A close-cut fracturing method

A fracturing and intensive technology, applied in the field of fracturing, can solve the problems of increasing the construction pressure window, reducing the displacement and construction pressure requirements, and the horizontal principal stress difference, so as to increase the construction pressure window, improve the fracture complexity, The effect of reducing the difficulty of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

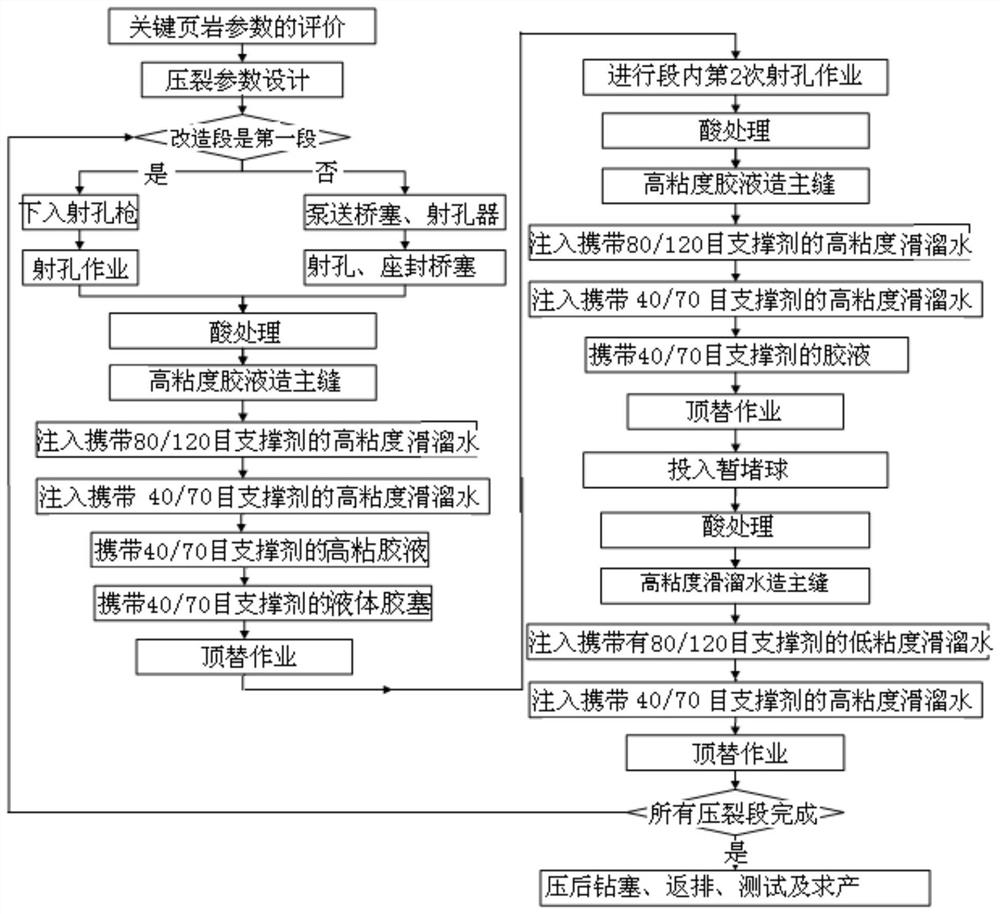

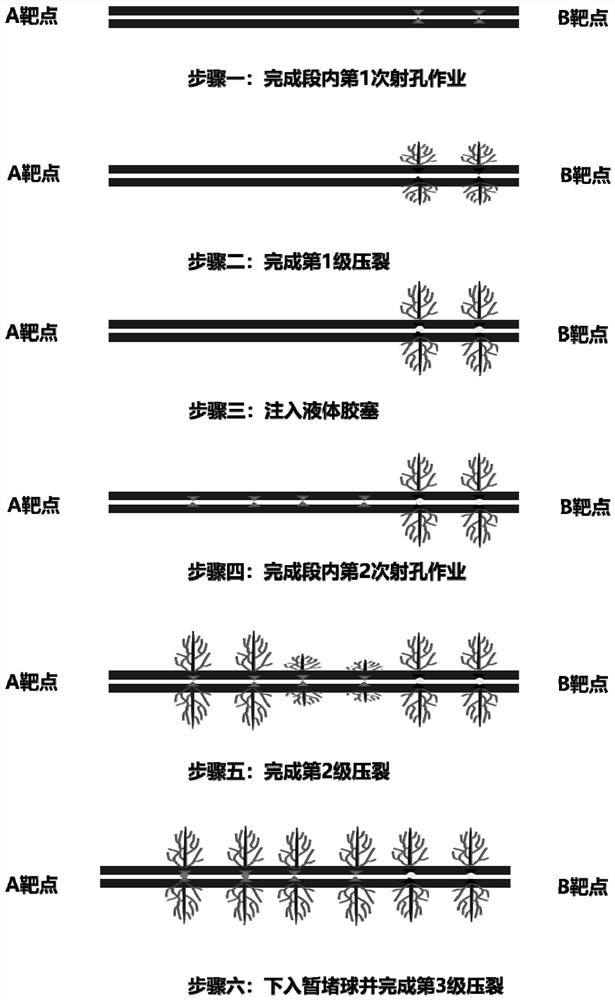

Method used

Image

Examples

Embodiment 1

[0111] The shale gas well is located in the southwest of Sichuan, with a vertical depth of 4127m, a sounding depth of 6109, and a horizontal section of 1530m. The well is buried deep and has high construction pressure. The method proposed in the present invention is used for reservoir stimulation. For details, refer to the examples. Before stimulation, evaluation of shale parameters and optimization of fracturing construction parameters are carried out respectively.

[0112] (1) Two clusters of perforating operations close to the B target are carried out by using the injection hole gun under the coiled tubing;

[0113] (2) With 1.5m 3 A total of 20m of pretreatment acid was injected at the displacement of / min 3 . Then take 5m 3 Displacement / min injection of high viscosity slick water 60m 3 Acid replacement; displacement reduced to 1m 3 / min, then continue to inject high-viscosity glue for 30m 3 , while the displacement is rapidly increased to 8m 3 / min;

[0114] (3) ...

Embodiment 2

[0136] The shale gas well is located in the southwest of Sichuan, with a vertical depth of 4250m, a sounding depth of 6278, and a horizontal section of 1435m. The well is buried deep and has high construction pressure. The method proposed in the present invention is used for reservoir stimulation. For details, refer to the examples. Before stimulation, evaluation of shale parameters and optimization of fracturing construction parameters are carried out respectively.

[0137] (1) Two clusters of perforating operations close to the B target are carried out by using the injection hole gun under the coiled tubing;

[0138] (2) by 1m 3 A total of 10m of pretreatment acid is injected at the displacement of / min 3 . Then take 3m 3 Displacement / min injection of high viscosity slick water 60m 3 Acid replacement; displacement reduced to 0.8m 3 / min, then continue to inject high-viscosity glue for 30m 3 , while the displacement is rapidly increased to 8m 3 / min;

[0139] (3) Inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com