Process for manufacturing solar cell by twice screen printing and grooving

A technology of solar cells and screen printing, applied in the direction of sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve the problems of unsuitability for industrialization and increased production costs, to increase the conductive cross-sectional area and reduce the grid line The effect that the efficiency of resistance and photoelectric conversion is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

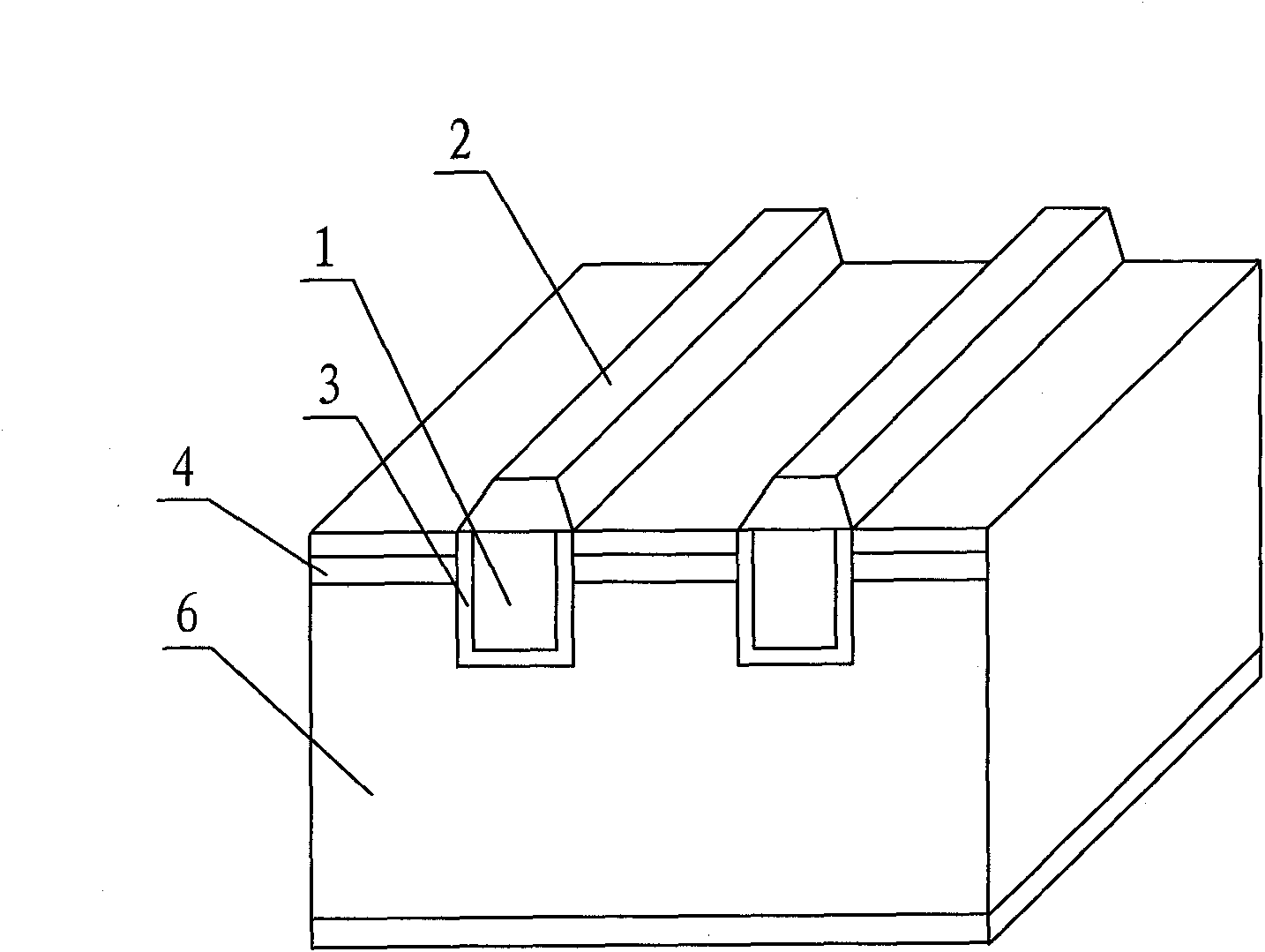

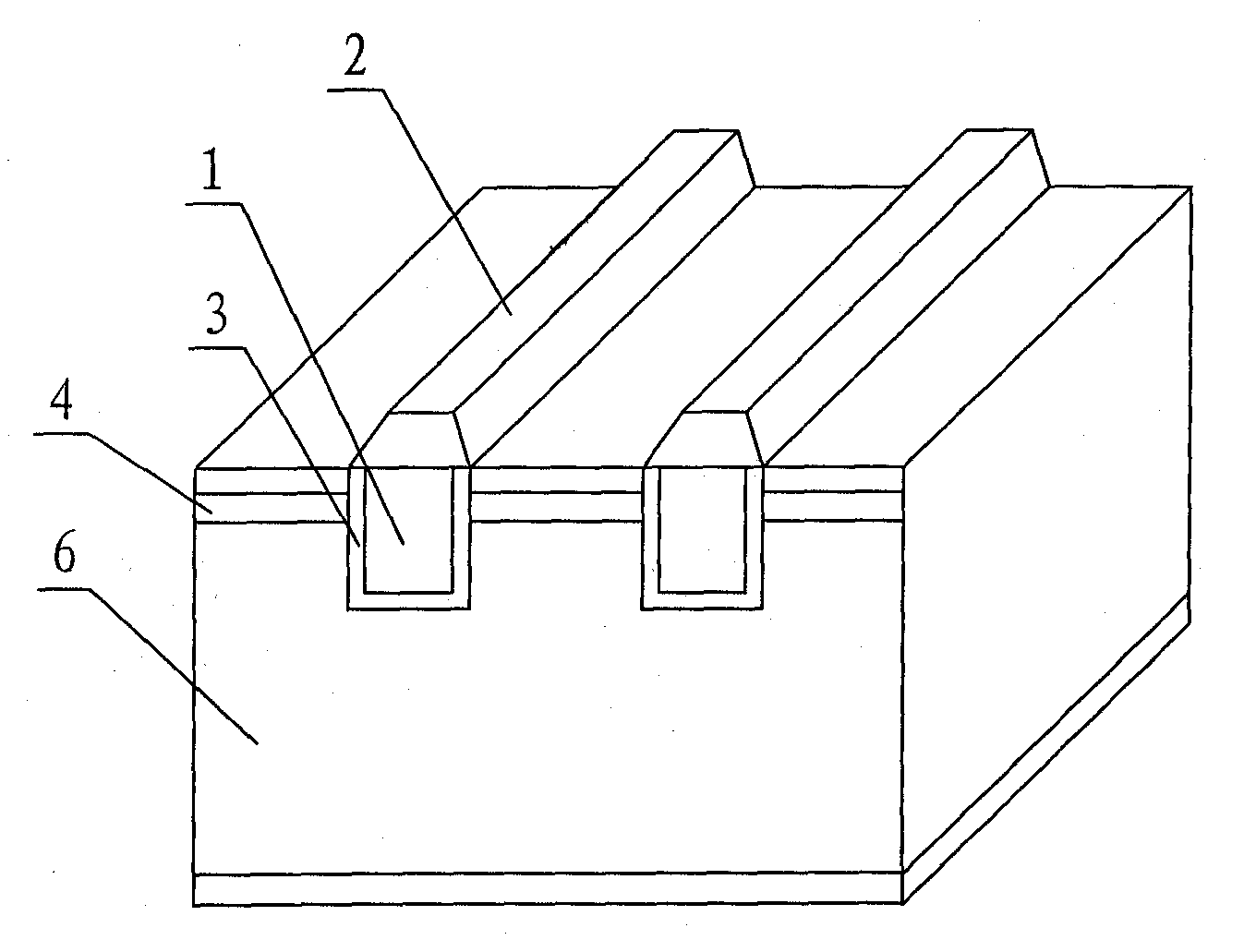

[0024] A solar cell manufacturing process combining two-time screen printing and grooving for manufacturing such as figure 1 A solar cell with twice printed electrodes is shown. The solar cell has a silicon wafer, and the silicon wafer adopts a P-type substrate 6. The surface of the silicon wafer is divided into an electrode grid line area and an electrode non-grid line area. The solar cell manufacturing process has the following step:

[0025] i) removing the damaged surface layer of the silicon wafer and texturizing the surface of the silicon wafer;

[0026] ii) Oxide mask layer process: grow an oxide mask layer under TCA conditions;

[0027] iii) Grooving process: laser grooves are made in the electrode grid line area of the front electrode on the surface of the silicon wafer, so that the electrode grid line area of the front electrode forms an etching groove, and the oxide mask layer above the etching groove is removed;

[0028] iv) cleaning process: NaOH cleaning,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com