High-temperature resistant wallpaper

A technology of high temperature resistance and wallpaper, applied in the field of decorative materials, can solve the problems of lack of comprehensive performance and single decoration of wallpaper, and achieve the effects of good high temperature resistance, anti-aging performance and simple formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

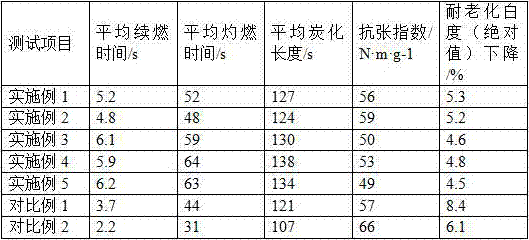

Examples

Embodiment 1

[0014] A high-temperature-resistant wallpaper, characterized in that it comprises the following components in parts by weight: horn melon fiber 11, mulberry fiber 23, antioxidant 6, compatibilizer 2, flame retardant 0.8, wheat bran fiber 35, acrylic tree Ester powder 19, polylactic acid fiber 6, yam slurry 52; the soluble solids content of the yam slurry is 39%; the monofilament diameter of the polylactic acid fiber is 0.1mm, and the monofilament length of the polylactic acid fiber is 22mm.

[0015] The croissant melon fiber, mulberry bark fiber, wheat bran fiber, acrylic resin powder, polylactic acid fiber and yam slurry described in the present invention can all be prepared by any prior art.

[0016] Further, the compatibilizer includes the following components in parts by weight: hydroxyethyl cellulose 2, mannitol 0.2, potassium chlorate 0.03, potassium sodium tartrate 1, gelatin 4, polyvinyl alcohol 0.8; the compatibilizer can Significantly improve the compatibility betwe...

Embodiment 2

[0023] A high-temperature-resistant wallpaper, characterized in that it comprises the following components in parts by weight: horn melon fiber 17, mulberry fiber 34, antioxidant 11, compatibilizer 7, flame retardant 3.4, wheat bran fiber 52, acrylic tree Ester powder 31, polylactic acid fiber 13, yam slurry 69; the soluble solids content of the yam slurry is 39%-48%; the monofilament diameter of the polylactic acid fiber is 0.3mm, and the polylactic acid fiber The monofilament length is 34mm.

[0024] The croissant melon fiber, mulberry bark fiber, wheat bran fiber, acrylic resin powder, polylactic acid fiber and yam slurry described in the present invention can all be prepared by any prior art.

[0025] Further, the compatibilizer includes the following components in parts by weight: hydroxyethyl cellulose 6, mannitol 0.7, potassium chlorate 0.09, potassium sodium tartrate 6, gelatin 11, polyvinyl alcohol 2.2; the compatibilizer can Significantly improve the compatibility b...

Embodiment 3

[0030] A high temperature resistant wallpaper, characterized in that it comprises the following components in parts by weight: 14 horn melon fibers, 29 mulberry fibers, 9 antioxidants, 4.5 compatibilizers, 2.1 flame retardants, 44 wheat bran fibers, acrylic tree Ester powder 25, polylactic acid fiber 10, yam slurry 60; the soluble solids content of the yam slurry is 44%; the monofilament diameter of the polylactic acid fiber is 0.2mm, and the monofilament length of the polylactic acid fiber is 28mm.

[0031] The croissant melon fiber, mulberry bark fiber, wheat bran fiber, acrylic resin powder, polylactic acid fiber and yam slurry described in the present invention can all be prepared by any prior art.

[0032] Further, the compatibilizer includes the following components in parts by weight: hydroxyethyl cellulose 4, mannitol 0.45, potassium chlorate 0.06, potassium sodium tartrate 3.5, gelatin 7.5, polyvinyl alcohol 1.5; the compatibilizer can Significantly improve the compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Monofilament length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com