Motor with novel reversing structure

A new type of commutator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of complicated wire embedding and welding process, affect the service life of the motor, increase manufacturing costs, etc., and achieve simple wire embedding and welding process , Improve commutation reliability, and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

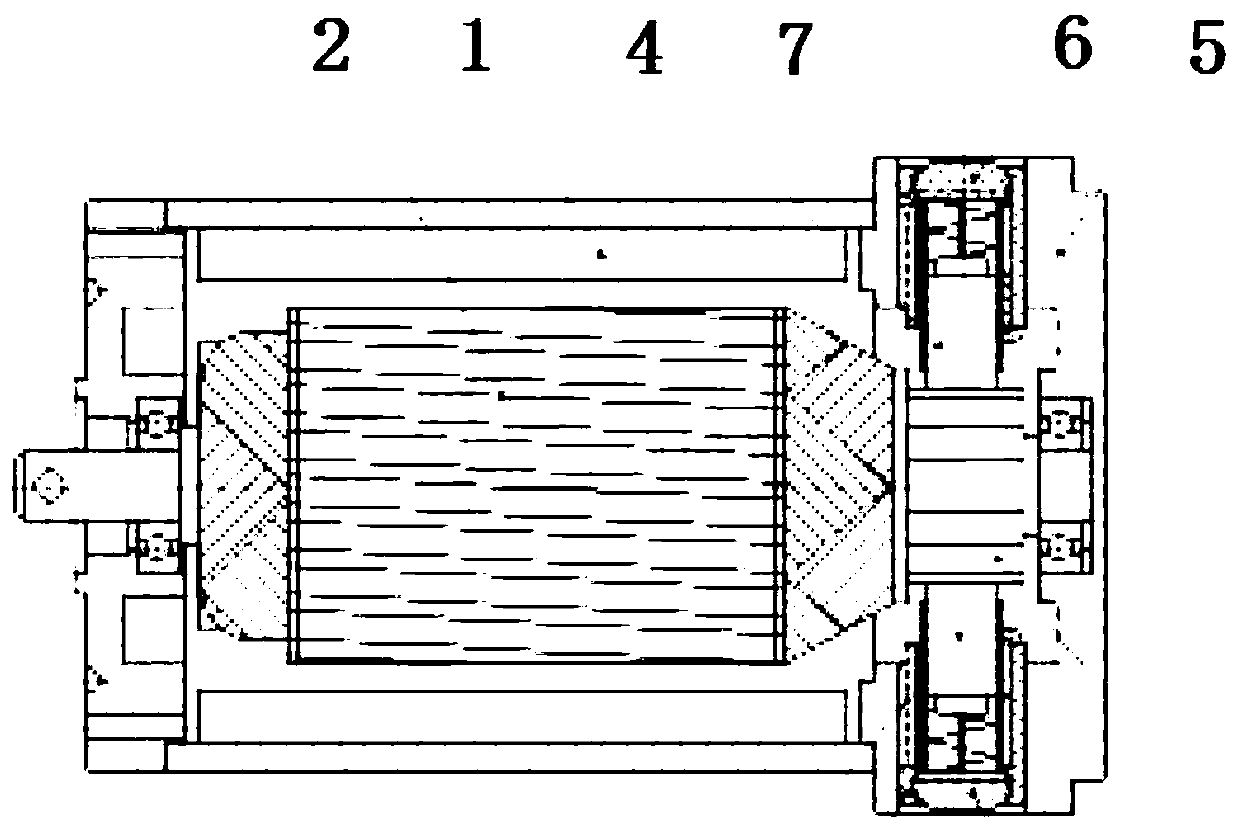

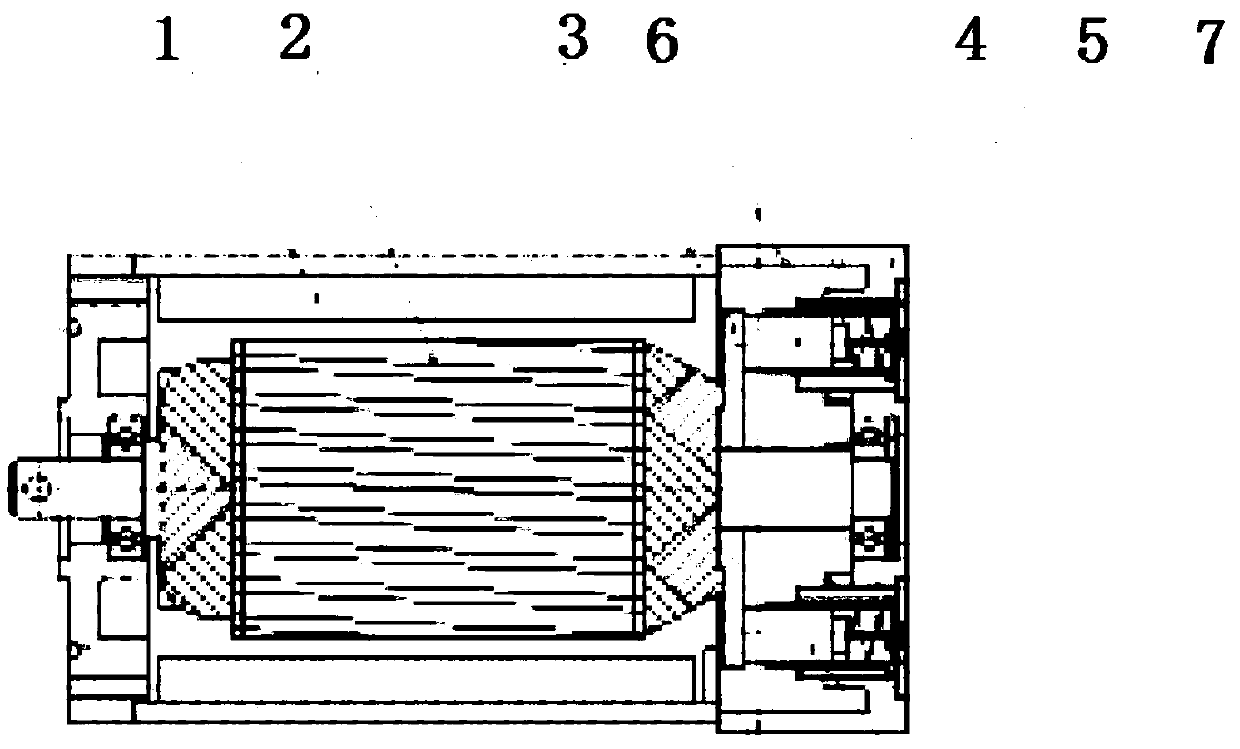

[0018] Such as figure 2 As shown, the present invention provides a motor with a novel commutation structure, including a stator 1, a rotor 2, a commutator 3 and a brush 4, a disk-shaped commutator 3 is installed on the rotor 2, and the commutator 3 The outer end surface is in contact with one end of the brush 4, the other end of the brush 4 extends along the non-radial direction of the commutator 3, and the brush 4 is connected to a power source.

[0019] By adopting the technical solution of the present invention, by changing the connection contact between the brush and the commutator to an axial contact mode, that is, the central axis of the brush intersects the radial direction of the commutator perpendicularly, so that the brush and the commutator The contact area between them increases, and the conductive cross-sectional are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com