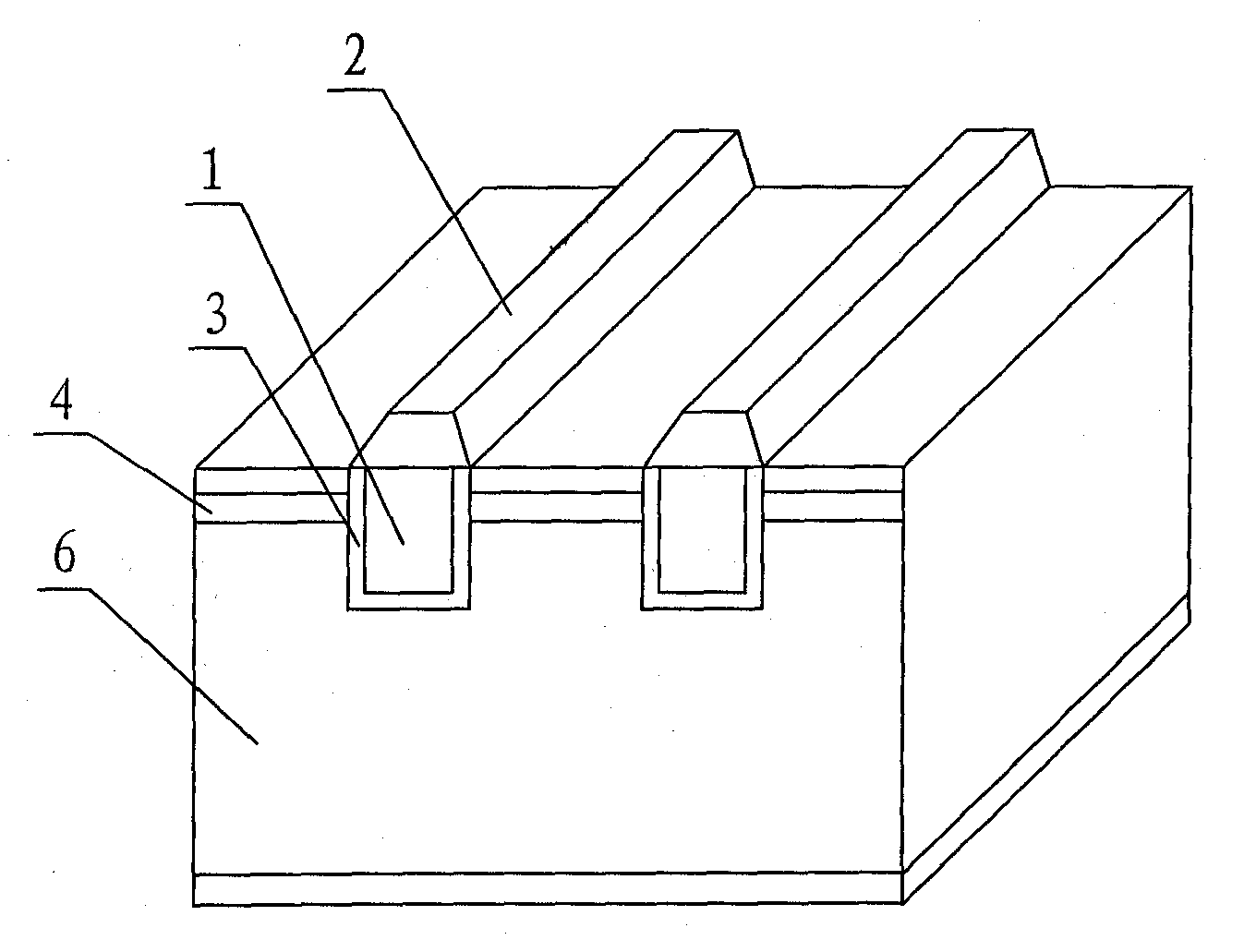

Process for manufacturing solar cell by twice screen printing and grooving

ActiveCN101969082AReduced series resistanceIncrease the conductive cross-sectional areaFinal product manufactureSemiconductor devicesScreen printingEngineering

The invention discloses a process for manufacturing a solar cell by twice screen printing and grooving, which is used for manufacturing the solar cell by twice electrode printing and comprises a grooving process and a twice printing process, wherein the grooving process comprises the step of performing grooving on an electrode grid line area on the surface of a silicon wafer so as to form an etched groove in the electrode grid line area; and the twice printing process comprises the following steps of: a, primary electrode printing, namely, filling printing electrode paste into the etched groove and performing drying to form a first layer of electrode in the etched groove; and b, secondary electrode printing, namely, printing the electrode on the outer surface of the first layer of electrode so as to form a second layer of electrode in the electrode grid line area on the surface of the silicon wafer. The solar cell manufactured by the method has relatively lower series resistance, a selective emitter and relatively higher conversion efficiency, and can reduce shading loss; and the electrode paste is difficult to spread in a sintering process.

Owner:TRINA SOLAR CO LTD

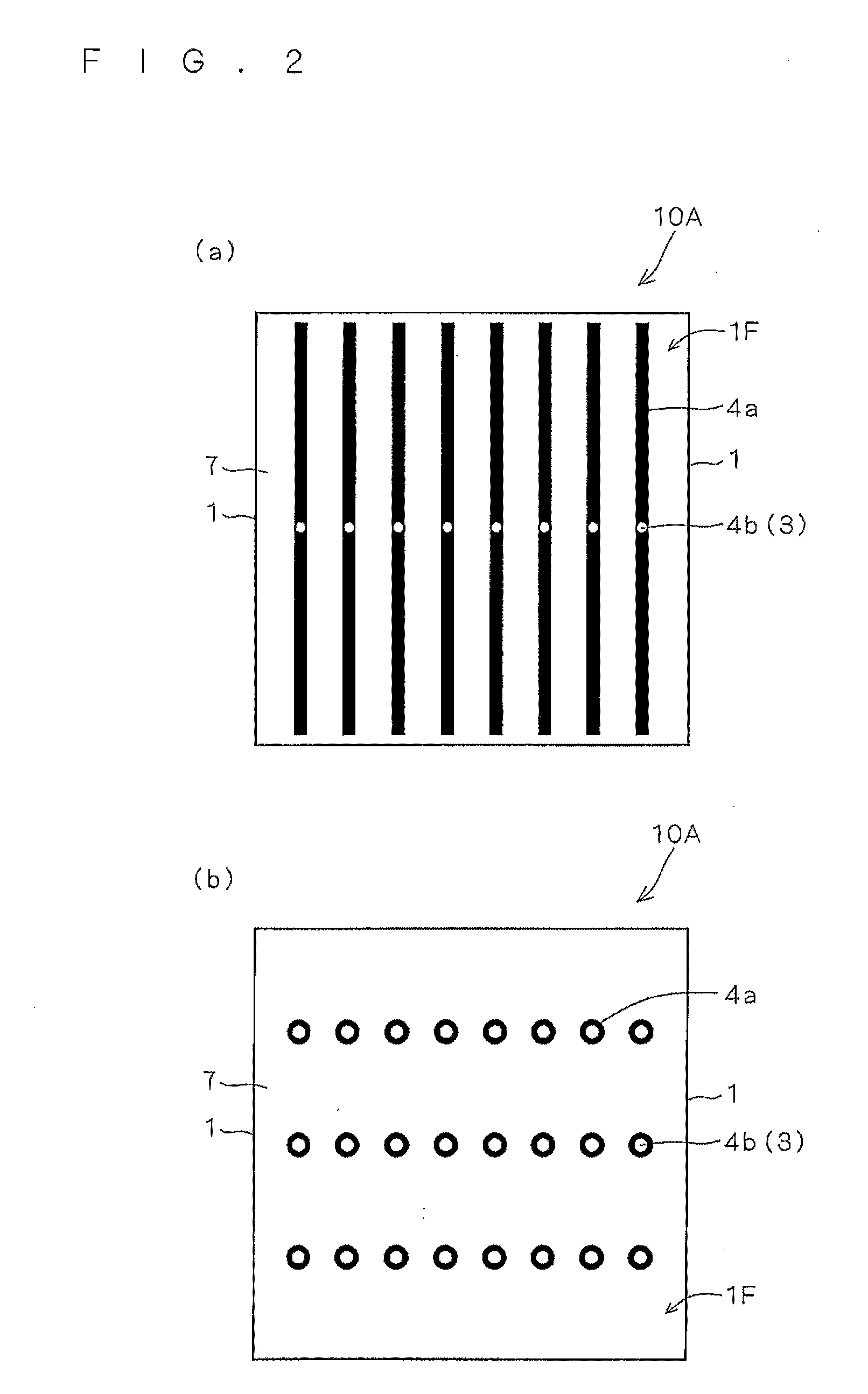

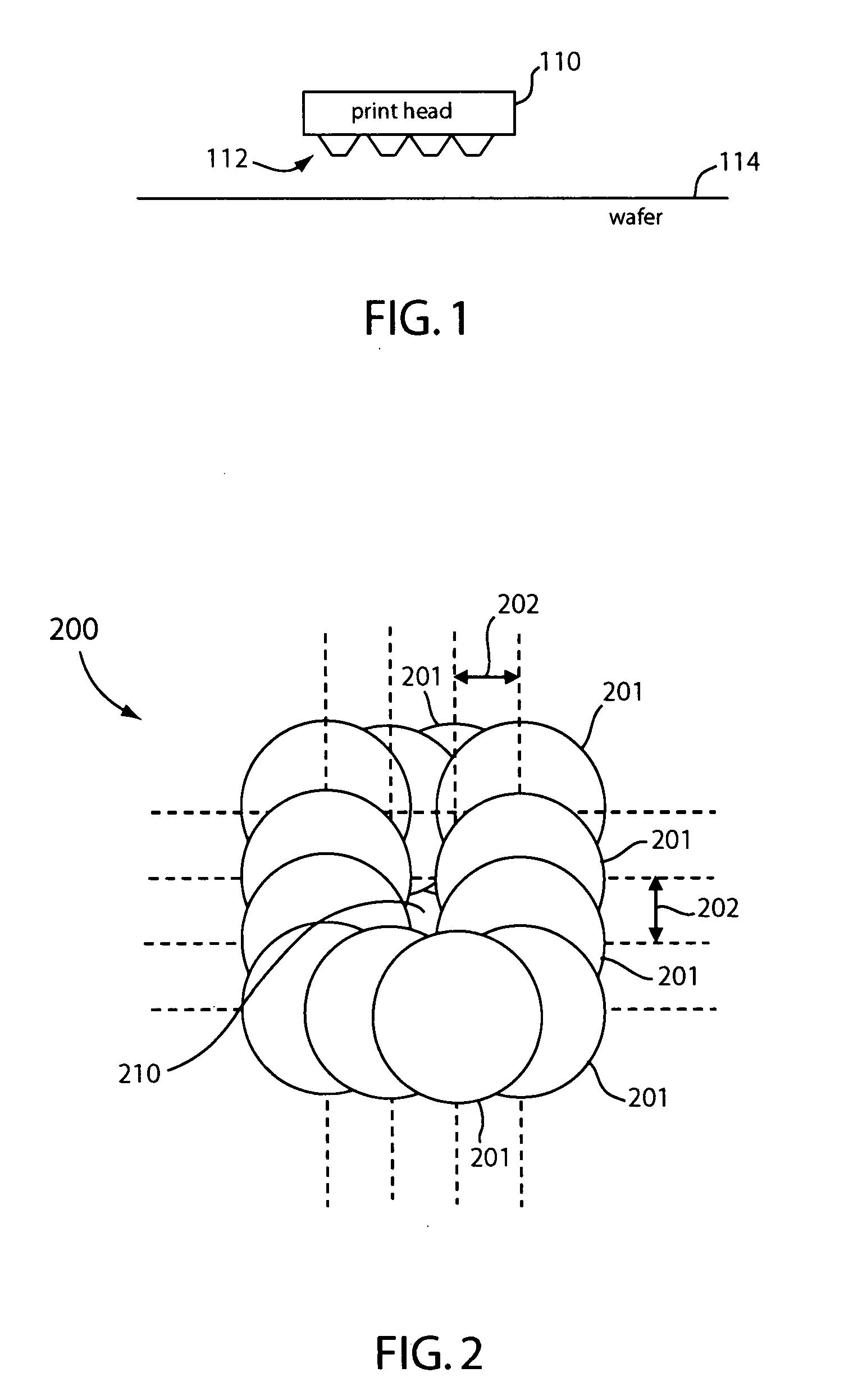

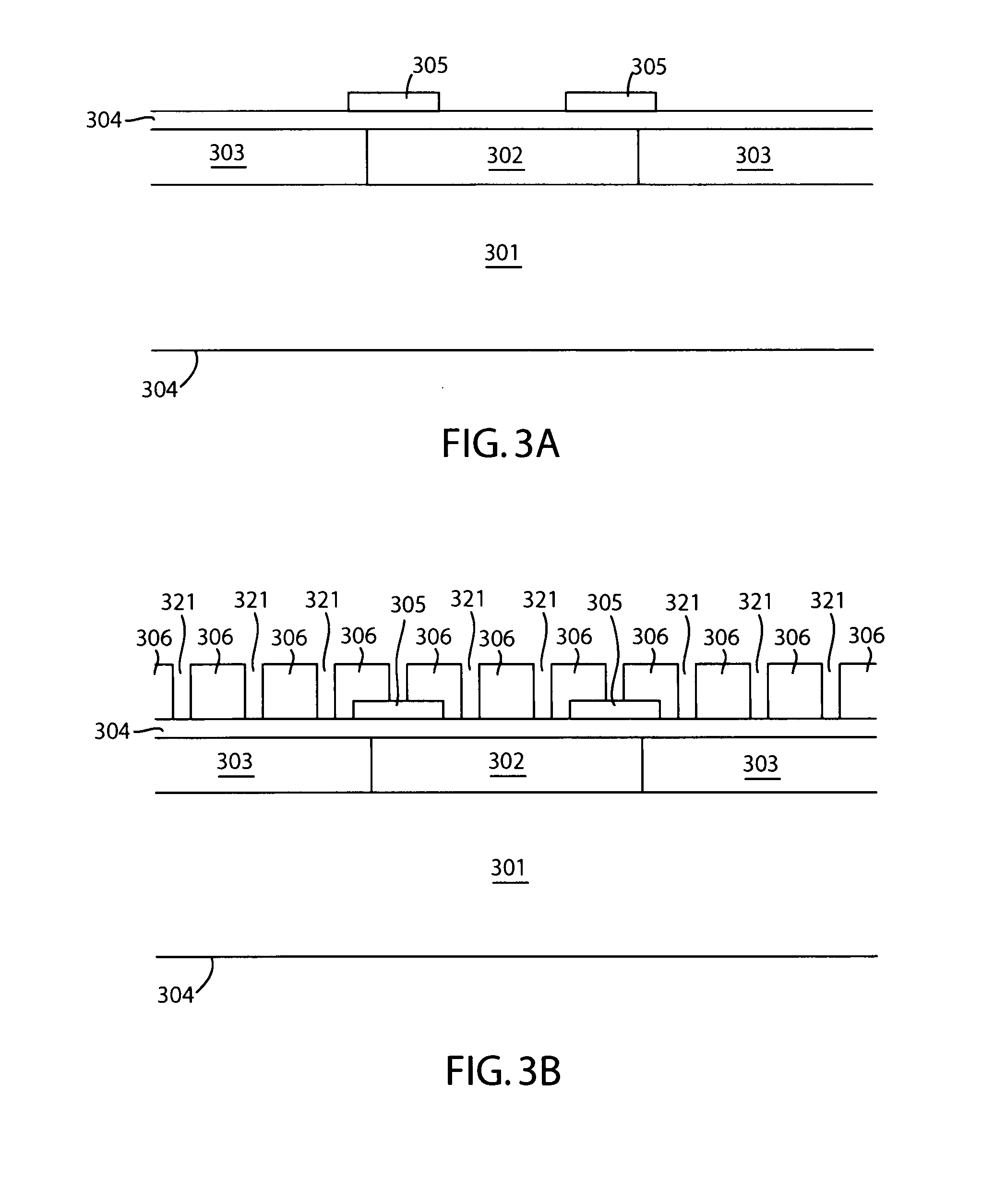

Array of small contacts for solar cell fabrication

ActiveUS20080299297A1Readily apparentSemiconductor/solid-state device manufacturingSpecial surfacesSpray nozzleElectrical connection

Fabrication of a solar cell using a printed contact mask. The contact mask may include dots formed by inkjet printing. The dots may be formed in openings between dielectric layers (e.g., polyimide). Intersections of overlapping dots may form gaps that define contact regions. The spacing of the gaps may be dictated by the alignment of nozzles that dispense the dots. Using the dots as a contact mask, an underlying dielectric layer may be etched to form the contact regions through the underlying dielectric layer. Metal contact fingers may be formed over the wafer to form electrical connections to corresponding diffusion regions through the contact regions.

Owner:MAXEON SOLAR PTE LTD

Phosphorus gettering process of silicon chip

InactiveCN101667605AImprove electrical performance parametersIncreased average life expectancyFinal product manufactureSemiconductor devicesEtchingSurface oxidation

The invention relates to a phosphorus gettering process of silicon chips in the manufacture of solar cells, which comprises the following steps: putting sueded silicon chips into a diffusion furnace for pre-deposition, removing a phosphorosilicate glass layer after diffusion, soaking the silicon chips through distributed processing in a hydrofluoric acid solution, and removing oxide layers from the surfaces of the silicon chips; then putting the silicon chips after washing into the diffusion furnace for secondary diffusion processing, taking the silicon chips out from the diffusion furnace after the processing of the secondary diffusion working procedure, cooling the silicon chips to room temperature, and measuring the square resistance of the silicon chips. The invention can effectively decrease heavily doped 'dead layers' and greatly prolong the average minority carrier lifetime of the silicon chips; after the processes including etching, PECVD, silk screen sintering and the like arefinished according to the normal process of a cell chip, the average transformation efficiency of the made cell chip is further improved, and the cell chip has better electrical performance parameters.

Owner:无锡尚品太阳能电力科技有限公司

Technique for doping compound layers used in solar cell fabrication

InactiveUS20080023336A1Low material utilizationIncrease equipment costPhotovoltaic energy generationSemiconductor devicesDopantSolar cell

The present invention includes methods and apparatus therefrom for preparing thin films of doped semiconductors for radiation detector and photovoltaic applications, and particularly method and apparatus that increase dopants of alkali metals in Group IBIIIAVIA layers. In a particular aspect, the present invention includes a method of preparing a doped Group IBIIIAVIA absorber layer for a solar cell, with the absorber layer being formed by reaction, with a Group VIA material, of a metallic stack with a plurality of layers, in which each layer contains a concentration of an alkali metal selected from the group of Na, K and Li.

Owner:SOLOPOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com