Acrylate polymer composite waterproof system and construction method thereof

An acrylate and polymer technology, which is applied in the direction of ester copolymer adhesives, adhesive types, building structures, etc., can solve the problem of the overlapping joints and edges of the coils, the difficulty of bonding the coils and the base surface, etc. Problems such as inability to bond firmly, lap joints, and slits at the edges have been achieved to overcome functional limitations, good rigidity, and ultra-high waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

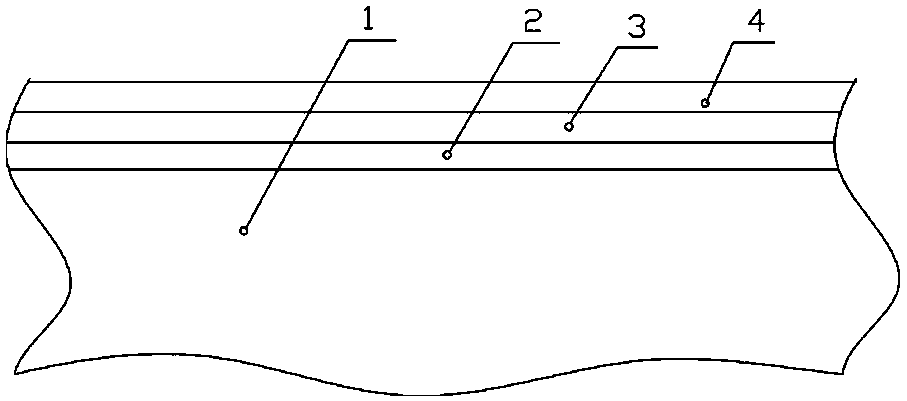

[0019] Such as figure 1 As shown, the acrylate polymer composite waterproofing system of the present invention is composed of the base adhesive layer 2 sprayed on the building base 1, the acrylate polymer waterproof coiled material 3 pasted on the base adhesive layer 2 and the waterproofing membrane 3 sprayed on the base layer 1. The protective layer 4 on the surface of the coiled material is made up, wherein the acrylate polymer waterproof coiled material 3 used in the present invention is made of polyester filament cloth as the tire base, and its two surfaces are impregnated with high molecular polymer emulsion (made of acrylate emulsion, synthetic Film agent, thickener, defoamer, antifungal agent, solid filler, etc.) and then dried to form a three-layer composite structure.

[0020] The basic adhesive layer material of the present invention is composed of 40-60 parts of acrylate emulsion, 8-15 parts of film-forming agent, 2-6 parts of thickener, 2-6 parts of anti-fungal age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com