Modified emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and modified asphalt, which is applied in the direction of asphalt material adhesive, adhesive type, building components, etc. High problems, to achieve the effect of short demulsification curing time, simple and reliable method, and easy spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of modified emulsified asphalt, the method comprises:

[0030] Take 55-65wt% of SBS modified asphalt heated to 168-180°C and 35-45wt% of soap liquid heated to 55-70°C and put them into emulsification equipment for shear emulsification to obtain the modified emulsified asphalt .

[0031] Further, the emulsification equipment is a colloid mill. The working pressure of the colloid mill is 0.18-0.25 MPa.

[0032] Further, the softening point of the SBS modified asphalt is not lower than 75°C, the penetration is not higher than 62 (0.1mm, 25°C), the elastic recovery is not less than 90% (25°C), and the viscosity at 135°C is not less than 1.6 Pa·s, storage stability segregation is not more than 2 ℃ (48 hours softening point difference).

[0033] Further, the pH value of the soap liquid is 1.5-2.5. The soap liquid is prepared by mixing 0.75-2.5wt% of alkyl imidazoline emulsifier, 1.75-3.5wt% of additives and 32.5-40wt% of...

Embodiment 1~5

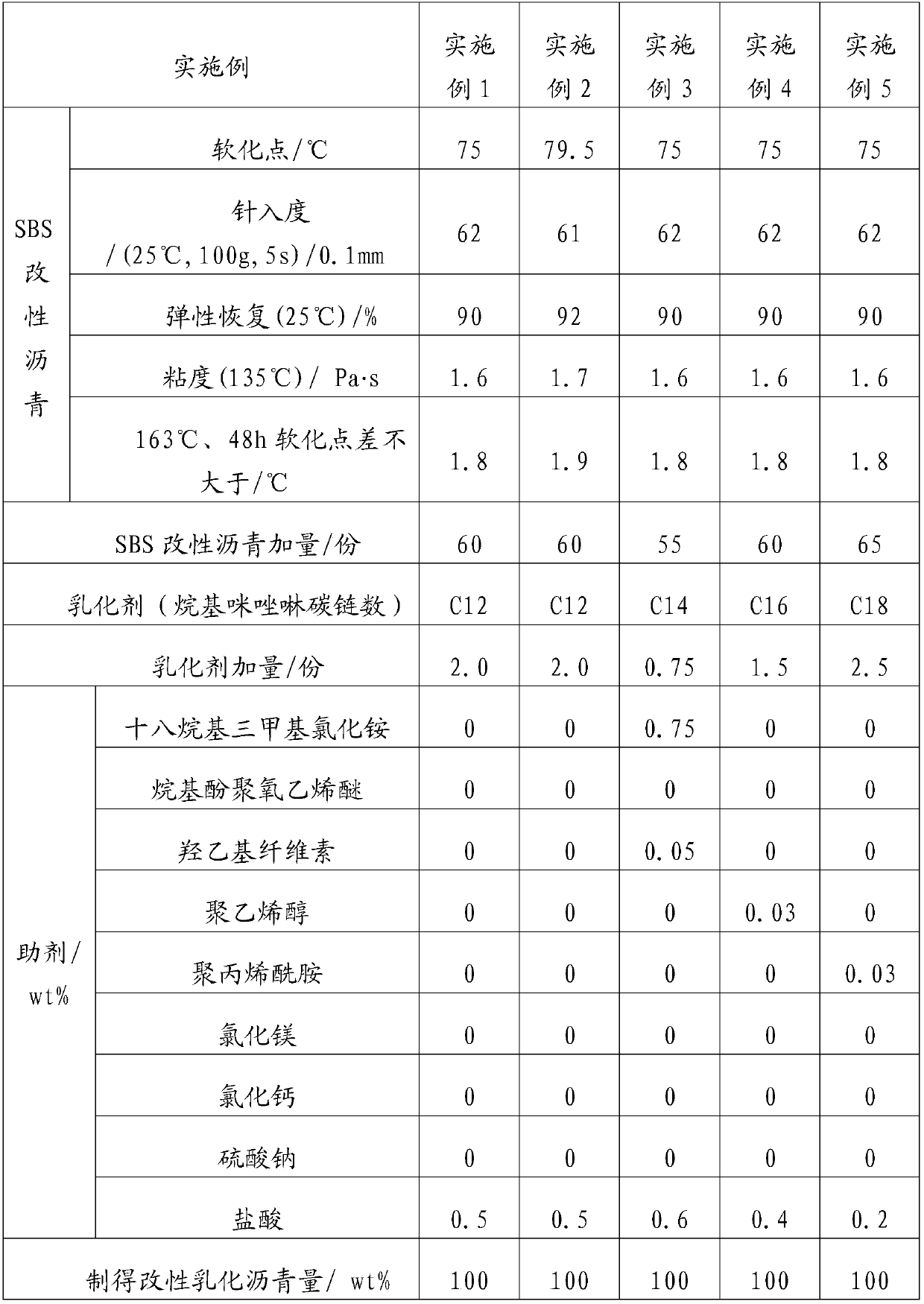

[0039] The parameters of Examples 1 to 5 are shown in Table 1. The soap solution after heating and preheating the SBS modified asphalt shown in Table 1 is emulsified under a certain pressure through a colloid mill to prepare a sponge-type urban road drainage pavement. The special modified emulsified asphalt used for the waterproof adhesive layer, the preparation process and the parameters of the modified emulsified asphalt are shown in Table 1.

[0040] Table 1 Examples 1-5 The implementation conditions, asphalt performance and application performance of the special modified emulsified asphalt prepared for the waterproof adhesive layer of the sponge-type urban road drainage pavement.

[0041]

[0042]

Embodiment 6~10

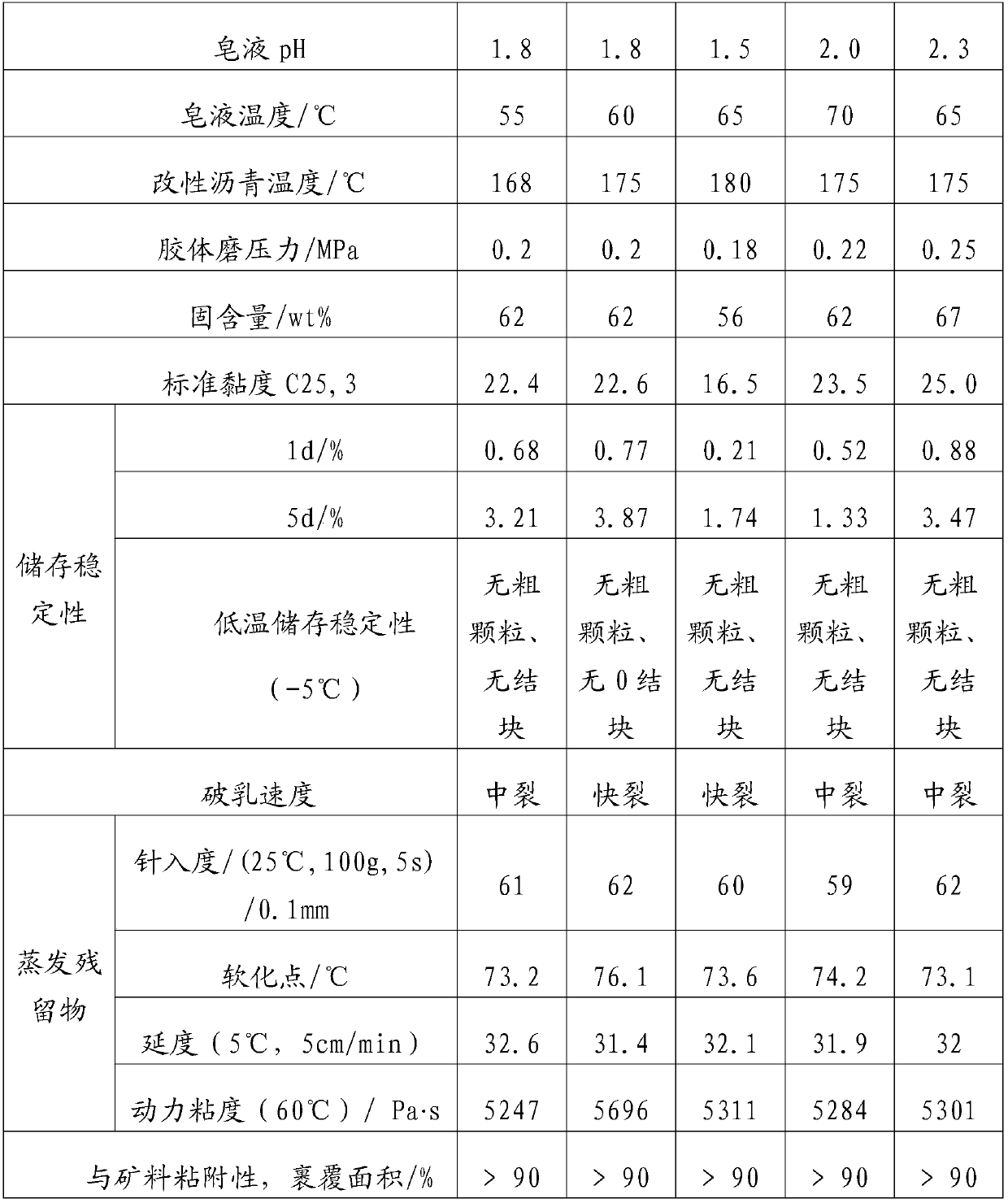

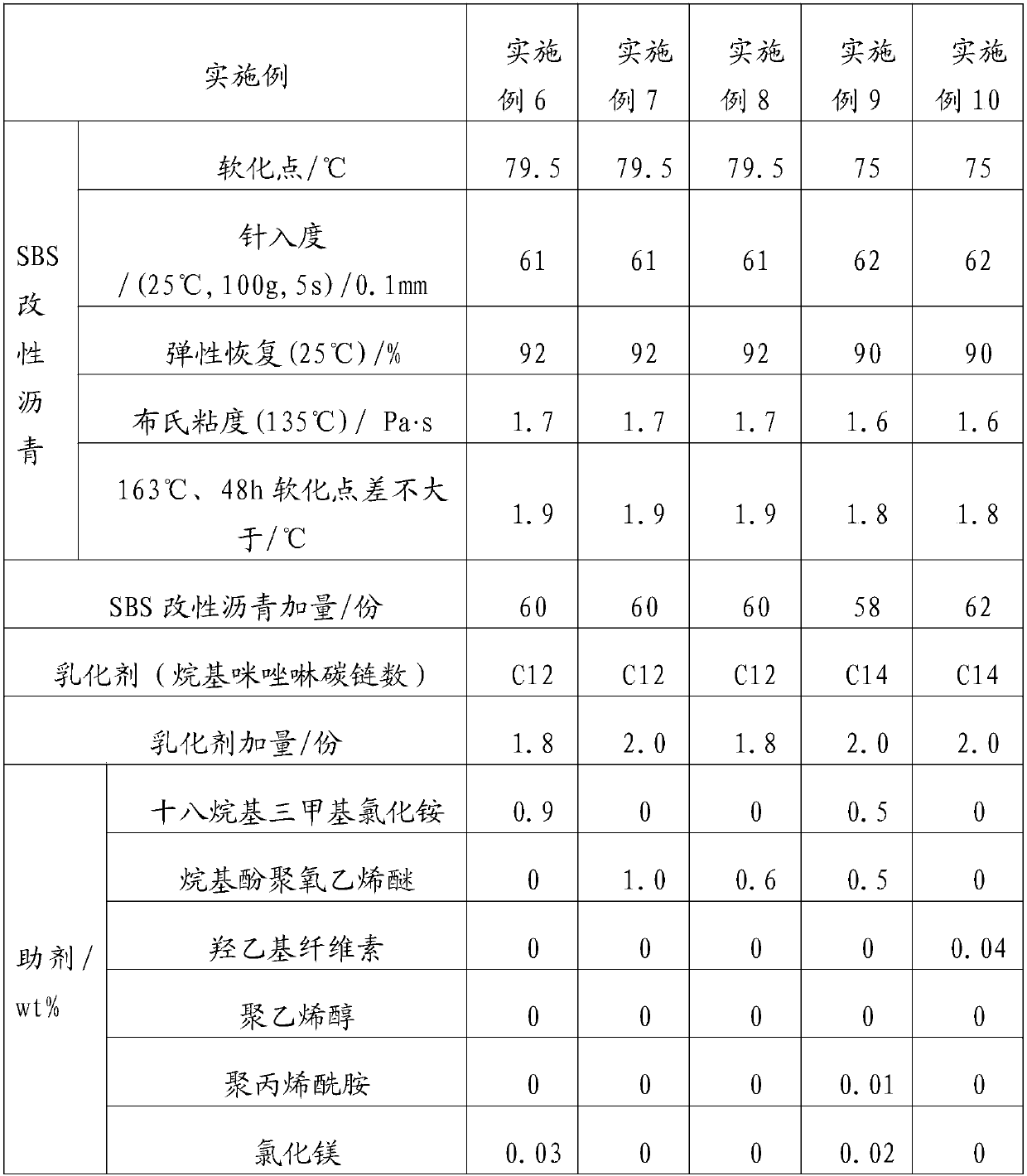

[0044] The parameters of Examples 6 to 10 are shown in Table 2. The soap solution after heating and preheating the SBS modified asphalt shown in Table 2 is emulsified under a certain pressure through a colloid mill to prepare a sponge-type urban road drainage pavement. The special modified emulsified asphalt used for the waterproof adhesive layer, the preparation process and the parameters of the modified emulsified asphalt are shown in Table 2.

[0045] Table 2 Implementation conditions, asphalt performance and application performance of special modified emulsified asphalt prepared for sponge-type urban road drainage pavement waterproof adhesive layer in Examples 6-10.

[0046]

[0047]

[0048]

[0049] In the technical scheme provided by this application, SBS modified asphalt is used as the raw material, and at the same time, higher requirements are placed on the high temperature softening point, viscosity and 5°C ductility of the SBS modified asphalt raw material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com