Unbonded post-tensioning prestress concrete-filled double-wall steel pipe prefabricated assembly piers with additional dampers

A post-tensioning prestressing and additional damper technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of reducing the horizontal bearing capacity of bridge piers, large gaps in the joint surface, and low manufacturing accuracy, so as to improve the construction speed , avoid buckling, reduce the effect of residual displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

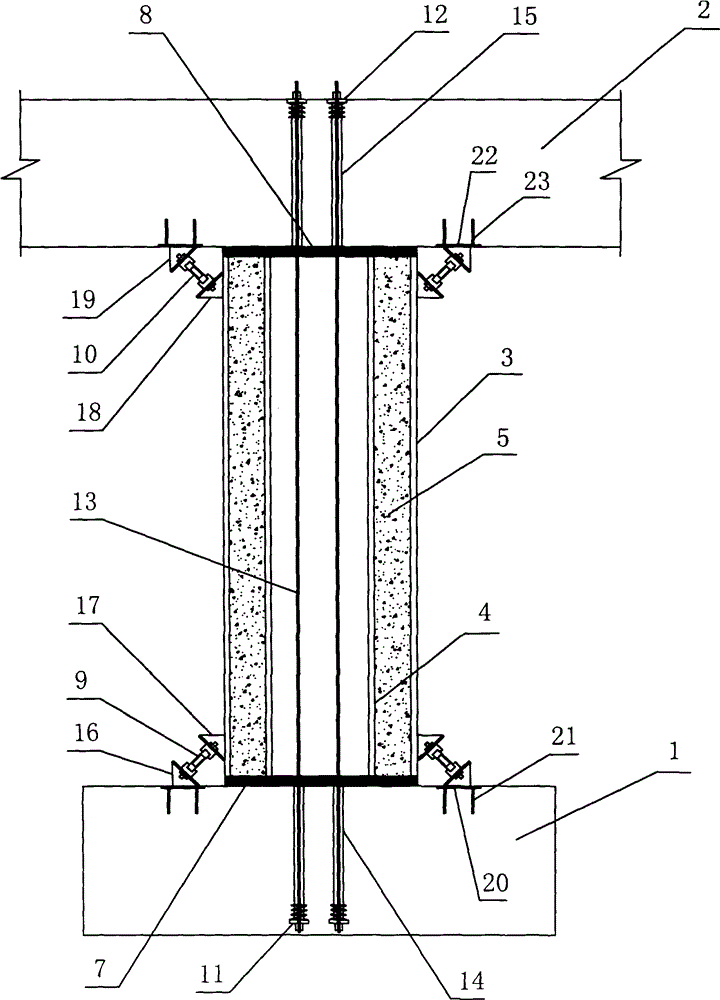

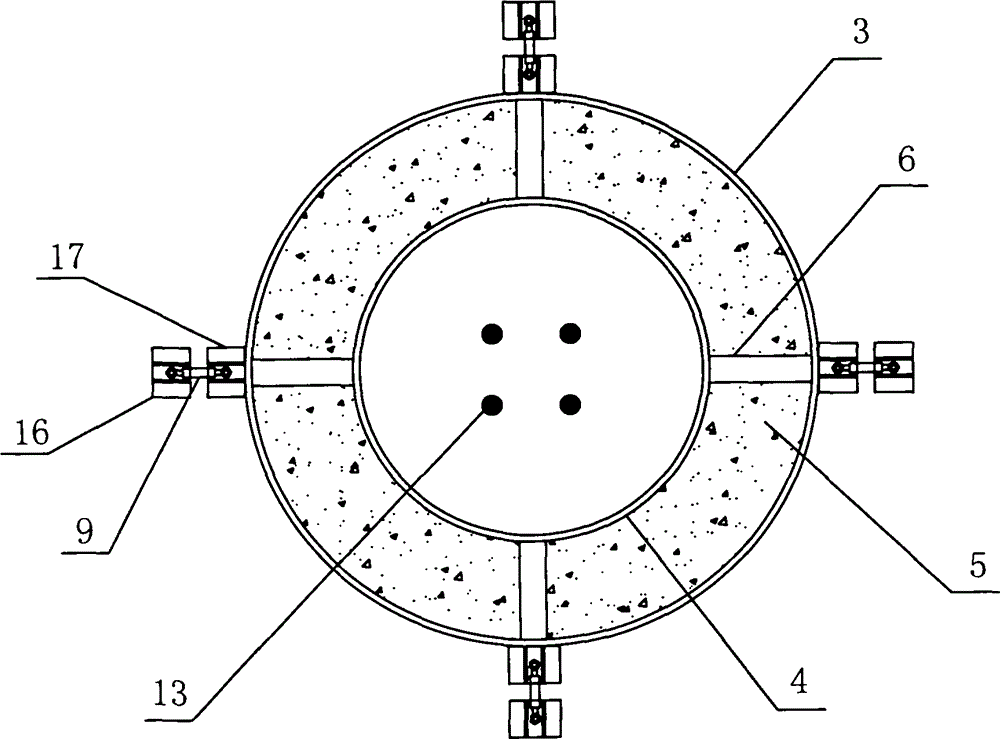

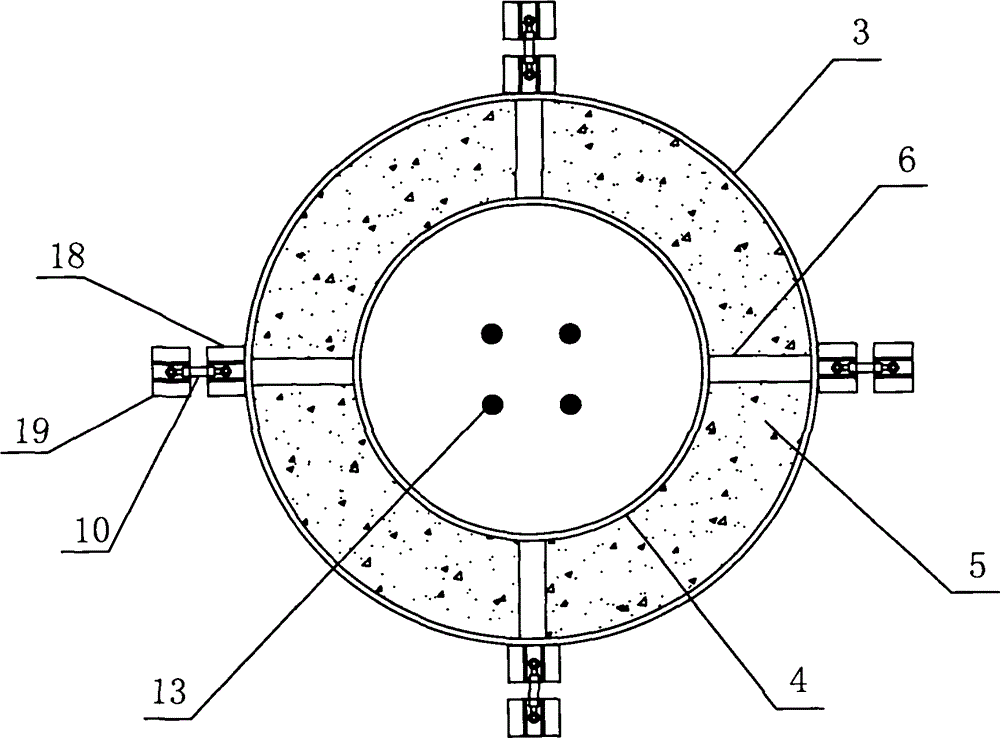

[0036] Such as figure 1 As shown, a non-bonded post-tensioned prestressed concrete filled double-walled steel pipe prefabricated bridge pier with additional damper includes cap 1, prefabricated piers and cover beam 2. The prefabricated bridge pier is set on cap 1 and covered The beam 2 is arranged on the prefabricated assembled bridge pier, which is a prefabricated assembled bridge pier filled with concrete double-walled steel pipes. The prefabricated assembled bridge pier includes outer steel pipes 3, inner steel pipes 4 and filled concrete 5. and the bottom end face are respectively connected by four steel sheets 6 ( figure 2 ), a lower fiber reinforced mortar layer 7 is set between the top surface of the cap 1 and the bottom end surface of the prefabricated assembled pier, and an upper fiber reinforced mortar layer 8 is set between the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com