Patents

Literature

40results about How to "Increase the conductive cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

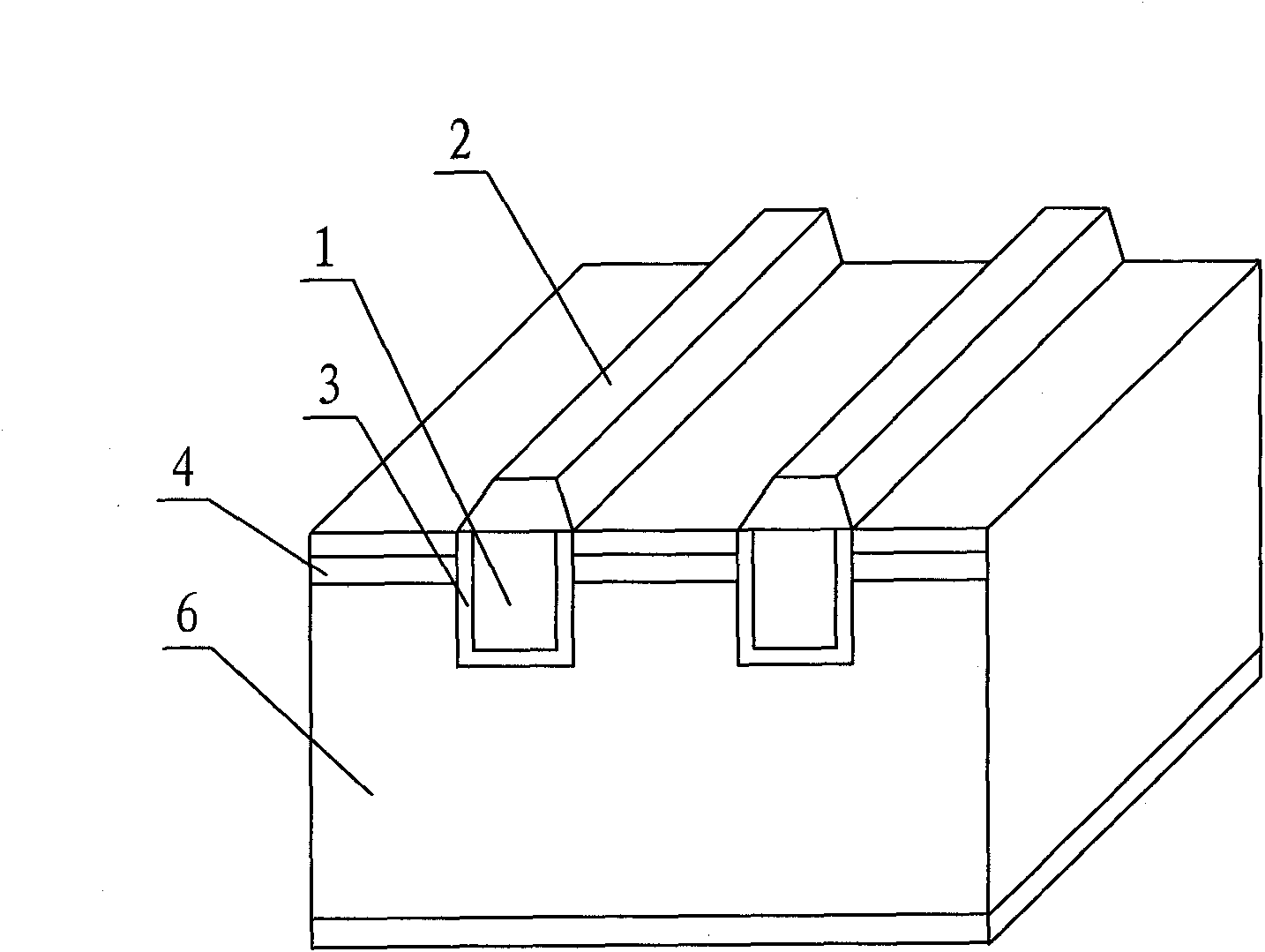

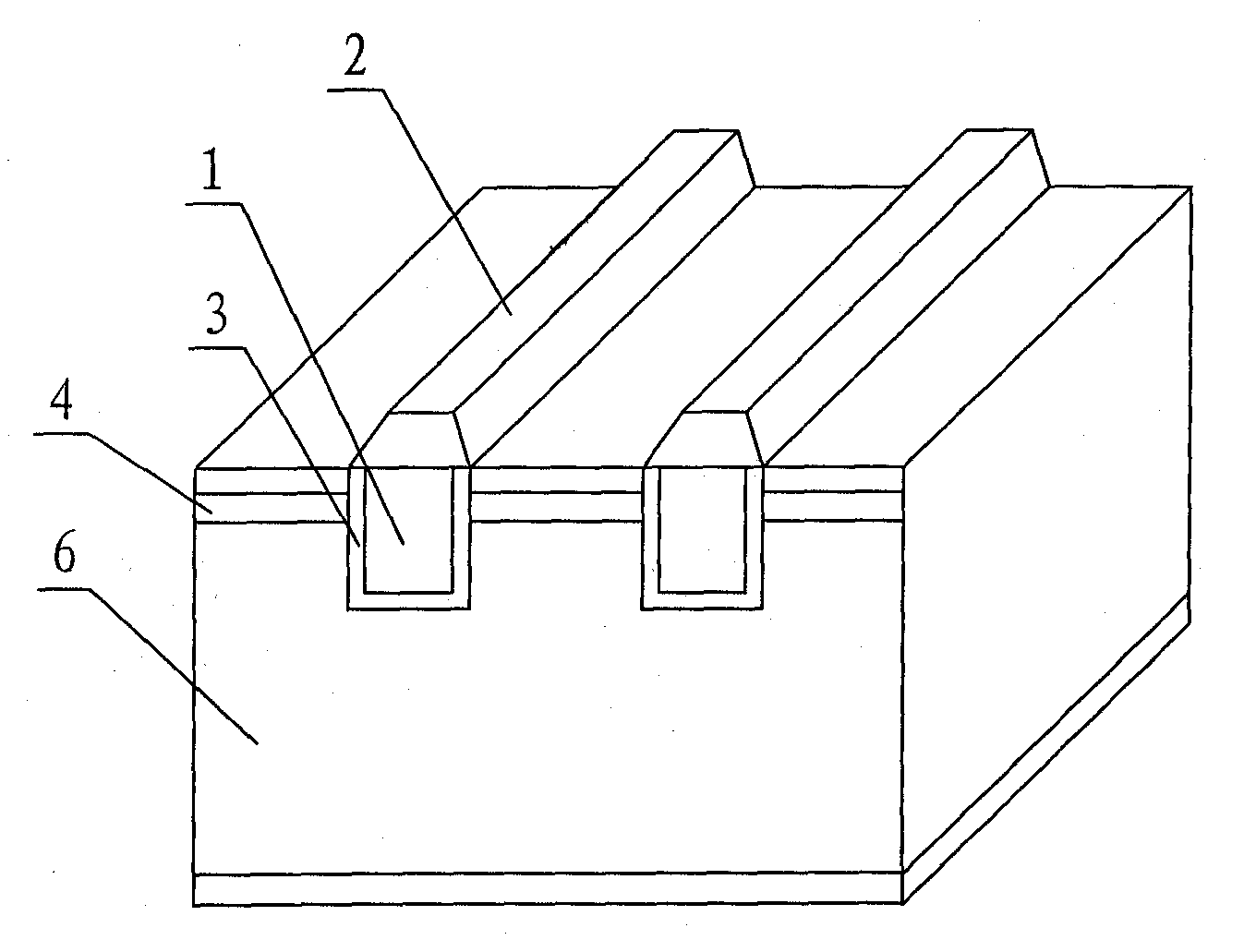

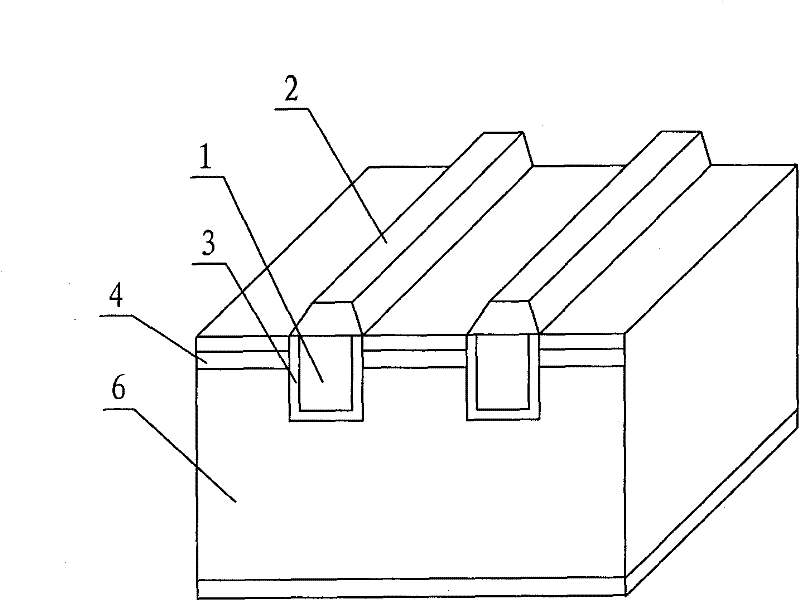

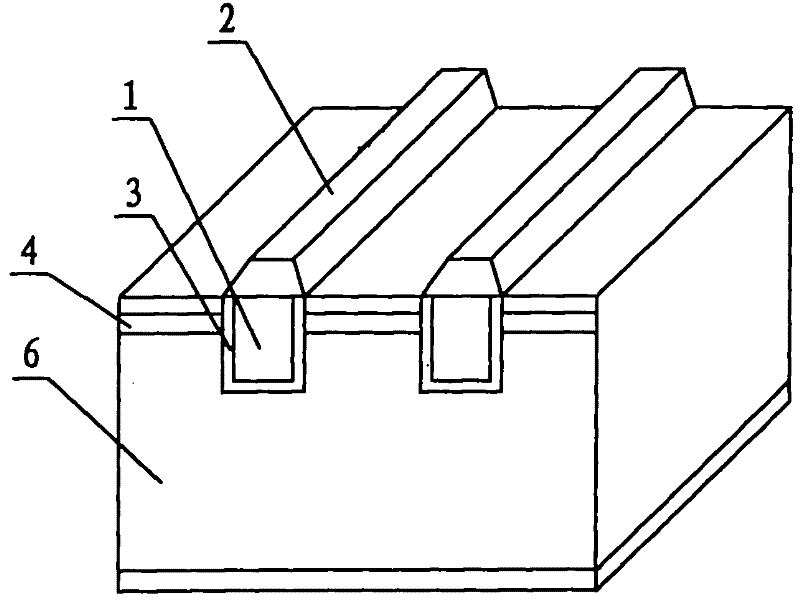

Process for manufacturing solar cell by twice screen printing and grooving

ActiveCN101969082AReduced series resistanceIncrease the conductive cross-sectional areaFinal product manufactureSemiconductor devicesScreen printingEngineering

The invention discloses a process for manufacturing a solar cell by twice screen printing and grooving, which is used for manufacturing the solar cell by twice electrode printing and comprises a grooving process and a twice printing process, wherein the grooving process comprises the step of performing grooving on an electrode grid line area on the surface of a silicon wafer so as to form an etched groove in the electrode grid line area; and the twice printing process comprises the following steps of: a, primary electrode printing, namely, filling printing electrode paste into the etched groove and performing drying to form a first layer of electrode in the etched groove; and b, secondary electrode printing, namely, printing the electrode on the outer surface of the first layer of electrode so as to form a second layer of electrode in the electrode grid line area on the surface of the silicon wafer. The solar cell manufactured by the method has relatively lower series resistance, a selective emitter and relatively higher conversion efficiency, and can reduce shading loss; and the electrode paste is difficult to spread in a sintering process.

Owner:TRINA SOLAR CO LTD

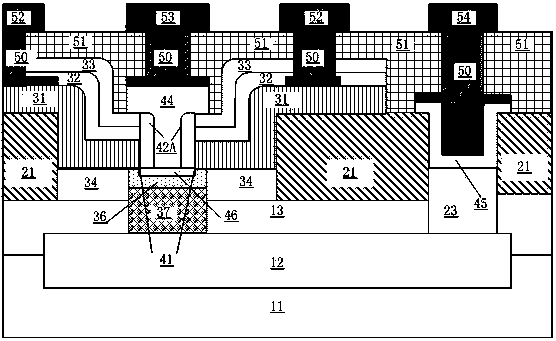

Method for manufacturing high-performance double-layer polysilicon bipolar transistor

ActiveCN103915334AReduce doping upamplificationReduce high temperature process timeTransistorSemiconductor/solid-state device manufacturingIsolation effectElectrical resistance and conductance

The invention discloses a method for manufacturing a high-performance double-layer polysilicon bipolar transistor. The method comprises the following steps that 1), LOCOS and CVD are adopted to deposit SiO2 to form a composite isolation structure, and high-temperature process time is reduced; 2), the SiO2 is used as an etching stopping layer of base polysilicon, and etching damage is avoided; 3), a composite side wall structure is formed through SiO2 and N+polysilicon, and emitter resistance is reduced. The method has the advantages that on the premise of not lowering the isolation effect, the high-temperature process time is reduced, therefore, a relatively thin epitaxial layer can be adopted, the better microwave performance is obtained, SiO2 is adopted as the etching stopping layer, the etching damage to the silicon epitaxial layer is eliminated, breakdown characteristics are improved, current amplifying coefficients are increased, and noise coefficients are reduced. The composite side wall structure with SiO2 and N+polysilicon is adopted, it can be guaranteed that emitter-base electric isolation is carried out, and meanwhile the emitter resistance is lowered, the current amplifying coefficients are increased, and the noise coefficients are reduced.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

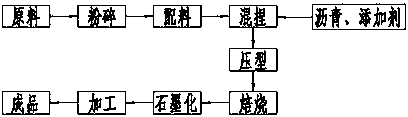

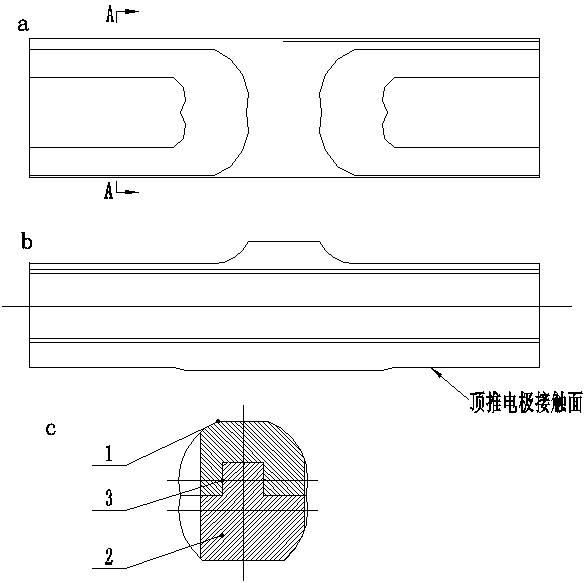

Cross-connection electrode for internal thermal serial graphitization furnace and production method thereof

InactiveCN108276000AIncrease the conductive areaImprove flexural strengthElectric discharge heatingCross connectionStearic acid

The invention provides a cross-connection electrode for an internal thermal serial graphitization furnace and a production method thereof. The cross-connection electrode is prepared from a dry material composed of large-grained petroleum based needle coke, medium-grained petroleum based needle coke and small-grained powder, a binding agent, additives, green ground components and roasted ground components through crushing, screening, mixing, kneading, shaping, roasting, dipping, graphitizing, processing and assembling, wherein the formula is as follows: the percentage of the large-grained petroleum based needle coke is 30-40%, the percentage of medium-grained petroleum based needle coke is 20-30%, the percentage of small-grained powder is 35-45%, the content of the binding agent is 25-30% of the total weight of the dry material, the content of the additive stearic acid is 0.5-0.8% of the total weight of the dry material, the content of the additive Fe2O3 is 0-1% of the total weight of the dry material, the content of the green ground components is 10-20% of the total weight of the dry material and the content of the roasted ground components is 0-10% of the total weight of the dry material; the binding agent is modified asphalt, and the grain size of the large-grained petroleum based needle coke is 15-25mm, the grain size of the medium-grained petroleum based needle coke is 5-15mm and the small-grained powder is 200-mesh powder.

Owner:KAIFENG CARBON CO LTD OF CHINA PINGMEI SHENMA GRP

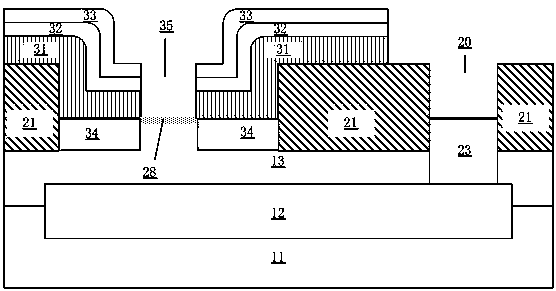

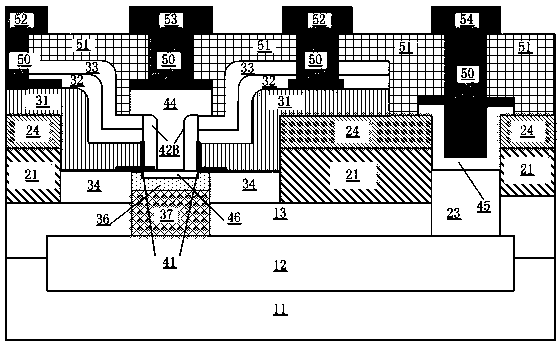

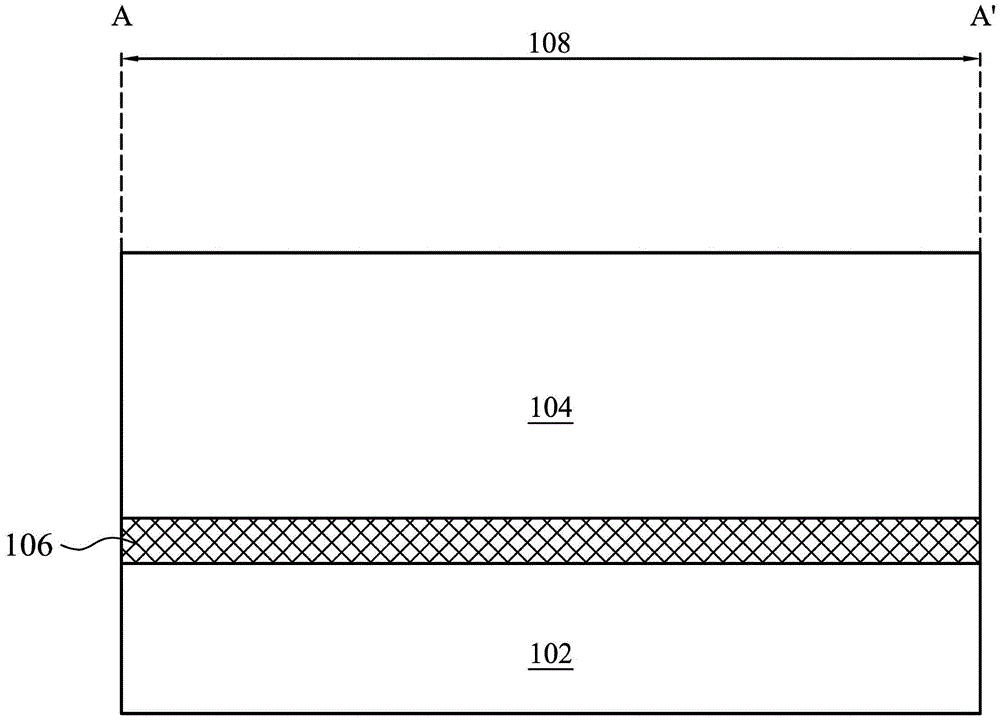

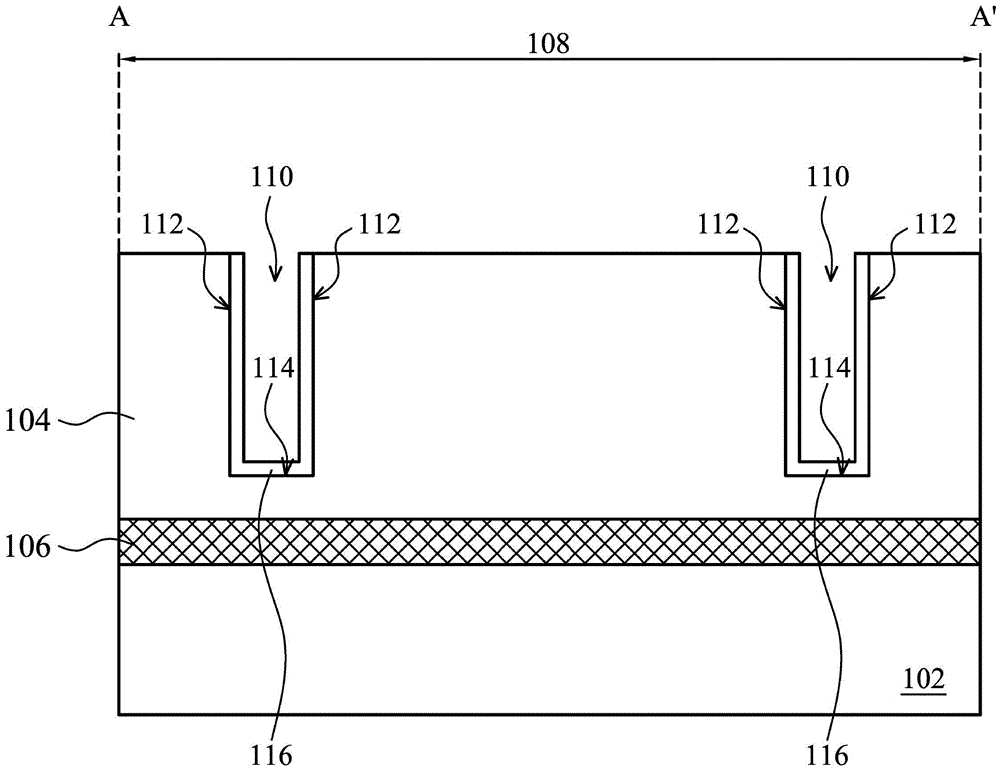

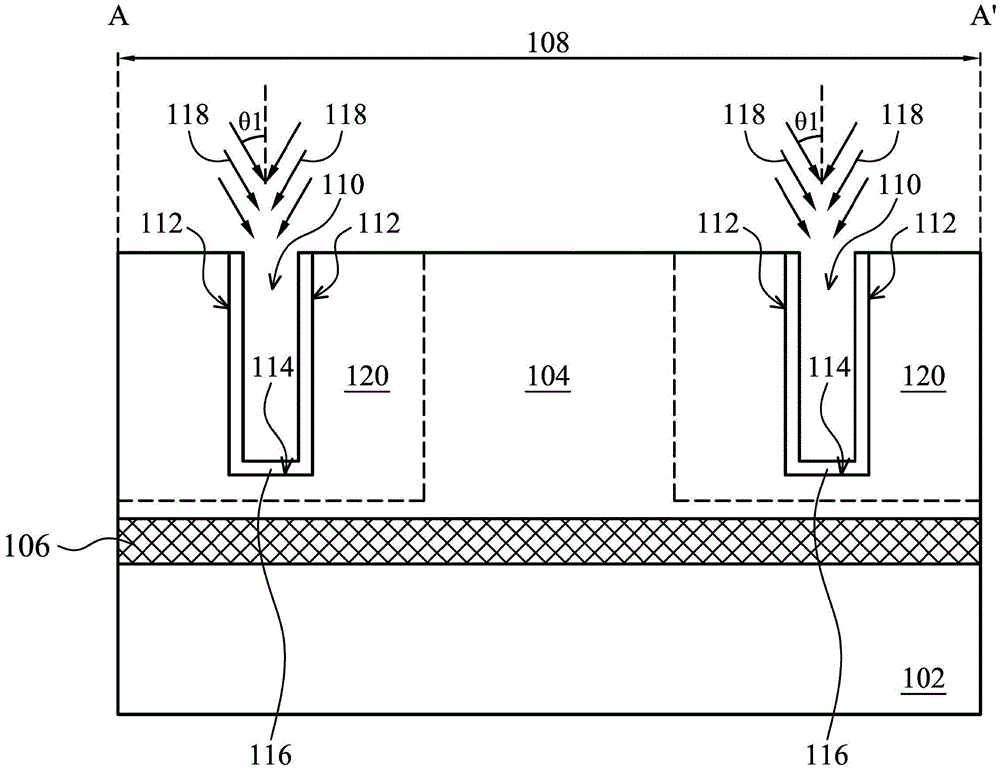

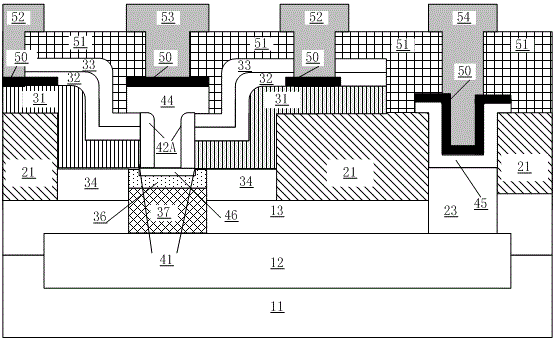

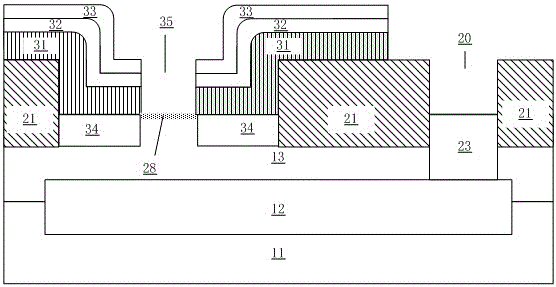

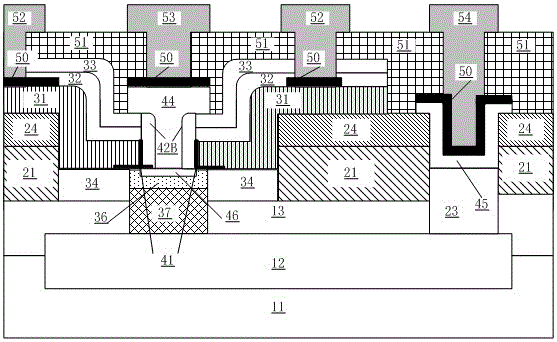

Semiconductor device and manufacturing method thereof

ActiveCN104900697AIncrease the conductive cross-sectional areaLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentEngineering

Provided are a semiconductor device and a manufacturing method thereof. The semiconductor device comprises a substrate, an epitaxial layer, and a gate electrode structure. The epitaxial layer is disposed on the top of the substrate and comprises multiple first trenches and multiple second trenches which are arranged alternately in the first direction. The epitaxial layer between each pair of the first trench and the second trench which are adjacent comprises a first doped region and a second doped region which have different conductive types. An interface between the each first doped region and the corresponding second doped region forms a super junction structure. The epitaxial layer under the gate electrode structure comprises a channel extending in the second direction vertical to the first direction. Compared with a product in the prior art, the semiconductor device is increased in driving current gate-on sectional area, improved in driving current, and decreased in gate-on resistance.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

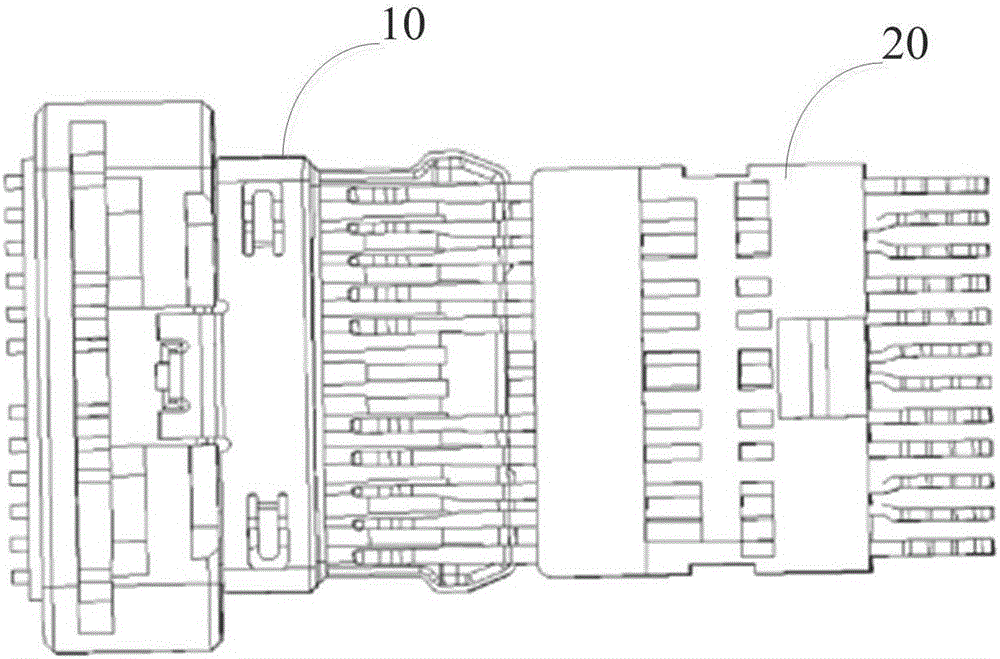

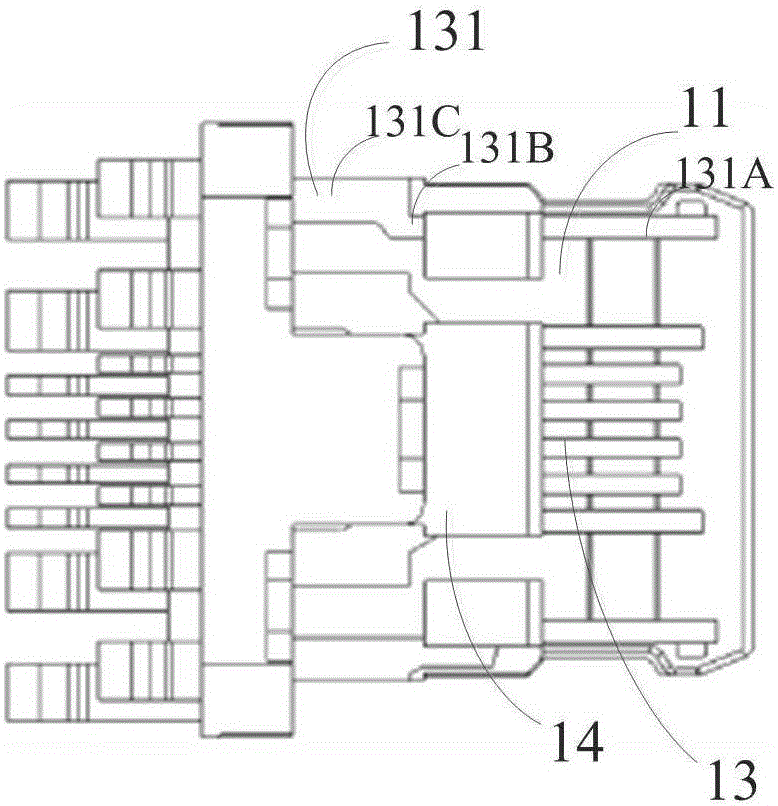

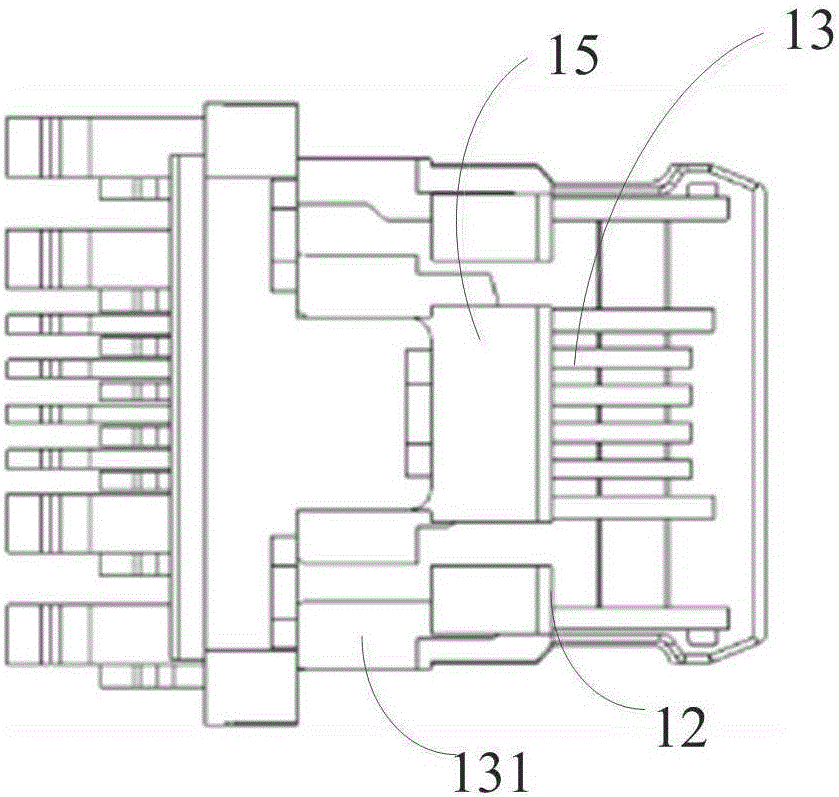

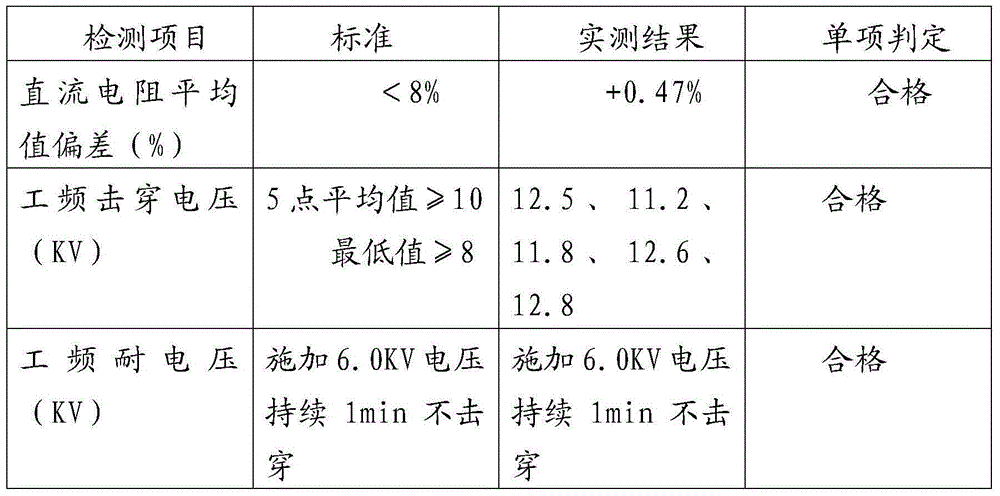

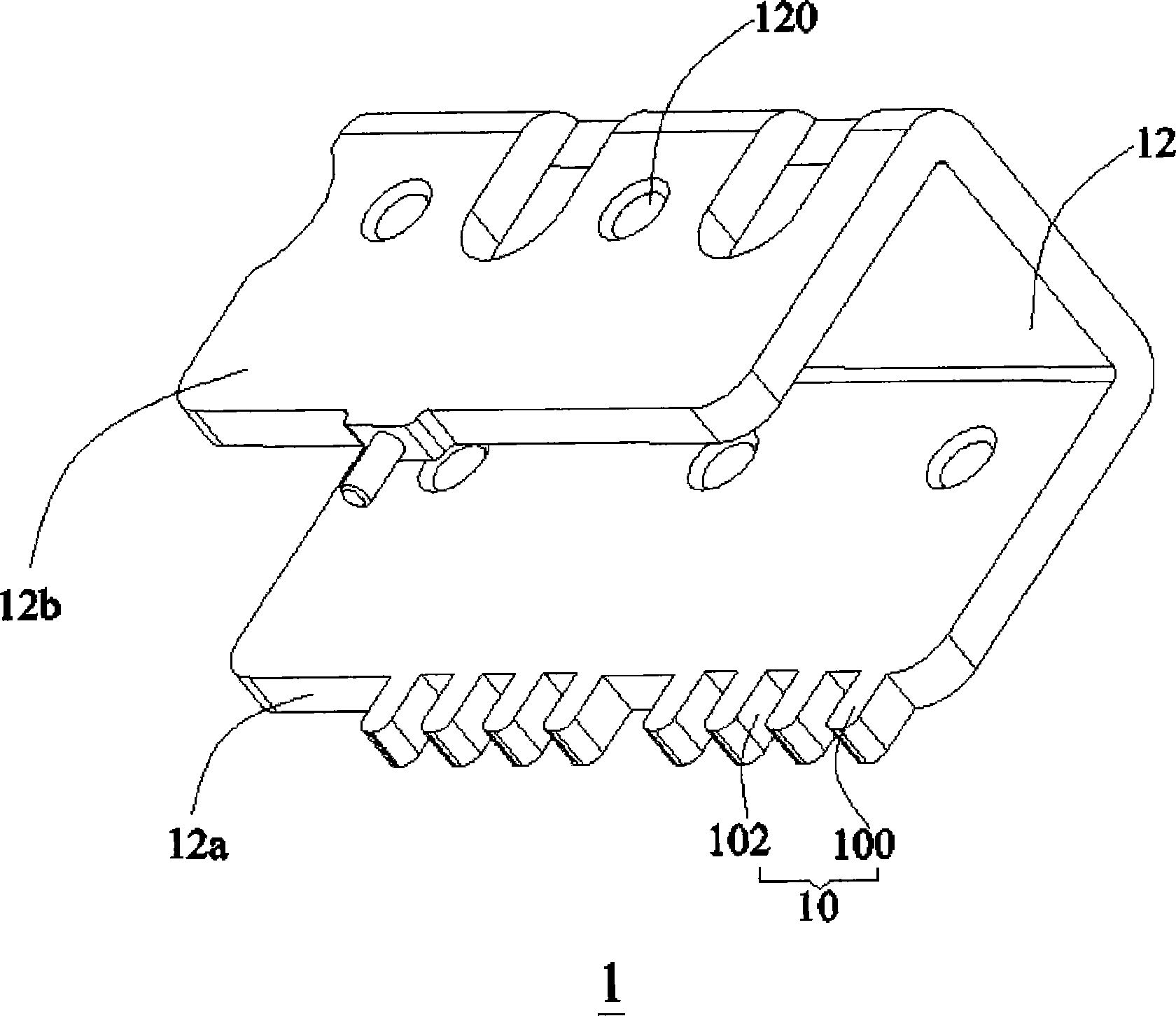

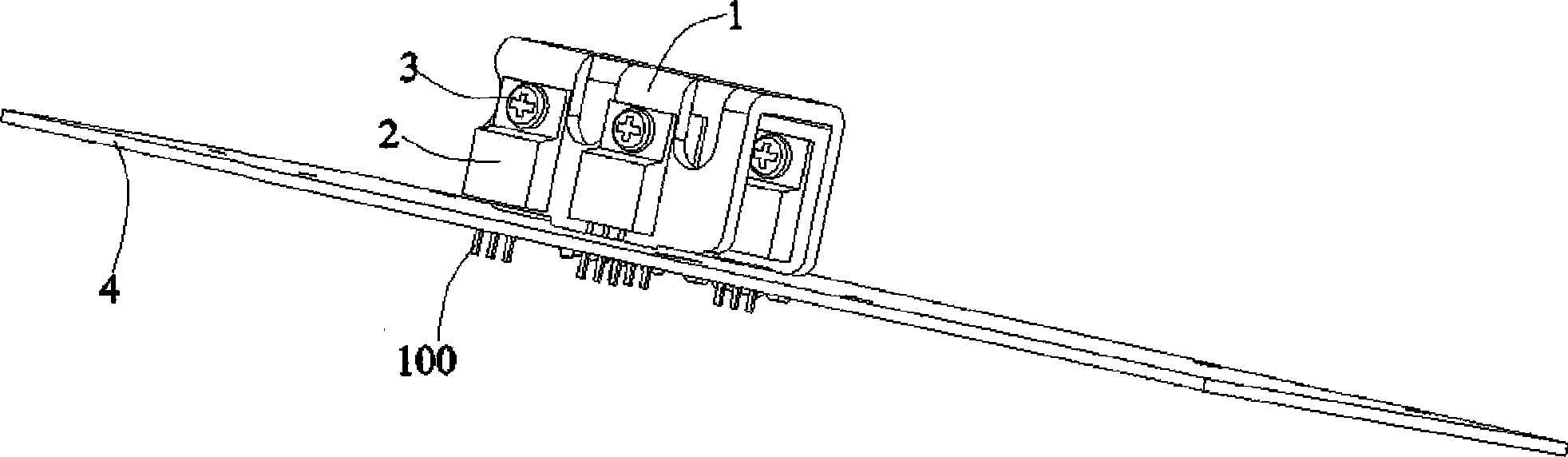

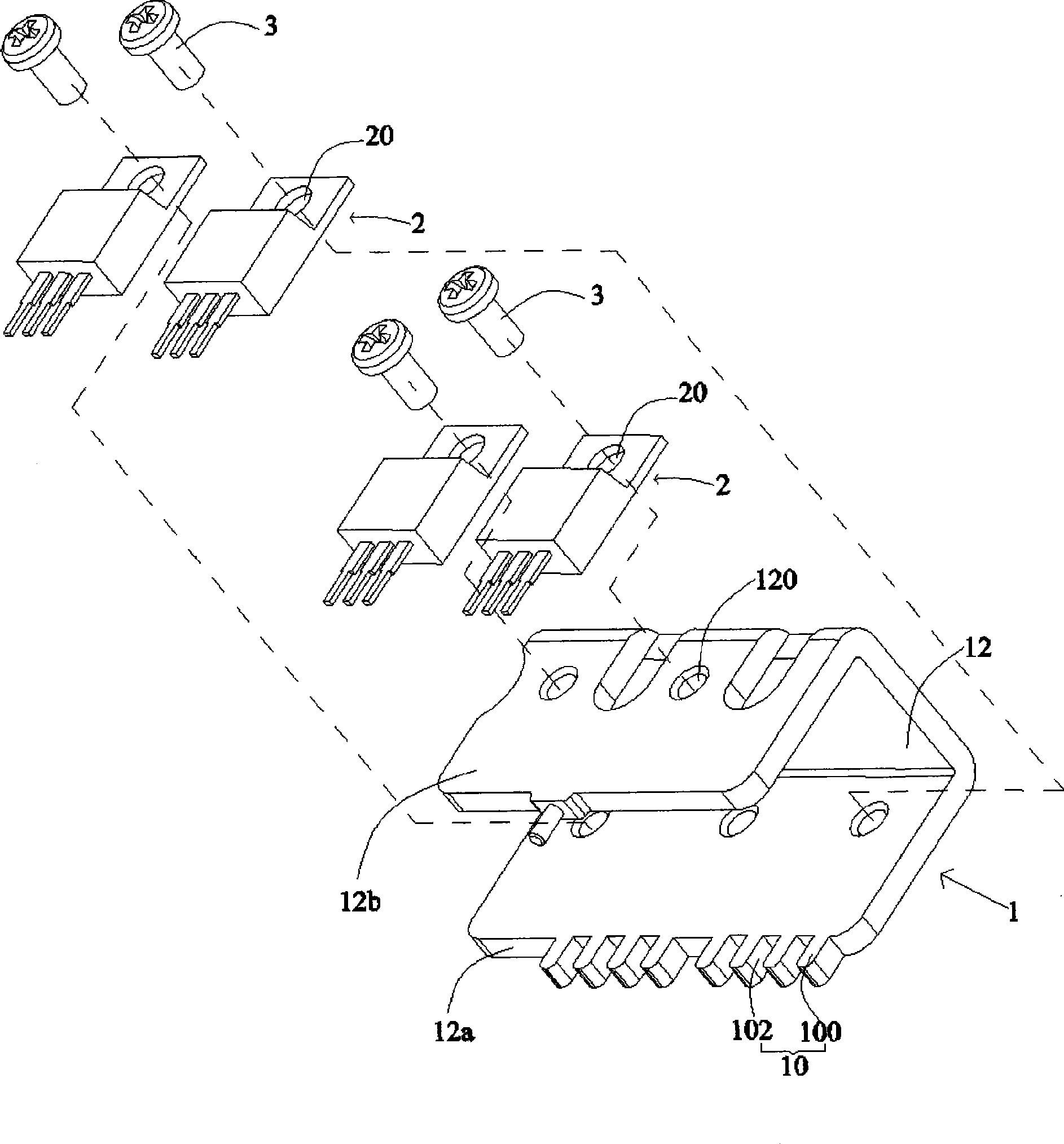

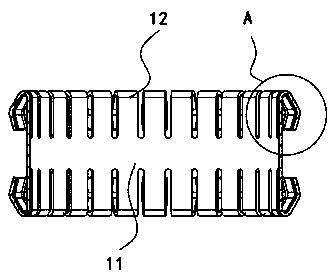

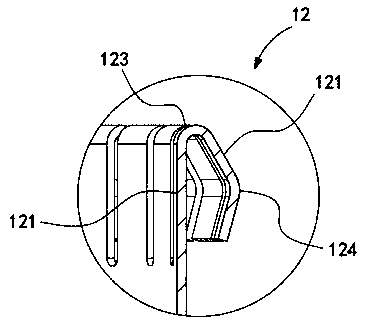

Connector plug and socket

ActiveCN105977675AIncrease contact positionIncrease the conductive cross-sectional areaContact member manufacturingCoupling contact membersPower flowElectrical and Electronics engineering

Owner:VIVO MOBILE COMM CO LTD

Heater and smoking set comprising same

ActiveCN113080519AIncrease the conductive cross-sectional areaImprove the electrothermal conversion rateHeating element shapesTobaccoInfraredElectric power

The invention relates to the field of smoking sets, and provides a heater and a smoking set comprising the heater. The heater comprises a base body which is provided with a surface, and a first electrode film layer, an infrared film layer and a second electrode film layer which are sequentially formed on the surface of the base body in the direction perpendicular to the surface of the base body, wherein the first electrode film layer and the second electrode film layer are electrically connected with a power supply; and the infrared film layer is used for generating heat under the action of electric power and transmitting the generated heat to an aerosol forming matrix at least in an infrared radiation mode so as to generate aerosol for smoking. Through the first electrode film layer, the infrared film layer and the second electrode film layer which are sequentially formed on the surface of the base body in the direction perpendicular to the surface of the base body, the conductive cross-sectional area of the infrared film layer is increased, the electro-thermal conversion rate of the infrared film layer is increased, the preheating time of the aerosol forming matrix is shortened, and the user experience is improved.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Aluminum electrolysis anode hollow aluminum pouring steel claw

The invention discloses an aluminum electrolysis anode hollow aluminum pouring steel claw. A hollow steel claw steel shell is included. An aluminum guide rod connecting plug is arranged at the upper end of the hollow steel claw steel shell. A steel claw beam is arranged at the lower end of the hollow steel claw steel shell. A set of steel claw feet are arranged at the lower end of the steel claw beam. The steel claw beam and the steel claw feet are each of a hollow structure. An aluminum core is poured into the aluminum guide rod connecting plug on the hollow steel claw steel shell, the steelclaw beam and the steel claw feet. By means of the aluminum electrolysis anode hollow aluminum pouring steel claw, the electrical resistivity of an anode guide rod and the steel claw is reduced, electrical losses are reduced, the production cost is reduced, and the beneficial effect that the integral mechanical strength is high is achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

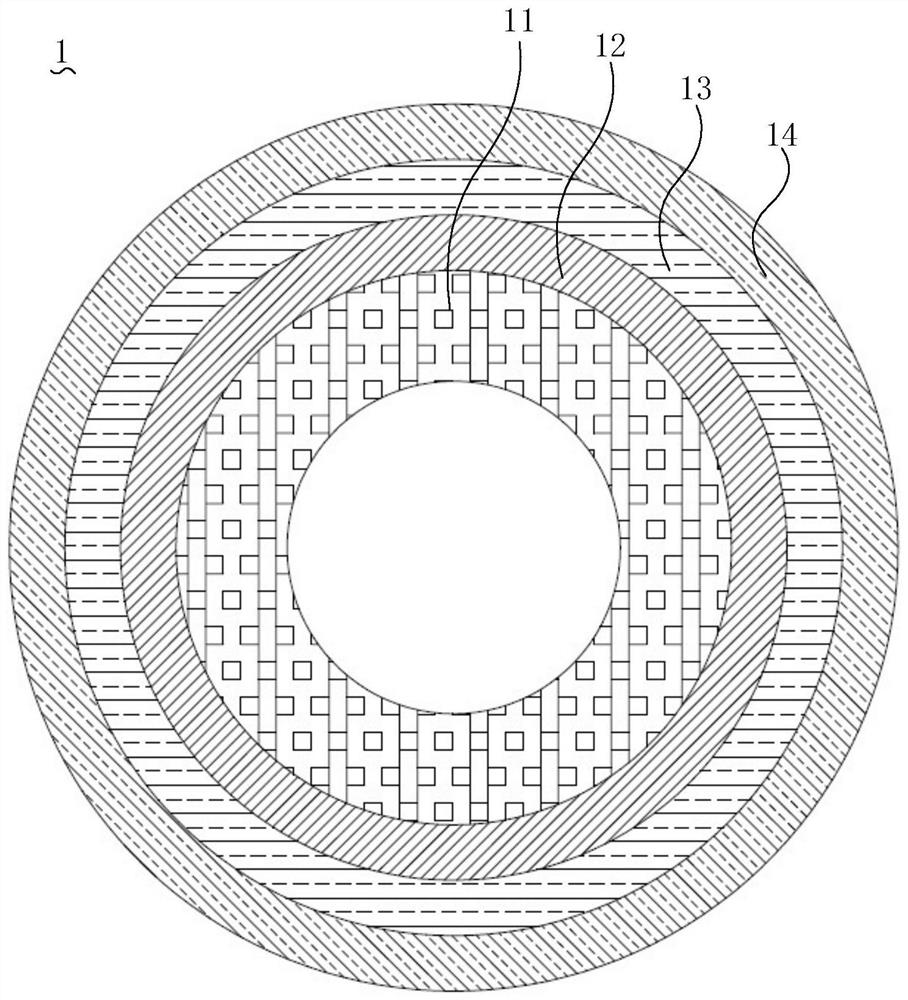

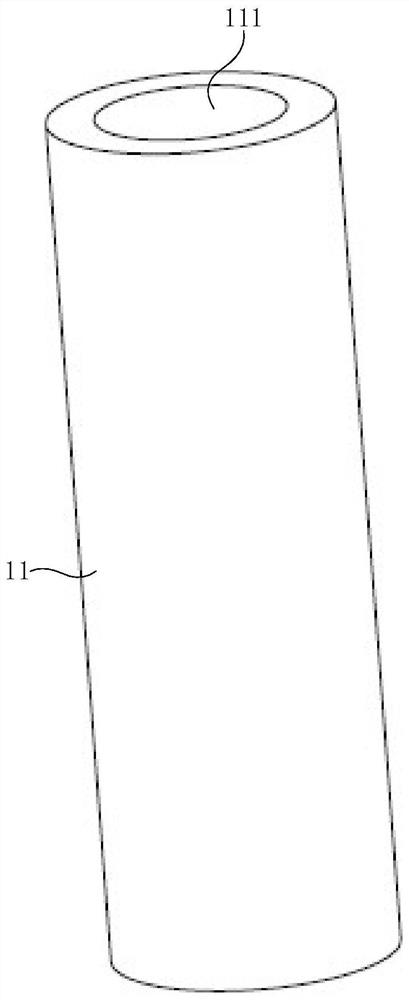

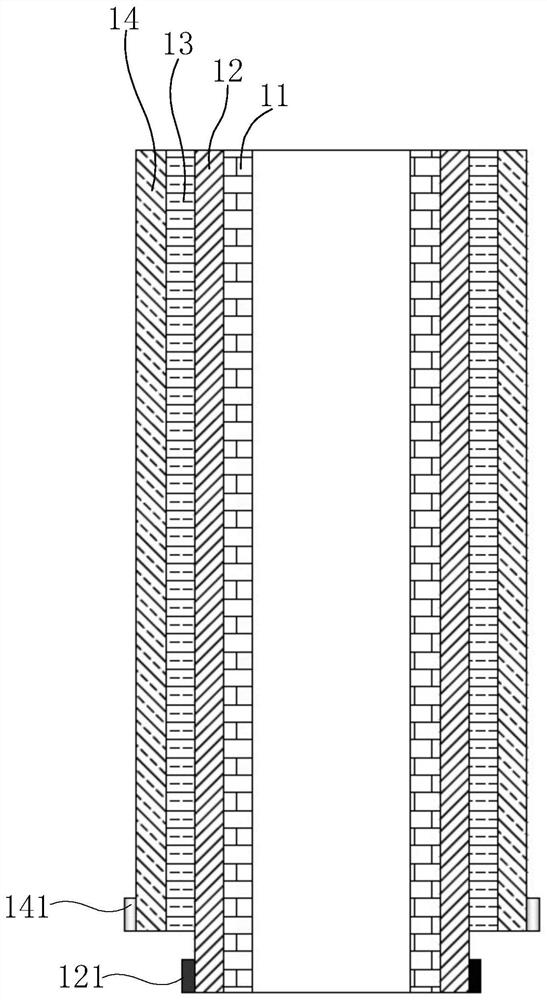

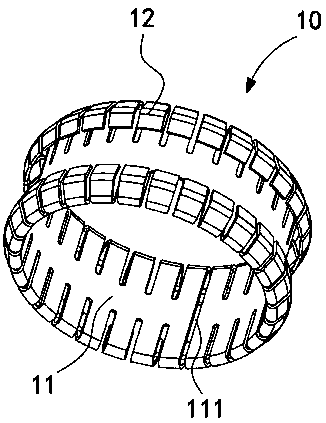

Glass-fiber and film wrapped all-insulated squared aluminum strand wire

PendingCN105139934AGuaranteed insulation performanceImprove adaptabilitySingle bars/rods/wires/strips conductorsTransformers/inductances coils/windings/connectionsGlass fiberFiber

The invention provides a glass-fiber and film wrapped all-insulated squared aluminum strand wire with small overall dimension change. The glass-fiber and film wrapped all-insulated squared aluminum strand wire comprises a rectangular strand wire, an insulating layer and a glass fiber yarn wrapping layer, wherein the rectangular strand wire is formed by layered arrangement and transposition of a plurality of round aluminum wires; aluminum wire insulating films coat outer layers of the round aluminum wires; the insulating layer comprises a first insulating film layer and a second insulating film layer; the first insulating film layer coats the outer side of the rectangular strand wire; the second insulating film layer coats the outer side of the first insulating film layer; the glass fiber yarn wrapping layer coats the outer side of the second insulating film layer, and comprises a first insulating paint layer, a first glass fiber yarn layer, a second insulating paint layer, a second glass fiber yarn layer and a third insulating paint layer; the first insulating paint layer coats the outer side of the second insulating film layer; the first glass fiber yarn layer coats the outer side of the first insulating paint layer; the second insulating paint layer coats the outer side of the first glass fiber yarn layer; the second glass fiber yarn layer coats the outer side of the second insulating paint layer; the third insulating paint layer coats the outer side of the second glass fiber yarn layer; and the wrapping direction of the first glass fiber yarn layer is opposite to that of the second glass fiber yarn layer.

Owner:TIANJIN JINGWEI HUIKAI OPTOELECTRONICS CO LTD

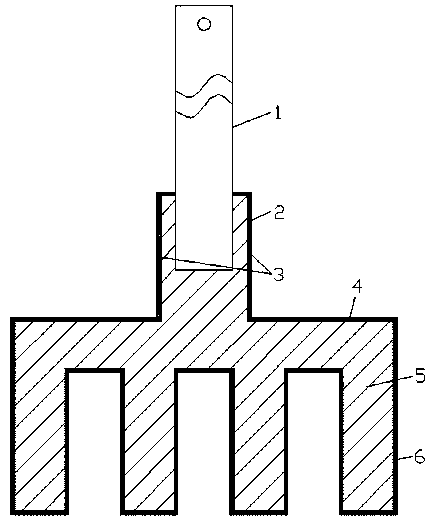

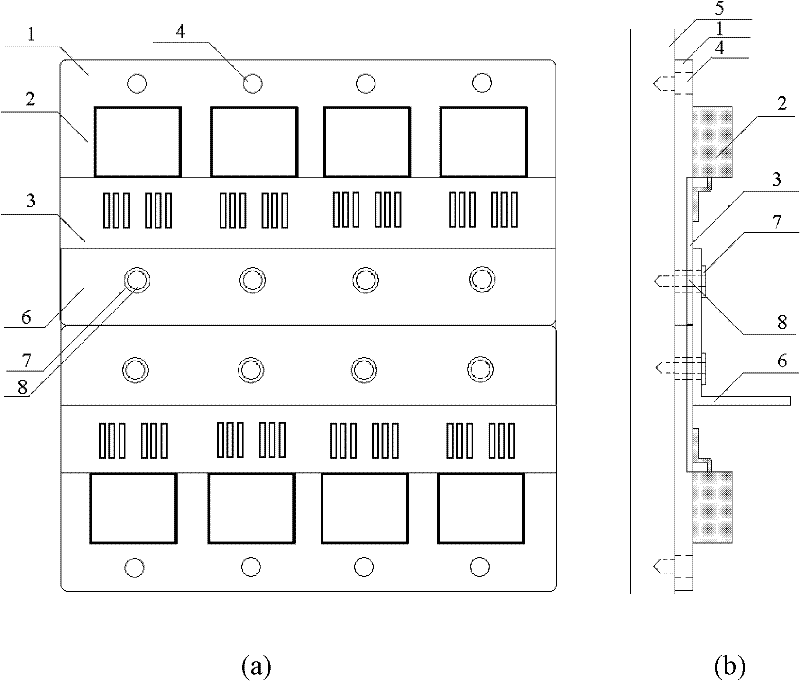

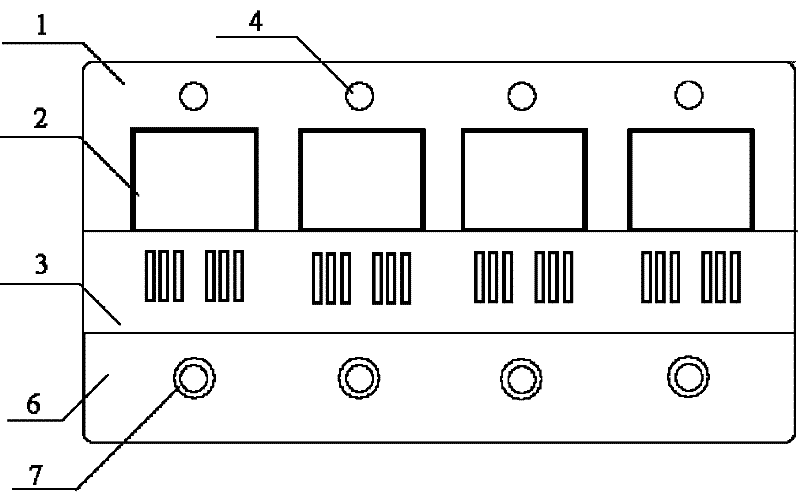

Heat radiating mechanism

ActiveCN101420841ATightly bondedLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectricityHeat conducting

The invention relates to a radiating mechanism used for radiating for an electronic element which is arranged on the radiating mechanism; the radiating mechanism is provided with a radiating body and an interconnecting piece which are mutually connected, the interconnecting piece is provided with a plurality of pins, the radiating mechanism can be fixed on a print circuit board by the pins, the pins are mutually spaced, a filling opening is formed between each two adjacent pins and is filled with conducting material. In the radiating mechanism of the invention, a cellular type interconnecting piece is electrically connected with the print circuit board; the interconnecting piece is provided with a plurality of pins and is inserted and connected with corresponding inserting holes of the print circuit board by a plurality of pins, thus the radiating mechanism and the print circuit board can be jointed more tightly and steadily; furthermore, the more the filling openings are formed, the more conducting material is filled, thus increasing the conducting section area, reducing the resistance between the radiating mechanism and the print circuit board and effectively improving the electricity conducting efficiency and heat conducting efficiency.

Owner:LITE ON TECH CHANG ZHOU CO LTD +2

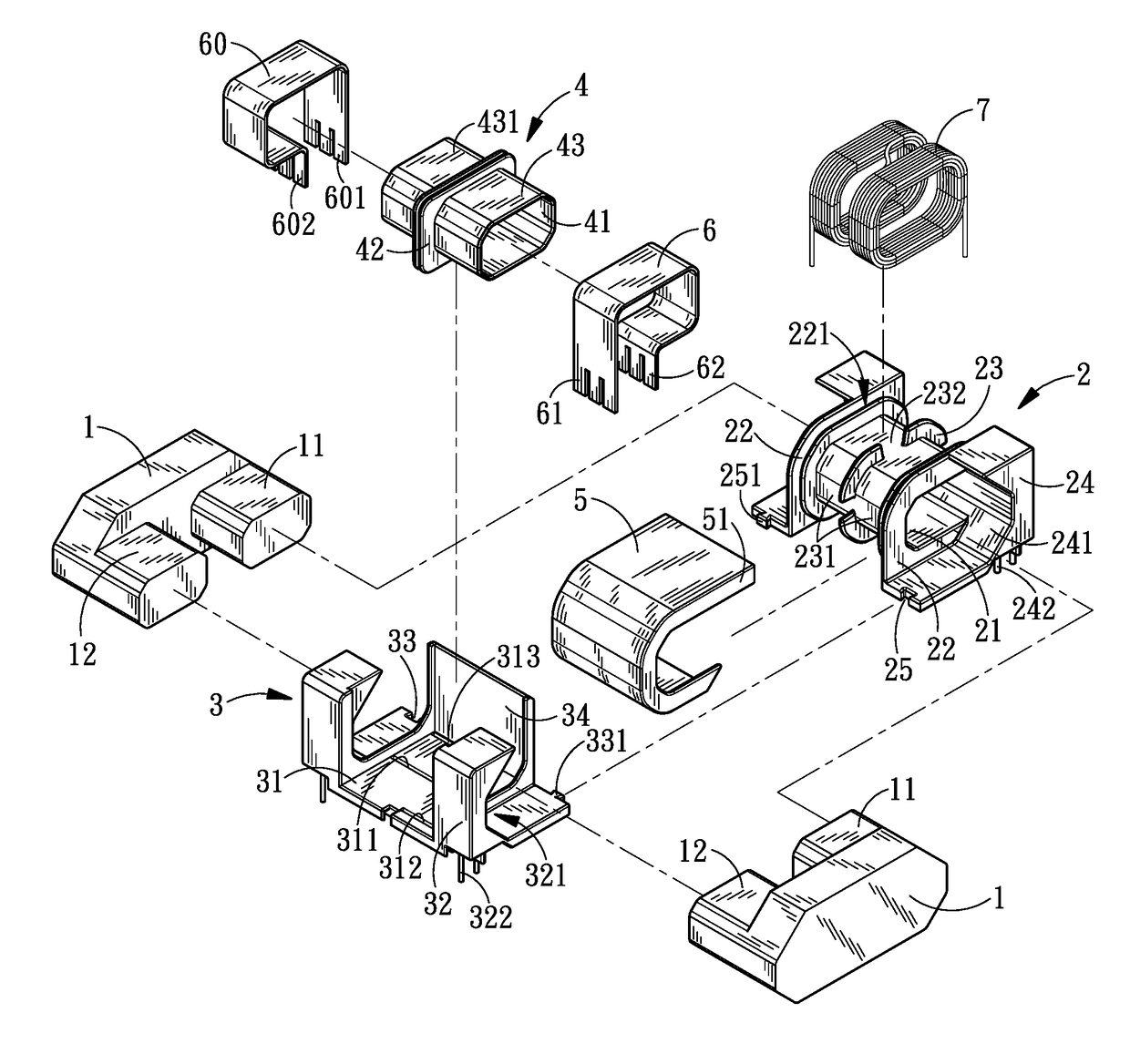

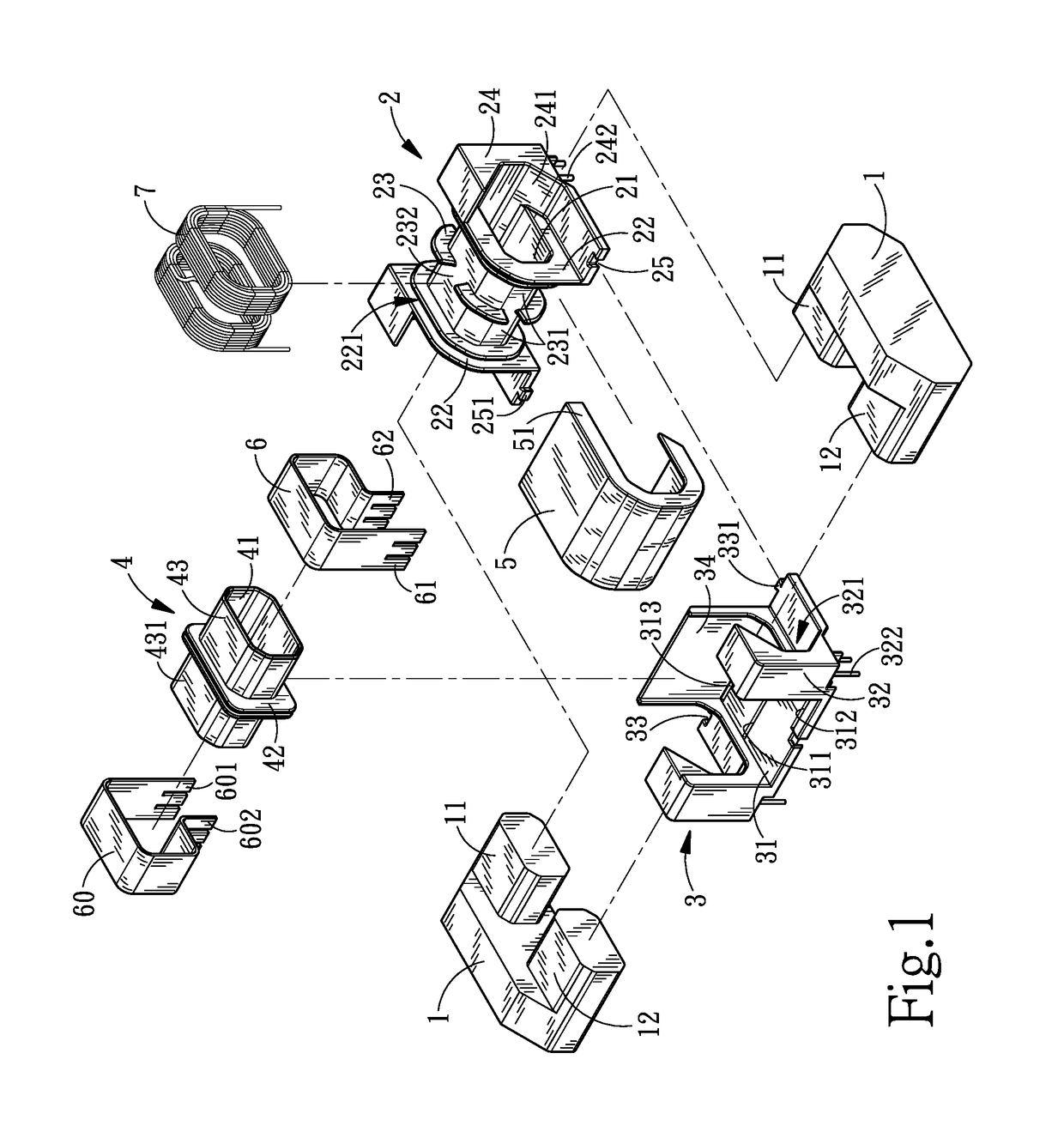

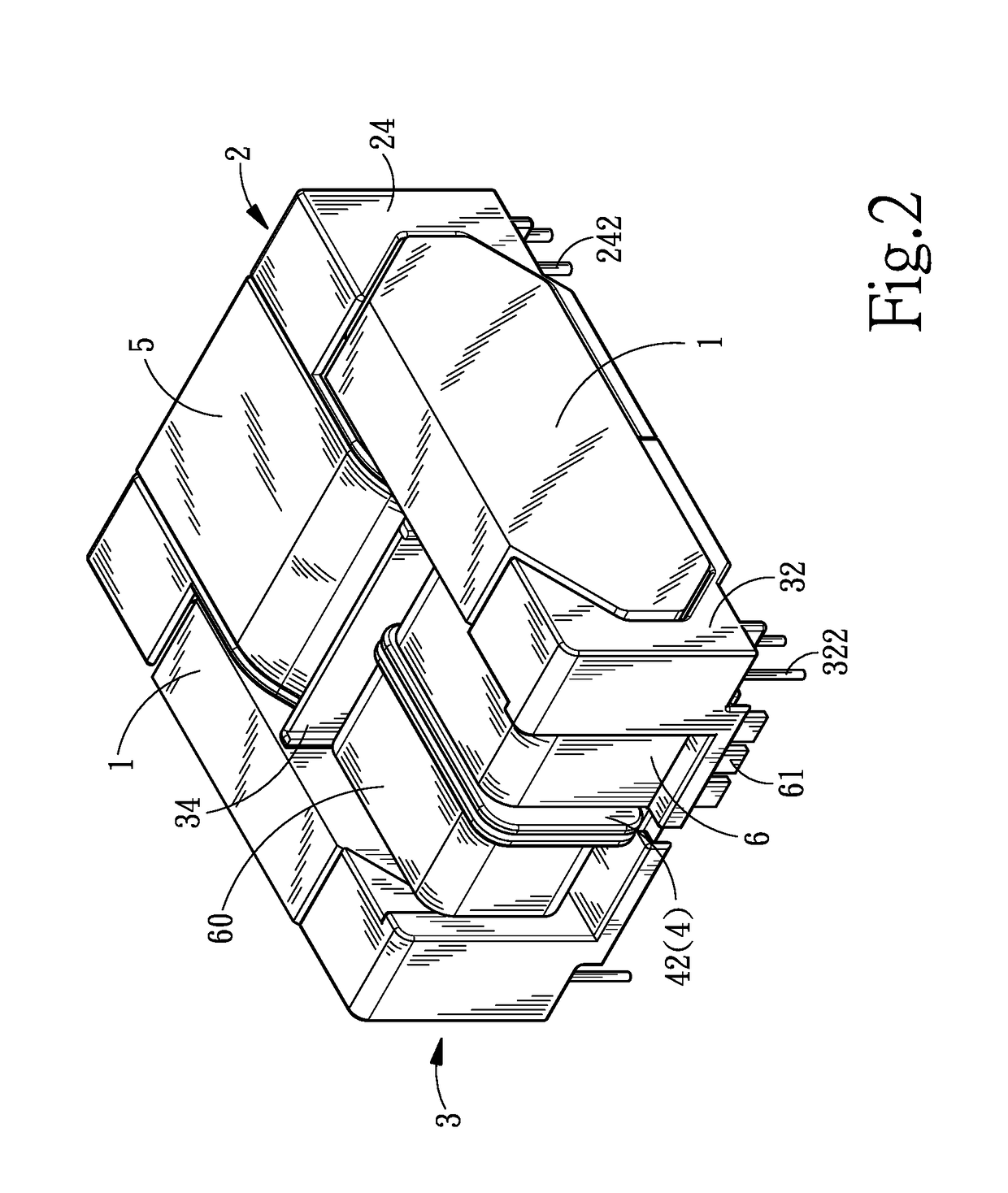

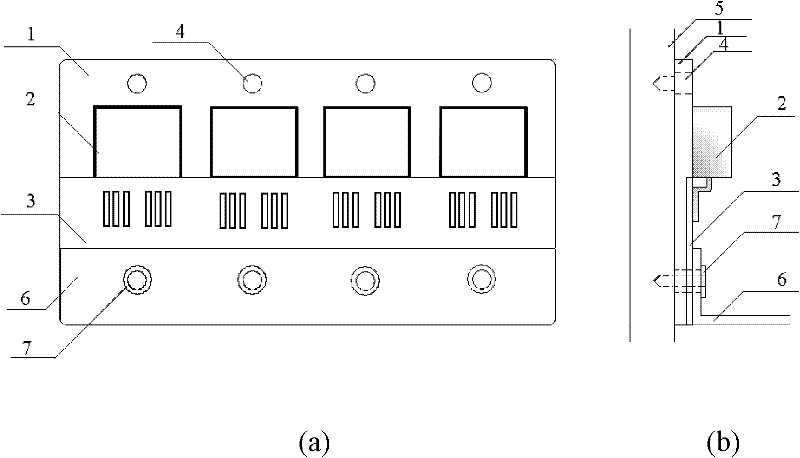

Resonant high current density transformer

ActiveUS20170110241A1Increase effective conductive cross-sectional areaSmall sizeTransformersTransformers/inductances coils/windings/connectionsHigh current densityBobbin

A resonant high current density transformer including two cores that are abut against each other with their first and second side posts on two sides thereof. A first bobbin envelops the first side posts on the same side of the two cores. A side plate is provided on either end of the first bobbin. The space between the two side plates is divided into two coil slots with a spacer, and at least a wire is wound in each coil slot to form a primary winding. A further second bobbin envelops the second side posts on the same side of the two cores. The outer periphery of the second bobbin is divided into two winding regions by another spacer, and a metal plate envelops each of the winding regions to form a secondary winding. A bobbin mount is disposed at the external flank of the second bobbin with a barrier plate at a side thereof for separating the first and the second bobbins. An insulating separating cover is provided on a side of the first bobbin closer to the bobbin mount, and the two ends of the separating cover cover the top and bottom sides of the first bobbin, respectively.

Owner:YUJING TECH CO LTD

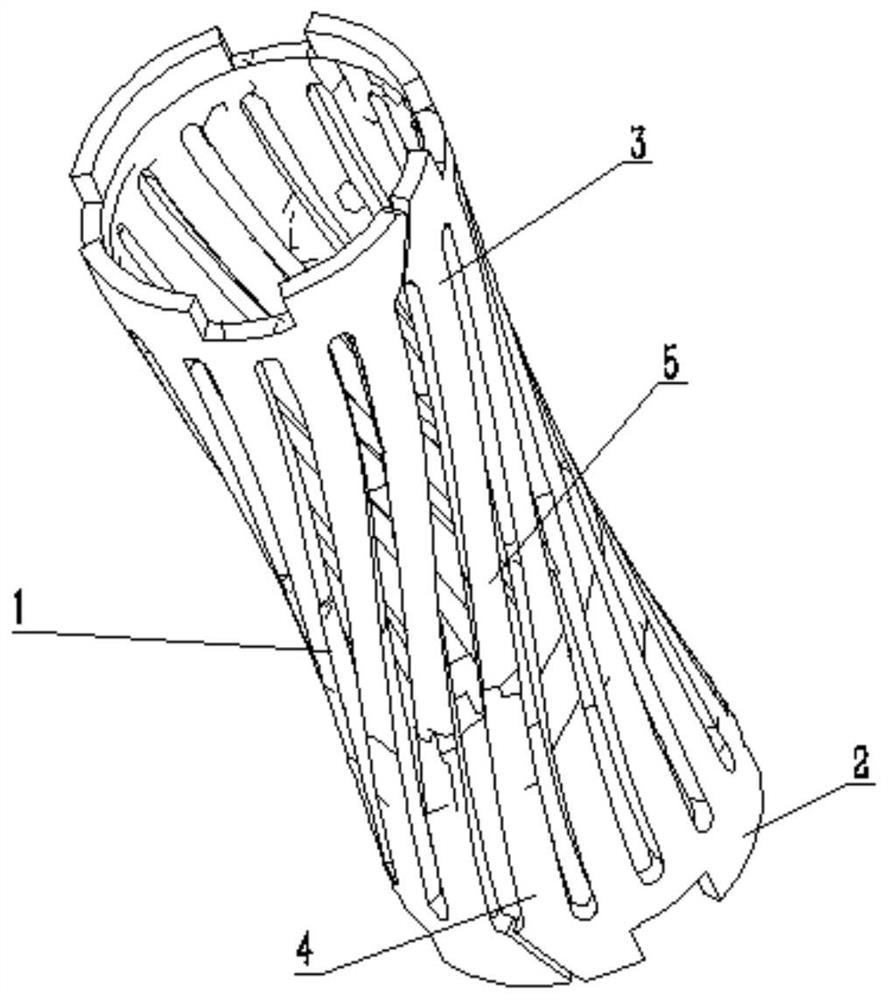

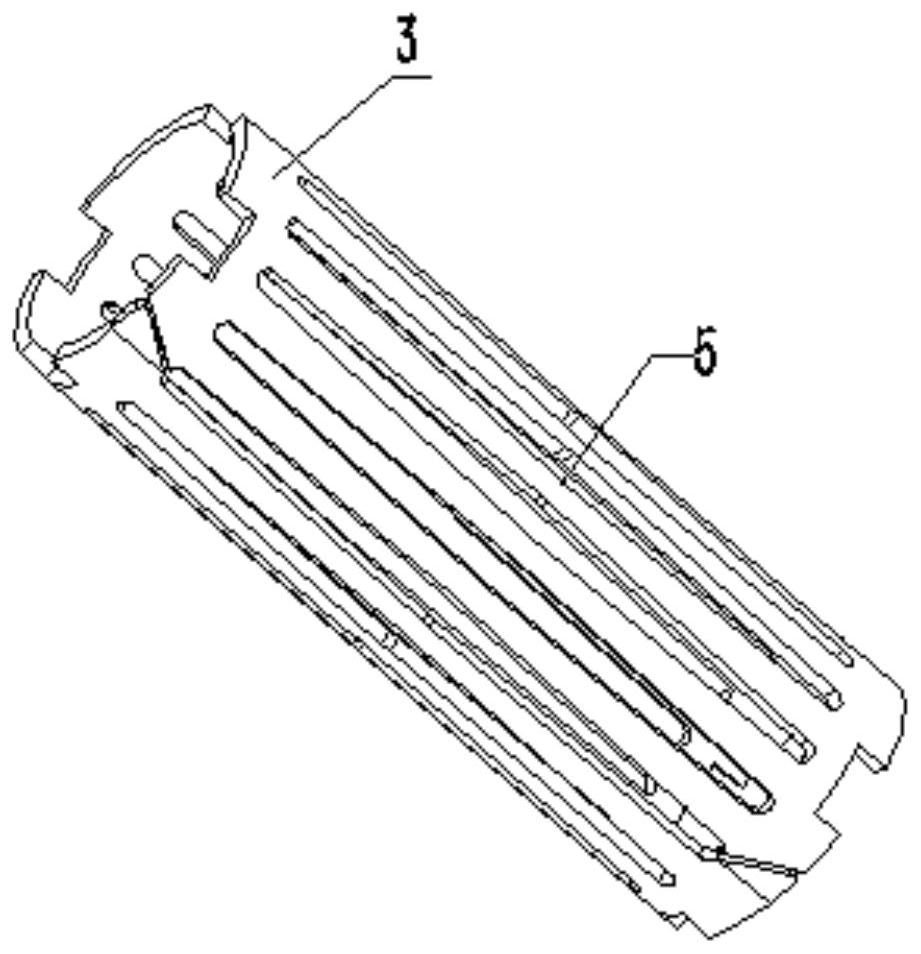

Contact member, insert sleeve structure, and composite hole sleeve structure

PendingCN109546404AThe contact resistance R decreasesConduction length shortenedCoupling device detailsEngineeringMechanical engineering

The invention discloses a contact member. The contact member includes a metal cylinder; the metal cylinder is provided with a slit in the axial direction; two ends of the metal cylinder are respectively provided with a plurality of bending shrapnel pieces separated from each other; and bending directions of the bending shrapnel pieces bend toward the direction of the outer wall of the metal cylinder from the center of the metal cylinder. The invention provides the contact member with short structure and excellent conductive effect.

Owner:倪泉

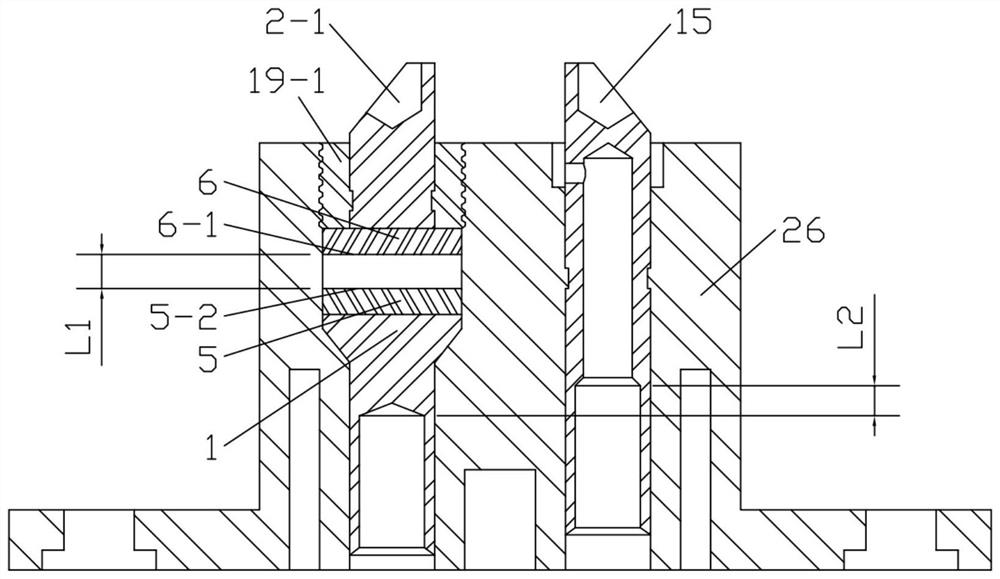

Anti-electric shock connector with built-in magnet

InactiveCN112086782AOvercome mutual repulsionClose contactCoupling contact membersTwo-part coupling devicesMagnetic polesEngineering

The invention provides an anti-electric shock connector with a built-in magnet. A first magnet and a second magnet are arranged in the anti-electric shock connector, and conduction and disconnection of the anti-electric shock front-end electrode and the anti-electric shock rear-end electrode are ingeniously realized by utilizing the characteristic that like magnetic poles of the magnets repel eachother so that the occurrence of an electric shock accident of a human body is avoided. A fuse is arranged in the other conductive part of the anti-electric shock connector, so the connector has anti-short circuit and anti-electric shock functions. According to the anti-electric shock connector, the signal transmission electrode is added to the anti-electric shock connector, so signal communication can be performed to monitor the state of the battery in real time, and the connector has a signal transmission function and an anti-electric shock function or has a signal transmission function, ananti-short-circuit function and an anti-electric shock function.

Owner:东莞市恩赞科技有限公司

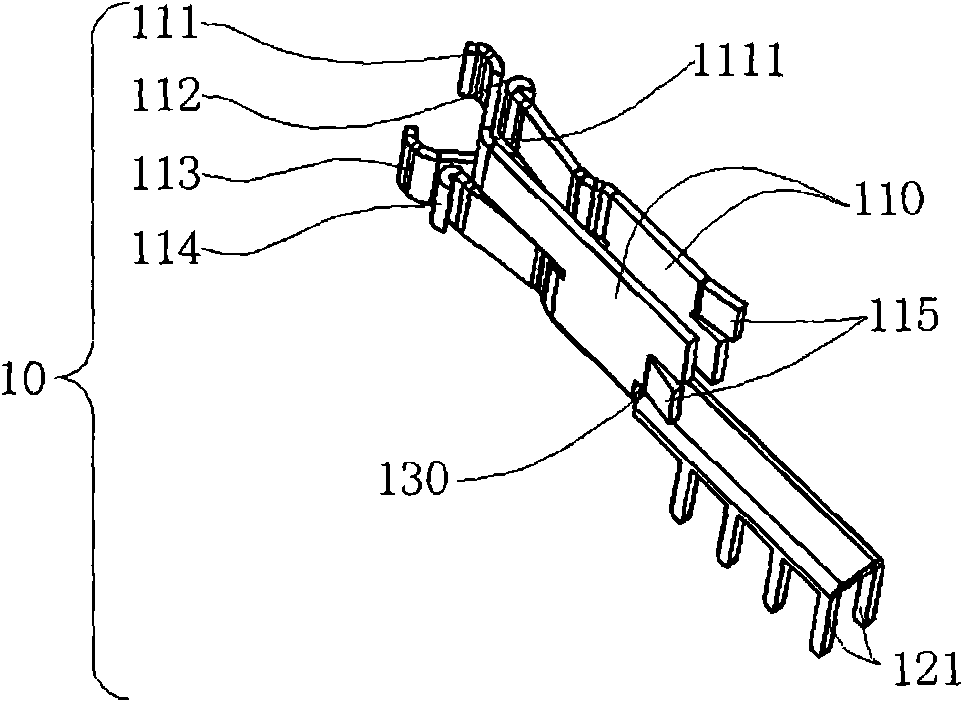

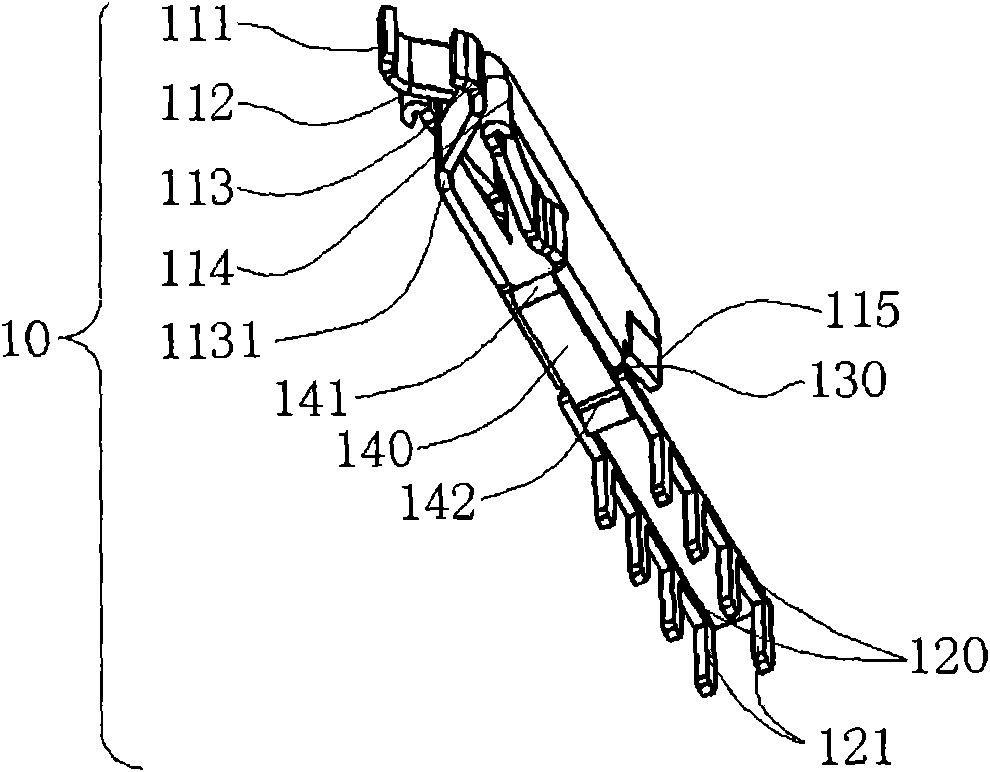

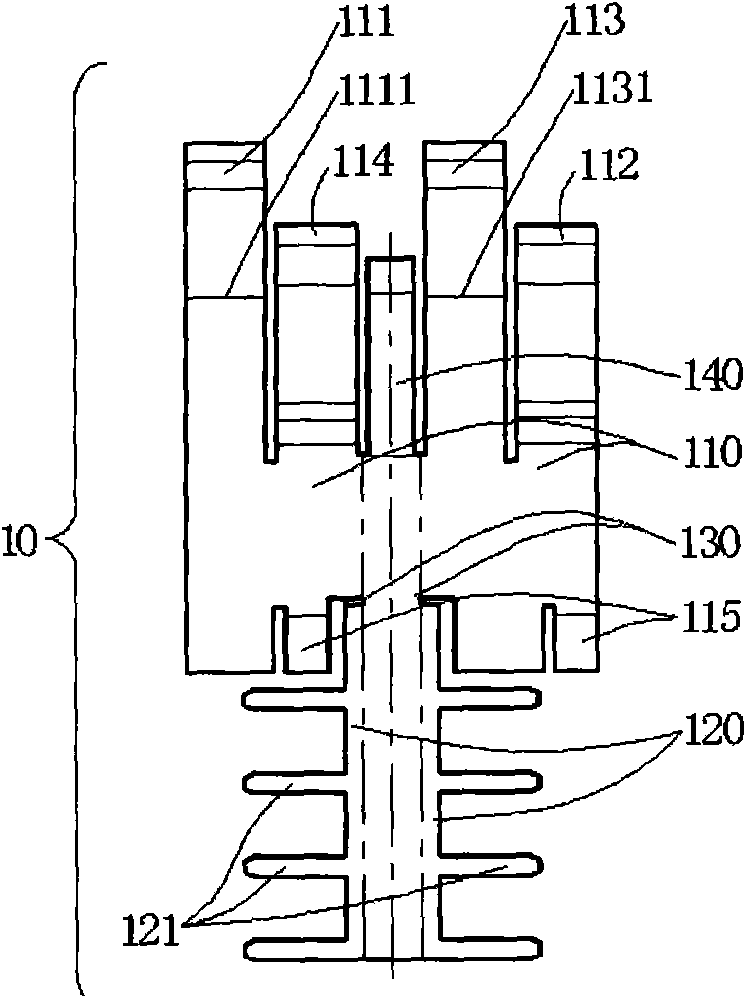

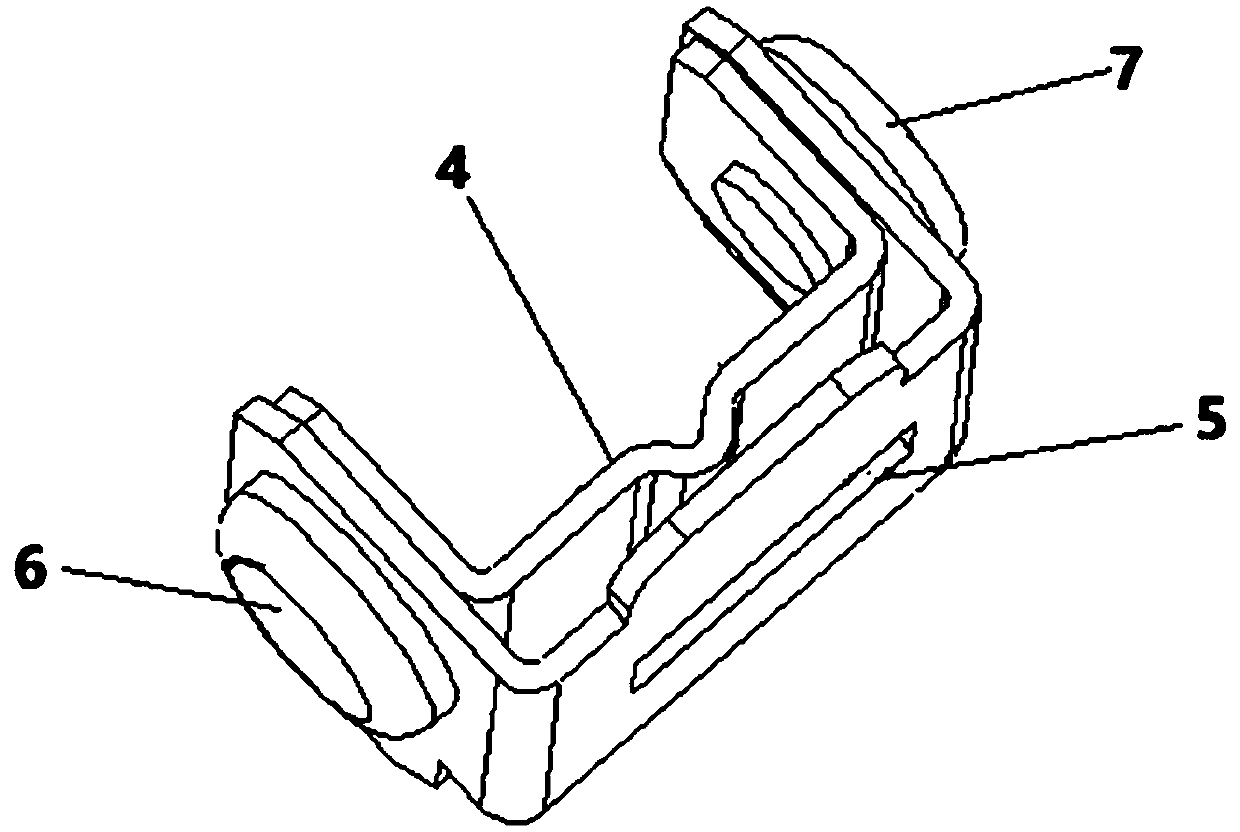

Multi-contact high current elastic contact element terminal

InactiveCN102055094AIncrease the areaImprove connection reliabilityCoupling contact membersContact highEngineering

The invention discloses a multi-contact high current elastic contact element terminal. The contact element terminal comprises an abutting end region (110) and a terminal connecting region (120), wherein the abutting end region (110) comprises a plurality of long contact regions and a plurality of short contact regions, and the contact regions have metal plate stagger structures and form a plurality of front and rear contact zones so as to form multi-contact. The roots of the long contact regions and the roots of the short contact regions are correspondingly distributed on two sides of the abutting end region (110), and the long contact regions are turned to be distributed on the same side as the opposite short contact regions and form contact regions of the same side together with the opposite short contact regions. The abutting end region (110) and the terminal connecting region (120) have mutually reverse folded structures. The contact element terminal has large contact region area and high connecting reliability, effectively reduces the calorific power in the high current transmission process, optimizes a heat dissipation channel, improves the current carrying capability, has small volume, saves the materials, and has low cost.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

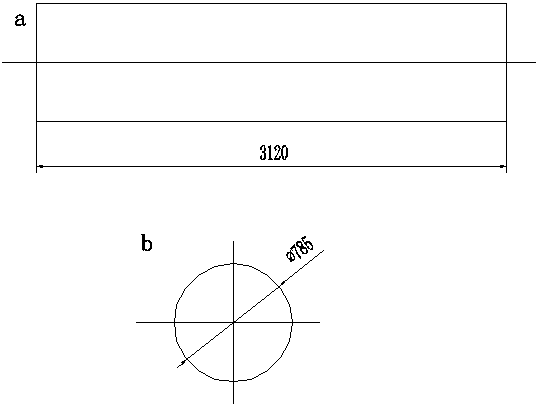

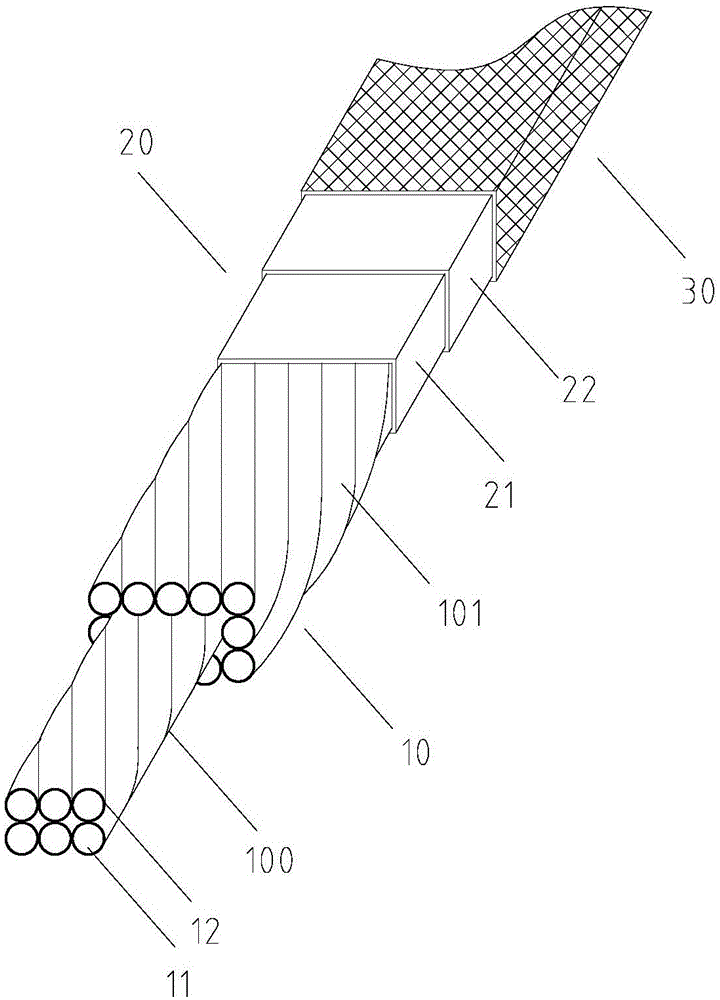

Aluminum alloy shaped wire photoelectric composite cable

InactiveCN103383878AIncrease the conductive cross-sectional areaRealize energy saving in power transmissionPower cablesElectrical conductorAluminium alloy

The invention discloses an aluminum alloy shaped wire photoelectric composite cable which comprises a core wire. The core wire is formed by stranding a plurality of galvanized stranded steel wires, a plurality of trapezoid aluminum alloy single wires and a trapezoid optical unit are concentrically stranded outside the core wire, and a plurality of fan-shaped aluminum alloy single wires are concentrically stranded outside the trapezoid aluminum alloy single wires and the trapezoid optical unit. The defects that common round wire aluminum conductor stranded wires are large in loss and low in tensile strength, and cannot be laid in an overhead mode in long distance in actual use are overcome. Shaped wires are tightly stranded, and the maximum electric conduction sectional area is made to exist in limited space of the equal outer diameters of wires. When wire transmission capacity is increased to 180%-200% of a conventional wire, a wire sag increment is still within the range allowed by the conventional wire, and the aims of power transmission energy saving and capacity improving are achieved.

Owner:HENAN KOSEN CABLE

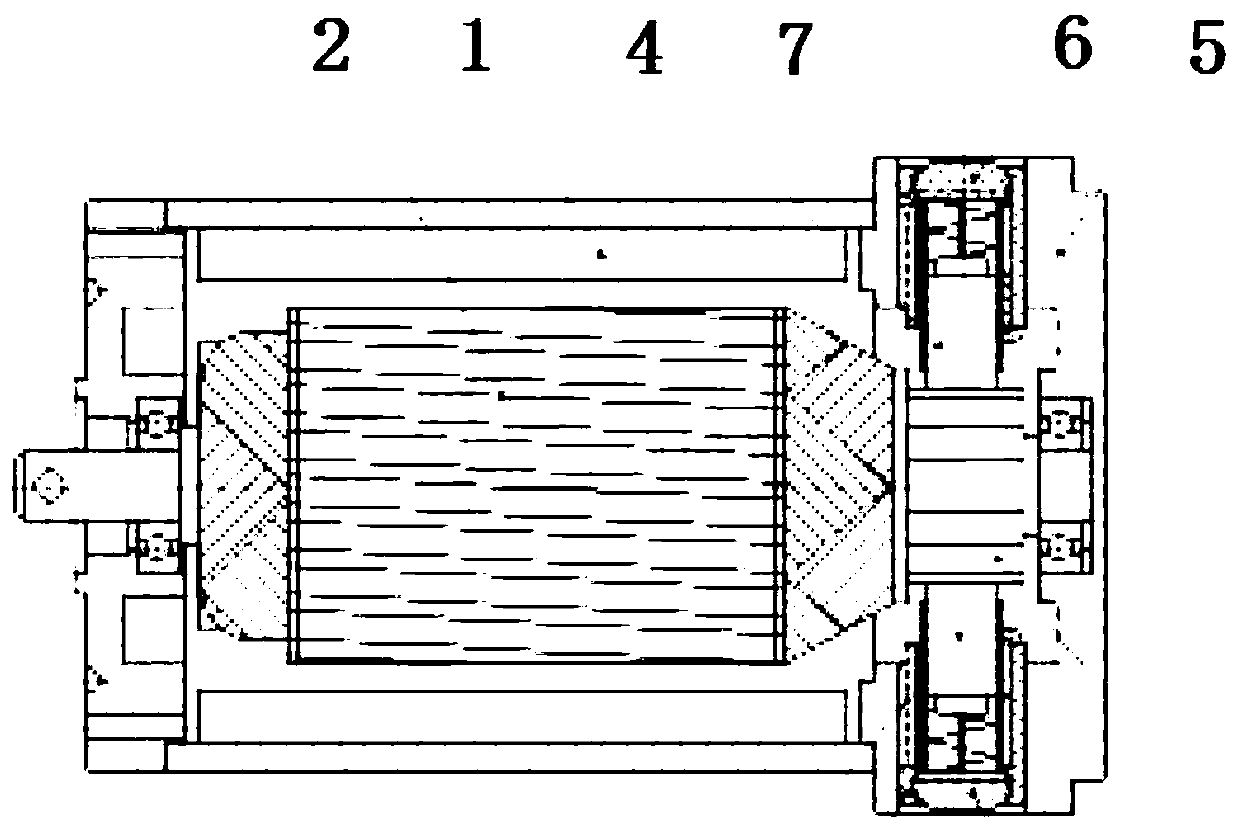

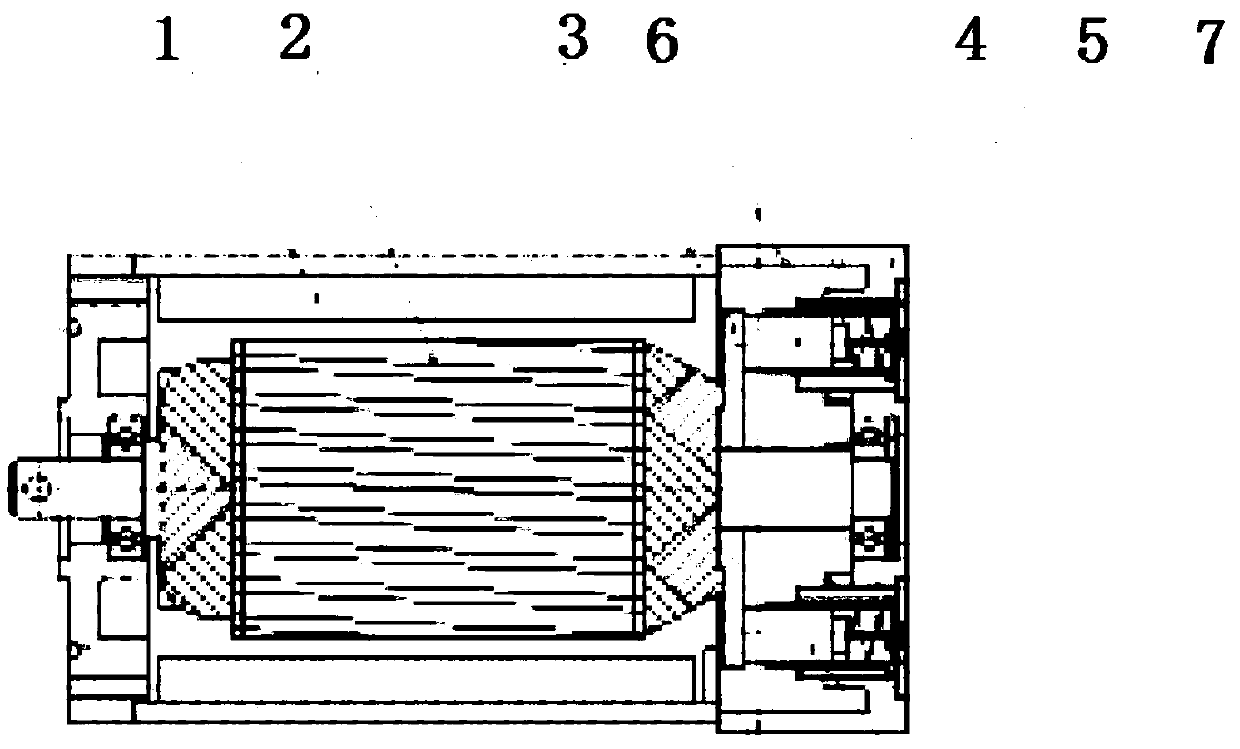

Motor with novel reversing structure

PendingCN109687651AIncrease contact areaImprove commutation reliabilitySupports/enclosures/casingsElectric energyStator

The invention provides a motor with a novel reversing structure. The motor comprises a stator, a rotor, a commutator and a brush. The disc-shaped commutator is mounted on the rotor, the outer end surface of the commutator is in contact with one end of the brush, the other end of the brush extends along the non-radial direction of the commutator, and the brush is connected to a power source. By adopting the technical scheme, the contact area between the brush and the commutator is increased, the conductive cross-sectional area which the electric energy can flow is larger, the reversing reliability is improved, the noise during running of the motor is reduced, the brush and the commutator are in close contact under the action of the brush, and the reversing reliability is further improved. In addition, components inside the motor casing are more easily arranged, the brush is connected to the power source through a wire extending from the end surface of the motor casing. For a motor manufacturer, the motor is more convenient to assemble, an armature line inserting and welding process is also relatively simple, and the cost for the motor manufacturing enterprise is reduced.

Owner:GUIZHOU HUAFENG ELECTRICAL APPLIANCES

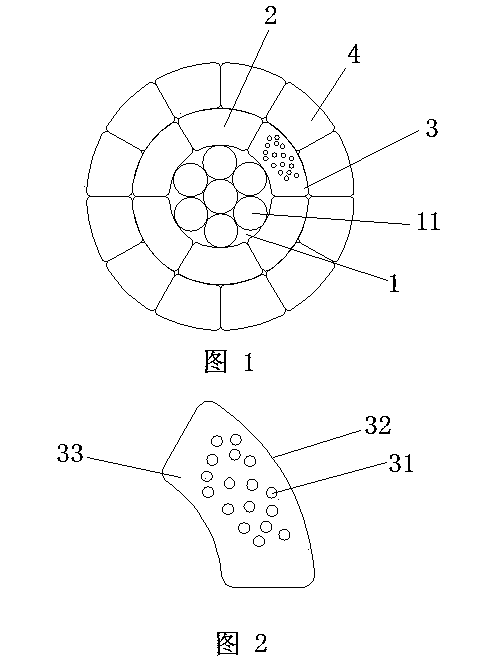

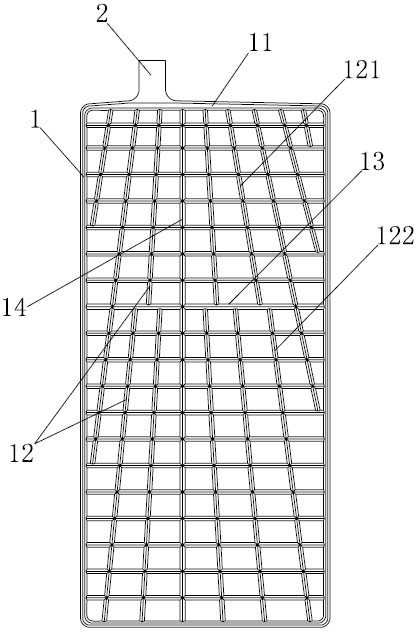

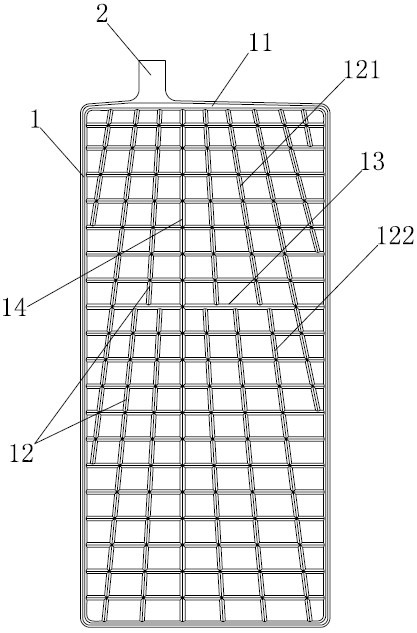

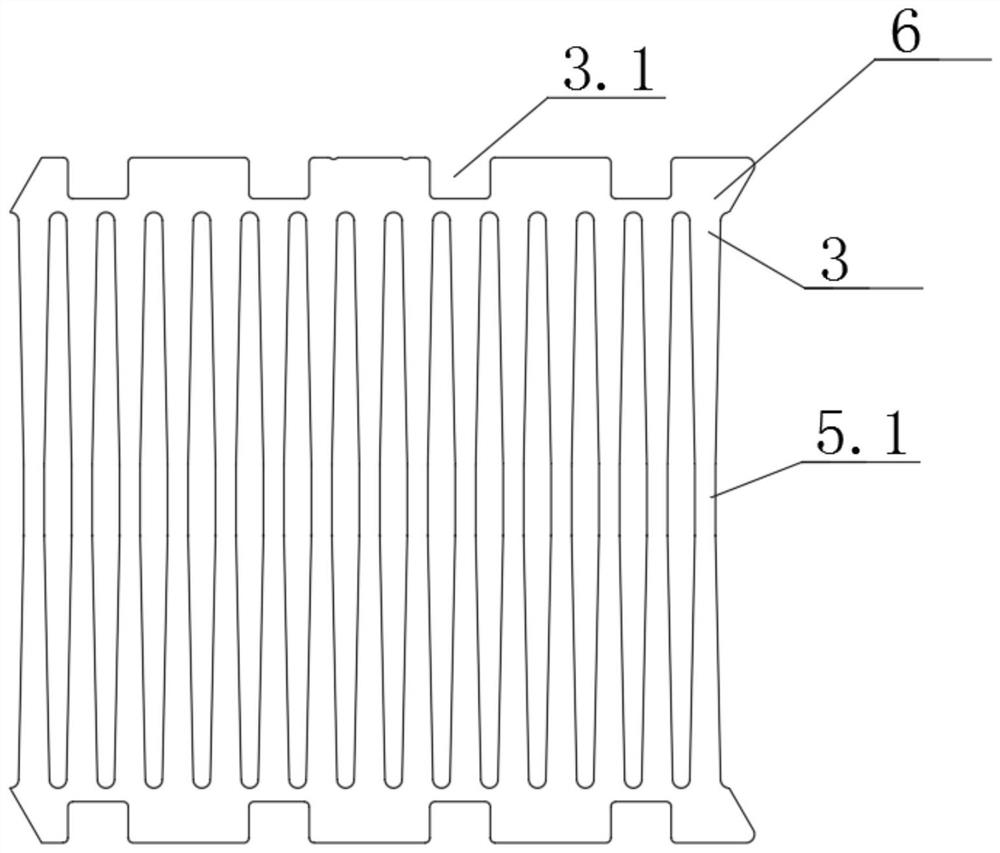

Storage battery grid plate

InactiveCN101877409AAvoid breakingEffective protectionElectrode carriers/collectorsElectrical and Electronics engineering

Owner:长兴诺力电源有限公司

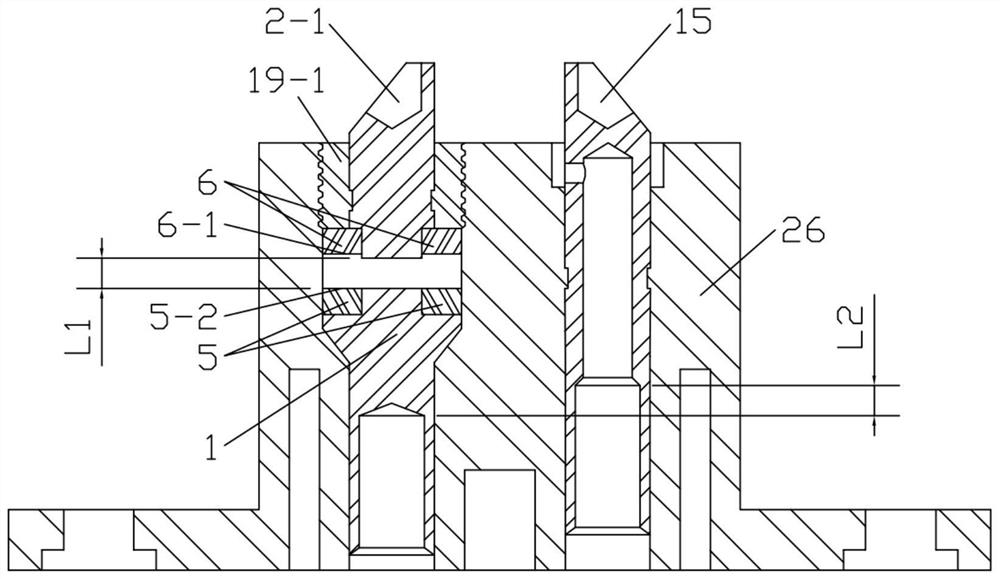

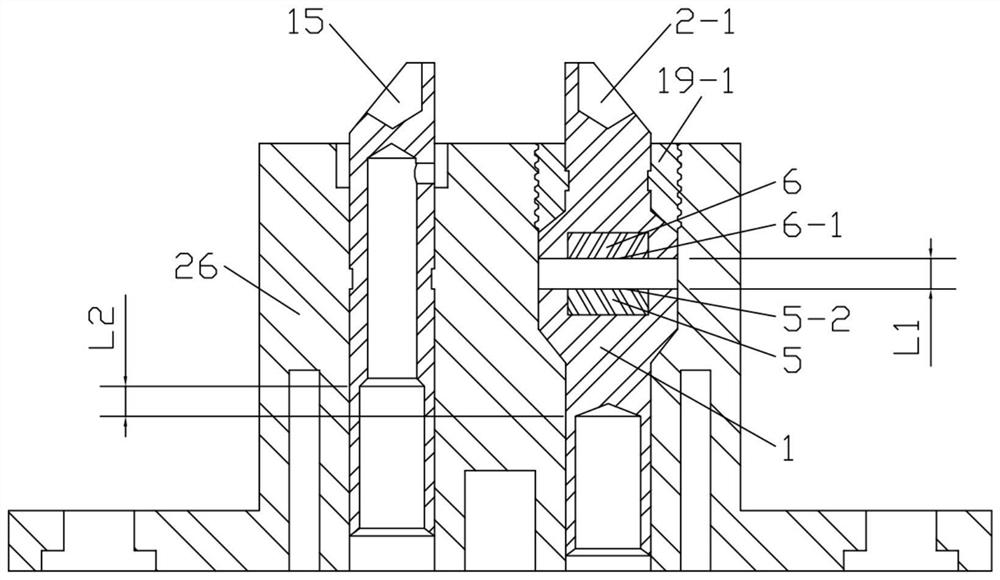

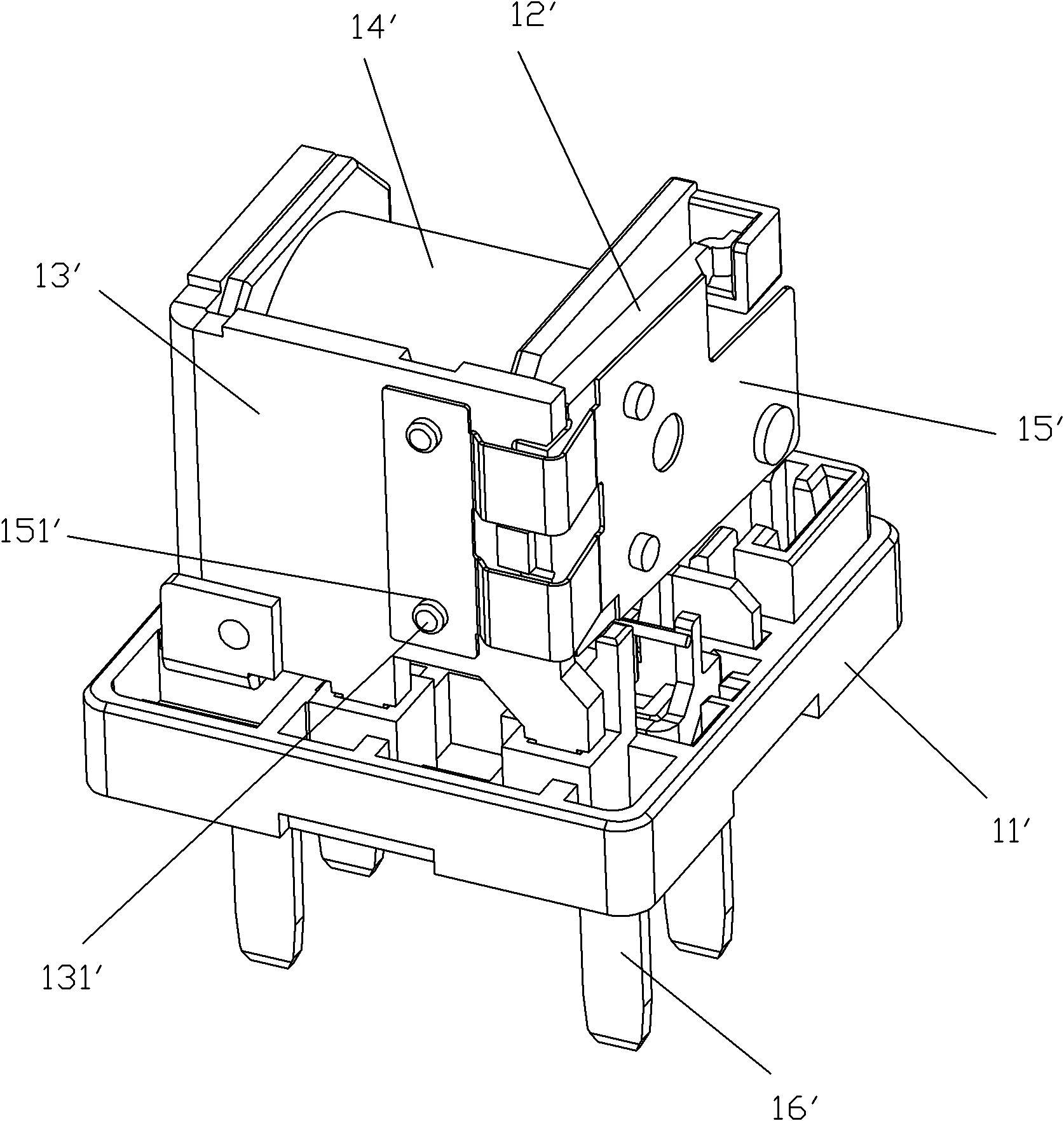

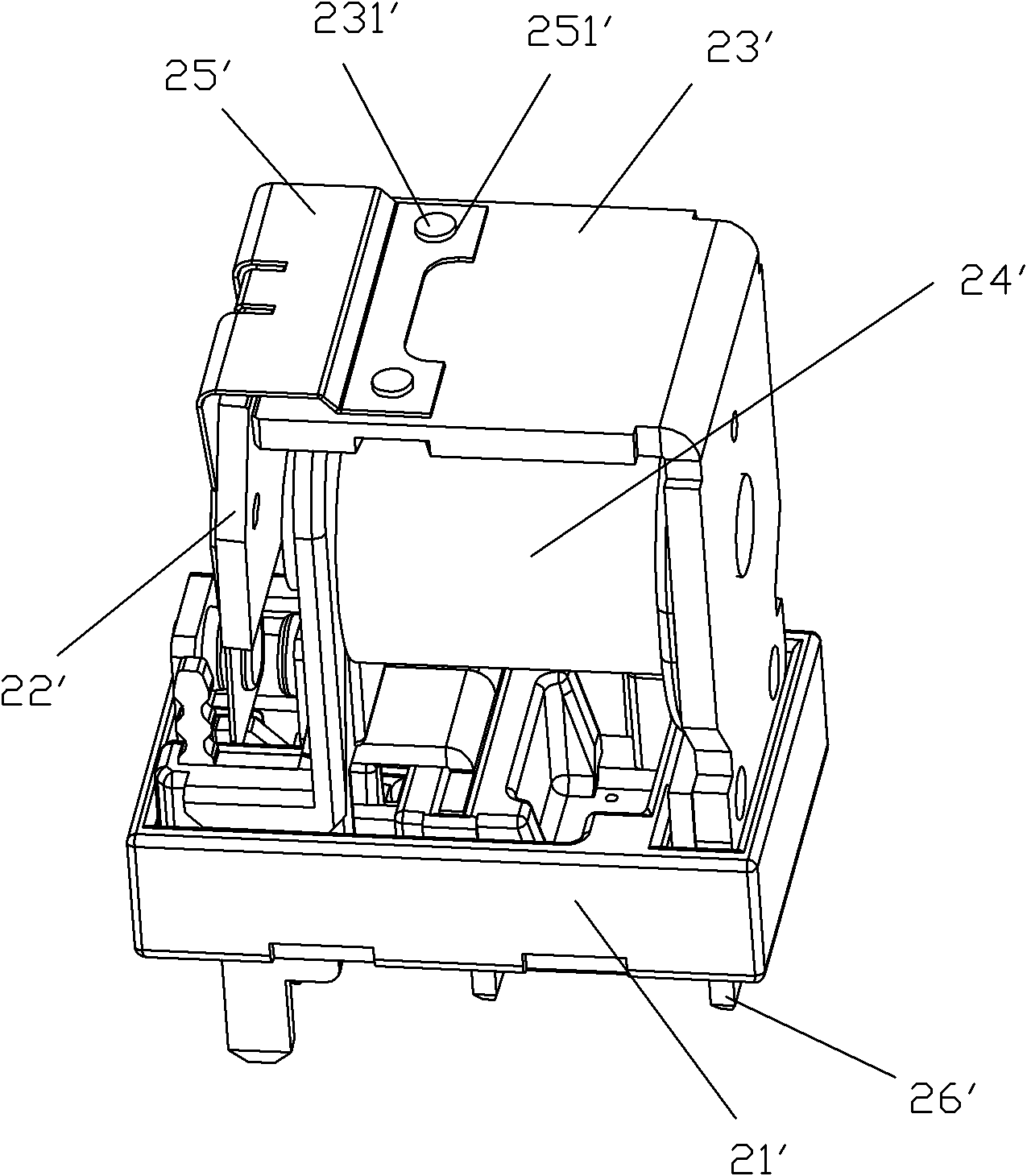

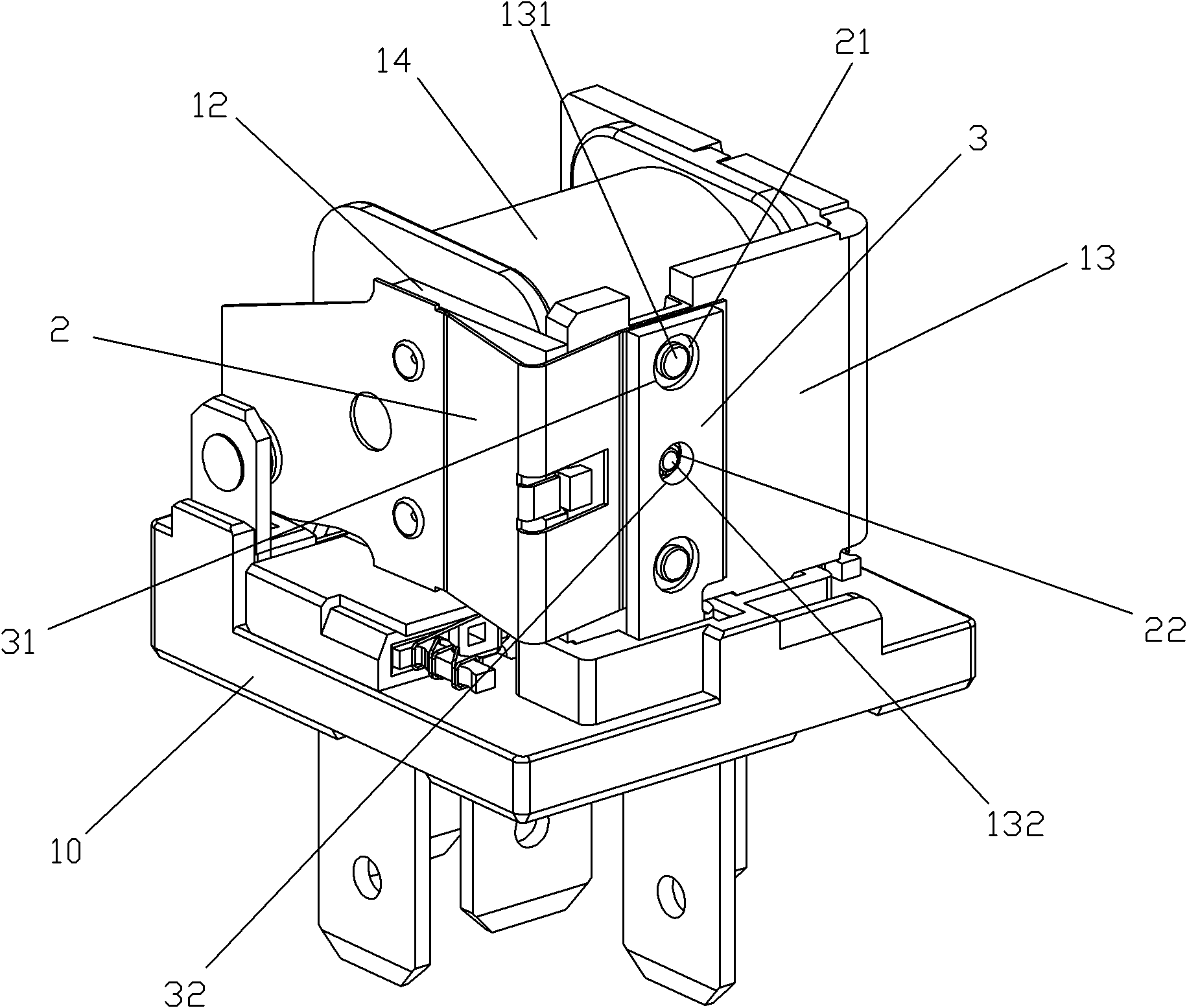

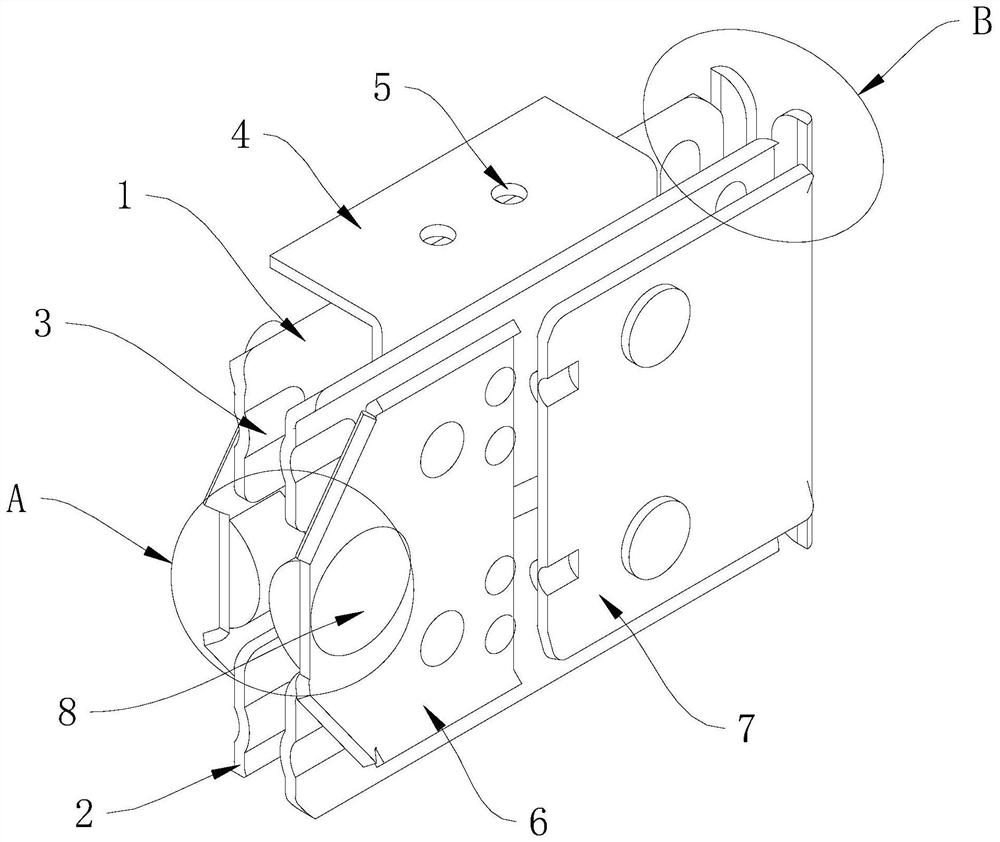

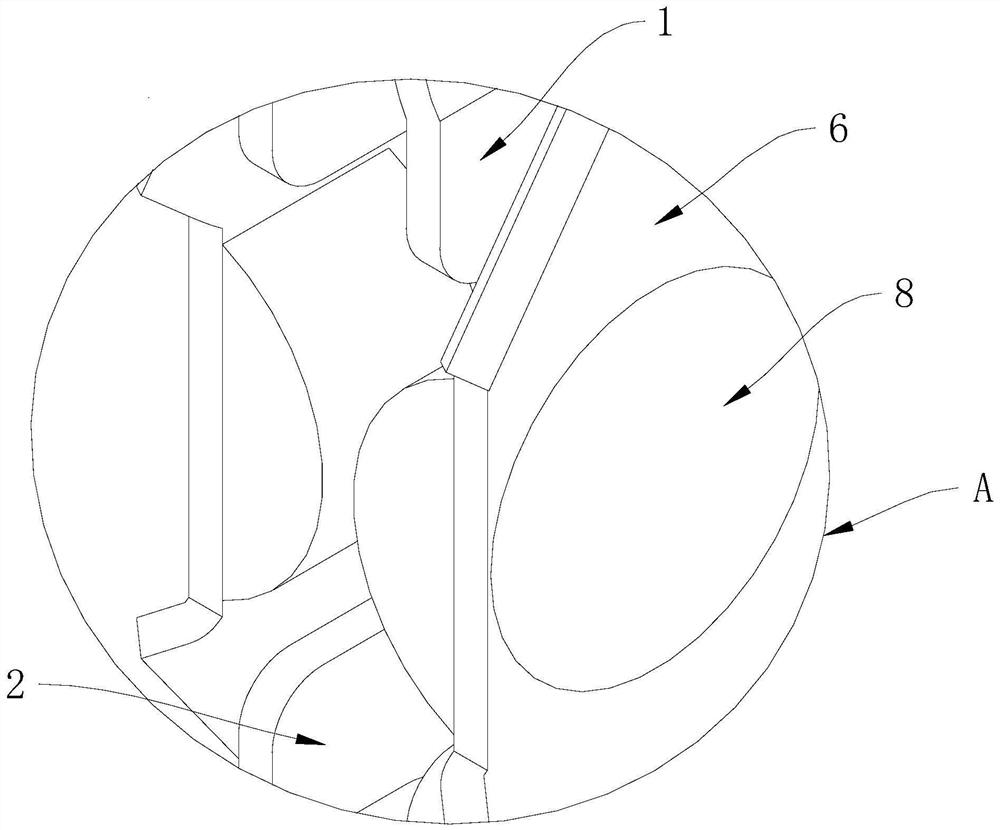

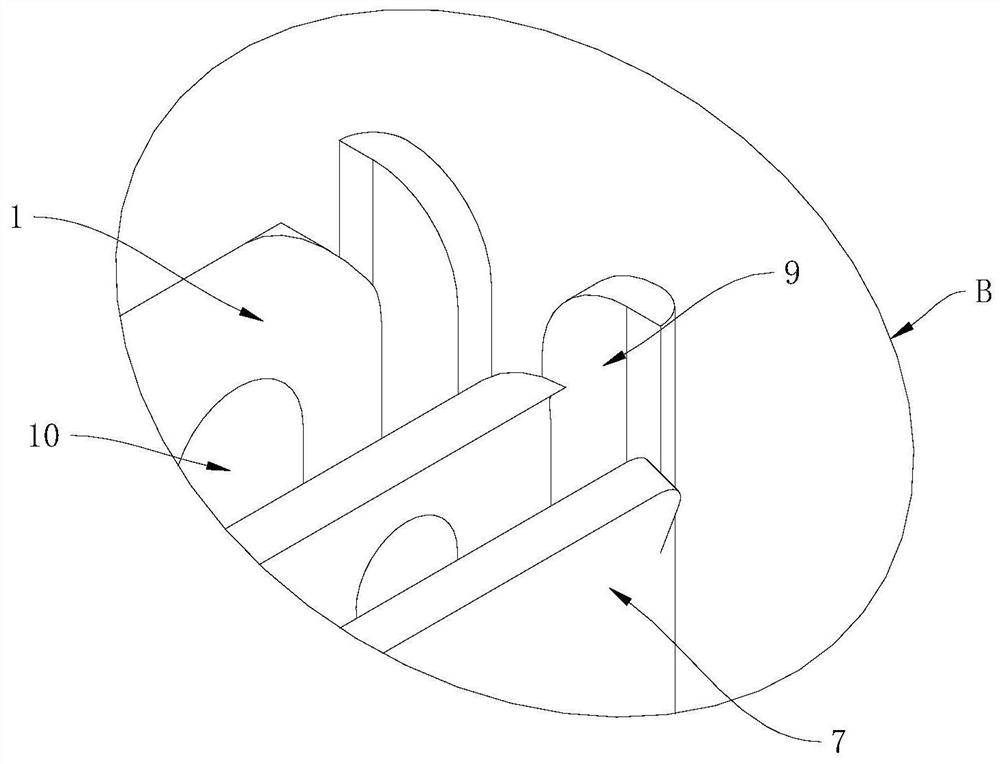

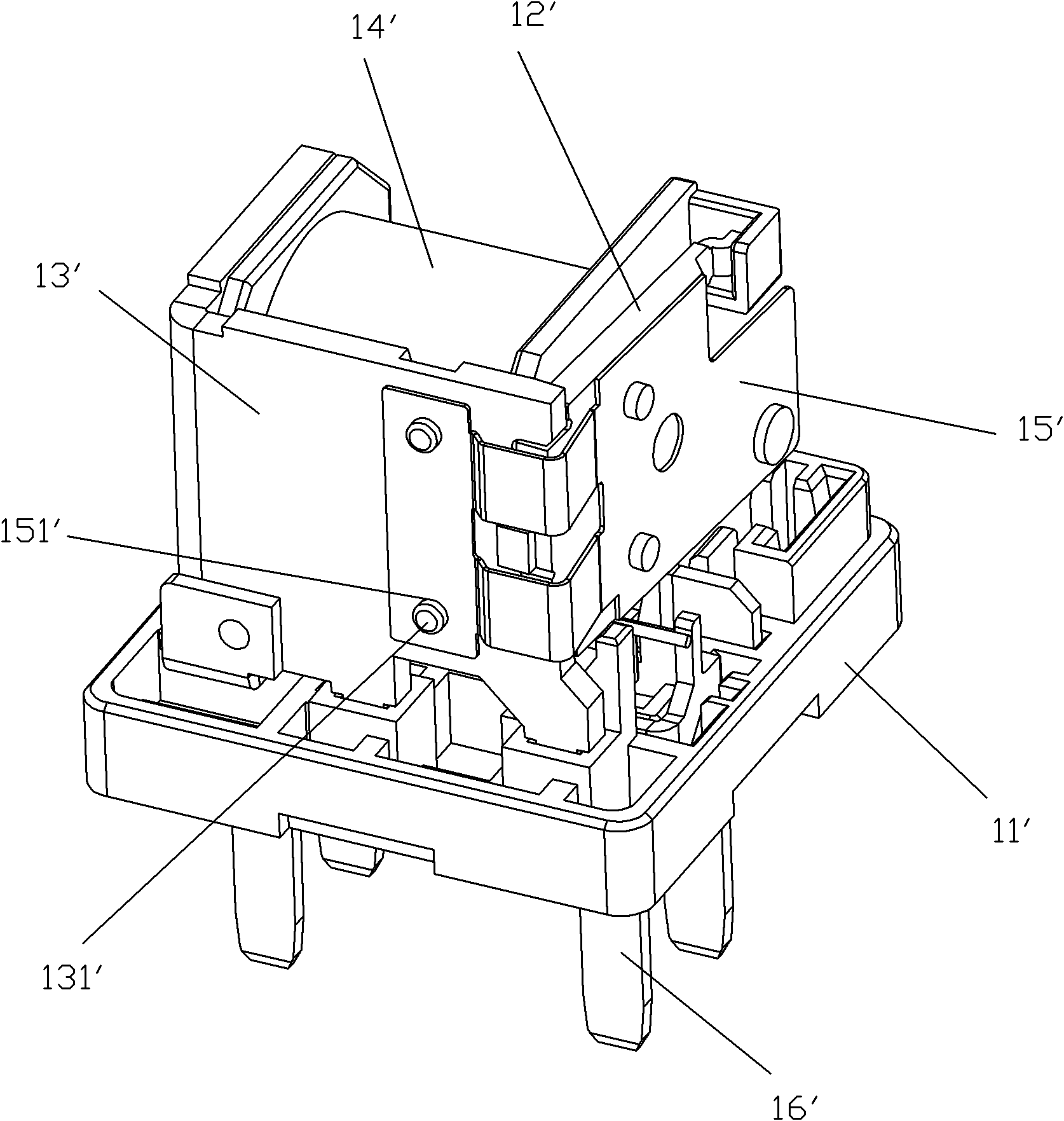

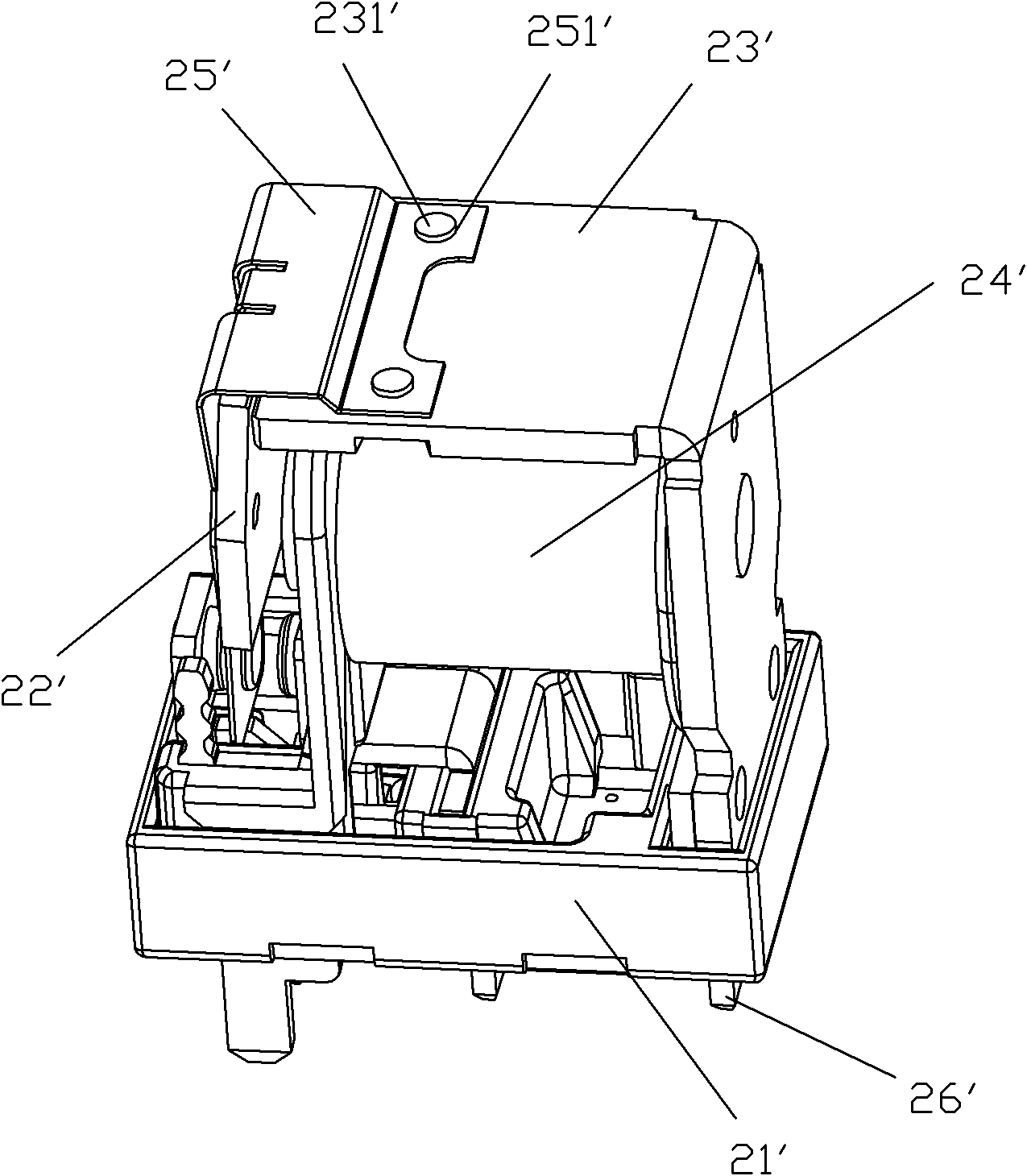

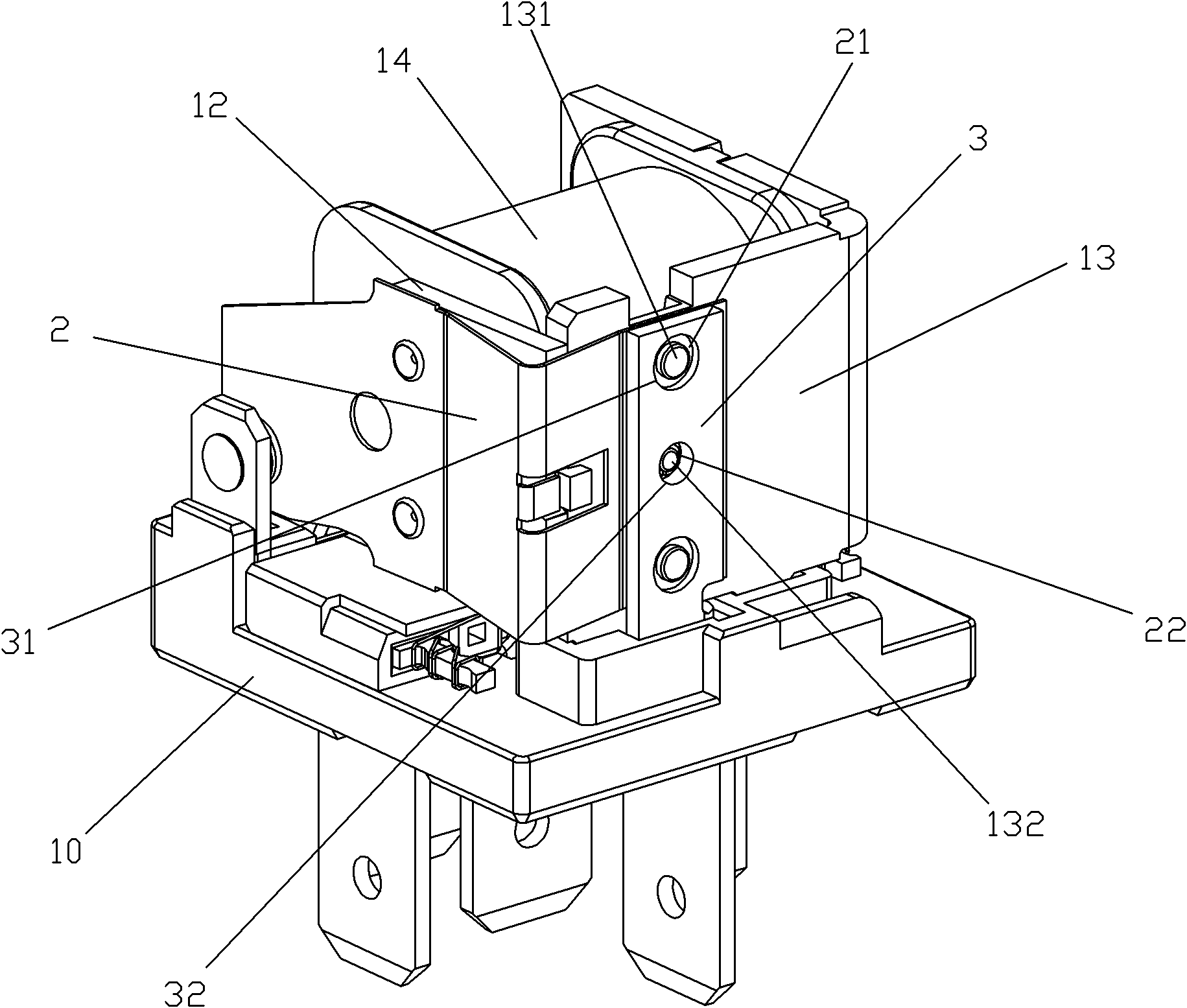

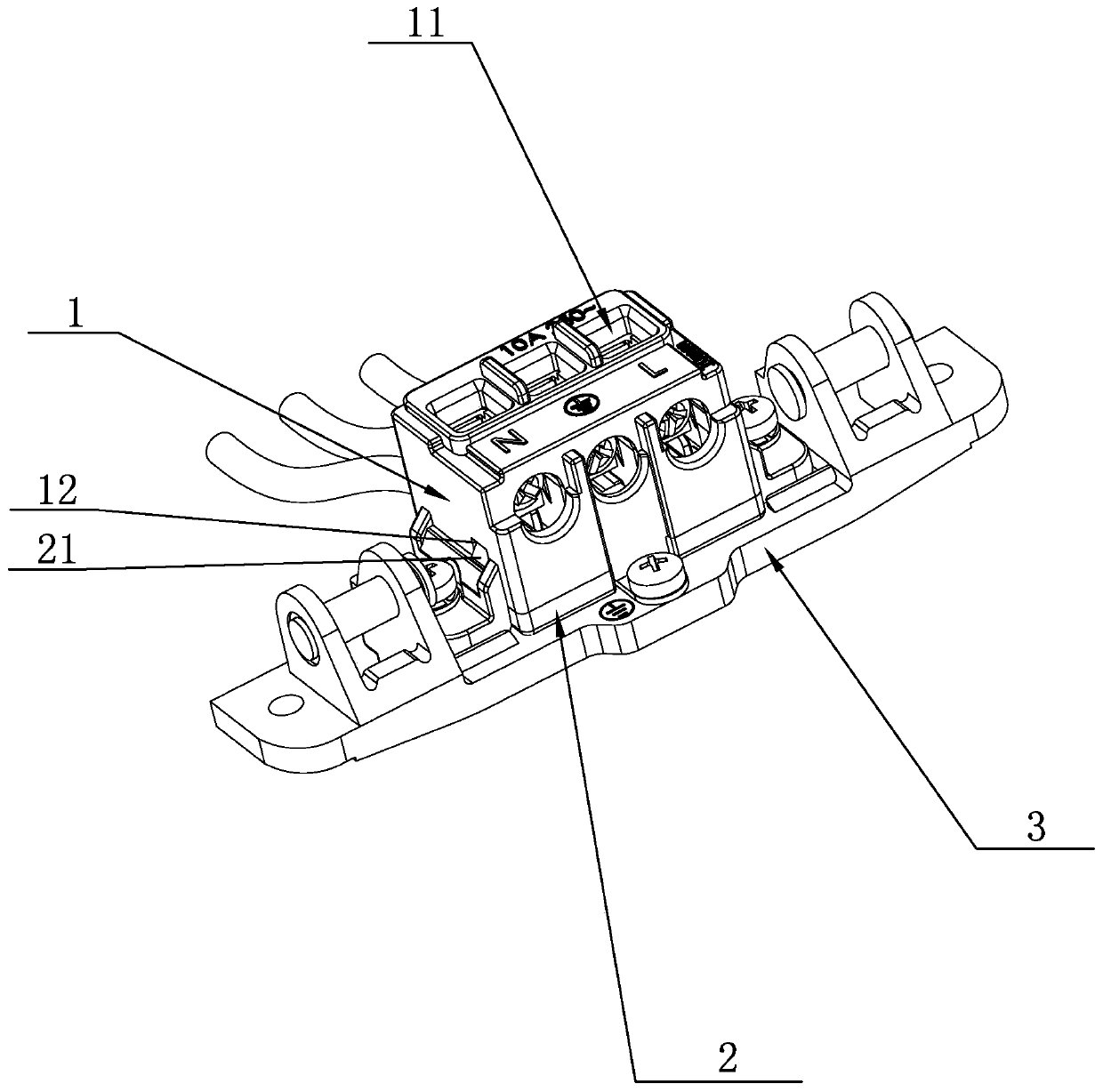

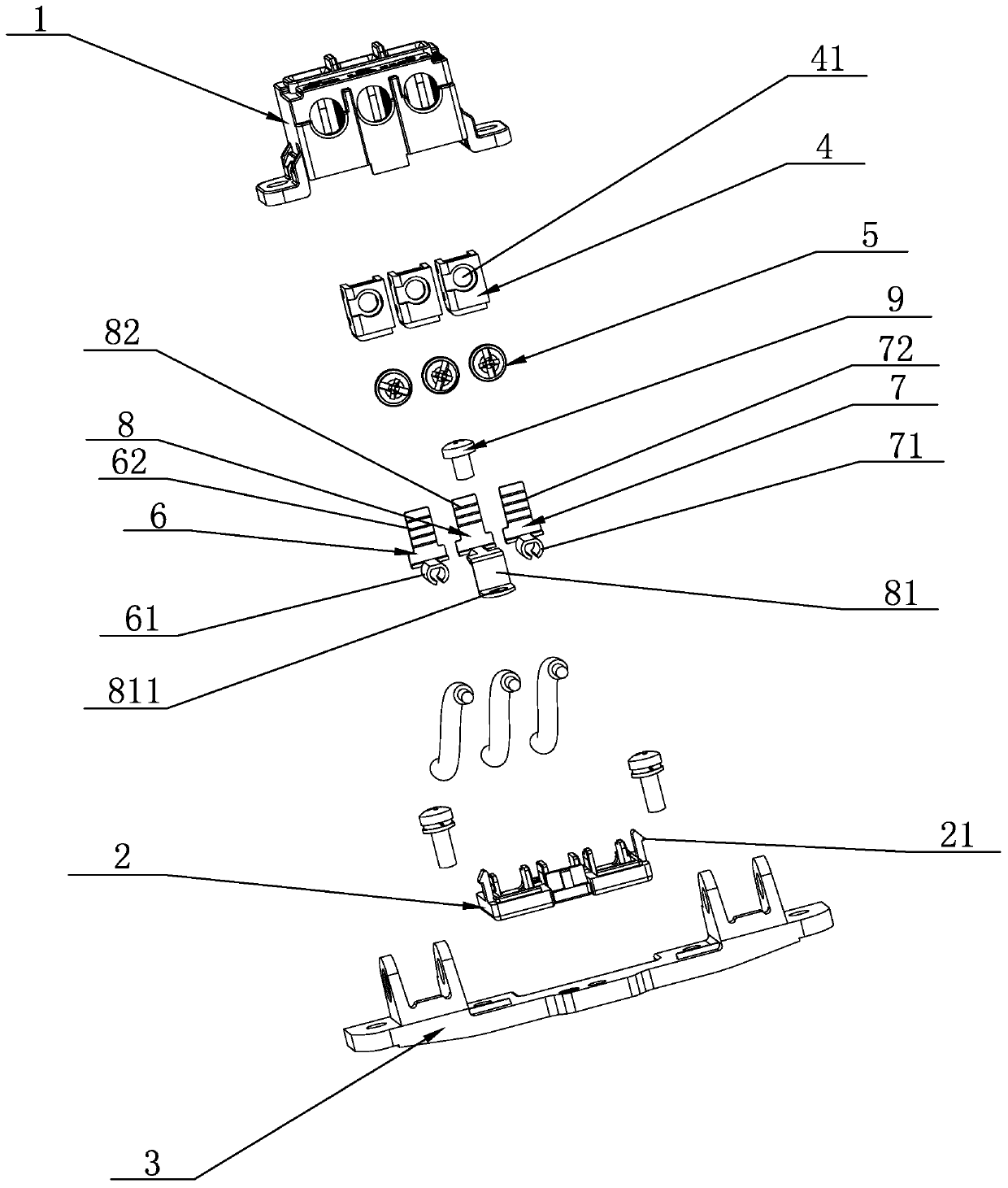

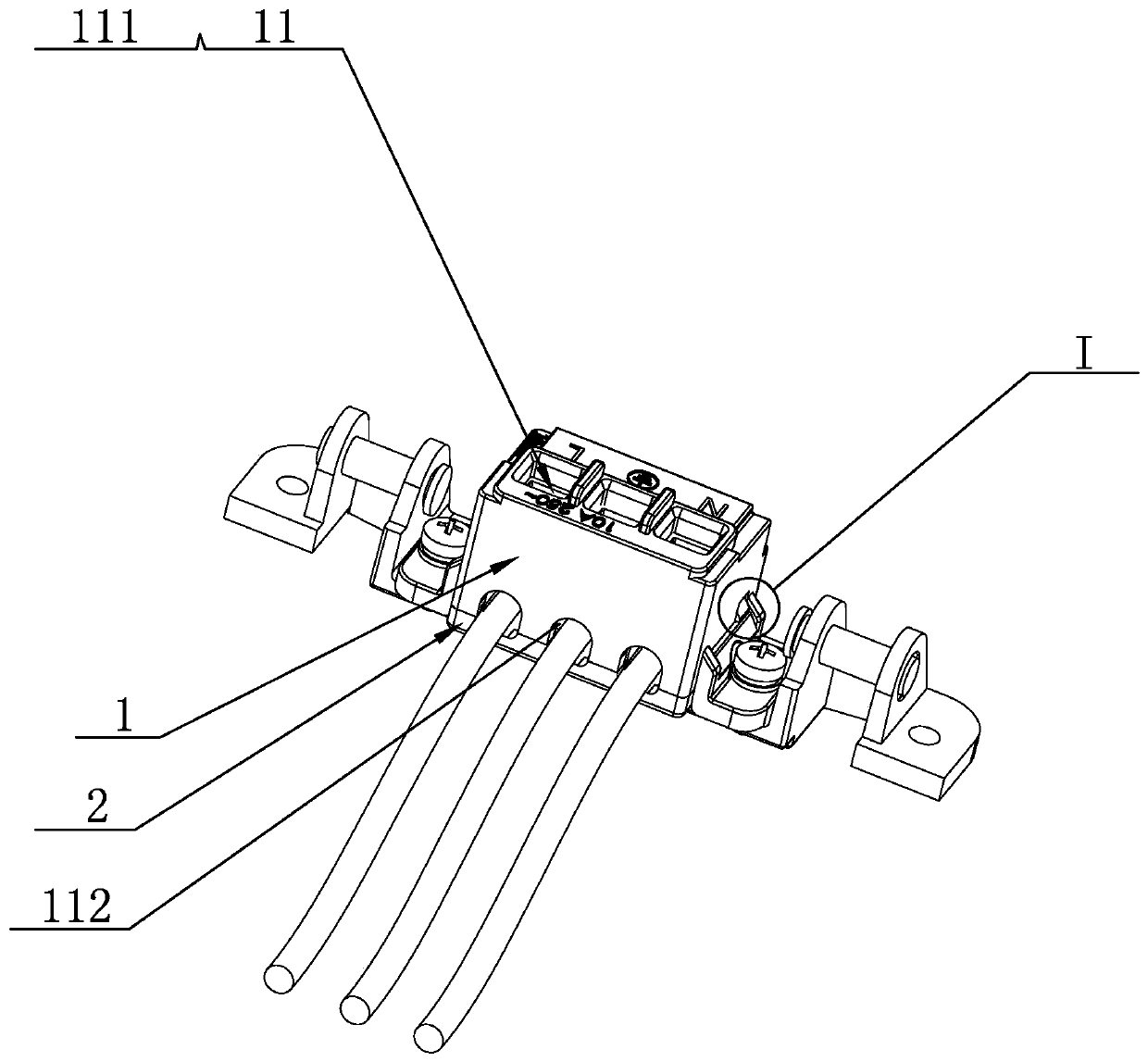

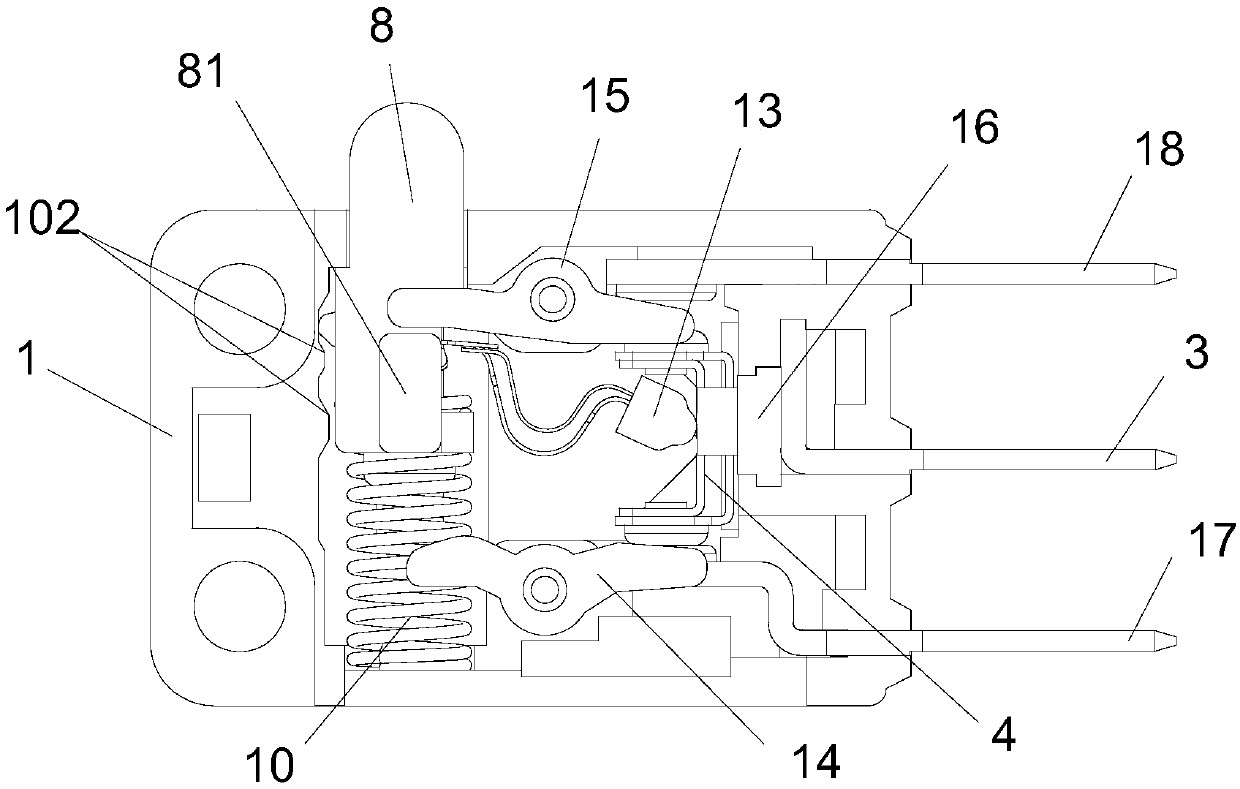

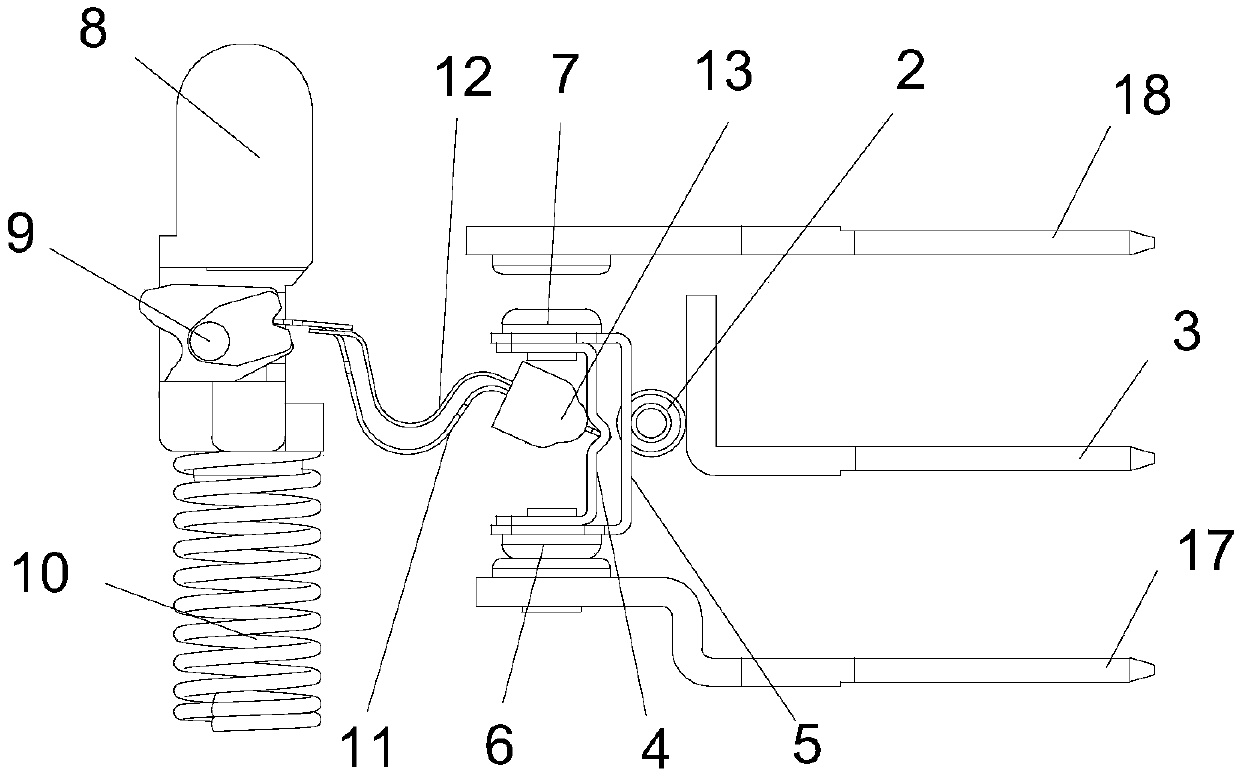

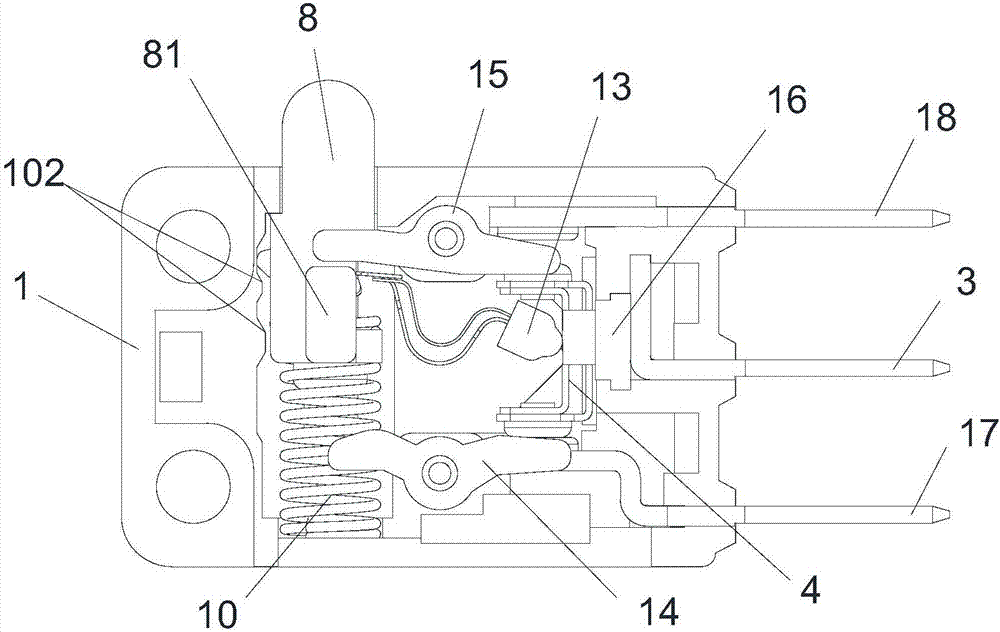

Electromagnetic relay suitable for automatic production and with reliable electroconductivity and assembling method thereof

ActiveCN102592889AGuaranteed reliabilityIncrease the conductive cross-sectional areaElectromagnetic relay detailsMechanical engineeringHeat generation

The invention discloses an electromagnetic relay suitable for automatic production and with reliable electroconductivity and an assembling method of the electromagnetic relay. The electromagnetic relay comprises yoke, a movable spring and a movable spring leading pin, wherein the yoke is provided with a second bulge, and the movable spring is provided with a clamping hole correspondingly matched with the second bulge of the yoke; a second positioning hole correspondingly matched with a first bulge of the yoke is arranged on the movable spring leading pin; the movable spring is correspondingly matched with the first bulge and the second bulge of the yoke through a first positioning hole and the clamping hole to be positioned and clamped on the yoke; and the movable spring leading pin is arranged on the yoke by being matched with the first bulge of the yoke via the second positioning hole and performs riveting on the first bulge so that the movable leading pin, the movable spring and the yoke are fixed together, and the movable spring is clamped between the movable spring leading pin and the yoke. By adopting the structure, on one hand, the electromagnetic relay can eliminate the disadvantage that the movable spring is easily divorced from the bulges of the yoke in an automatic assembling process, and on the other hand, the electromagnetic relay can realize the effects of improving a current-carrying area, shortening a conducting path and reducing heat generation, thereby achieving the purposes of high-current and high-reliability electroconductivity.

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS CO LTD

Method for manufacturing double-layer polysilicon bipolar transistor

ActiveCN103915334BDoes not affect doping profileReduce the risk of electric leakageTransistorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceIsolation effect

The invention discloses a method for preparing a high-performance double-layer polysilicon bipolar transistor, which includes the following steps: 1) using LOCOS and CVD to deposit SiO2 to form a composite isolation structure to reduce high-temperature process time; 2) using SiO2 as the base The etch stop layer of extremely polysilicon prevents etching damage; 3) SiO2 and N+ polysilicon are used to form a composite sidewall structure to reduce emitter resistance. Advantages: Reduce the high-temperature process time without reducing the isolation effect, so that a relatively thin epitaxial layer can be used to obtain better microwave performance, and silicon dioxide is used as the etch stop layer to eliminate the etching of the silicon epitaxial layer Corrosion damage, improve breakdown characteristics, increase current amplification factor, reduce noise figure. The silicon dioxide and N+ polysilicon composite sidewall structure can reduce the emitter resistance while ensuring the electrical isolation of the emitter-base, increase the current amplification factor, and reduce the noise figure.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Synchronous rectifying circuit structure for high-frequency switch power supply

InactiveCN101834544BLower working temperatureReduce feverAc-dc conversionCooling/ventilation/heating modificationsFull waveTransformer

The invention discloses a synchronous rectifying circuit structure for a high-frequency switch power supply and provides a field effect transistor parallel connection structure based on a copper base plate and a connecting way of a field effect transistor, a high-frequency transformer and a heat radiator. In a full-wave synchronous rectifying circuit adopting a common drain electrode connecting method, drain electrodes of a plurality of surface mounting type encapsulated field effect transistors are welded with a copper base plate; and grid electrodes and source electrodes are welded with a printed circuit board and connected with an output terminal of the high-frequency transformer. The copper base plate provided with the field effect transistors is connected with the heat radiator in use, and the heat radiator is meanwhile used as an output positive bus. Finally, the terminal of the high-frequency transformer is in compression joint with the printed circuit board, the copper base plate and the heat radiator to meanwhile play roles of fixation and support.

Owner:XI AN JIAOTONG UNIV

Optimized jack contact element, composite hole sleeve structure and manufacturing method of optimized jack contact element and composite hole sleeve structure

PendingCN113013654AOptimize the axial cross-sectional areaIncrease the conductive cross-sectional areaCoupling contact membersStructural engineeringContact element

The invention belongs to the field of high-current connectors, and particularly relates to an optimized jack contact, a composite hole sleeve structure and a manufacturing method of the optimized jack contact. Aiming at the problems of poor conductivity, poor supporting capability and short service life of the existing jack contact, the invention provides the following scheme: the jack contact comprises a jack contact, and the jack contact comprises a simply supported beam group; the simply supported beam group comprises an upper part, a middle part and a lower part, wherein the cross sectional areas of the upper part, the middle part and the lower part are (1-2): 1: (1-2) respectively, and the top and the bottom of the simply supported beam set are both fixedly provided with edge rolling metal; the simply supported beam set comprises a plurality of first simply supported beams, and each first simply supported beam comprises an upper portion, a middle portion and a lower portion. According to the invention, after the torsion process treatment, the simply supported beam becomes a rotary hyperboloid. The projection of the axial cross section of the spiral cylinder wall is a rotary hyperboloid, the rotary hyperboloid is uniformly distributed in a circle, the conductive sectional area of the contact element is large, the load is large, and the weight of the contact element is reduced.

Owner:深圳先启能源技术有限公司

Semiconductor device and manufacturing method thereof

ActiveCN104900697BIncrease the conductive cross-sectional areaLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentDevice material

A semiconductor device and its manufacturing method, the semiconductor device includes: a substrate; and an epitaxial layer located above the substrate, wherein the epitaxial layer includes a plurality of first grooves and a plurality of second trenches arranged alternately along a first direction Groove; wherein the epitaxial layer between each adjacent first groove and second groove includes a first doped region and a second doped region, and the first doped region and the second doped region have different The conductivity type, and the interface between the first doped region and the second doped region forms a super junction structure; and a gate structure, located above the epitaxial layer, wherein the epitaxial layer below the gate structure includes along a second A channel extending in a direction, wherein the first direction is perpendicular to the second direction. Compared with the prior art, the present invention can increase the conduction cross-sectional area of the drive current, improve the drive current and reduce the conduction resistance.

Owner:VANGUARD INTERNATIONAL SEMICONDUCTOR CORPORATION

Heavy-current moving contact structure

PendingCN112635211AEffective contactIncrease the conductive cross-sectional areaContact surface shape/structureContact electric connectionElectrically conductiveEngineering

The invention discloses a heavy-current moving contact structure, and relates to the technical field of electric power. The heavy-current moving contact structure comprises two first moving contact connecting plates, two second moving contact connecting plates, first connecting sheets and second connecting sheets, and the opposite surfaces of the two first moving contact connecting plates are fixedly provided with the first connecting sheets and the second connecting sheets, and the opposite surfaces of the two second moving contact connecting plates are fixedly connected with the opposite surfaces of the two first connecting sheets and the two second connecting sheets respectively. Conductive contact plates are formed by bending the second connecting sheets and are matched with third conductive contact points, so that an effective conductive contact point is additionally arranged at the back ends of the first moving contact connecting plates and the second moving contact connecting plates, and meanwhile, second conductive contact points are additionally arranged at the front ends of the first moving contact connecting plates and the second moving contact connecting plates, therefore, the overall conductive sectional area is increased, and larger load current can be borne.

Owner:SHUANGCHENG ELECTROMECHANICAL TECH DEV

Electromagnetic relay suitable for automatic production and with reliable electroconductivity and assembling method thereof

ActiveCN102592889BGuaranteed reliabilityIncrease the conductive cross-sectional areaElectromagnetic relay detailsPower flowEngineering

Owner:XIAMEN HONGFA AUTOMOTIVE ELECTRONICS CO LTD

Process for manufacturing solar cell by twice screen printing and grooving

ActiveCN101969082BReduced series resistanceIncrease the conductive cross-sectional areaFinal product manufactureSemiconductor devicesScreen printingEngineering

The invention discloses a process for manufacturing a solar cell by twice screen printing and grooving, which is used for manufacturing the solar cell by twice electrode printing and comprises a grooving process and a twice printing process, wherein the grooving process comprises the step of performing grooving on an electrode grid line area on the surface of a silicon wafer so as to form an etched groove in the electrode grid line area; and the twice printing process comprises the following steps of: a, primary electrode printing, namely, filling printing electrode paste into the etched groove and performing drying to form a first layer of electrode in the etched groove; and b, secondary electrode printing, namely, printing the electrode on the outer surface of the first layer of electrode so as to form a second layer of electrode in the electrode grid line area on the surface of the silicon wafer. The solar cell manufactured by the method has relatively lower series resistance, a selective emitter and relatively higher conversion efficiency, and can reduce shading loss; and the electrode paste is difficult to spread in a sintering process.

Owner:TRINA SOLAR CO LTD

A hollow aluminum-injected steel claw for an aluminum electrolytic anode

The invention discloses an aluminum electrolysis anode hollow aluminum pouring steel claw. A hollow steel claw steel shell is included. An aluminum guide rod connecting plug is arranged at the upper end of the hollow steel claw steel shell. A steel claw beam is arranged at the lower end of the hollow steel claw steel shell. A set of steel claw feet are arranged at the lower end of the steel claw beam. The steel claw beam and the steel claw feet are each of a hollow structure. An aluminum core is poured into the aluminum guide rod connecting plug on the hollow steel claw steel shell, the steelclaw beam and the steel claw feet. By means of the aluminum electrolysis anode hollow aluminum pouring steel claw, the electrical resistivity of an anode guide rod and the steel claw is reduced, electrical losses are reduced, the production cost is reduced, and the beneficial effect that the integral mechanical strength is high is achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

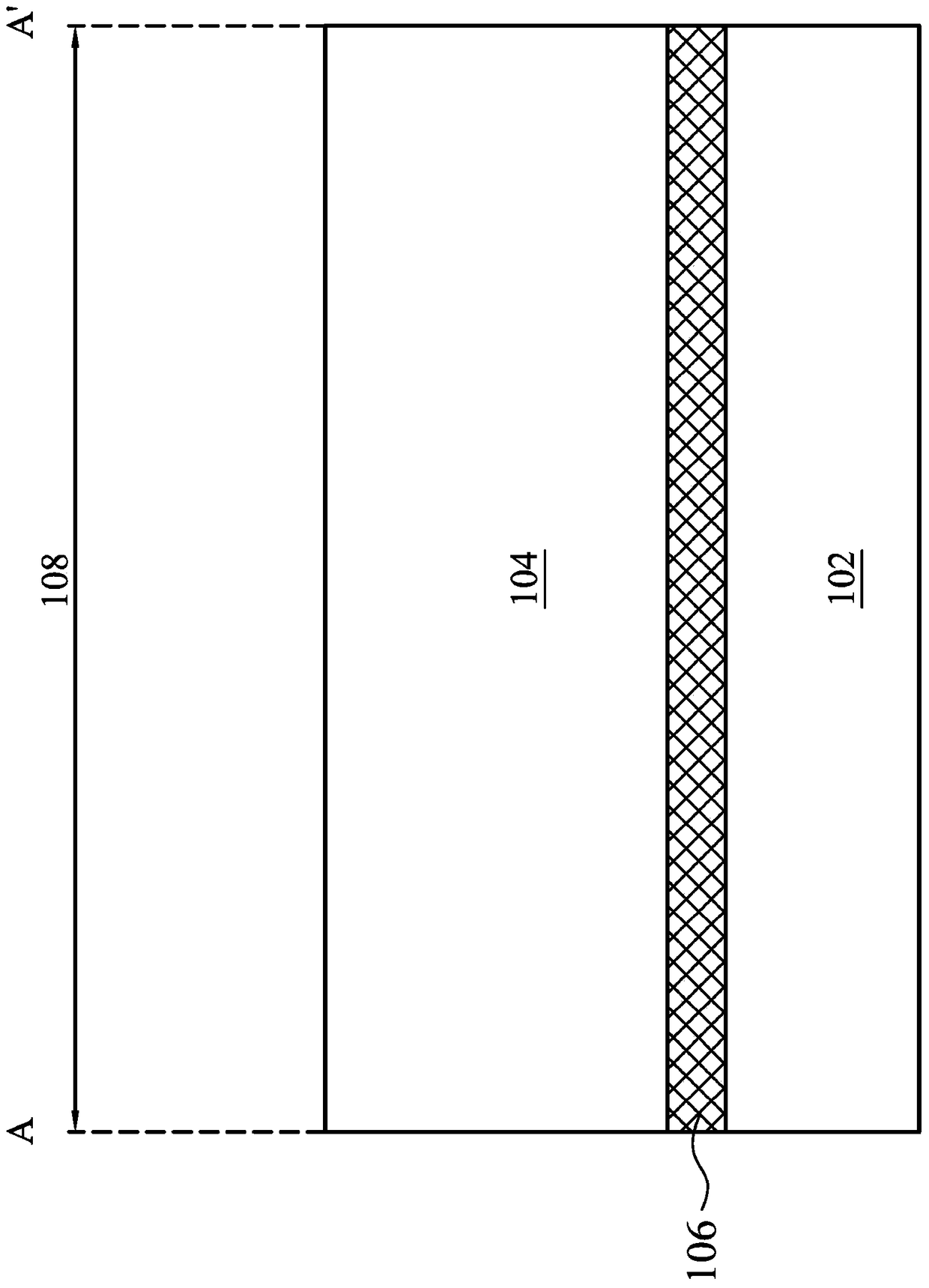

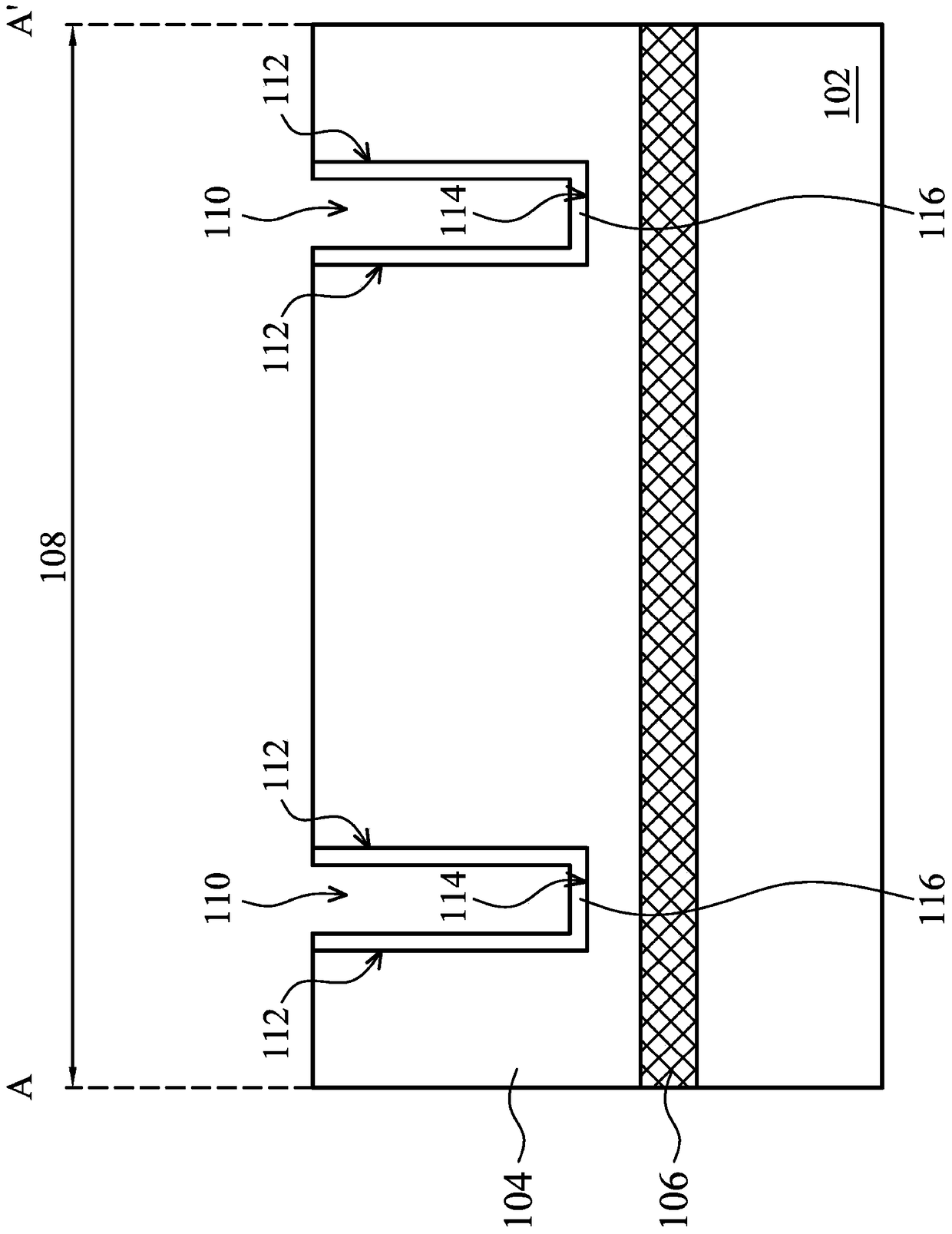

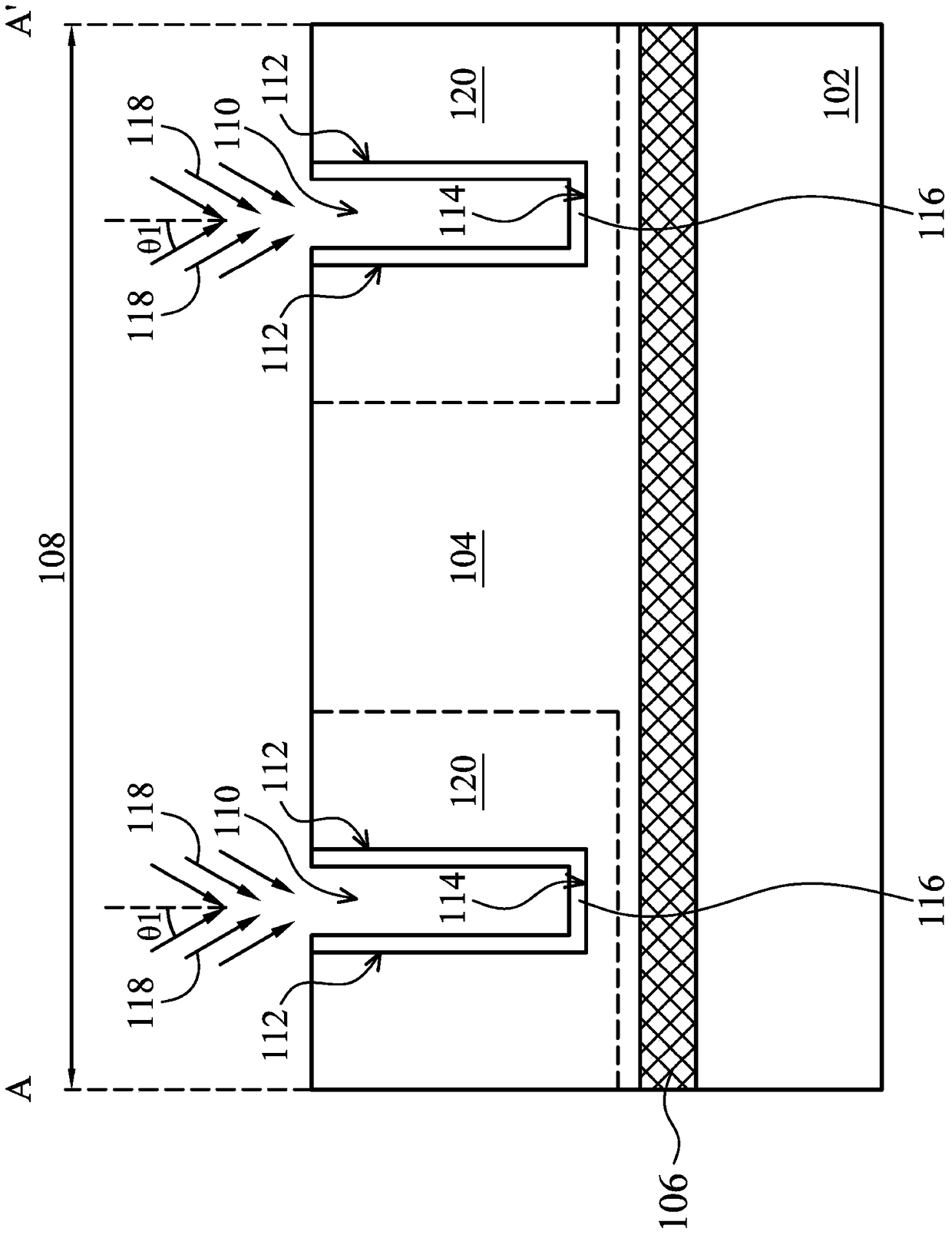

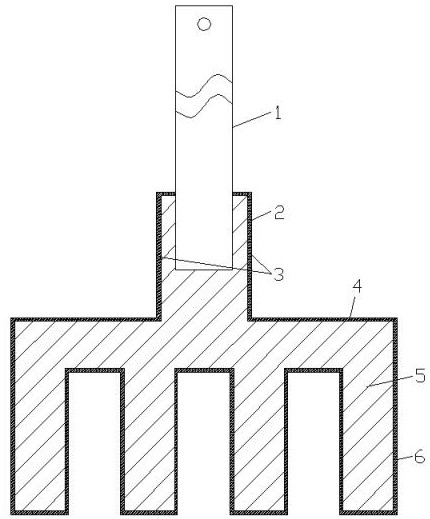

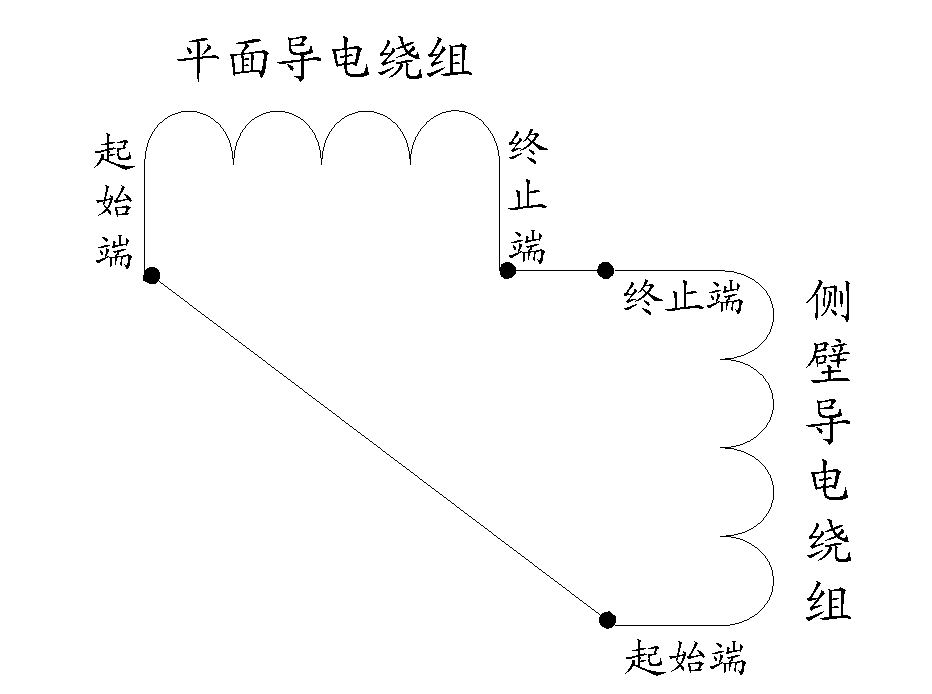

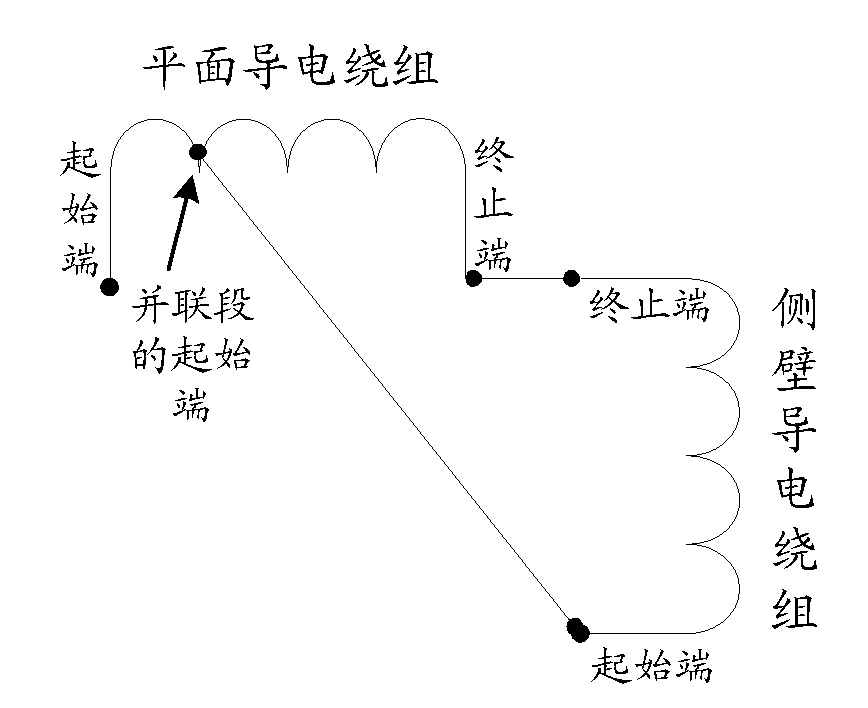

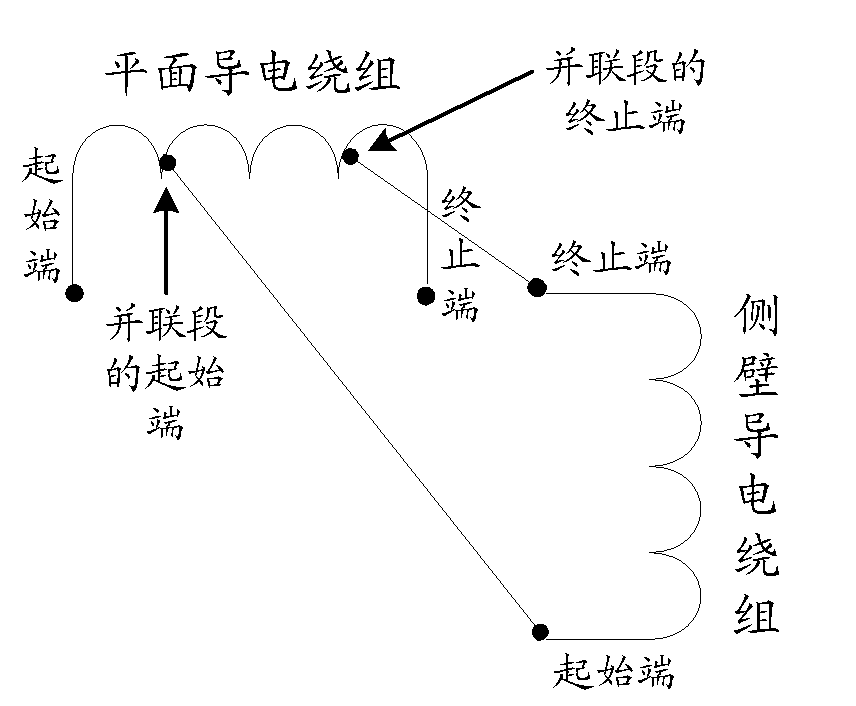

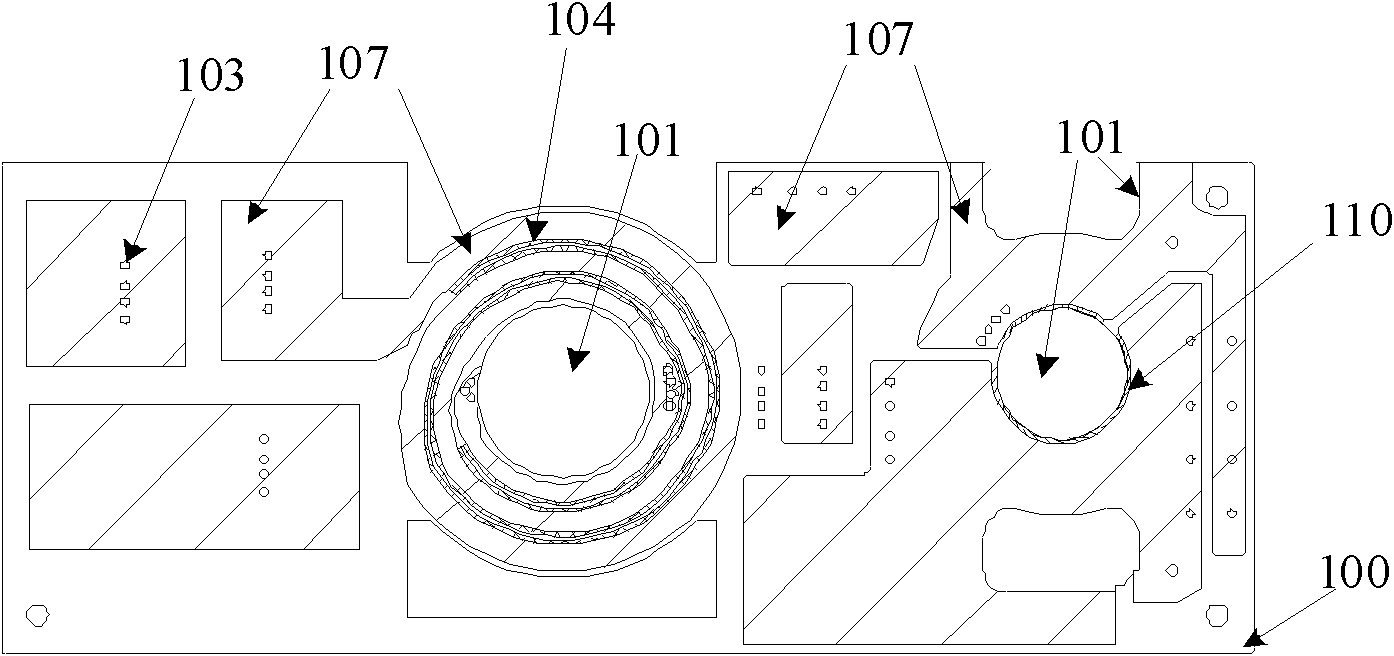

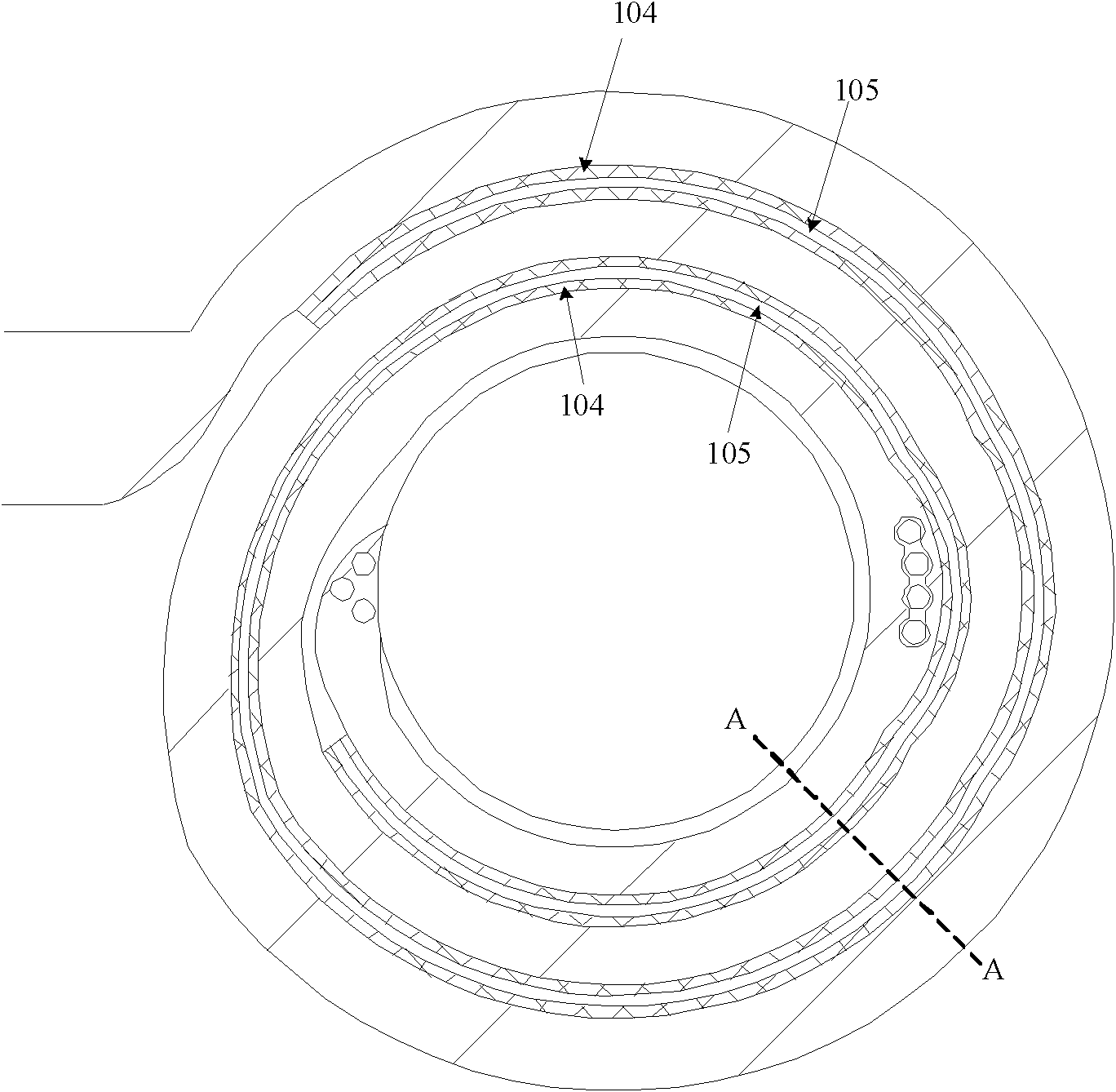

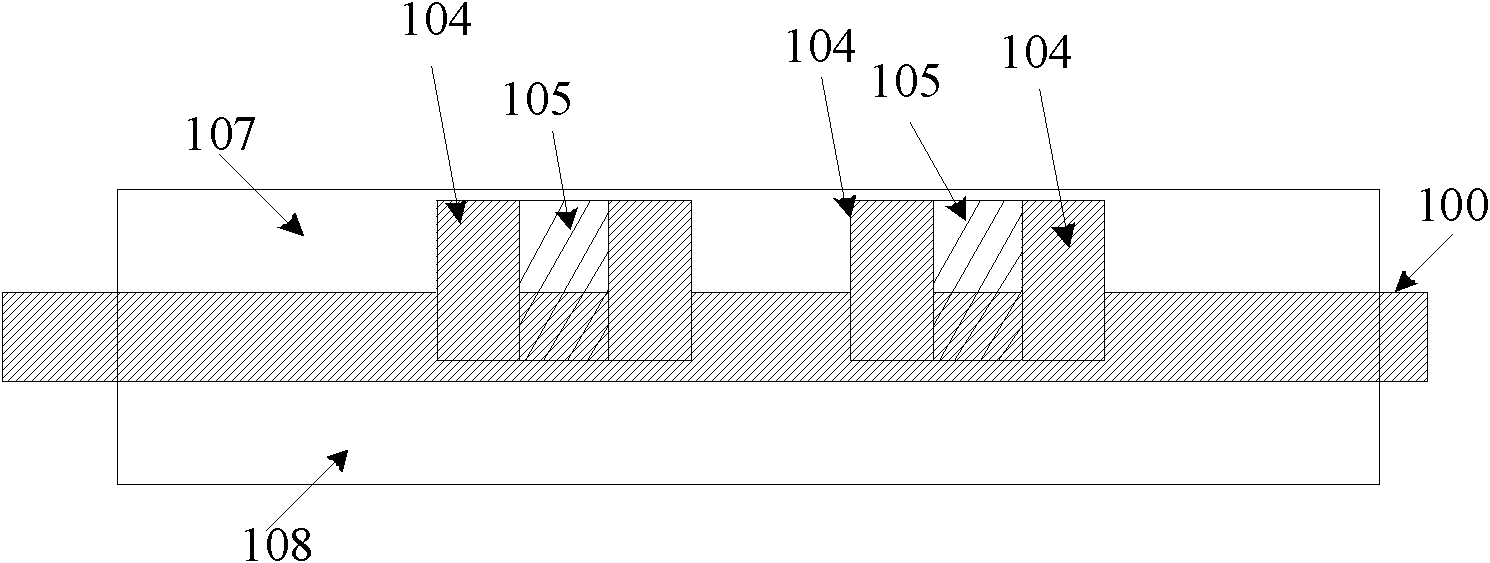

Power supply device and manufacturing method of printed circuit board winding

ActiveCN102158051BImprove cooling efficiencyIncrease the conductive cross-sectional areaPrinted circuit aspectsTransformers/inductances detailsConductor CoilPrinted circuit board

A power device and a method for manufacturing a printed circuit board winding are disclosed. The power device includes: at least one printed circuit board (100), at least one magnetic core (201,202), and at least one group of semiconductor transforming units (301). The printed circuit board (100) is provided with magnetic core slots for installing magnetic cores (201, 202). The side wall of at least one magnetic core slot is provided with conductive side wall windings (102, 105, 107). The conductive side wall windings carry out an electromagnetic transformation in coordination with the magnetic cores (201, 202) installed in the magnetic core slots. The conductive side wall windings adhere to part or all of the surface on the side wall of the slots. The semiconductor transforming unit (301) carries out an electrical energy transformation in coordination with the magnetic cores (201, 202) and the conductive side wall windings (102, 105, 107). The breakover impedance of the conductive windings on the printed circuit board (100) can be reduced.

Owner:HUAWEI TECH CO LTD

Ground insertion wiring terminal

PendingCN109904639AGood anti-loose effectReasonable structureClamped/spring connectionsCopper-wiringEngineering

The invention discloses a ground insertion wiring terminal. The ground insertion wiring terminal comprises a terminal shell and a terminal base, wherein the terminal shell and the terminal base are detachably connected; the lower end of the terminal base is detachably provided with a jump seat; the terminal shell is internally provided with a plurality of insulating wiring cavities; a wire incoming hole is formed in the upper end of each insulating wiring cavity; a wire outgoing hole is formed in the lower end of the back end surface of each insulating wiring cavity; each insulating wiring cavity is internally provided with a copper wiring piece and a wiring positioning block from bottom to top in sequence respectively; a first screw hole is formed in the front end surface of each wiring positioning block respectively; each first screw hole is internally provided with a positioning screw respectively; and the head of each positioning screw is used for compressing the upper end of the aligned copper wiring piece by locking the corresponding positioning screw. Through the technical scheme, the ground insertion wiring terminal is reasonable in structure design, simple in structure, easy in wiring operation, safe, reliable and high in practicability, wires are separated from one another, and electric arcs are unlikely to generate.

Owner:江苏杰豪电气有限公司

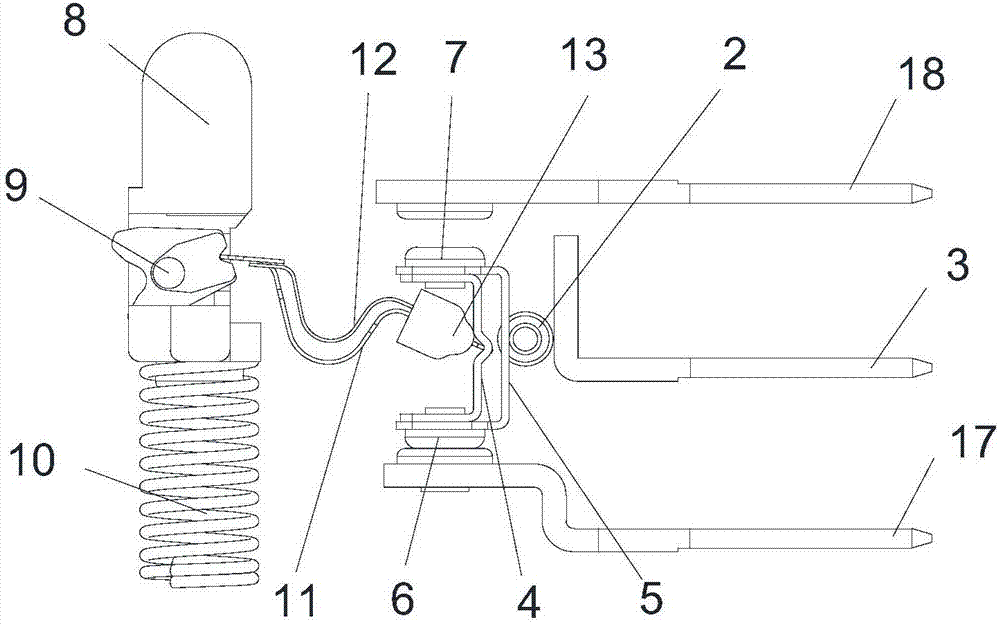

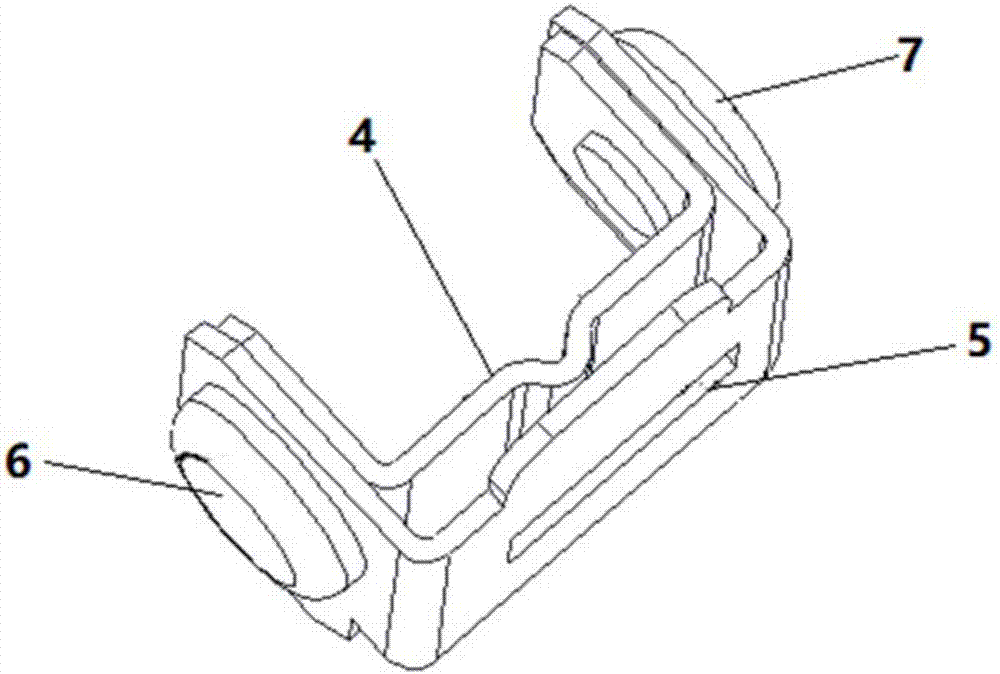

Sliding micro limit general switch

ActiveCN107134385BAvoid power outagesAvoid flickeringContact electric connectionCritical positionSurface cover

The invention discloses a sliding type micro limit general switch. The switch comprises a bottom casing, a surface cover and working assemblies arranged between the bottom casing and the surface cover; the working assemblies include a moving contact assembly, a movable assembly, a movable rod assembly, a roller, a public pin and a plug pin assembly; the two ends of the movable assembly compresses the moving contact assembly and the movable rod assembly respectively; the moving contact assembly keeps making contact with the roller under the pressure effect of the movable assembly, the roller keeps making contact with the public pin under the pressure effect of the moving contact assembly, the moving contact assembly makes contact and is electrically connected with the public pin via the roller, and the moving contact assembly can slide up and down under the thrust effect of the movable assembly; and the plug pin assembly can make contact with the end portion of the moving contact assembly. Thus, the switch is avoided from a power-off or flickering phenomenon in a critical position, the metal conductive sectional area is increased, heavier current can be born, and the switch is safer and more reliable.

Owner:ZHANGZHOU JUANMEI ELECTRIC TECH CO LTD

Printed circuit board and power supply module

ActiveCN102369790BReduce AC impedanceReduce skin effectPrinted circuit aspectsTransformers/inductances detailsAlternating currentElectrical impedance

Embodiments of the present invention provide a printed circuit board and a power module. The printed circuit board comprises an insulating layer, a first planar conductive layer located above the insulating layer, and a second planar conductive layer located below the insulating layer. The insulating layer, the first planar conductive layer and the second planar conductive layer each are provided with a magnetic core groove having a penetrating magnetic core. The printed circuit board further comprises: at least one group of vertical conductive winding, configured to cooperate with the magnetic core mounted in the magnetic core groove to perform electromagnetic conversion. In the direction perpendicular to the insulating layer, one side of the at least one group of vertical conductive winding is located a position on the insulating layer or the first planar conductive layer except the magnetic core groove, and the other side of the at least one group of vertical conductive winding is located on a position on the insulating layer or the second planar conductive layer except the magnetic core groove. The printed circuit board can expand the sectional area of the conductive winding, and reduce the alternating current impedance of the power module.

Owner:HUAWEI TECH CO LTD

Sliding type micro limit general switch

ActiveCN107134385AAvoid power outagesAvoid flickeringContact electric connectionCritical positionEngineering

The invention discloses a sliding type micro limit general switch. The switch comprises a bottom casing, a surface cover and working assemblies arranged between the bottom casing and the surface cover; the working assemblies include a moving contact assembly, a movable assembly, a movable rod assembly, a roller, a public pin and a plug pin assembly; the two ends of the movable assembly compresses the moving contact assembly and the movable rod assembly respectively; the moving contact assembly keeps making contact with the roller under the pressure effect of the movable assembly, the roller keeps making contact with the public pin under the pressure effect of the moving contact assembly, the moving contact assembly makes contact and is electrically connected with the public pin via the roller, and the moving contact assembly can slide up and down under the thrust effect of the movable assembly; and the plug pin assembly can make contact with the end portion of the moving contact assembly. Thus, the switch is avoided from a power-off or flickering phenomenon in a critical position, the metal conductive sectional area is increased, heavier current can be born, and the switch is safer and more reliable.

Owner:ZHANGZHOU JUANMEI ELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com