Synchronous rectifying circuit structure for high-frequency switch power supply

A high-frequency switching power supply and synchronous rectification technology, applied in the electrical field, can solve the problems of connection, heat dissipation and extra heat, and achieve the effects of improving performance, reducing lead loss, and reducing lead length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

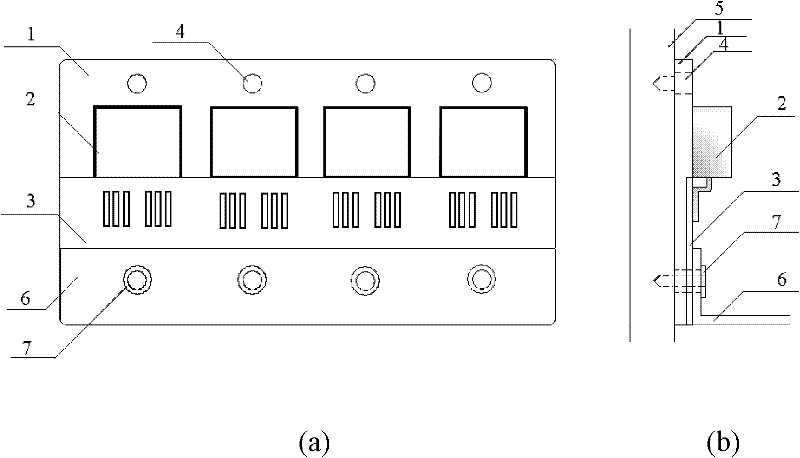

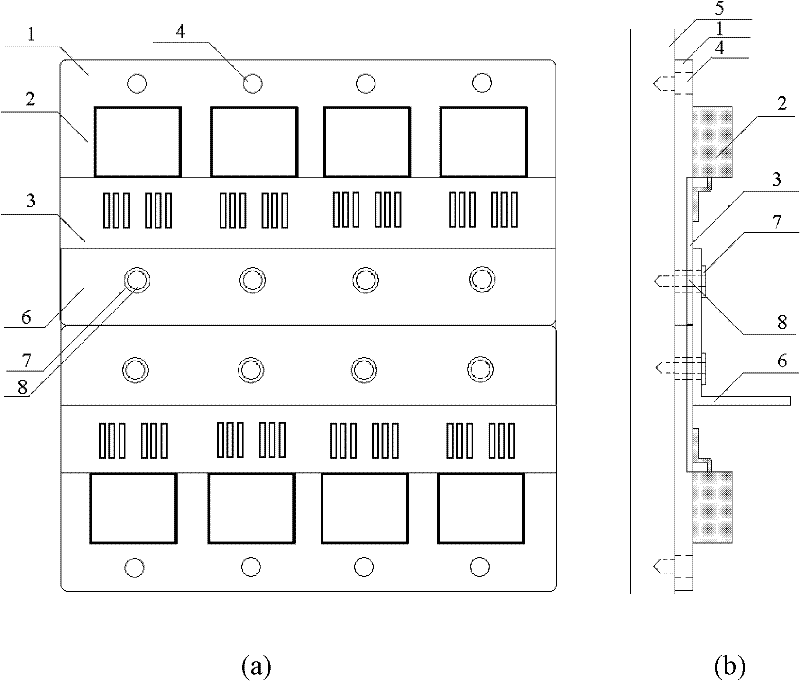

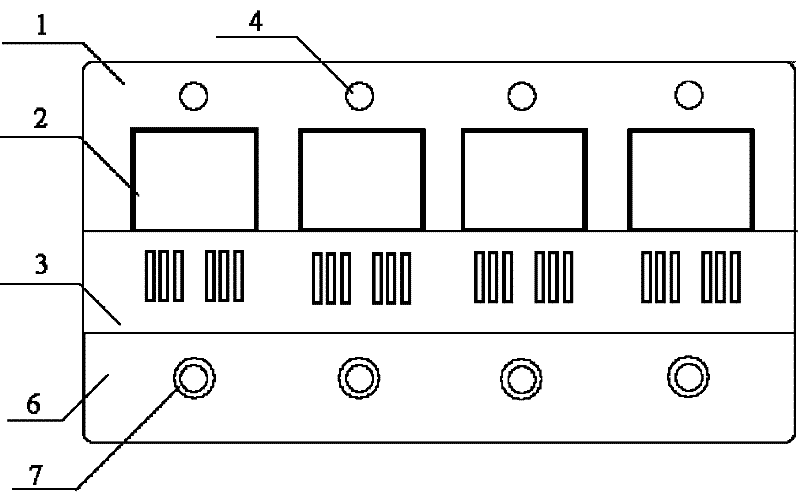

[0009] refer to figure 1 As shown, it includes a copper base plate 1, a surface mount package field effect transistor 2, and a printed circuit board 3. A groove is provided at one end of the copper base plate 1, and the printed circuit board 3 is installed in the groove of the copper base plate 1. The printed circuit board 3 The height of the upper surface is the same as that of the copper base plate. The other end of the copper base plate 1 is connected to the drain of the field effect transistor 2, and the gate and source of the field effect transistor 2 are connected to the printed circuit board 3. The number of field effect transistors used in the circuit Adjust according to needs, the copper base plate 3 is connected with the radiator 5, and the radiator is used as the output positive bus bar at the same time, a high-frequency transformer is installed on the printed circuit board 3, and the output terminal 6 of the high-frequency transformer is connected to the source of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com