Solar cell fabrication using implantation

a technology of solar cells and implantation, applied in the field of solar cells, can solve the problems of lack of utilization of blue light, excessive accumulation of unactivated dopants near the surface, and use of diffusion in forming dopants on the surface of semiconductor substrates, etc., and achieve the effect of low temperature annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In the following description, numerous details and alternatives are set forth for the purpose of explanation. However, one of ordinary skill in the art will realize that the invention can be practiced without the use of these specific details. In other instances, well-known structures and devices are shown in block diagram form in order not to obscure the description of the invention with unnecessary detail.

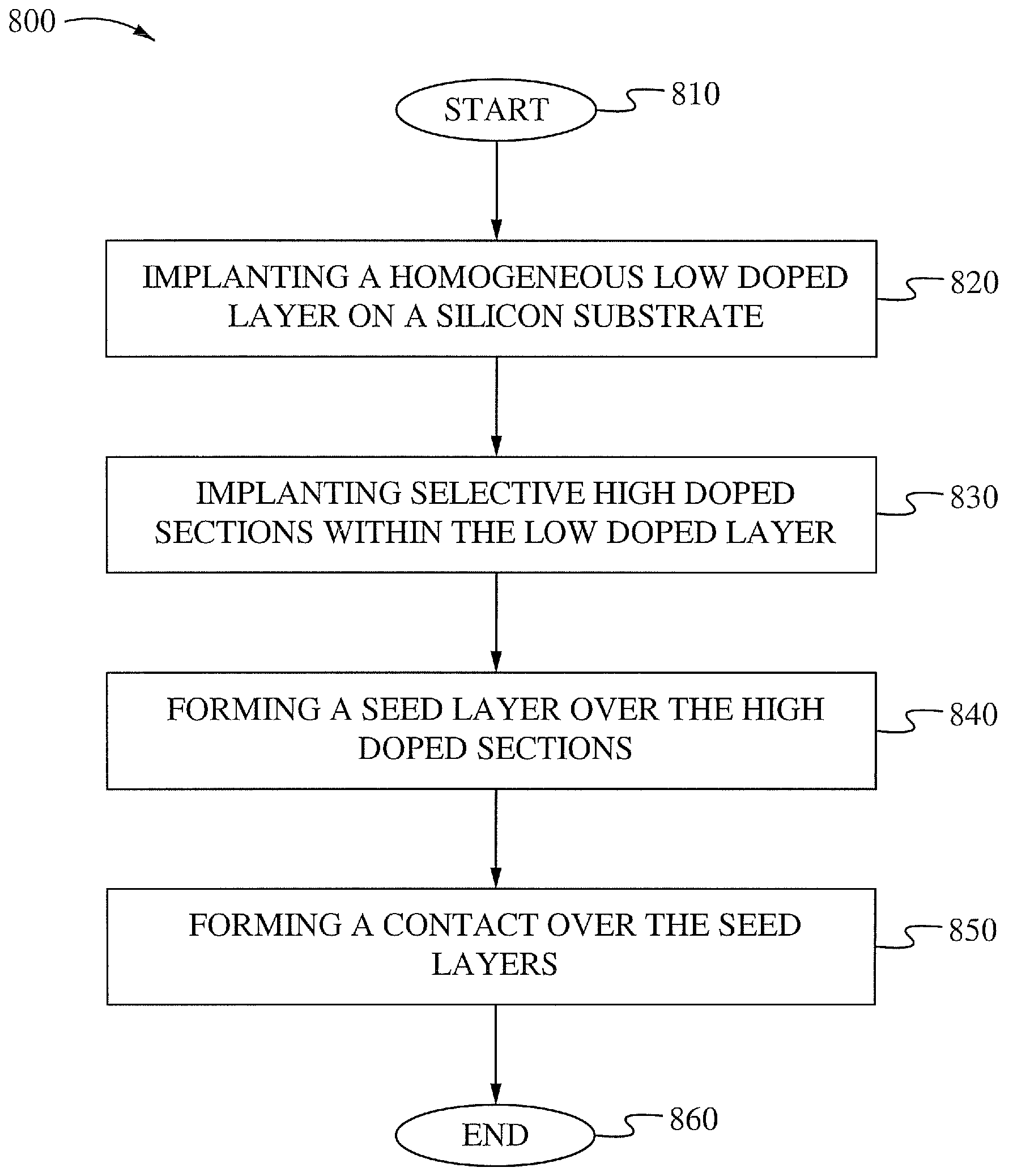

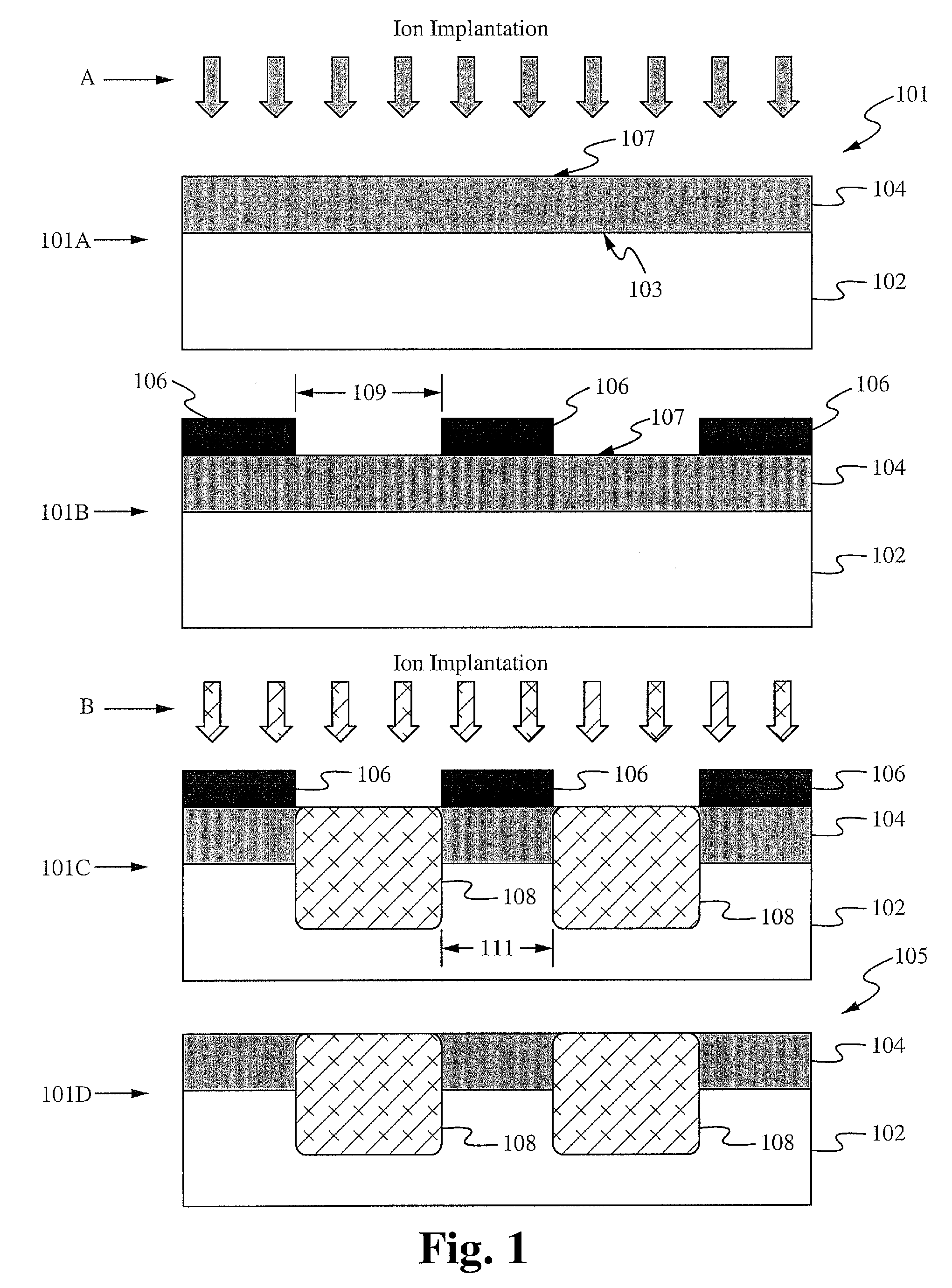

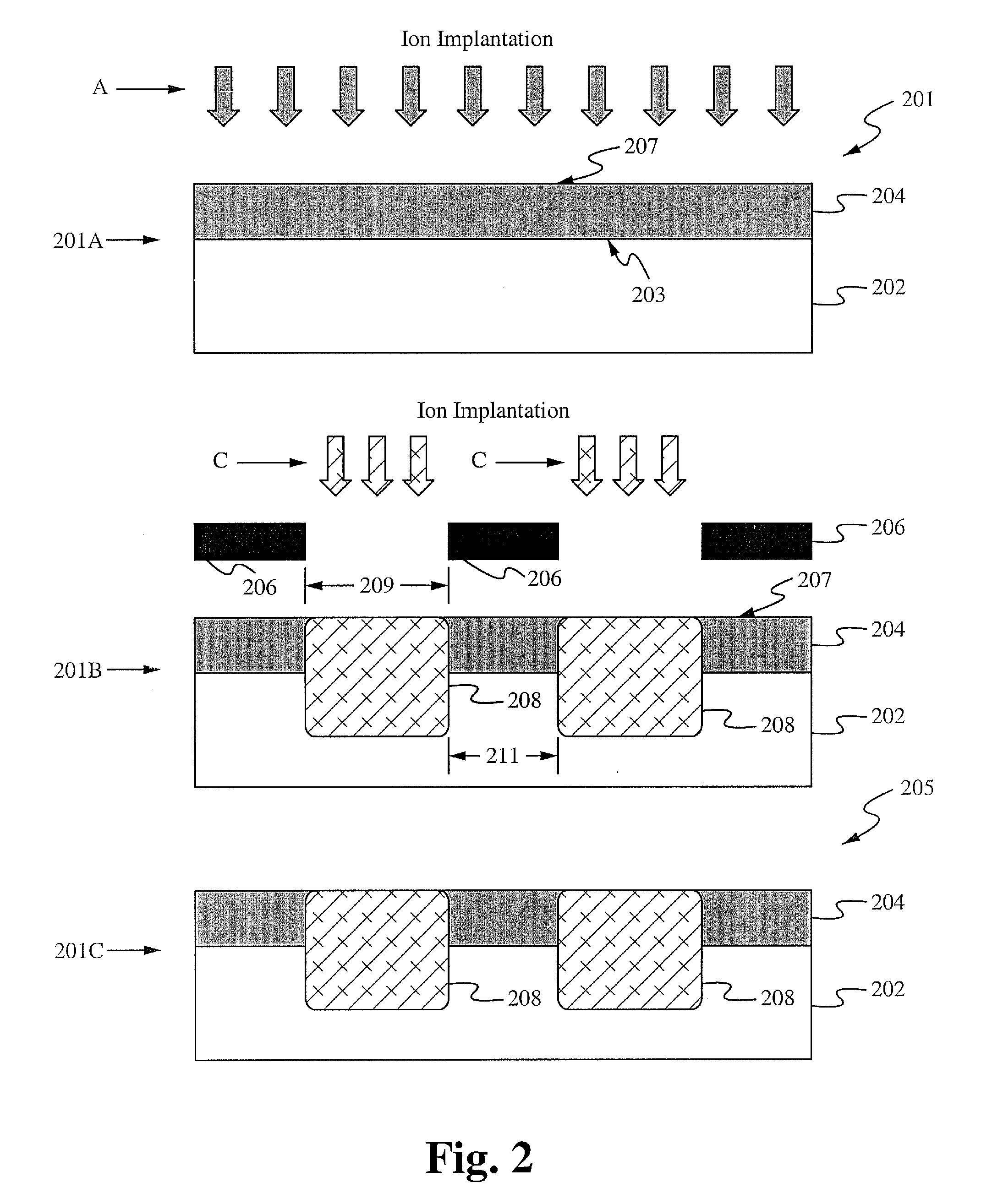

[0027]The present invention uses implantation to form homogeneous and selective emitter regions. The present invention addresses the methods for the formation of solar cells and in particular formation of a selective emitter through a series of implantation processes. Presently, such ability to manipulate and place the dopant laterally is difficult with conventional diffusion or screen printing processes. The present invention selectively controls the resistance of gridlines, contacts, and selectively controls contact resistance of a metal / semiconductor interface. Moreover,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com