Electromagnetic relay suitable for automatic production and with reliable electroconductivity and assembling method thereof

An electromagnetic relay, a technology of electrical conductivity, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of excessive heat generation of yoke iron, low conductivity of iron copper, and rise in temperature of relays, etc., to improve production efficiency, Simplify the effect of improving and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

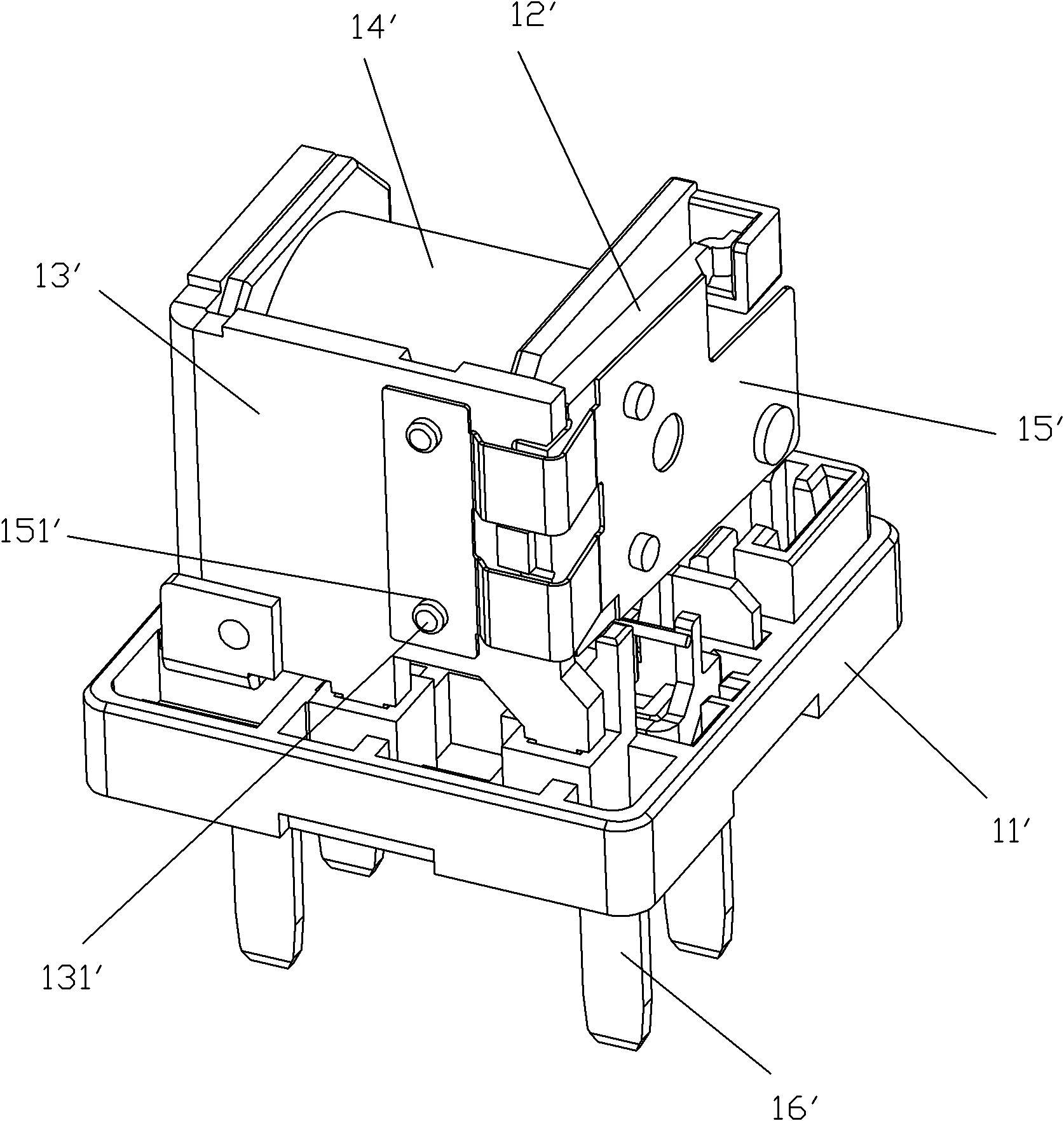

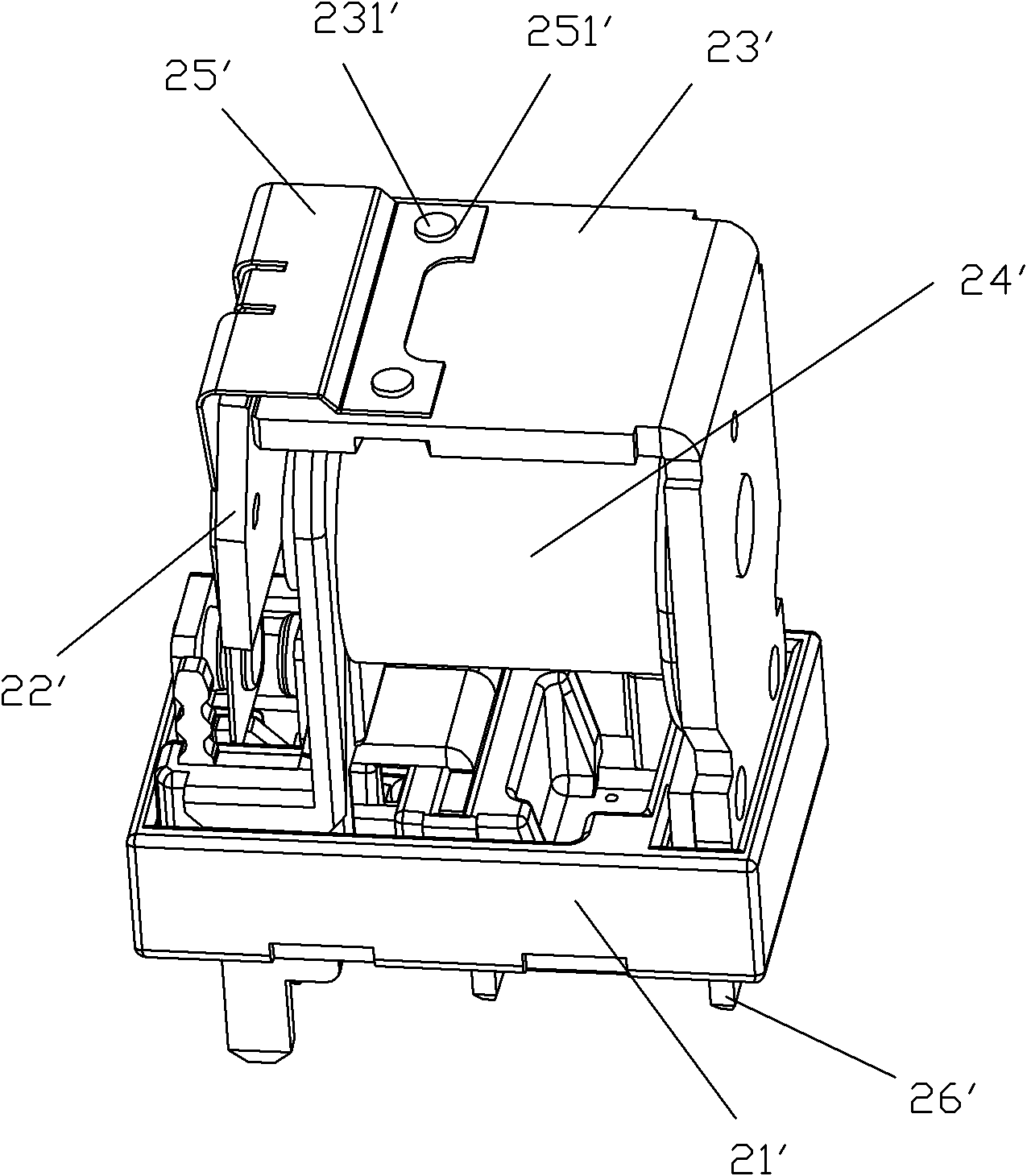

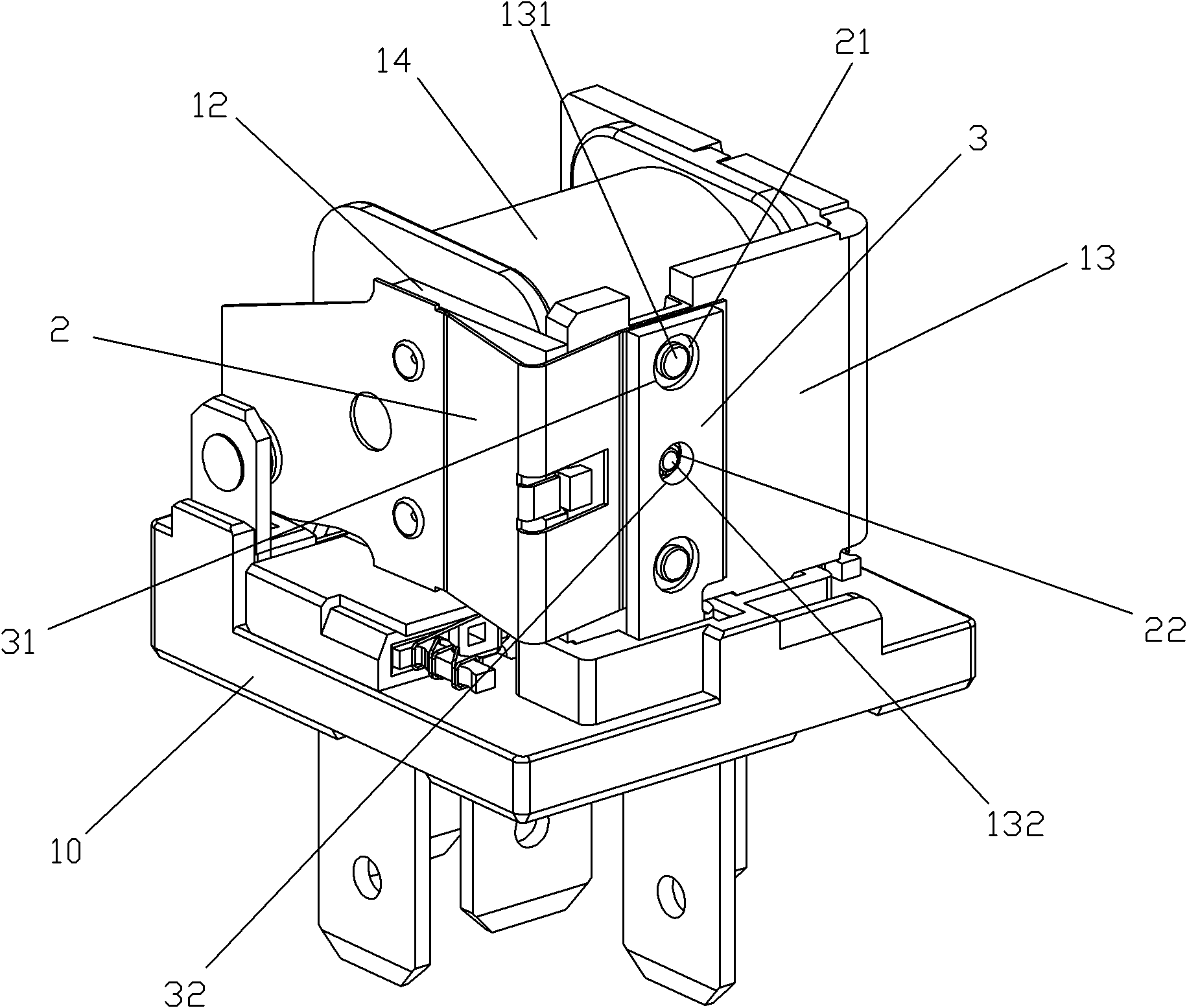

[0023] Examples, see Figure 3 to Figure 5 As shown, a kind of electromagnetic relay suitable for automatic production and reliable conductivity of the present invention includes a magnetic circuit part, a moving spring part, a lead-out pin part and a base 10; the magnetic circuit part, a moving spring part and a lead-out pin part are mounted on the base 10; the magnetic circuit part includes an iron core 11, an armature 12, a yoke 13 and a coil 14; the moving spring part includes a moving spring 2; 2 The two first protruding buds 131 fixed by riveting are provided with two first positioning holes 21 for matching with the two first protruding buds of the yoke on the moving spring 2; A second protruding bud 132, on the moving spring 2 is also provided with a clamping hole 22 for matching with the second protruding bud 132 of the yoke; The foot 3 is provided with two second positioning holes 31 that can be matched with the two first convex buds of the yoke; 1. The correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com