Powerful anti-aging coating for shell of electric control cabinet and preparation method of powerful anti-aging coating

An anti-aging, electric control cabinet technology, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of electric control cabinet shell protection, poor anti-aging performance, short service life, etc., to prevent heat melting, Improved heat resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

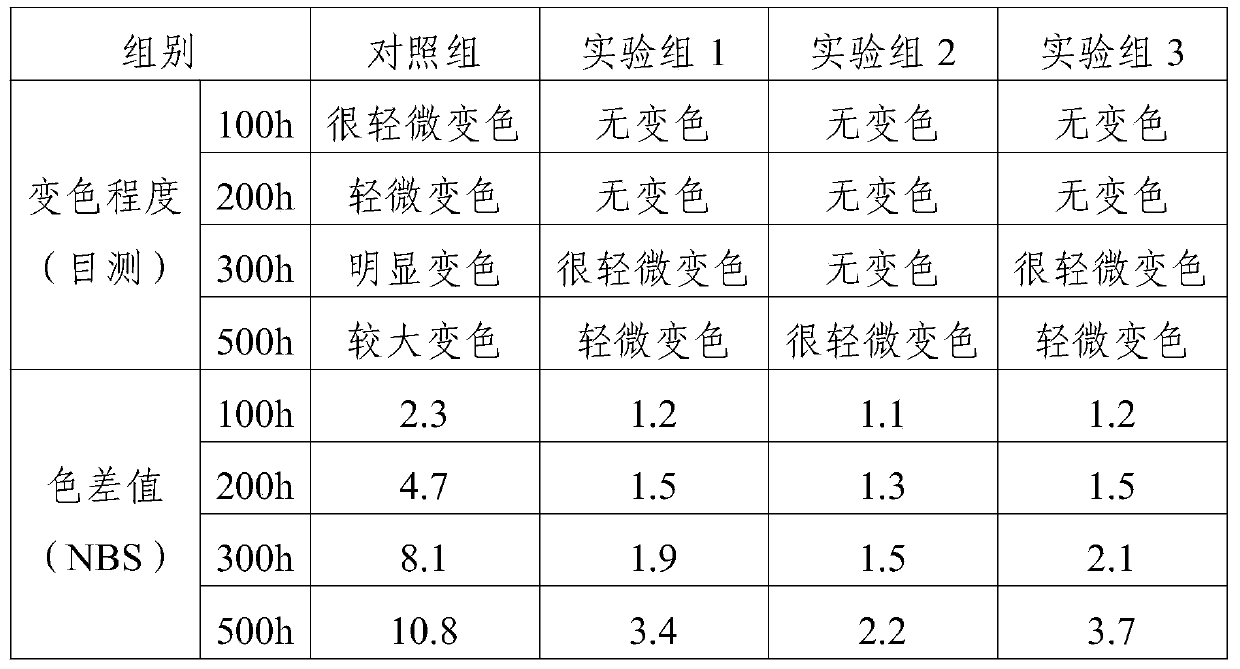

Examples

Embodiment 1

[0025] A powerful anti-aging coating for an electric control cabinet shell, the anti-aging coating is made of the following raw materials in parts by weight: 45 parts of novolac epoxy resin, 2 parts of nano-tungsten trioxide, 0.8 parts of crosslinking agent, vinyl resin 10 parts, 5 parts of polymethyl acrylate, 15 parts of organic solvent, 8 parts of 2,6-di-tert-butylphenol, 4 parts of N-phenyl-α-naphthylamine, 6 parts of dioctadecyl pentaerythritol diphosphite, 3 parts of bis-salicylidene diamine, 6 parts of parylene, 4 parts of polydimethylsiloxane, 2 parts of nano-silica, 3 parts of clay, and 2 parts of thickener.

[0026] Wherein, the crosslinking agent is formed by mixing dicumyl peroxide and bis-2,4-dichlorobenzoyl peroxide with a mass ratio of 3:1; the organic solvent is acetone, butyl acetate, acetone One or more of triol and polyethylene glycol; the thickener is one or more of sodium bentonite, diatomaceous earth, modified polyacrylamine and hydroxypropyl methylcellul...

Embodiment 2

[0035] A powerful anti-aging coating for an electric control cabinet shell, the anti-aging coating is made of the following raw materials in parts by weight: 50 parts of novolac epoxy resin, 2.5 parts of nano-tungsten trioxide, 1.0 parts of crosslinking agent, vinyl resin 12.5 parts, 7.5 parts of polymethyl acrylate, 17.5 parts of organic solvent, 10 parts of 2,6-di-tert-butylphenol, 5 parts of N-phenyl-α-naphthylamine, 8 parts of dioctadecyl pentaerythritol diphosphite, 4 parts of bis-salicylidene diamine, 7 parts of parylene, 5 parts of polydimethylsiloxane, 3 parts of nano-silica, 4 parts of clay, and 3 parts of thickener.

[0036] Wherein, the crosslinking agent is formed by mixing dicumyl peroxide and bis-2,4-dichlorobenzoyl peroxide with a mass ratio of 3:1; the organic solvent is acetone, butyl acetate, acetone One or more of triol and polyethylene glycol; the thickener is one or more of sodium bentonite, diatomaceous earth, modified polyacrylamine and hydroxypropyl met...

Embodiment 3

[0045] A powerful anti-aging coating for an electric control cabinet shell, the anti-aging coating is made of the following raw materials in parts by weight: 55 parts of phenolic epoxy resin, 3 parts of nano-tungsten trioxide, 1.2 parts of crosslinking agent, vinyl resin 15 parts, 10 parts of polymethyl acrylate, 20 parts of organic solvent, 12 parts of 2,6-di-tert-butylphenol, 6 parts of N-phenyl-α-naphthylamine, 10 parts of dioctadecyl pentaerythritol diphosphite, 5 parts of bis-salicylidene diamine, 8 parts of parylene, 6 parts of polydimethylsiloxane, 4 parts of nano-silica, 5 parts of clay, and 4 parts of thickener.

[0046] Wherein, the crosslinking agent is formed by mixing dicumyl peroxide and bis-2,4-dichlorobenzoyl peroxide with a mass ratio of 3:1; the organic solvent is acetone, butyl acetate, acetone One or more of triol and polyethylene glycol; the thickener is one or more of sodium bentonite, diatomaceous earth, modified polyacrylamine and hydroxypropyl methylce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com