High strength core material used for VIP thermal insulation boards

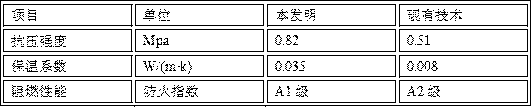

A high-strength, thermal insulation board technology, used in thermal insulation, insulation improvement, building components and other directions, can solve the problems of VIP thermal insulation board being easily damaged, the flame retardant performance can not meet the requirements, the core material is not resistant to impact, etc., to ensure anti-aging performance, excellent filling performance, the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The present invention proposes a high-strength core material for VIP insulation boards. The raw materials include: 5 parts of phenolic resin, 20 parts of oxidized starch, 6 parts of methyl vinyl phenyl silicone rubber, 12 parts of polyurethane, straw 35 parts of silk, 16 parts of zein fiber, 25 parts of asbestos compound, 18 parts of diatomite, 10 parts of calcined kaolin, 20 parts of nano bentonite, 5 parts of activated calcium oxide, 4 parts of anti-light oxidant, 1 part of silane coupling agent , 0.9 parts of cationic polyacrylamide, 0.6 parts of dihydrodihydroxyanthracene disodium salt.

Embodiment 2

[0018] The present invention proposes a high-strength core material for VIP insulation boards. The raw materials include: 10 parts of phenolic resin, 10 parts of oxidized starch, 12 parts of methyl vinyl phenyl silicone rubber, 6 parts of polyurethane, straw 55 parts of silk, 10 parts of zein fiber, 45 parts of asbestos compound, 6 parts of diatomite, 20 parts of calcined kaolin, 10 parts of nano-bentonite, 10 parts of activated calcium oxide, 2 parts of anti-light oxidant, 3 parts of silane coupling agent , 0.4 parts of cationic polyacrylamide, 1.2 parts of dihydrodihydroxyanthracene disodium salt.

[0019] The asbestos compound is prepared by the following process: mix and stir asbestos, sodium diisooctylsulfosuccinate and water, add asbestos tailings powder and continue stirring, then add sodium hydroxide and continue stirring, filter, dry, pulverize, and under nitrogen protection Add guar gum and sodium chloride and stir, then add sodium hydroxide and stir, then add ethyle...

Embodiment 3

[0021] The present invention proposes a high-strength core material for VIP insulation boards. The raw materials include: 6 parts of phenolic resin, 18 parts of oxidized starch, 8 parts of methyl vinyl phenyl silicone rubber, 10 parts of polyurethane, straw 40 parts of silk, 14 parts of zein fiber, 30 parts of asbestos compound, 14 parts of diatomite, 12 parts of calcined kaolin, 18 parts of nano-bentonite, 6 parts of activated calcium oxide, 3.5 parts of anti-light oxidant, 1.5 parts of silane coupling agent , 0.7 parts of cationic polyacrylamide, 0.8 parts of dihydrodihydroxyanthracene disodium salt.

[0022] The asbestos compound is prepared by the following process: 30 parts of asbestos, 9 parts of sodium diisooctyl sulfosuccinate, and 80 parts of water are mixed and stirred for 50 minutes by weight, and 20 parts of asbestos tailings powder are added to continue stirring for 20 minutes, and then 3 parts of Sodium hydroxide continued to stir for 40 minutes, filtered, dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com