Patents

Literature

51results about How to "Guaranteed anti-aging properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt regenerating agent for recycling waste asphalt, and preparation method and application thereof

ActiveCN103275501AImprove flash point and stabilityImproved high temperature performance and bonding abilityBuilding insulationsPlasticizerAsphalt

The invention discloses an asphalt regenerating agent for recycling waste asphalt. The asphalt regenerating agent comprises 70-90mass% of rubber oil, 2-10mass% of an asphalt modifier TPS, 2-10mass% of a terpene resin, 2-5mass% of a plasticizer and 2-5mass% of an anti-stripping agent. A preparation method of the asphalt regenerating agent comprises the following steps: preheating the rubber oil to 140-160DEG C; sequentially adding the asphalt modifier TPS and the terpene resin to a stirring kettle, and carrying out stirring dispersion at a constant temperature; and sequentially adding the plasticizer and the anti-stripping agent to the stirring kettle, uniformly mixing, cooling to room temperature, and carrying out sealed preservation of the prepared asphalt regenerating agent. The asphalt regenerating agent can be added to aged modified asphalt to controllably adjust the performances and the effects of regenerated asphalt through adjusting the proportion of the asphalt regenerating agent. The asphalt regenerating agent is excellent, has a simple process operation, can recover the performances of the aged asphalt, and allows the regenerated asphalt to reach performance index requirements.

Owner:HUNAN YUNZHONG REGENERATION TECH CO LTD

Recycled polyester material and preparation method thereof

ActiveCN111978686AHigh tensile strengthImprove bending strengthPlastic recyclingPolyesterGlass fiber

The invention discloses a recycled polyester material and a preparation method thereof. The recycled polyester material is composed of waste polyester, an inorganic filler, glass fiber, a chain extender, a deodorant, a dispersant, an antioxidant, an ultraviolet absorber and a heat stabilizer. The preparation method of the recycled polyester material includes the following steps: 1) preparing wastepolyester particles; 2) mixing the waste polyester particles, the inorganic filler, the glass fiber, the chain extender, the deodorant and the dispersant uniformly, and carrying out extrusion granulation to obtain the recycled material; and 3) mixing the recycled material, the antioxidant, the ultraviolet absorber and the heat stabilizer uniformly, and then performing extrusion granulation to obtain the recycled polyester material. The recycled polyester material has high tensile strength, high bending strength, high elongation at break, good aging resistance and good workability, the recycling preparation process is simple, and the recycled polyester material can be used as an injection molding raw material of helmets, household appliance shells, building boards and toys without additionof new resin.

Owner:GUANGZHOU UNIVERSITY

Environment-friendly and anti-bacterial wallpaper

InactiveCN107956185AImprove fire and flame retardant performanceMeet application requirementsSpecial paperNon-macromolecular organic additionFiberSlurry

The invention provides an environment-friendly and antibacterial wallpaper, which comprises the following components in parts by weight: 11-17 Ulagrass fiber, 23-34 sodium alginate, 6-11 antioxidant, 2-7 compatibilizer, and 0.8-8 flame retardant 3.4, alfalfa fiber 26-43, nano-graphene particles 22-35, polylactic acid fiber 6-13, glutinous rice slurry 36-49; the soluble solid content of the glutinous rice slurry is 45%-55%; the poly The monofilament diameter of the lactic acid fiber is 0.1-0.3mm, and the monofilament length of the polylactic acid fiber is 22-34mm. The invention integrates the functionalization into the wallpaper, which meets the application and development requirements of the wallpaper in modern household.

Owner:姚景城

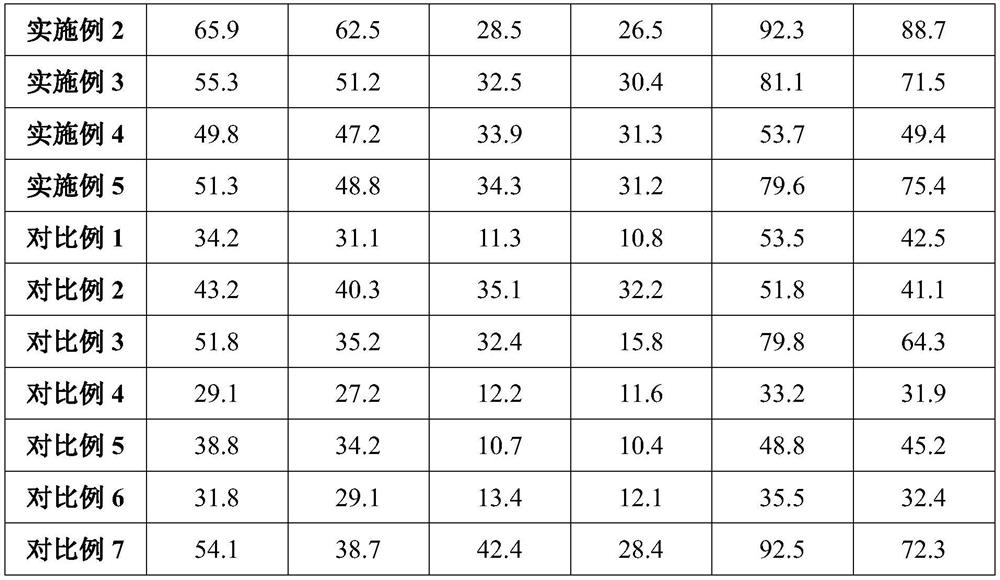

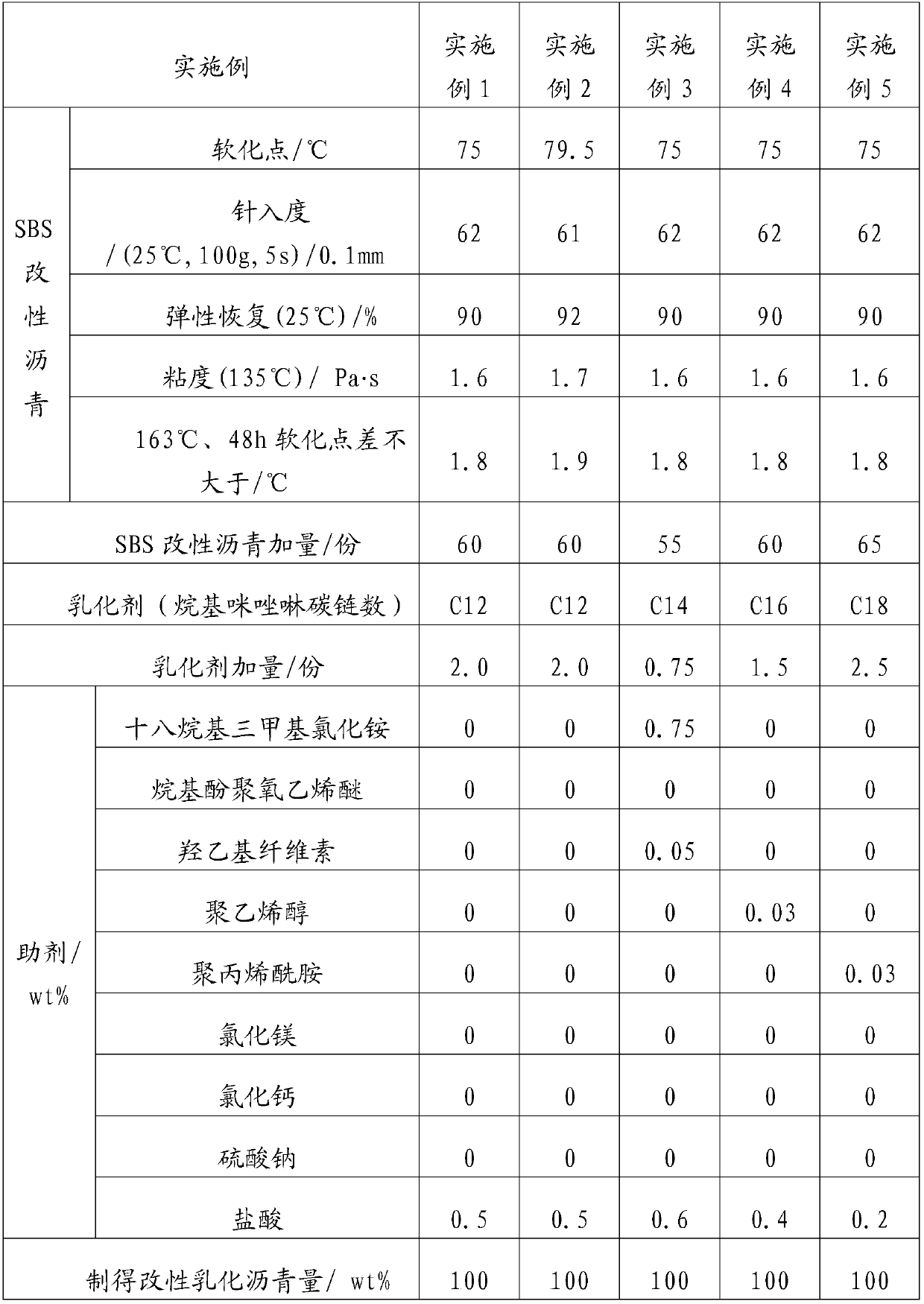

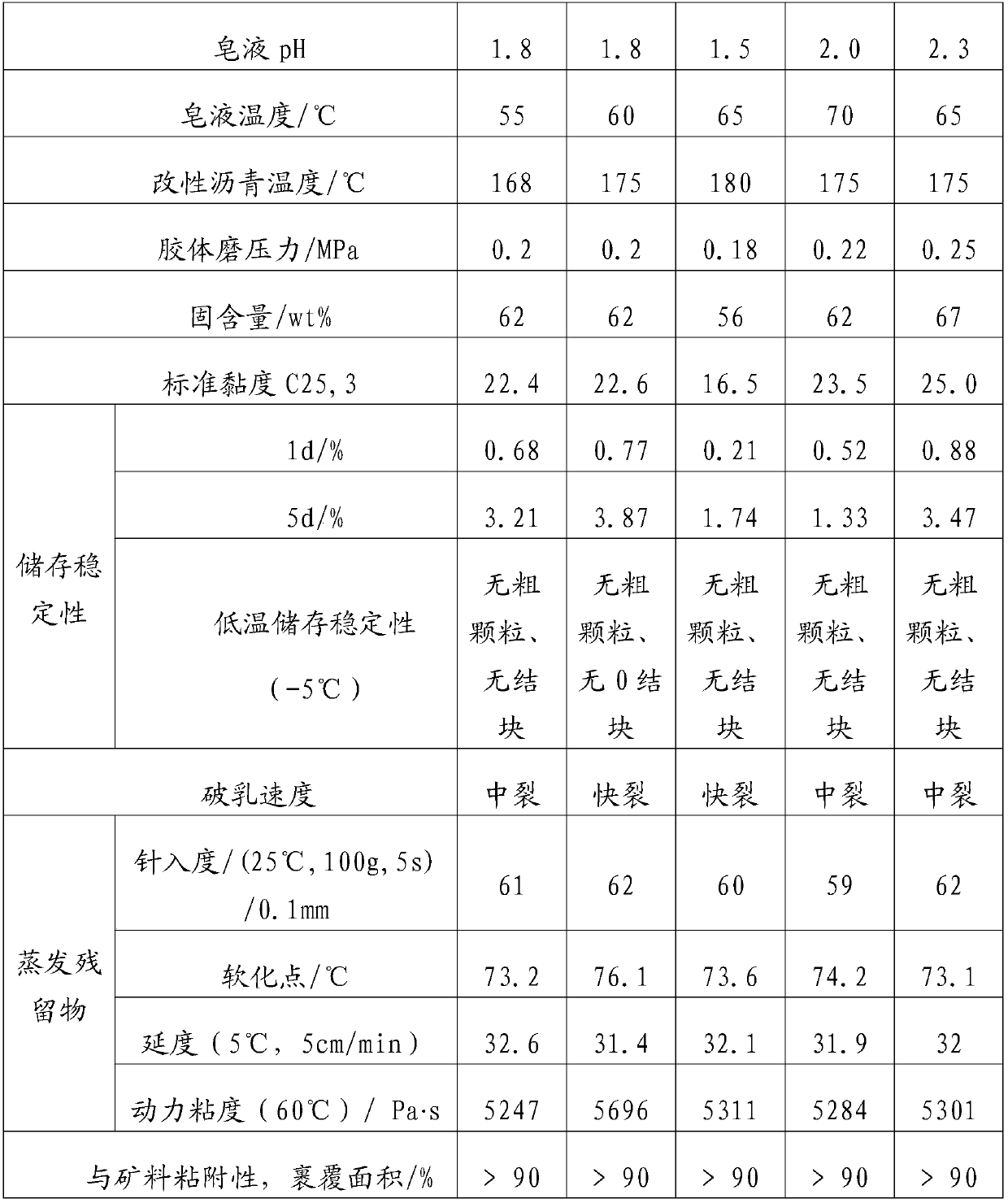

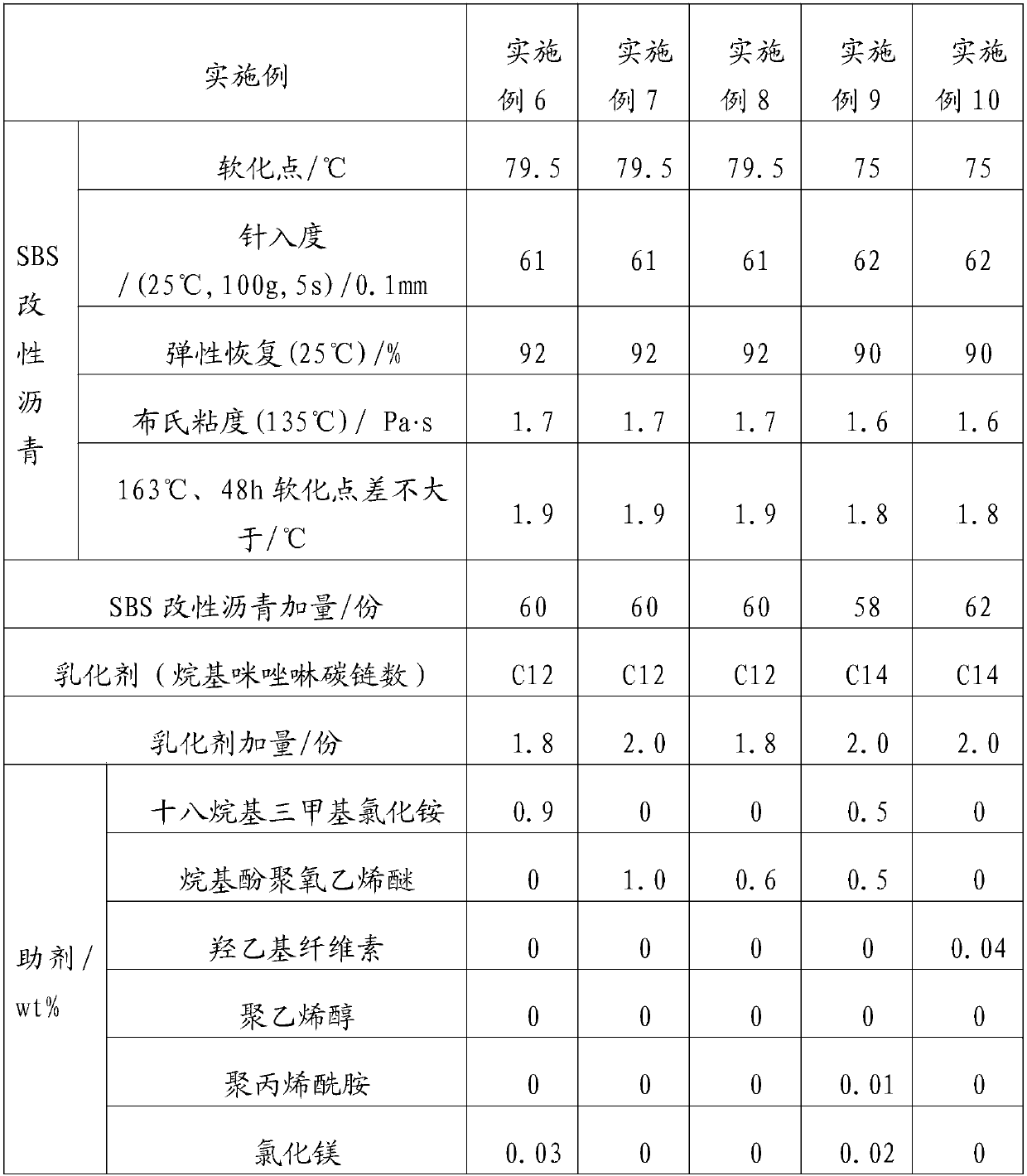

Modified emulsified asphalt and preparation method thereof

PendingCN109096781AStable storageUpper limit temperature controlBituminous material adhesivesBuilding insulationsCeiling temperatureAging resistance

The invention discloses modified emulsified asphalt and a preparation method thereof. According to the method, SBS modified asphalt heated to 168-180 DEG C and liquid soap heated to 55-70 DEG C are added to emulsifying equipment together for shear emulsification, and the modified emulsified asphalt is obtained. The method is simple and reliable; ceiling temperature of the modified asphalt and theliquid soap is controlled, energy is saved, and manufacture cost is reduced. The prepared modified emulsified asphalt is stored stably, the demulsification speed being rapid breaking or medium breaking of the emulsified asphalt is taken into consideration, so that the asphalt is easy to spray in construction, the demulsification curing time is short, and follow-up construction is not affected. Waterproofness and bonding performance of the modified emulsified asphalt when applied to a bonding layer material are obviously higher than those of the modified emulsified asphalt material in the priorart. The prepared bonding layer material can have excellent ageing resistance, bonding performance, waterproofness and high-low-temperature stability.

Owner:PETROCHINA CO LTD +1

Novel heat-preservation wallpaper

InactiveCN108004852AGood compatibilityExtended service lifeSpecial paperPaper/cardboardGlass fiberAlkali free

The invention provides novel heat-preservation wallpaper. The novel heat-preservation wallpaper is prepared from the following components in parts by weight: 10 to 15 parts of ramie fibers, 21 to 31 parts of chitosan fibers, 8 to 12 parts of an antioxidant, 2 to 7 parts of a compatilizer, 0.8 to 3.4 parts of a flame retardant, 22 to 42 parts of silicon dioxide aerogel particles, 26 to 34 parts ofpolypropylene fibers, 6 to 13 parts of alkali-free and low-floating long glass fibers and 51 to 69 parts of glutinous rice milk; the content of soluble solid matters of the glutinous rice milk is 48 percent to 62 percent; the monofilament diameter of the alkali-free and low-floating long glass fibers is 33 to 45mum; the monofilament length of the alkali-free and low-floating long glass fibers is 9to 18mm. According to the novel heat-preservation wallpaper provided by the invention, the wallpaper are endowed with functionality and the requirements on application and development of the wallpaper in modern homes are met.

Owner:姚景城

Moistureproof material for Xuan paper

InactiveCN108411703AExtended service lifeImprove fire and flame retardant performanceInorganic fibres/flakesOrganic non-cellulose fibresVegetable fibersBasalt

The invention provides a moistureproof material for Xuan paper. The moistureproof material comprises, by weight, 9-14 parts of Pteroceltis tatarinowii bark fibers, 18-32 parts of Shatian straw fibers,6-11 parts of an antioxidant, 2-7 parts of a compatibilizer, 0.8-3.4 parts of a flame retardant, 26-43 parts of clover fibers, 22-35 parts of reed fibers, 14-29 parts of basalt fibers, 23-37 parts ofsoybean powder and 32-46 parts of glutinous rice slurry, wherein the content of soluble solids in the glutinous rice slurry is 42 to 52%, and the monofilament of the basalt fibers has a diameter of 0.35 to 0.65 [mu]m and a length of 3 to 9 mm. According to the invention, a combination of plant fibers and organic fibers is employed to replace a part of traditional raw materials for Xuan paper, socost is saved, good pulping effect is obtained, and the service life, fireproof performance and flame retardation performance of Xuan paper are improved.

Owner:霍文慧

Preparation method of pastry compound emulsifier

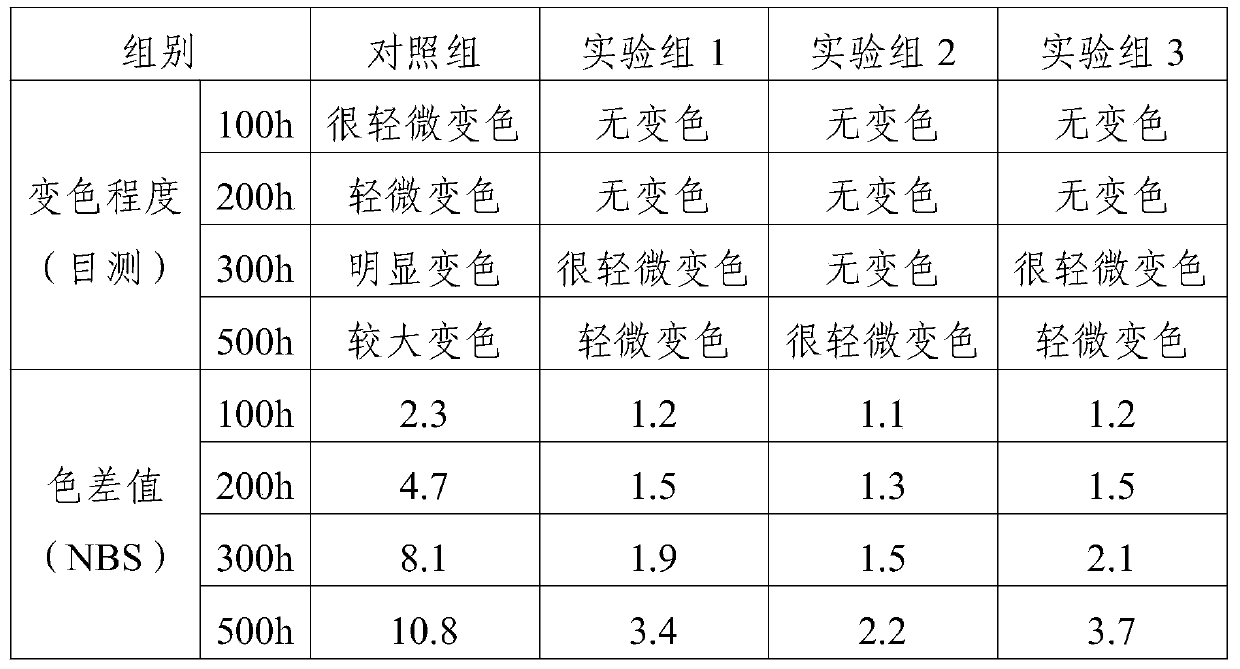

PendingCN111685142AGuaranteed anti-aging propertiesGuaranteed softnessDough treatmentBakery productsBiotechnologyMonoglyceride

The present invention relates to a food emulsifier, in particular to a preparation method of a pastry compound emulsifier. The preparation method comprises the following steps: preparing a powder foaming emulsifier which is prepared by the following steps: a, uniformly mixing molecular distilled monoglyceride and polyglycerol fatty acid ester according to a weight part ratio of 1:(0.8-0.91) to form a component A; b, uniformly mixing the component A with a carrier japonica rice in a weight ratio of 1:(1.6-2), spraying purified water, and adjusting the moisture to 12-15% to form a component B; and c, extruding and puffing the component B by using a double-screw extrusion puffing machine at an extrusion temperature of 85-115 DEG C until the volume of the japonica rice powder is increased by at least 300%, and after puffing, performing cooling, crushing, sieving and packaging for later use. The emulsifier does not contain cake oil, avoids the harm of propylene glycol to human bodies, protects the health of the human bodies, ensures that the softness and freshness of cakes can be continuously maintained within the quality guarantee period, and remarkably improves the quality of cake bread.

Owner:禾川(泉州)生物科技有限责任公司

Novel Chinese art paper material

InactiveCN108301250AImprove fire and flame retardant performanceExtended service lifeNon-macromolecular organic additionVegetable material additionGlass fiberAlkali free

The invention provides a novel Chinese art paper material including the following components in parts by weight: 11-17 parts of wingceltis bark fibers, 23-34 parts of sand field rice straw fibers, 6-11 parts of an antioxidant, 2-7 parts of a compatibilizer, 0.8-3.4 parts of a flame retardant, 18-31 parts of pineapple peel pomace fibers, 24-33 parts of sisal hemp fibers, 6-13 parts of alkali-free low-floating long glass fibers and 36-49 parts of glutinous rice slurry, wherein the soluble solid content of the glutinous rice slurry is 45%-55%, the monofilament diameter of the alkali-free low-floating long glass fibers is 28-35 [mu]m, and the monofilament length of the alkali-free low-floating long glass fibers is 9-18 mm. The plant fibers and the organic fibers are combined to replace a partof traditional raw materials of Chinese art paper, the cost is saved, the slurry making effect is good, and at the same time, the service life of the Chinese art paper is prolonged and fire preventionand flame retardancy are improved.

Owner:霍文慧

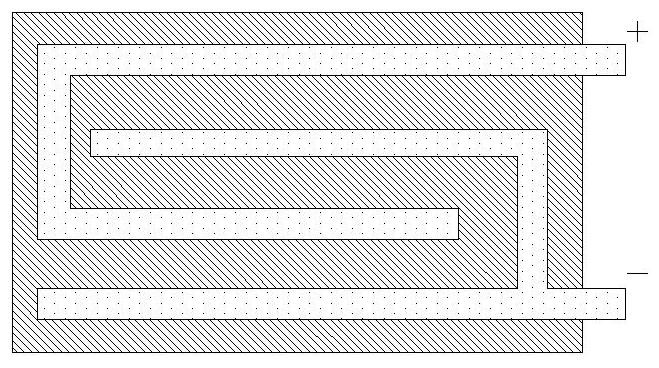

Prefabricated sandwich building wallboard and preparation technology thereof

InactiveCN109057139ASolve the problem of perishable deteriorationGuaranteed stabilityBuilding componentsAlkaline waterFiber

The invention discloses a prefabricated sandwich building wall panel. The prefabricated sandwich building wallboard comprises an outer wall panel and an inner wall panel, wherein the outer wall panelcomprises a facing layer, a thermal insulation layer and a structural layer, and the inner wall panel comprises a facing layer, a thermal insulation layer and a facing layer. According to the preparation technology of the prefabricated sandwich building wallboard, crushed straw is subjected to pre-treatment, the pre-treatment comprises alkaline water soaking, filtering and drying, according to effects of size of untreated and treated crop straw fibers on dissolved matters and water-absorbing swelling / drying shrinkage performance, effects of the straw particle size and corresponding technologyparameters on the performance of a straw / foam concrete compound material are studied, and the corresponding technology parameters and a mixing proportion are optimized; a heat conductivity coefficientand the ageing resistance performance of the prefabricated sandwich panel are ensured, based on the proper mixing proportion, a high polymer material is added, an optimal binding mode of inner panels, the thermal insulation layers and outer panels is fished out, moreover, the problem that the straw is prone to rotting and going bad is solved, the stability of the straw is maintained, and the mechanical strength and the durability of the novel wallboard are guaranteed.

Owner:JIANGSU JINMAO TECH DEV

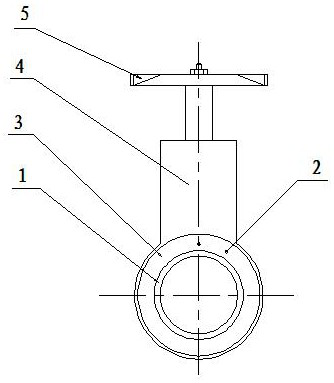

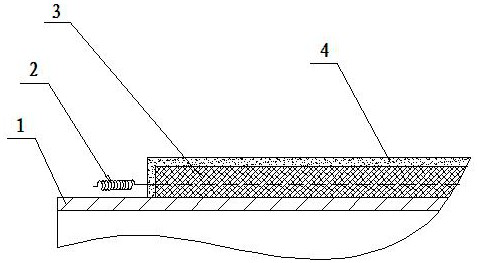

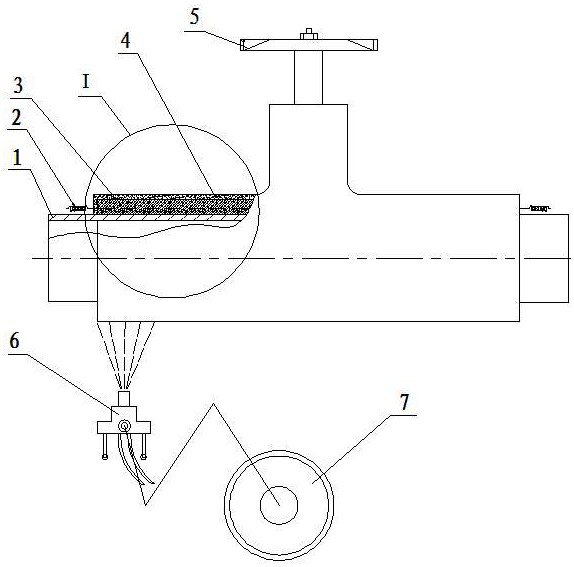

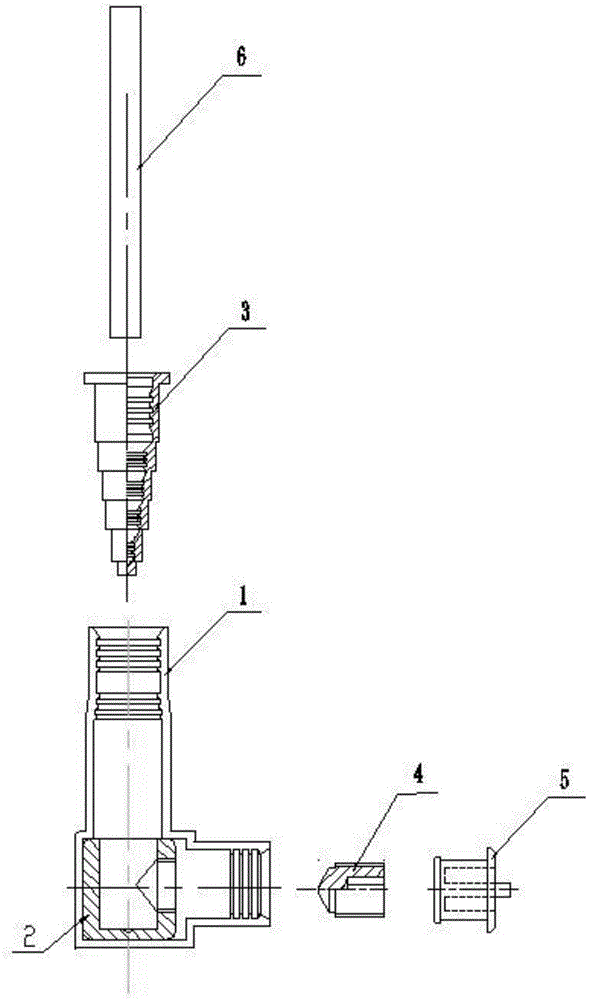

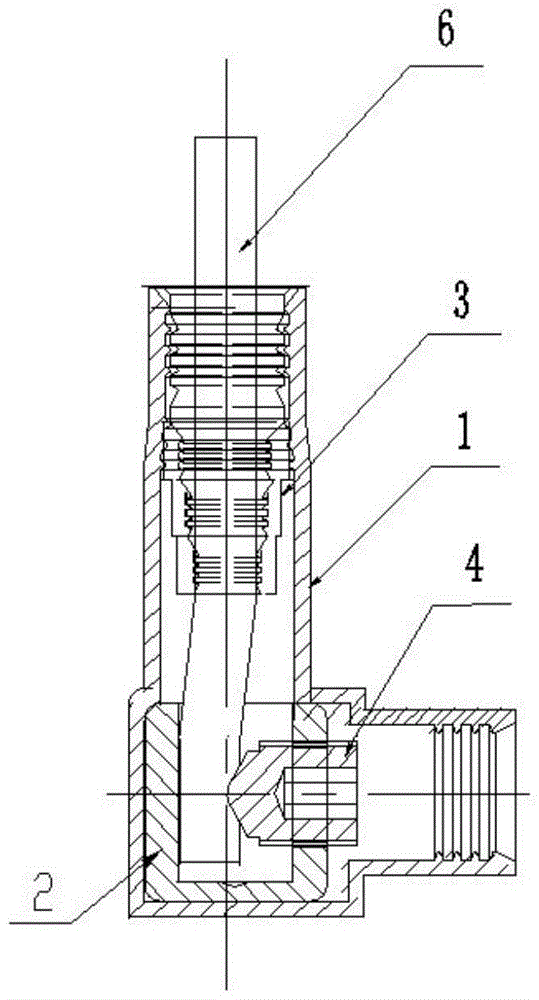

Polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve and spraying method

PendingCN112161101AAvoid economic lossSolve common technical problemsThermal insulationPipe protection by thermal insulationPolymer scienceHeat conservation

The invention discloses a polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve and a spraying method. By adopting a traditional prefabricated directly-buried heat preservation process, a heat supply pipe network and a pipeline valve have the disadvantages of uneven heat preservation forming, halfway splicing and welding of an outer protectionpipe, great heat loss for integral heat preservation and short service life of a heat preservation valve. The heat preservation valve comprises a prefabricated directly-buried heat preservation valvewhich comprises a working pipe, wherein polyurethane protection layers (3) are sprayed to the outer layers of a horizontal pipe and a vertical pipe of the working pie separately through a polyurethane mixing spray head (6), valve welding ports (1) without the polyurethane protection layer are left at two ends of the horizontal pipe, high polymer liquid protection layers (4) are sprayed to the outer surfaces of the polyurethane protection layers by a high pressure spray gun, a group of alarm lines (2) is mounted in each polyurethane protection layer, and the high polymer liquid protection layers are made of high polymer liquid elastic materials with densities being 1.2 q / cm<3> and the coatings are 1-20 mm thick. The invention relates to the polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve.

Owner:融克(北京)资本投资管理有限公司

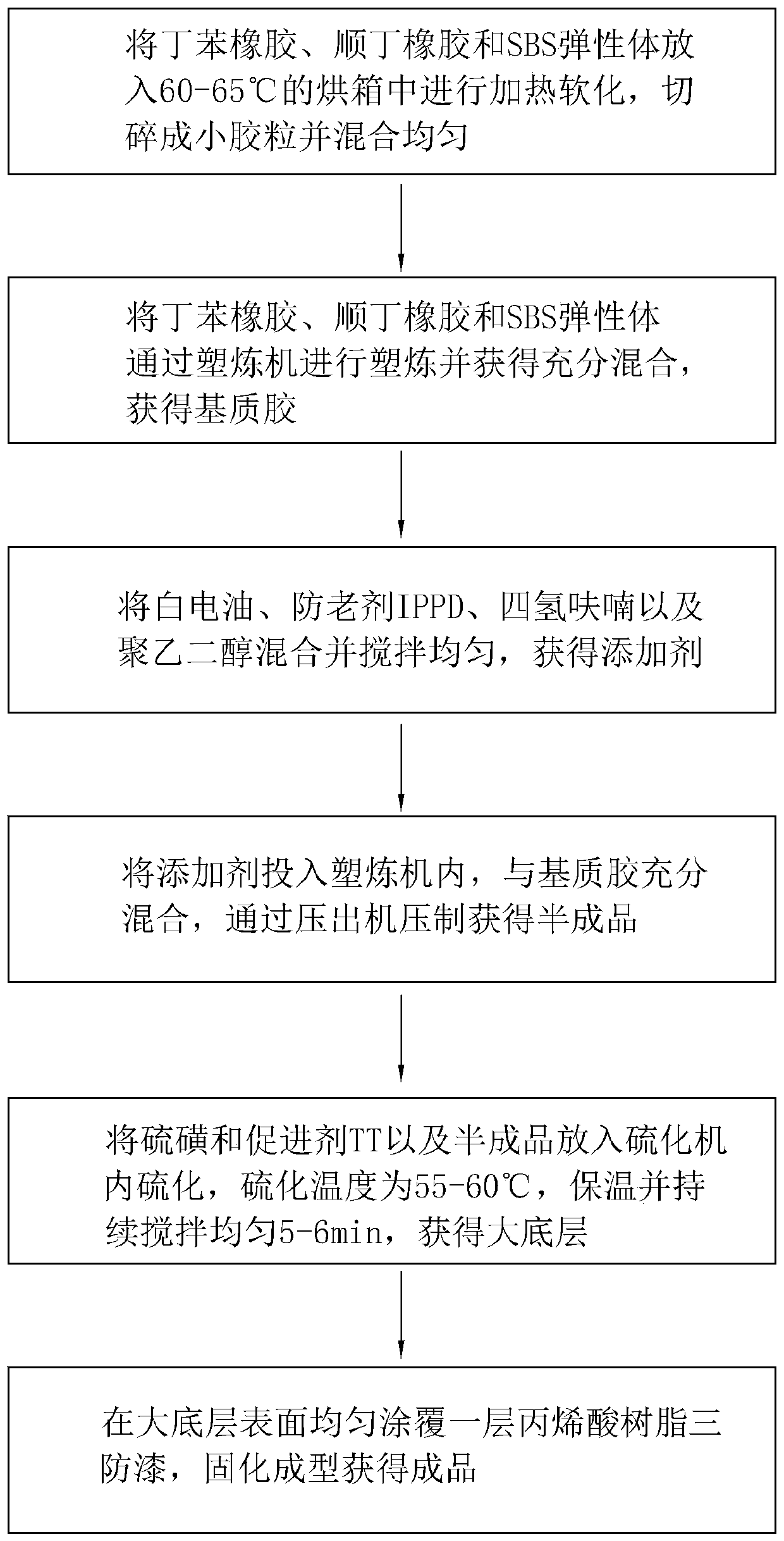

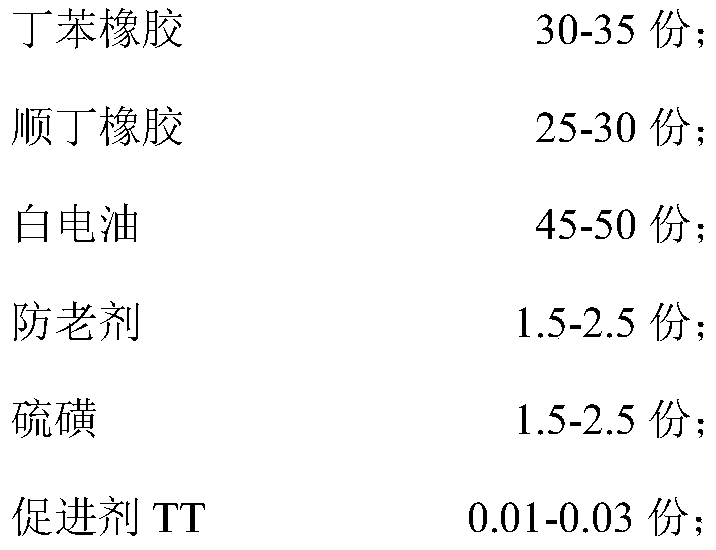

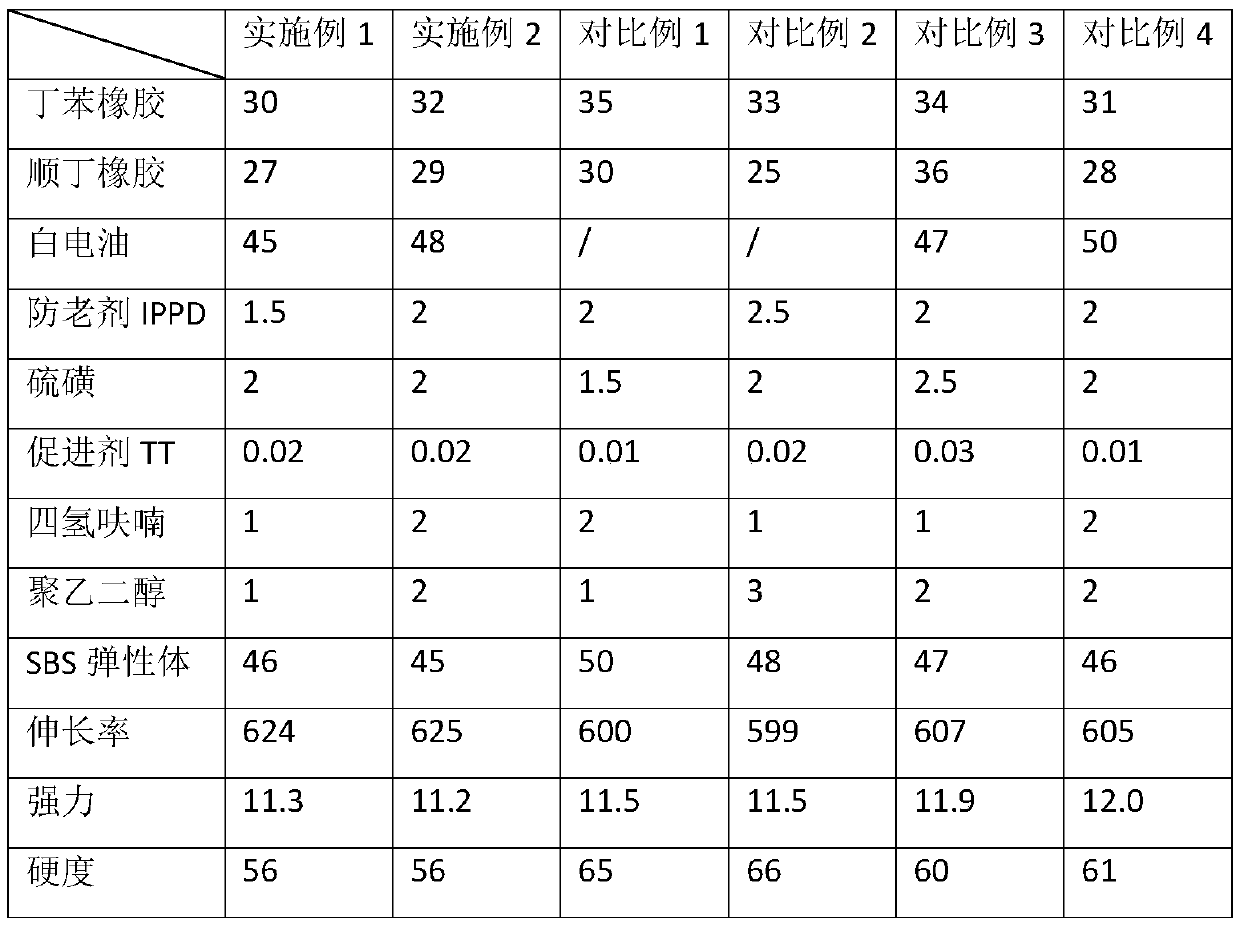

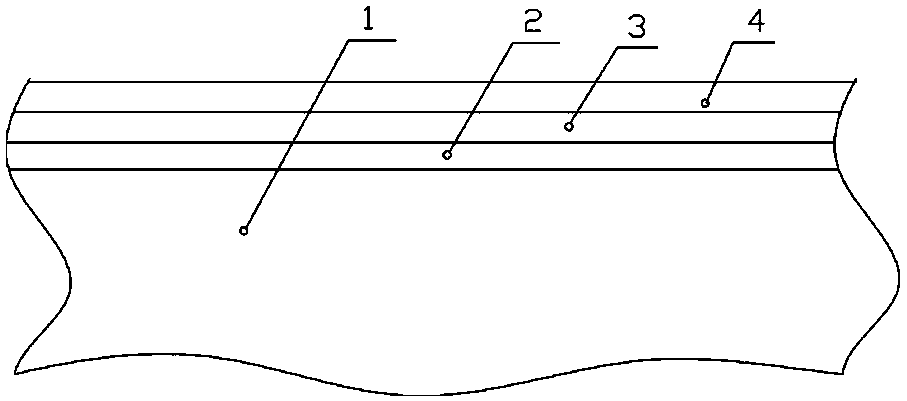

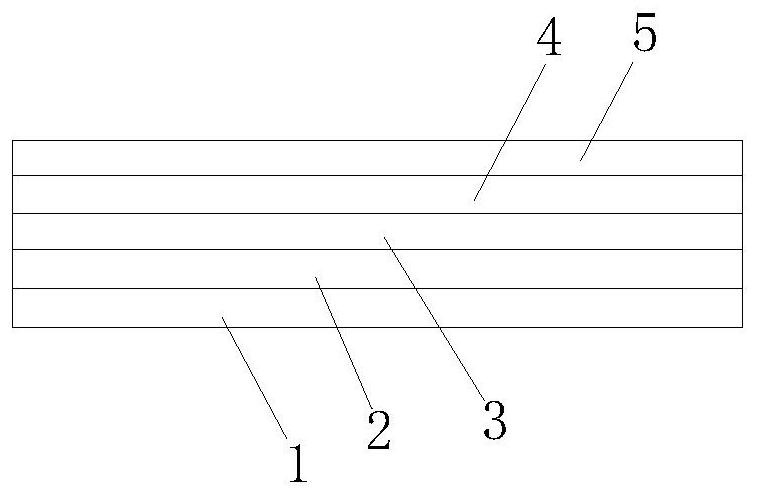

High-heeled shoe outsole and preparation method thereof

The invention discloses a high-heeled shoe outsole, which comprises an outsole layer and a coating layer, wherein the outsole layer comprises the following raw materials by weight: 30-35 parts of styrene butadiene rubber, 25-30 parts of cis-polybutadiene rubber, 45-50 parts of n-heptane, 1.5-2.5 parts of an antioxidant, 1.5-2.5 parts of sulfur and 0.01-0.03 part of accelerator TT, and the coatinglayer is obtained by curing and molding acrylic resin three-proof paint on the surface of the outsole layer. The high-heeled shoe outsole has the following advantages: the n-heptane can be used as a main solvent to enable the system to be more evenly mixed, and at the same time, the system can be more wetted, so that the plasticity of the system is improved, and the adhesion degree of the outsoleto a sole during wearing is improved. The n-heptane volatilizes easily. The outsole layer is outside coated with the acrylic resin three-proofing paint to prevent the n-heptane from volatilizing and ensure the storage effect. In the wearing process, after the coating layer is worn, the n-heptane obtains a volatilization space, so that the moisture content of the system is continuously reduced, thecuring degree is continuously improved, and in the process, the outsole can quickly form a fit with the sole of a foot.

Owner:温州市三盟鞋业有限公司

Acrylate polymer composite waterproof system and construction method thereof

ActiveCN106499068BHigh strengthIncreasing the thicknessRoof covering using flexible materialsEster polymer adhesivesAdhesiveProtection layer

Owner:平顶山环宇星防水科技有限公司

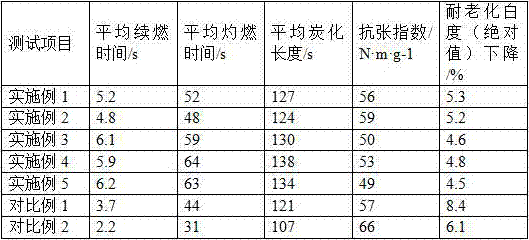

Self-cleaning light-color sidewall rubber composition

InactiveCN112250956AAccelerates the ozone aging processReduce intensitySpecial tyresAntioxidantKaolin clay

The invention discloses a self-cleaning light-color sidewall rubber composition which comprises 5.0-35.0 parts of natural rubber, 40.0-70.0 parts of brominated isobutylene p-methylstyrene rubber, 10.0-40.0 parts of ethylene propylene diene monomer, 20.0-60.0 parts of kaolin, 20.0-60.0 parts of titanium dioxide, 0.5-3.0 parts of ultramarine, 0.5-2.0 parts of stearic acid, 2.0-4.0 parts of a chemical antioxidant, 1.0-10.0 parts of nano-zinc oxide, 0.5-3.0 parts of a vulcanizing agent, and 2.0-5.0 parts of anaccelerant. Through adjustment of a raw rubber system and a protection system, the self-cleaning function of the light-color sidewall rubber composition is realized by utilizing a phenomenon that a surface layer is easy to fall off due to slight ozone aging while conventional physical andmechanical performance requirements such as aging resistance and the like is guaranteed.

Owner:SAILUN GRP CO LTD

Novel carrier material for calligraphy and painting

InactiveCN108411700AImprove fire and flame retardant performanceExtended service lifeNon-macromolecular organic additionVegetable material additionTO-18Glass fiber

The invention provides a novel carrier material for calligraphy and painting. The novel carrier material comprises, by weight, 10-15 parts of Pteroceltis tatarinowii bark fibers, 21-31 parts of Shatian straw fibers, 8-12 parts of an antioxidant, 2-7 parts of a compatibilizer, 0.8-3.4 parts of a flame retardant, 22-42 parts of wheat bran fibers, 26-34 parts of sisal fibers, 6-13 parts of alkali-free low-float long glass fibers and 51-69 parts of glutinous rice slurry, wherein the content of soluble solids in the glutinous rice slurry is 48 to 62%, and the monofilament of the alkali-free low-float long glass fibers has a diameter of 33 to 45 [mu]m and a length of 9 to 18 mm. According to the invention, a combination of plant fibers and organic fibers is employed to replace a part of traditional raw materials for Xuan paper, so cost is saved, good pulping effect is obtained, and the service life, fireproof performance and flame retardation performance of Xuan paper are improved.

Owner:谷文

Ageing-resistant packaging carton

The invention discloses an ageing-resistant packaging carton. Raw materials of the ageing-resistant packaging carton comprise, by weight, 20-40 parts of cotton linter, 40-50 parts of bamboo fibers, 12-15 parts of synthetic fibers, 1-3 parts of polyvinyl alcohol, 1-2 parts of shellac, 0.5-2 parts of phenolic resin, 5-10 parts of active calcium oxide, 1-3 parts of an anti-photooxidation agent, 2-6 parts of gypsum, 20-30 parts of talcum powder, 2-8 parts of sodium aluminosilicate, 1-2 parts of a surfactant, 0.5-1.5 parts of dimethicone, 10-20 parts of nanometer calcium carbonate, 5-15 parts of nanometer silica, 1-4 parts of N-oleylpalmitamide, 1-3 parts of alkylamine ethoxylate and 30-40 parts of water. The ageing-resistant packaging carton has the advantages of excellent ageing resistance and durability, long service life, wide sources of the raw materials, and low cost.

Owner:BENGBU ZHONGBANG PACKAGING FACTORY

High-temperature resistant rubber pad and preparation method

InactiveCN106867055AHigh heat resistancePromotes the development of heat-resistant propertiesPolymer scienceCarbon fibers

The invention discloses a high temperature-resistant rubber pad. The weight ratio of each component is 60-80 parts of nitrile rubber, 5-10 parts of polyacrylonitrile carbon fiber, 10-15 parts of nano-zinc oxide, and 2-2 parts of nano-graphite powder. 5 parts, 1~2 parts of accelerator, 3~5 parts of carbon black, 1~2 parts of stearic acid, 2~5 parts of calcium carbonate, 1~2 parts of rare earth and 2~4 parts of metal cobalt, of which rare earth and metal cobalt The weight ratio is 1:2. The high temperature-resistant rubber mat obtained by the present invention has high heat resistance and excellent mechanical properties. After testing, the high-temperature-resistant rubber mat can work at high temperature for a long time, and its service life is doubled compared with traditional rubber mats. above.

Owner:徐丹峰

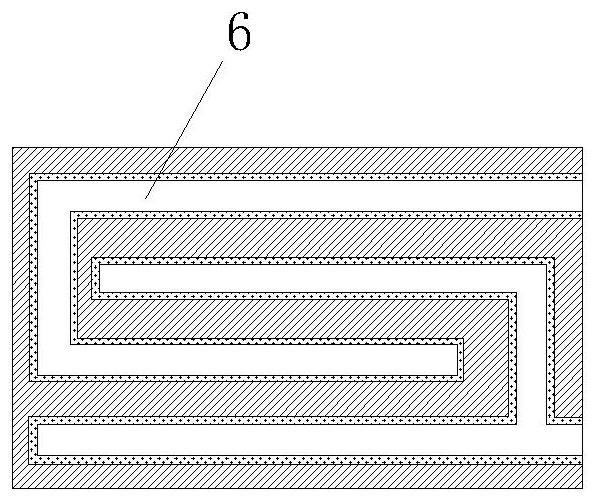

A heating film with graphene-based hot-pressed copper sheet structure and preparation method thereof

ActiveCN109362131BImproves UV resistanceExtended service lifeOhmic-resistance electrodesHeating element materialsTurpentineSodium sulfate

The invention discloses a heating film with a graphene-based hot-pressed copper sheet structure and a preparation method thereof. The heating film includes a first insulating layer, a heating layer located on the first insulating layer, an electrode layer located on the heating layer, The protective layer positioned on the electrode layer, the second insulating layer positioned on the protective layer; the heat generating layer is a graphene layer, and the electrode layer is two electrode copper strips fixed on the heat generating layer by hot pressing, so Described graphene layer is made of following raw materials by weight, graphene 24-34, carbon black 6-8, polyol ester 2-5, bamboo charcoal powder 1-2, polydimethylsiloxane 1-3, turpentine 12‑18, Sodium Lauryl Sulfate 1‑3. The graphene heating film of the invention is resistant to aging and rubbing, and has a simple and easy manufacturing method.

Owner:安徽希飞科技有限公司

Trampoline mesh surface and preparation method thereof

ActiveCN106267685AGood coating effectImprove bindingSpring boardsTrampolinesStructural engineeringProtection layer

The invention discloses a trampoline mesh surface which comprises cords. The cords comprise the first cords arranged in the X direction and the second cords arranged in the Y direction. The first cords have an arrangement mode A and an arrangement mode B, the second cords have an arrangement mode C and an arrangement mode D, and the surfaces of the cords are coated with protective layers. The trampoline mesh surface is prepared through the following steps that 1, the first cords are pulled in the X direction firstly to form a first mesh surface; 2, the second cords in the Y direction are threaded through a shuttle, and a second mesh surface is formed; 3, the surface mesh surface is coated with the protective layers, and the trampoline mesh surface is formed. The cord components are improved, the protective layers which have good binding performance with the cords and good anti-ultraviolet and anti-aging effects are used in cooperation, and the anti-aging effect and use firmness of the trampoline mesh surface are improved; a preparation method assists in improvement of the materials and the structure, the anti-aging effect of the protective layers and the strength of the mesh surfaces are guaranteed, and the machining difficulty is low.

Owner:浙江金耐斯体育用品有限公司

The special material for high-density and high-strength polyethylene optical cable sheath is produced by utilizing waste polyethylene plastic

The invention relates to a special material for a high-density high-strength polyethylene optical cable sheath, and the material is prepared from the following main components in parts by weight: 70-80 parts of waste plastic of which the polyethylene purity is more than or equal to 95%, 10-20 parts of refined high-density master batch, 1-9 parts of carbon black master batch, 1-1.5 parts of a compatilizer, 0.5-0.9 part of a lubricant, 0.1-0.6 part of an antioxidant, 6.5-8.5 parts of a filler, 0.9-1.1 parts of an auxiliary antioxidant, 0.9-1.1 parts of a coupling agent, and 0.03-0.04 part of a dispersing agent. The polyethylene optical cable sheath prepared by the preparation method disclosed by the invention has high strength, high wear resistance and high voltage resistance, cracking resistance and aging resistance of an optical cable are ensured, and the polyethylene optical cable sheath can replace imported similar materials and brand-new high-density ethylene optical cable sheath materials.

Owner:HUANGMEI KEPUDA INDAL

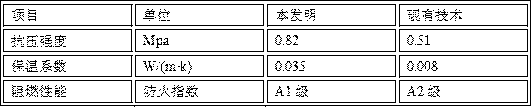

High strength core material used for VIP thermal insulation boards

InactiveCN108165037AImprove insulation effectEasy to fillClimate change adaptationInsulation improvementThermal insulationMechanical property

The invention discloses a high strength core material used for VIP thermal insulation boards. The high strength core material comprises, by weight, 5 to 10 parts of phenolic resin, 10 to 20 parts of oxidized starch, 6 to 12 parts of methyl vinyl phenyl polysiloxane rubber, 6 to 12 parts of polyurethane, 35 to 55 parts of straw filament, 10 to 16 parts of corn protein fiber, 25 to 45 parts of asbestos compound, 6 to 18 parts of diatomite, 10 to 20 parts of calcined kaolin, 10 to 20 parts of nanometer bentonite, 5 to 10 parts of active calcium oxide, 2 to 4 parts of an anti-light oxidant, 1 to 3parts of silane coupling agent, 0.4 to 0.9 part of cation polyacrylamide, and 0.6 to 1.2 parts of disodium dihydro dihydroanthracene. The high strength core material used for VIP thermal insulation boards is extremely excellent in compact resistance and mechanical properties; fracture is not easily caused by intensive impact; shrinkage is not easily caused in processing; the thermal insulation performance and the flame resistance are extremely high; and the service life is long.

Owner:安徽宇力环保科技有限公司

High-roughness wallpaper

InactiveCN109898368AGuaranteed anti-aging propertiesExtended service lifeSpecial paperPaper/cardboardCalcium carbonatePolylactic acid

The invention provides high-roughness wallpaper. The high-roughness wallpaper is prepared from the following components in parts by weight: 11-17 parts of meyer sedge fibers, 23-34 parts of polyamidefibers, 6-11 parts of antioxidants, 2-7 parts of compatilizers, 0.8-3.4 parts of fire retardants, 26-43 parts of alfalfa fibers, 22-35 parts of calcium carbonate, 6-13 parts of polyactic acid fibers and 36-49 parts of glutinous rice paste, wherein the soluble solid content of the glutinous rice paste is 45%-55%; the monofilament diameter of the polyactic acid fibers is 0.1-0.3 mm; and the monofilament length of the polyactic acid fibers is 22-34 mm. According to the high-roughness wallpaper, functionalization is integrated into the wallpaper, so that the requirements on the application and development of the wallpaper in modern home are met.

Owner:姚景城

Anti-aging painting and calligraphy carrier material

InactiveCN108385431AImprove lubricityGood ink absorptionOrganic non-cellulose fibresNon-macromolecular organic additionAlkali freeAntioxidant

The invention provides an anti-aging painting and calligraphy carrier material, which comprises, by weight, 13-22 parts of Pteroceltis tatarinowii bark fiber, 23-34 parts of Shatian straw fiber, 8-15parts of an antioxidant, 3-9 parts of a compatibilizer, 1.4-2.9 parts of a flame retardant, 12-28 parts of bagasse fiber, 8-13 parts of bamboo fiber, 19-32 parts of soybean protein fiber, 9-17 parts of alkali-free low-floating short glass fiber, and 45-58 parts of rice slurry, wherein the soluble solid content of the rice slurry is 52-68%, and the alkali-free low-floating short glass fiber has themonofilament diameter of 9-17 [mu]m and the monofilament length of 5-12 mm. According to the present invention, the partial traditional Xuan paper raw material is replaced by combining the plant fiber and the organic fiber, such that the cost is saved, the pulping effect is good, and the service life and the fire retarding performance of the Xuan paper are improved.

Owner:谷文

Aging-resistant wallpaper

InactiveCN107956184AImprove fire and flame retardant performanceMeet application requirementsSpecial paperNon-macromolecular organic additionFiberEpoxy

The invention provides an aging-resistant wallpaper, comprising the following components in parts by weight: mulberry fiber 13-22, shatian straw fiber 23-34, antioxidant 8-15, compatibilizer 3-9, and flame retardant 1.4- 2.9, epoxy resin powder 18-31, glass fiber 14-25, polylactic acid fiber 6-13, rice slurry 45-58; the soluble solid content of the rice slurry is 52%-68%; The monofilament diameter of the lactic acid fiber is 0.3-0.6 mm, and the monofilament length of the polylactic acid fiber is 22-35 mm. The present invention integrates the functionality into the wallpaper, which meets the requirements of the application and development of the wallpaper in modern households.

Owner:姚景城

Fireproof anti-flaming wallpaper

InactiveCN108018737AGuaranteed anti-aging propertiesExtended service lifeInorganic fibres/flakesCovering/liningsBasaltFire retardant

The invention provides a fireproof anti-flaming wallpaper. The wallpaper is prepared from, by weight, 11-17 parts of polyvinyl acetate powder, 23-34 parts of l-lactic acid-caprolactone nanofiber, 6-11parts of antioxidant, 2-7 parts of compatilizer, 0.8-3.4 parts of fire retardant, 15-24 parts of reed fiber, 23-39 parts of corn fibers, 14-29 parts of basalt fiber and 57-169 parts of Chinese yam pulp. The content of soluble solids in the Chinese yam pulp is 39-48%; the monofilament diameter of the basalt fibers is 0.25-0.45 micrometer, and the monofilament length of the basalt fibers is 6-12 mm. Functionalization is blended into the wallpaper, and the wallpaper is in accordance with the requirements for application and development of modern home decoration.

Owner:姚景城

High-temperature resistant wallpaper

InactiveCN107988848AGuaranteed anti-aging propertiesExtended service lifeSpecial paperPaper/cardboardPolylactic acidWheat bran fiber

The invention provides high-temperature resistant wallpaper which comprises the following components in parts by weight: 11-17 parts of mudar fiber, 23-34 parts of a mulberry bark fiber, 6-11 parts ofan antioxidant, 2-7 parts of a compatilizer, 0.8-3.4 parts of a flame retardant, 35-52 parts of a wheat bran fiber, 19-31 parts of acrylic acid resin powder, 6-13 parts of a polylactic acid fiber and52-69 parts of Chinese yam pulp, wherein the content of soluble solids of the Chinese yam pulp is 39-48%; the filament diameter of the polylactic acid fiber is 0.1-0.3mm; the filament length of the polylactic acid fiber is 22-34mm. Functional components are combined with wallpaper, so that application and development requirements of wallpaper in modern home decoration can be met.

Owner:姚景城

Powerful anti-aging coating for shell of electric control cabinet and preparation method of powerful anti-aging coating

InactiveCN110343442AImprove performanceImprove anti-aging propertiesFireproof paintsEpoxy resin coatingsCross-linkXylylene

The invention provides a powerful anti-aging coating for a shell of an electric control cabinet and a preparation method of the powerful anti-aging coating, and relates to the technical field of electric control cabinet production. The anti-aging coating is prepared from the following raw materials in parts by weight: 45-55 parts of novolac epoxy, 2-3 parts of nano-tungsten trioxide, 0.8-1.2 partsof a cross-linking agent, 10-15 parts of vinylite, 5-10 parts of polymethyl acrylate, 15-20 parts of an organic solvent, 8-12 parts of 2,6-di-tert-butylphenol, 4-6 parts of N-phenyl-alpha-naphthylamine, 6-10 parts of distearyl pentaerythrityl diphosphite, 3-5 parts of bi-salicylidene diamine, 6-8 parts of poly-p-xylylene, 4-6 parts of polydimethylsiloxane, 2-4 parts of nano-silica, 3-5 parts of clays and 2-4 parts of a thickener. According to the powerful anti-aging coating for the shell of the electric control cabinet and the preparation method of the powerful anti-aging coating, the shortcomings of the prior art are overcome, the anti-aging performance of the coating can be effectively improved, heat resistance of the coating can further be effectively improved, the coating is preventedfrom aging under the action of external light, heat and oxygen and then thawing, powdering, falling off and the like, the overall performance of the coating is excellent, the protection effect is good, the service life is long, and the powerful anti-aging coating is suitable for promotion.

Owner:ANHUI LANRUN AUTOMATION INSTR

Modification material for cathode electrophoretic paint color paste, color paste and preparation method

InactiveCN107057526AHigh purityHigh glossPaints for electrolytic applicationsEpoxy resin coatingsWeather resistanceElectrophoresis

The invention provides a modification material for cathode electrophoretic paint color paste, color paste and a preparation method. The modification material comprises epoxy grinding resin, wet-method mica powder, a cosolvent and water. The cathode electrophoretic paint color paste comprises base color paste, the modification material and water. The base color paste comprises epoxy type grinding resin, titanium dioxide, carbon black, kaolin, a dispersing auxiliary, a base materai moistening agent and deionized water; the modification material comprises epoxy type grinding resin, wet-method mica powder, the cosolvent and water; the base color paste and the modification material are blended according to a ratio, and the preparation method is simple. Compared with the prior art that the electrophoretic paint is poor in weather resistance and has the phenomenon of powdering, the modification material for the cathode electrophoretic paint color paste, the color paste and the preparation method, which are provided by the invention, are capable of effectively improving the anti-aging property of an electrophoretic paint membrane.

Owner:湖北同邦达科技有限公司

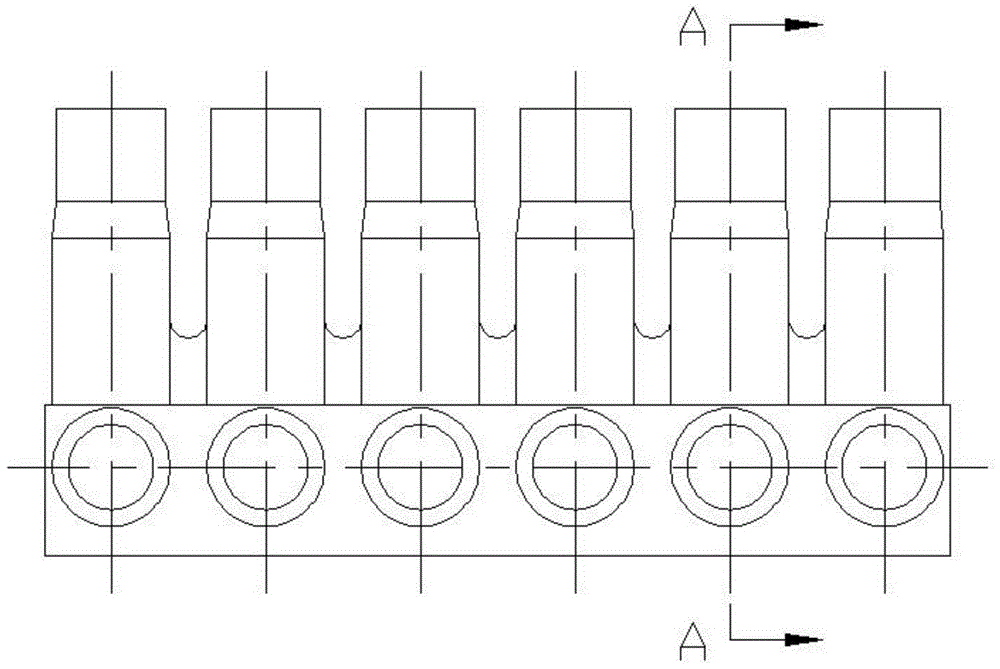

Low-voltage cable distribution joints and low-voltage cable distribution boxes

ActiveCN104332938BGuaranteed insulation recoveryGuaranteed insulation performanceCable junctionsLow voltageEngineering

The invention discloses a low-voltage cable branching connector and a low-voltage cable distribution box. The low-voltage cable branching connector is characterized in that annular tooth grooves are machined inside vertical side pipeline openings and horizontal side pipeline openings of right-angle pipelines inside a connector body cover; right-angle portions of the right-angle pipelines are communicated through a connector body; two adjacent surface positions of the connector body, which are opposite to vertical side pipelines and horizontal side pipelines, are provided with circular holes; every two circular holes are communicated; internal threads are machined on the circular holes which are corresponding to horizontal pipelines; middle sleeves are arranged inside the vertical side pipeline openings of the connector body cover; the annular tooth grooves are formed inside the middle sleeves and cables are inserted inside the annular tooth grooves; ends of the cables are inserted into the connector body circular holes which are corresponding to the vertical side pipelines and are compressed through cable pressing nuts. The low-voltage cable distribution box is characterized in that the above four rows of low-voltage cable branching connectors are installed on trapezoid folding plates of a box body base plate. The low-voltage cable branching connector and the low-voltage cable distribution box can safely and efficiently achieve load distribution.

Owner:HUNAN HAOSHENG ELECTROMECHANICAL EQUIP

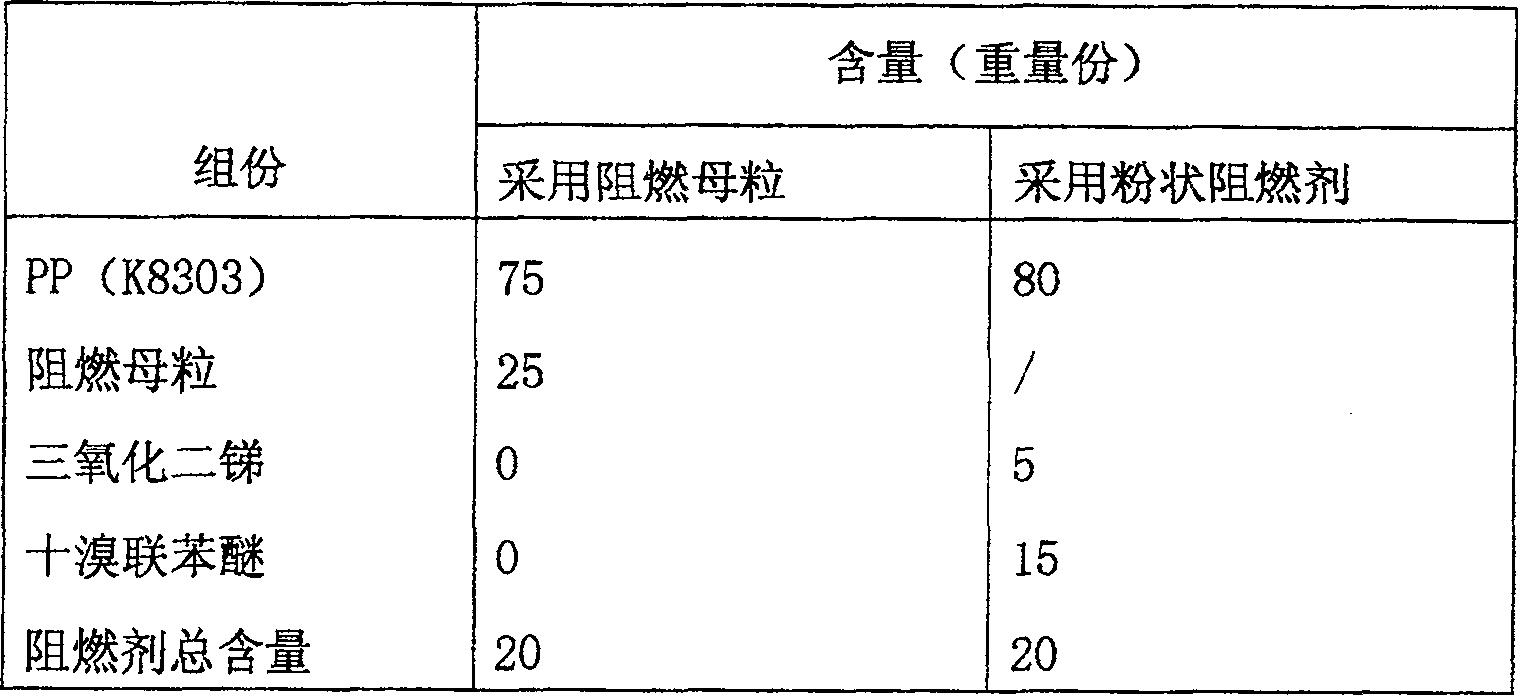

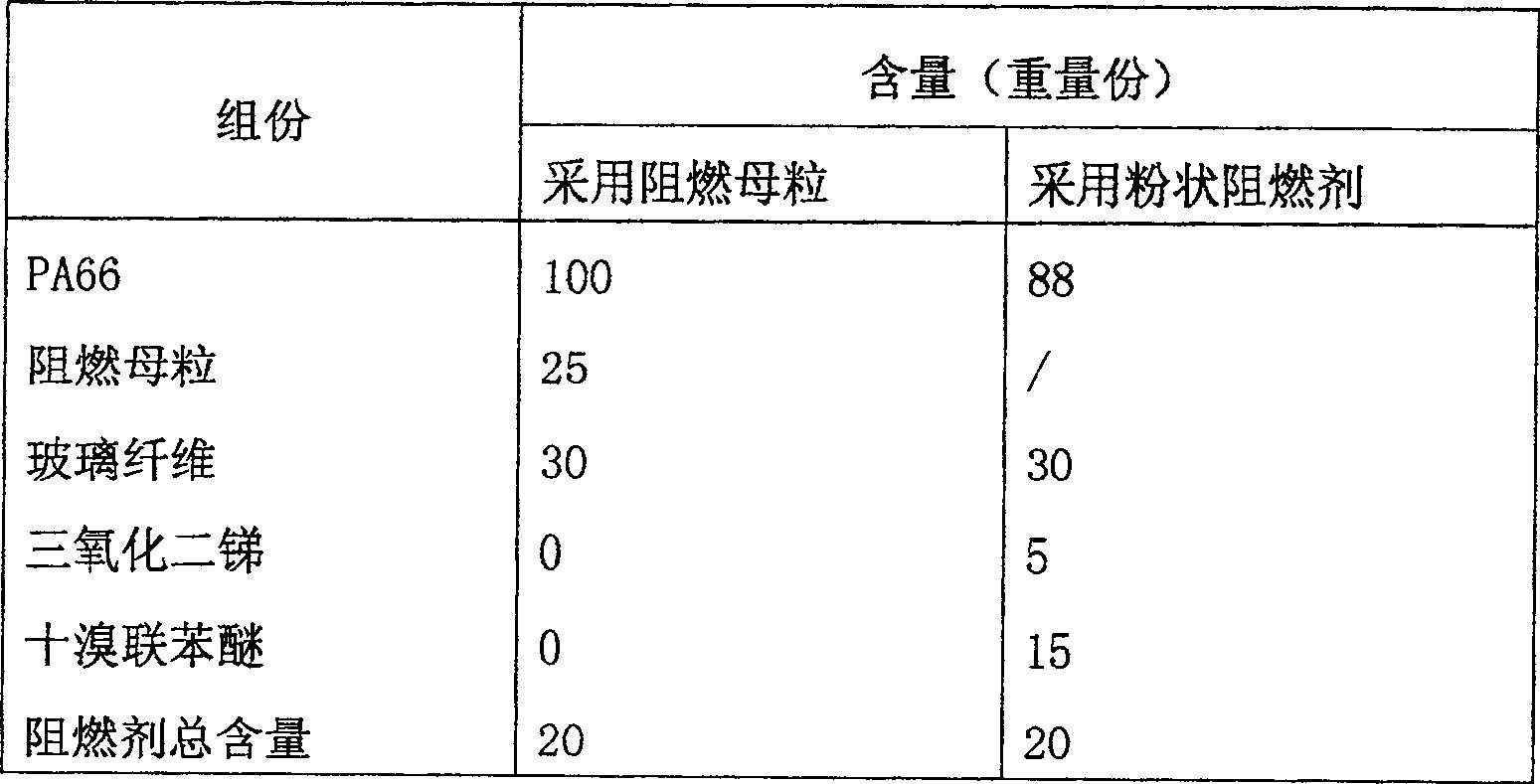

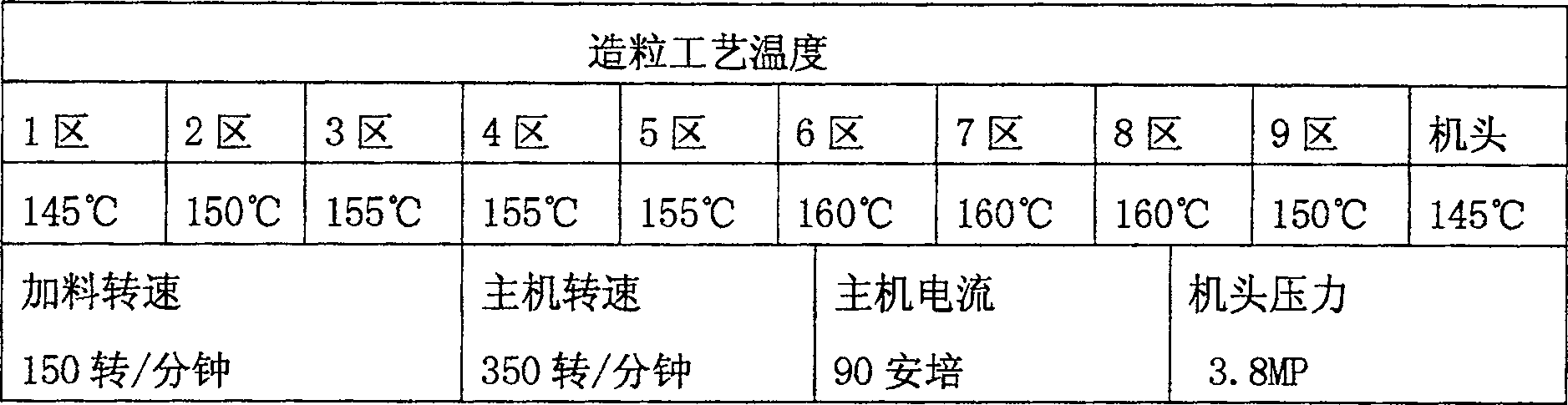

High concentration plastic nano flame-proof agglomerate production method

InactiveCN100494266CGood dispersionImprove flame retardant performanceFireproof paintsHigh concentrationEngineering plastic

The invention relates to a process for producing high concentration plastic nanometer flame-proof agglomerates, which comprises carrying out powdery combustion inhibitor surface modification, high speed kneading, mixing homogeneously, activation processing. According to the disclosed process, nanometer magnesium hydroxide is employed to charge silicane coupling agent A-174%, surface active dispersing agent KO-311 are charged into anhydrous alcohol for homogeneous dilution, finally spraying into homogenizer using high pressure mist.

Owner:李彦波

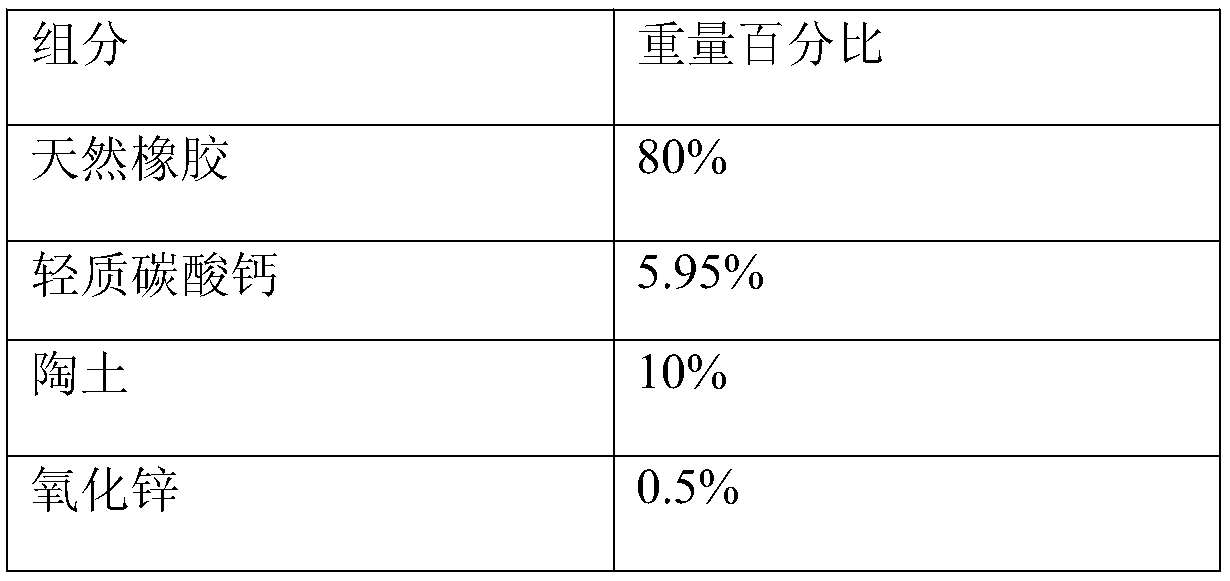

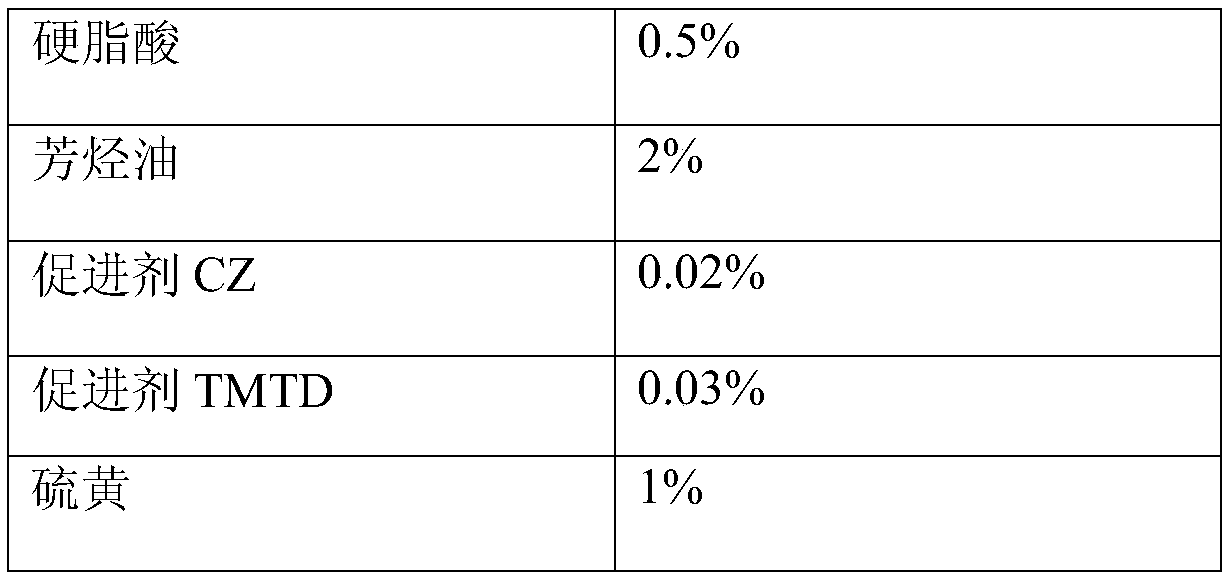

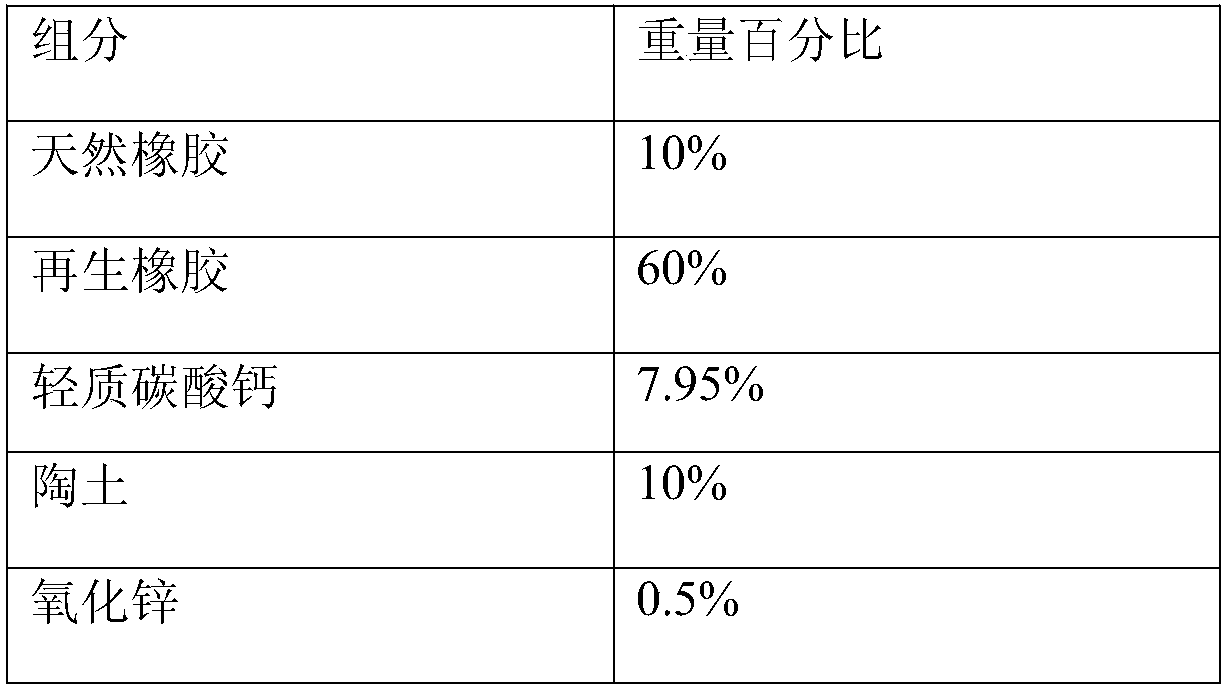

Flexible rubber covering member for steel rail waist and preparation method thereof

InactiveCN109280235AStrong vibration dampingImprove anti-agingRubber insulatorsEngineeringNoise reduction

The invention relates to a flexible rubber covering member for a steel rail waist and a preparation method thereof. The flexible rubber covering member comprises, by weight, 1 to 10% of natural rubber, 60 to 75% of reclaimed rubber, 15 to 28% of a filling material, 0.5 to 5% of an activator, 0.5 to 5% of a softener, 0.02 to 0.1% of a promoter and 0.5 to 4% of a vulcanizing agent. The rubber covering member manufactured in the invention has better physical properties and substantial vibration damping and noise reduction effect, and is simple in formula and low in cost.

Owner:四川川鼎轨道技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com