High concentration plastic nano flame-proof agglomerate production method

A nano flame retardant and production method technology, applied in the direction of fire retardant coatings, can solve the problems of large decline in mechanical properties, large decline in material properties, general flame retardant effect, etc., and achieve the effects of low cost, improved material performance, and convenient procurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

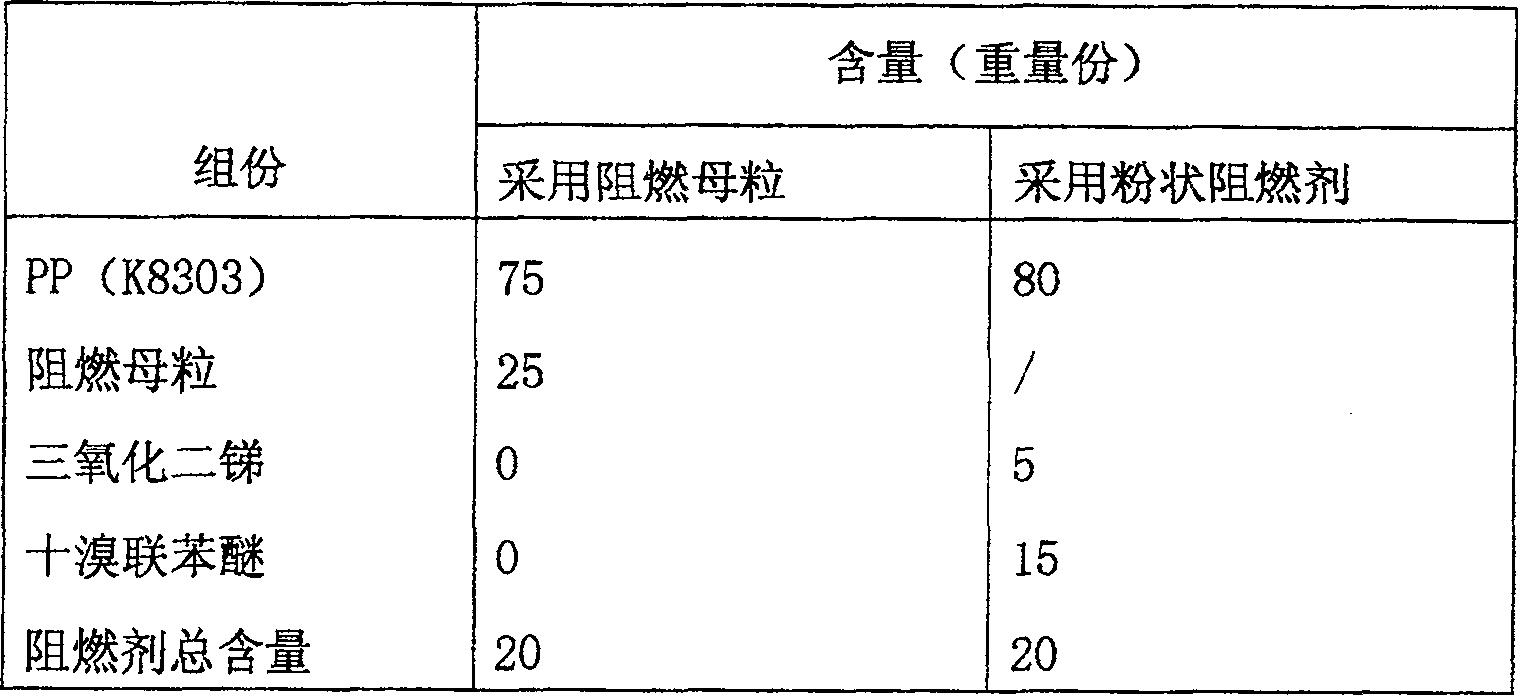

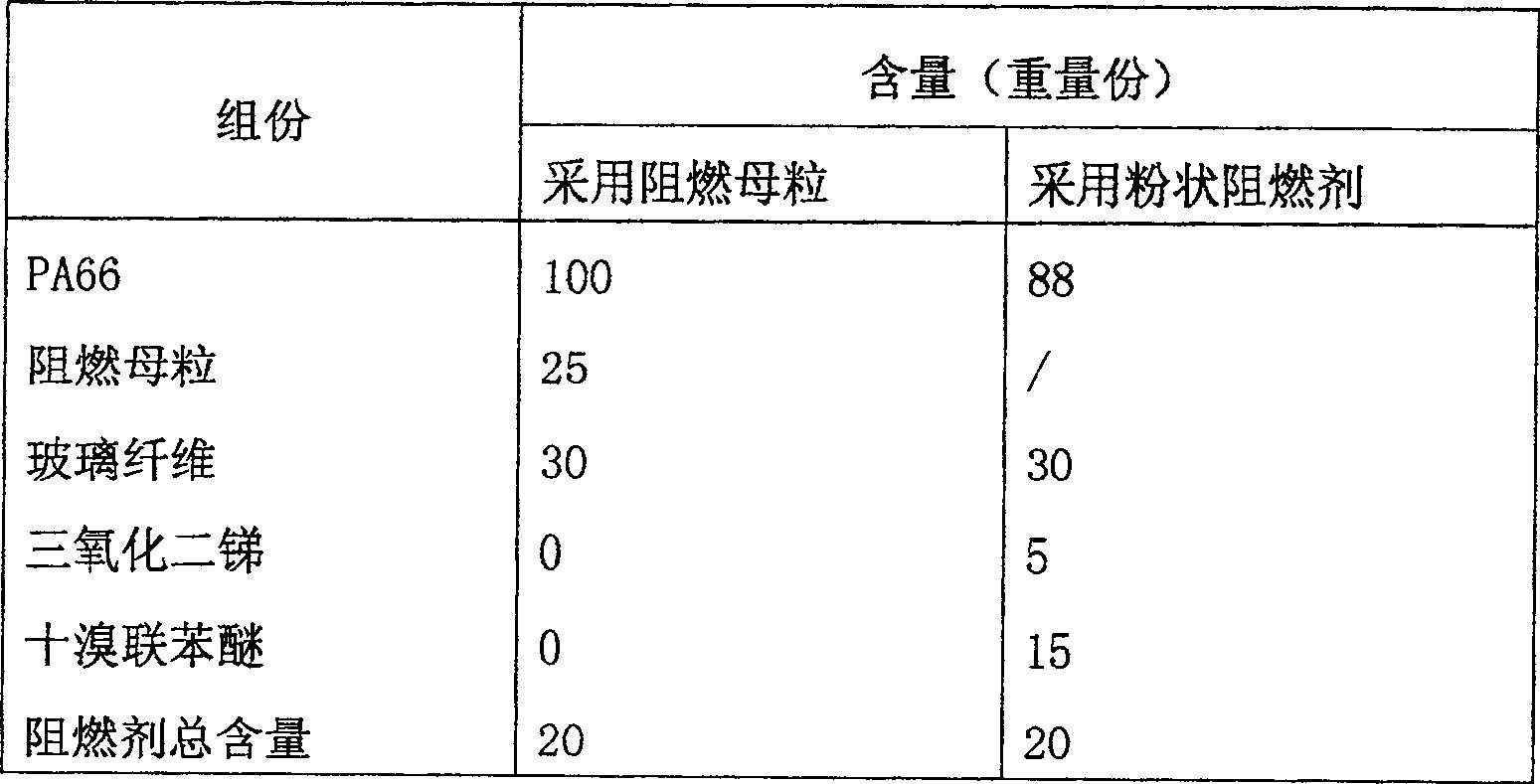

[0044] Embodiment 1: one, adopt the parts by weight ratio component described in the following table

[0045] Component Content (parts by weight) Antimony trioxide 25 Decabromodiphenyl ether 50 Nano Magnesium Hydroxide 10 EVA(VA18-MI3) 18 Antioxidant B-215 0.25 polyethylene wax 1.4

[0046] Coupling agent KH550 0.6 Silane coupling agent A-174

Surface active dispersant KO-311

Thinner ethanol 0.40

0.35

1.5

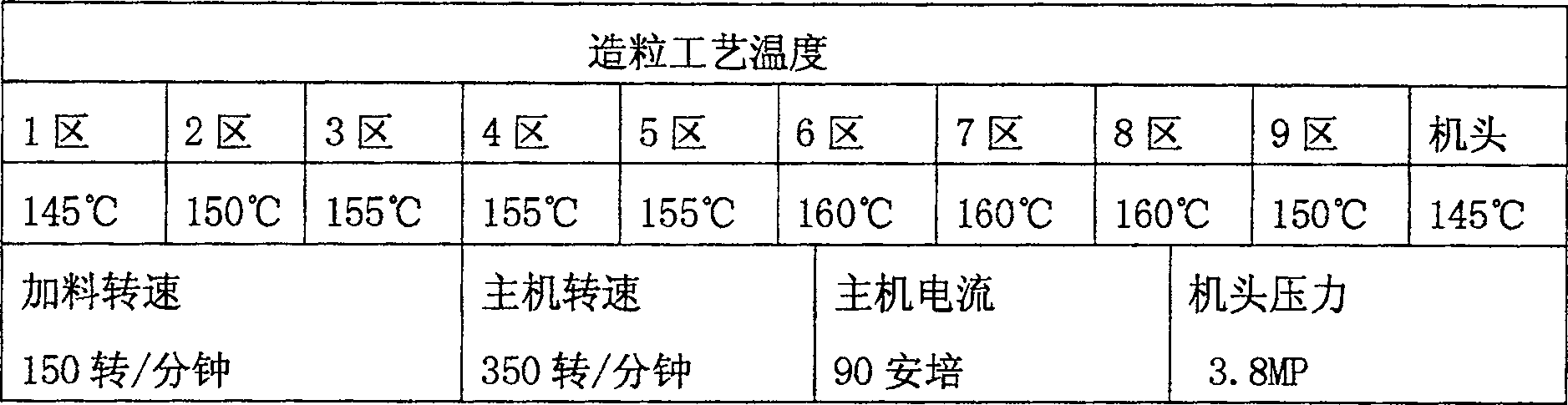

[0047] 2. Production method:

[0048] 1. Surface modification of powdered flame retardants;

[0049] After weighing antimony trioxide and decabromodiphenyl ether flame retardants, put them into a high-speed mixer (speed: 2500 rpm), and start high-speed stirring and mixing for 7 minutes. Put in the coupling agent KH550, mix for 3.5 minutes, put the surface coupling activated material into the low-speed stirring tank (speed: 140 rpm), and keep stirring.

[0050] 2. After weighing the nano-ma...

Embodiment 2

[0057] Embodiment 2: one, adopt the parts by weight ratio component described in the following table

[0058] Component Content (parts by weight) Antimony trioxide 20 Decabromodiphenyl ether or decabromodiphenylethane 60 Nano Magnesium Hydroxide 6 EVA(VA18-MI3) 10 Antioxidant B-215 0.27 polyethylene wax 1.2 Coupling agent KH550 0.4 Silane coupling agent A-174

Surface active dispersant KO-311

Thinner ethanol 0.45

0.4

1.2

[0059] 2. Production method:

[0060] 1. Surface modification of powdered flame retardants;

[0061] After weighing antimony trioxide and decabromodiphenylethane flame retardants, put them into a high-speed mixer (speed: 3000 rpm), and start high-speed stirring and mixing for 6 minutes. Put in the coupling agent KH550, mix for 3 minutes, put the surface coupling activated material into the low-speed stirring tank (speed: 120 rpm), and keep stirring.

[0062] 2. After weighing the n...

Embodiment 3

[0068] Embodiment 3: one, adopt the parts by weight ratio component described in the following table

[0069] Component Content (parts by weight) Antimony trioxide 25 Decabromodiphenyl ether or decabromodiphenylethane 52 Nano Magnesium Hydroxide 8 LDPE 1F7B 9 Antioxidant B-215 0.3 polyethylene wax 1.5 Coupling agent KH550 0.5 Silane coupling agent A-174

Surface active dispersant KO-311

Thinner ethanol 0.5

0.45

1.4

[0070] 2. Production method:

[0071] 1. Surface modification of powdered flame retardants;

[0072] After weighing antimony trioxide and decabromodiphenyl ether flame retardants, put them into a high-speed mixer (speed: 2700 rpm), start high-speed stirring and mixing for 8 minutes. Put in the coupling agent KH550, mix for 4 minutes, put the surface coupling activated material into the low-speed stirring tank (speed: 150 rpm), and keep stirring.

[0073] 2. After weighing the nano-magnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com