Patents

Literature

374results about How to "Reduce on-site workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

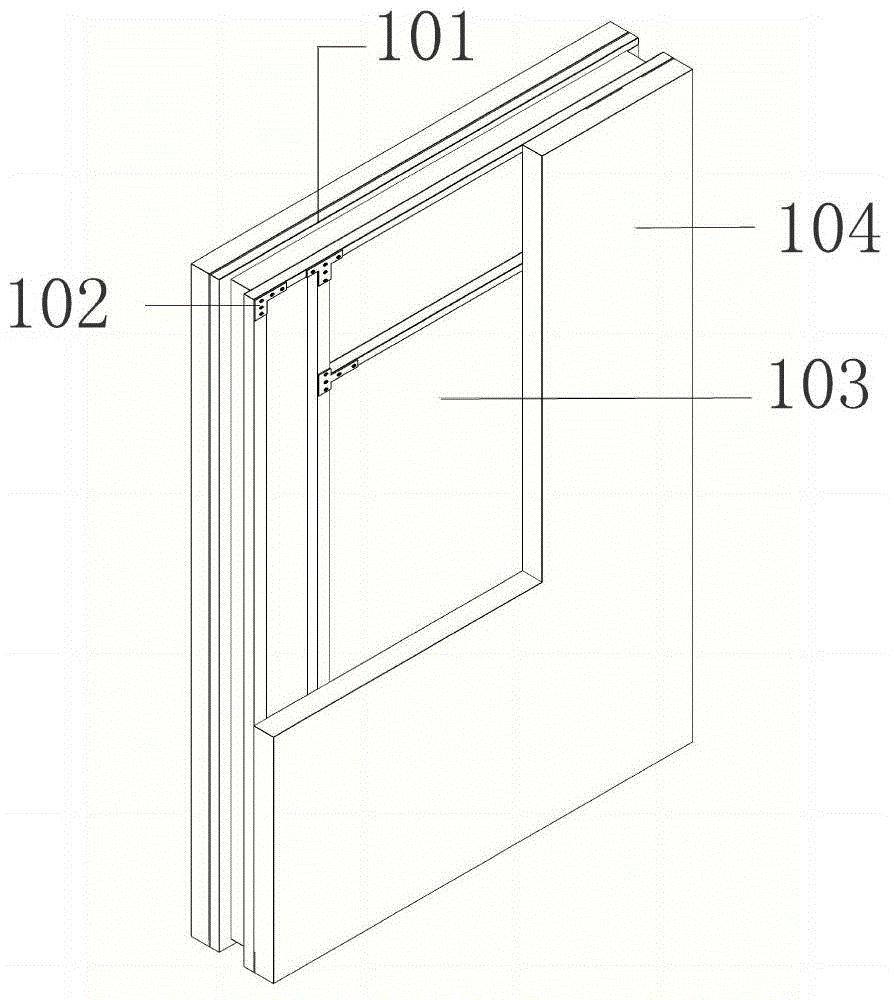

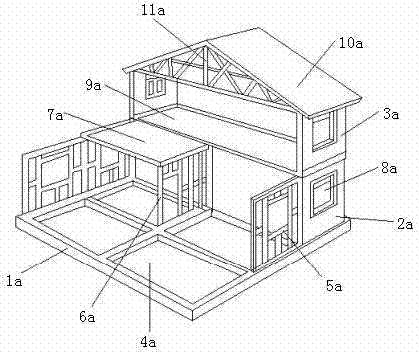

DGC modular fabricated building system and building method thereof

Provided are a DGC modular fabricated building system and a building method thereof. Wallboards are composite boards prefabricated in a factory. Light steel profiles and light steel keels are connected through self-tapping screws. The corners of the light steel profiles with grooves in frames are connected through self-tapping screws and light steel keel connecting pieces. The interiors of the wallboards are filled with heat preservation materials. Pouring layers of modified cement mortar or light aggregate concrete materials are arranged on the outermost sides of the wallboards. Floors are composite boards prefabricated in the factory, and each composite board is a foundation bottom plate or a floorboard or a roof panel of the DGC modular fabricated building system. The wallboards are connected through board connecting pieces, the wallboards and the floors are connected through board connecting pieces, and the floors are connected through board connecting pieces. The DGC modular fabricated building system is simple in structure, convenient to mount and low in cost, the construction period can be saved, and therefore the defects that an existing fabricated building is single in structure, complex in mounting process and high in manpower cost are overcome.

Owner:江苏保力装配式住宅工业有限公司

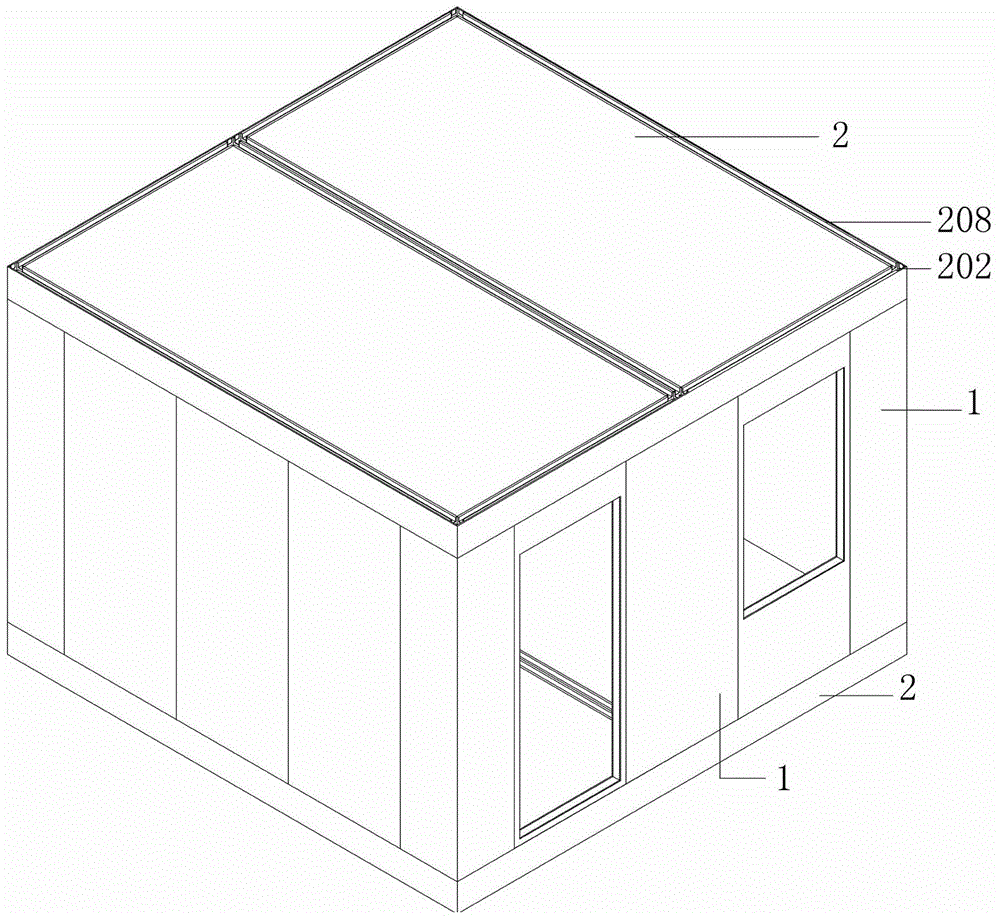

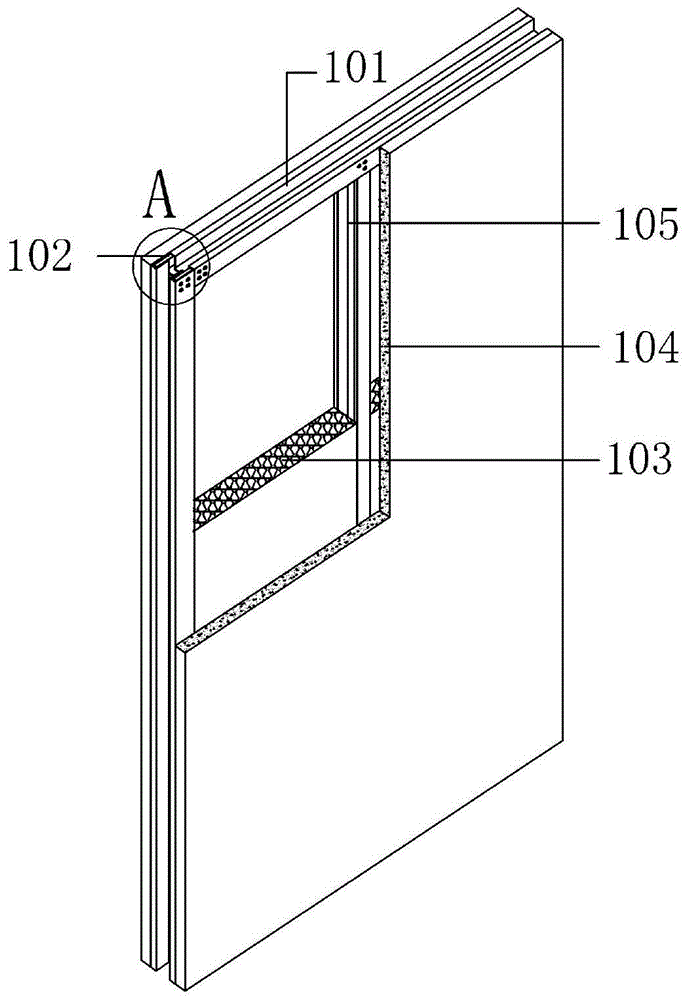

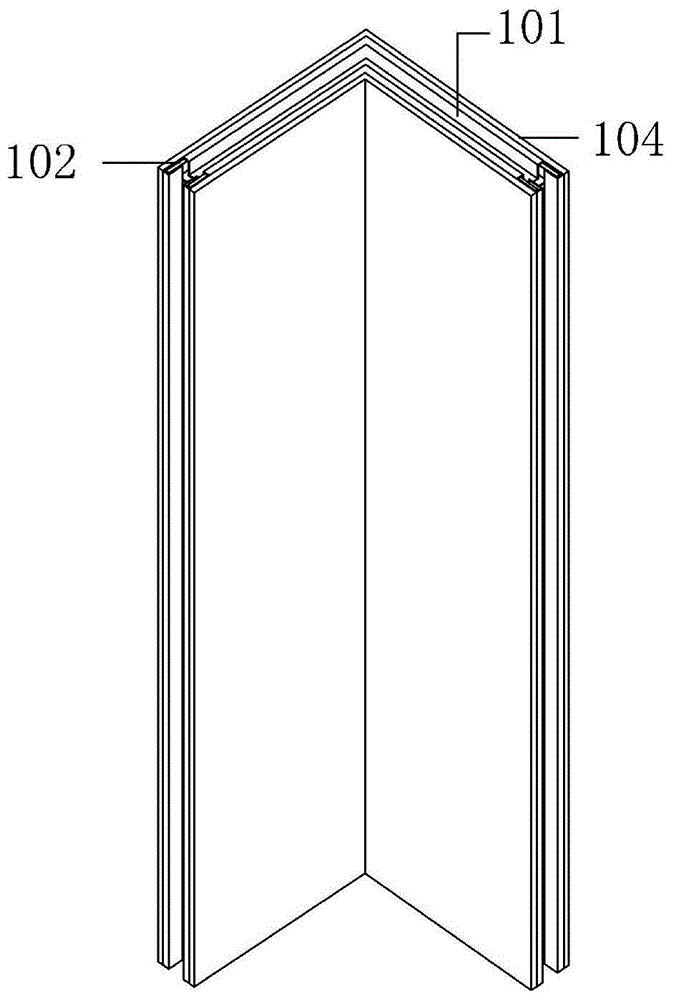

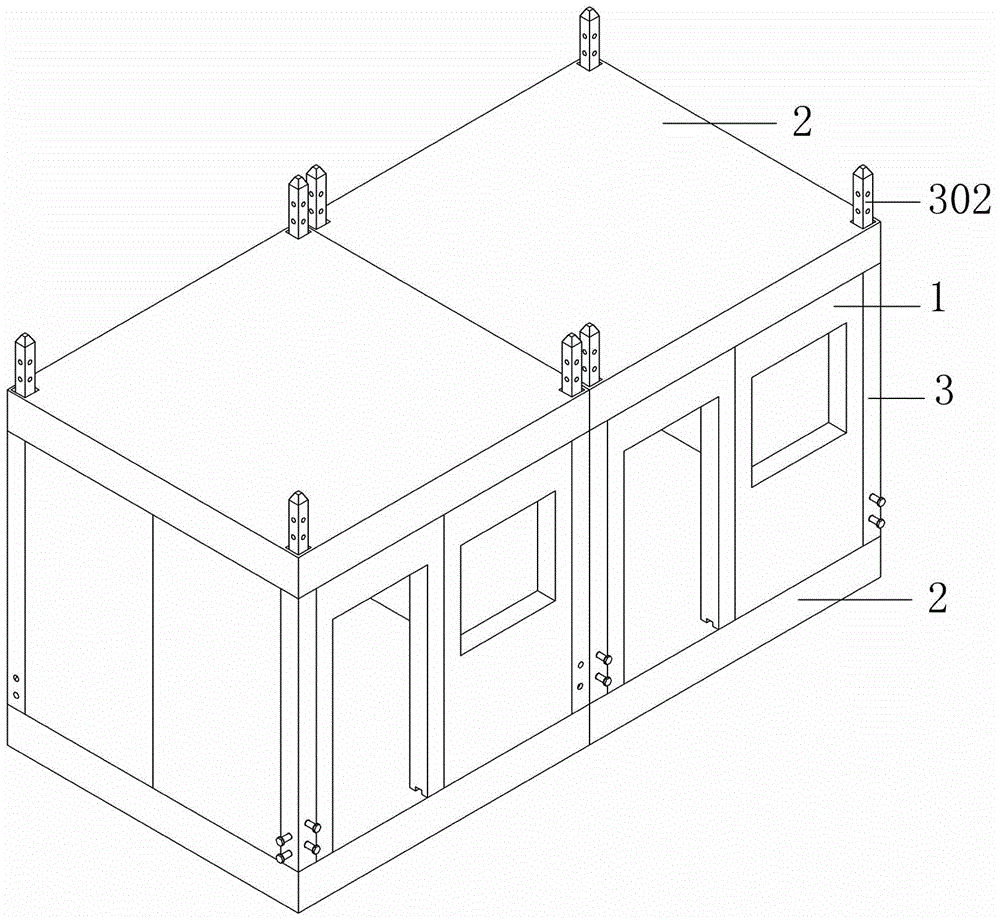

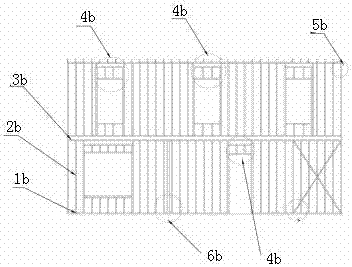

Simply-built green light steel fabricated building and installation method

ActiveCN104947792AImprove prefabrication rateEnsure structural safetyBuilding componentsBuilding material handlingPollutionPrefabrication

The invention provides a simply-built green light steel fabricated building and an installation method. The fabricated building comprises wall plates, main plates, composite frame columns and main connection pieces. The two wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. The composite frame columns and the wall plates are connected by means of the corresponding main connection pieces through self-tapping screws. In the connection process, firstly the main connection pieces abut against the composite frame columns, the self-tapping screws are screwed into the composite frame columns to fix the composite frame columns, the wall plates are then arranged in place, and the main connection pieces are clamped into lateral side grooves of the wall plates. The main boards are connected with the composite frame columns, and body column sleeves of the portions, on the top layers of the main plates, of the composite frame columns are inserted in upwards-exposed tenon columns in a sleeved mode and are then fixed through bolts. By means of the full industrialized prefabrication of the wall plates and the main plates, the prefabrication rate of main components of the building is greatly increased, and therefore the structure safety and quality of the building are better facilitated, site workloads are reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

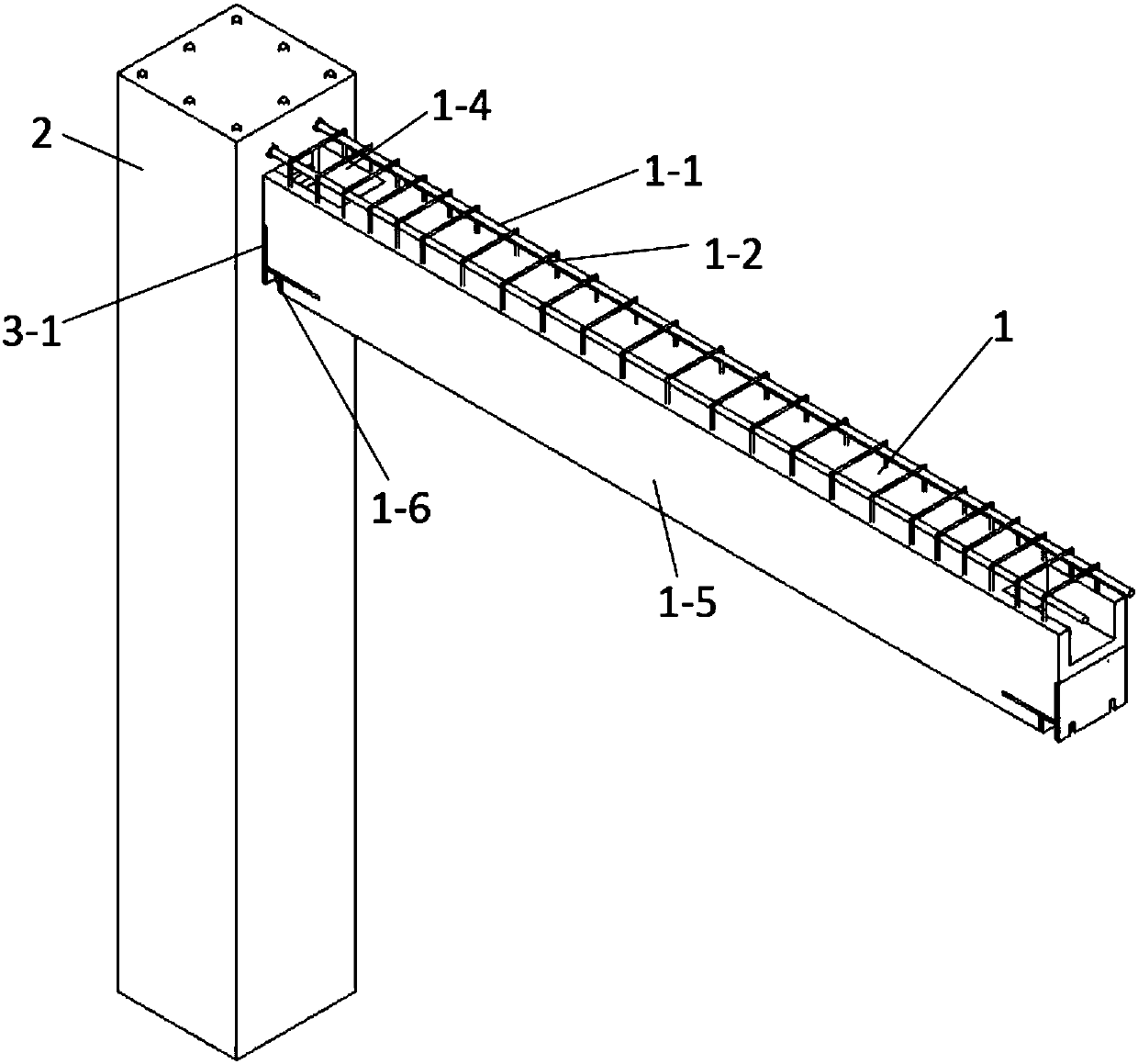

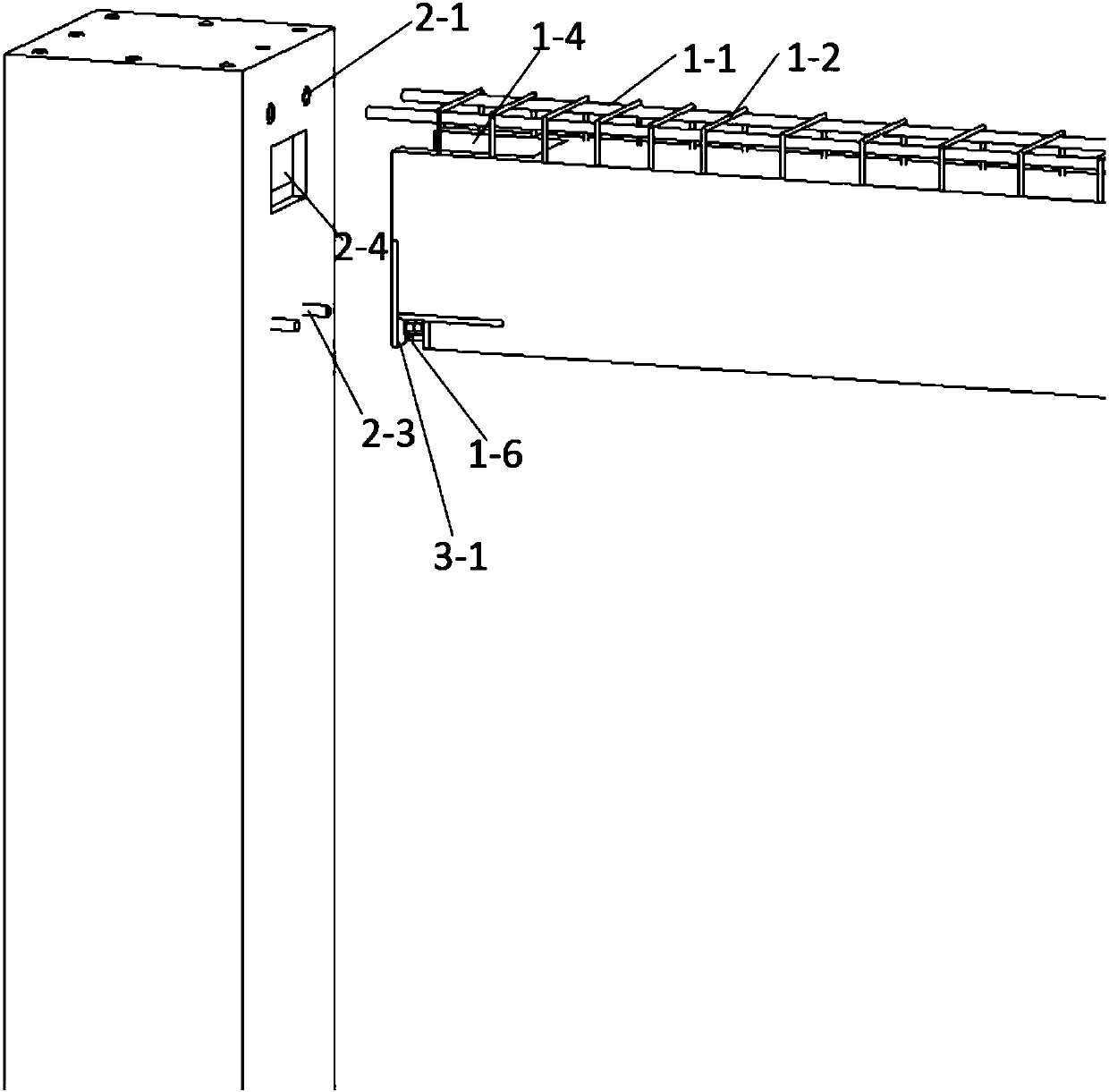

Prefabricated concrete frame beam-column joint construction method

The invention discloses a prefabricated concrete frame beam-column joint construction method, and relates to connection of a prefabricated column and a superposed beam. High-strength bolt bars and threaded sleeves are pre-buried in the column side of the prefabricated column, and a column side key groove is pre-formed; a beam end key groove is pre-formed in the beam end of a prefabricated beam, and a connection plate is pre-buried; the construction method adopts the following steps that (1), mounting of the prefabricated column is completed; (2) the prefabricated beam is mounted from top to bottom, so that the high-strength bolt rods penetrate through bolt connection holes; (3), upper longitudinal ribs of the superposed beam are mounted, firstly connection of the upper longitudinal ribs ofthe superposed beam and the threaded sleeves is completed, and then tying of the upper longitudinal ribs of the superposed beam and stirrups of the superposed beam is completed; (4) a washer and a lock nut are connected to each high-strength bolt rod to form pretightening force; and (5), templates are supported on the two sides of the prefabricated beam, concrete is poured, and a post-cast concrete anti-shear key integrated with a post-cast part of the superposed beam is formed in each of the beam end key groove and the column side key groove. The prefabricated concrete frame beam-joint construction method can achieve easy, rapid and convenient on-situ connection of the prefabricated column and the superposed beam, and connection is stable and reliable.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING

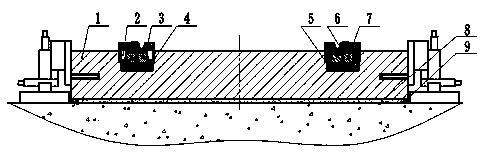

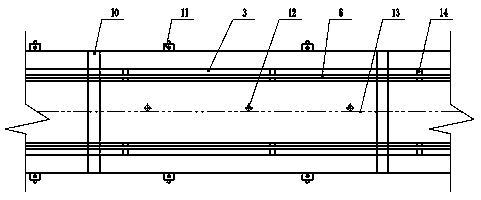

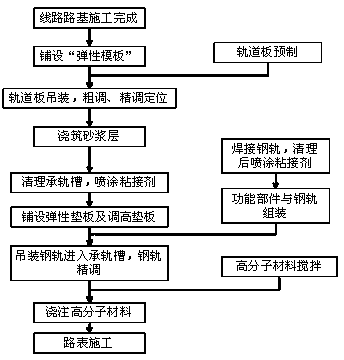

Quick construction method of embedded rail system

ActiveCN103362036ANovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

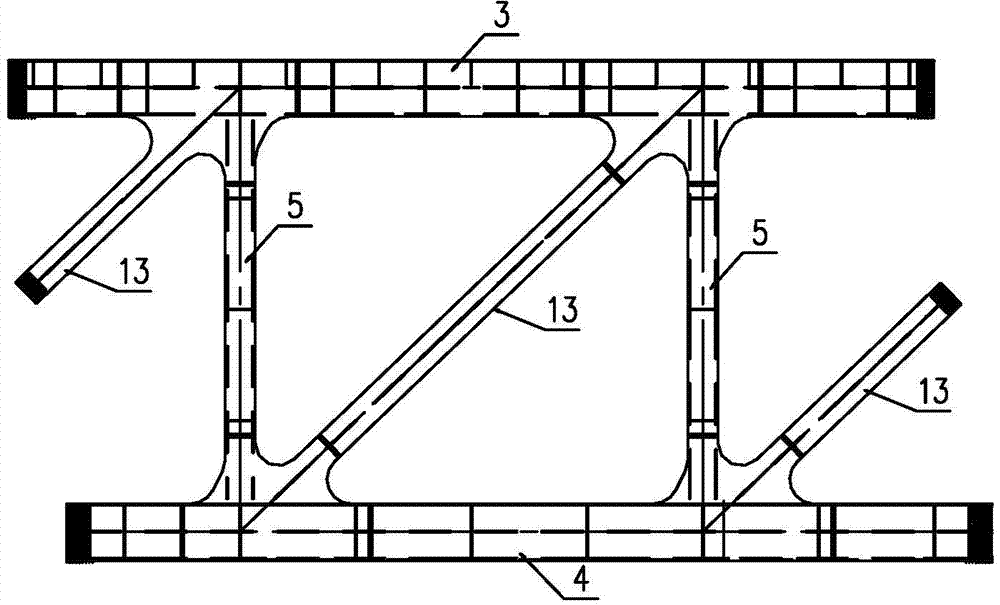

Novel assembled integral-type hollow shear wall structure

The invention relates to a novel assembled integral-type reinforced concrete shear wall structure. The assembled integral-type reinforced concrete shear wall structure is characterized in that prefabricated square-hole hollow reinforced concrete shear wall slabs, cast-in-place edge components, cast-in-place walls and floor ring beams are configured into an organic combination body through special connection, thereby forming the equivalent cast-in-place assembled integral shear wall structure; the assembled integral-type reinforced concrete shear wall structure is suitable for multiple-layer, small high-rise and high-rise buildings. The assembled integral-type reinforced concrete shear wall structure has the beneficial effects that the anti-seismic property of the structure can reach and even exceed the cast-in-place shear wall structure; concrete materials are saved beyond 40% and the structure can be produced in an industrialization flow line; the assembling rate of the building is greatly improved, and thus the production amount on the site is reduced, the resources are saved extremely, the efficiency is increased, the cost is reduced and the environment is protected; the dead weight of the prefabricated wallboard is less than 1.5 tons, and hoisting demands can be met by the routine hoisting equipment; thus the novel assembled integral-type reinforced concrete shear wall structure is suitable to be popularized widely.

Owner:倪文蛟

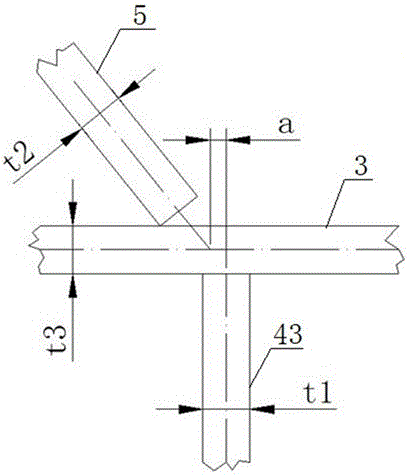

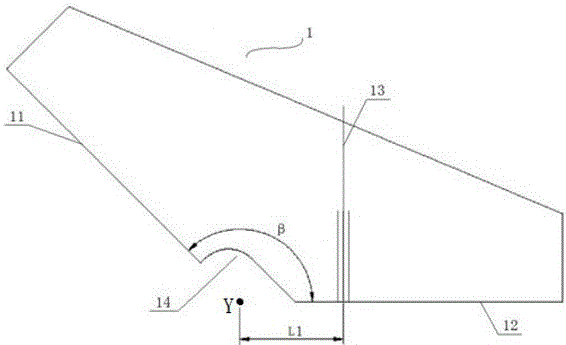

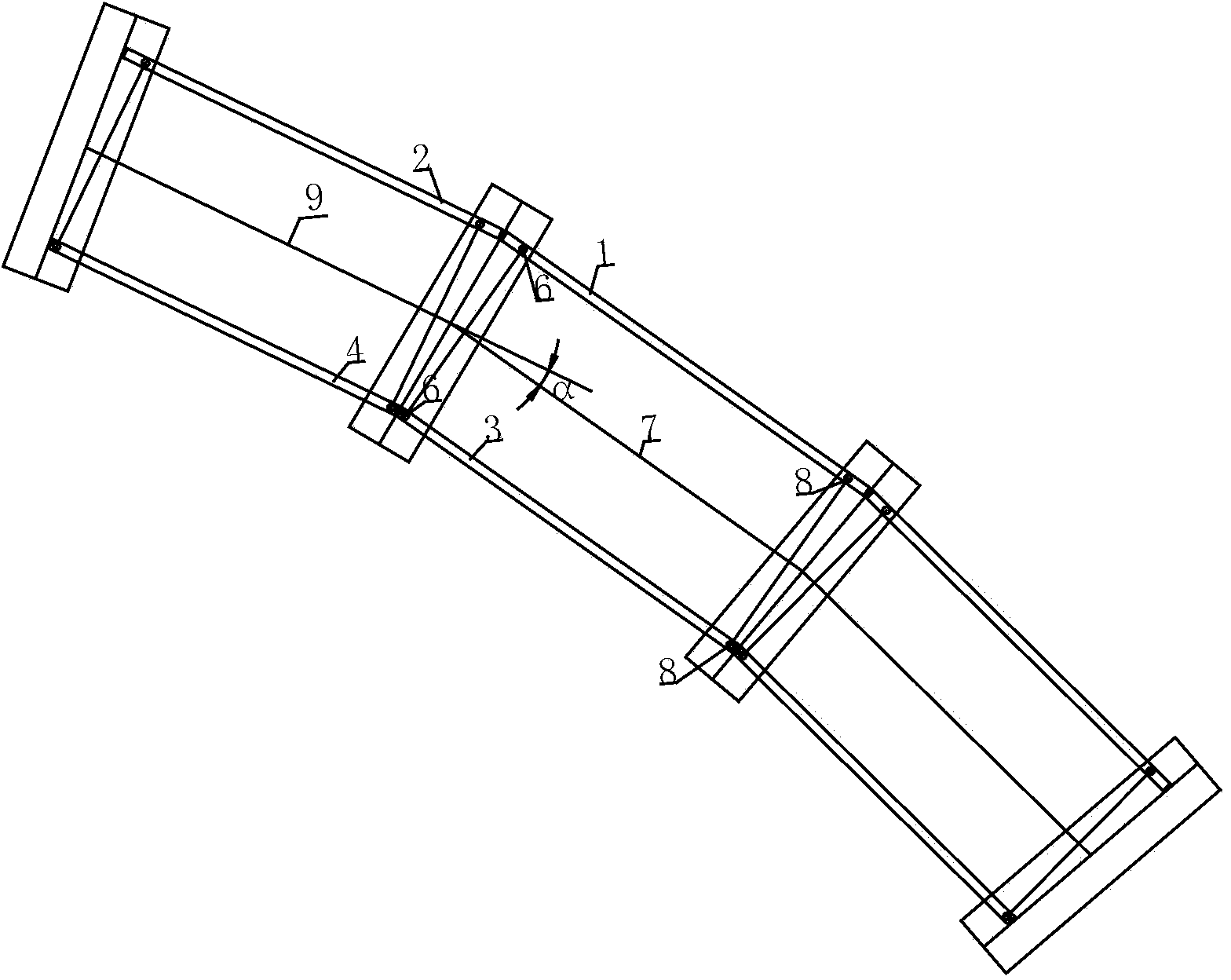

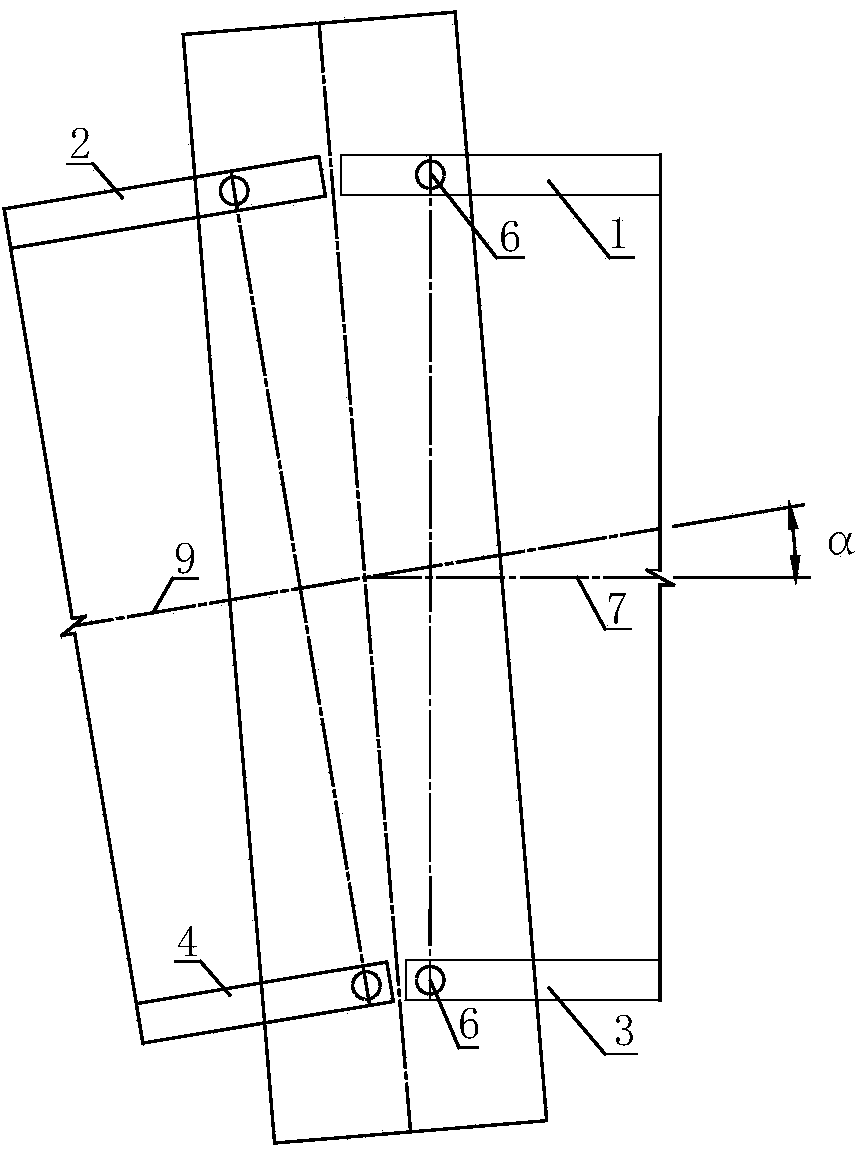

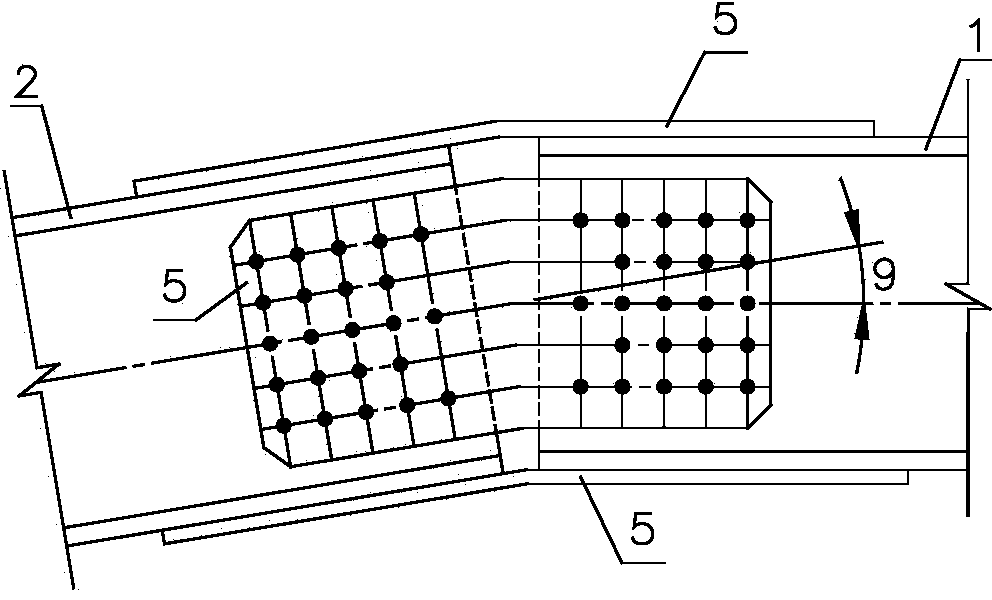

Testing tool system and testing method for LNG ship liquid cargo compartment three-dimensional board CM nodes

ActiveCN106679533AQuick assembly and loadingImprove build accuracyMechanical measuring arrangementsGreek letter alphaElectrical and Electronics engineering

The invention discloses a testing tool system for LNG ship liquid cargo compartment three-dimensional board CM nodes. The testing tool system comprises an inner clamping template and an outer clamping template. The inner clamping template is used for aligning the LNG ship liquid cargo compartment three-dimensional board CM node. The outer clamping template is used for verifying in a CM node verification stage after welding of the LNG ship liquid cargo compartment three-dimensional board CM node. The three-dimensional board comprises a transverse board, a vertical board and an oblique board. An included angle between the transverse board and the oblique board is alpha. A first reference line which is perpendicular with the transverse board is engraved on the transverse board. A second reference line which is perpendicular with the vertical board is engraved on the vertical board. According to the testing tool system, testing templates which matches the three-dimensional board are utilized. The testing templates comprise the inner clamping template for quick assembling and loading, thereby ensuring high precision and high stability in assembly. The testing templates further comprise the outer clamping template for after-welding verification. For ensuring high accuracy in final state measurement, the specialized outer clamping template is utilized, thereby truly testing the final deviation of each node.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

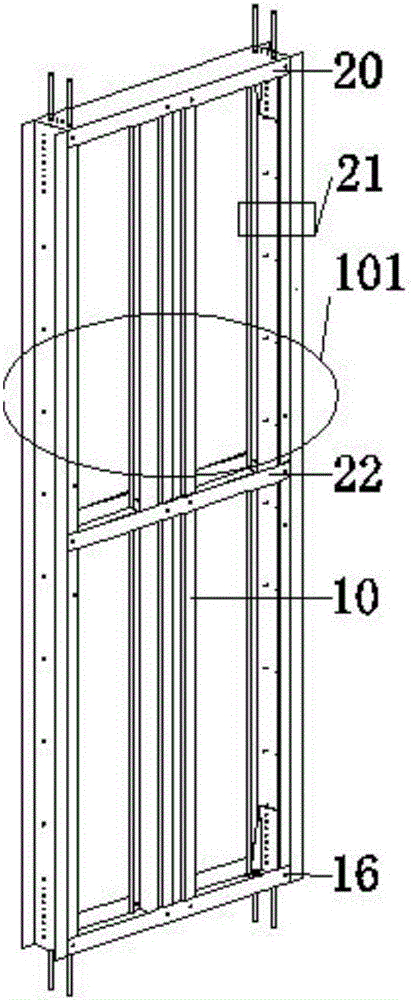

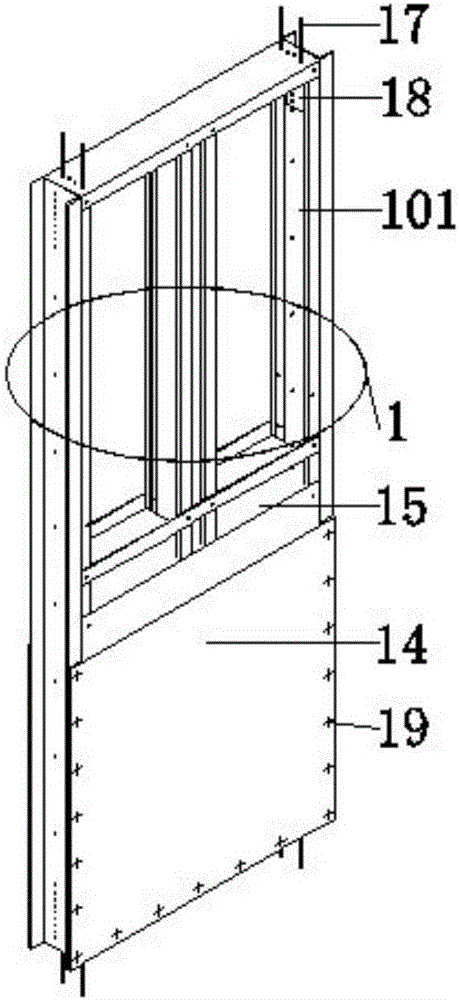

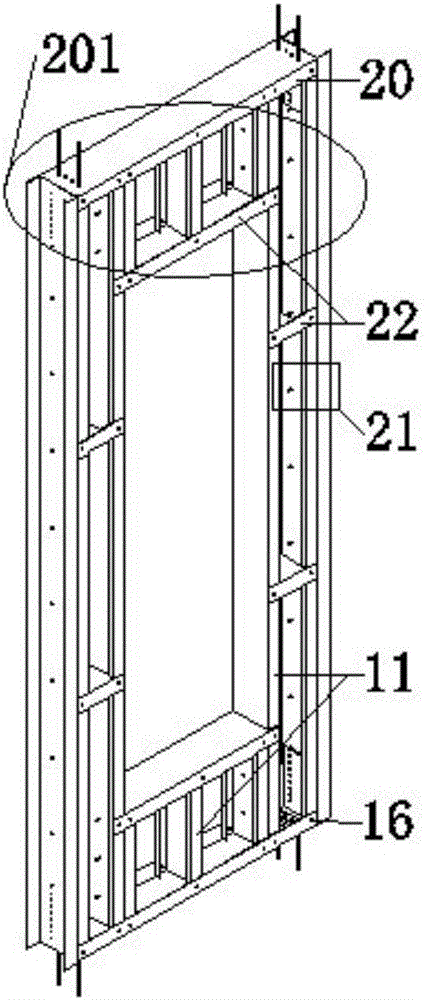

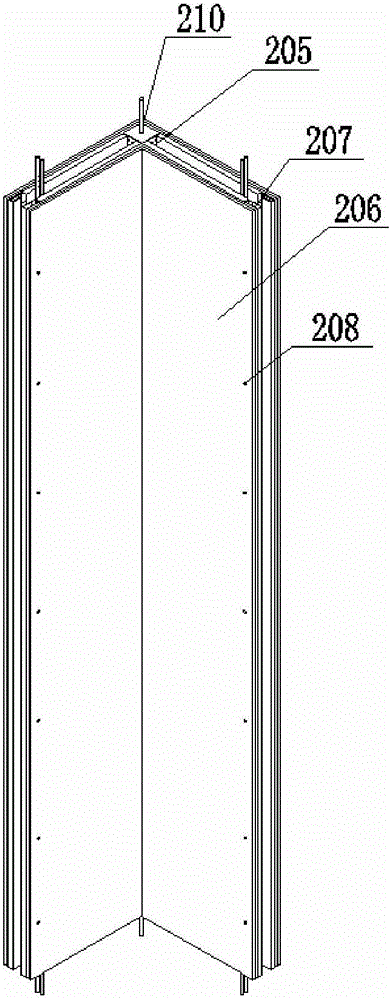

Modular assembling type cold-bent thin-wall type steel wall board structural system

Provided is a modular assembling type cold-bent thin-wall type steel wall board structural system. A vertical body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially connecting a common wall body module, an opened wall body module, an L-shaped wall body module and a T-shaped wall body module. A horizontal body structure of the cold-bent thin-wall type steel wall board structural system is formed by sequentially splicing slab modules. The slab modules are spliced by being connected. The vertical body structure and the slab modules are connected in the mode that the wall body and the slab module are connected. By optimizing the wall body module connection mode, the slab module connection mode, and the wall body and slab module connection mode, the site assembly difficulty and site construction workload are reduced to a great extent, and the whole structural system can be safer and better in anti-seismic property. The modular assembling type cold-bent thin-wall type steel wall board structural system is low in mass, good in anti-seismic property, capable of preserving heat, insulating heat and saving energy, environmentally friendly, low in manufacturing cost, suitable for mid-rise buildings and low-rise buildings, and high in economic and social benefit.

Owner:BEIJING UNIV OF TECH

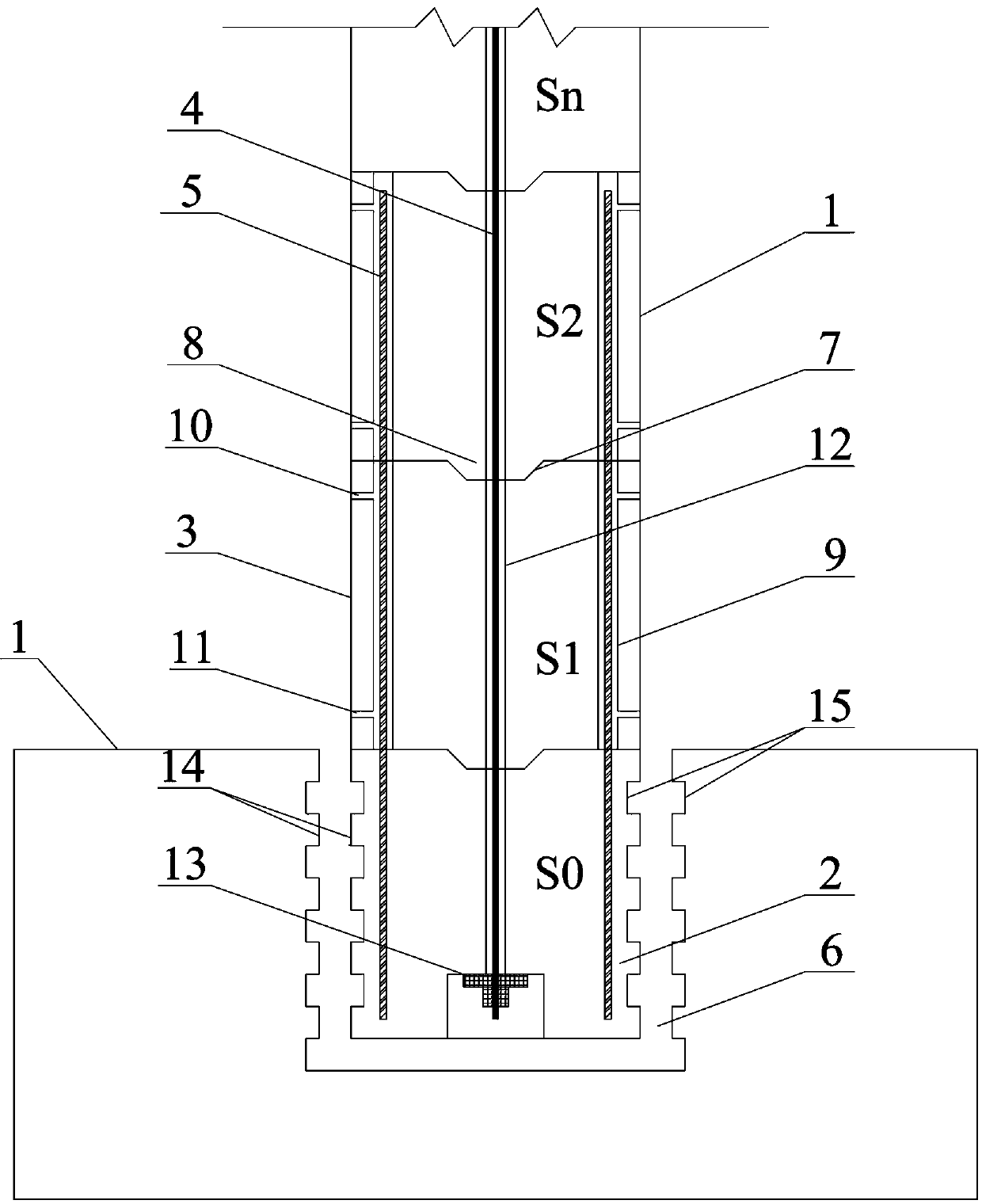

Socket type self-returning multi-section prefabricated pier and assembly method thereof

PendingCN110468694AAvoid working at heightsImprove durabilityBridge structural detailsFoundation engineeringCement slurryEngineering

The invention provides a socket type self-returning multi-section prefabricated pier and an assembly method thereof. The multi-section prefabricated pier comprises a bearing platform and the prefabricated bridge pier, wherein the prefabricated pier comprises a inserting bearing platform section, a plurality of pier body sections, a prestressed tendon, and energy dissipation ribs; the assembly method comprises the following steps that the prefabricated pier is prefabricated; a horizontal assembly method is adopted in a prefabricated factory, and the prestressed tendon is tensioned to enable allthe sections to be connected into a whole; and high-strength non-shrinkage cement slurry is injected into a pier grouting sleeve through grouting holes. On the site, the pier is lifted and is inserted into a pier installing hole, so that a certain gap is kept between the outer wall of the inserting bearing platform section and the inner wall of the pier installing hole; and after the prefabricated bridge pier is positioned, a guide pipe is inserted into the bottom of the gap, the high-strength non-shrinkage cement slurry is injected into the bottom through the guide pipe, and the slurry is discharged from bottom to top until the gap between the inserting bearing platform section and the pier installing hole is completely filled.

Owner:ZHENGZHOU UNIV

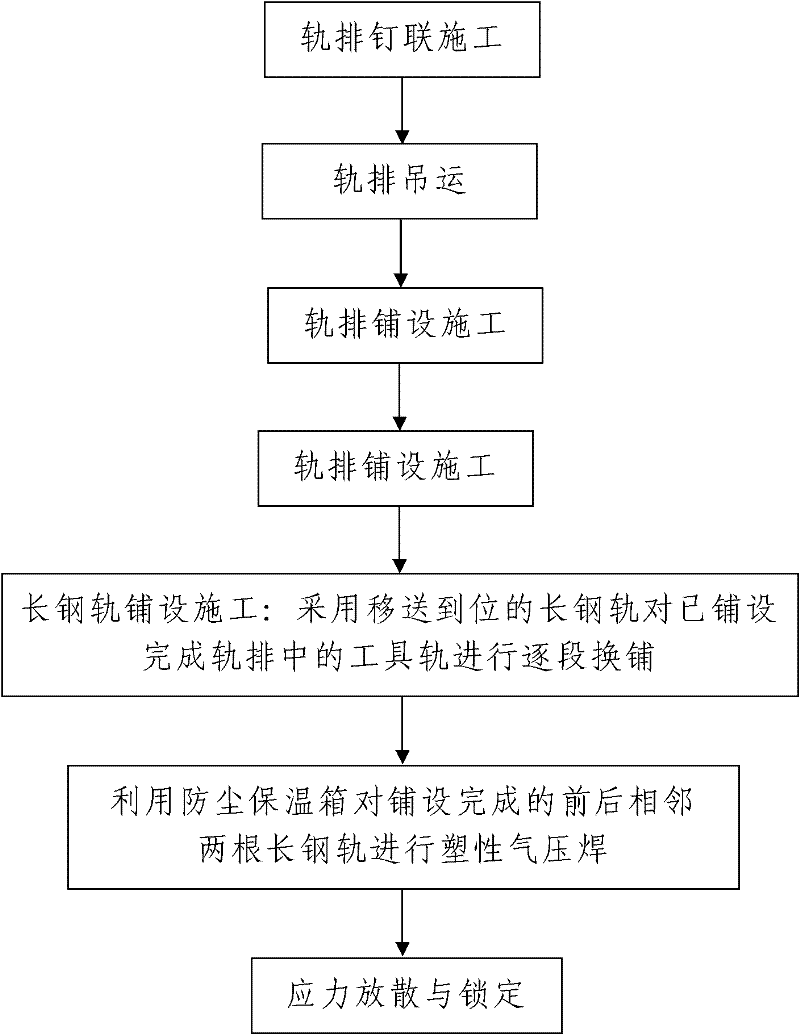

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

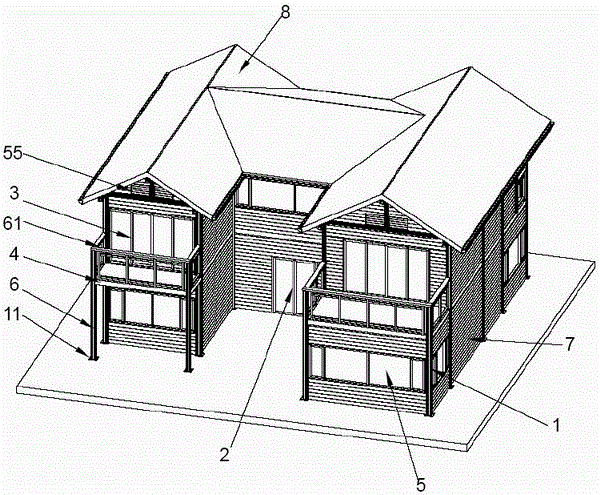

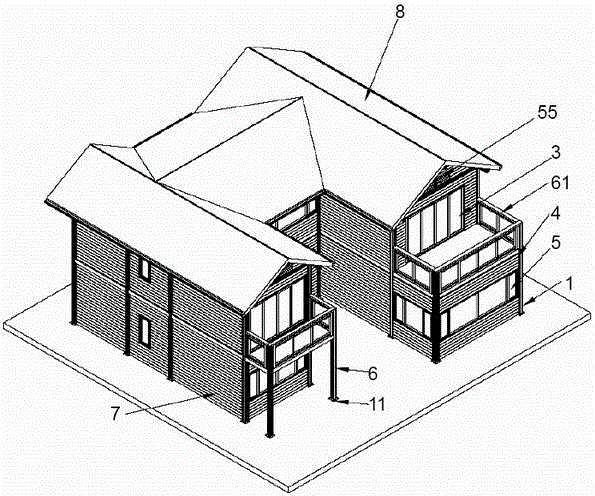

Aluminum alloy house

ActiveCN105040812AFirmly connectedShort design and manufacturing cycleBuilding roofsFloorsSection planeUltimate tensile strength

The invention relates to an aluminum alloy house. Aluminum alloy stand columns are arranged on the periphery and the inner ring of the house at intervals. Aluminum alloy beams are connected to the middle positions, in the height direction, of the aluminum alloy beams on the periphery and the inner ring of the house in a longitudinal and transverse segmented mode to form structures of the bottom layer and the second layer of the aluminum alloy house. Roof supporting columns are arranged on the aluminum alloy beams of the second layer. A roof is arranged on the roof supporting columns and the aluminum alloy stand columns. Three inwards-concave vertical face aluminum alloy combined wall plates are arranged in the middle of the aluminum alloy house in the foresight direction. An aluminum alloy gate is arranged in the middle of the front vertical face aluminum alloy combined wall plate, and therefore an inwards-concave space is formed in the aluminum alloy gate. Reverse Y-shaped sectional structures are arranged on the two sides of the roof. The front portion and the rear portion of the middle part of the roof are each in a slope shape. The two ends of each slope shape are connected with the middle rear portions of the reverse Y shapes on the two sides respectively. The aluminum alloy house is simple and firm in arrangement and connection structure, short in construction period, convenient to install, high in roof bearing strength and excellent in anti-seismic property.

Owner:ALUHOUSE TECHGD CO LTD

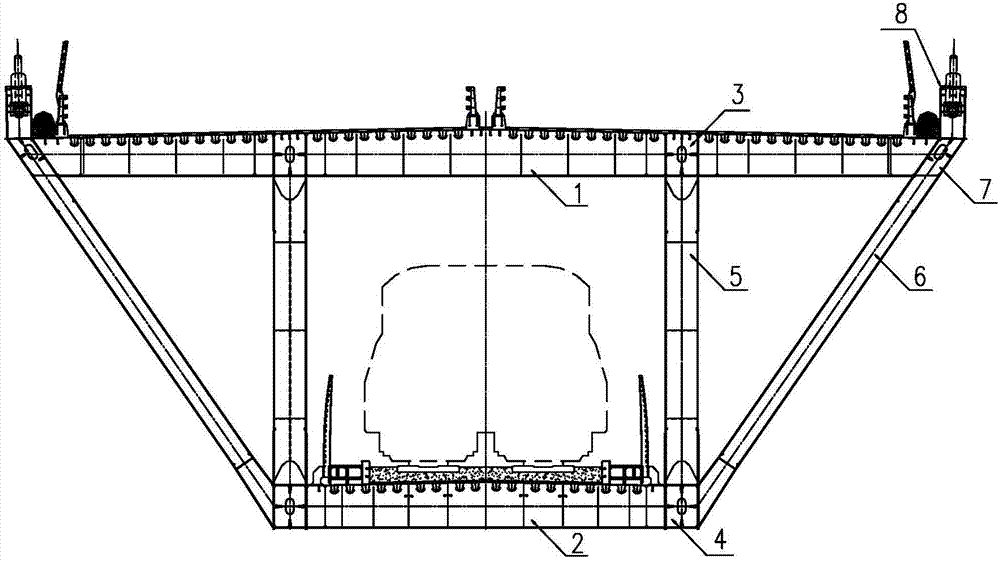

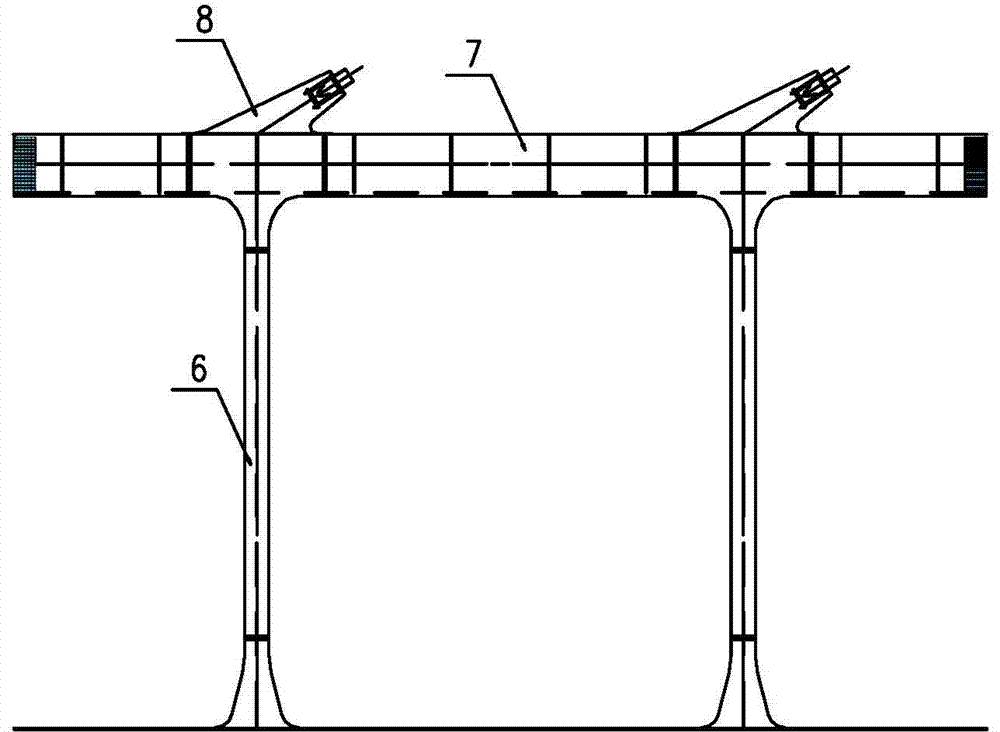

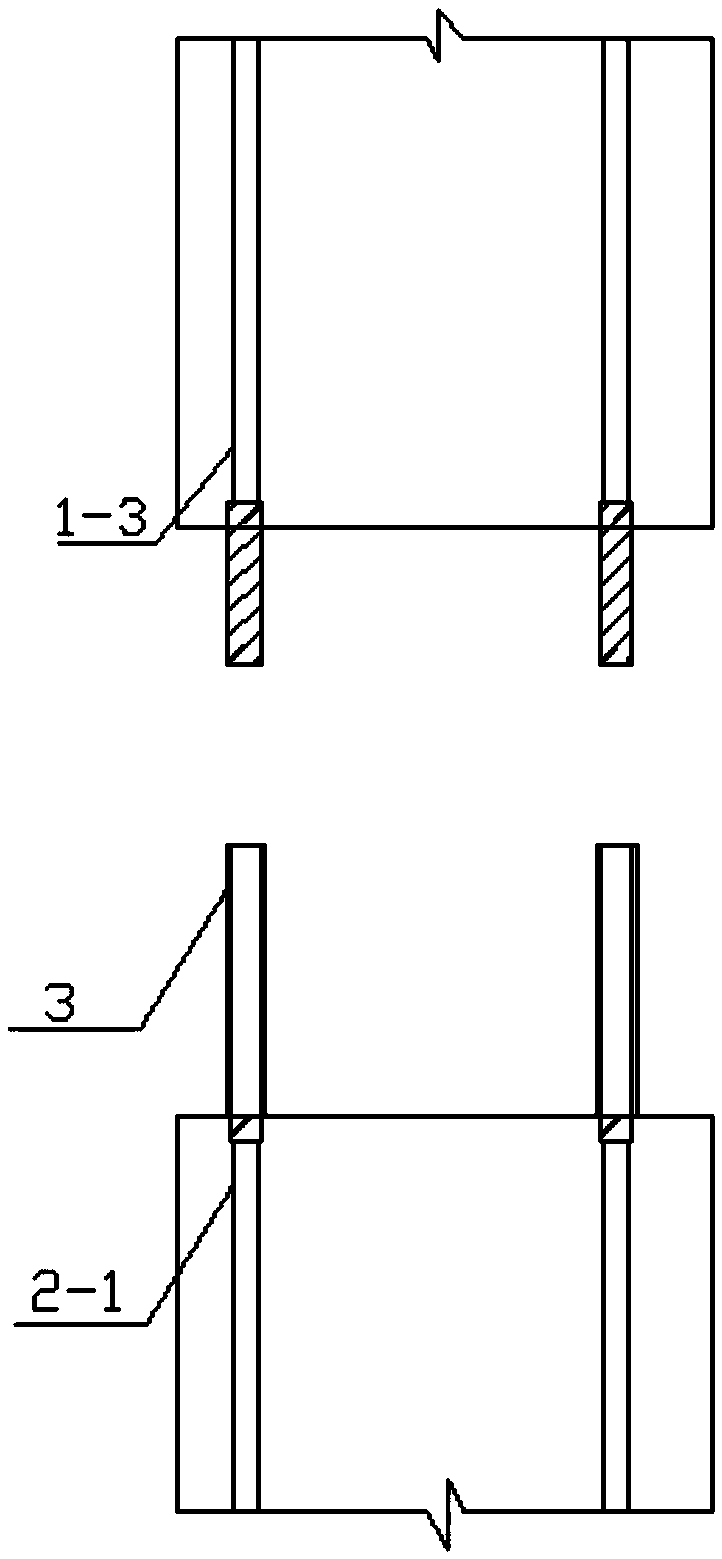

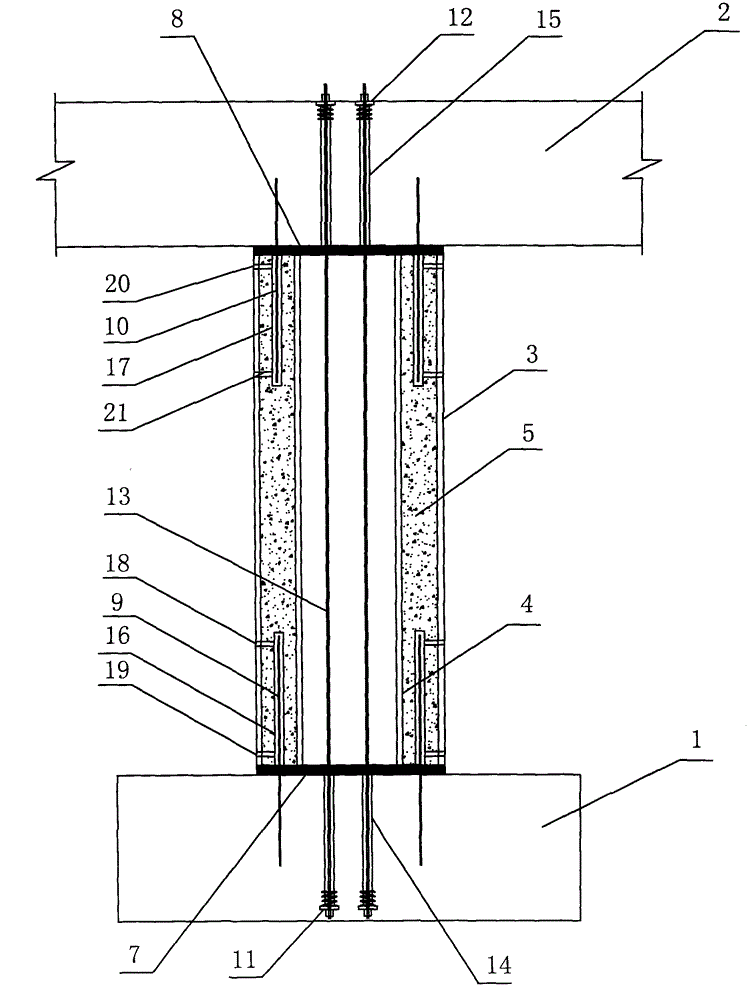

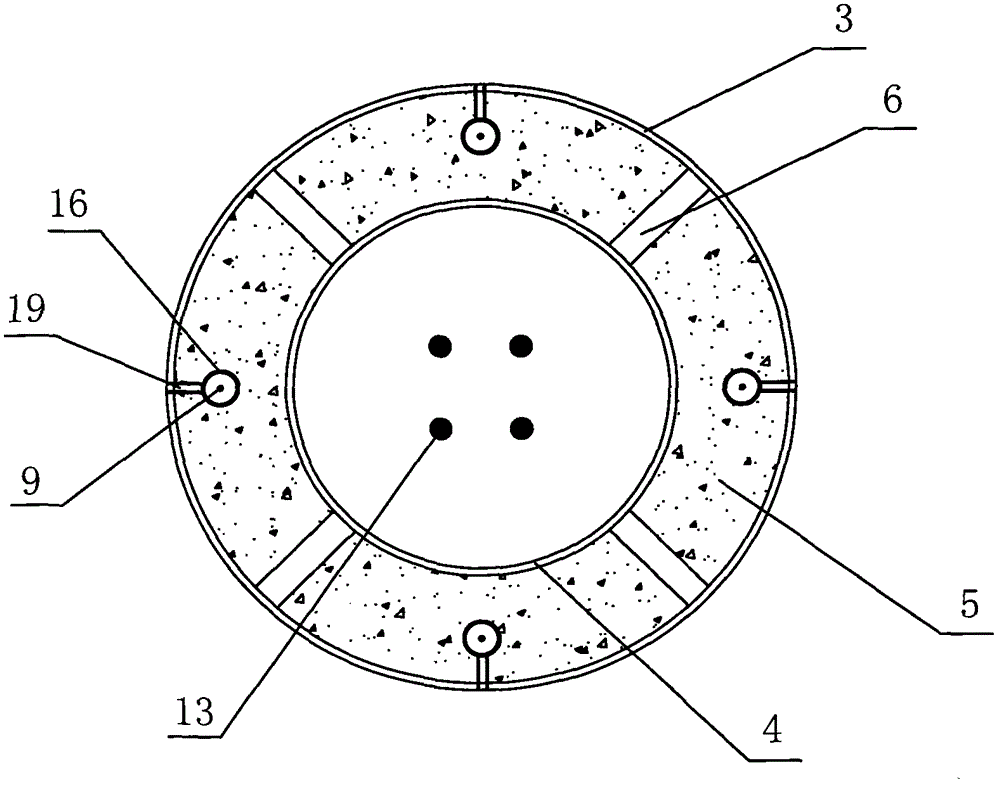

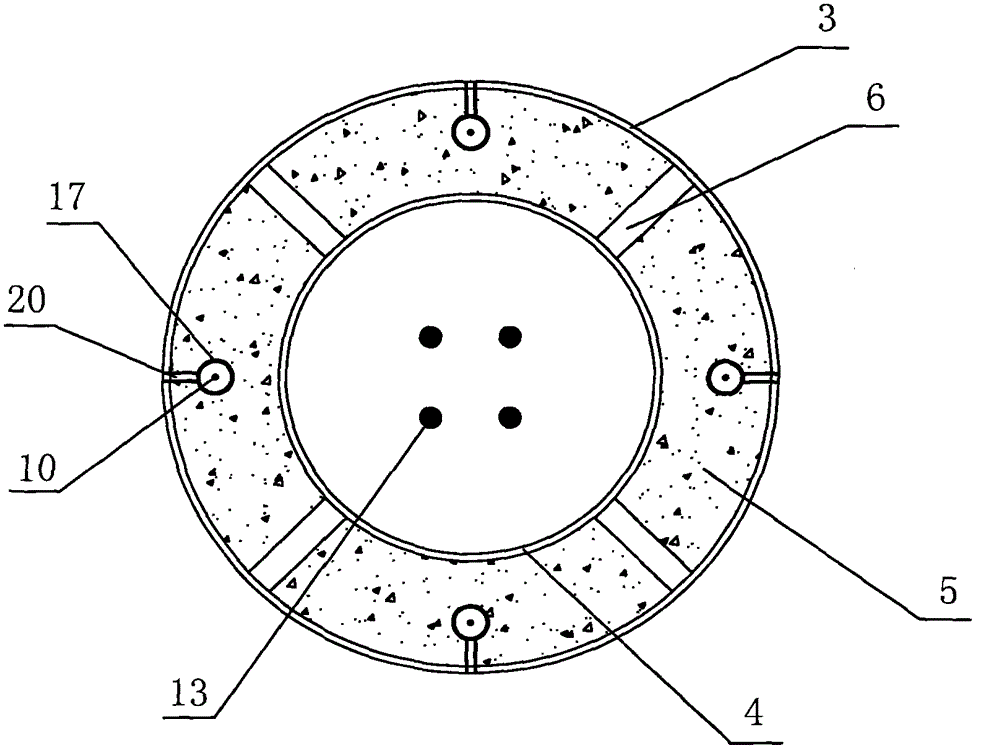

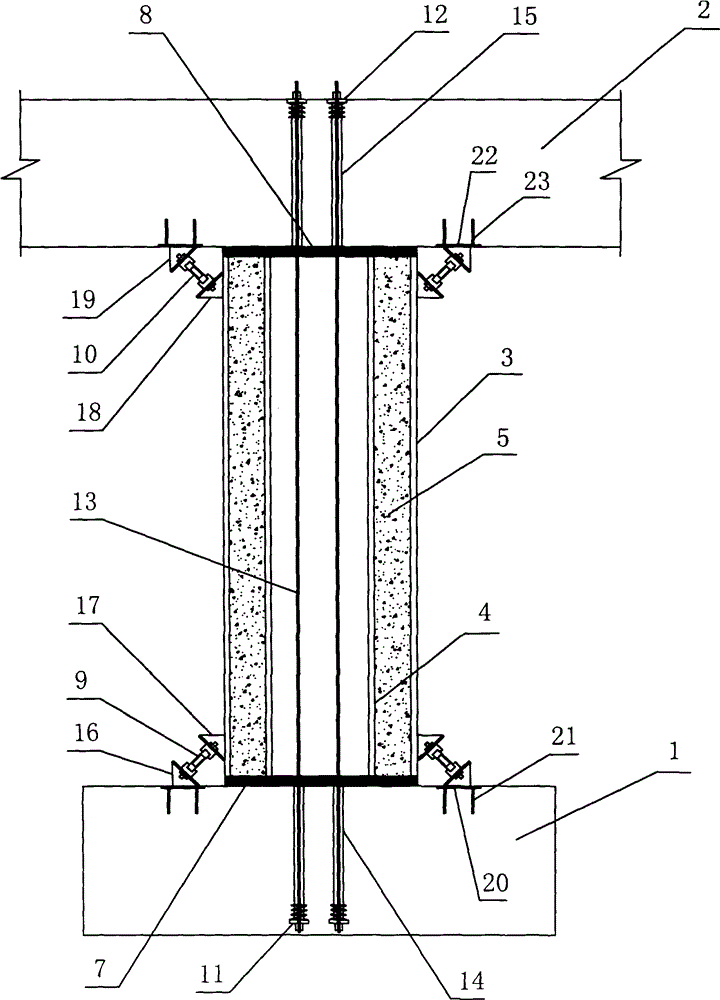

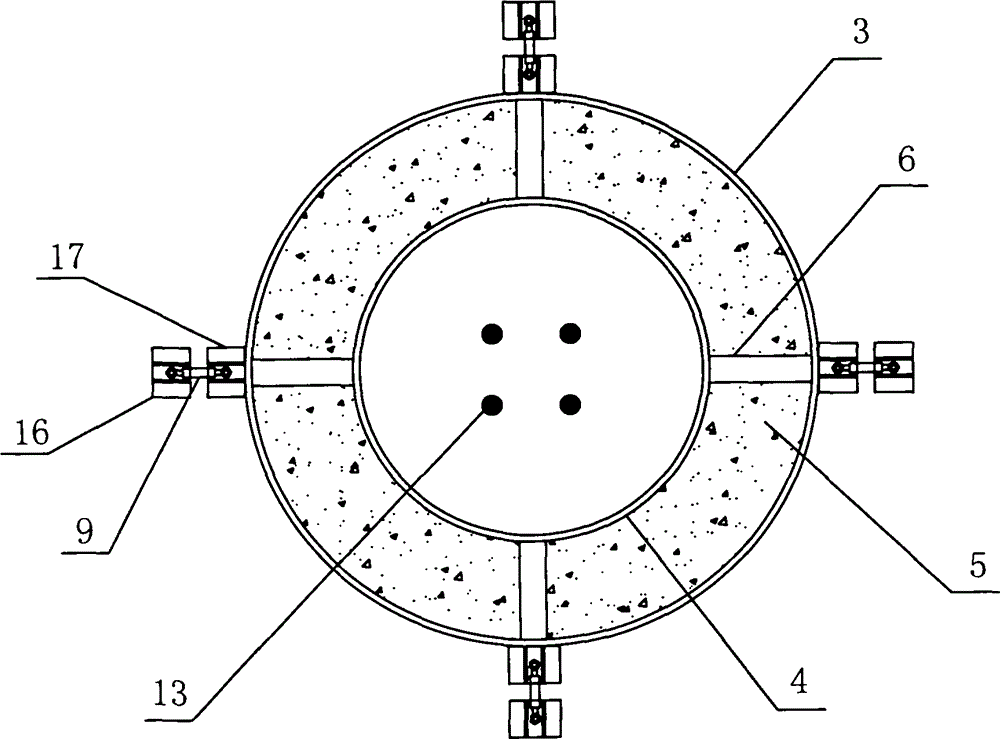

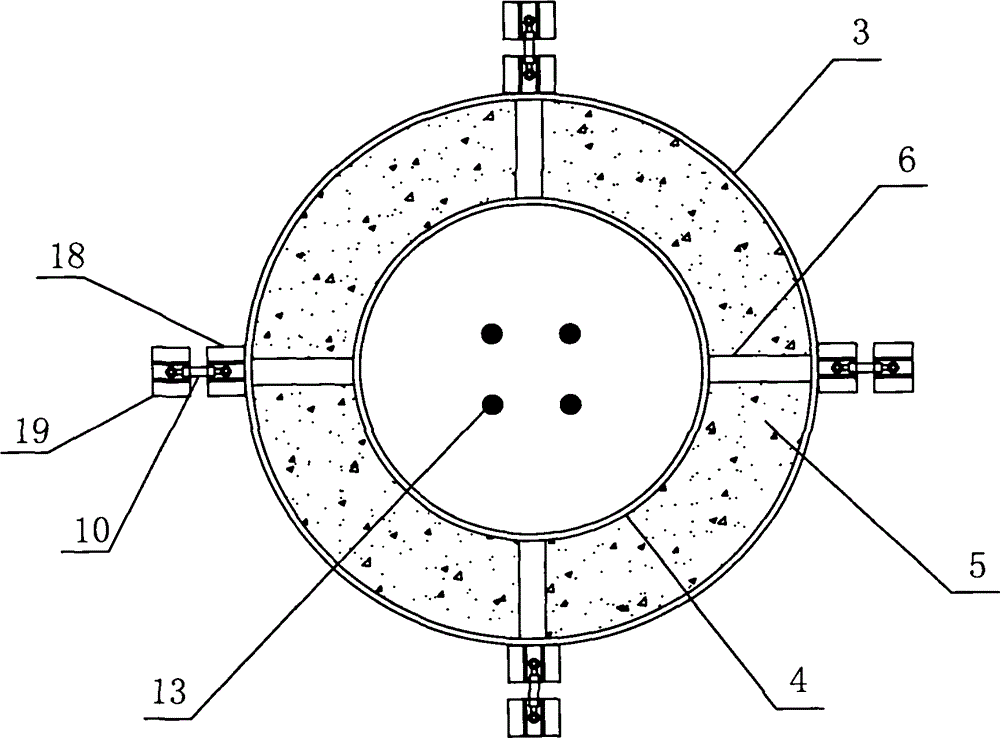

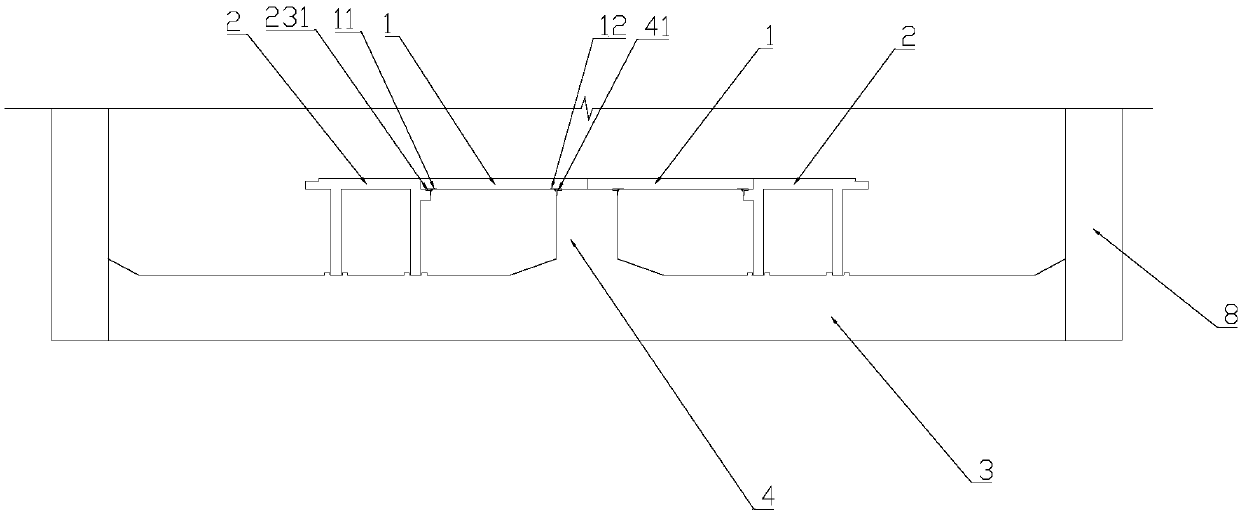

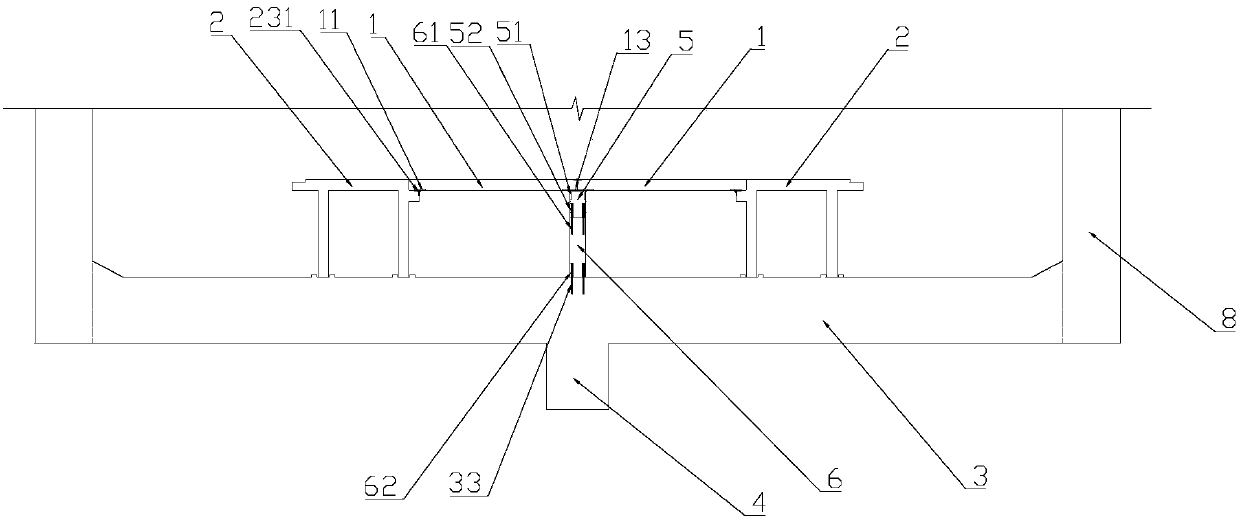

Preset nut type steel-reinforced concrete compound pier template fixing device and construction method thereof

ActiveCN101538939ASolve fixed puzzlesEnsure construction safetyForms/shuttering/falseworksCompound pierReinforced concrete

The invention discloses a preset nut type steel-reinforced concrete compound pier template fixing device and a construction method thereof. The fixing device mainly comprises a template, a nut, a screw rod, a PVC protecting pipe, an inner keel and an outer keel. The nut is welded on a steel column, the template surrounds the periphery of the steel column, the outer keel is arranged around the outer side of the template, the inner keel is arranged between the template and the outer keel, one end of the screw rod is connected with the nut by a thread, the PVC protecting pipe is sleeved on the screw rod, and the other end of the screw rod is fixed on the outer keel by a 3-shaped buckle. The invention has simple structure, low cost, and simple and convenient construction, solves the difficulty of fixing the steel-reinforced concrete compound pier template, is convenient for the field construction operation and lightens the workload and the labor intensity. The inner keel, the outer keel, the template and the screw rod can be repeatedly used so as to save the cost, ensure the construction safety of the template and improve the forming quality of the concrete column; meanwhile, the fixing device adopts common materials, thereby lowering the cost and being convenient for popularization and application.

Owner:JIANGSU HUAJIAN CONSTR

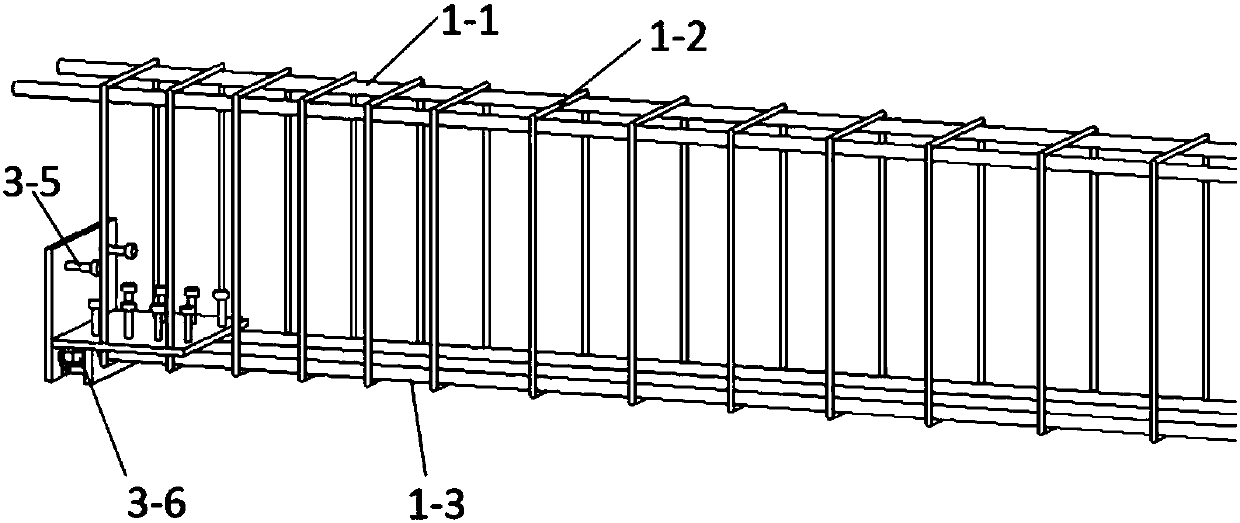

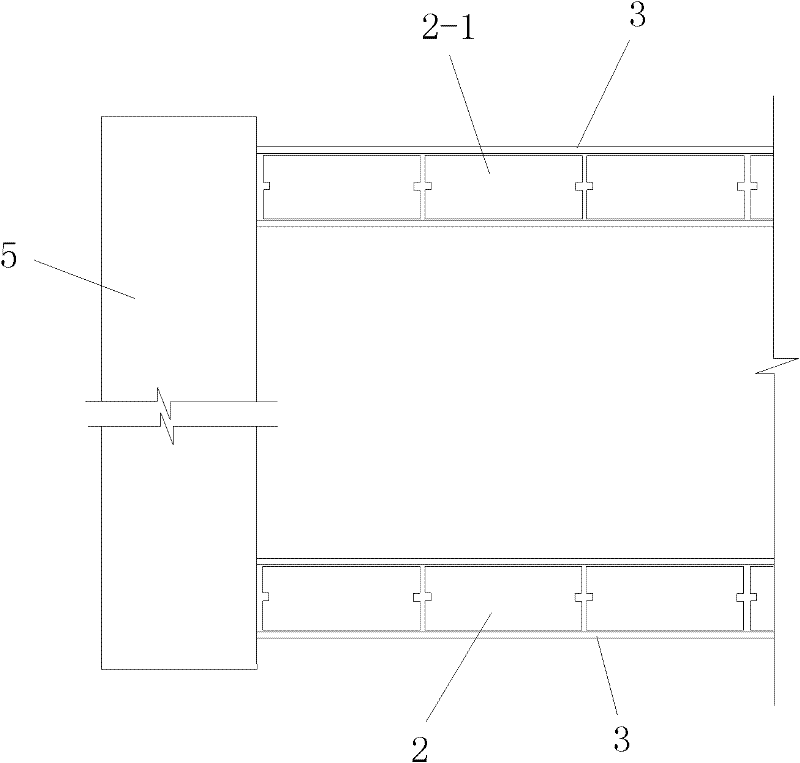

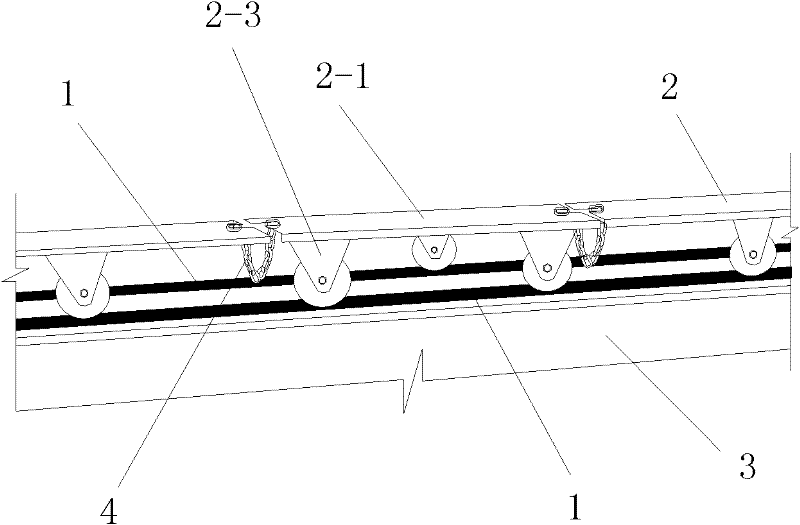

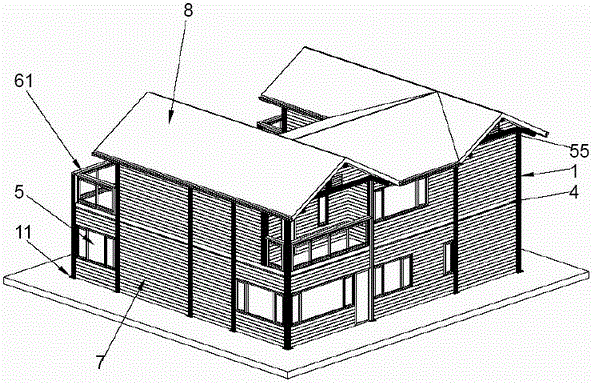

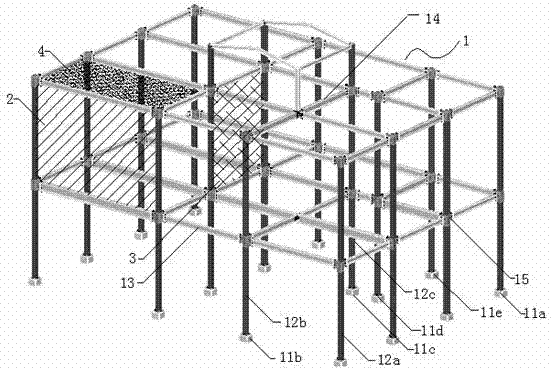

Light-weight steel structure house and construction method thereof

ActiveCN106948472AFast adjustmentEasy to adjustFloorsFoundation engineeringNoise reductionUltimate tensile strength

The invention relates to a light-weight steel structure house and a construction method thereof. The light-weight steel structure house comprises a house frame, double-layer outer wall plates, inner wall plates and lightweight floor plates. The house frame comprises a foundation, supporting upright columns, truss beams and cross sleeve connecting pieces; the supporting upright columns comprise four corner supporting upright columns, a plurality of outer supporting upright columns and a plurality of inner supporting upright columns; each supporting upright column is of an I-shaped steel structure; and the supporting upright columns are mounted on the foundation in mutually-parallel mode. The double-layer outer wall plates are arranged between every two adjacent outer supporting upright columns or between the adjacent corner supporting upright columns and the outer supporting upright columns. The inner wall plates are arranged between every two adjacent inner supporting upright columns or between the adjacent inner supporting upright columns and the outer supporting upright columns. The lightweight floor plates are parallelly arranged between every two adjacent truss beams. The light-weight steel structure house and the construction method thereof have the advantages that by means of the house frame, the double-layer outer wall plates, the inner wall plates and the lightweight floor plates and adjustment of connection of all the structures, the house is convenient for correction, effective heat dissipation and noise reduction are achieved, and meanwhile the overall strength of the house is guaranteed.

Owner:西藏藏建科技股份有限公司

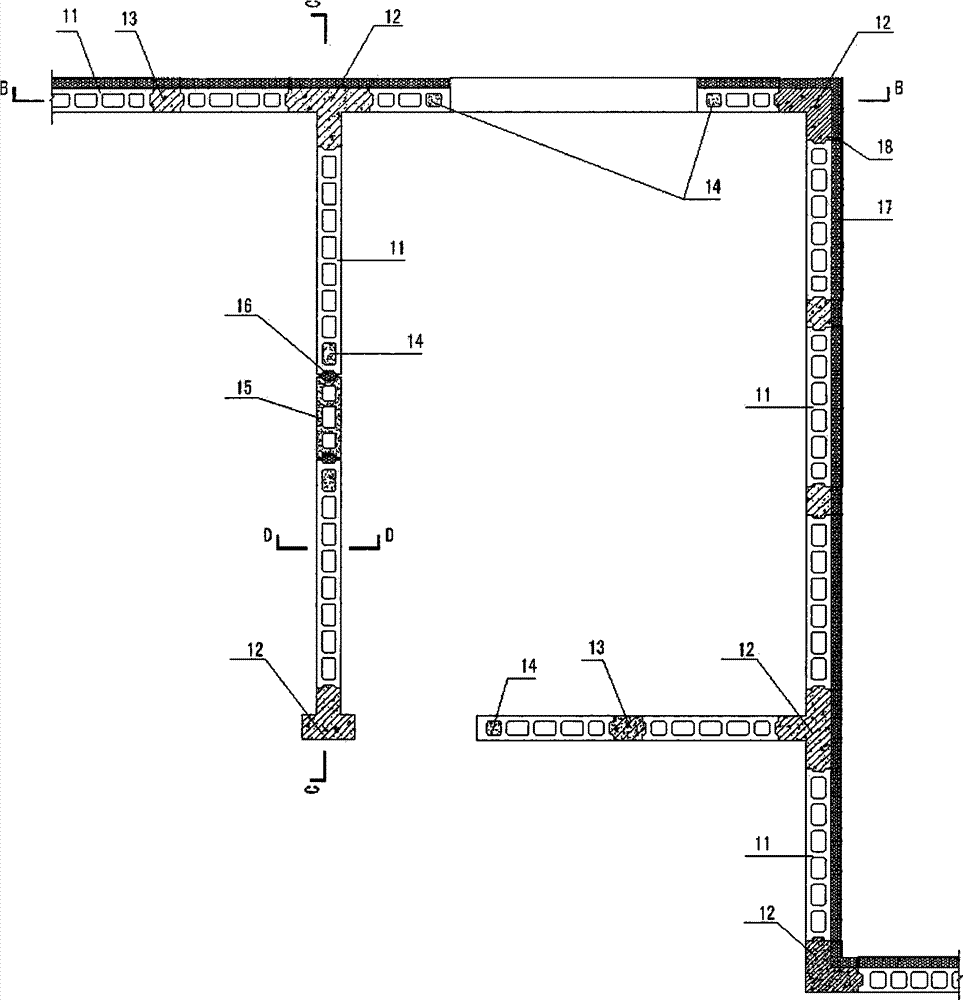

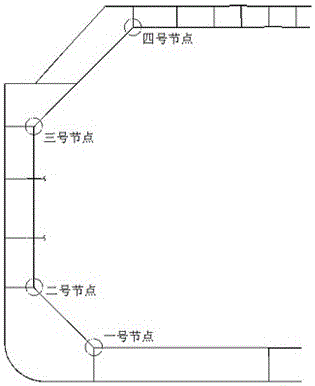

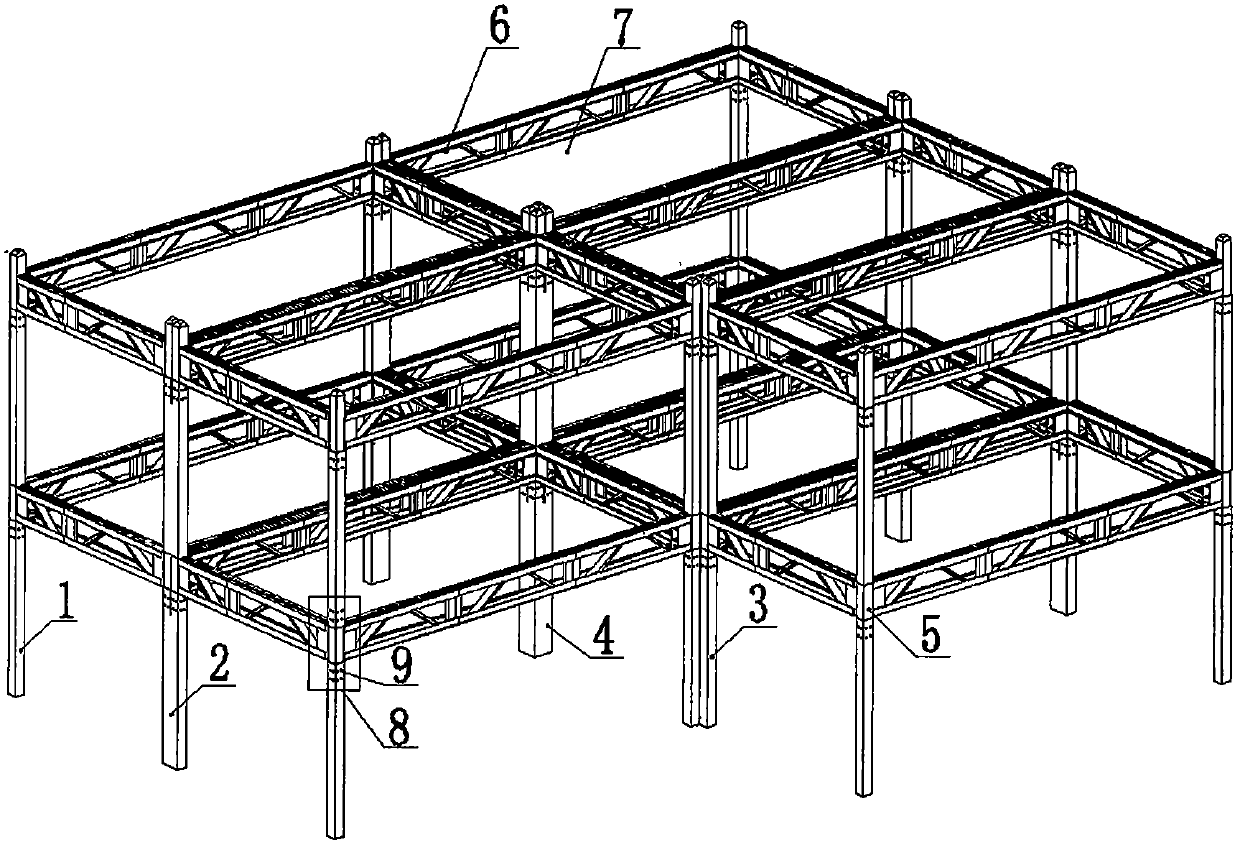

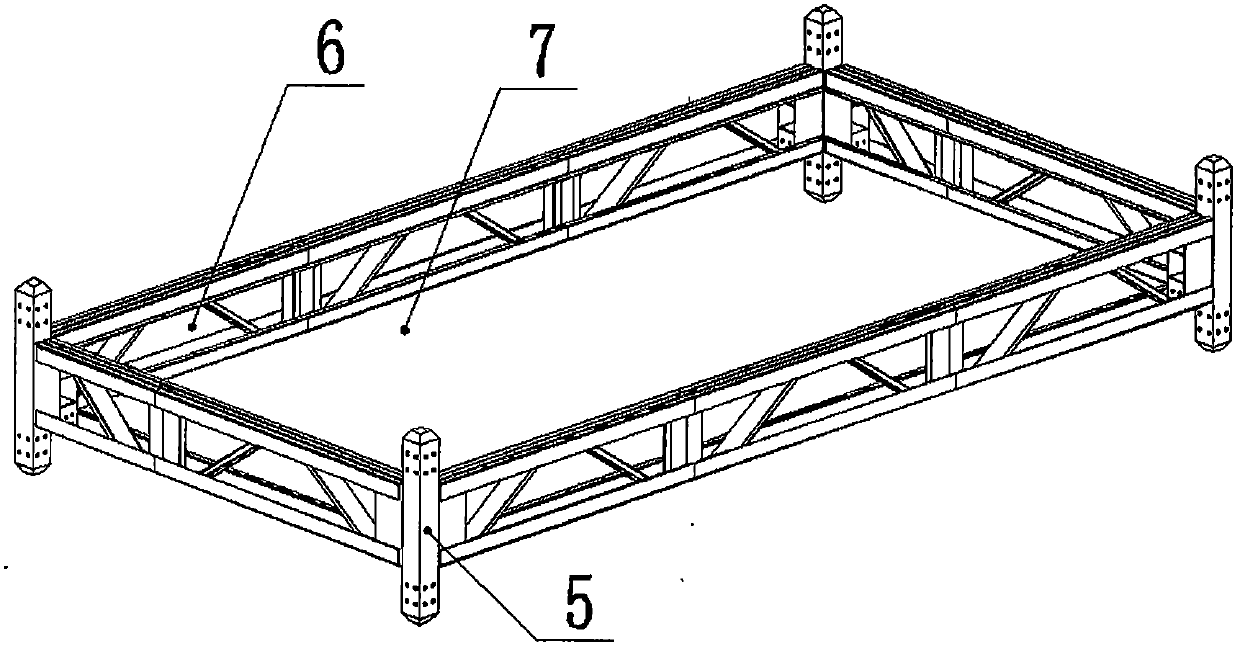

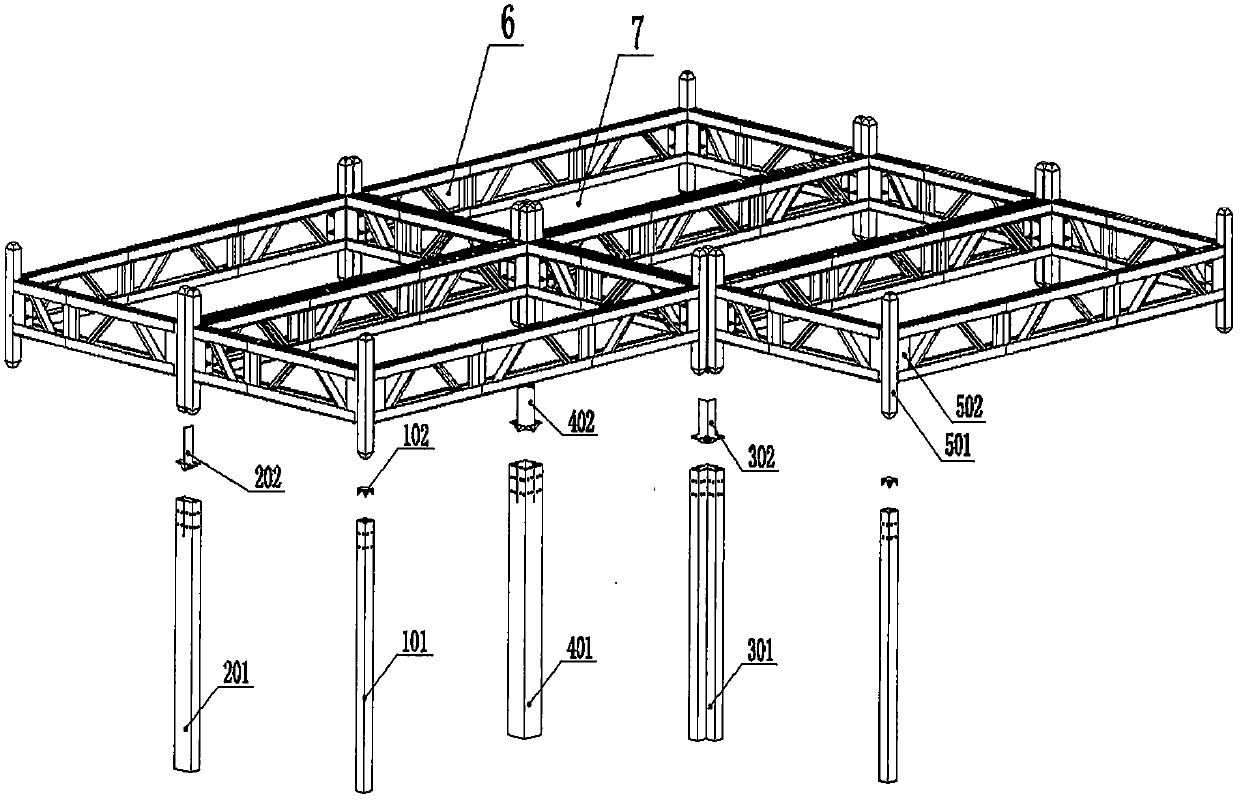

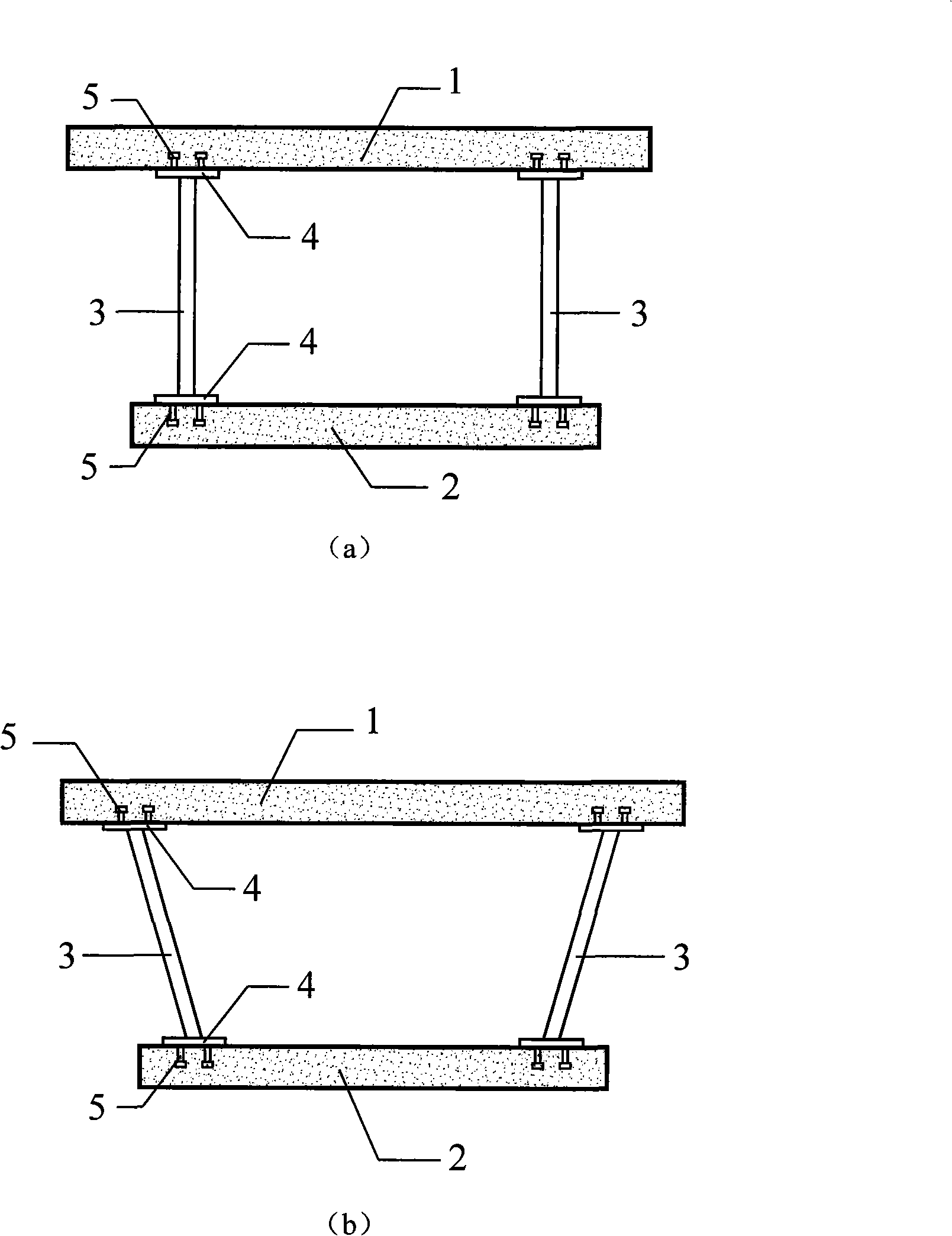

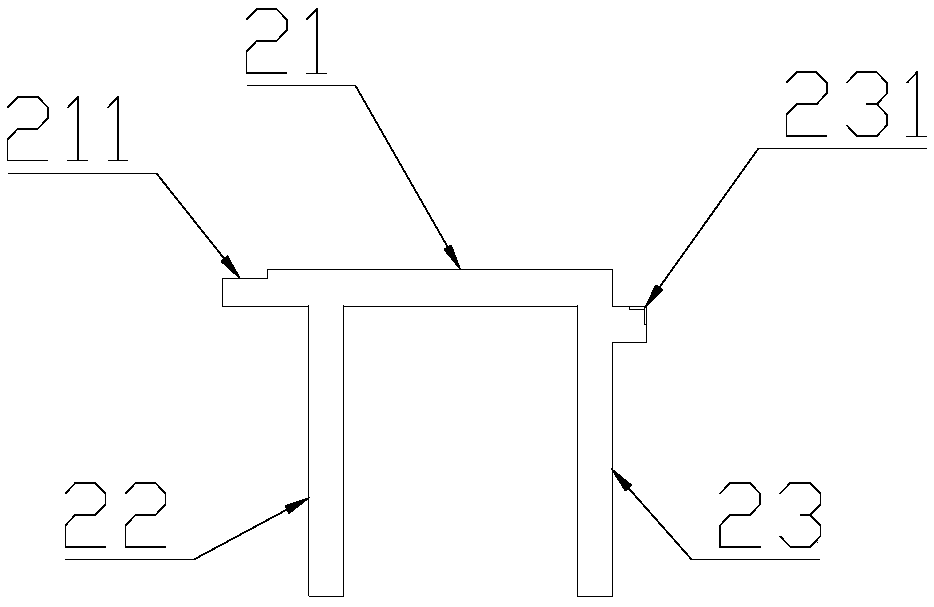

Prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and construction method thereof

InactiveCN107795013AImprove prefabrication rateEnsure structural safetyStrutsPillarsCold formedHouse building

The invention relates to a prefabricated cold-formed thin-walled steel plate column structure tenon and mortise connection system and a construction method thereof, and belongs to the technical fieldof structural engineering. Single-hole columns, double-hole columns, three-hole columns and four-hole columns are support columns of the system. A floor module is the main structure of the system. Theconnection mode between the floor and the columns is the connection mode between the support columns and the main structure of the system. The single-hole columns and the double-hole columns are respectively arranged at joint connection support parts at the bottom of the floor module. The three-hole columns are arranged at corner support parts at the bottom of the floor module. The four-hole columns are located at center cross support parts at the bottom of the floor module. Through the method of optimizing the light steel plate column structure system by implanting beam-column joints in thefloor, the structure is allowed to bear the force more reasonably, the consumption of building materials and the amount of construction work at a construction site are greatly reduced, and a rapid green construction is truly realized. The whole building is sturdy and durable, thermal-insulating, lightweight, energy-saving, environmentally friendly, suitable for all kinds of housing construction and highly applicable, and will bring good economic and social benefits.

Owner:谢志强 +1

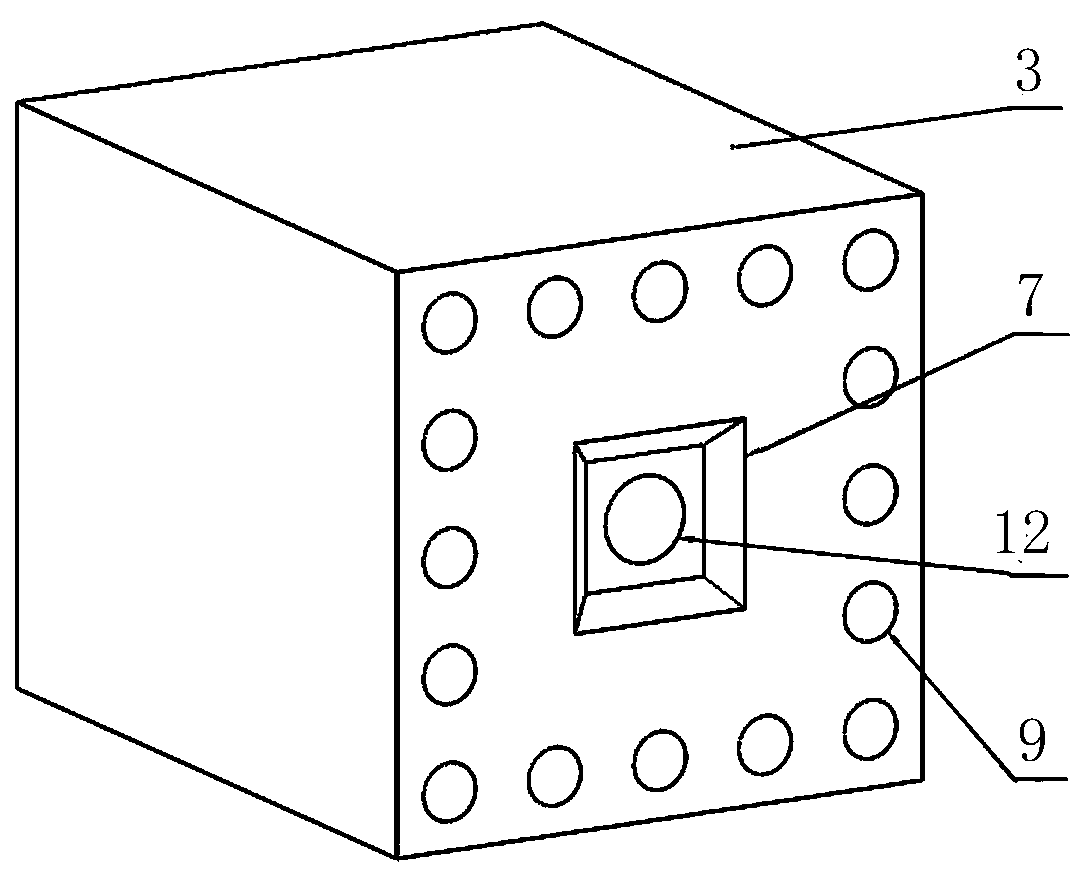

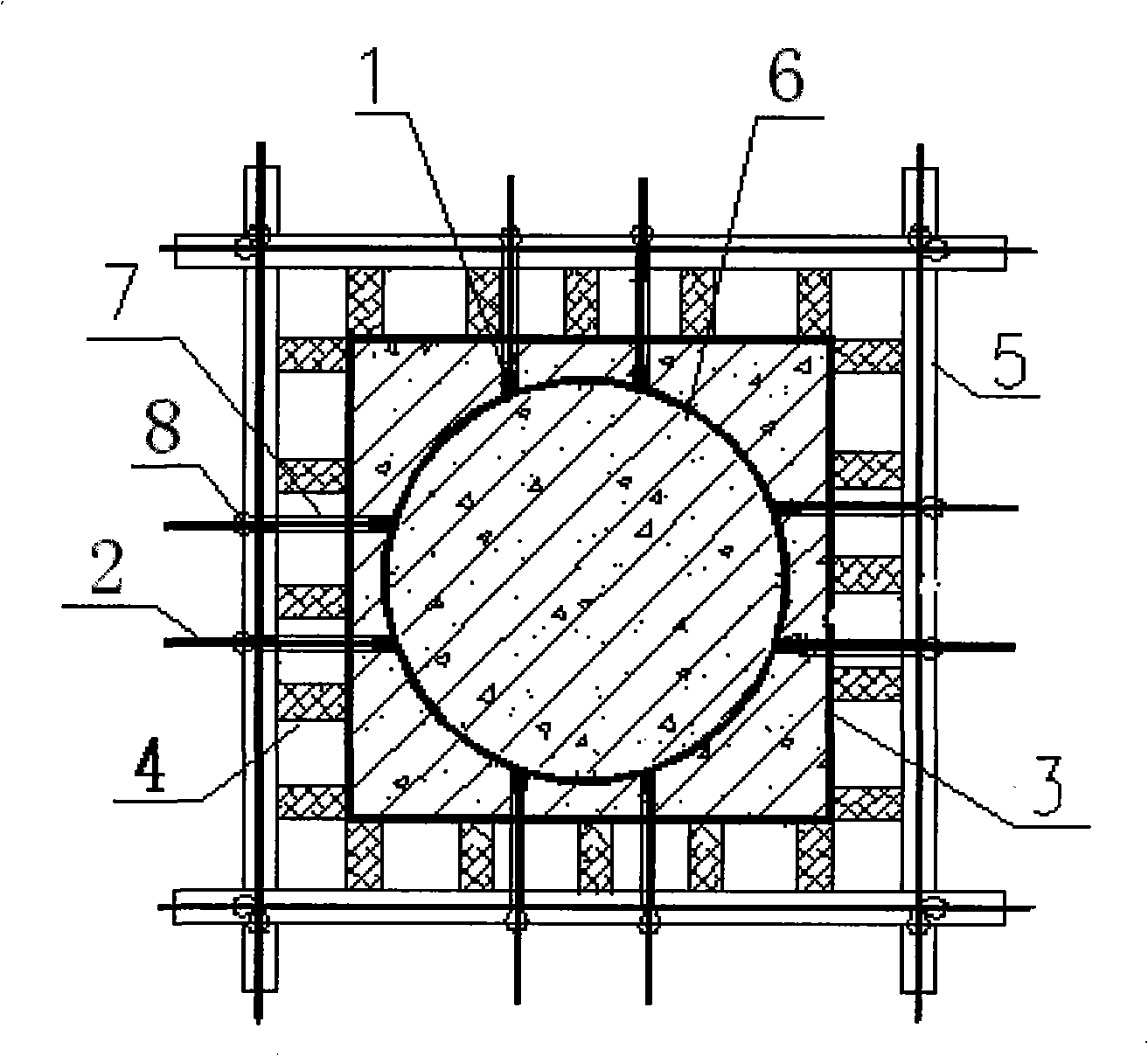

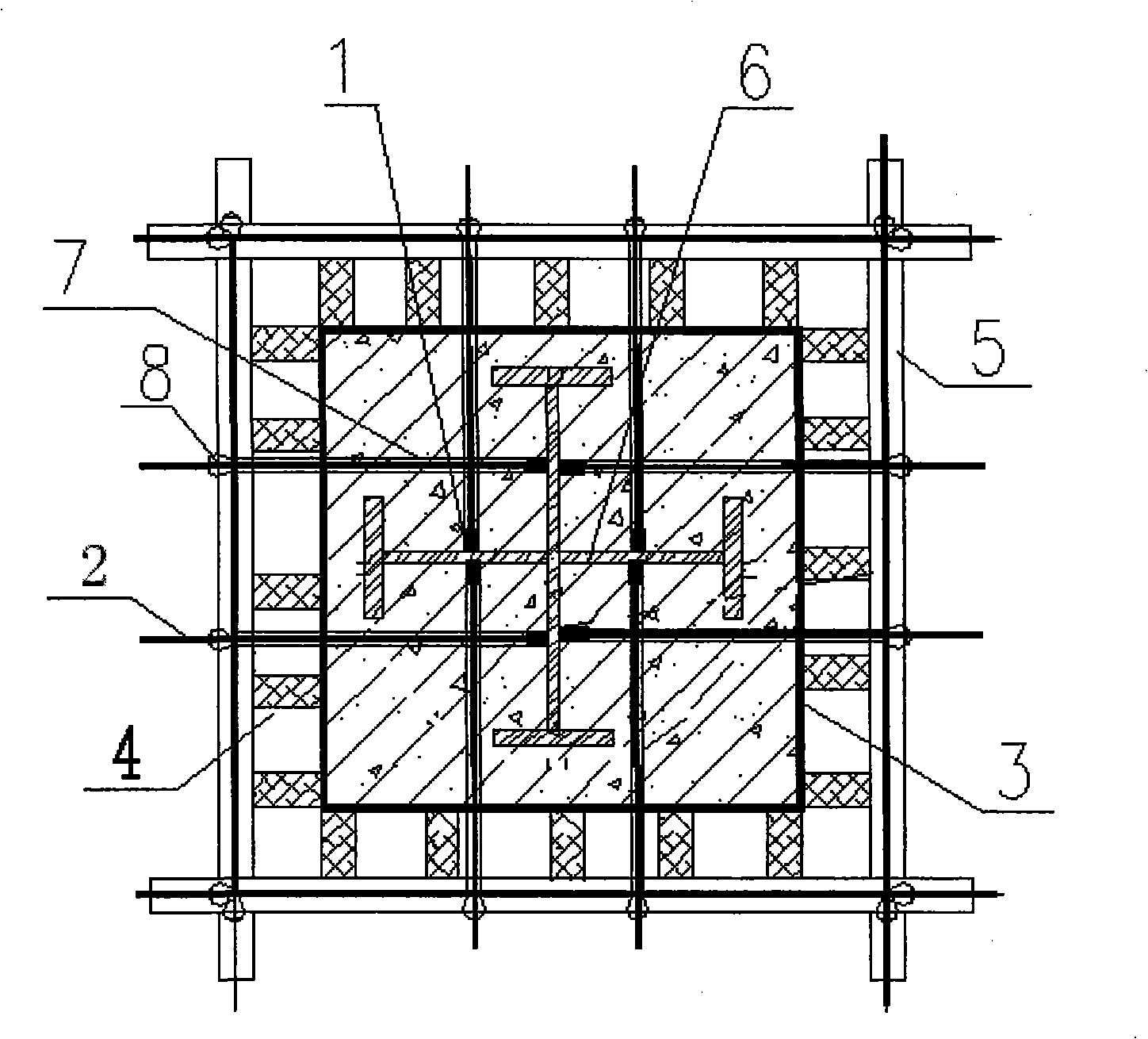

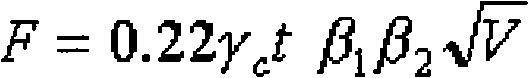

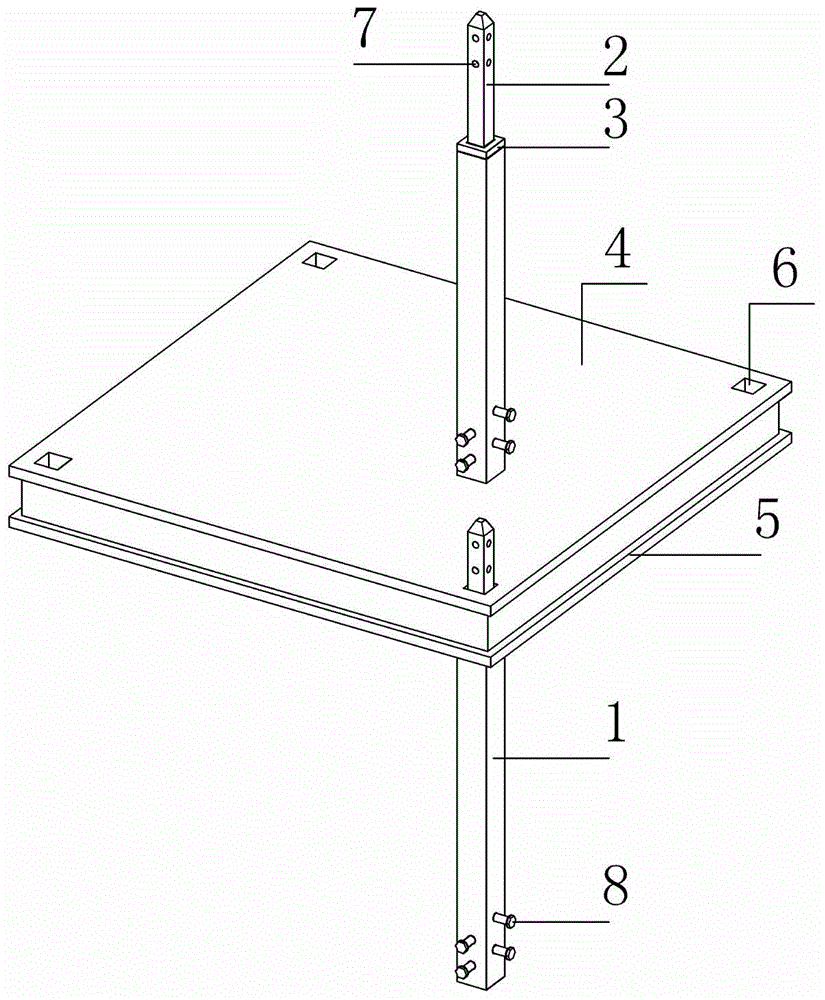

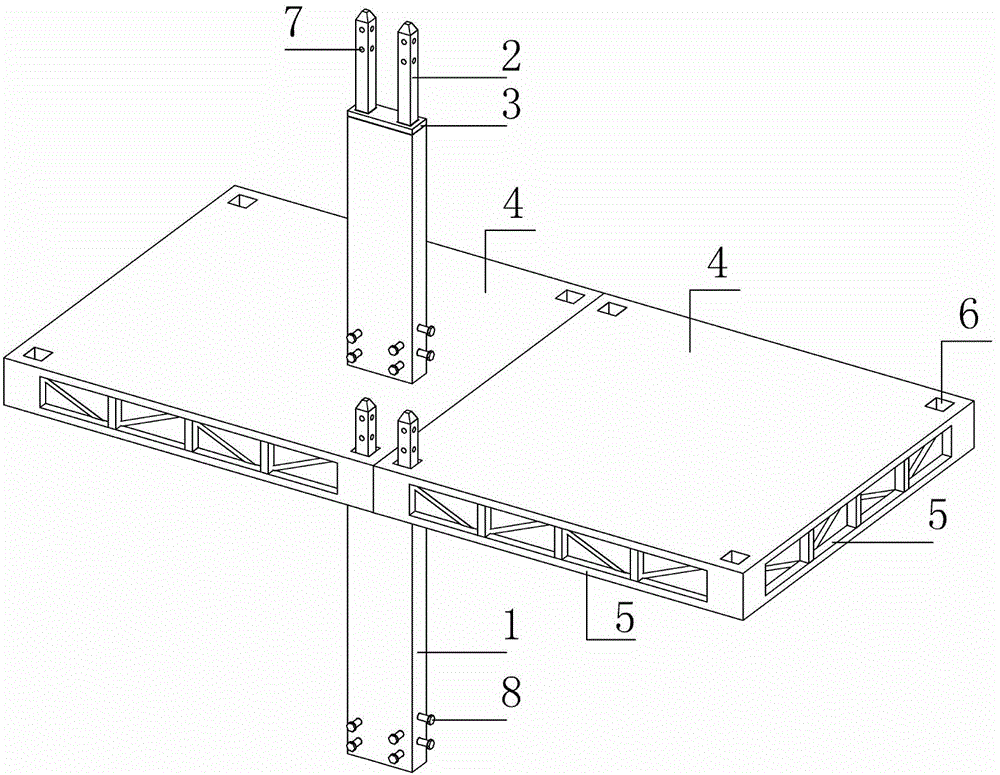

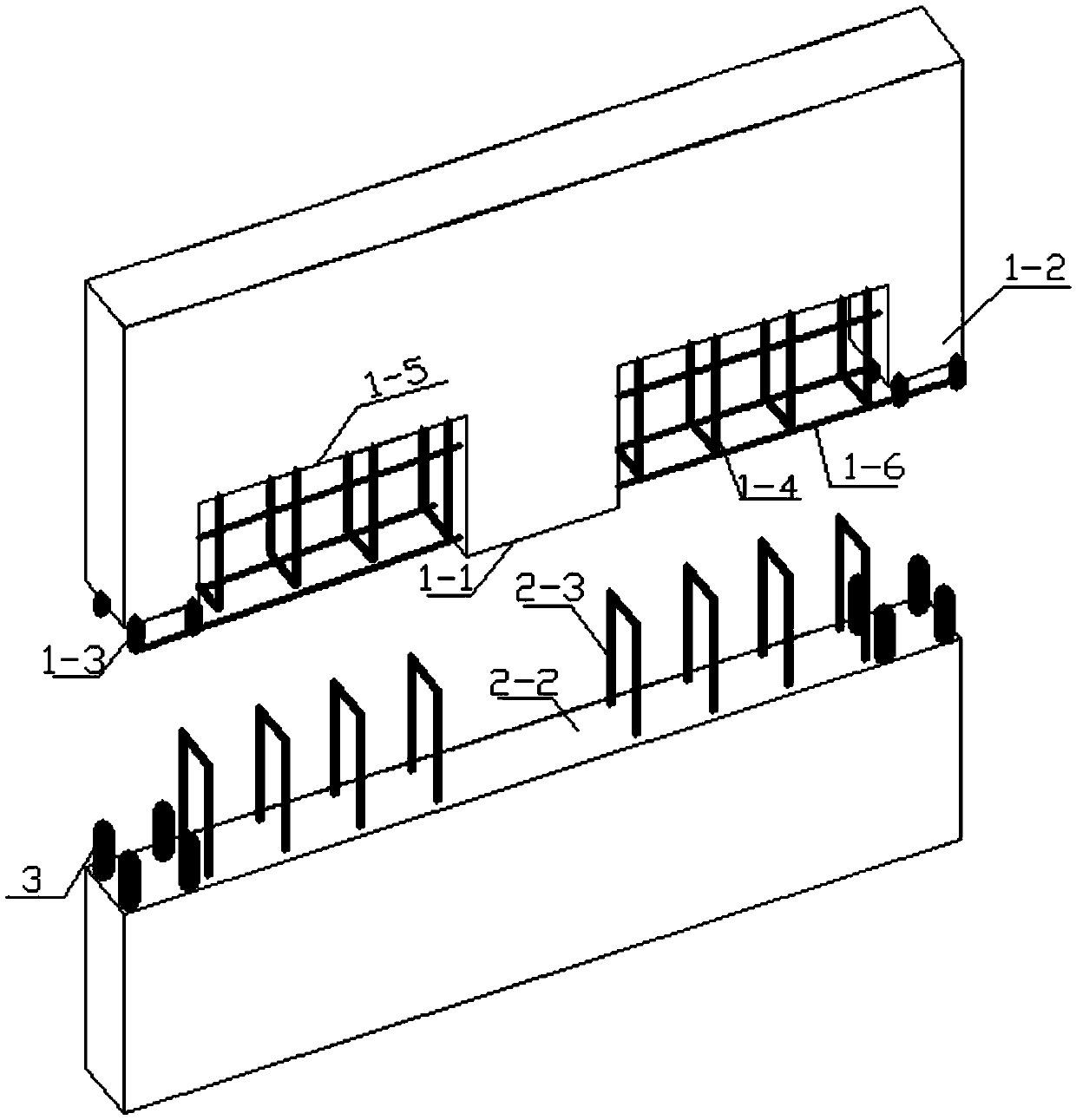

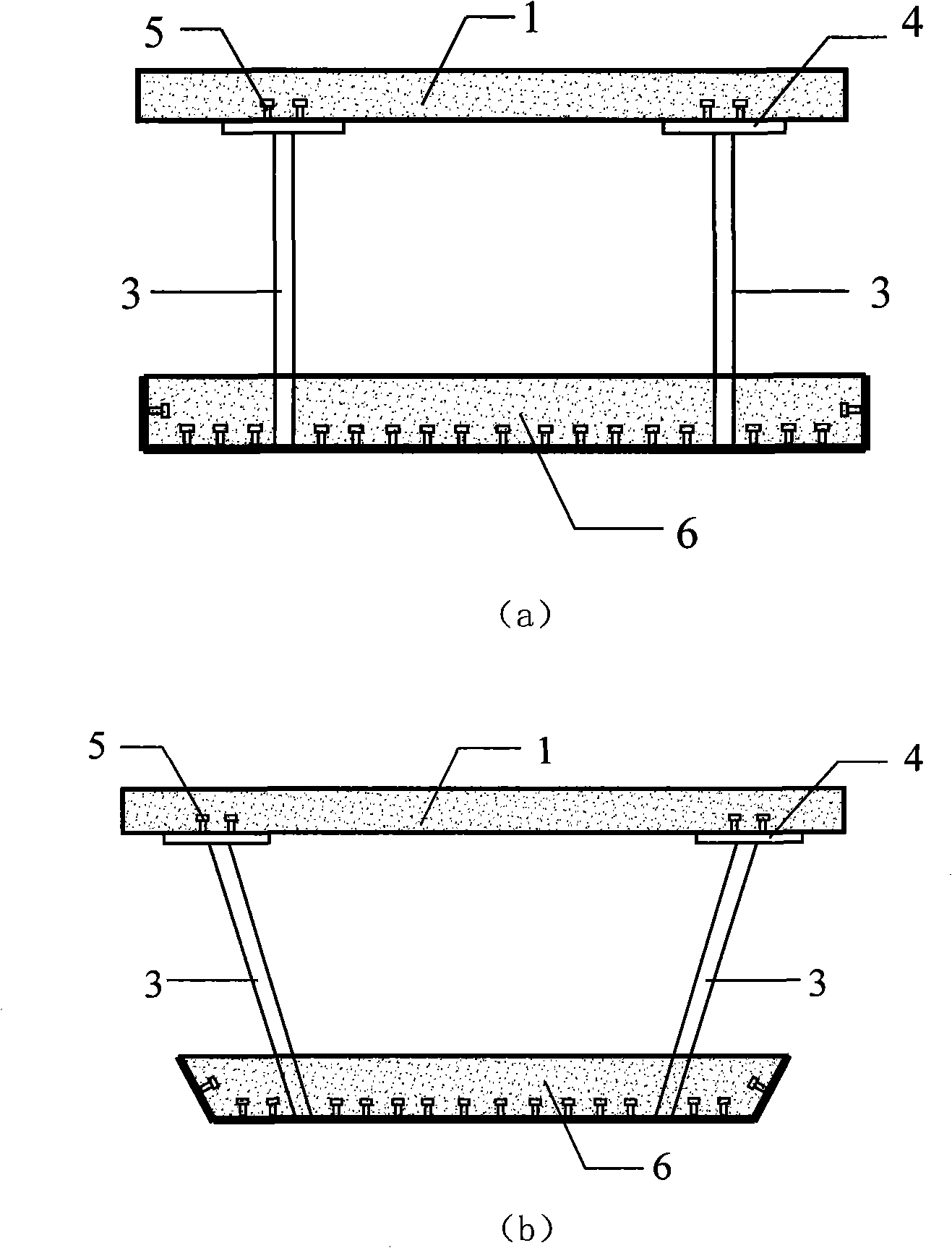

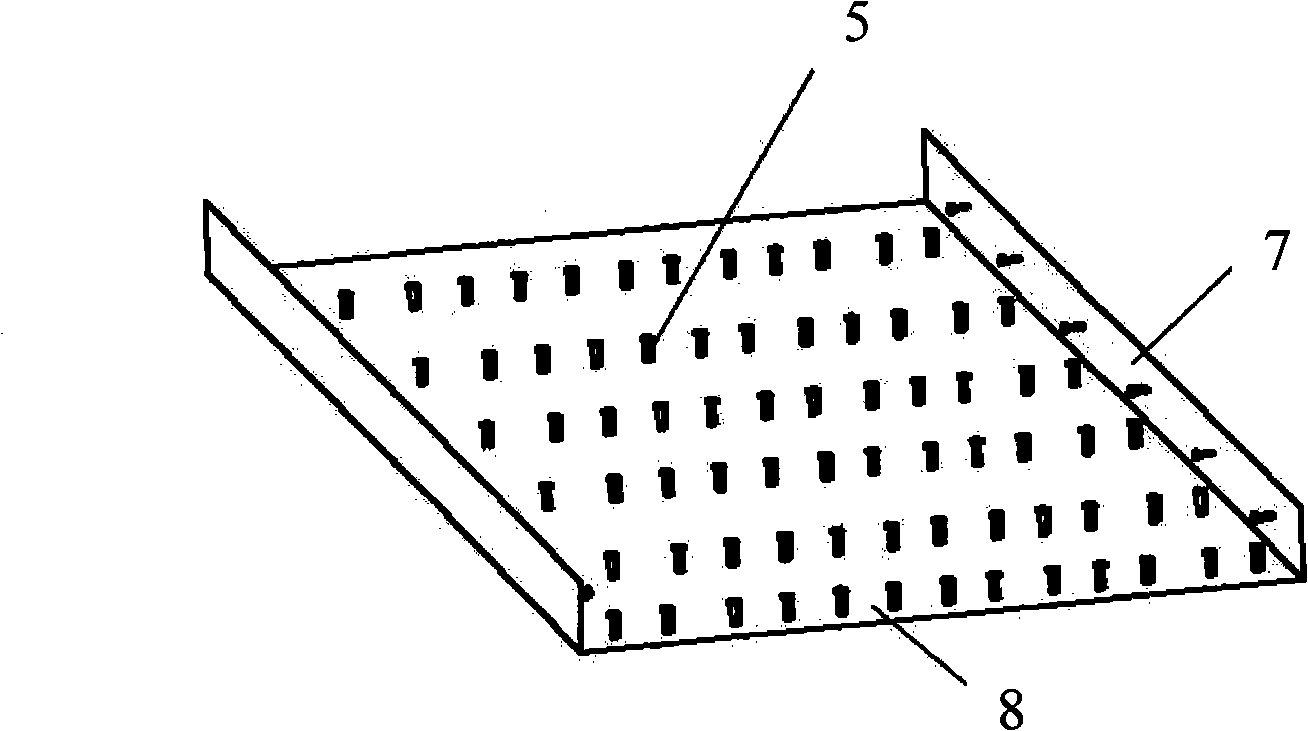

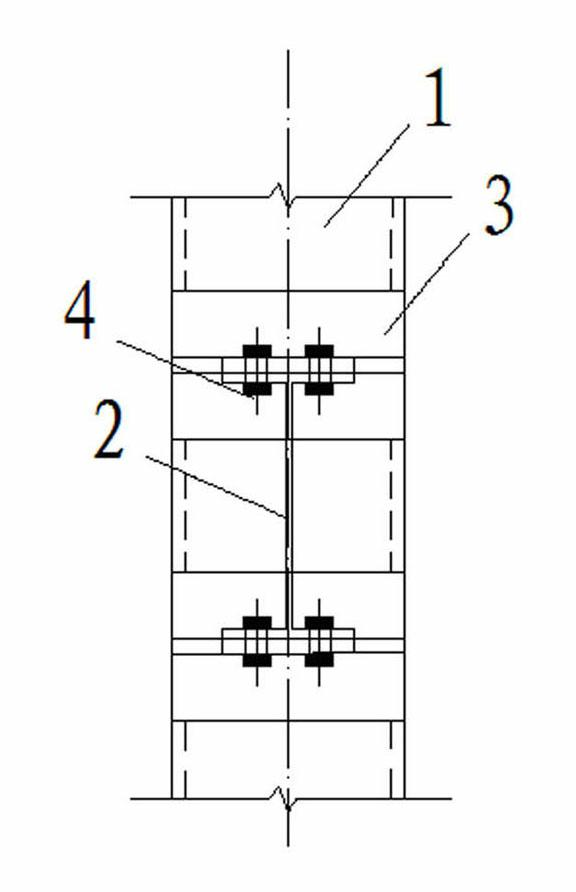

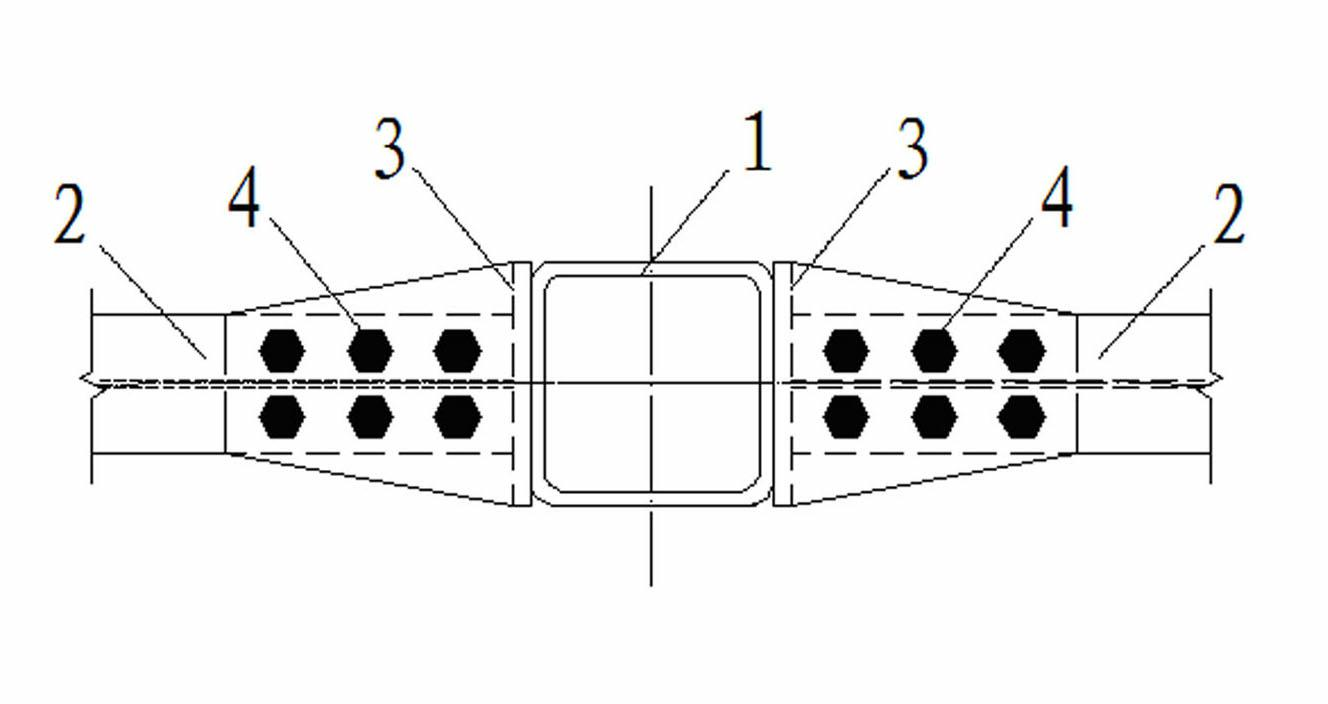

Prefabricated slab and column mortise and tenon type connecting joint and installation method

ActiveCN104947803AEnsure structural safetyGuaranteed structural qualityBuilding material handlingFloor slabMortise and tenon

The invention discloses a prefabricated slab and column mortise and tenon type connecting joint and an installation method. The connecting joint comprises a composite frame column, a floor slab and a high-strength bolt. A column end sealing plate is welded to the top end of a column body, and the bottom end of a column tenon is welded to the column end sealing plate. Frame beams on the periphery are structural steel or structural steel combination trusses. Tenon holes are hollow steel members connected with the frame beams, the cross section shape of the tenon holes is the same as that of the column tenon, and the cross sections of the tenon holes are larger than the cross section of the column tenon but small than the cross section of a body of the composite frame column. Composite frame columns and floor slabs are sequentially connected and fixed through bolt holes and high-strength bolts. By means of tenon and mortise type connection of slabs and columns prefabricated in a factory, the structure form and the installation mode are greatly simplified, the structural safety and quality of a building can be guaranteed better, the field workload is reduced, the construction environment pollution is reduced, the construction period is shortened, and cost is saved.

Owner:江苏保力装配式住宅工业有限公司

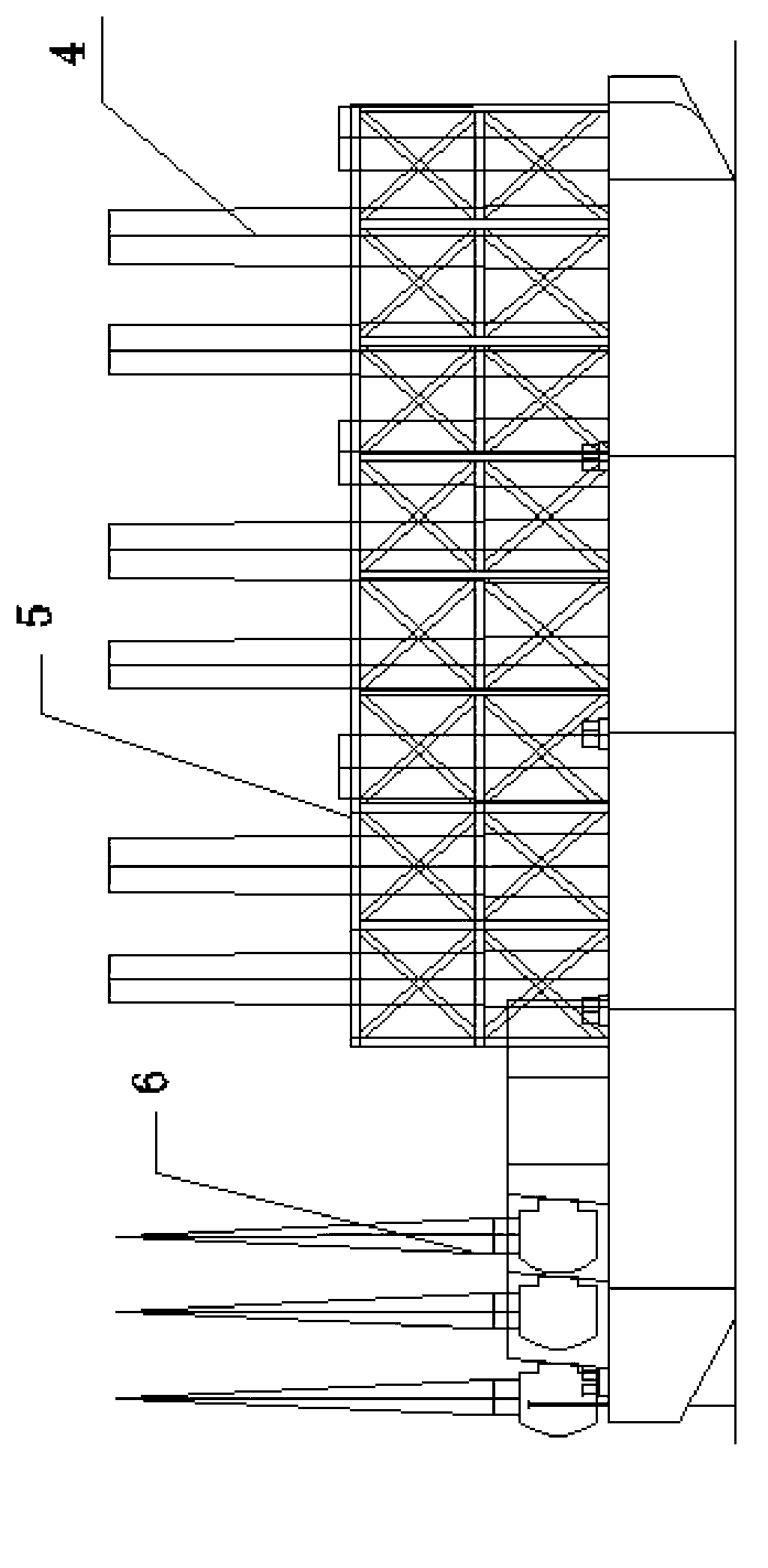

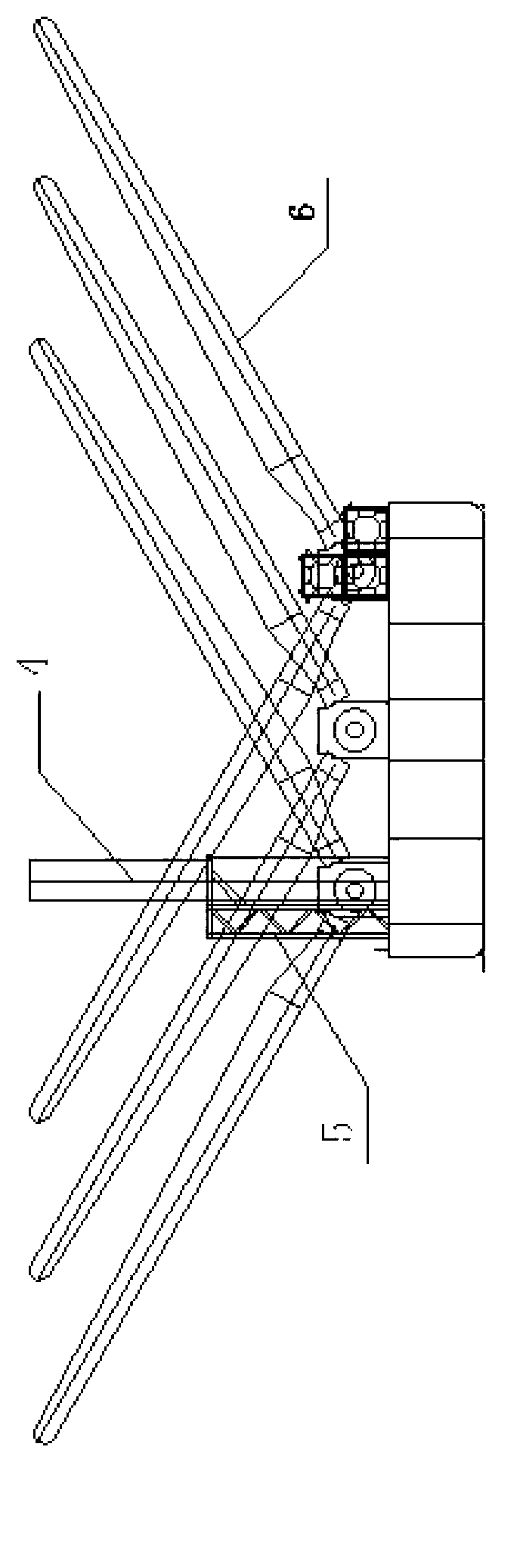

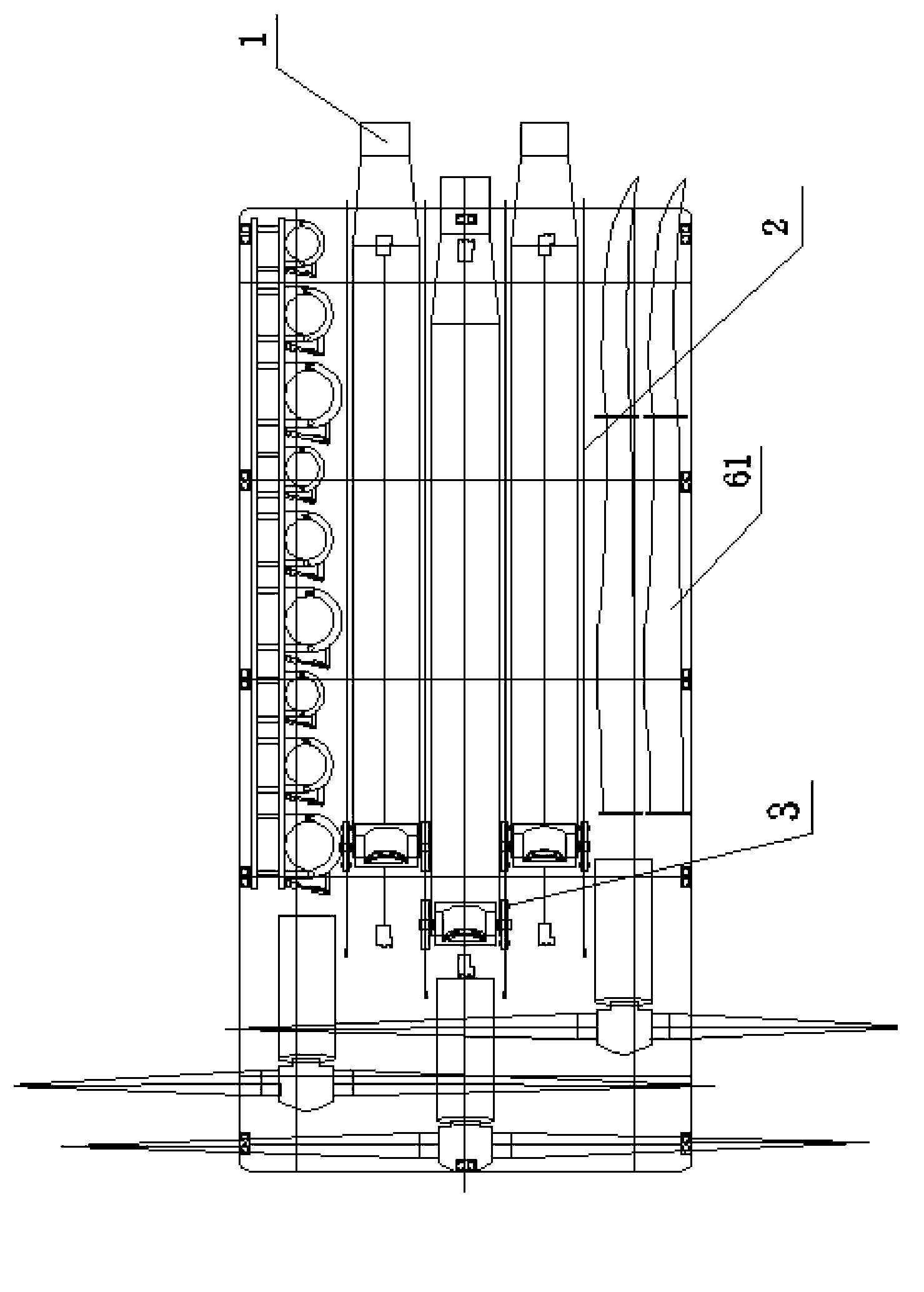

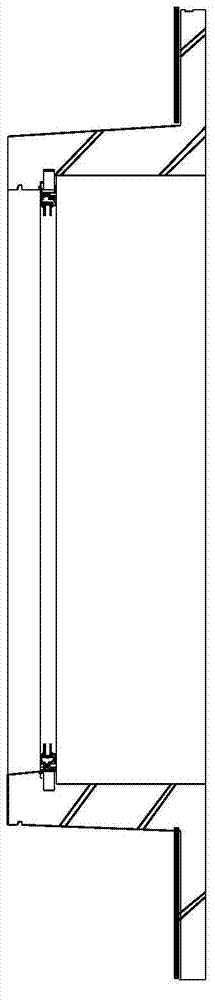

Transition-section-free single-pile foundation construction and fan equipment installation process for shallow sea area wind farm

ActiveCN103015445AReduce on-site workloadThe effect of reduced wind speedFoundation engineeringShallow seaMature technology

The invention discloses a transition-section-free single-pile foundation construction and fan equipment installation process for a shallow sea area wind farm. The process comprises a transportation method. The transportation method comprises the following steps of: arranging single pipe piles on a transportation ship, arranging tracks and pulley devices below the single pipe piles, hanging a rigging after arriving at a construction sea area, and directly erecting piles; dividing a tower into two or three sections, placing each section of tower onto a tower bracket for transporting vertically, erecting, and arranging all small parts including electrical appliance cabinets and the like in the tower to lower field workload; constructing rabbit assemblies by using a cabin, hubs and two blades for transportation to lower field workload and lower the influence of wind speed; and designing a special tool for remaining blades, wherein overlaid transportation can be performed to fully utilize the space of the transportation ship. The transition-section-free single-pile foundation construction and fan equipment installation process for the shallow sea area wind farm disclosed by the invention has the advantages of mature technology, low tool cost, easiness in operating, vertical degree adjusting function, reduction in hoisting times, great increase in the construction efficiency, great saving of ship renting and amortizing cost, and reduction in the construction cost.

Owner:JIANGSU LONGYUAN ZHENHUA MARINE ENG

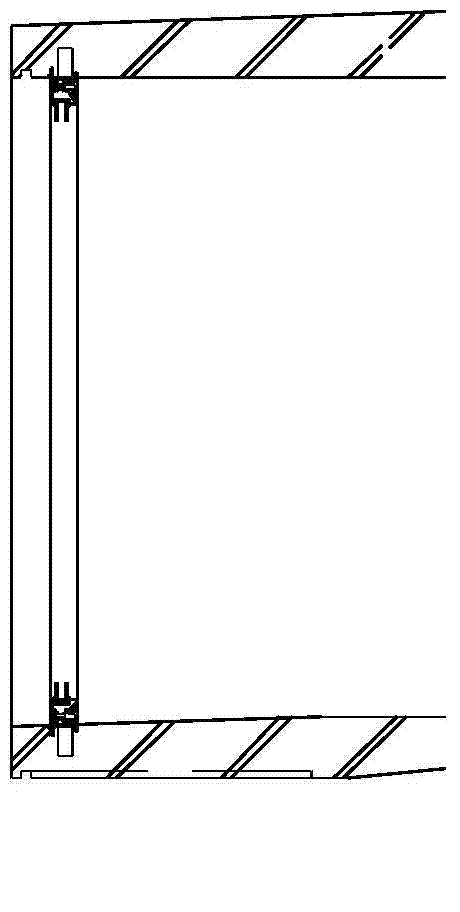

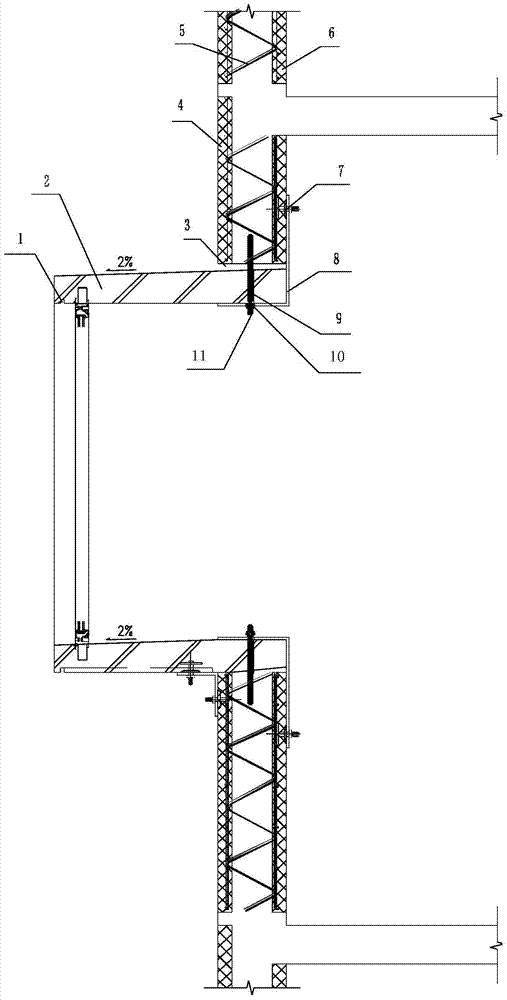

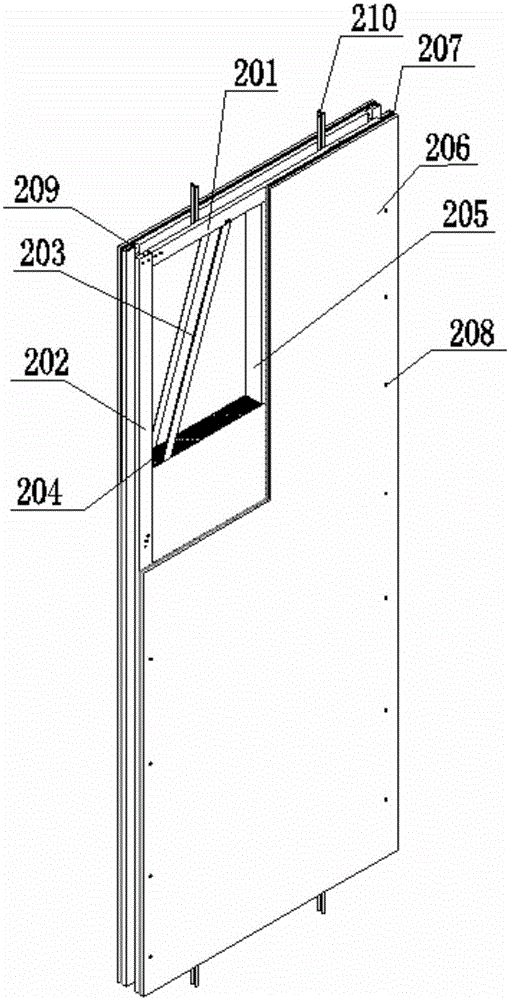

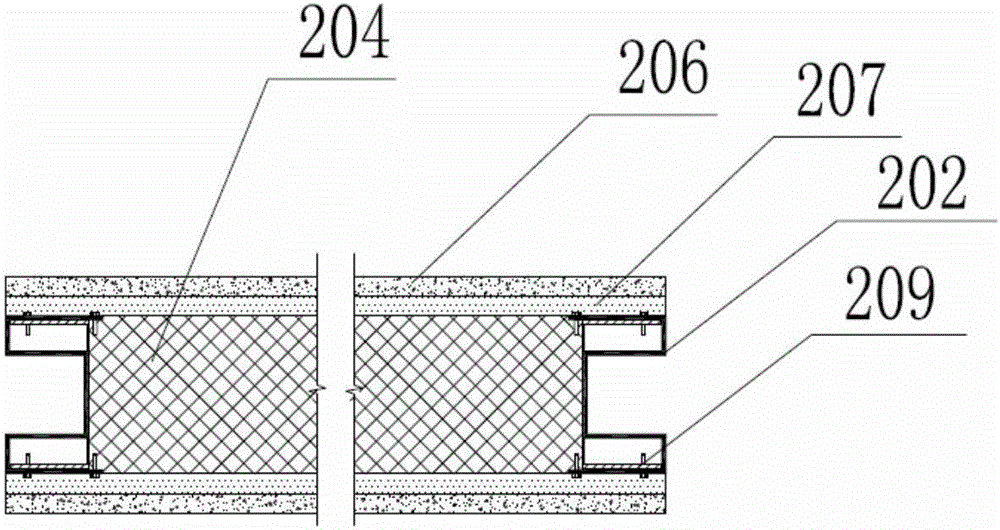

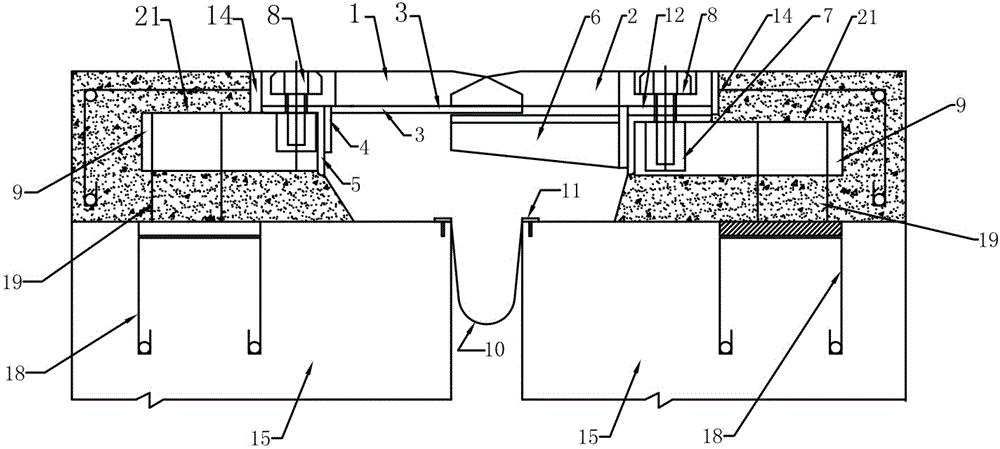

Prefabricated bay window structure installed on laminated wall board and installing method

The invention relates to the window installing technology in the building field, in particular to a prefabricated bay window structure installed on a laminated wall board. A prefabricated bay window (2) is composed of an upper eave, a lower eave, a left vertical face and a right vertical face of the prefabricated cement board bay window, and embedded screw tubes (9) or nuts (7) are arranged at the corresponding joints of the periphery of the prefabricated bay window (2) and the laminated wall board. An installing method of the prefabricated bay window comprises the steps that firstly, a rectangular frame is formed; secondly, the nuts (7) are embedded; thirdly, the prefabricated bay window (2) is inserted and is flush with the inner wall of the laminated wall board; fourthly, a plurality of pieces of L-shaped angle iron (8) are prepared; fifthly, the inequilateral L-shaped angle iron (8) is arranged on the inner wall, and long screw rods (11) are screwed in the embedded screw tubes (9) through nuts; sixthly, the equilateral L-shaped angle iron (8) is arranged on the outer wall; seventhly, caulking is carried out through mortar (3) for blockage, and concrete is poured in a middle cast-in-place layer of the laminated wall board. The prefabricated bay window is not provided with an outer folded edge, the occupied space is small, manufacturing, storing and transporting are very easy and convenient, the prefabricated bay window structure is suitable for building window frame and laminated wall board factory-like line production, field assembling is easy, the construction speed is increased, the work period is shortened, the construction quality is high, and cost is saved.

Owner:BAOYE GROUP CO LTD +1

Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

ActiveCN102146658AReduce stress concentrationReduced risk of crackingSuspension bridgeBridge structural detailsCrack resistanceBridge deck

The invention discloses a locally uncombined suspension bridge steel-concrete combined bridge deck system and a construction method of the combined bridge deck system, and belongs to the technical field of bridge structures. The bridge deck system consists of concrete slabs, longitudinal steel beams, cross steel beams, air nozzles and toggle pin connectors; and a suspension bridge section steel-concrete combined bridge deck system is prefabricated in a factory. The prefabricated concrete slabs and section steel main beams form a whole through concrete wet joints and the toggle pin connectors. The prefabricated concrete slabs and cast-in-place concrete joints are only connected with the cross steel beams to form a whole through the toggle pin connectors, the longitudinal steel beams are not provided with the toggle pin connectors, and meanwhile, the toggle pin connectors are not arranged in a certain area of the ends of the cross steel beams at hoisting points. The problems of cracking, complex structures of toothed grooves at the slab ends of the prefabricated concrete slabs and the like due to the factors of temperature, contraction, creep and the like of the concrete slabs of the traditional suspension bridge combined bridge deck system are solved by adopting a locally uncombined technology on the premise of keeping the consumption of steel, the manufacturing process of the prefabricated slabs is simplified, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved.

Owner:TSINGHUA UNIV

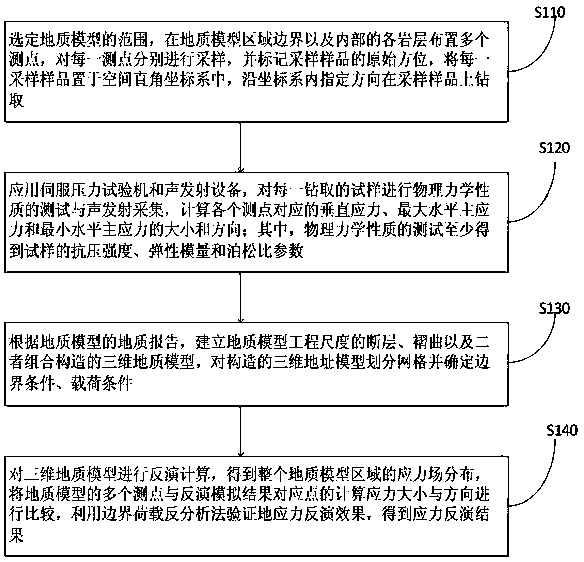

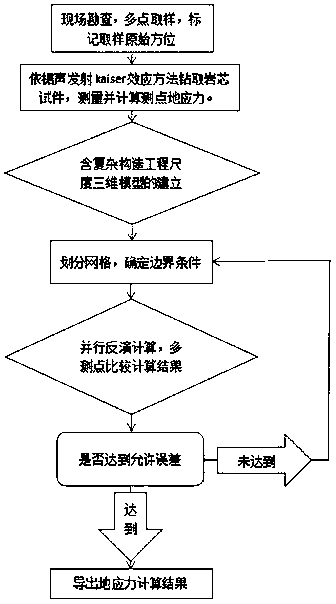

Crustal stress field inversion method based on three-dimensional modeling

ActiveCN108693572ARealize fine measurementReduce on-site workloadMaterial analysis using acoustic emission techniquesMaterial strength using tensile/compressive forcesStress distributionNumerical models

The invention discloses a crustal stress field inversion method based on three-dimensional modeling, and the method just needs the sampling operation on an engineering site, thereby reducing the onsite workload, achieving multi-point sampling and achieving the fine measurement of a crustal force at multiple points. An engineering large-scale three-dimensional numerical model comprising a single structure or a complex structure can be constructed, and the parallel computing is employed for the inversion of the distribution features of the crustal force of an inversion research area. The methodcan obtain the overall distribution conditions of the crustal force visually, and achieves the effective extraction and checking of the information of vertical stress, maximum horizontal main stress,minimum horizontal main stress and directions of a model at different horizontal planes, different inclined surfaces and different structures.

Owner:TAIYUAN UNIV OF TECH

Segment assembled type combined highway and railway cable-stayed bridge with inconsistent bridge deck widths of highway and railway

ActiveCN103882801AReduce on-site workloadReduce construction difficultyCable-stayed bridgeCable stayedBridge deck

The invention relates to a girder type of a segment assembled type combined highway and railway cable-stayed bridge with inconsistent bridge deck widths of a highway and a railway. A girder is composed of a main truss, an auxiliary truss, a highway bridge face and a railway bridge face. The upper-layer bridge face is wide, the lower-layer bridge face is narrow, the width of the main truss is determined by the railway bridge face, and the width of the auxiliary truss is determined by the highway bridge face. Supporting rods for supporting the highway bridge face on the two sides are arranged on a main truss bottom chord in a suspension mode. Auxiliary truss upper chords and the supporting rods form the auxiliary truss together. Stay cables are anchored on the auxiliary truss upper chords through anchor tensile plates. The highway bridge face is welded to main truss upper chords and the auxiliary truss upper chords. The railway bridge face is welded to main truss bottom chords. The upper ends and the lower ends of flange plates of the auxiliary truss supporting rods are welded to the auxiliary truss upper chords and the main truss bottom chords respectively. Web plates of the auxiliary truss upper chords and the flange plates of the auxiliary truss supporting rods are identical in inclined angle. The segment assembled type combined highway and railway cable-stayed bridge with the inconsistent bridge deck widths of the highway and the railway is simple in structure, economical in manufacturing cost and clear and direct in stress, is manufactured by welding whole segments in a factory, and is assembled and erected through the whole segments on a construction site, the construction difficulty in the severe environment of straits is greatly lowered, and the bridge is adopted in the combined highway and railway cable-stayed bridge of the Pingtan strait.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

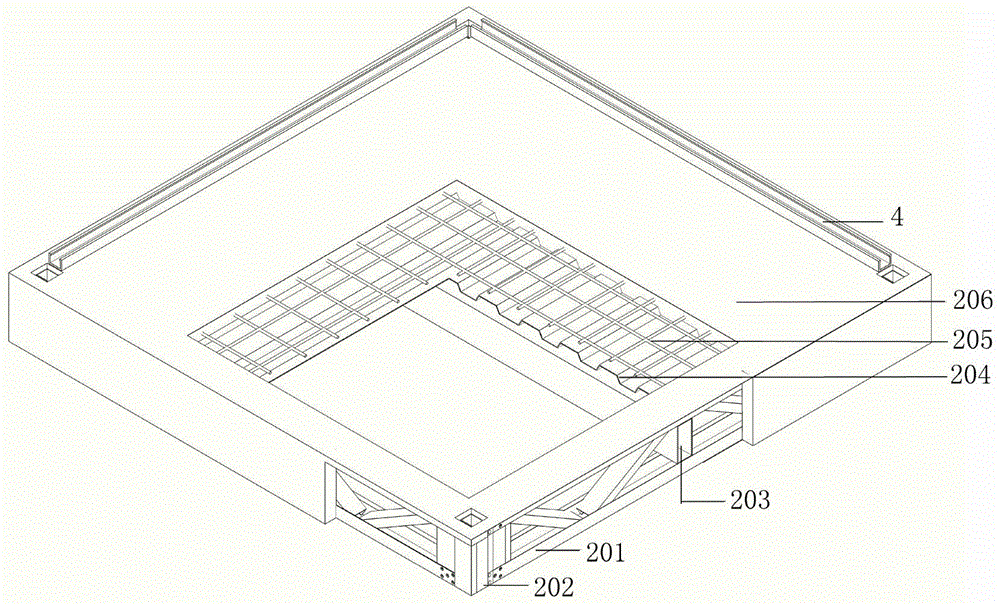

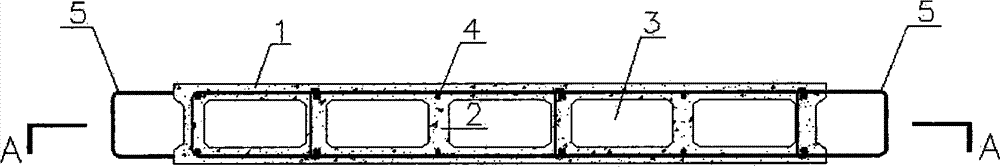

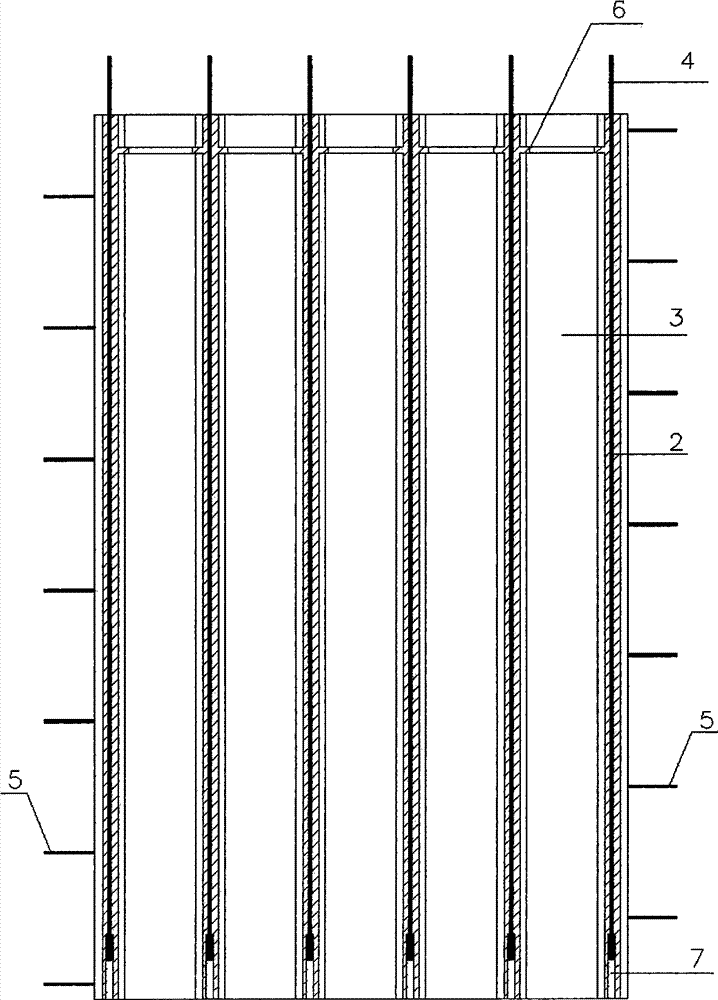

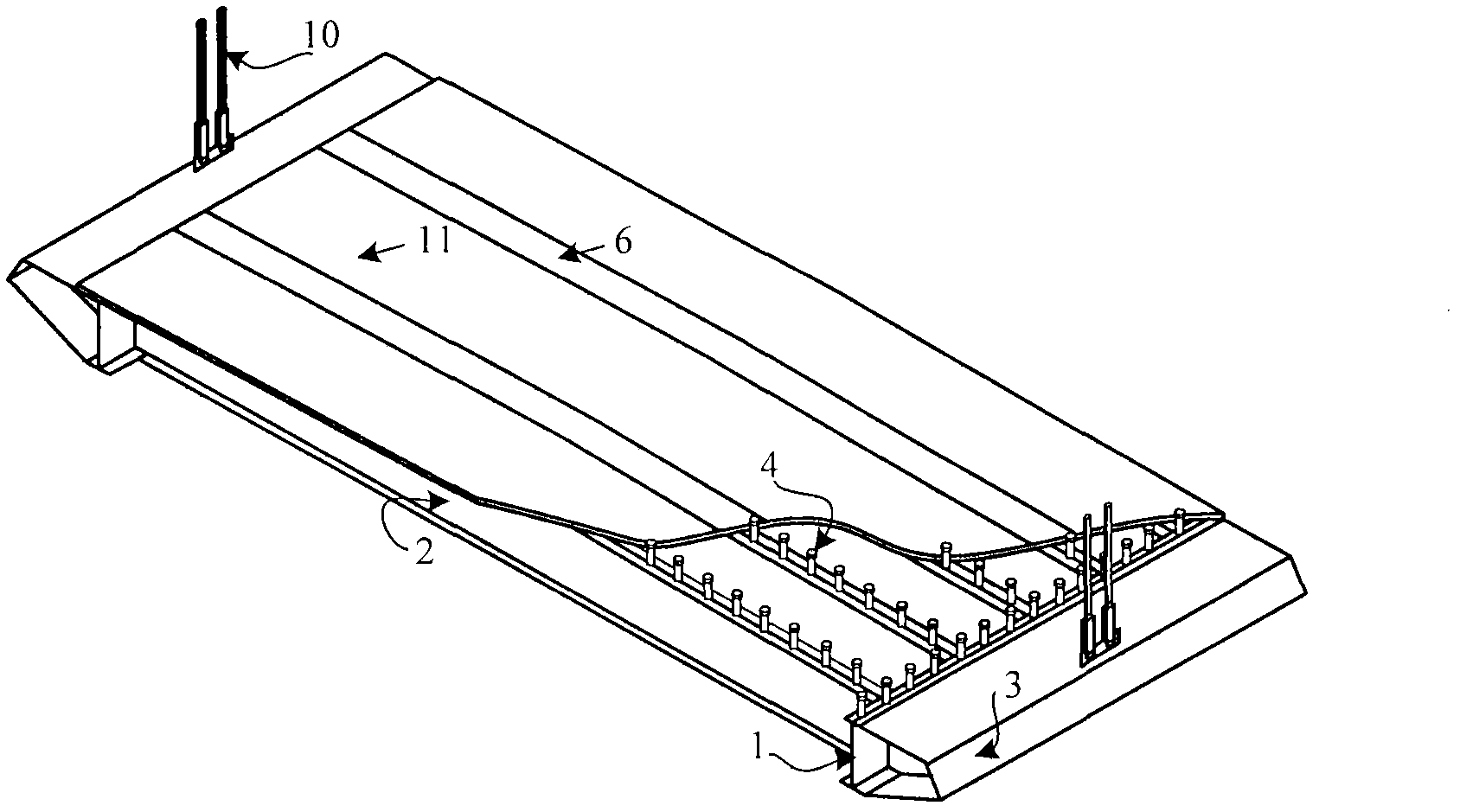

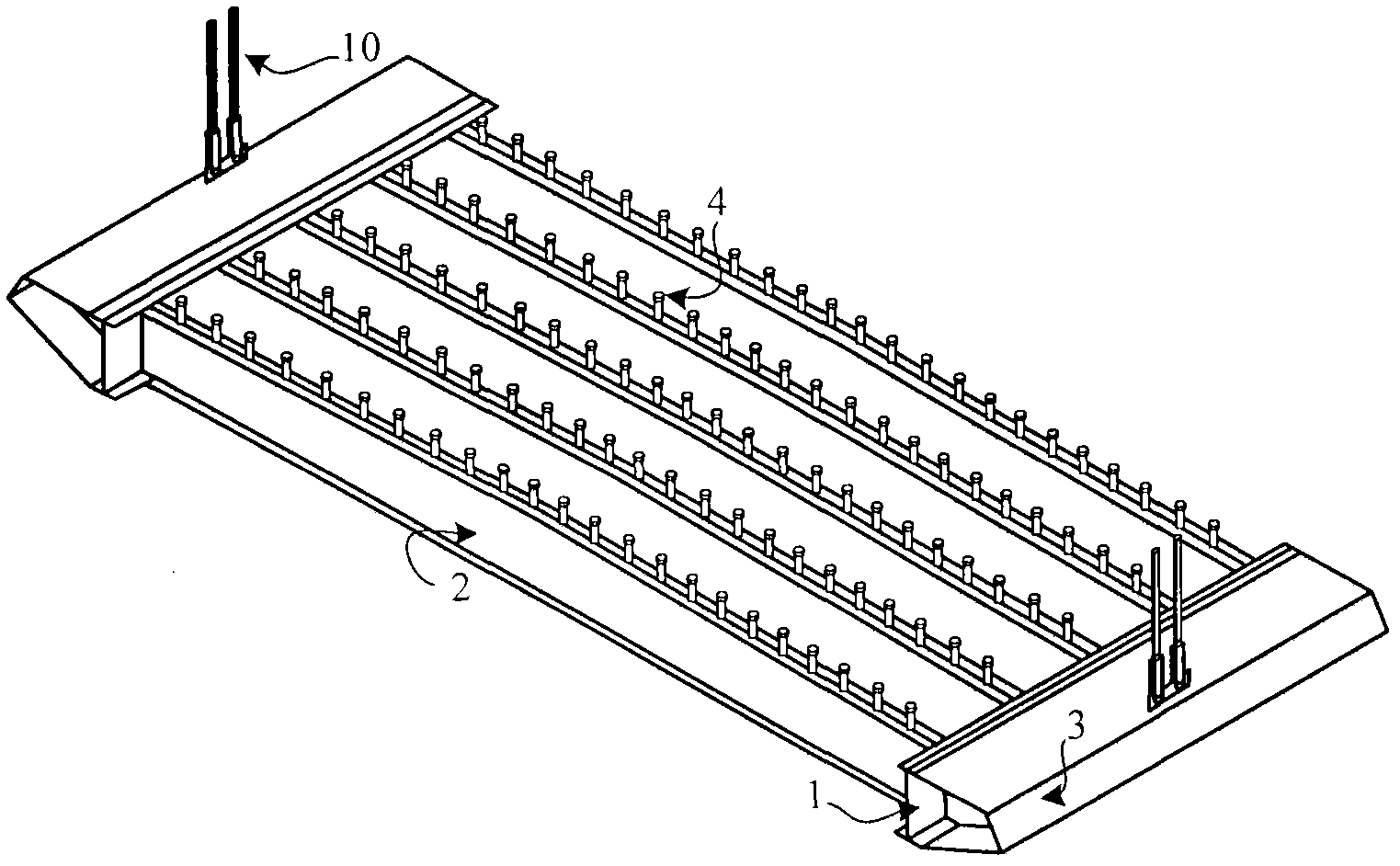

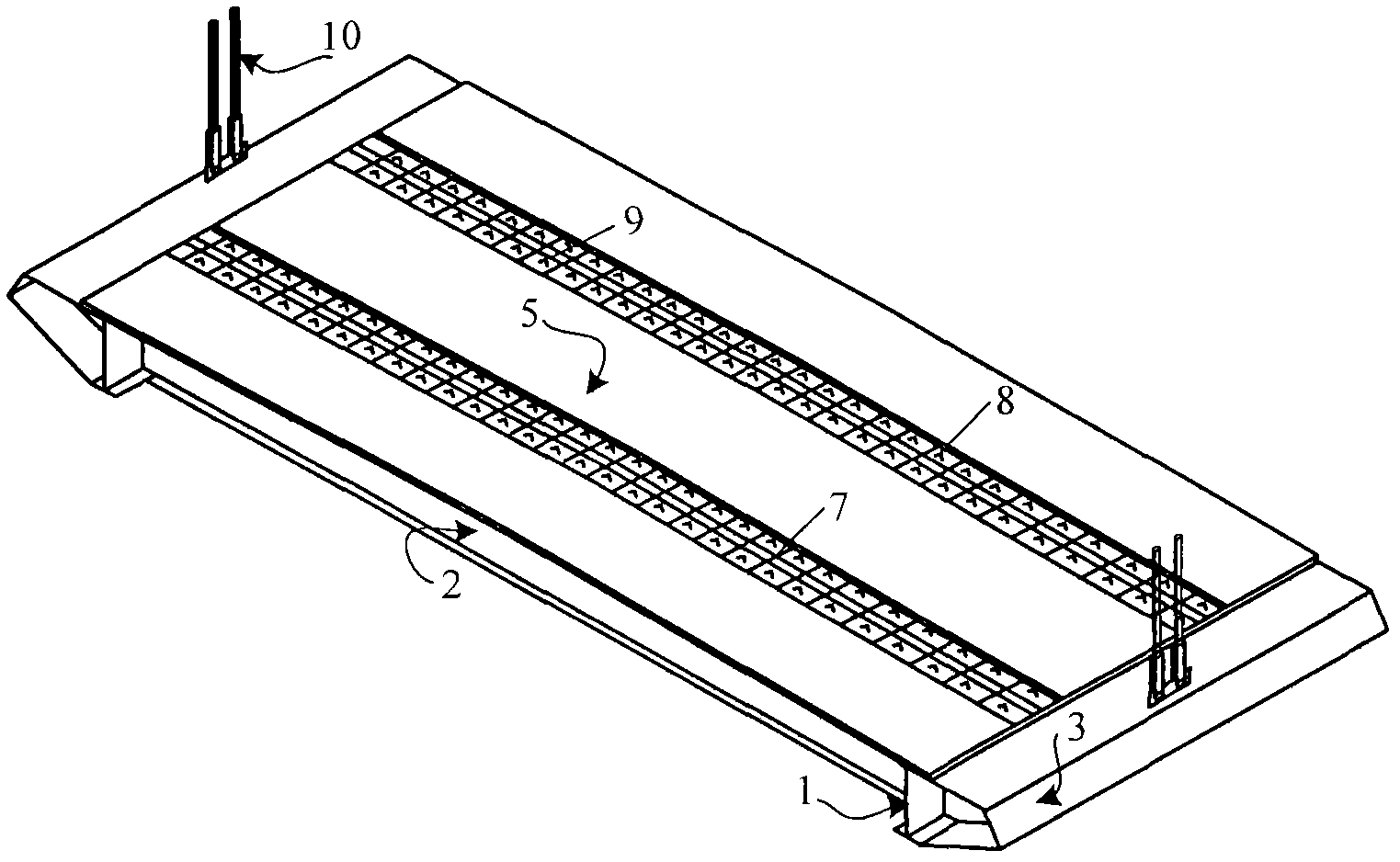

DGC board-type assembled house system and construction method and manufacturing method thereof

InactiveCN105804233AImprove prefabrication rateEnsure structural safetyWallsFloorsModular compositionInsulation layer

The invention discloses a DGC board-type assembled house system and a construction and a manufacturing method thereof. A basic unit of the system is formed by floor slabs and wallboards which are combined and assembled in a modularized manner; the wallboards are prefabricated composite boards, each wallboard mainly consists of a light-steel frame, a peripheral guard board, a sandwich insulation layer, a heat insulating layer and turnbuckles, and different wallboard standard modules such as in-line wallboards, L-shaped wallboards, T-shaped wallboards and cross-shaped wallboards are adopted and freely combined; the floor slabs are prefabricated composite boards, the floor slabs are used as foundation slabs, floor slabs or roof slabs of the DGC board-type assembled house system, and vertical connection between the floor slabs and the wallboards in the system consists of combined connection of lateral connection of horizontal M-shaped steel, M-shaped chord members and square steel pipes through tapping screws and vertical connection of the turnbuckles in trusses. According to the DGC board-type assembled house system and the construction method and the manufacturing method thereof, the structure is simple, the construction speed is fast, the construction period is reduced, the cost is low, and the defects of single structure, complex installation process and high labor cost of the existing assembled house structure can be overcome.

Owner:江苏保力自动化科技有限公司

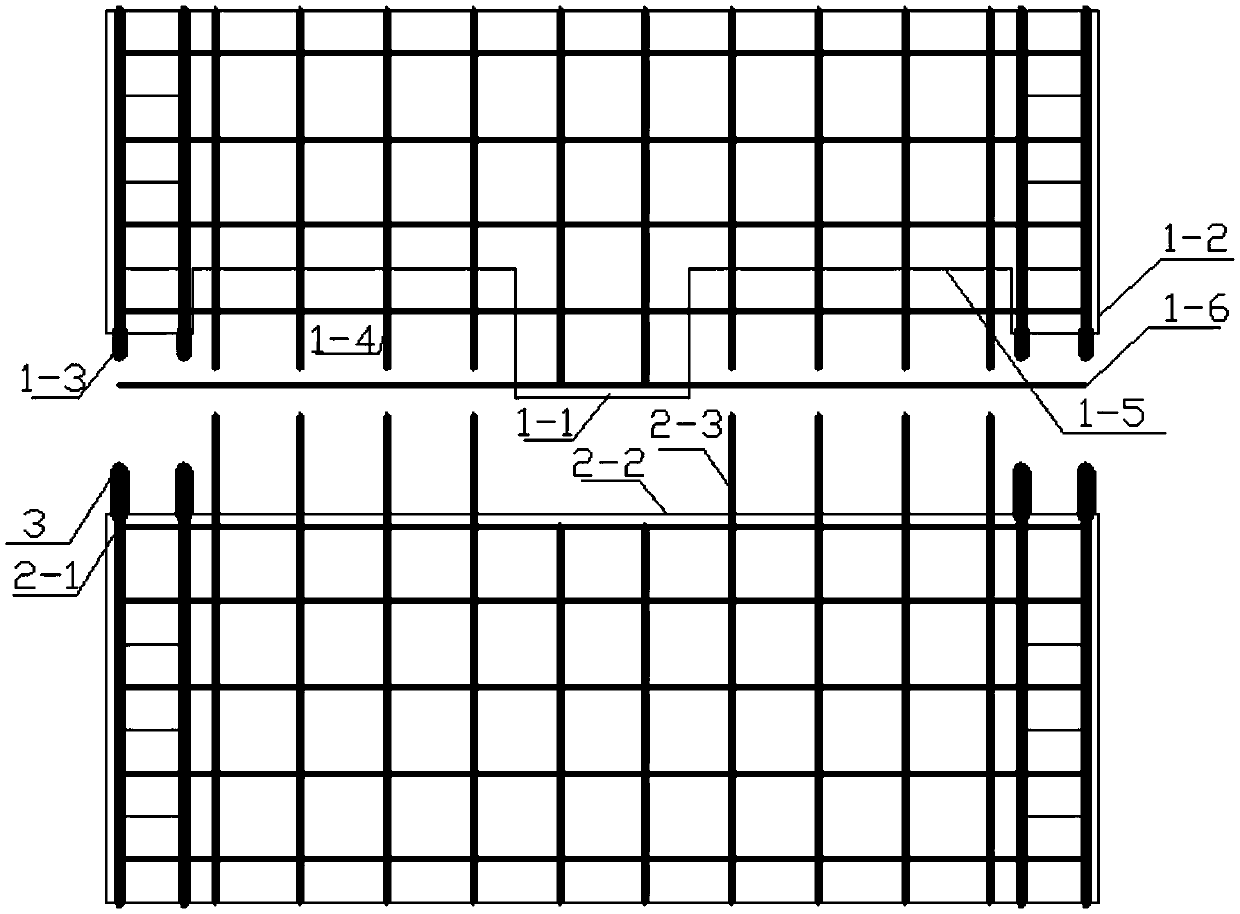

Assembled type shear wall upper-layer and lower-layer combined connection structure

The invention discloses an assembled type shear wall upper-layer and lower-layer combined connection structure which comprises an upper-layer prefabricated wall and a lower-layer prefabricated wall which are connected in a butted mode. When the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected in the butted mode, a downward-protruding supporting structure of the upper-layer prefabricated wall is supported on the lower-layer prefabricated wall, structural longitudinal ribs of an embedded column of the upper-layer prefabricated wall and structural longitudinal ribs of an embedded column of the lower-layer prefabricated wall are opposite in a one-to-one mode and are connected mechanically, the structural longitudinal ribs I of the upper-layer prefabricated wall and the structural longitudinal ribs II of the lower-layer prefabricated wall are connected in an overlapped mode, and the upper-layer prefabricated wall and the lower-layer prefabricated wall are connected at the joint through a cast-in-place concrete structure. The combined connection way combined with the cast-in-place concrete structure is formed through mechanical connection, steel bar splicing and concrete spraying, the wall prefabrication technology is simpler, on-site construction is more convenient and rapider, and the workpiece manufacturing cost and the construction cost can be reduced.

Owner:TIANJIN UNIV

Corrugated steel web box girder with steel-concrete combined board lower wing edges

InactiveCN101280547AOvercoming Construction ComplexityReasonable structureLoad-supporting elementsBridge materialsCrack resistanceSheet steel

The invention relates to a corrugated steel web box beam with steel-concrete composite plate bottom flange, in particular to a corrugated steel web box beam that is applied in railway and bridges. The corrugated steel web box beam is composed of a top flange concrete slab, a corrugated steel web and a steel-concrete composite plate bottom flange, wherein steel-concrete composite plate is composed of a slotted steel plate formed by side plates and bottom plates, and a concrete, the steel plate is welded with bolts and reinforced meshes are arranged at middle position of the concrete. The structure can overcome the problem that the traditional corrugated steel web box beam has complicated construction for steel structure positioning on the spot, and also can exert tensile strength of the steel plate so as to improve crack resistance of structure effectively and avoid crack from being exposed, so that structural endurance is improved obviously, therefore the work load and difficulty of the construction of concrete in-field casting of box beam bottom flange is reduced greatly. The corrugated steel web box beam with steel-concrete composite plate bottom flange has simple structure, rapid and convenient construction and is easy to meet the requirement of planar shape of bridge, and also has good technical economic benefit.

Owner:TSINGHUA UNIV

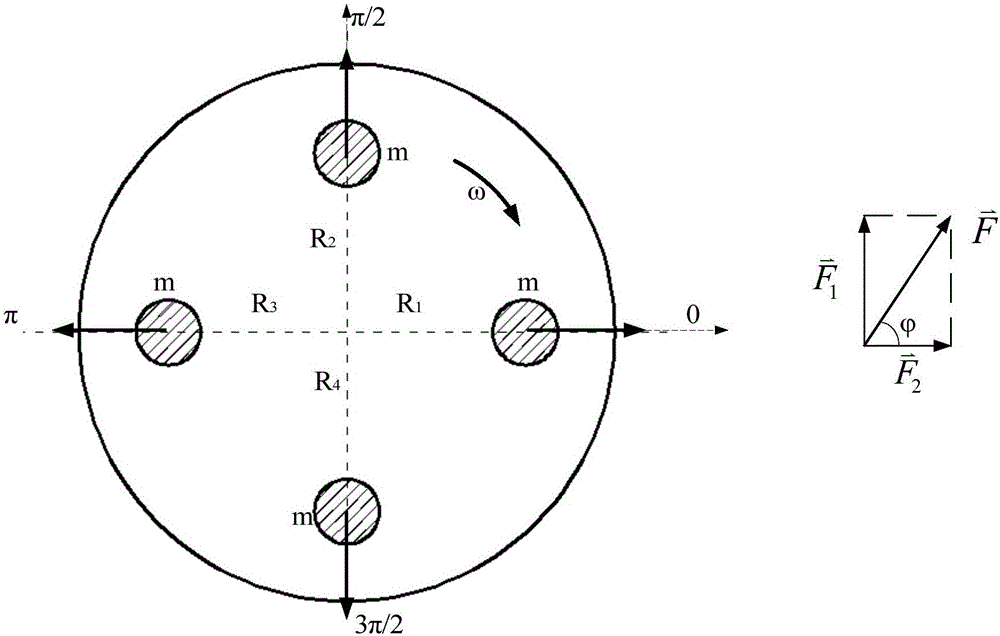

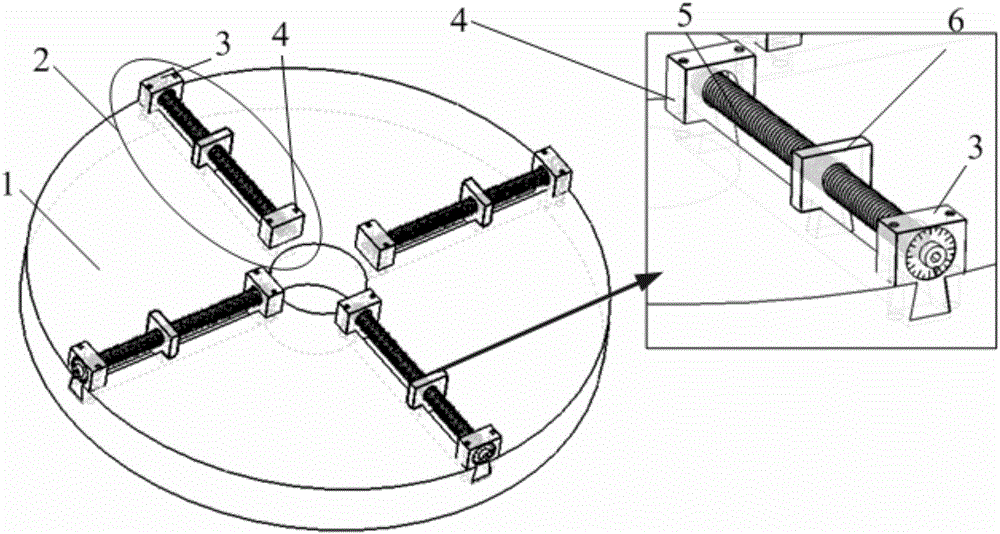

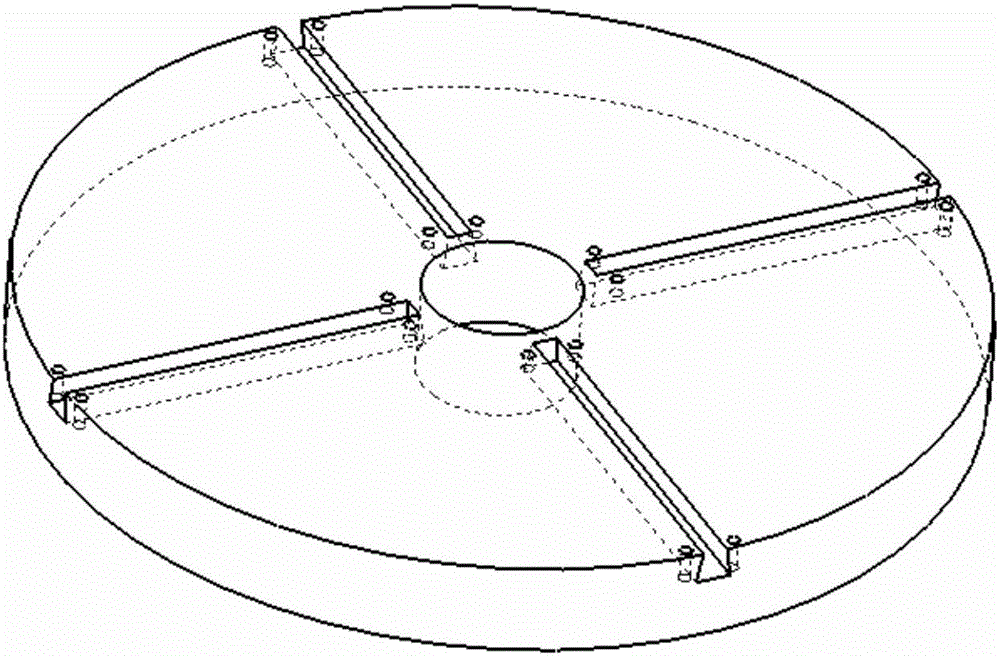

Rotary machinery dynamic balance quick weight-countering adjustment device and method

ActiveCN106768643AEasy to adjust and calculateSave on-site balancing timeStatic/dynamic balance measurementDynamic balanceEngineering

The present invention discloses a rotary machinery dynamic balance quick weight-countering adjustment device. The device comprises a balance disc and at least one pair of weight-countering adjusting components mounted on the balance disc, wherein the weight-countering adjusting components are distributed at equal intervals along the radial direction of the disc surface of the balance disc. According to the rotary machinery dynamic balance quick weight-countering adjustment device of the invention, after weight-countering mass, a weight-countering position and a weight-countering angle are obtained through a traditional dynamic balance algorithm, counterweights are not needed to be temporarily processed on a site, operation such as welding the counterweights is not required, and therefore, field dynamic balance time can be greatly decreased; as for field dynamic balance according to which a weight-countering position is provided with a cylinder or a shaft sleeve, it only needs to reserve adjustment holes, and a special wrench can be adopted to conveniently and fast adjust the weight-countering adjustment device of the invention through the adjustment holes, and therefore, field workload can be greatly decreased; and since the adjustment of the positions of the counterweights can be carried out through screw rods, and the positions of the counterweights can be adjusted very precisely, and the precision of dynamic balance is improved. The weight-countering adjustment algorithm of the invention is easy to understand and can facilitate field personnel to carry out adjustment and calculation.

Owner:STATE GRID CORP OF CHINA +2

Energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier

InactiveCN104532740AReduced displacement requirementsControl and reduce displacement requirementsBridge structural detailsBridge materialsFiberPre stress

The invention discloses an energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier comprising a bearing platform, a prefabricated assembly bridge pier and a cover beam. The energy-consuming rebar-attached unbonded post-tensioning prestressed concrete filled double-wall steel tube prefabricated assembly bridge pier is characterized in that the prefabricated assembly bridge pier is a concrete filled double-wall steel tube prefabricated assembly bridge pier; the prefabricated assembly bridge pier comprises an outer steel tube, an inner steel tube and filled concrete; the end faces of the top and the bottom of the outer steel tube and the inner steel tube are respectively connected by four steel sheets; fiber-reinforced mortar layers are arranged between the top face of the bearing platform and the end face of the prefabricated assembly bridge pier and between the bottom face of the cover beam and the end face of the prefabricated assembly bridge pier; the bearing platform, the prefabricated assembly bridge pier and the cover beam are assembled integrally by a prestressed tension device; and four common ribbed energy-consuming rebars are respectively between the top face of the bearing platform and the end face of the prefabricated assembly bridge pier and between the bottom face of the cover beam and the end face of the prefabricated assembly bridge pier. The energy-consuming rebar-attached unbonded post-tensioning prestressed concrete fill double-wall steel tube prefabricated assembly bridge pier has the advantages that the construction quality is improved, the construction speed is increased, operational quantity of the scene is reduced, and impact on environment is alleviated. The energy-consuming rebars provide attached energy-consuming capacity for the bridge pier, and the displacement demand of the bridge pier under the action of horizontal load, such as earthquake can be controlled and reduced.

Owner:NINGBO UNIV

Unbonded post-tensioning prestress concrete-filled double-wall steel pipe prefabricated assembly piers with additional dampers

InactiveCN104612036AReduced displacement requirementsControl and reduce displacement requirementsBridge structural detailsBridge materialsPre stressDouble wall

The invention discloses unbonded post-tensioning prestress concrete-filled double-wall steel pipe prefabricated assembly piers with additional dampers. The piers comprise a bearing table, prefabricated assembly pier bodies and a cover beam. The piers are characterized in that prefabricated assembly pier bodies are concrete-filled double-wall steel pipe prefabricated assembly pier bodies, each prefabricated assembly pier body comprises an outer steel pipe, an inner steel pipe and filled concrete, the end faces of the tops and the end faces of the bottoms of the outer steel pipes and the end faces of the tops and the end faces of the bottoms of the inner steel pipes are connected through four steel sheets respectively, fiber reinforcement mortar layers are arranged between the top face of the bearing table and the end faces of the prefabricated assembly pier bodies as well as between the bottom face of the cover beam and the end faces of the prefabricated assembly pier bodies, the bearing table, the prefabricated assembly pier bodies and the cover beam are assembled through prestress tension device to form a whole, and the four viscous dampers are arranged between the top face of the bearing table and the side faces of the prefabricated assembly pier bodies as well as between the bottom face of the cover beam and the side faces of the prefabricated assembly pier bodies. The piers have the advantages that the construction quality is improved, the construction speed is increased, the site operation amount is reduced, and the impact on the environment is reduced; the viscous dampers provide additional energy-consuming abilities for the piers, and therefore the displacement requirement of the piers under horizontal load effects of earthquakes and the like can be controlled and reduced.

Owner:NINGBO UNIV

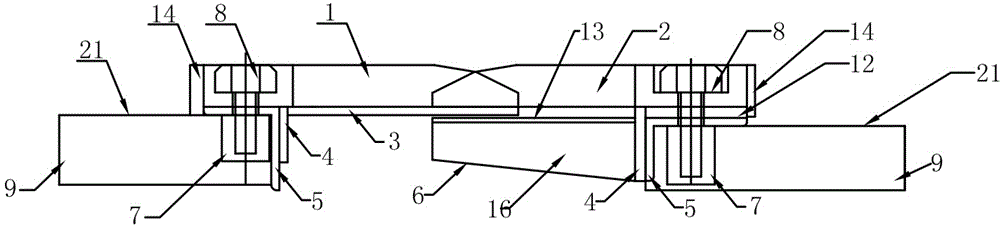

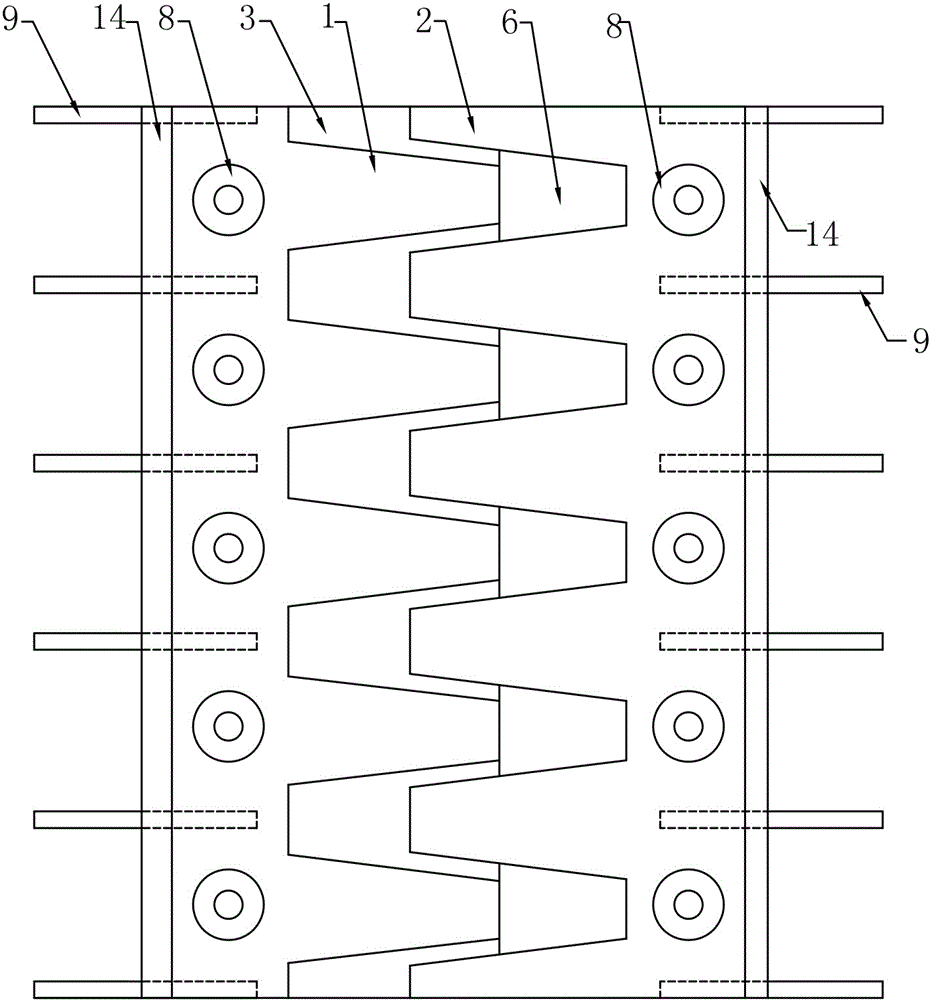

Cantilever and base bolt anchoring type comb plate retractor

InactiveCN104452581AReduce on-site workloadImprove installation qualityBridge structural detailsEngineeringCantilever

The invention discloses a cantilever and base bolt anchoring type comb plate retractor. The cantilever and base bolt anchoring type comb plate retractor comprises a movable tooth plate and a fixed tooth plate, an anti-falling steel plate is welded on the bottom surface of a comb tooth section of the movable tooth plate, and a backing plate is welded on the bottom surface of the rear end of the fixed tooth plate. The cantilever and base bolt anchoring type comb plate retractor is characterized in that an anti-bending steel plate is arranged on the rear end bottom surface of the movable tooth plate and the fixed tooth plate, and slide carriers are arranged on the anti-bending steel plate of the fixed tooth plate; comb teeth of the fixed tooth plate and the movable tooth plate are crossly arranged flatly on the anti-falling steel plate, the rear ends of the movable tooth plate and the fixed tooth plate are fixedly connected with two anchoring bases by bolts, and the anti-falling steel plate is arranged on the slide carriers and slidably connected with a slide steel plate. Compared with the prior art, the cantilever and base bolt anchoring type comb plate retractor has the advantages that assembly and checking can be completed within factories, on-site workload is reduced, mounting quality is improved, service life is prolonged, and on-site mounting, maintenance and replacement speed is accelerated.

Owner:SHANGHAI HUICHENG ARCHITECTURE DECORATION

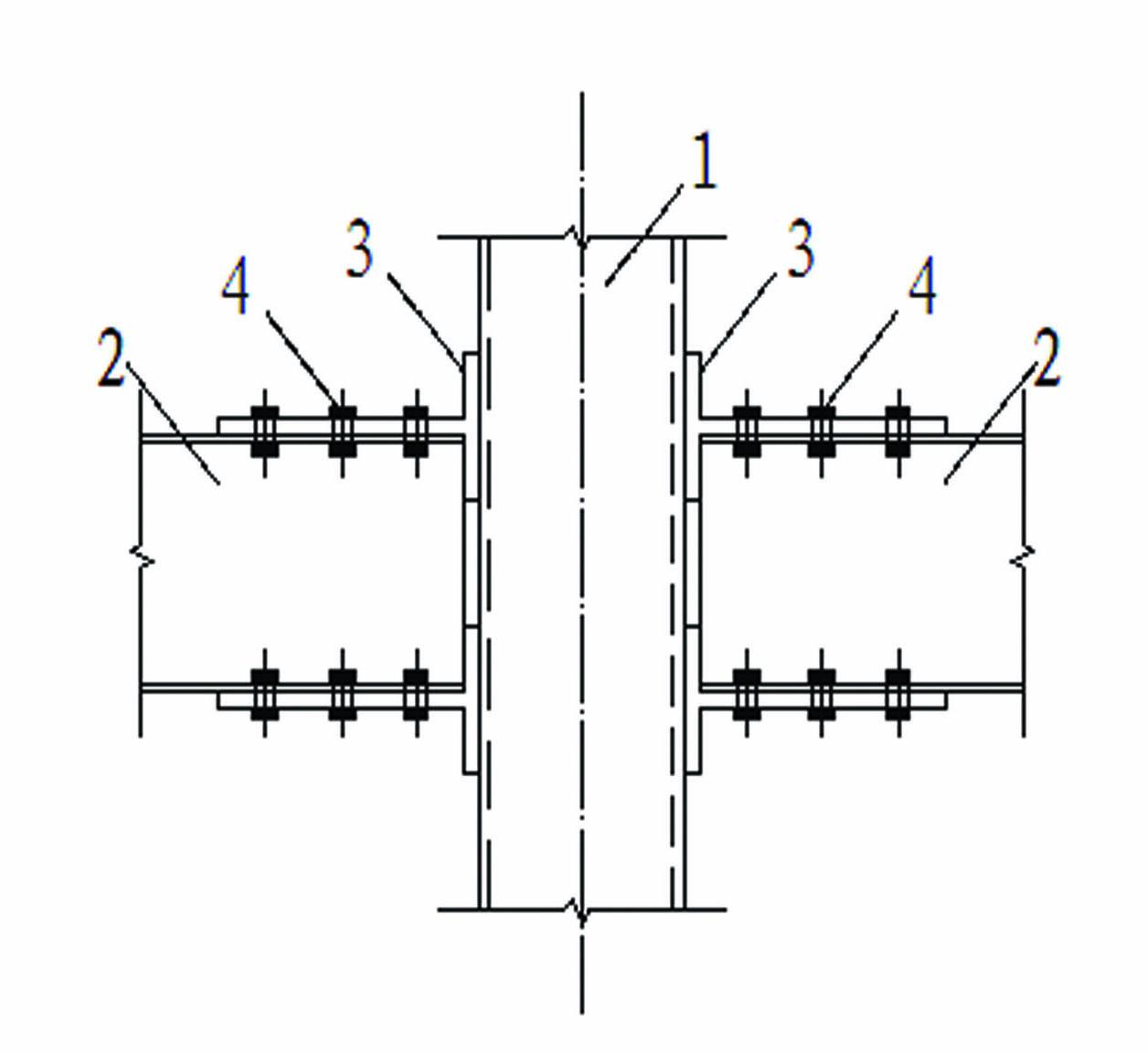

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

Prefabricated assembly type subway station platform and construction method thereof

PendingCN107939074AFlexible construction operationBuild fastSpecial buildingBuilding material handlingArchitectural engineeringSubway station

The invention provides a prefabricated assembly type subway station platform. The prefabricated assembly type subway station platform comprises a prefabricated platform plate and further comprises a prefabricated door type member and a bearing mechanism which are used for bearing the prefabricated platform plate, and the prefabricated door type member and the bearing mechanism are fixed to a station bottom plate. The invention further provides a construction method of the prefabricated assembly type subway station platform. The prefabricated assembly type subway station platform and the construction method have the advantages that construction operation is flexible, the construction speed is high, the site construction period is short, labor force is saved, and the labor cost is reduced are achieved; adopted prefabricated members are all produced in a prefabricating yard in a standardized mode, and materials and energy consumption can be controlled in the prefabricating yard in a centralized mode, so that the production efficiency is improved greatly, and the quality, time and material cost can be controlled simultaneously; and the construction environment is good, and site pollution and noise are low.

Owner:GUANGZHOU METRO DESIGN & RES INST

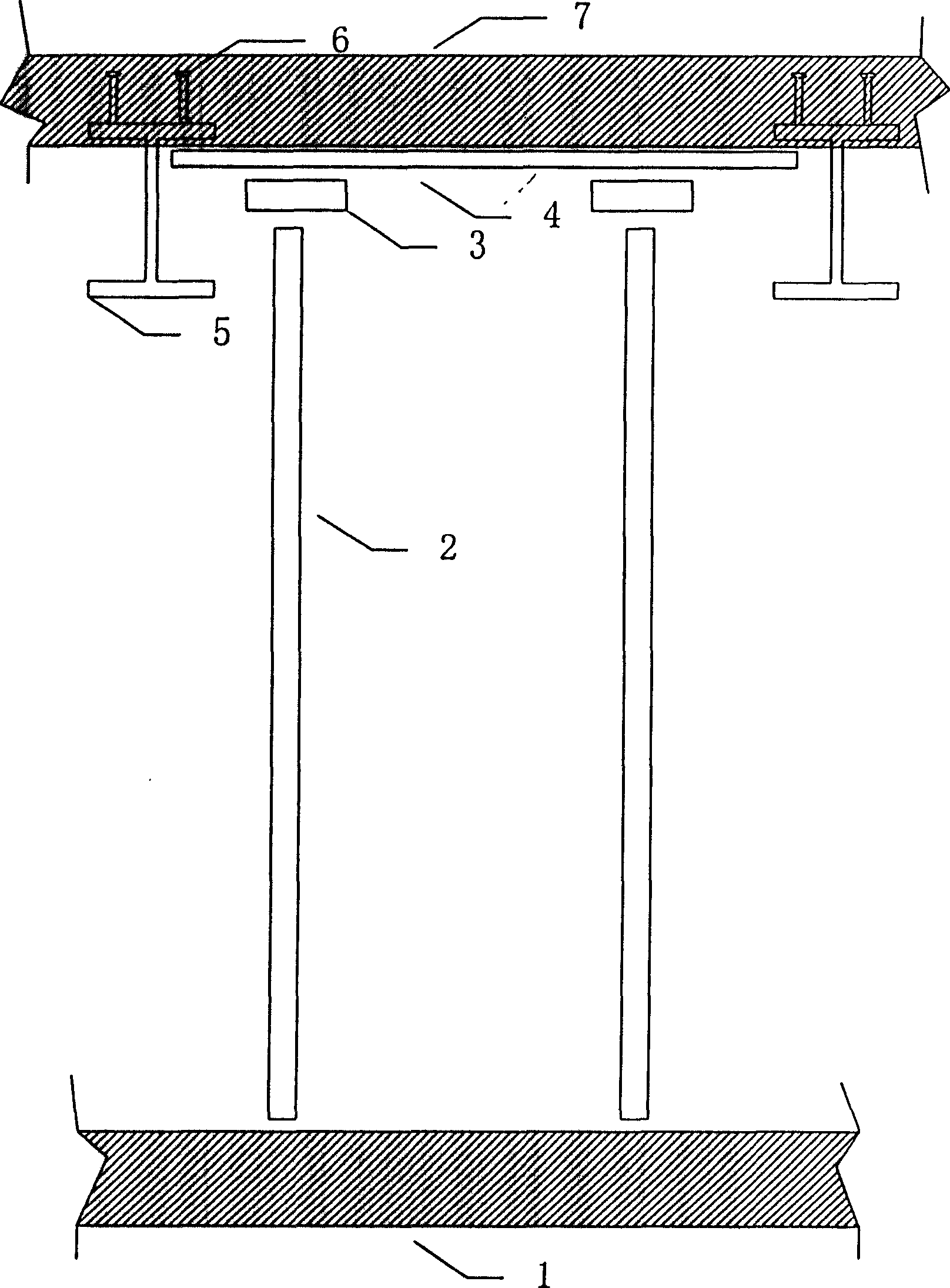

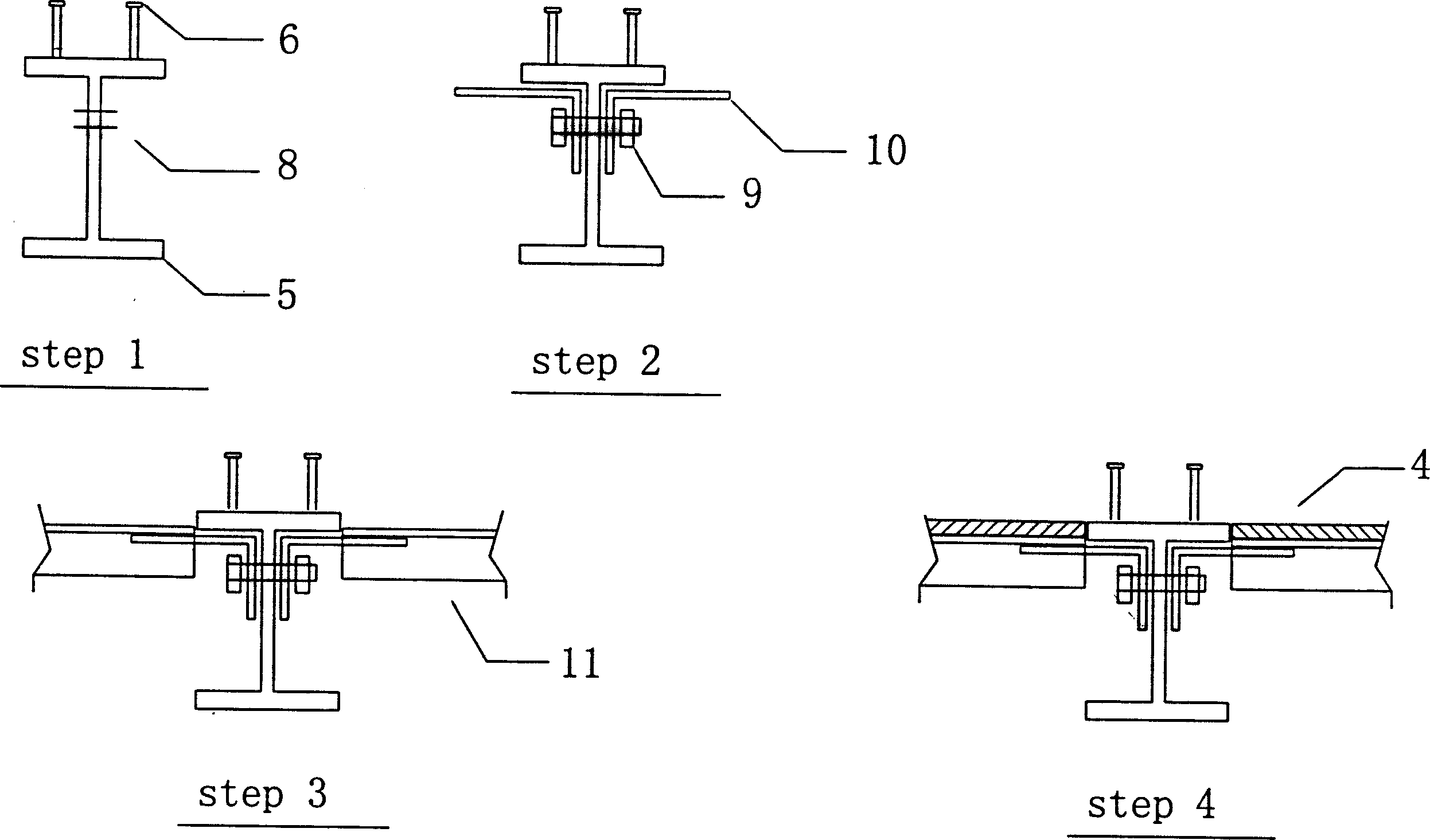

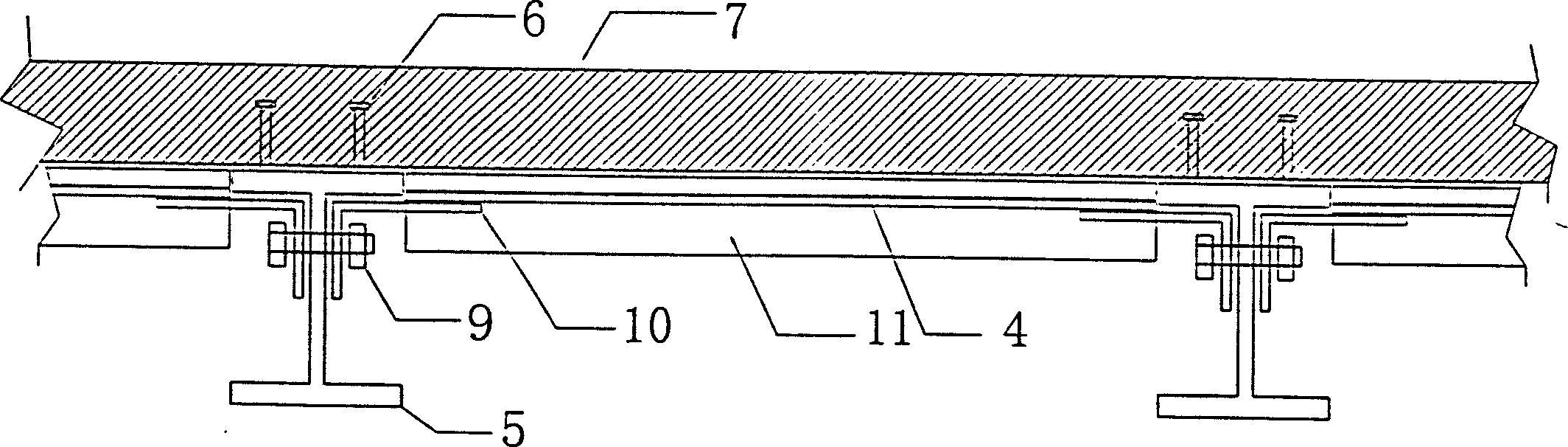

Construction method of steel-concrete composite storey

InactiveCN1534154ASimple and reliable connectionReduce on-site workloadForms/shuttering/falseworksShaped beamJoist

A construction method for steel-concrete floor includes drilling on the web plate of steel beam, connecting the steel beam with brackets mode of angle steel, arranging T-shaped steel beams between brackets, spreading shutterings on the T-shaped steel beams, binding reinforcing bars, pouring concrete, solidifying, and detaching the brackets, T-shaped beam and shutterings. Its advantages are low cost and high construction speed.

Owner:滕勇

Straddle method of cantilever of long-span simply supported steel truss beam of horizontal curve section

ActiveCN103696374AReduce temporary construction facilitiesReduce on-site workloadBridge erection/assemblyEconomic benefitsEngineering

The invention relates to a straddle method of a cantilever of a long-span simply supported steel truss beam of the horizontal curve section. The straddle method comprises calculating the lengths of main truss rods arranged on the inner side and the outer side of a cantilever span curve and main truss rods arranged on the inner side and the outer side of an anchor span curve according to the radius of a horizontal curve, the position on the horizontal curve of a bridge span structure and the main truss spacing; hoisting the main truss rods arranged on the inner side and the outer side of the cantilever span curve to the position of a permanent support arranged at the top of an Nth pier, enabling the permanent support arranged at the pier top and the main truss rods arranged on the inner side and the outer side of the anchor span curve to be connected together through a temporary connection structure and performing cantilever construction of steel beam rods along the design axis; removing the temporary connection structure after the bridge span is straddled in place. According to the straddle method of the cantilever of the long-span simply supported steel truss beam of the horizontal curve section, the horizontal pushing in-place operation of the steel beam in the process of construction is avoided successfully, the construction process is simplified, the straddle construction of the cantilever of the long-span simply supported steel truss beam of the horizontal curve section can be greatly simplified, the stress is reliable, the construction is convenient, the operation is simple, temporary construction facilities and field workloads of the pier top are reduced, the construction progress greatly speeds up, the construction cost is saved, and the economic benefit is remarkable.

Owner:CHINA MAJOR BRIDGE ENERGINEERING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com