Straddle method of cantilever of long-span simply supported steel truss beam of horizontal curve section

A technology of steel truss girder and curved section is applied in the field of cantilever erection of long-span simply supported steel truss girder in flat curve section, which can solve the problems of deviation of the span axis of cantilever bridges, achieve convenient construction, significant economic benefits, and reduce temporary construction of pier tops. Effects of facilities and site workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

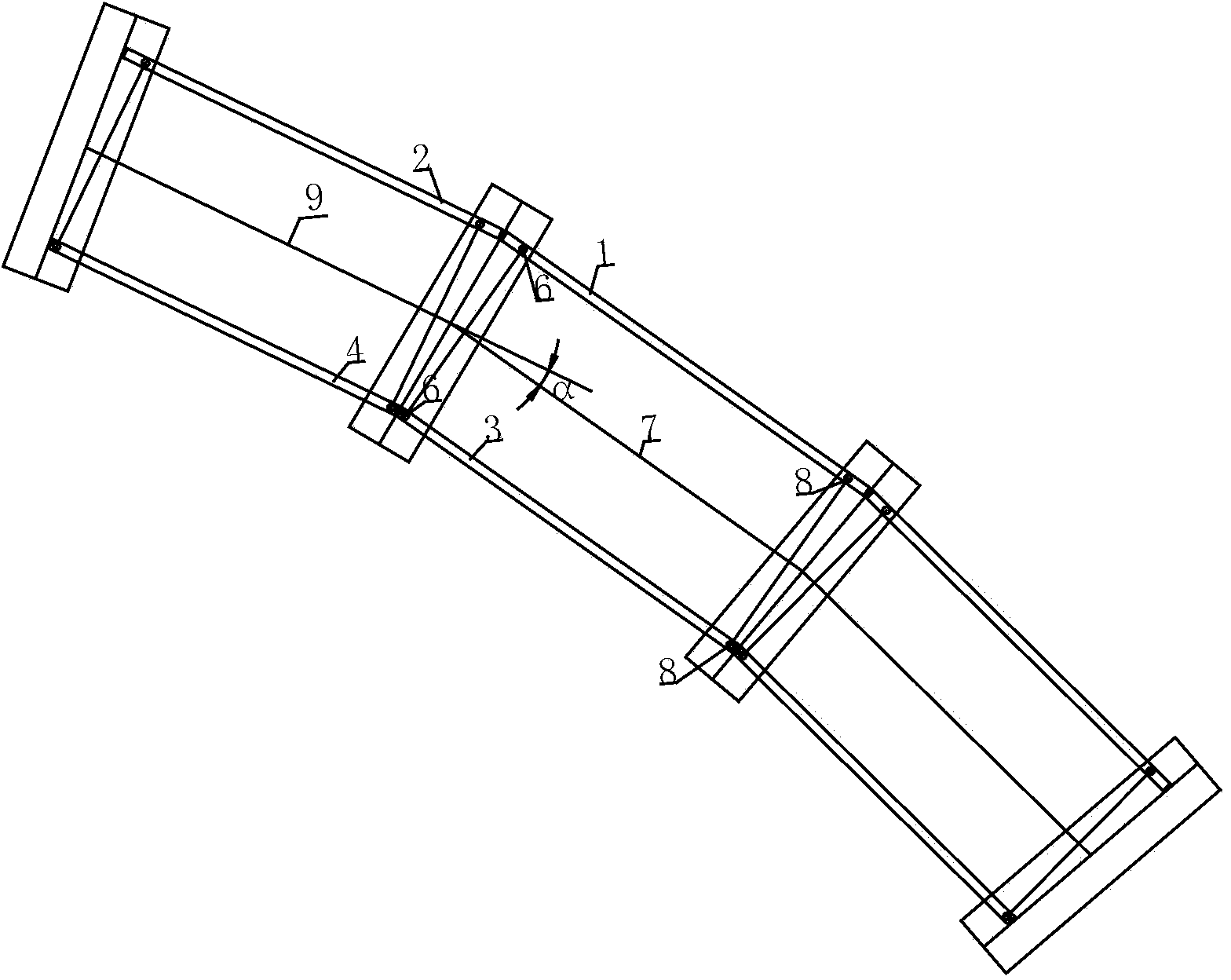

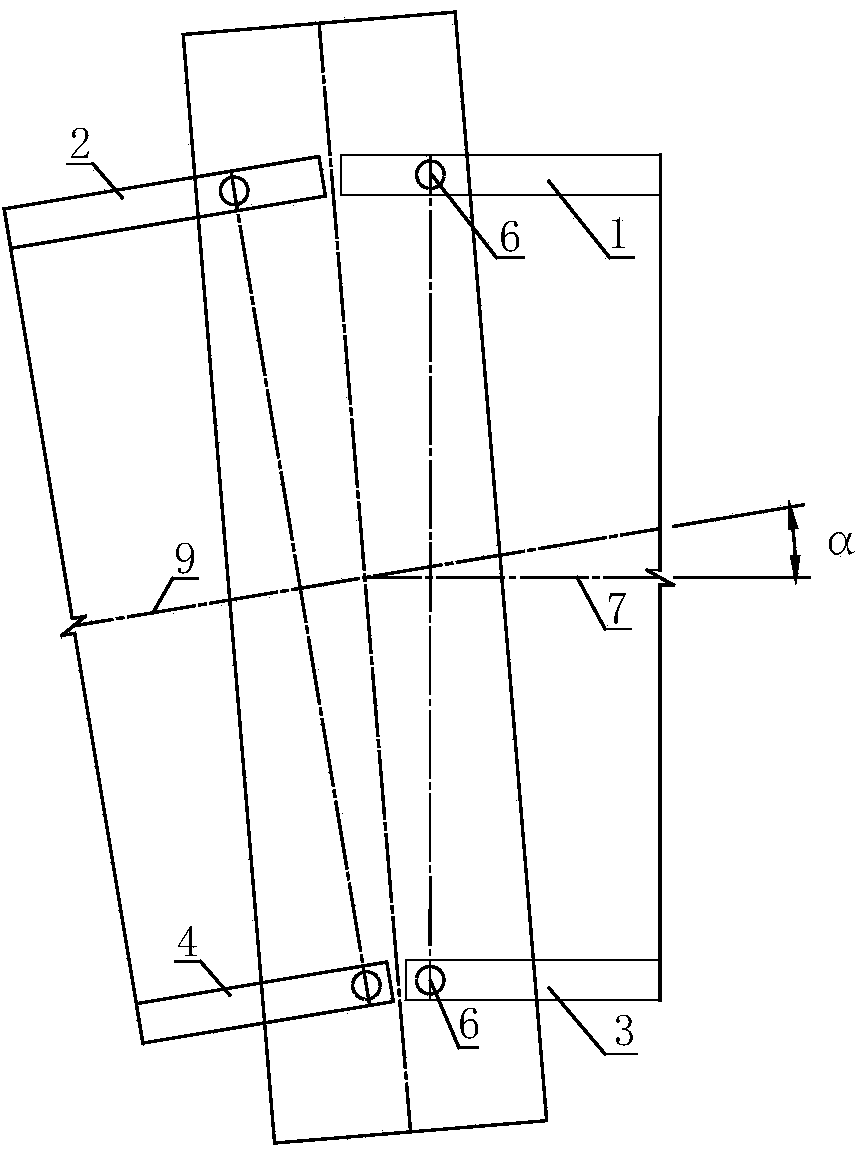

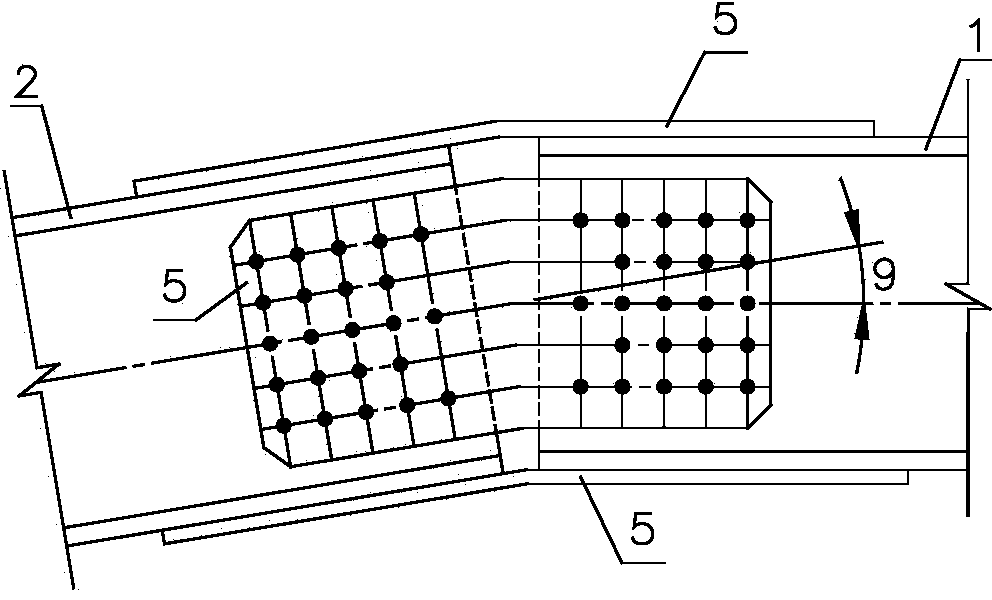

[0021] Refer to the attached figure 1 , 2 , 3, in conjunction with the specific steps of the cantilever erection method of simply supported steel truss girders in the horizontal curve section, the present invention is described in detail.

[0022] 1) Calculate the lengths of the inner and outer main truss members of the cantilever span curve and the inner and outer main truss members of the anchor span curve according to the radius of the horizontal curve, the position of the bridge span structure on the horizontal curve and the spacing of the main trusses.

[0023] The length of main truss members outside the curve = internode length + 1 / 2 x sinα x main truss spacing

[0024] The length of the main truss member inside the curve = internode length - 1 / 2 x sinα x main truss spacing

[0025] On the plane, the length of the outer main truss member of the cantilever span curve is greater than the length of the inner main truss member of the curve, and the difference is sinα×main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com