Patents

Literature

109 results about "Fracture treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Some of the possible treatments listed in sources for treatment of Fractures may include: Emergency treatment. Surgery. Reduction of fracture - aligning broken ends of a bone. Closed reduction. Open reduction. Plaster cast. Splinting.

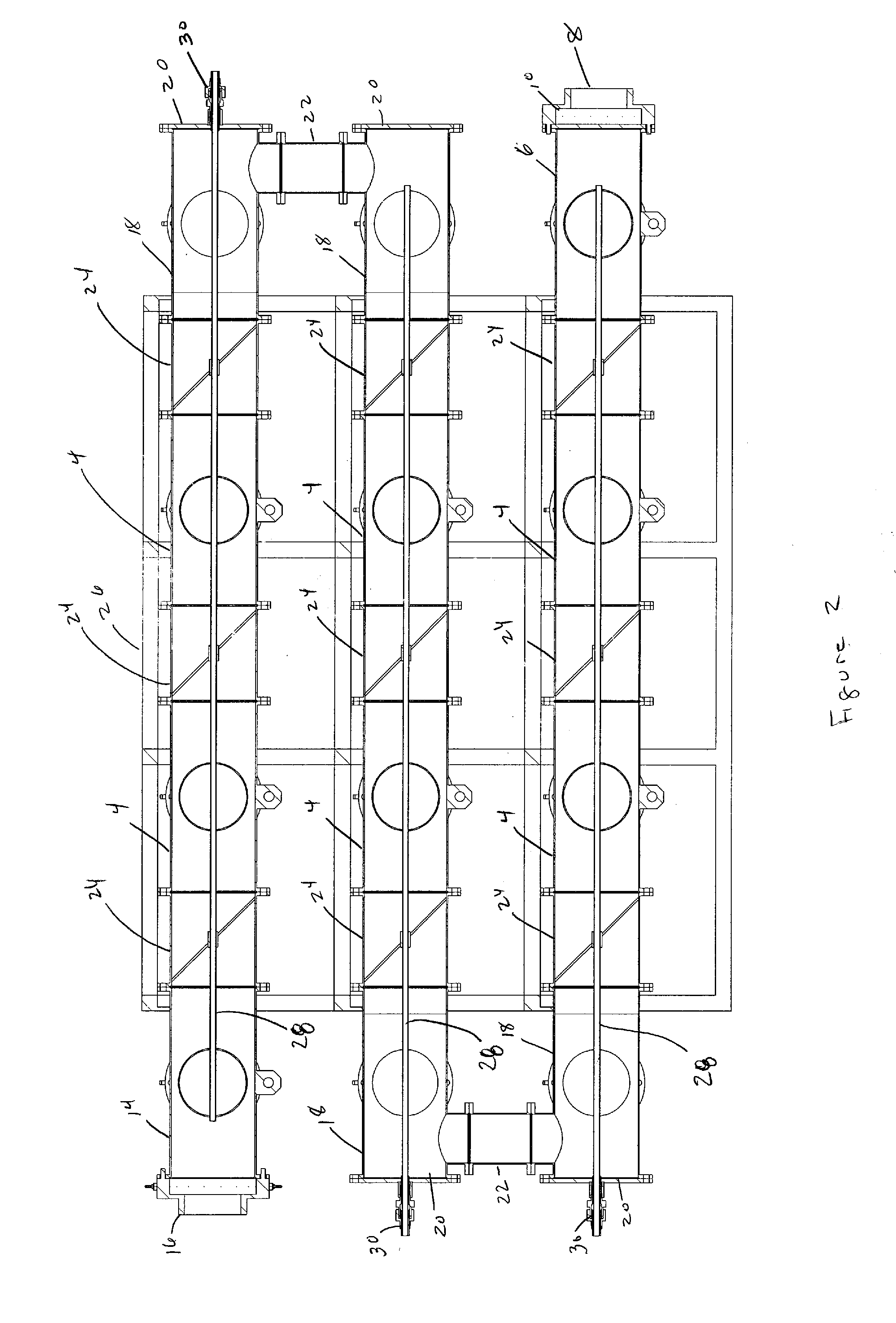

Methods and compositions of a storable relatively lightweight proppant slurry for hydraulic fracturing and gravel packing applications

InactiveUS20050028979A1Improve system performanceEliminate needFluid removalDrilling compositionParticulatesMetallurgy

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that utilize relatively lightweight and / or substantially neutrally buoyant particulates. Particles that may be employed include particulates of naturally occurring materials that may be optionally strengthened or hardened by exposure to a modifying agent; porous materials including selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials; and well treating aggregates composed of an organic lightweight material and a weight modifying agent. The relatively lightweight particulate may be suspended as a substantially neutral buoyant particulate and stored with a carrier fluid as a pumpable slurry.

Owner:BAKER HUGHES INC

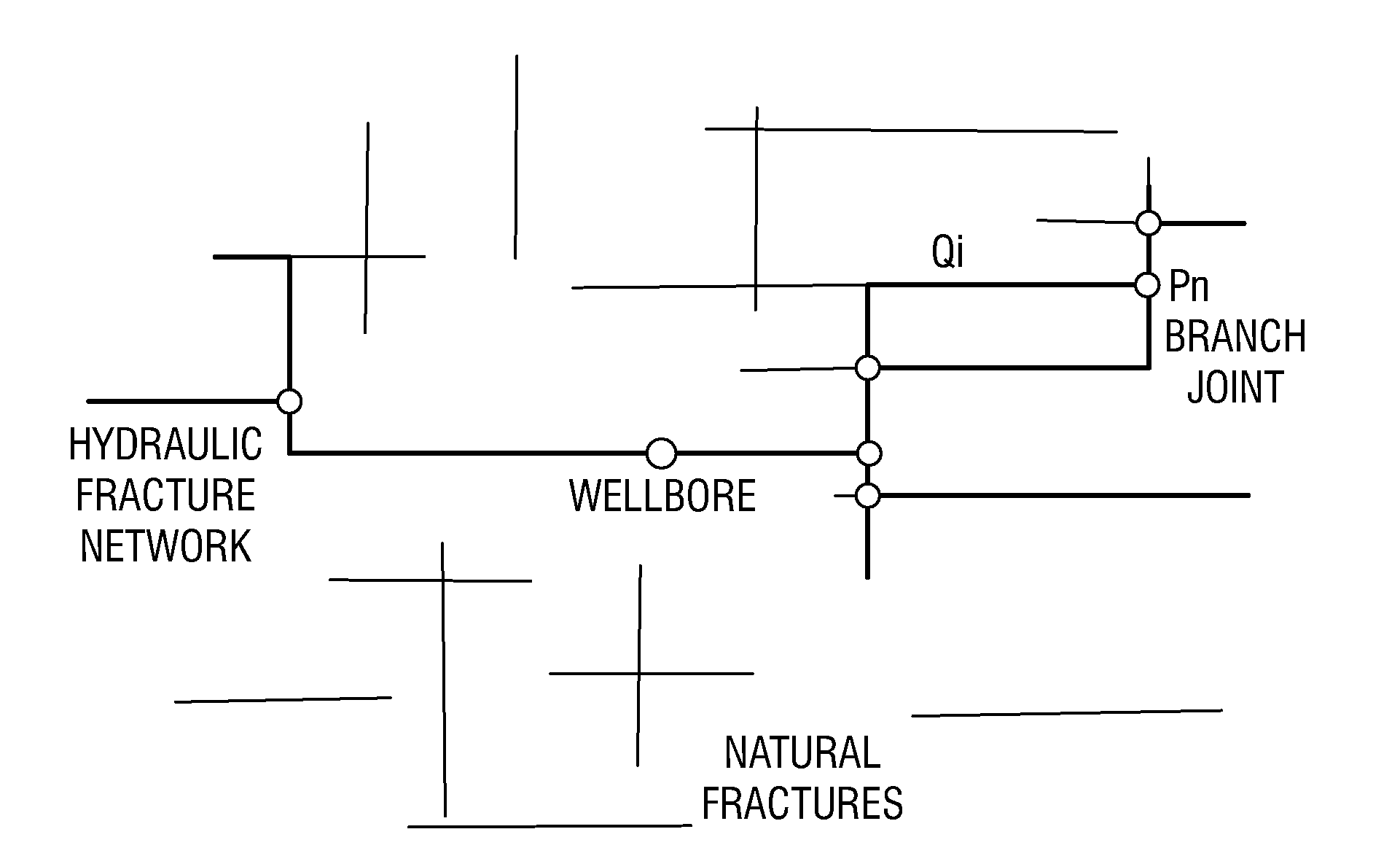

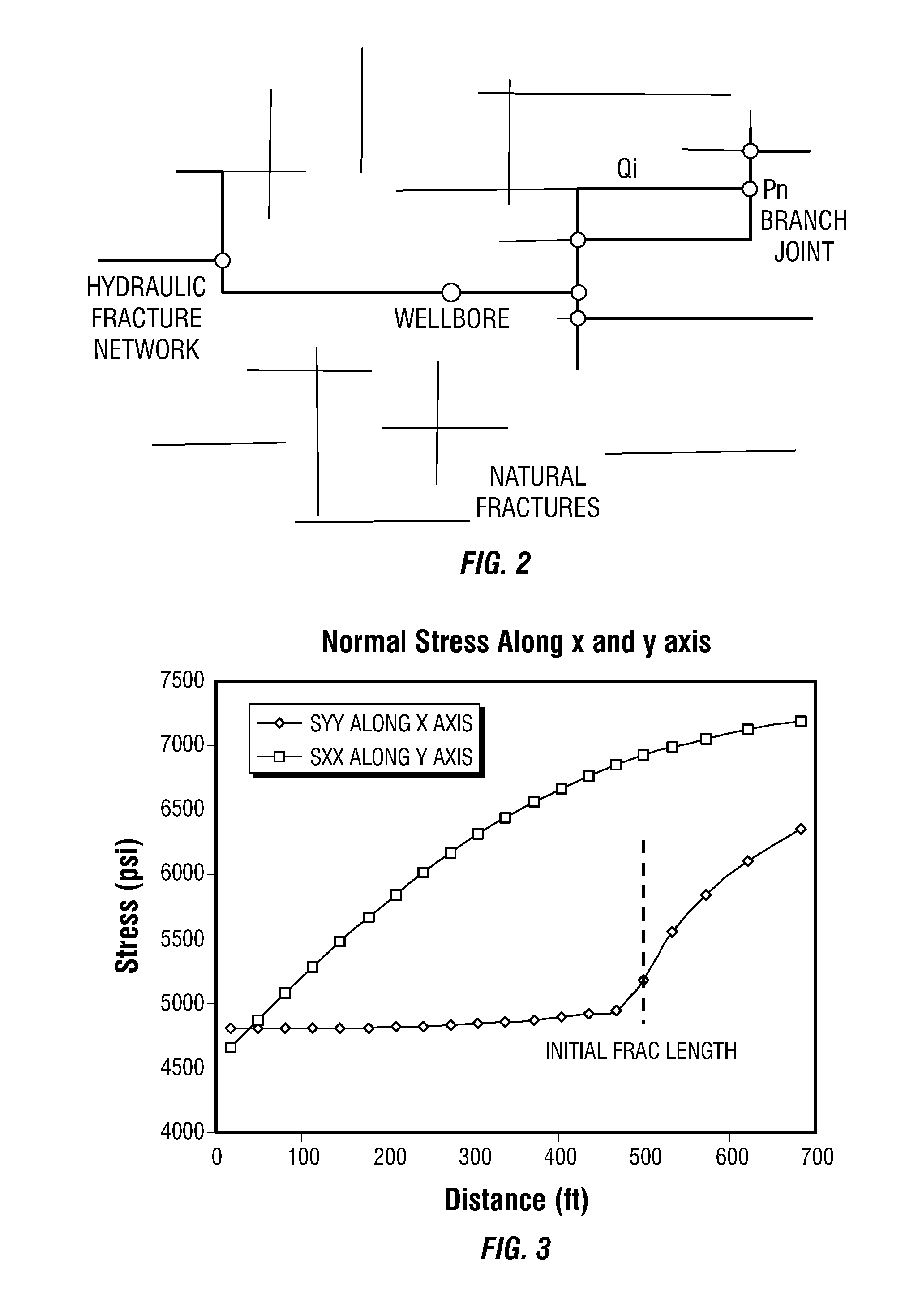

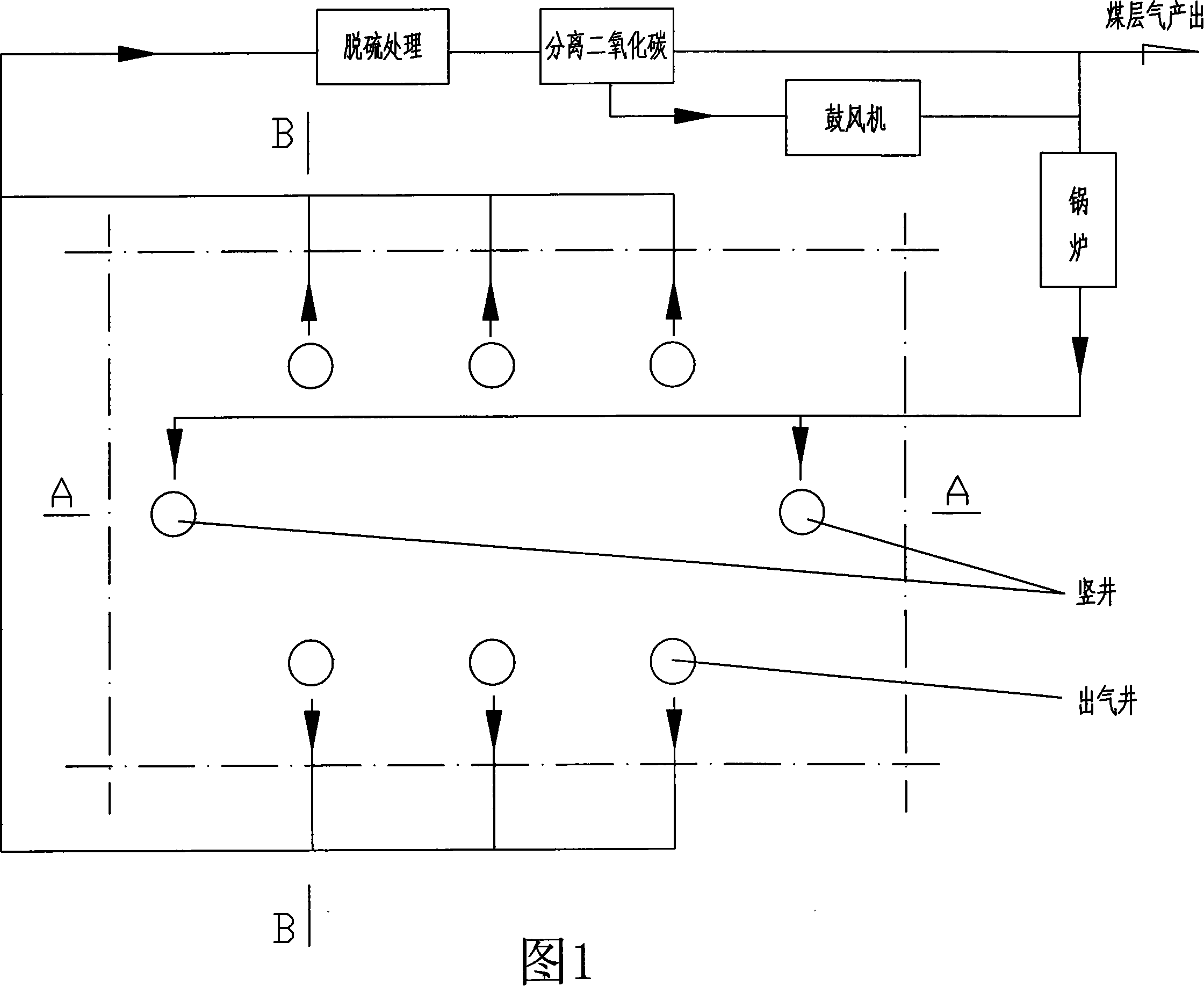

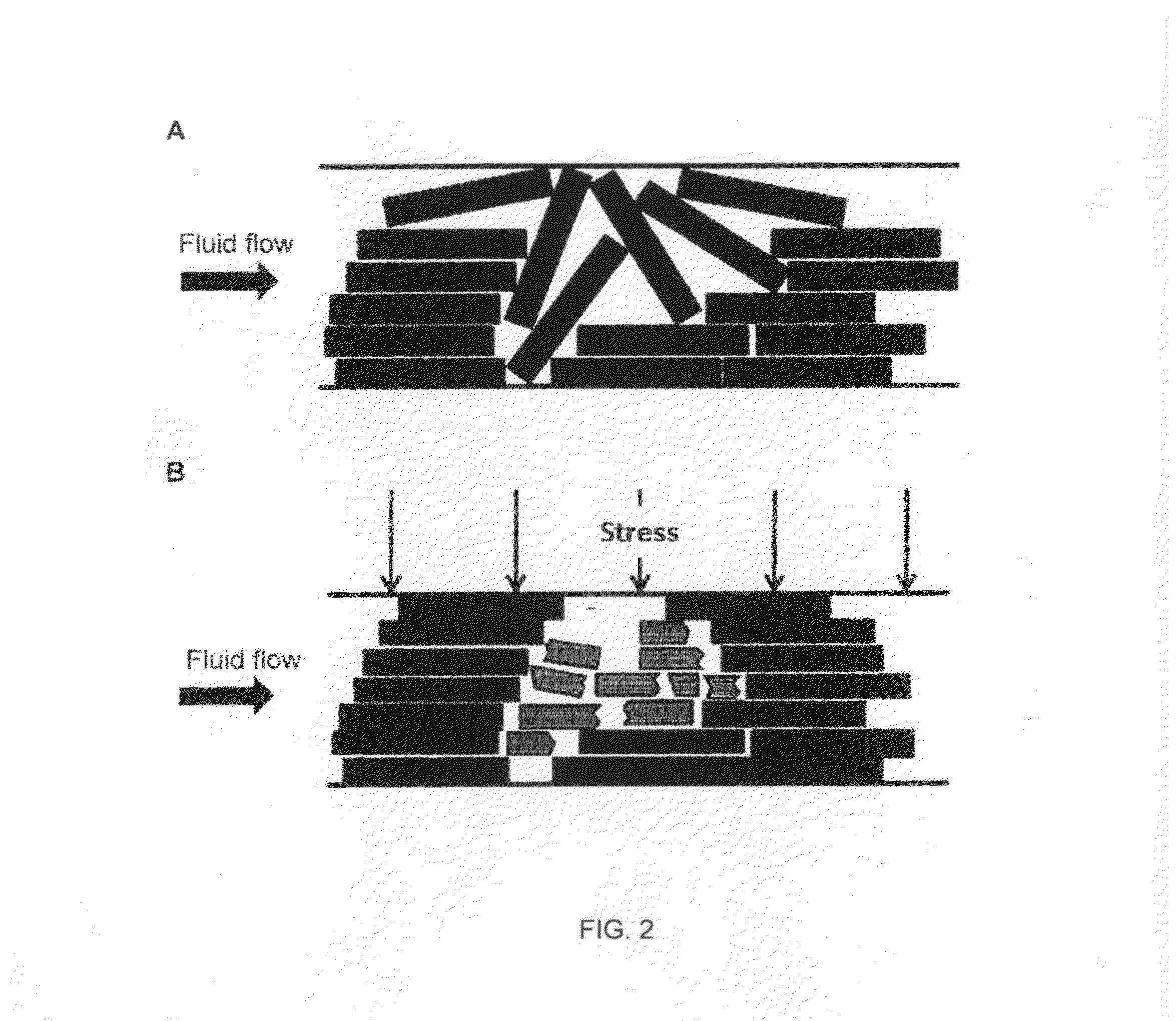

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

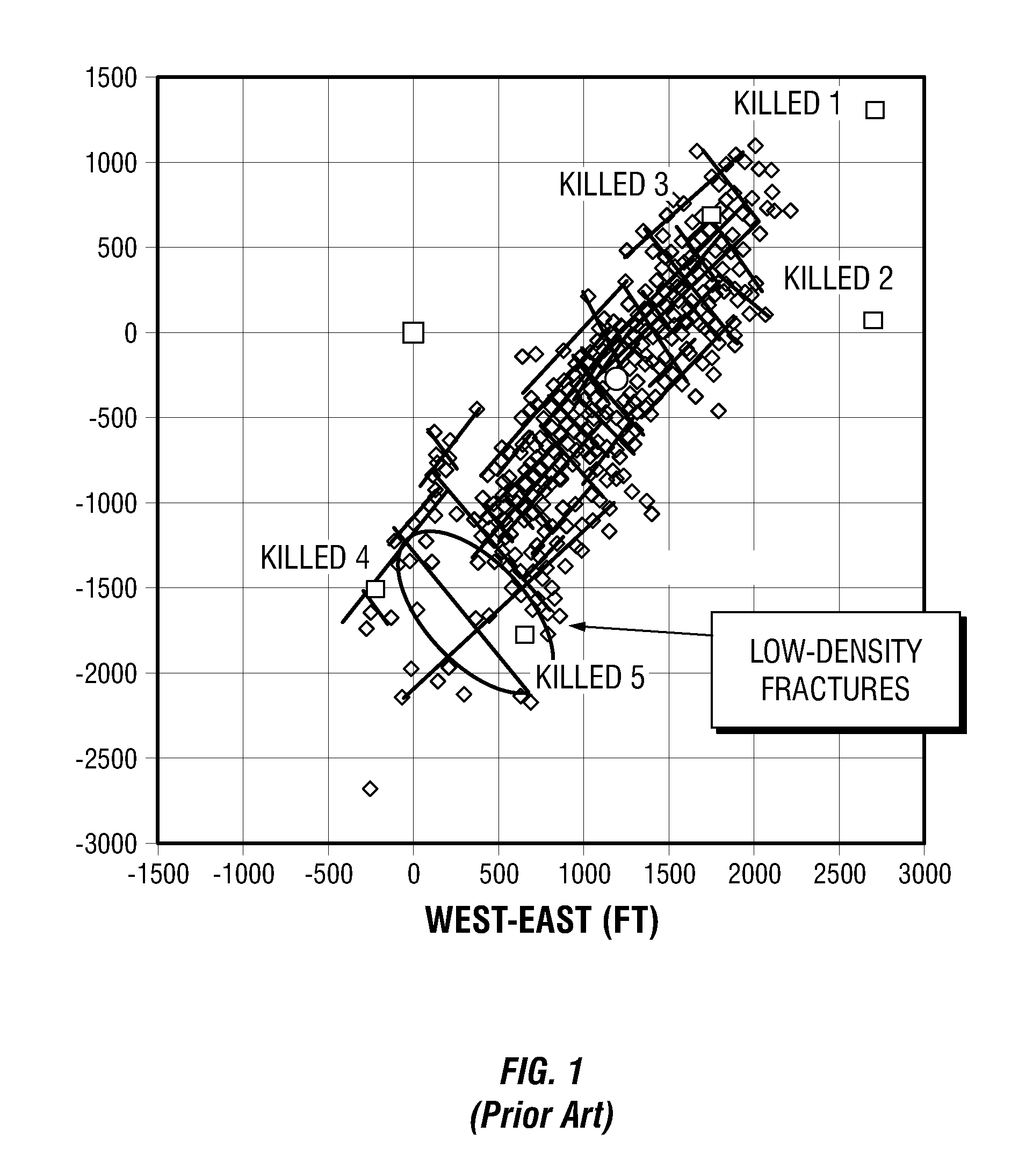

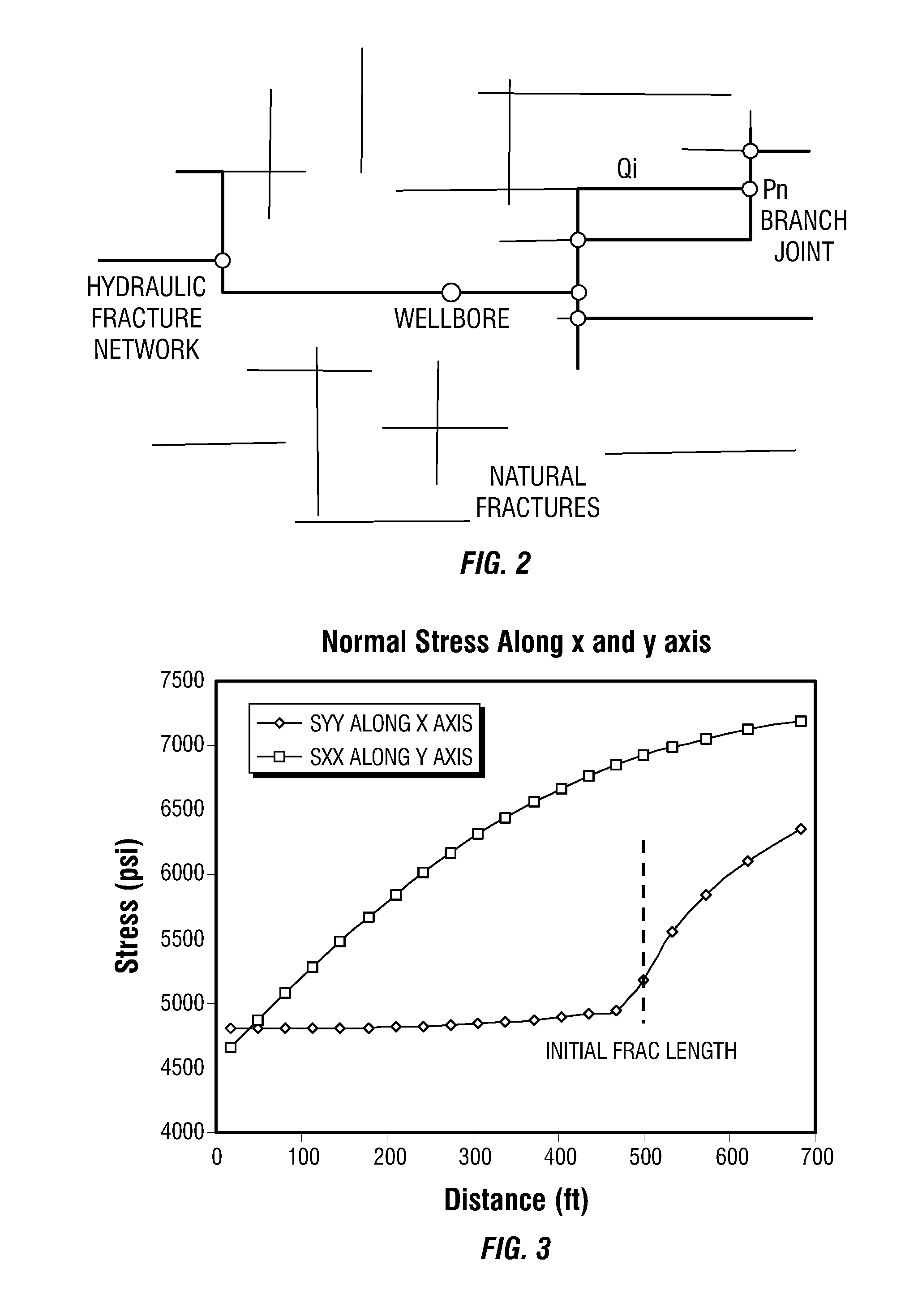

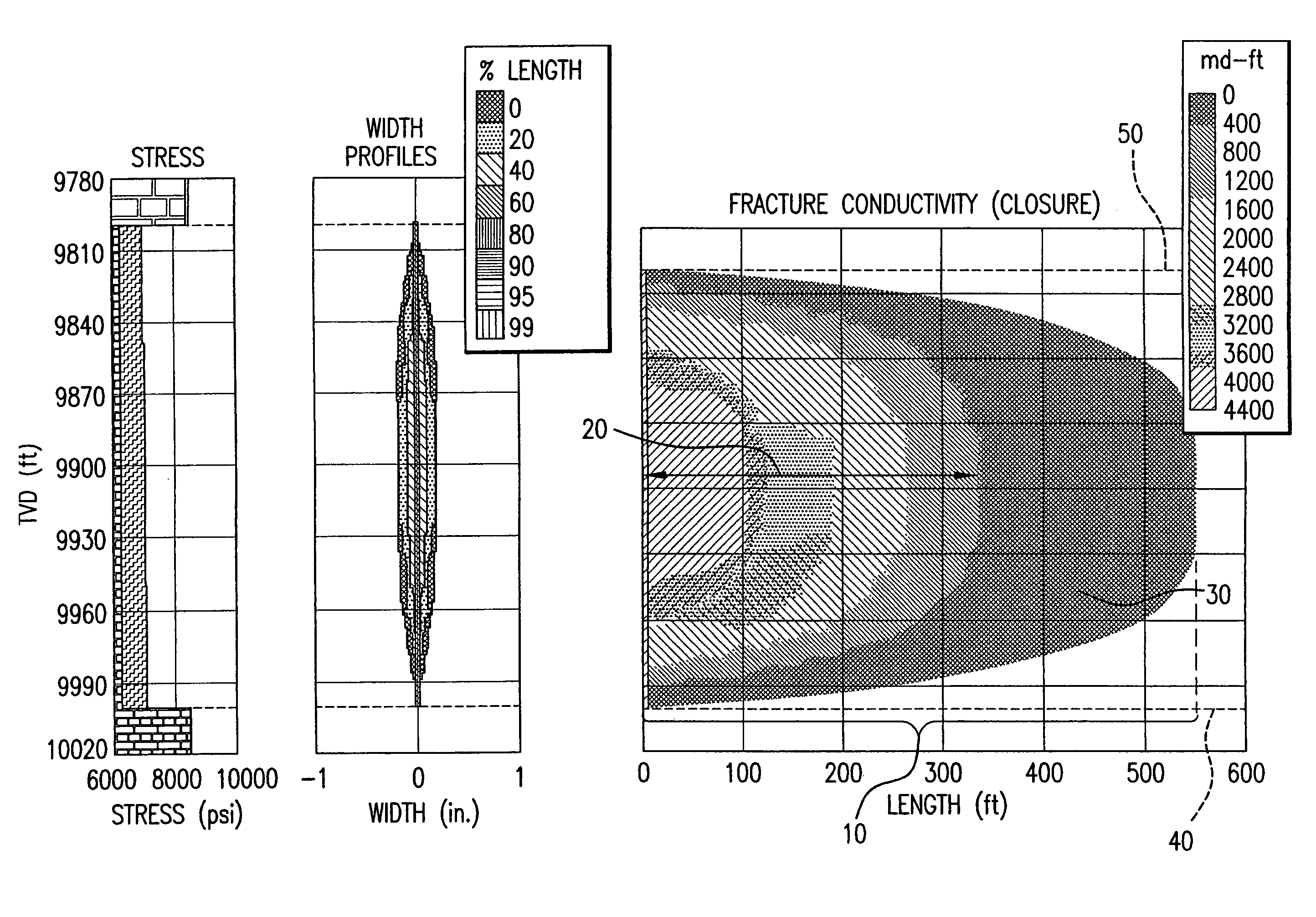

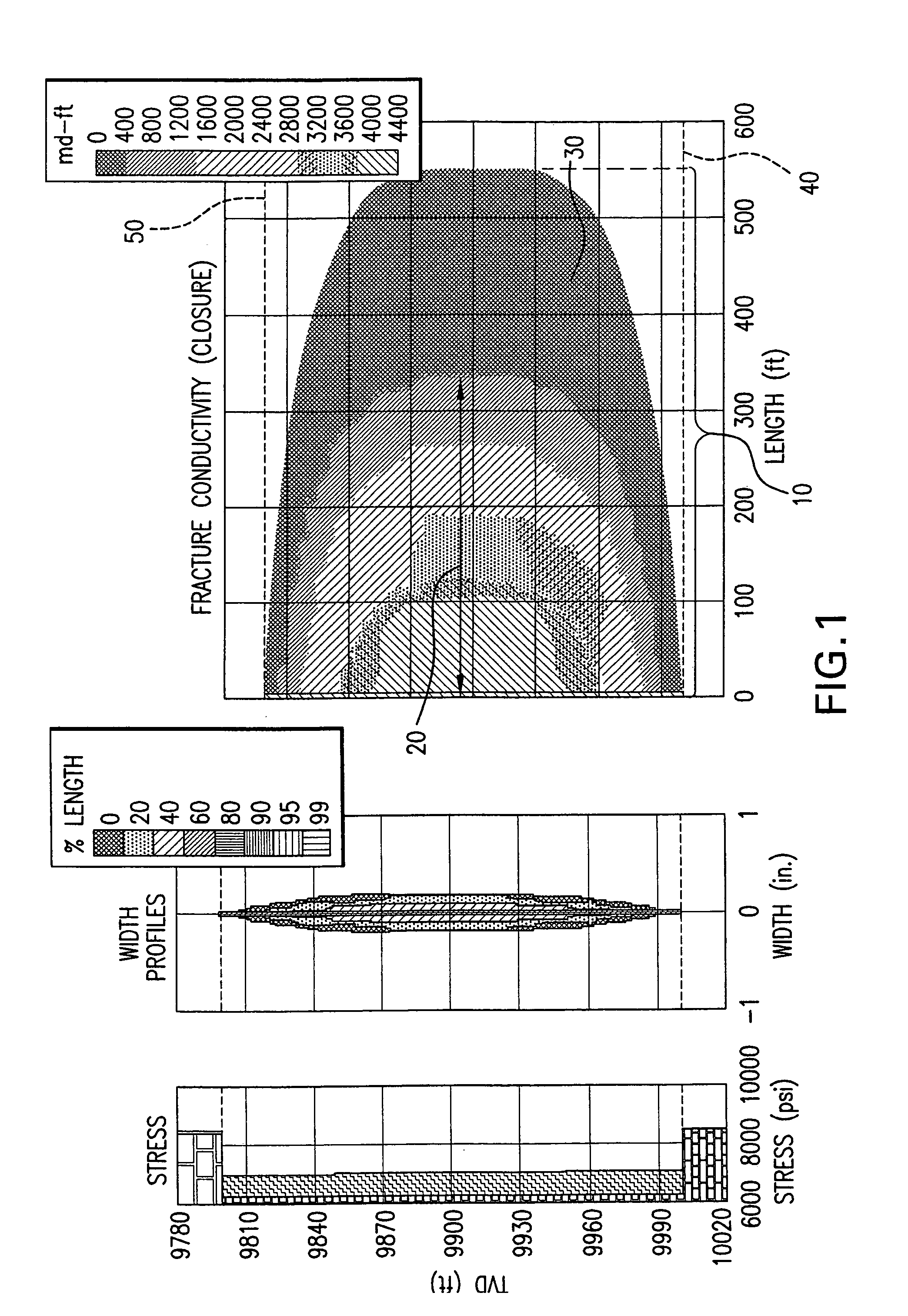

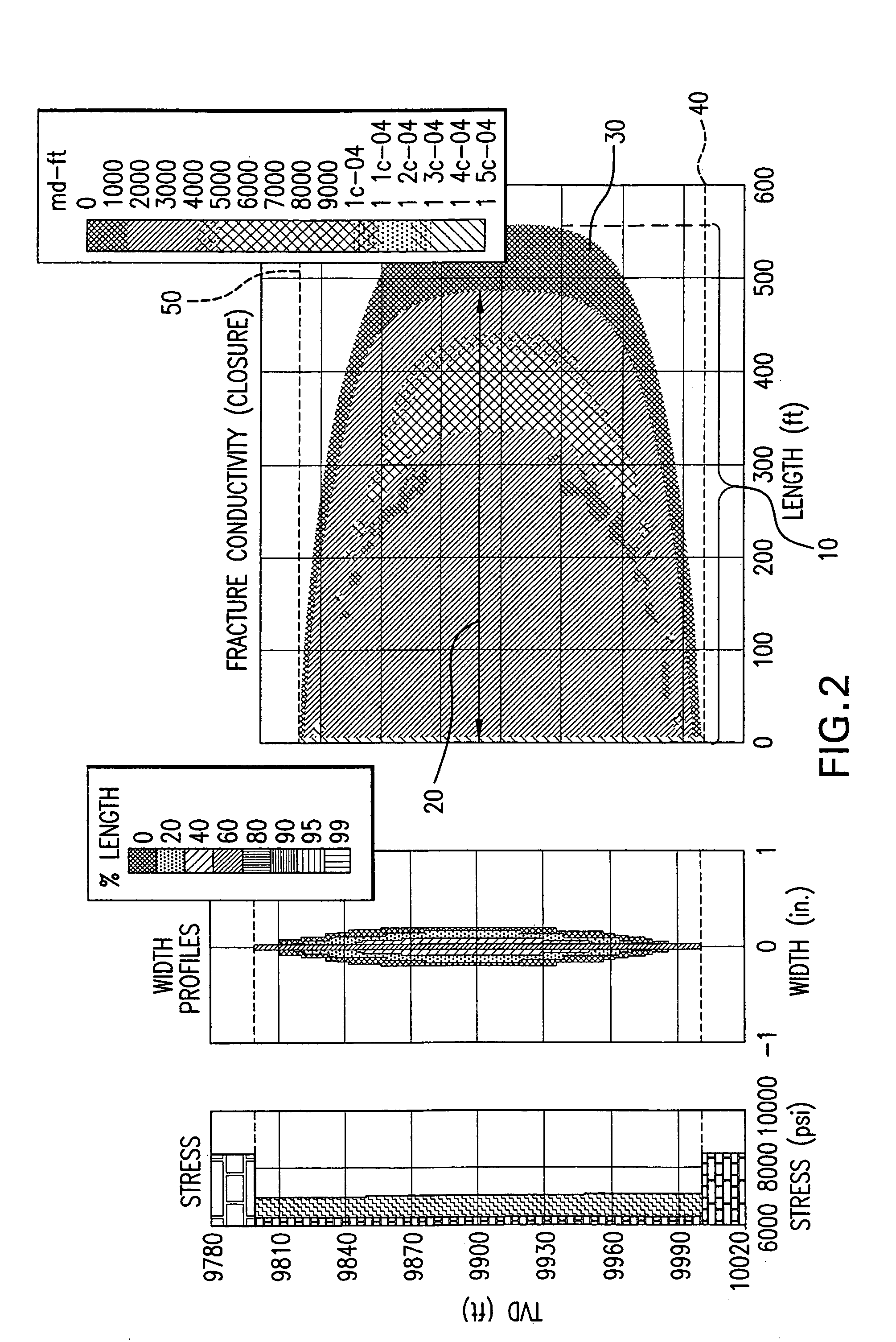

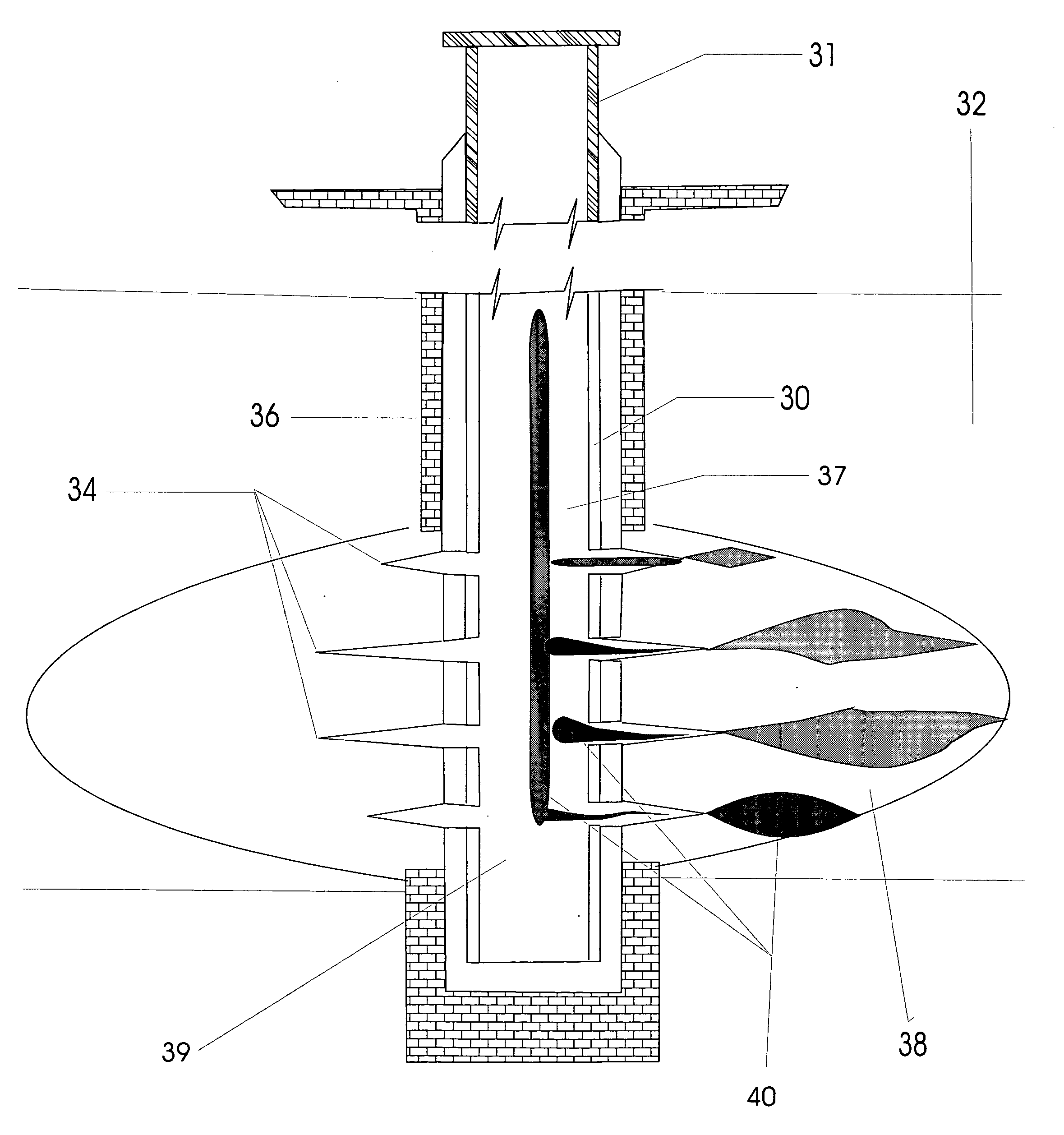

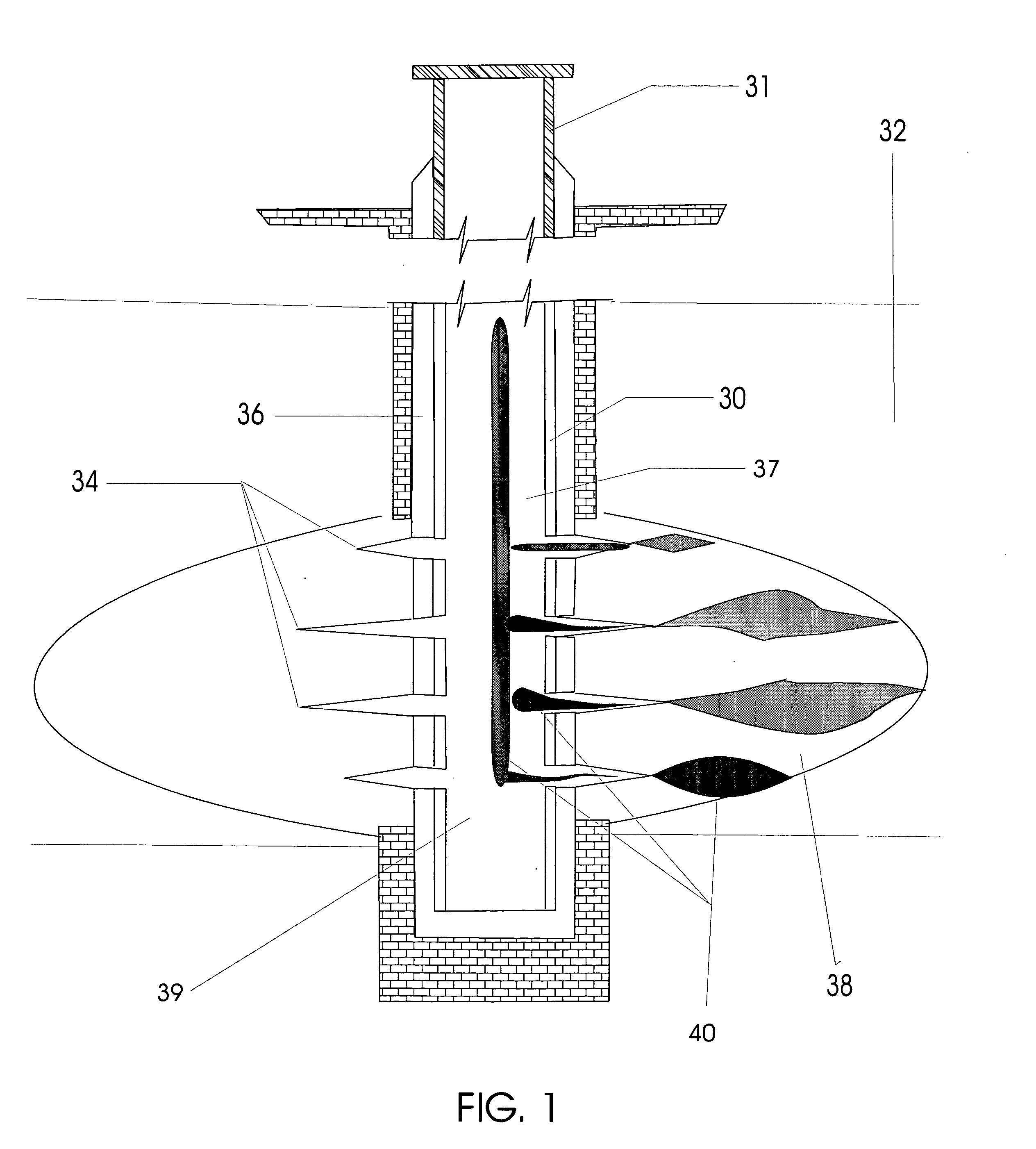

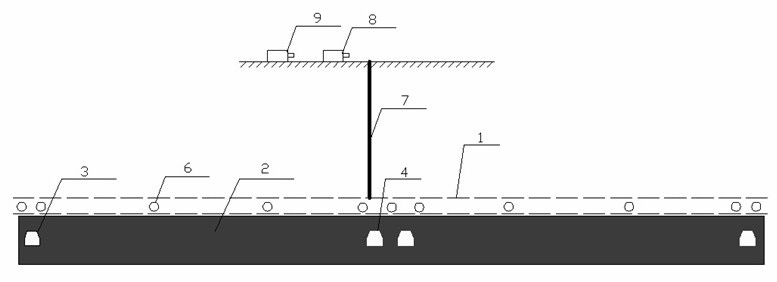

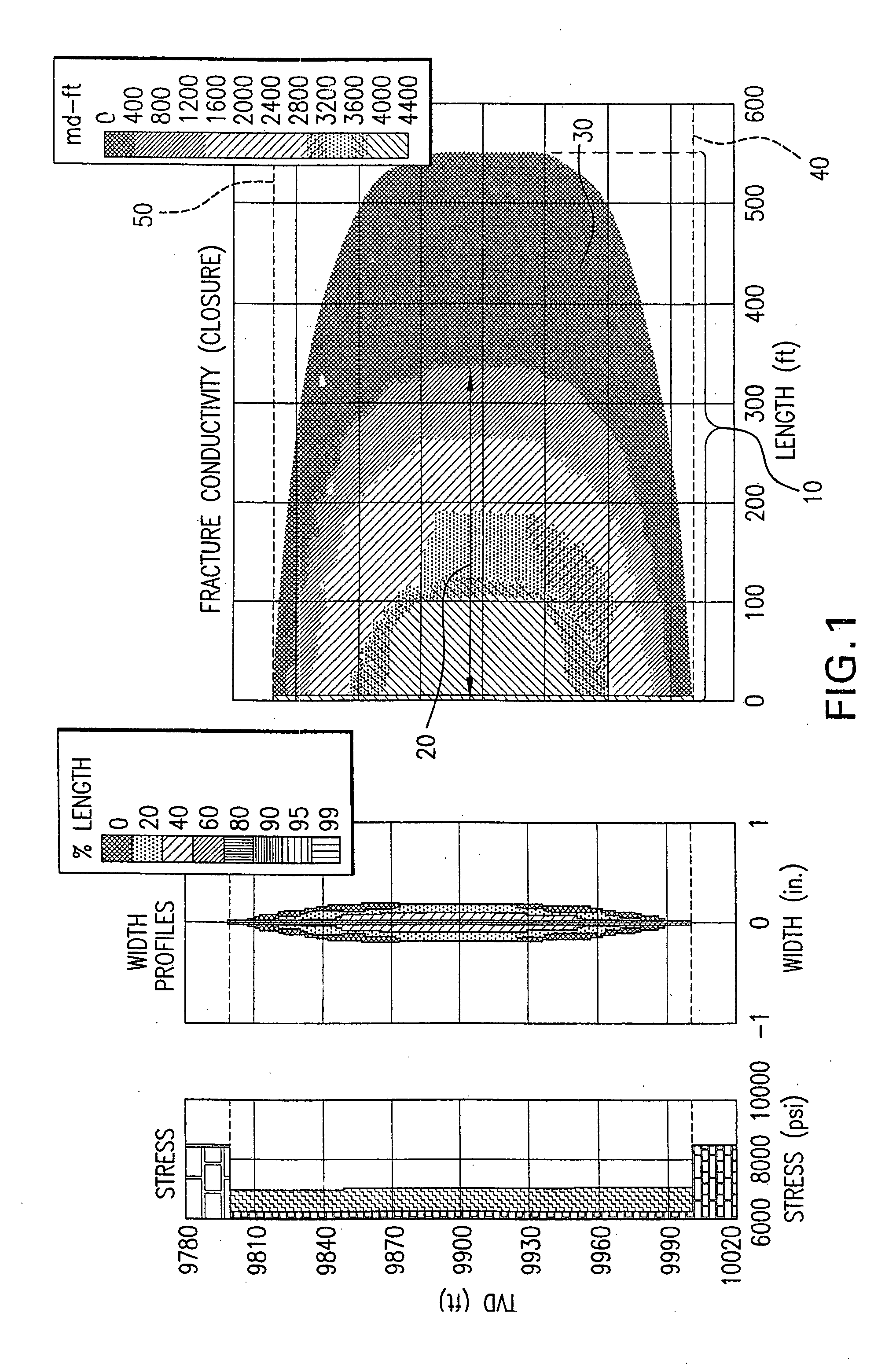

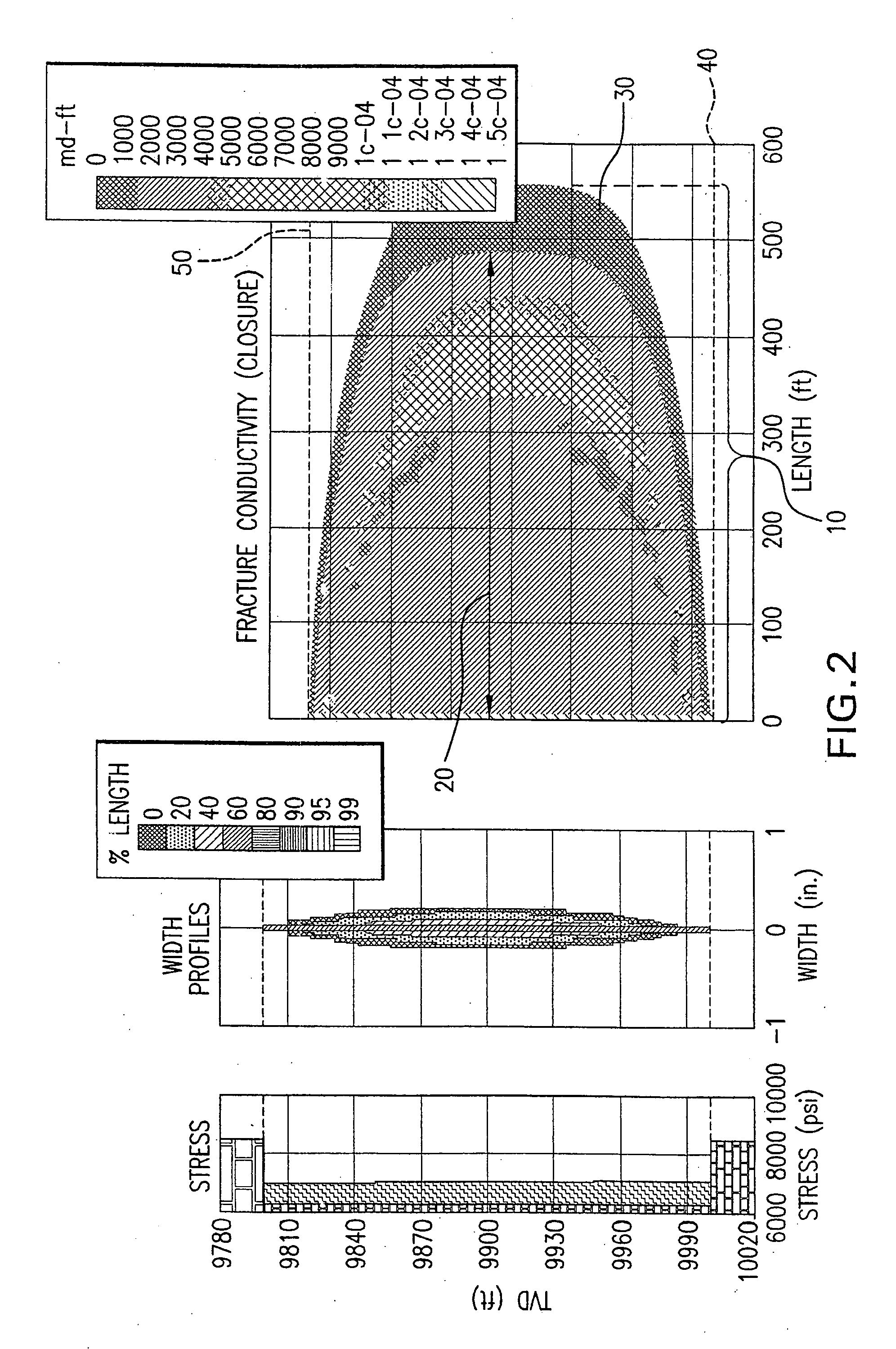

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

Method of treatment subterranean formations using multiple proppant stages or mixed proppants

ActiveUS7210528B1Low costIncrease the lengthFluid removalDrilling compositionMedicineHydraulic fracturing

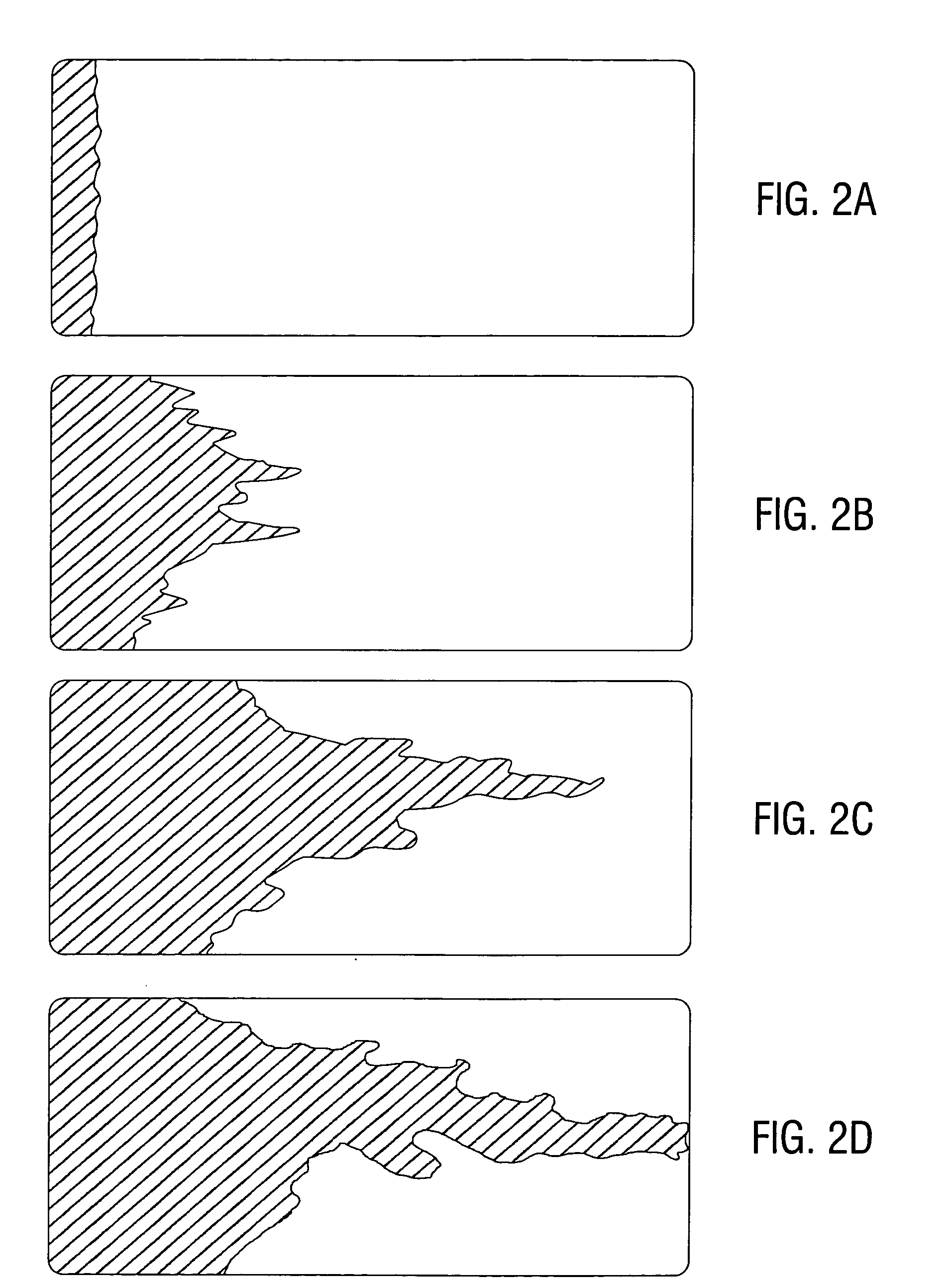

An increase in effective propped lengths is evidenced in hydraulic fracturing treatments by the use of ultra lightweight (ULW) proppants. The ULW proppants have a density less than or equal to 2.45 g / cc and may be used as a mixture in a first proppant stage wherein at least one of the proppants is a ULW proppant. Alternatively, sequential proppant stages may be introduced into the formation wherein at least one of the proppant stages contain a ULW proppant and where at least one of the following conditions prevails:(i.) the density differential between the first proppant stage and the second proppant stage is greater than or equal to 0.2 g / cc;(ii.) both the first proppant stage and the second proppant stage contain a ULW proppant;(iii.) the rate of injection of the second proppant stage into the fracture is different from the rate of injection of the first proppant stage; or(iv.) the particle size of the second proppant stage is different from the particle size of the first proppant stage.

Owner:BAKER HUGHES INC

Methods and compositions of a storable relatively lightweight proppant slurry for hydraulic fracturing and gravel packing applications

InactiveUS20080087429A1Improve system performanceHigh elastic modulusFluid removalDrilling compositionParticulatesMetallurgy

Methods and compositions useful for subterranean formation treatments, such as hydraulic fracturing treatments and sand control that utilize relatively lightweight and / or substantially neutrally buoyant particulates. Particles that may be employed include particulates of naturally occurring materials that may be optionally strengthened or hardened by exposure to a modifying agent; porous materials including selectively configured porous material particles manufactured and / or treated with selected glazing materials, coating materials and / or penetrating materials; and well treating aggregates composed of an organic lightweight material and a weight modifying agent. The relatively lightweight particulate may be suspended as a substantially neutral buoyant particulate and stored with a carrier fluid as a pumpable slurry.

Owner:BAKER HUGHES HLDG LLC

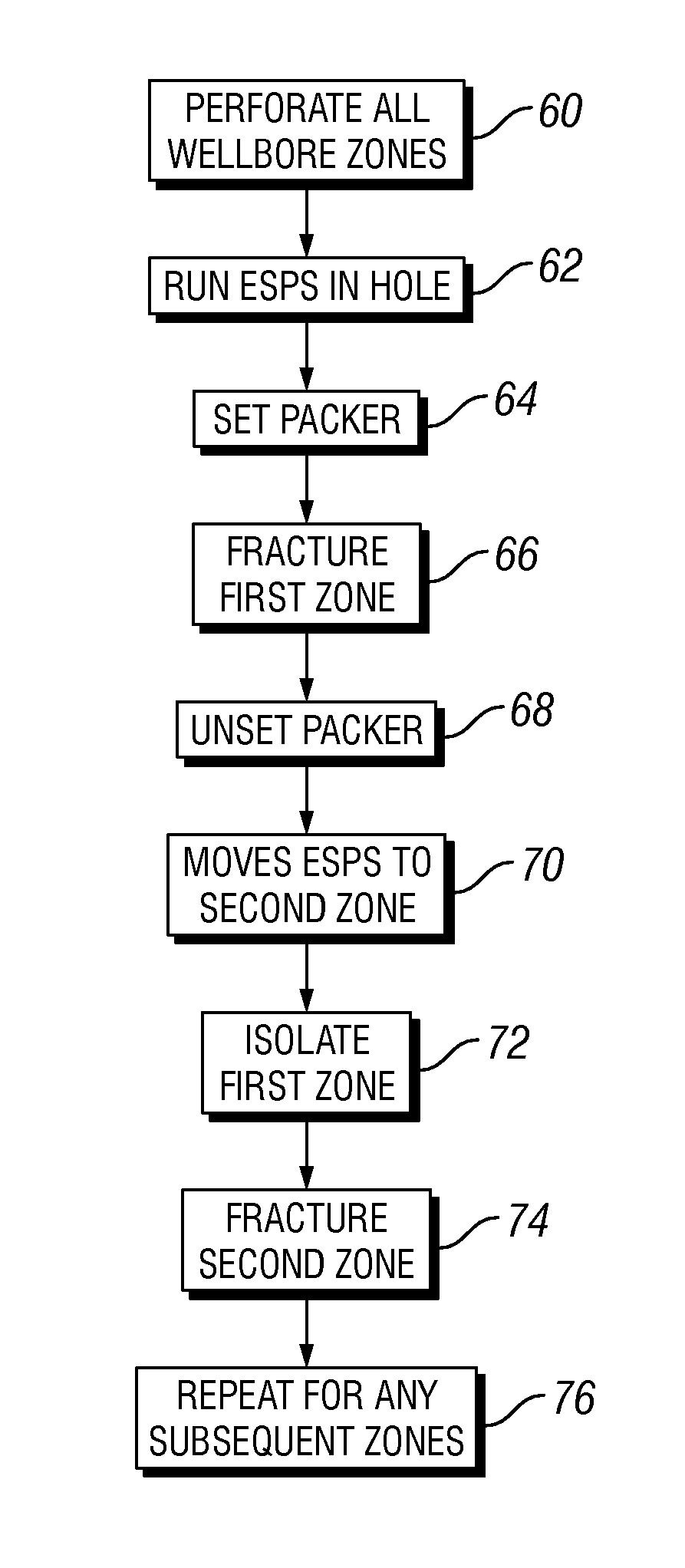

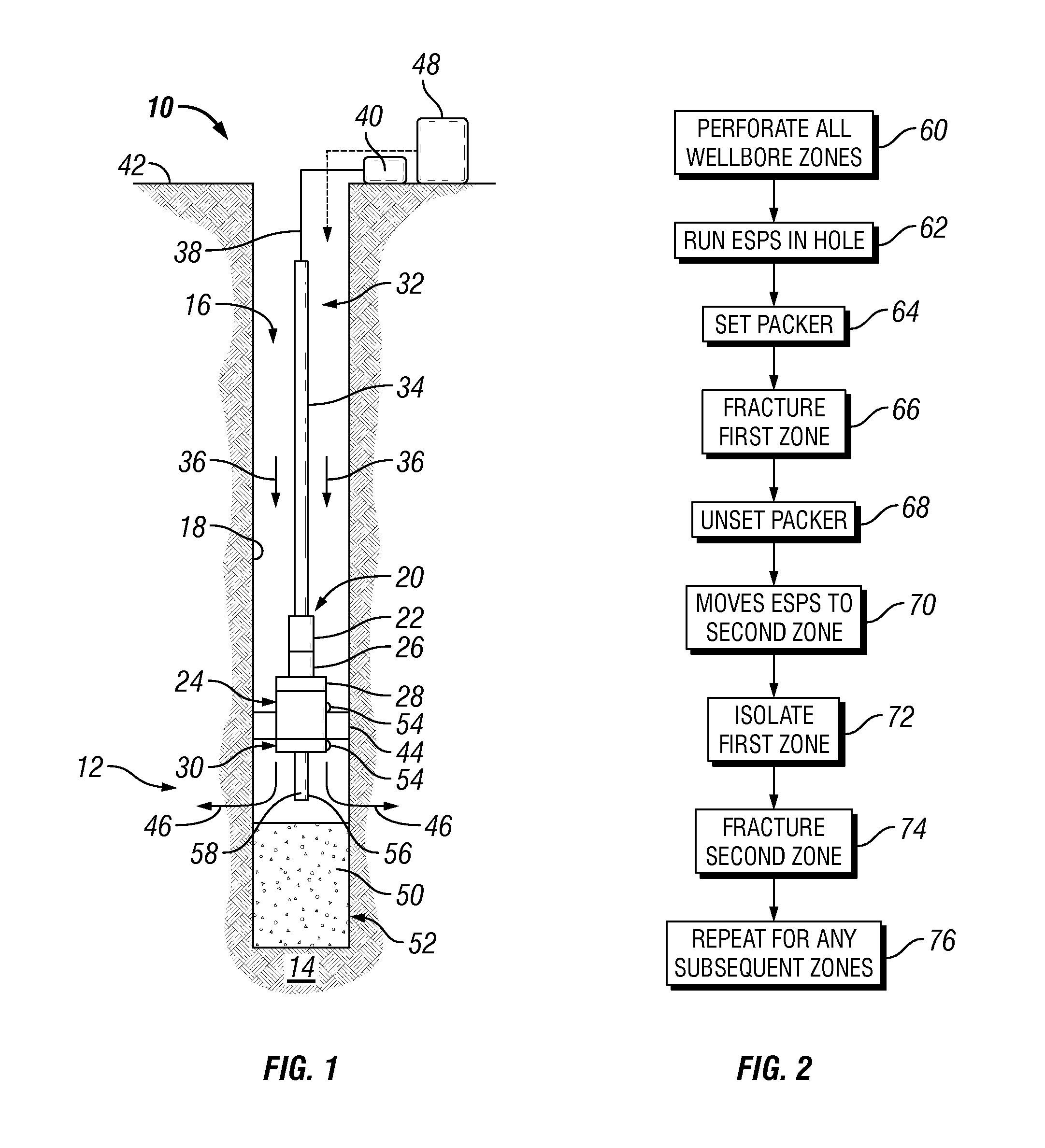

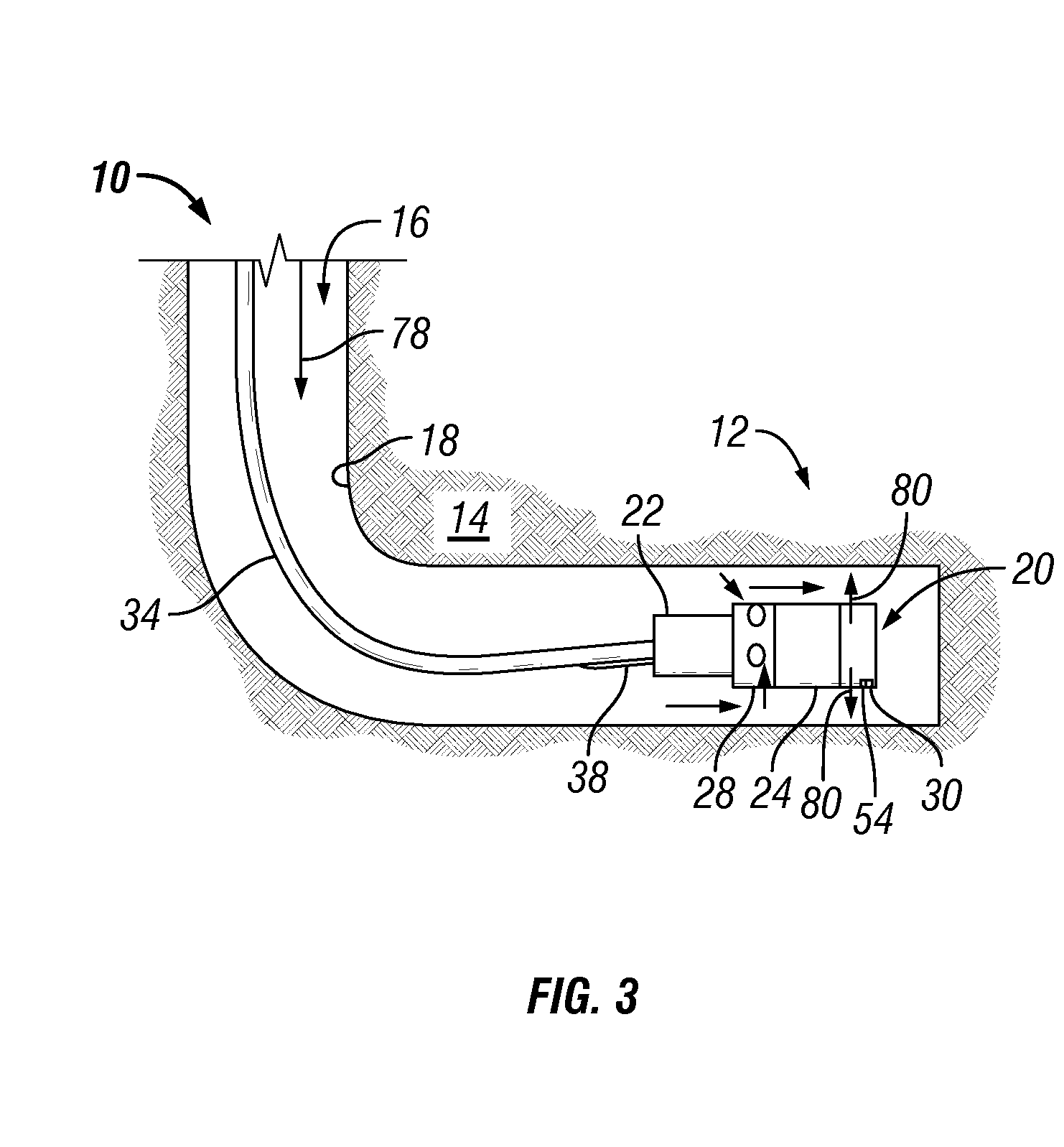

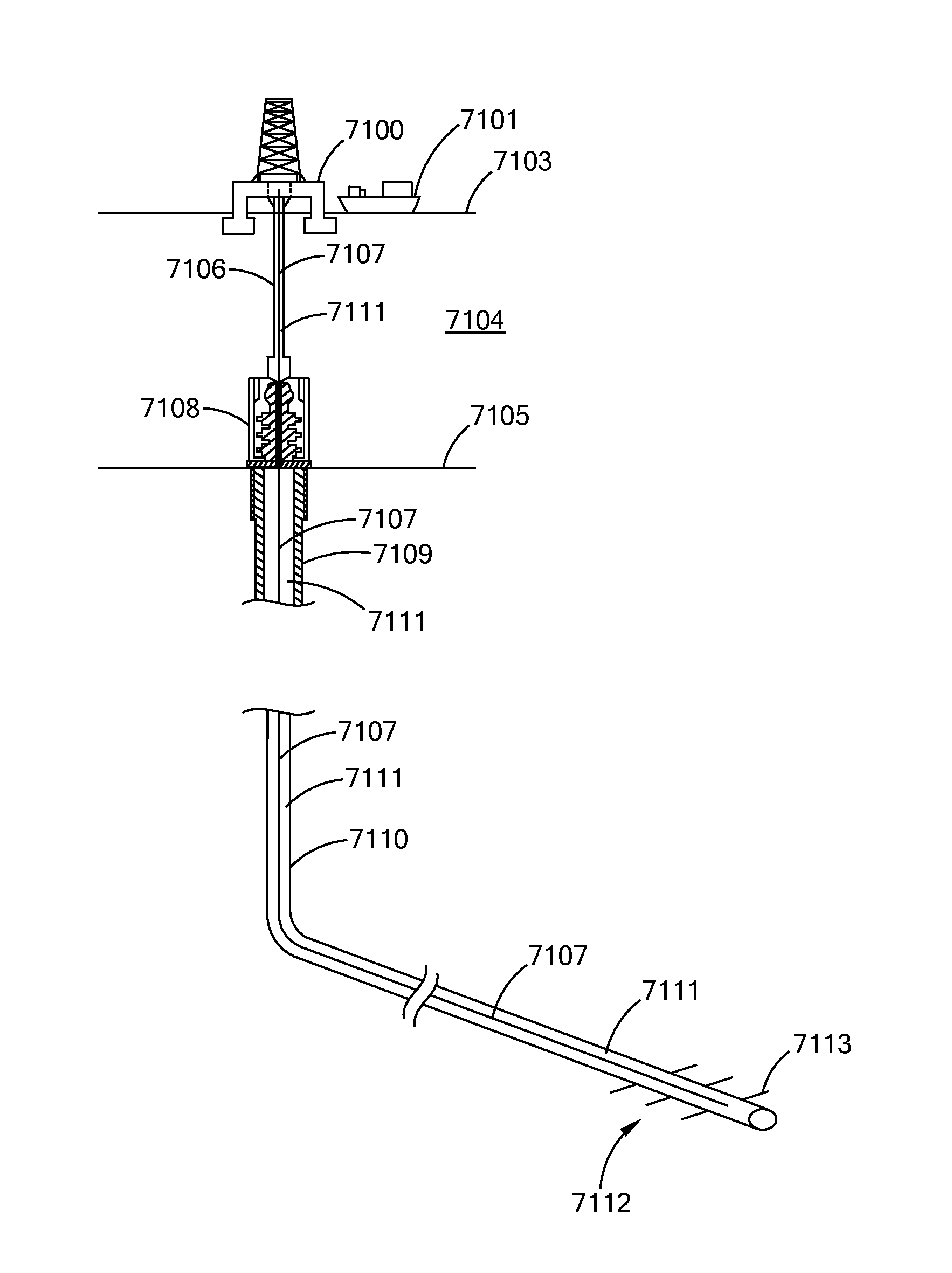

Well treatment using electric submersible pumping system

InactiveUS20080264640A1Convenient treatmentFacilitates well treatmentFluid removalSealing/packingElectricityHydrology

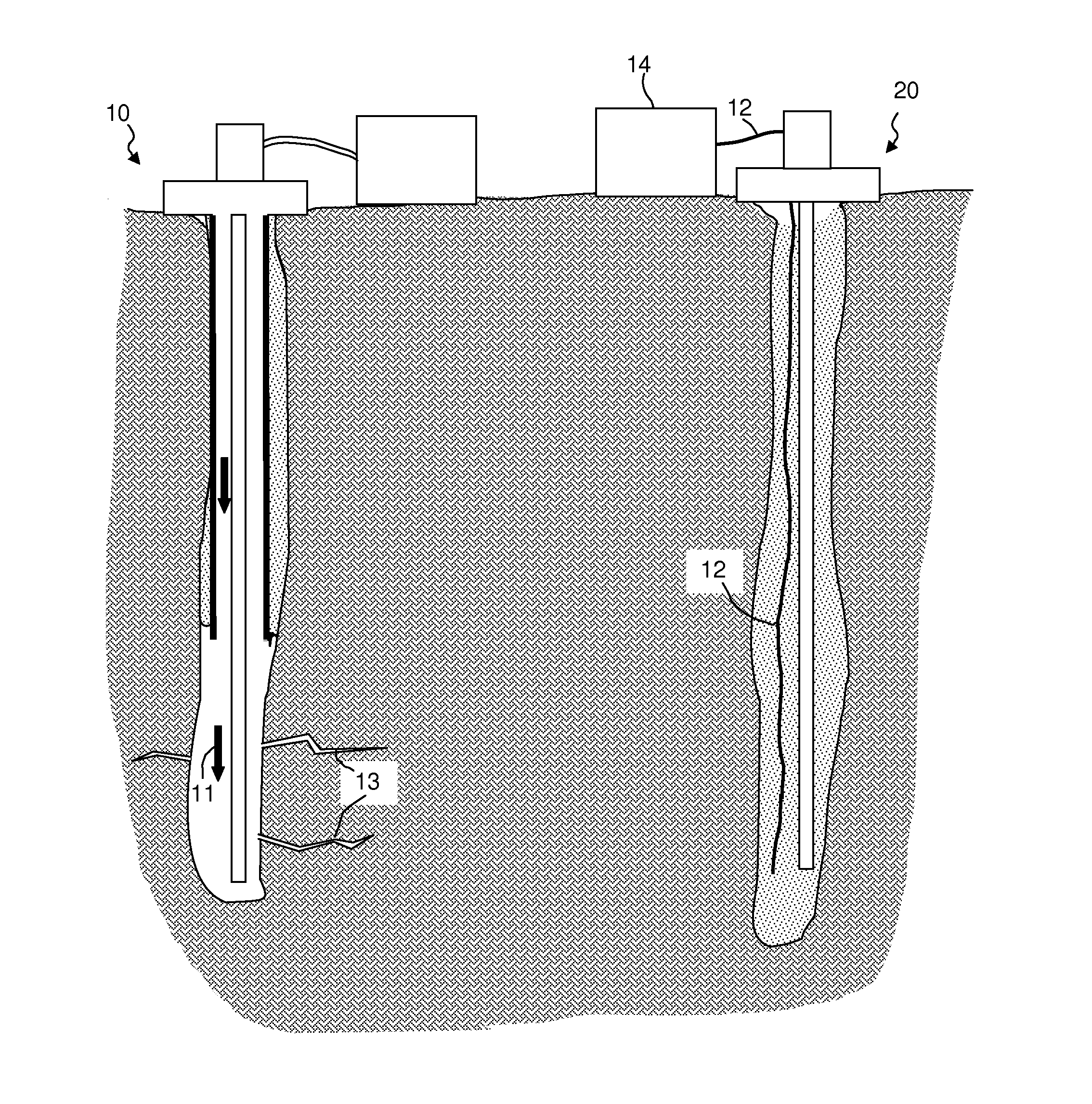

A technique provides an electric submersible pumping system to facilitate a well treatment, such as a hydraulic fracturing well treatment. The electric submersible pumping system is positioned downhole and oriented to intake a fluid delivered downhole for use in the well treatment. Once the fluid is delivered downhole, the electric submersible pumping system pumps, pressurizes and discharges this fluid to perform the well treatment, e.g. the hydraulic fracturing treatment. The pumping system reduces the pressure at which the treatment fluid must be delivered downhole.

Owner:SCHLUMBERGER TECH CORP

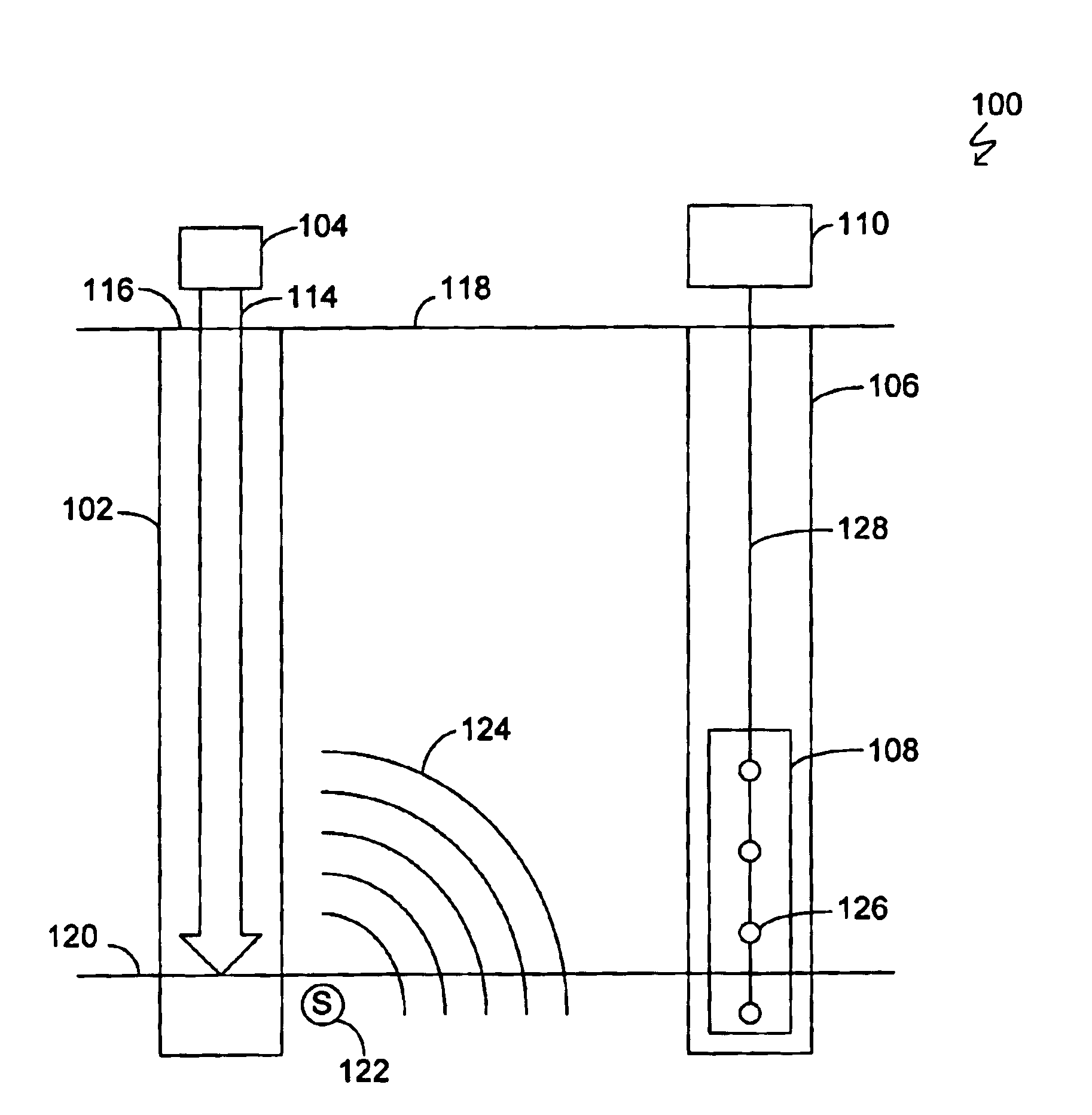

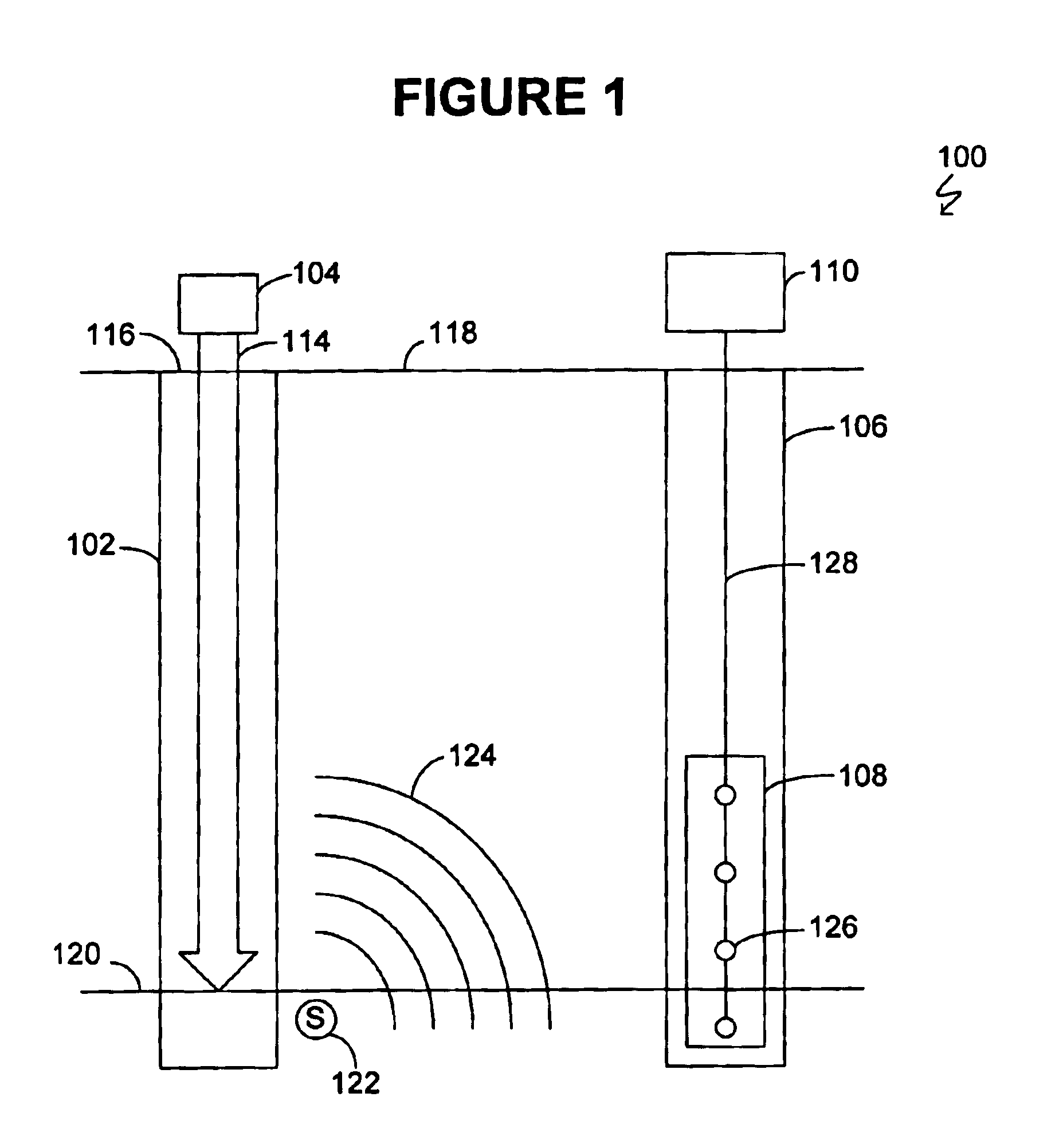

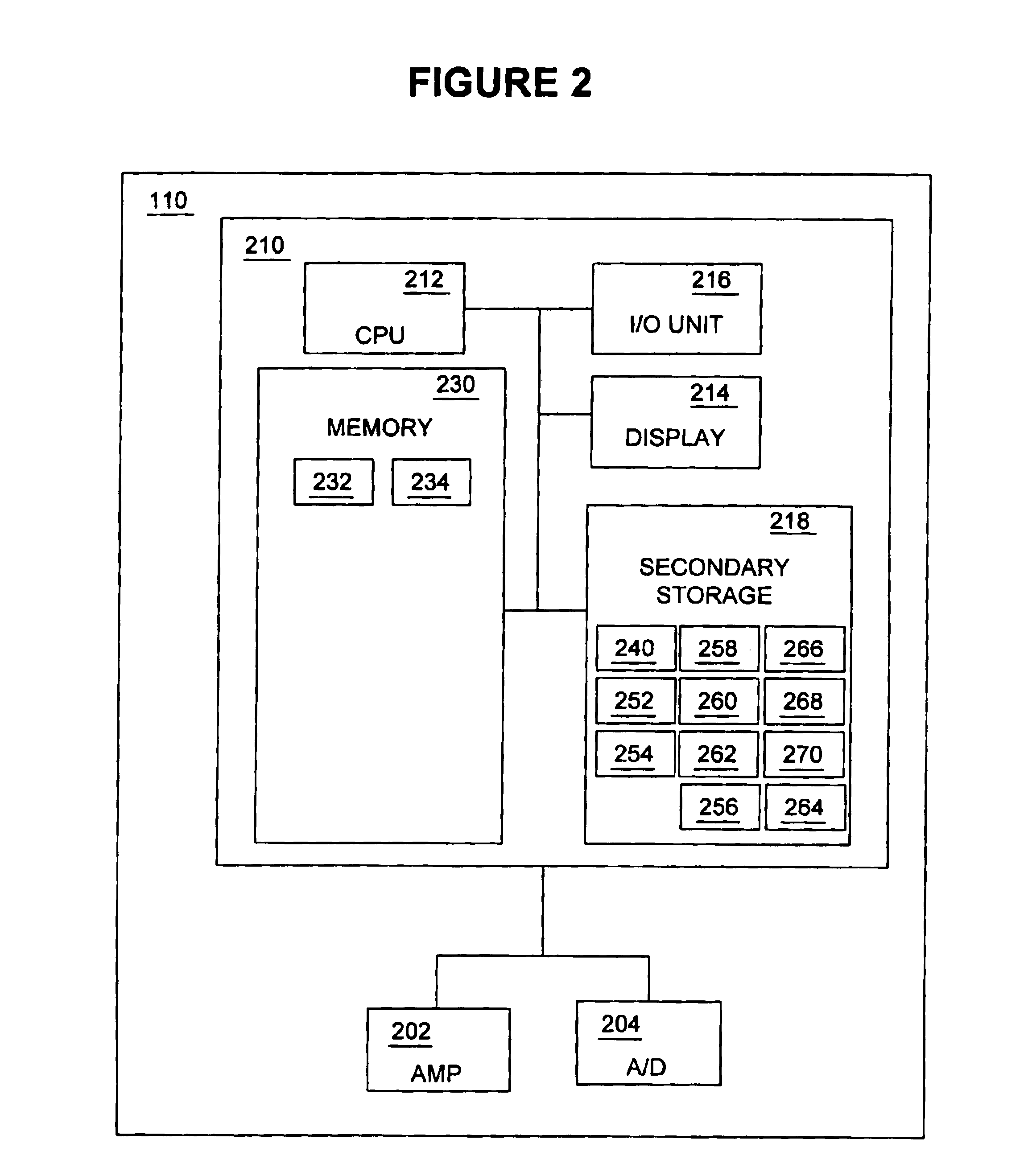

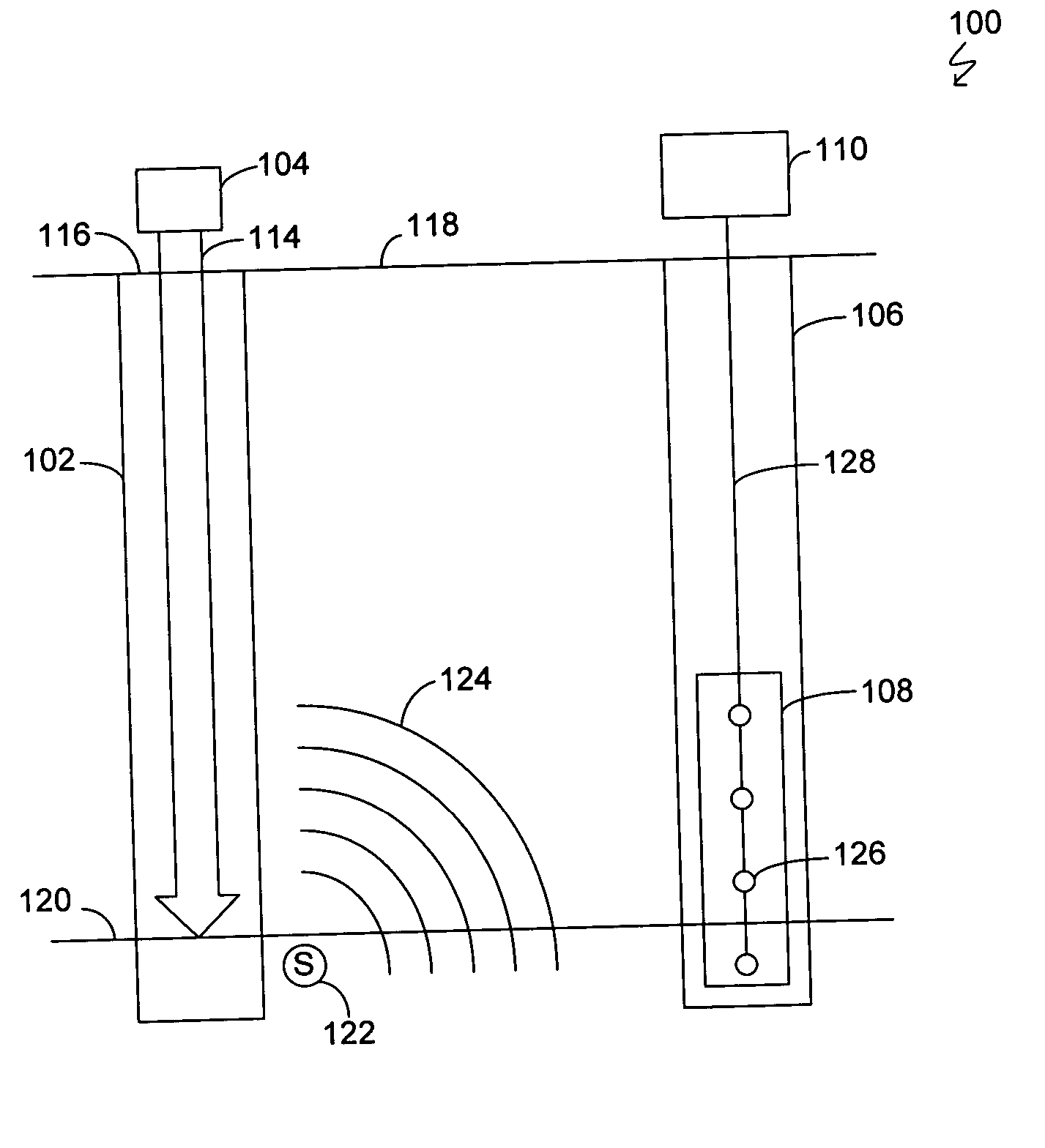

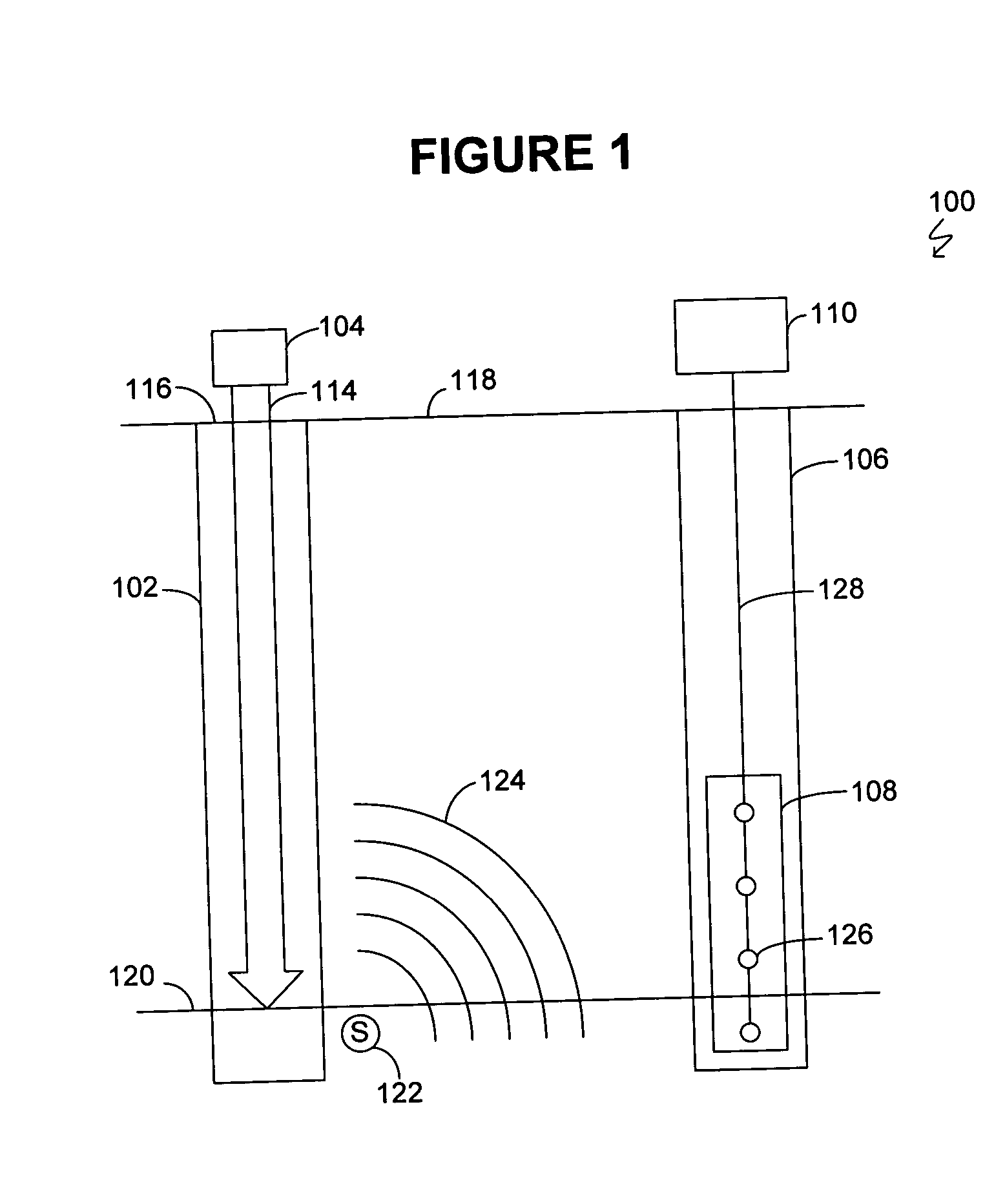

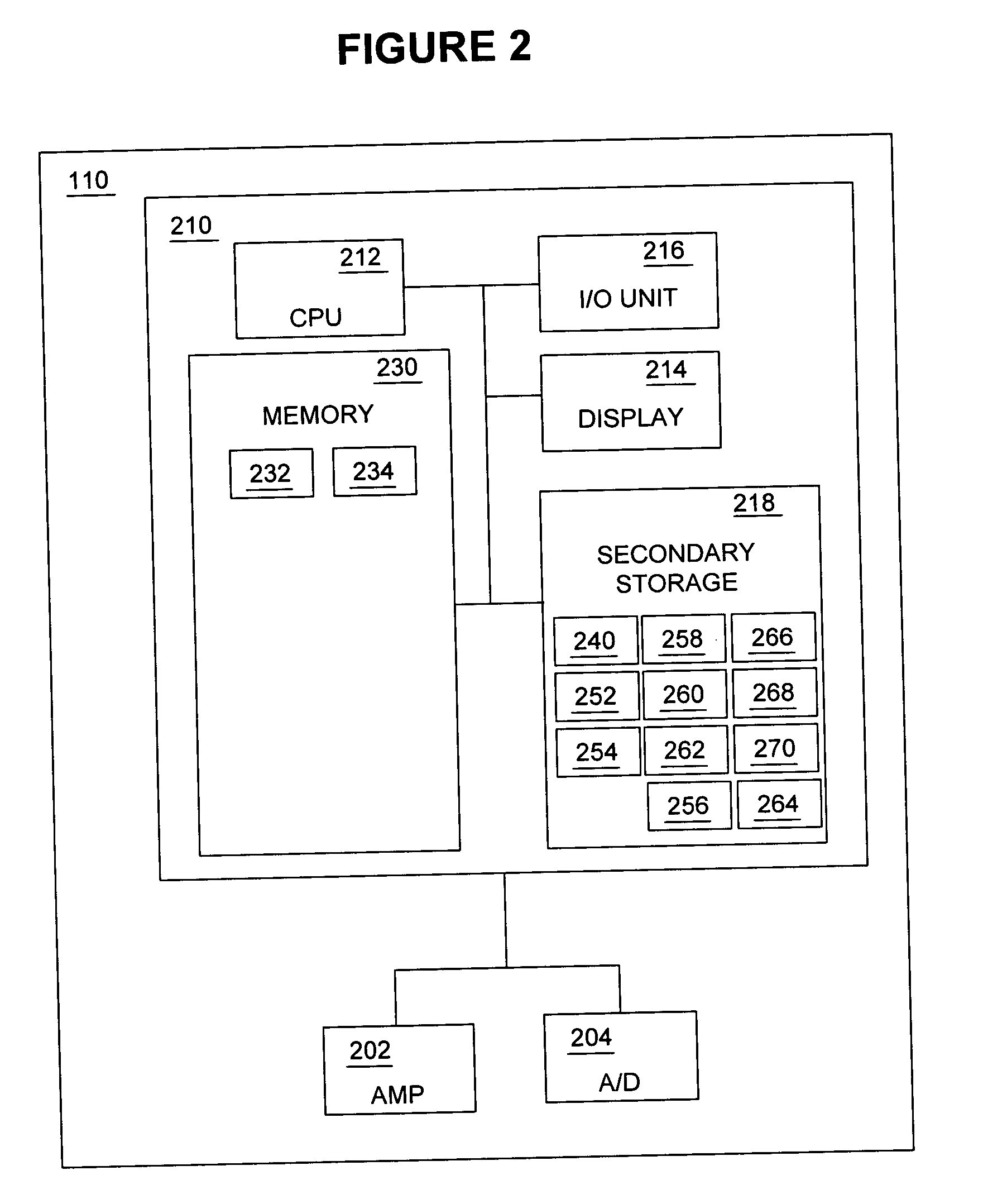

System and method for monitoring strain & pressure

A method for monitoring a well treatment, comprising the steps of installing at least one distributed acoustic strain sensor in at least one monitoring well, said monitoring well being a known distance from the treatment well, initiating a well treatment on the first well, monitoring the formation surrounding the monitoring well using the distributed acoustic strain sensor, and using the distributed acoustic strain sensor, detecting a change in strain at a first location in the monitoring well, using the change in strain to make determinations about the well treatment. The sensor may comprise a fiber optic cable. The change in strain may be used as an indicator that the effect of the well treatment has extended beyond a predetermined preferred treatment zone, the treatment may be a fracture treatment, and the well treatment may be controlled or ceased based on the determinations made in step e).

Owner:SHELL OIL CO

Methods and compositions for introducing conductive channels into a hydraulic fracturing treatment

InactiveUS7213651B2Affecting permeabilityAvoid flowFluid removalVibration devicesFracturing fluidVolumetric Mass Density

Owner:BAKER HUGHES INC

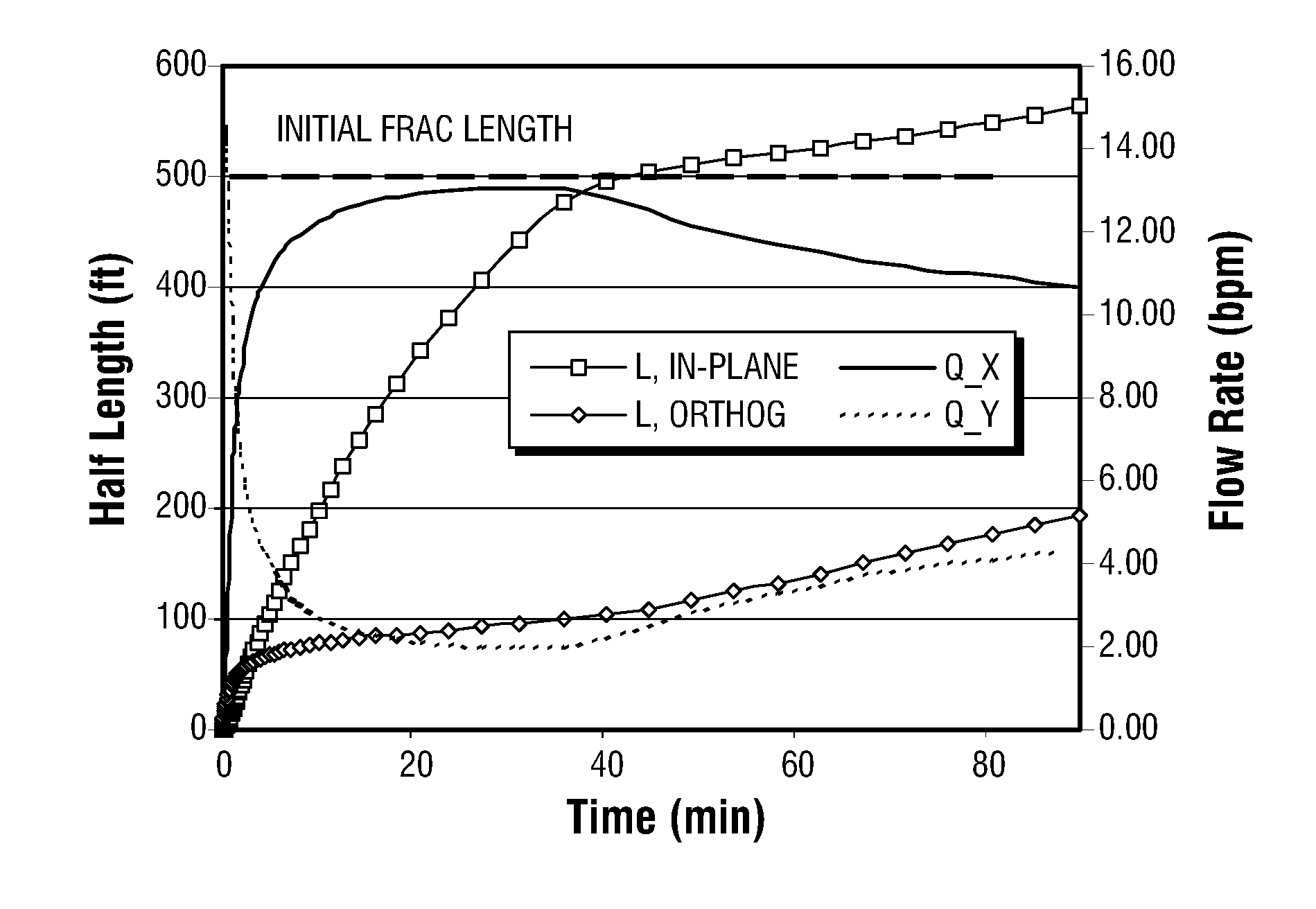

Methods and systems for determining the orientation of natural fractures

InactiveUS6985816B2Seismic signal processingSpecial data processing applicationsTime domainHydraulic fracturing

Methods, systems, and articles of manufacture consistent with the present invention provide for determining the orientation of natural fractures in the Earth resulting from hydraulic fracturing treatment. Data attribute information from a far-field point-source signal profile for a microseismic event is extracted in the time domain. An estimate of the orientation of the natural fracture is calculated in the time domain based on the extracted data attribute information.

Owner:HALLIBURTON ENERGY SERVICES INC

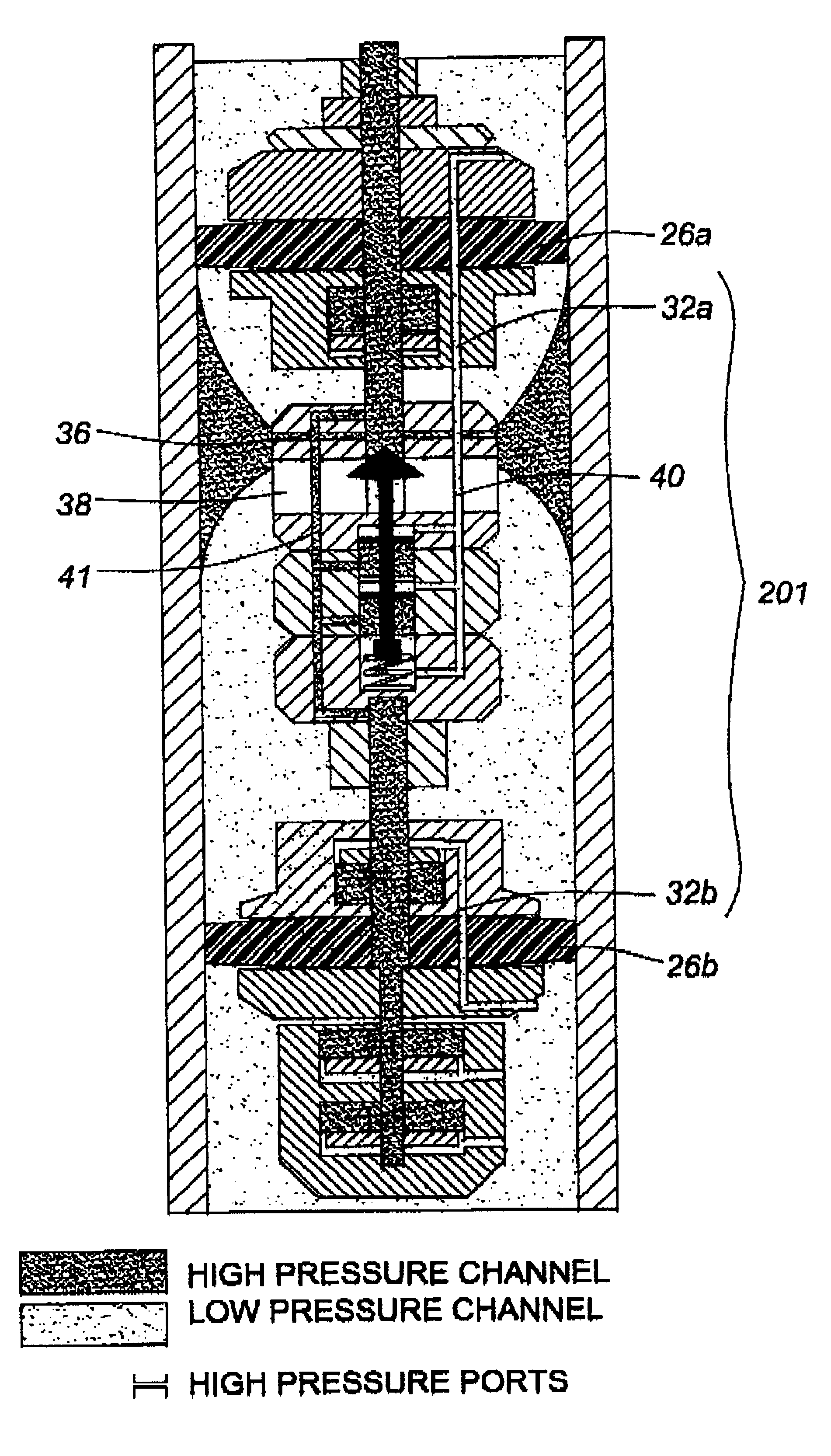

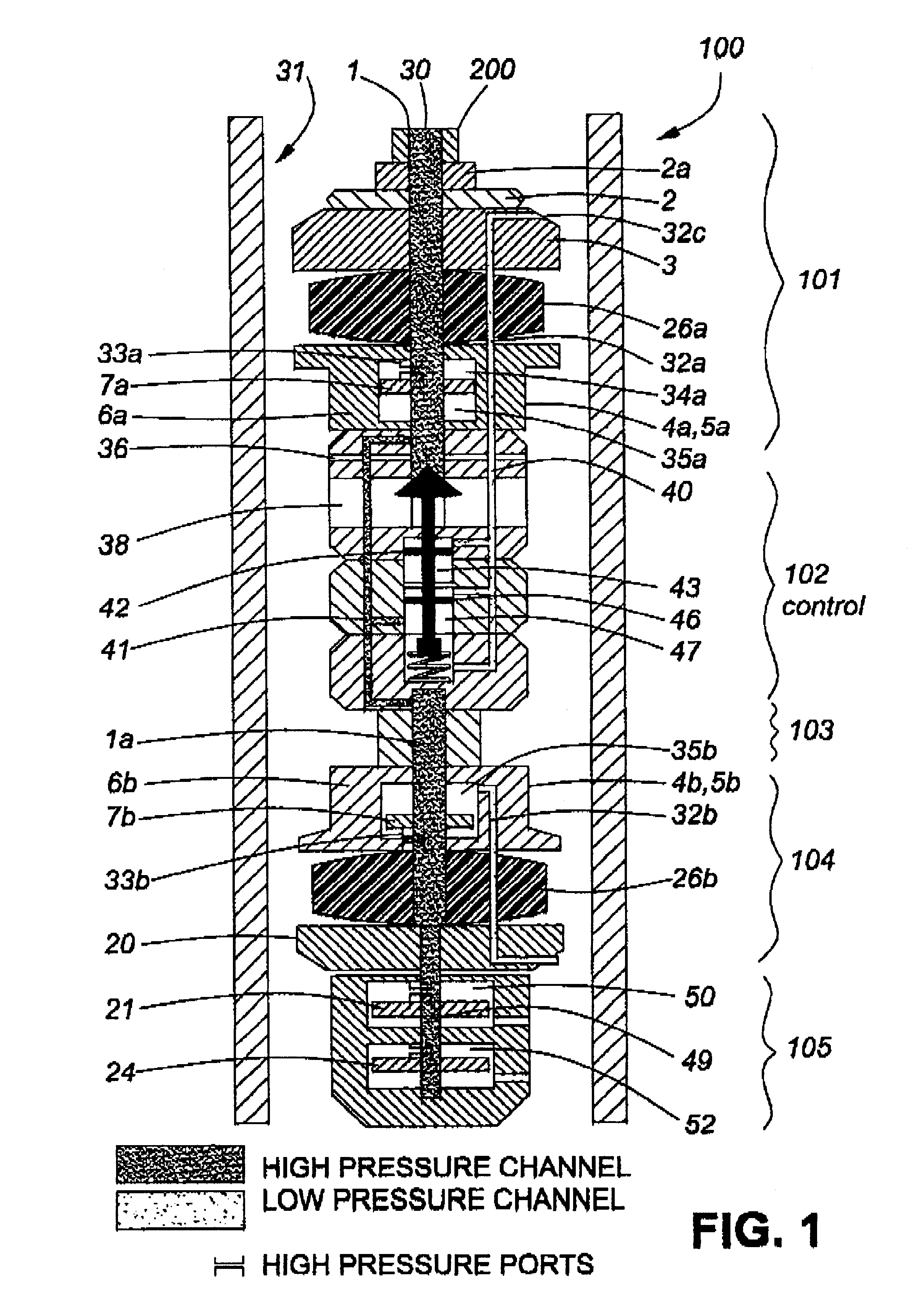

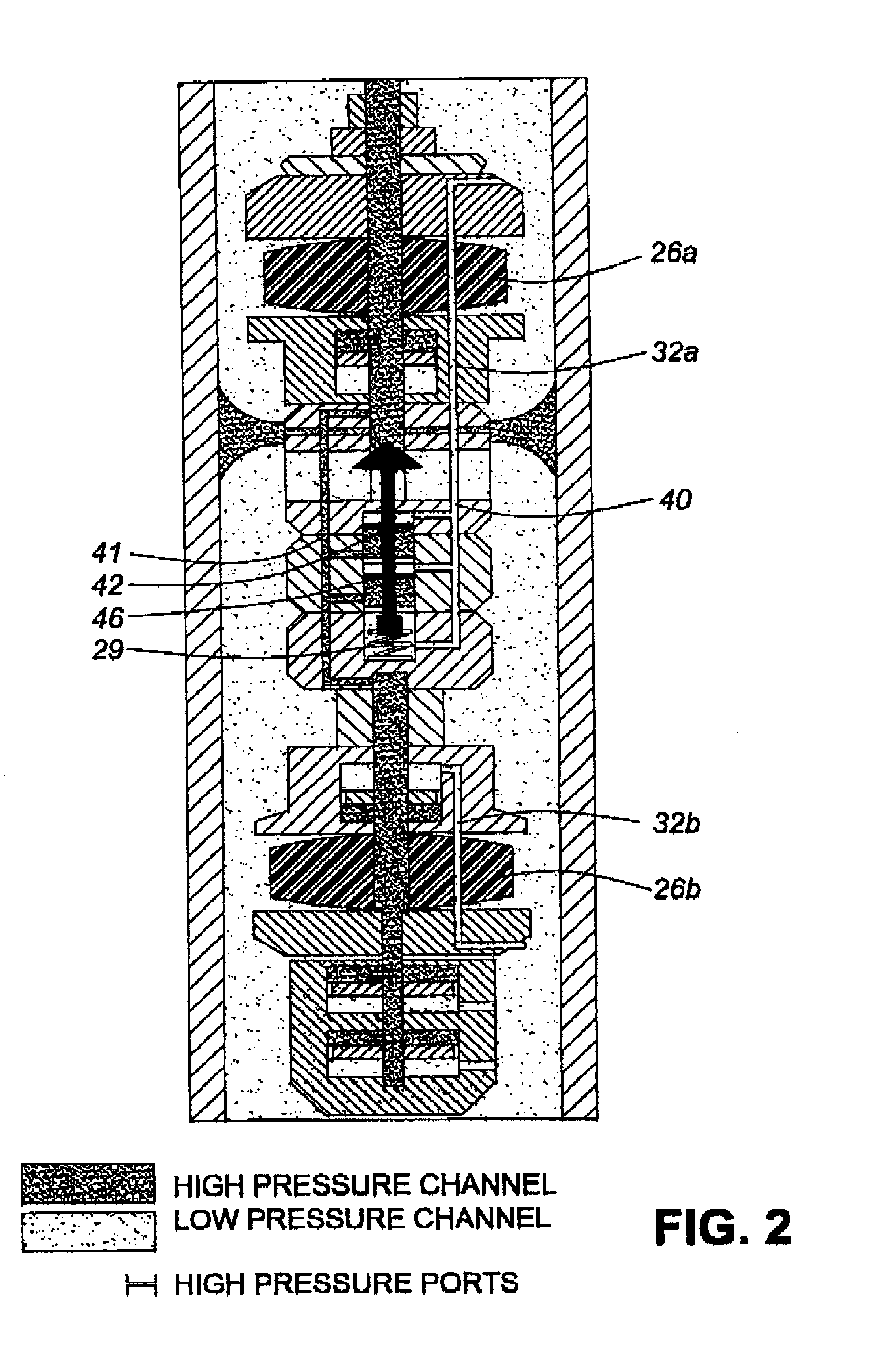

Straddle packer systems

InactiveUS6883610B2Efficient fracturing treatmentImprove sealingFluid removalVibration devicesControl systemStraddle

The present invention relates to straddle packer systems and methods of using them for downhole isolation of zones for fracturing treatment. More specifically, the system includes upper and lower seal systems having resiliently flexible sealing elements hydraulically and operatively connected to one another which are responsive to an increase in hydraulic pressure for setting the sealing elements at a first hydraulic pressure threshold. Additionally, the system includes a control system hydraulically and operatively connected between the upper and lower packer systems which is responsive to an increase in hydraulic pressure at a second hydraulic pressure threshold higher for activating a pressure switch system within the control system for opening at least one frac valve in the control system.

Owner:DEPIAK INDAL TECH CORP

Methods and systems for determining the orientation of natural fractures

ActiveUS20050060099A1Seismic signal processingSpecial data processing applicationsTime domainHydraulic fracturing

Methods, systems, and articles of manufacture consistent with the present invention provide for determining the orientation of natural fractures in the Earth resulting from hydraulic fracturing treatment. Data attribute information from a far-field point-source signal profile for a microseismic event is extracted in the time domain. An estimate of the orientation of the natural fracture is calculated in the time domain based on the extracted data attribute information.

Owner:HALLIBURTON ENERGY SERVICES INC

Simultaneous Method for Combined Acidizing and Proppant Fracturing

InactiveUS20140367100A1Improve CAPF technologyStimulated is largeFluid removalFlushingMedicineOil phase

A treatment fluid for use in a combined acidizing and proppant fracturing treatment, the treatment fluid comprising: (A) an emulsion comprising: (i) a continuous oil phase; (ii) an internal aqueous phase comprising: (a) water; and (b) a source of an acid; and (iii) an emulsifier; and (B) a proppant. A method of fracturing a treatment zone of a well, the method comprising the steps of: (I) forming a treatment fluid according to the invention; and (II) introducing the treatment fluid into the zone at a rate and pressure greater than the fracture gradient of the zone.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for improving isolation of flow to completed perforated intervals

A method for building a plug in a horizontal wellbore using a fluid pill containing a suspended well treatment composite. The well treatment composite contains a core comprising at least one deformable particulate and at least one dissolvable diverter. At least a portion of the surface of the core is coated with at least one viscosifying polymer and at least one crosslinking agent. The fluid pill is pumped into the wellbore at the end of a fracturing treatment and the fluid pill may be displaced by a displacement fluid. The fluid pill may be diverted to an area of lower permeability by disassociating the dissolvable diverter from the core. The disassociated diverter blocks an area of higher permeability. The sized particle distribution of the diverter is sufficient to at least partially block the penetration of fluid into the high permeability zone. In the lower permeability zone, a thickened gel is formed by the in-situ reaction of the viscosifying polymer and crosslinking. Deformable particulates in the gelled fluid form a bridge plug.

Owner:BAKER HUGHES INC

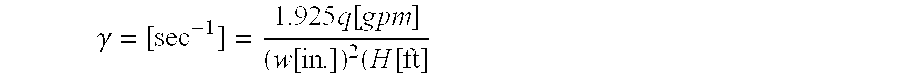

Method of fracturing a subterranean formation at optimized and pre-determined conditions

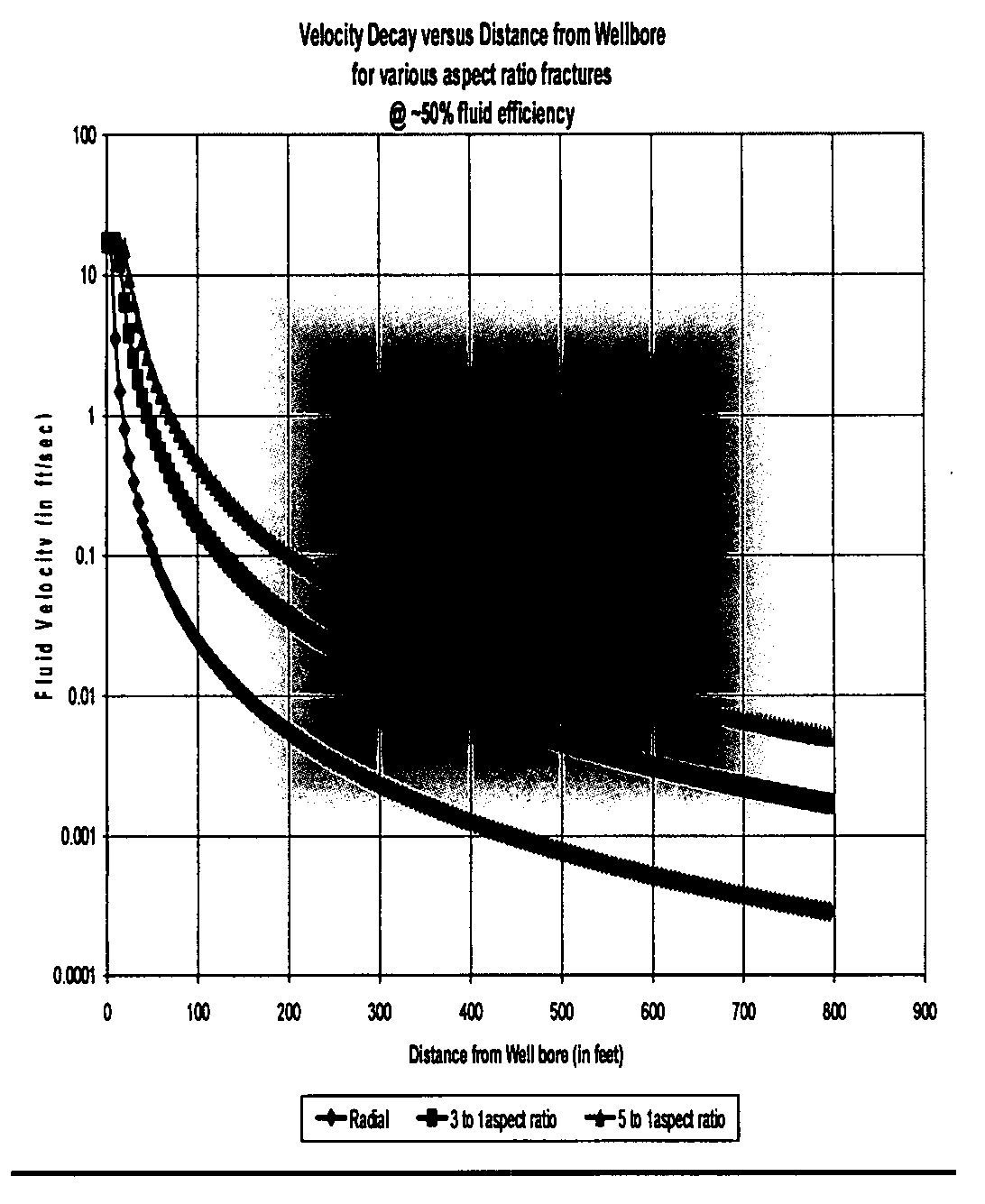

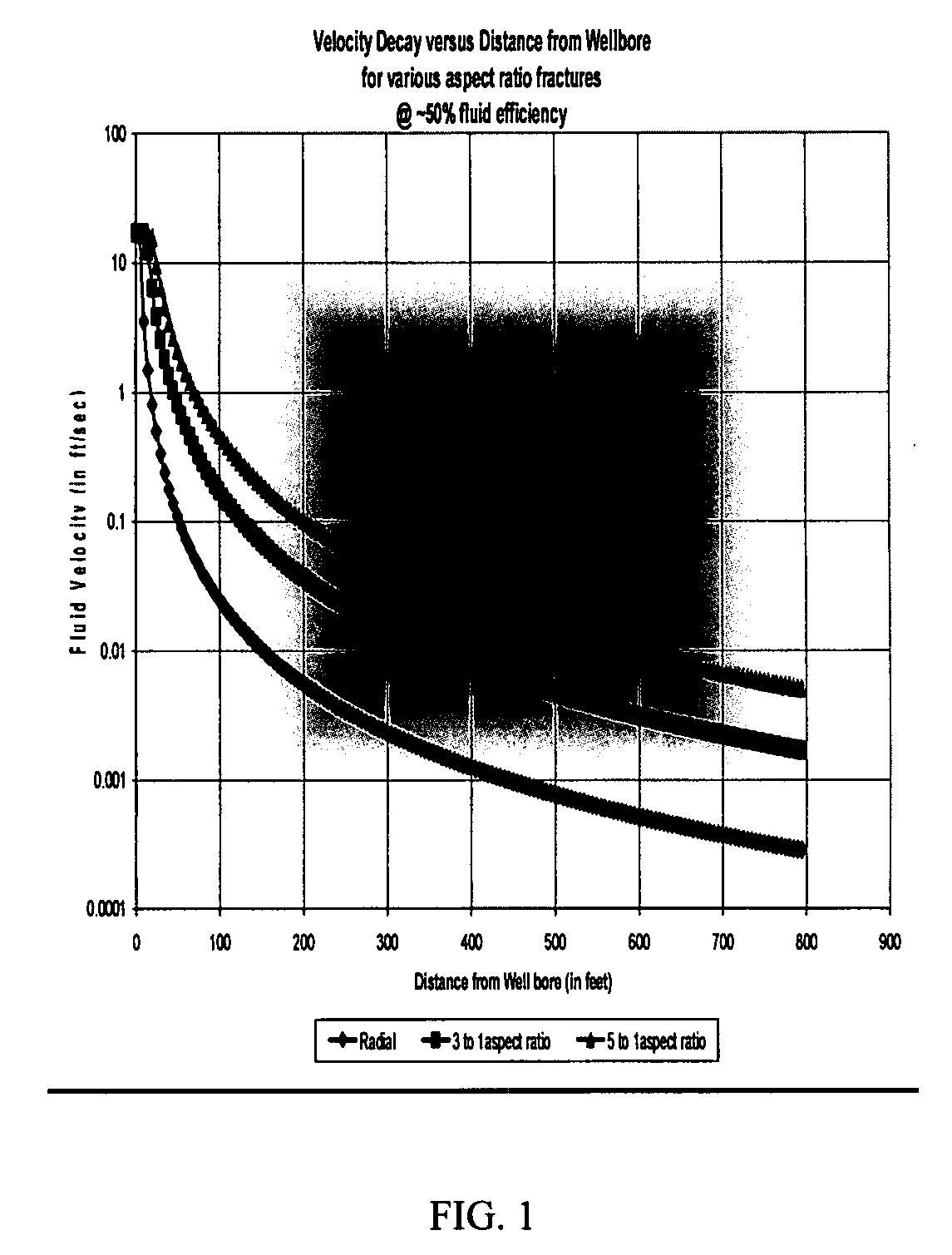

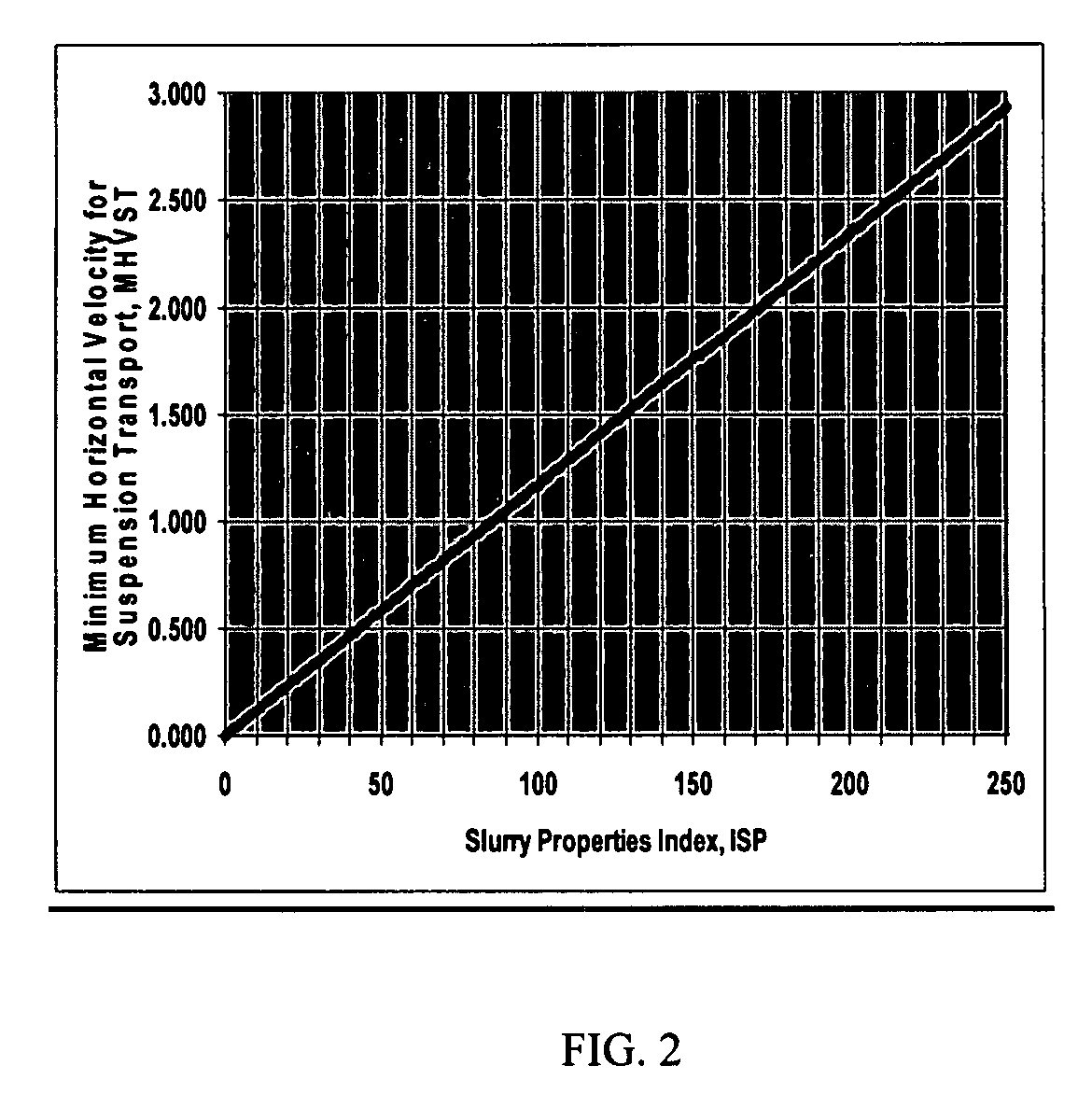

Prior to a hydraulic fracturing treatment, the estimated fracture length may be estimated with knowledge of certain physical properties of the proppant and transport fluid such as fluid viscosity, proppant size and specific gravity of the transport slurry as well as fracture geometry and the treatment injection rate. The estimated fracture length may be determined by the equation:(DPST)B=qi×(1 / A)×CTRANS×(d2prop)×(1 / μfluid)×(ΔSGPS) (I)wherein:DPST is thus the estimated propped fracture length;B is the exponent from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;qi is the injection rate per foot of injection height, bpm / ft.; andA is the multiplier from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;CTRANS, the transport coefficient, is the slope of the linear regression of the ISP vs. MHVST.dprop is the median proppant diameter, in mm.;μfluid is the apparent viscosity of the transport fluid, in cP; andΔ SGPS is SGprop−SGfluid, SGprop being the specific gravity of the proppant andSGfluid being the specific gravity of the transport fluid.The minimum horizontal flow velocity, MHVST, for transport of the transport slurry based upon the terminal settling velocity of the proppant, Vt, may be determined in accordance with Equation (II):MHVST, =Vt×10 (II)Via rearrangements of the same derived equations, a model for optimizing the transport fluid, proppant, and / or treating parameters necessary to achieve a desired propped fracture length may further be determined.

Owner:BAKER HUGHES INC

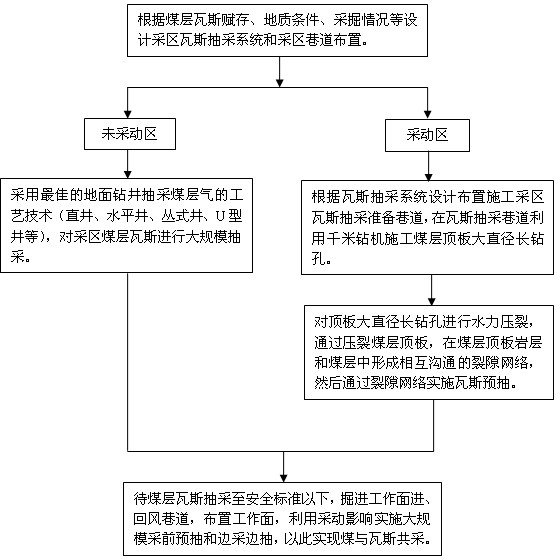

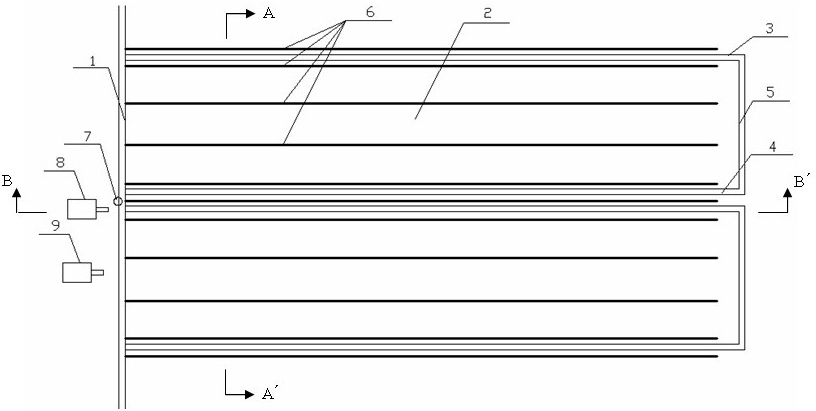

Integrated mining method for commonly mining coal and gas of high mine

The invention discloses an integrated mining method for commonly mining coal and gas of a high mine. The integrated mining method comprises the following steps of: adopting a process technology which utilizes ground drilling to drain coal bed gas for carrying out gas drainage on unmined areas, and carrying out coal mining on drainage areas when the safety standard is met; for mined areas, utilizing the space of the existing roadways and gas drainage special preparation roadways under the coal mine or additionally opening large-diameter long drilling holes which have different distances from a drill site to a coal bed top plate; selecting corresponding fracturing pump stations and fracturing process technologies to carry out fracturing treatment, forming a fracture network system communicated with the coal bed in the coal bed top plate to preextract the coal bed gas; when the preextraction meets the safety standard, firstly adopting a tunneling process to tunnel an intake airway and a return airway of a work surface; distributing a stopping work surface, then carrying out construction of the conventional drainage and drilling at the intake airway and the return airway of the work surface; and by utilizing the mine pressure rule caused by the stopping of the work surface, implementing the preextraction before mining and simultaneous mining and extraction with fracturing holes, and realizing integrated mining of the coal and the gas. In the integrated mining method, the safe high-efficiency common mining of the coal and the gas can be realized and the application prospect is wide.

Owner:HENAN COAL CHEM IND GROUP INST

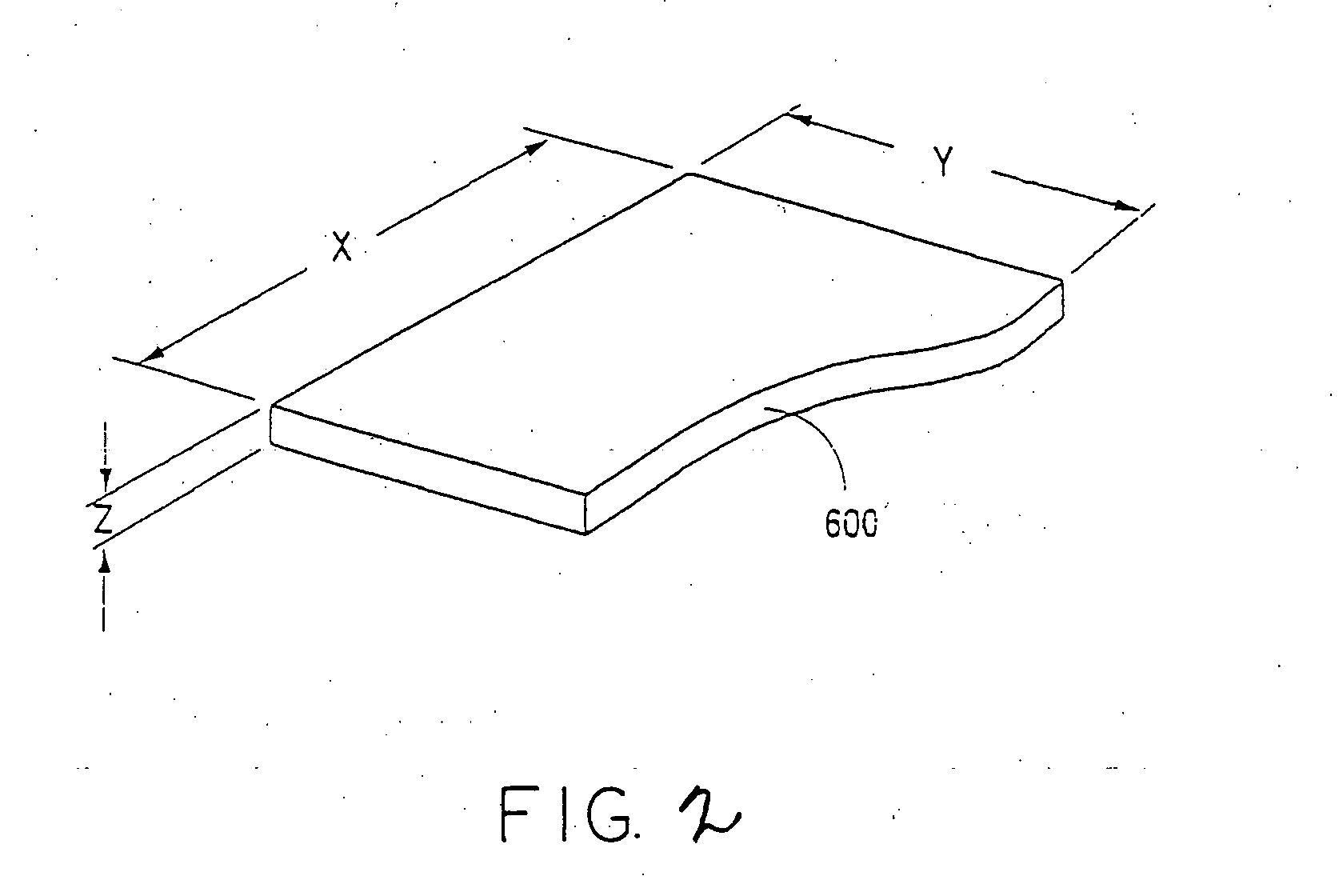

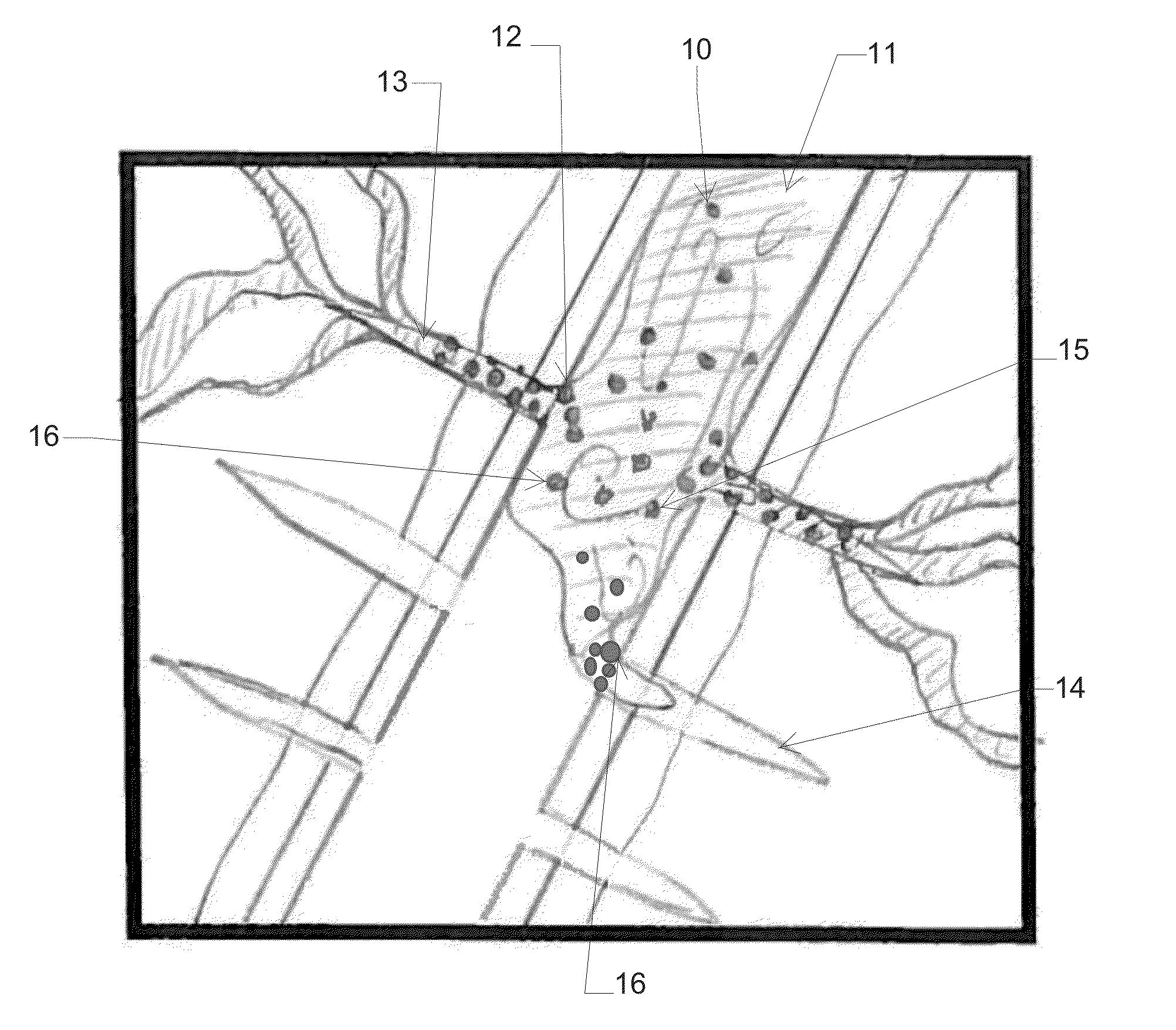

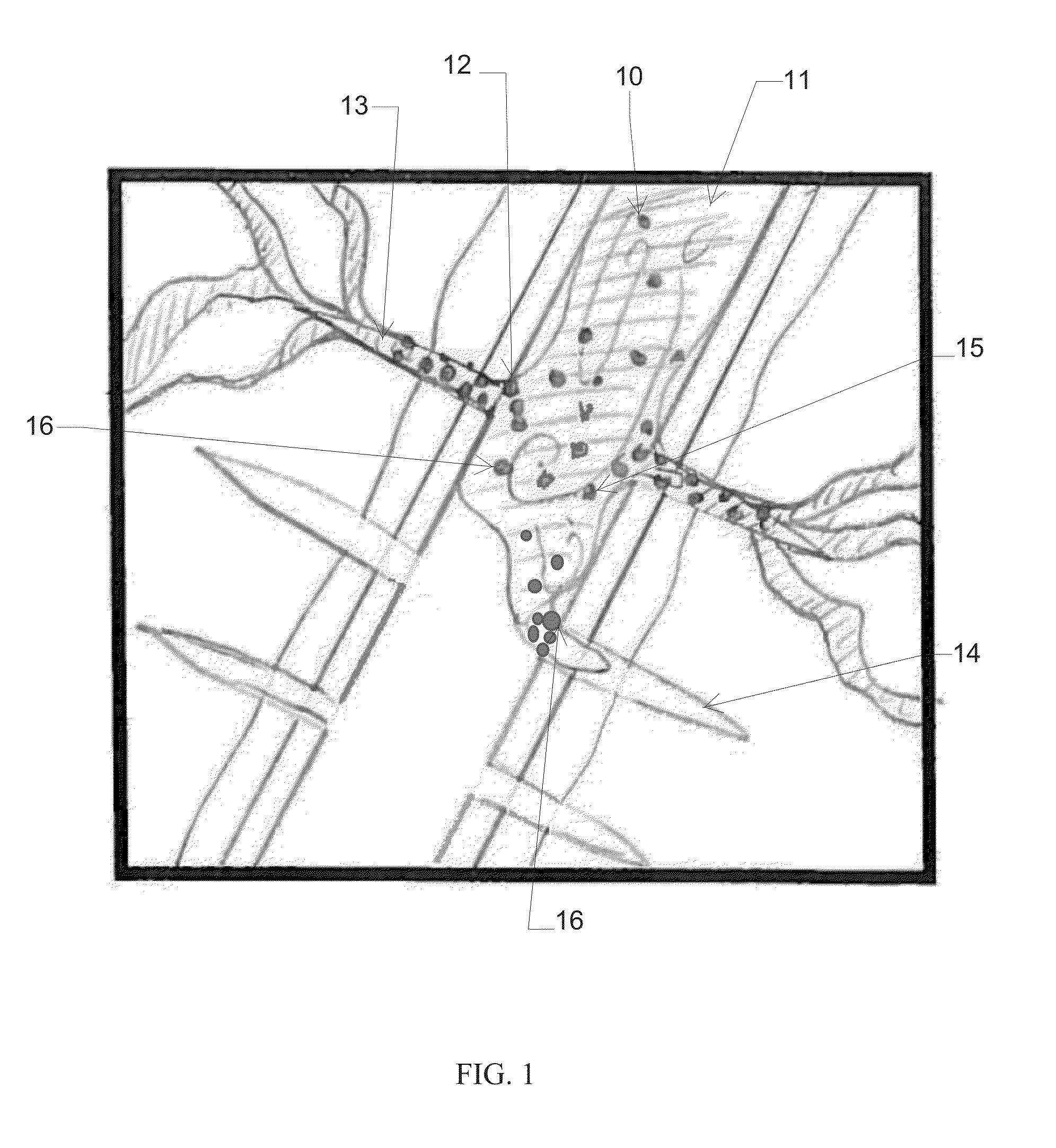

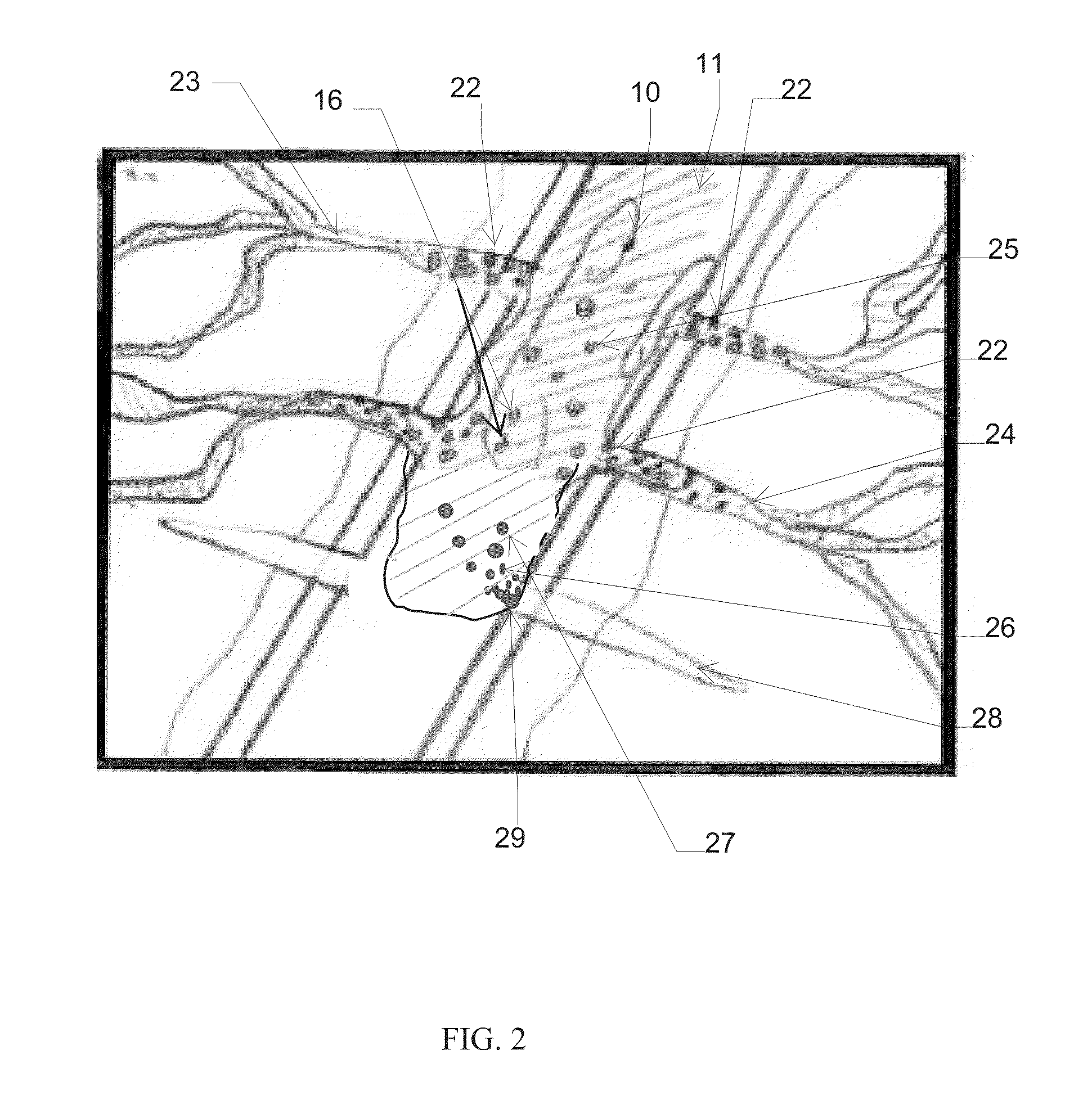

Simulations for hydraulic fracturing treatments and methods of fracturing naturally fractured formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

Means and method for assessing the geometry of a subterranean fracture during or after a hydraulic fracturing treatment

A method is given of fracturing a subterranean formation including the step of a) pumping at least one device actively transmitting data that provide information on the device position, and further comprising the step of assessing the fracture geometry based on the positions of said at least one device, or b) pumping metallic elements, preferably as proppant agents, and further locating the position of said metallic elements with a tool selected from the group consisting of magnetometers, resistivity tools, electromagnetic devices and ultra-long arrays of electrodes, and further comprising the step of assessing the fracture geometry based on the positions of said metallic elements. The method allows monitoring of the fracture geometry and proppant placement.

Owner:SCHLUMBERGER TECH CORP

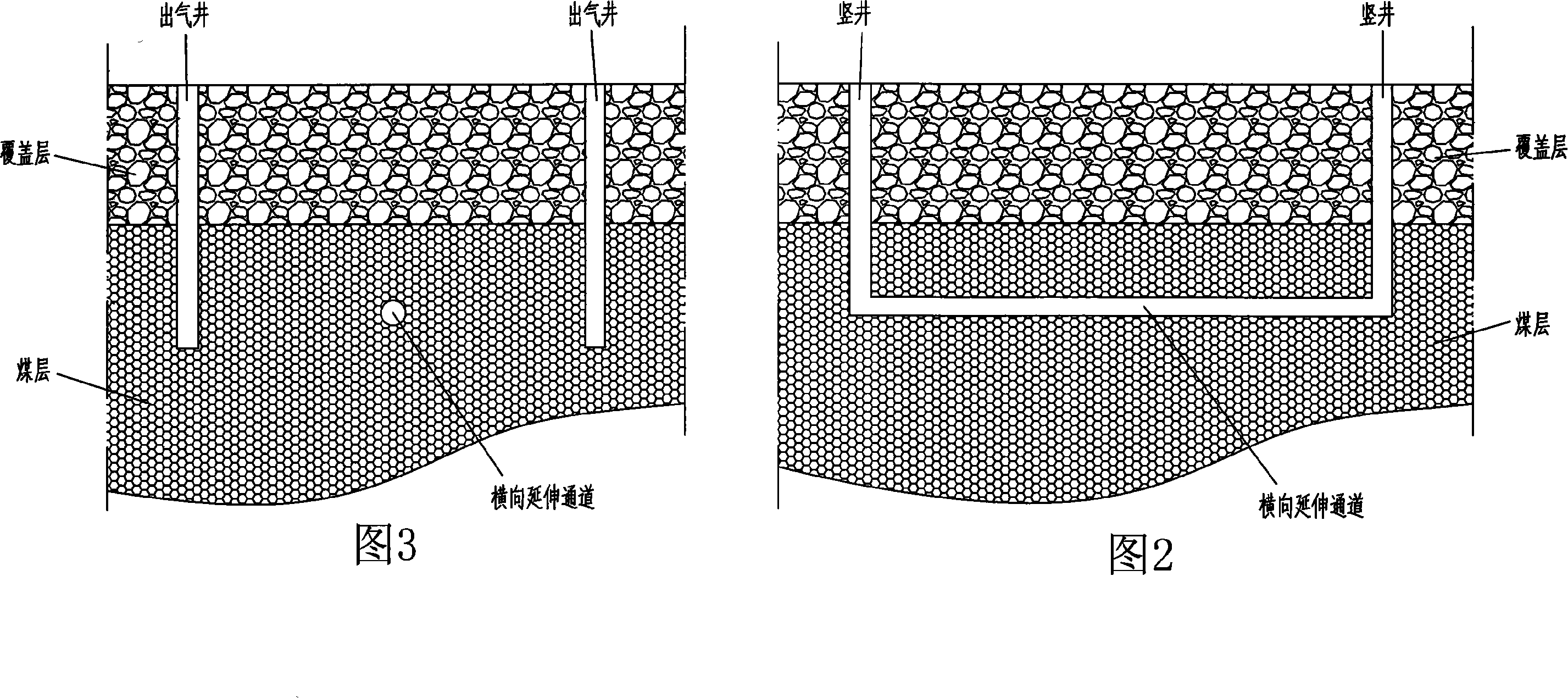

Coal bed gas mining novel technology

The invention discloses a new coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

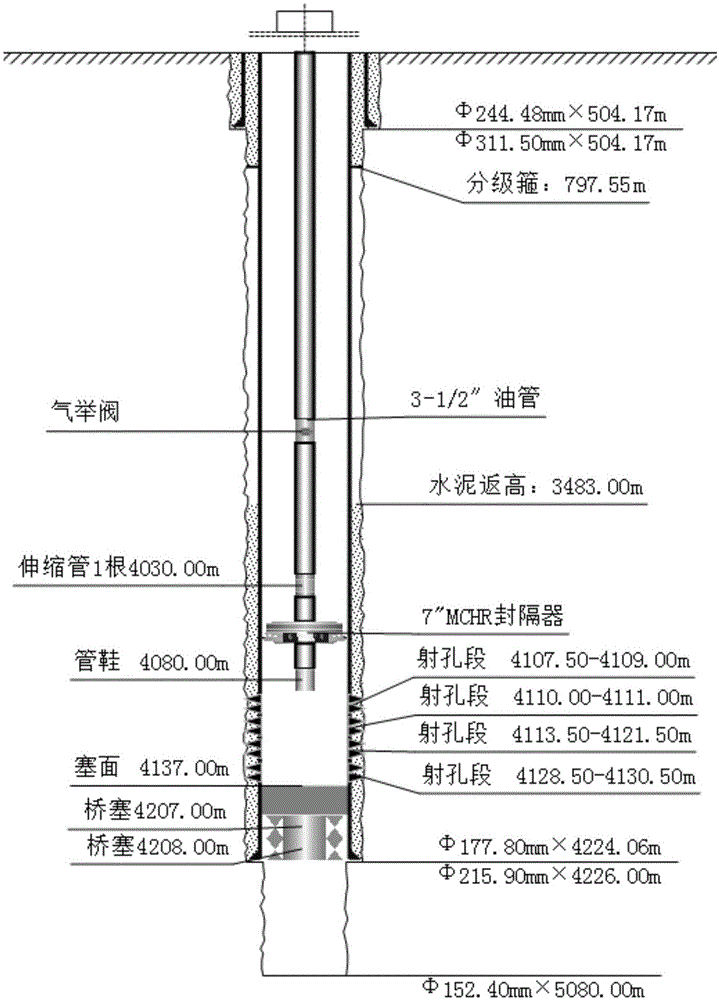

Hydraulic fracturing treatment method of an unconventional reservoir oil and gas well

The invention provides a hydraulic fracturing treatment method of an unconventional reservoir oil and gas well. The hydraulic fracturing treatment method comprises the following steps: injecting a material liquid into existing fractures of a reservoir; enabling a temporary plugging material in the material liquid to form bridge blinding at the seams of the fractures; performing hydraulic fracturing construction to force the fractures to turn; and injecting an active liquid to activate microfractures of the reservoir, and the steps are performed at least once. By the adoption of the hydraulic fracturing treatment method of the unconventional reservoir oil and gas well, not only can a plurality of man-made fractures be formed, the microfractures of the reservoir can be activated, the drainage area is enlarged, and the single-well yield and the economic benefits are improved. The hydraulic fracturing treatment method provided by the invention is not only suitable for unconventional oil and gas reservoirs such as shale gas, coal bed gas and tight oil and gas but also applied to low-permeability and superlow-permeability conventional oil and gas reservoirs; and meanwhile, the method can be used for straight-well capacity increasing revamp construction and can also be used for capacity increasing revamp construction of horizontal wells, deviated wells and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Method of treating subterranean formations using mixed density proppants or sequential proppant stages

ActiveUS20080032898A1Low costIncrease the lengthFluid removalDrilling compositionMedicineHydraulic fracturing

An increase in effective propped lengths is evidenced in hydraulic fracturing treatments by the use of ultra lightweight (ULW) proppants. The ULW proppants have a density less than or equal to 2.45 g / cc and may be used as a mixture in a first proppant stage wherein at least one of the proppants is a ULW proppant. Alternatively, sequential proppant stages may be introduced into the formation wherein at least one of the proppant stages contain a ULW proppant and where at least one of the following conditions prevails: (i.) the density differential between the first proppant stage and the second proppant stage is greater than or equal to 0.2 g / cc; (ii.) both the first proppant stage and the second proppant stage contain a ULW proppant; (iii.) the rate of injection of the second proppant stage into the fracture is different from the rate of injection of the first proppant stage; or (iv.) the particle size of the second proppant stage is different from the particle size of the first proppant stage.

Owner:BAKER HUGHES INC

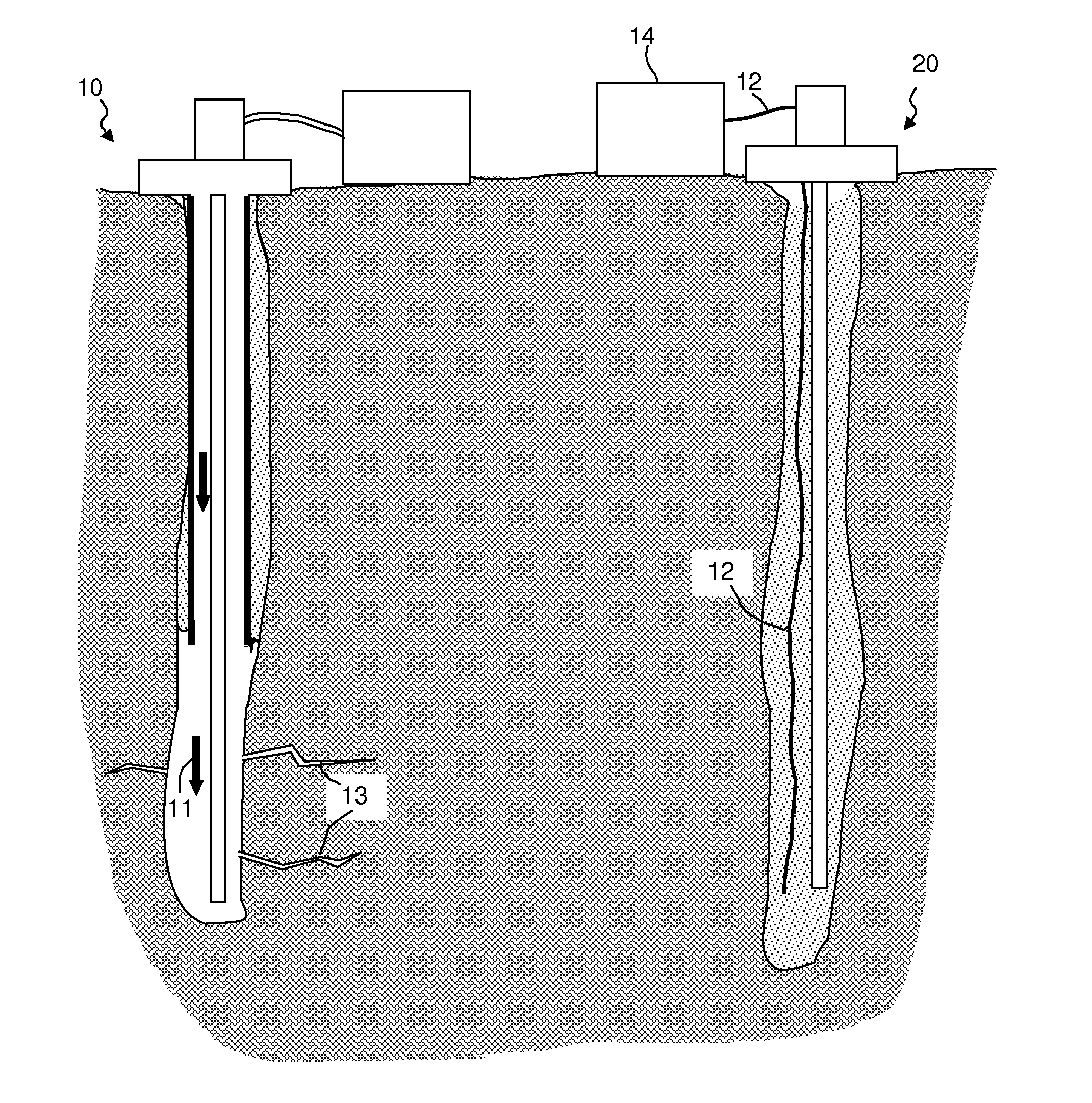

Increasing fracture complexity in ultra-low permeable subterranean formation using degradable particulate

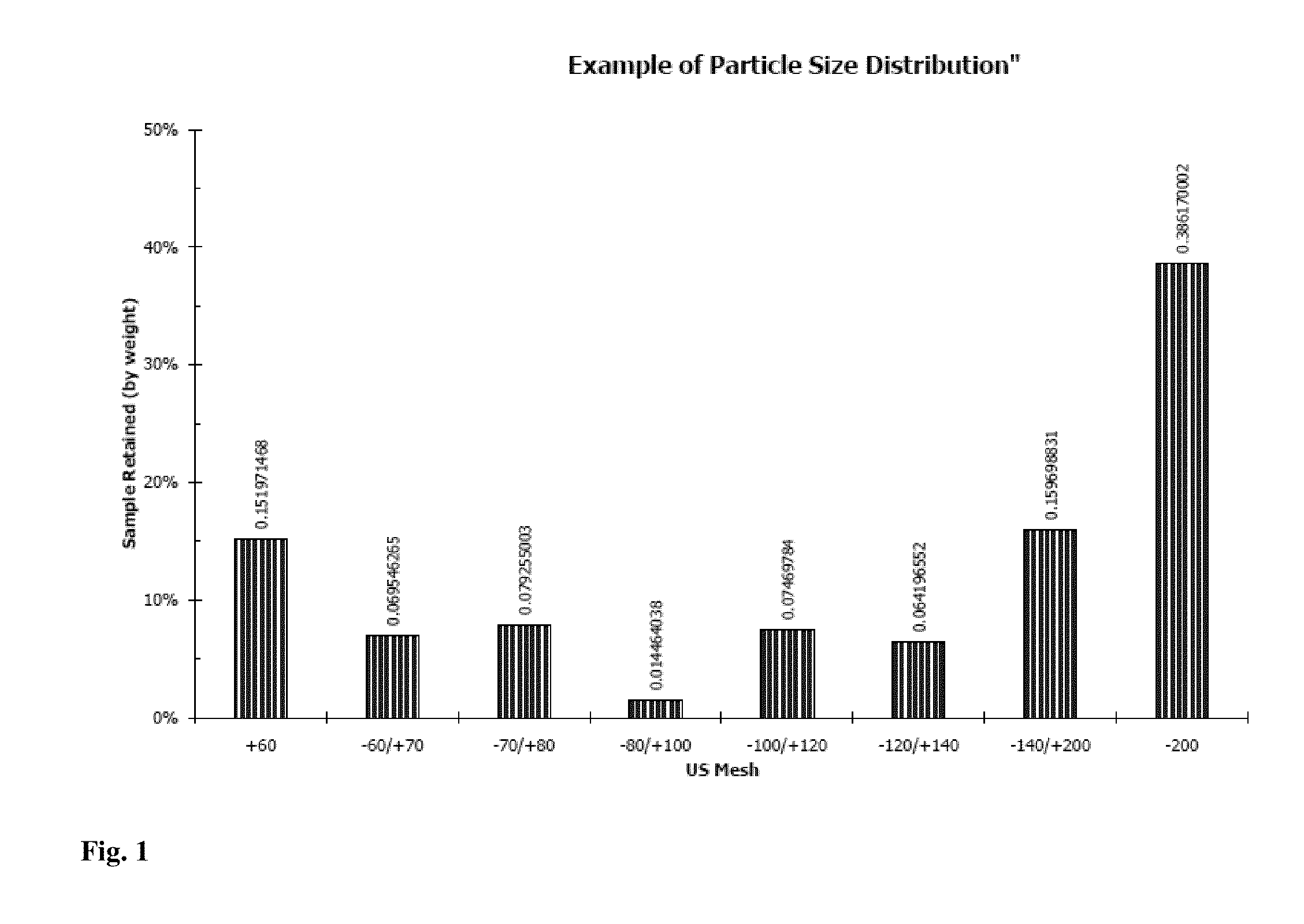

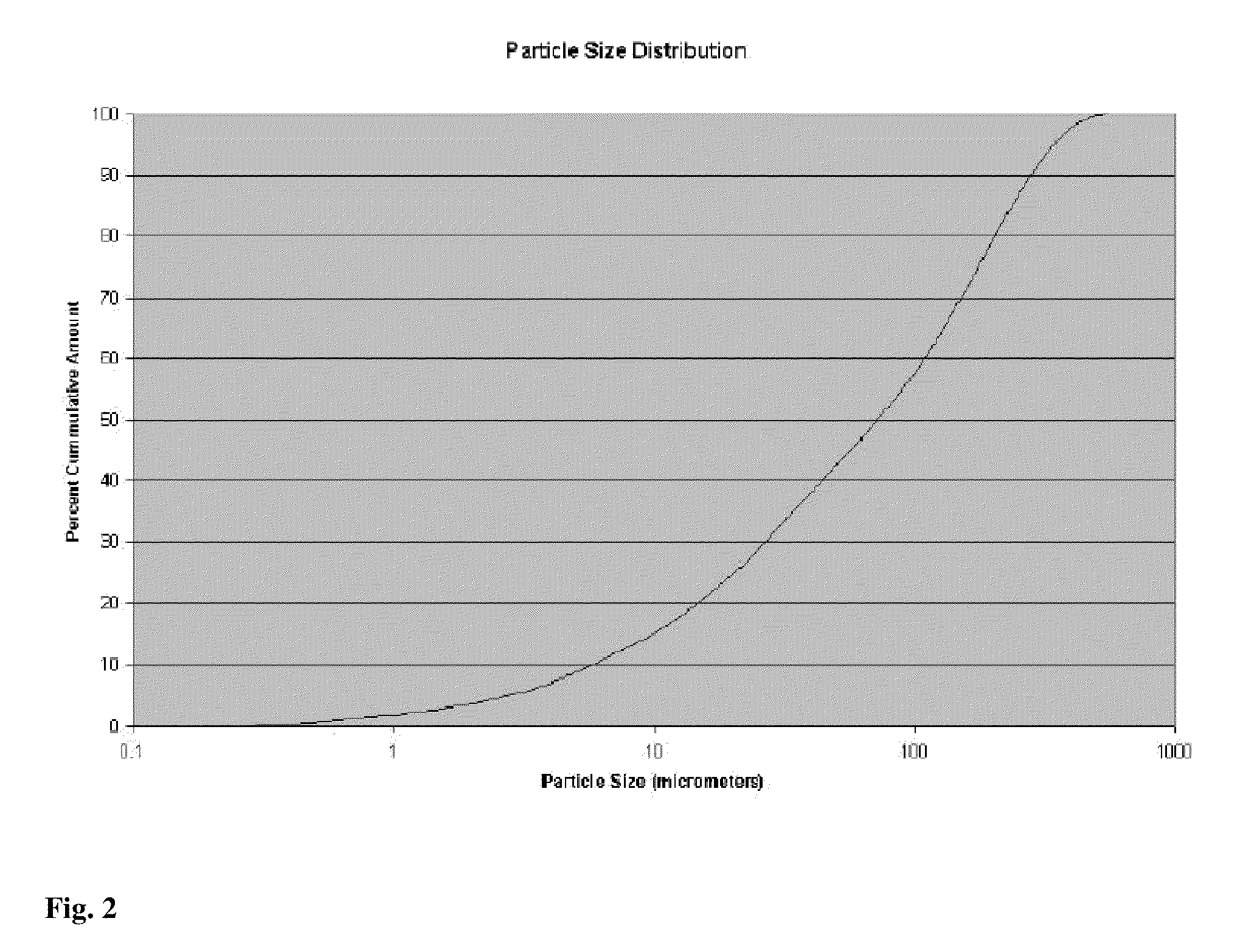

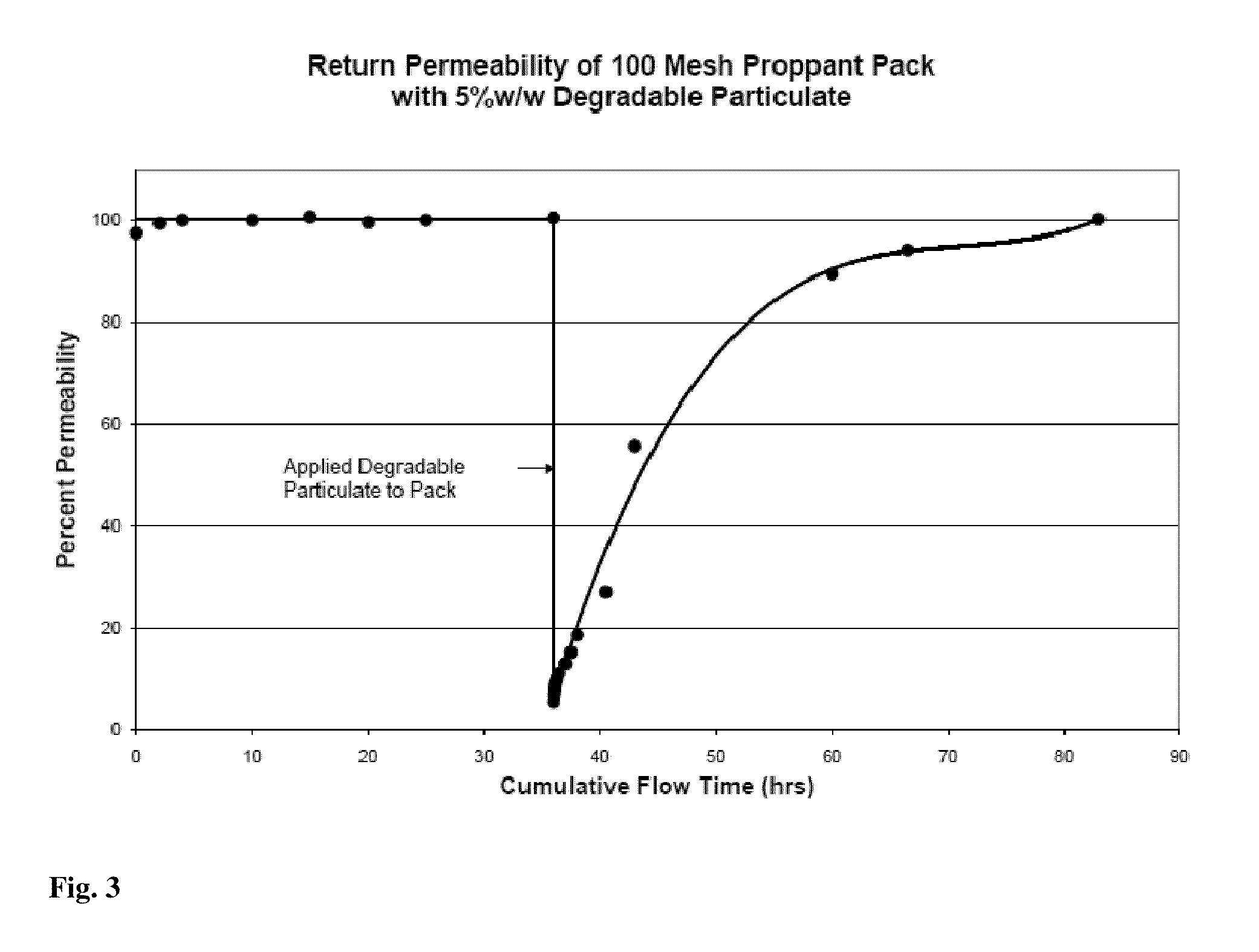

ActiveUS20110120713A1Increasing fracture complexityFluid removalDrilling compositionFracturing fluidSolid particle

A method of increasing the fracture complexity in a treatment zone of a subterranean formation is provided. The subterranean formation is characterized by having a matrix permeability less than 1.0 microDarcy. The method includes the step of pumping one or more fracturing fluids into a far-field region of a treatment zone of the subterranean formation at a rate and pressure above the fracture pressure of the treatment zone. A first fracturing fluid of the one or more fracturing fluids includes a first solid particulate, wherein: (a) the first solid particulate includes a particle size distribution for bridging the pore throats of a proppant pack previously formed or to be formed in the treatment zone; and (b) the first solid particulate comprises a degradable material. In an embodiment, the first solid particulate is in an insufficient amount in the first fracturing fluid to increase the packed volume fraction of any region of the proppant pack to greater than 73%. Similar methods using stepwise fracturing fluids and remedial fracturing treatments are provided.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods of Hydraulically Fracturing and Recovering Hydrocarbons

ActiveUS20140326453A1Promote recoveryImprove conductivityFluid removalDrilling compositionHydraulic fracturingMaterials science

There is provided synthetic proppants, and in particular polysilocarb derived ceramic proppants. There is further provided hydraulic fracturing treatments utilizing these proppants, and methods of enhance hydrocarbon recovery.

Owner:MELIOR INNOVATIONS

Precipitation of hardness salt in flow back and produced water

InactiveUS20110259761A1Effectively efficiently recyclingReduced fouling tendencyWaste water treatment from quariesWater treatment parameter controlUltrasonic sensorCavitation

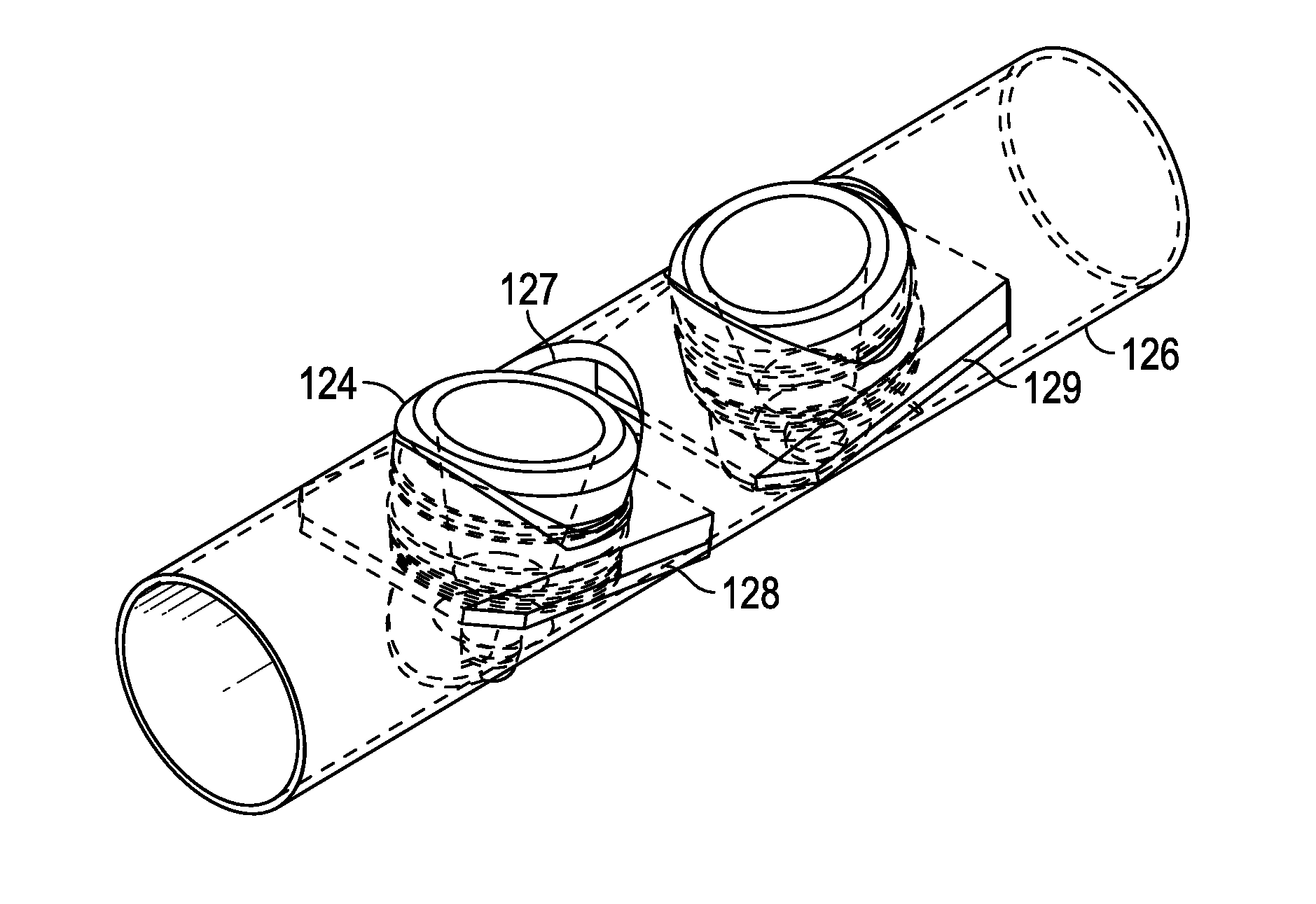

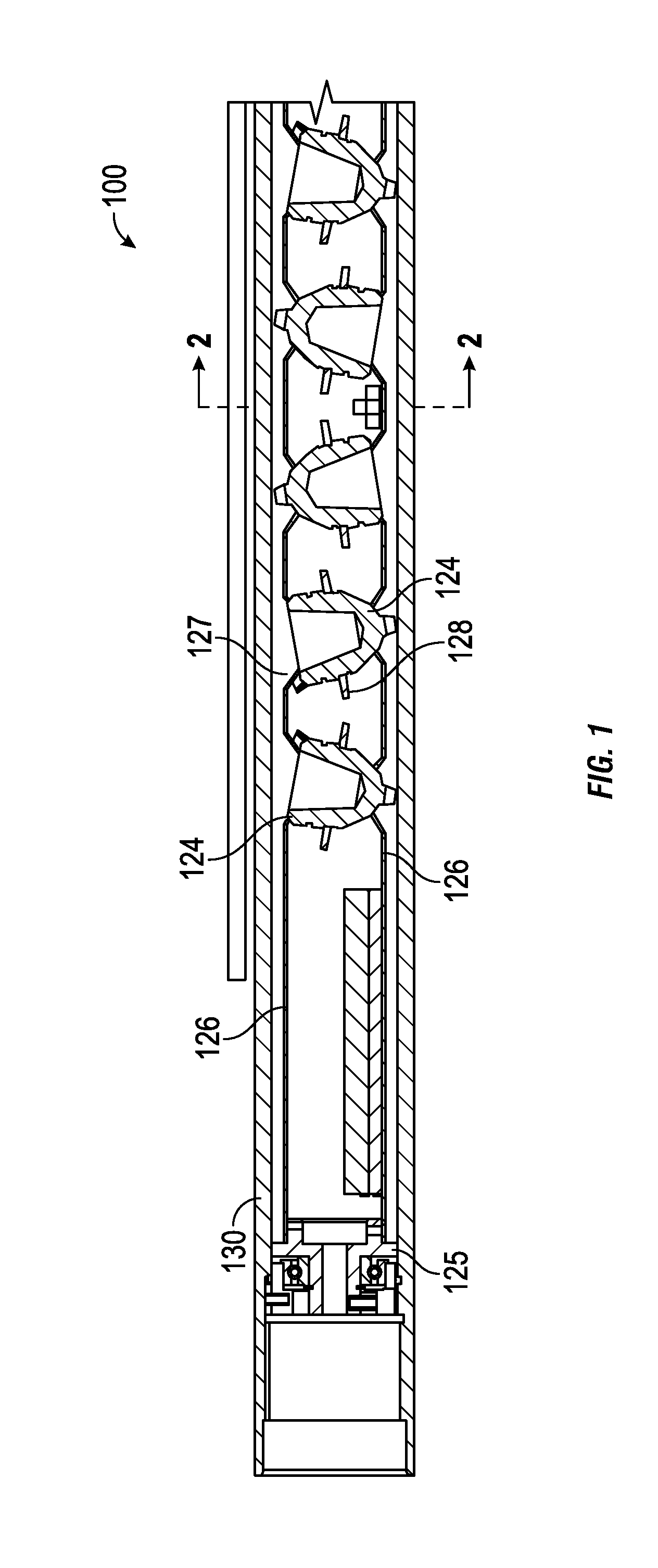

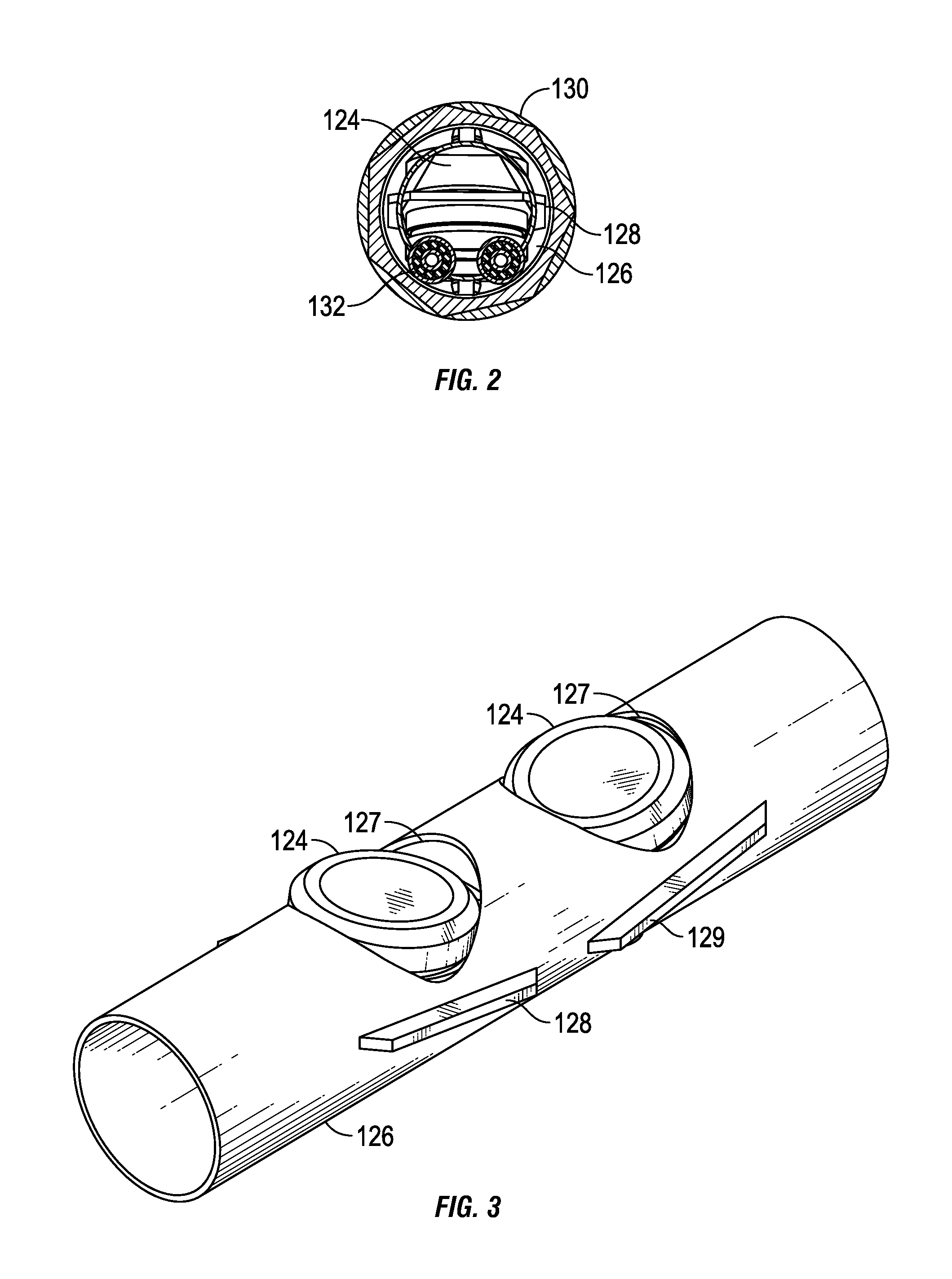

An apparatus and method for reducing the scaling tendency of fracture-treatment flow back water and oil field brine by the precipitation of hardness salts using carbon dioxide as a carbonate donor. The apparatus includes a treatment conduit comprised of a plurality of segments. The treatment conduit includes a plurality of anode surfaces, a plurality of heated cathode surfaces each associated with an ultrasonic transducer and an arrangement for injecting carbon dioxide into the stream of raw water. The injection of carbon dioxide from an external source helps to reduce the pH of the water and to prevent scaling by softening the water thereby eliminating the use of HCL at the frac job site. The treatment conduit further includes a plurality of static mixers each creating hydrodynamic cavitation thereby facilitating better mixing of the carbon dioxide and higher mass transfer efficiency.

Owner:ECOSPHERE TECH

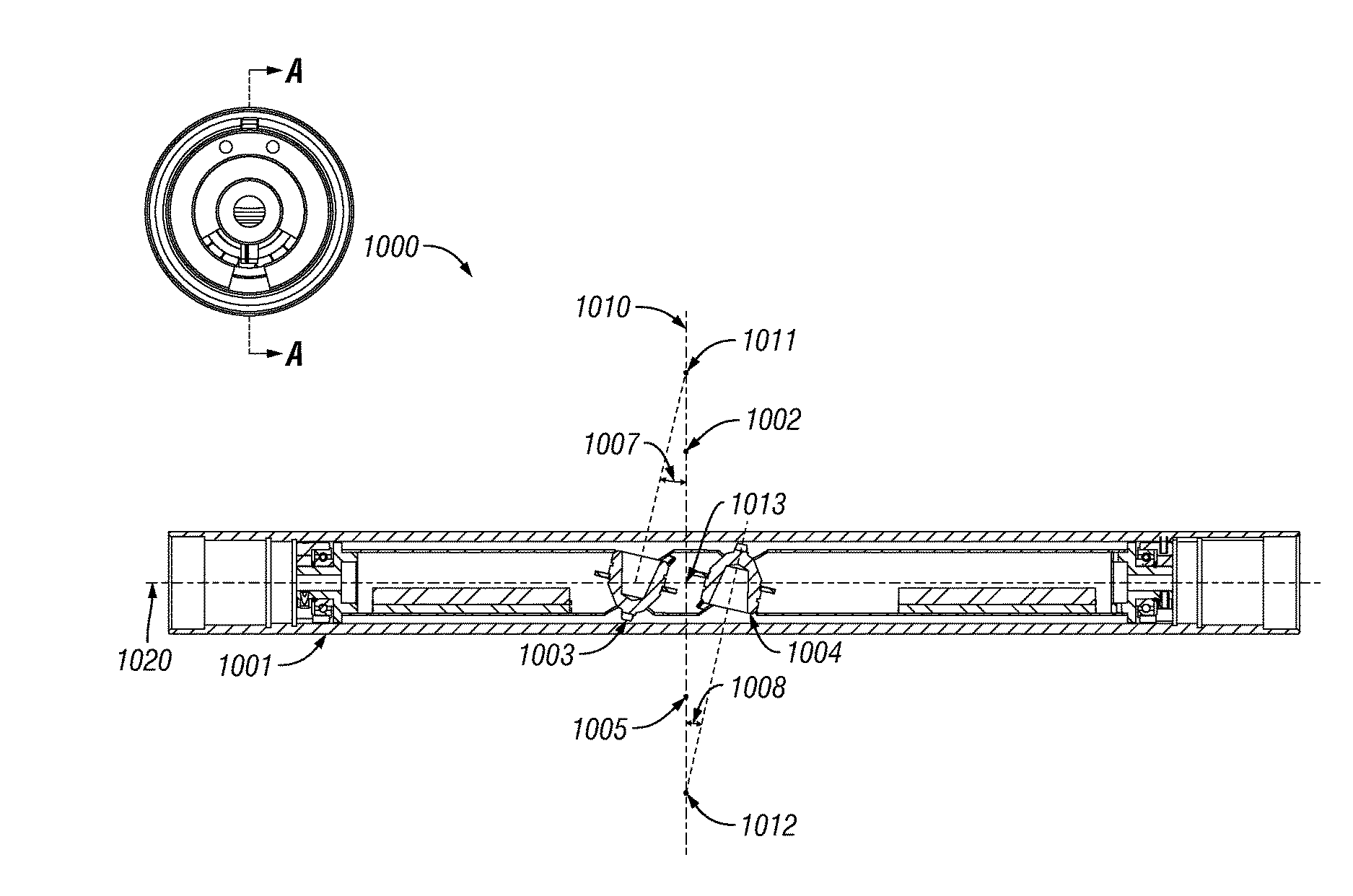

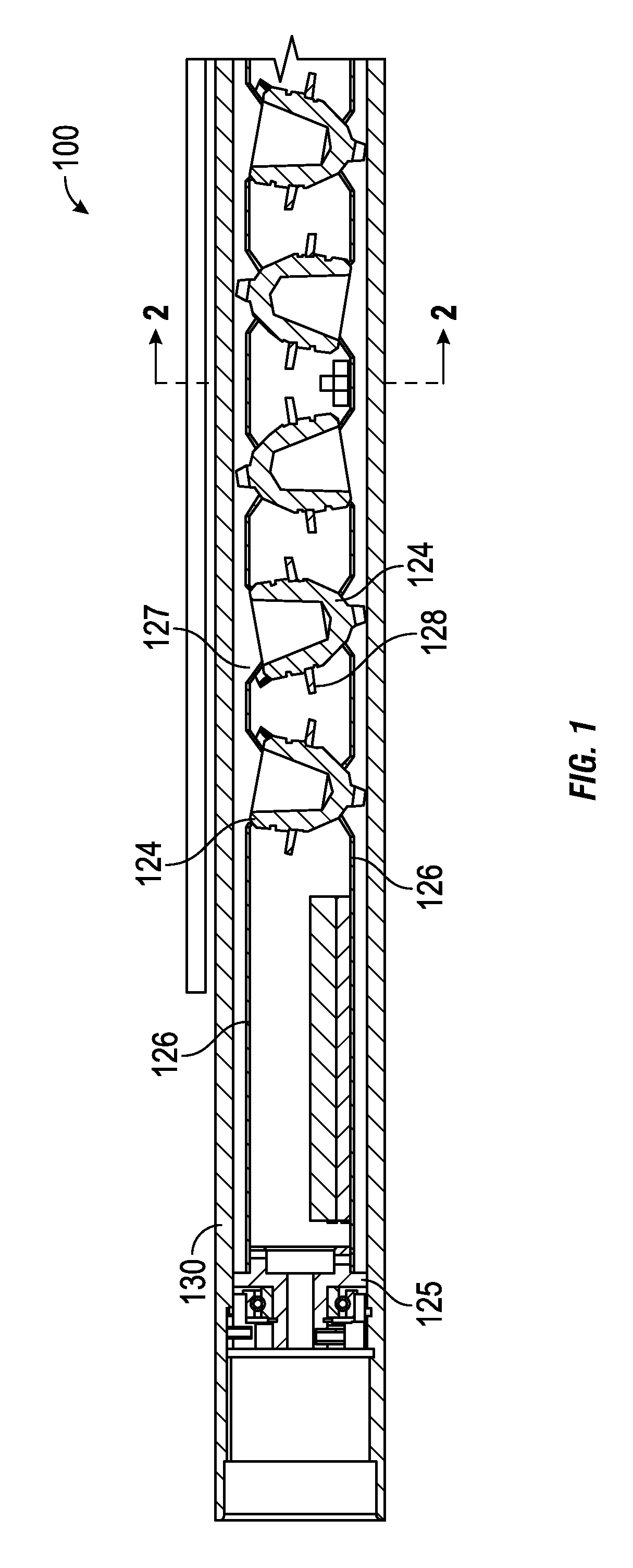

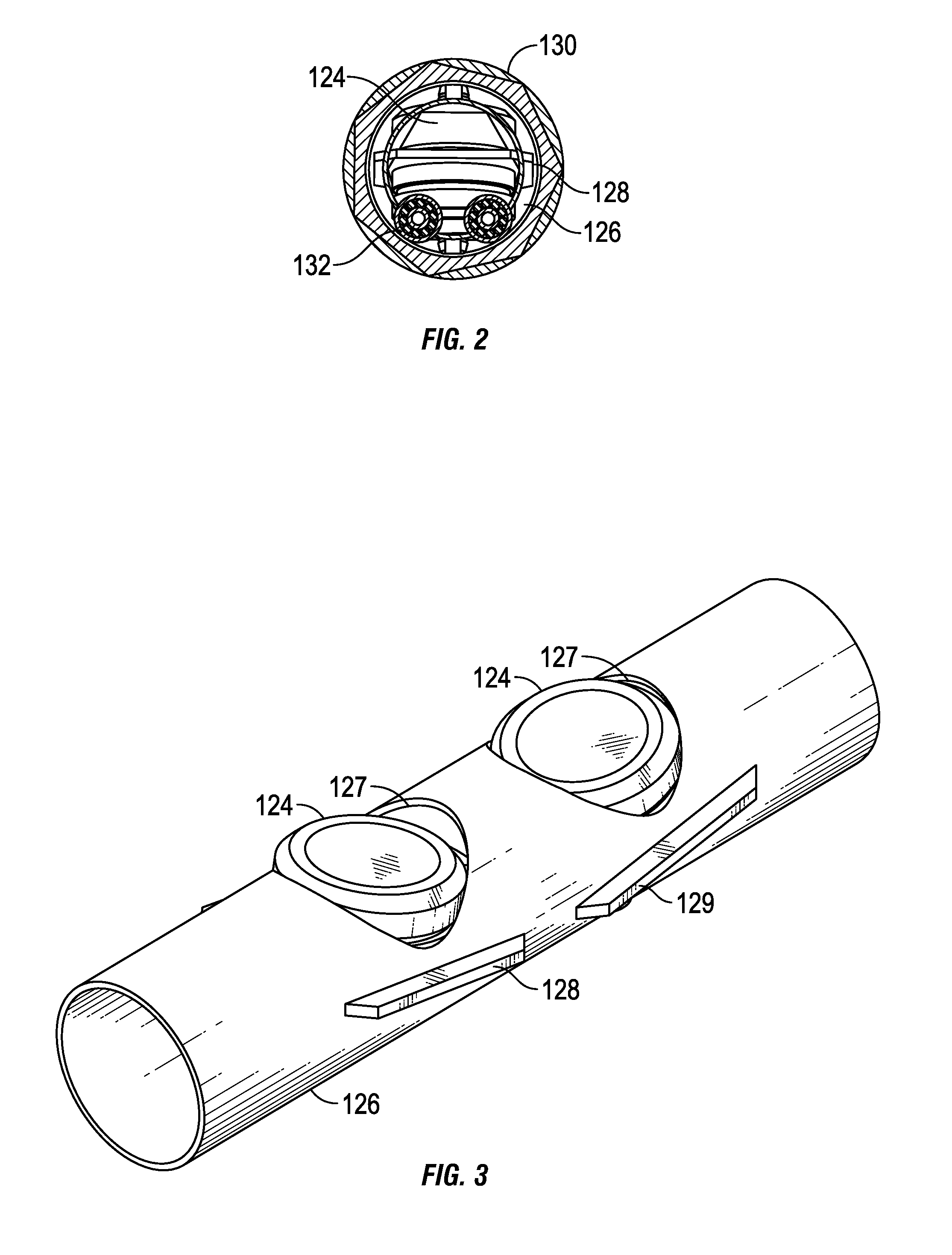

Limited entry phased perforating gun system and method

A limited entry perforating phased gun system and method for accurate perforation in a deviated / horizontal wellbore is disclosed. The system / method includes a gun string assembly (GSA) deployed in a wellbore with shaped charge clusters. The charges are spaced and angled such that, when perforated, they intersect at a preferred fracturing plane. Upon fracturing, the fractures initiate at least principal stress location in a preferred fracturing plane perpendicular to the wellbore from an upward and downward location of the wellbore. Thereafter, the fractures connect radially about the wellbore in the preferred fracturing plane. The fracture treatment in the preferred fracturing plane creates minimal tortuosity paths for longer extension of fractures that enables efficient oil and gas flow rates during production.

Owner:WELLS FARGO BANK NAT ASSOC +1

Limited Entry Phased Perforating Gun System and Method

ActiveUS20150267516A1Reduce twistFluid removalDrilling machines and methodsPrincipal stressShaped charge

A limited entry perforating phased gun system and method for accurate perforation in a deviated / horizontal wellbore is disclosed. The system / method includes a gun string assembly (GSA) deployed in a wellbore with shaped charge clusters. The charges are spaced and angled such that, when perforated, they intersect at a preferred fracturing plane. Upon fracturing, the fractures initiate at least principal stress location in a preferred fracturing plane perpendicular to the wellbore from an upward and downward location of the wellbore. Thereafter, the fractures connect radially about the wellbore in the preferred fracturing plane. The fracture treatment in the preferred fracturing plane creates minimal tortuosity paths for longer extension of fractures that enables efficient oil and gas flow rates during production.

Owner:WELLS FARGO BANK NAT ASSOC +1

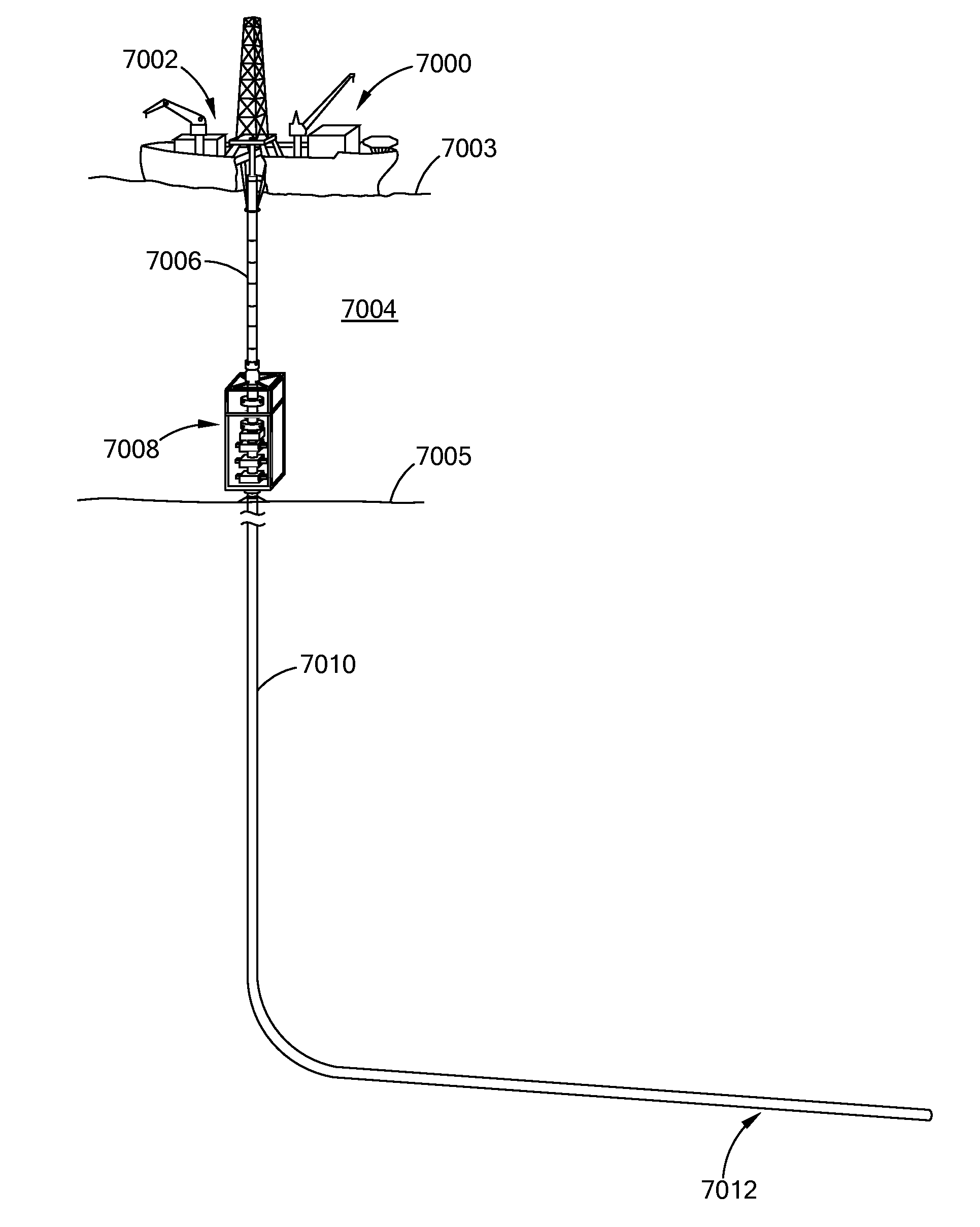

Offshore Methods of Hydraulically Fracturing and Recovering Hydrocarbons

InactiveUS20140318799A1Enhanced recovery of hydrocarbonImprove conductivityFluid removalUnderwater drillingHydraulic fracturingMaterials science

There is provided synthetic proppants, and in particular polysilocarb derived ceramic proppants. There is further provided hydraulic fracturing treatments utilizing these proppants, and methods of enhance hydrocarbon recovery.

Owner:MELIOR INNOVATIONS

Well treating materials comprising coated proppants, and methods

InactiveUS8003214B2Liquid surface applicatorsSynthetic resin layered productsParticulatesHydraulic fracturing

The present invention is directed to an improved thermoplastic material-coated particulate composition useful for hydraulic fracturing treatments, gravel packing for sand control or other well formation treatments and especially the related methods of its use and is particularly directed to using a thermoplastic material as part of a particulate composition in a method for enhancing the stabilization of and reducing particulate flowback and fines transport in a well formation.

Owner:GEORGIA PACIFIC CHEM LLC

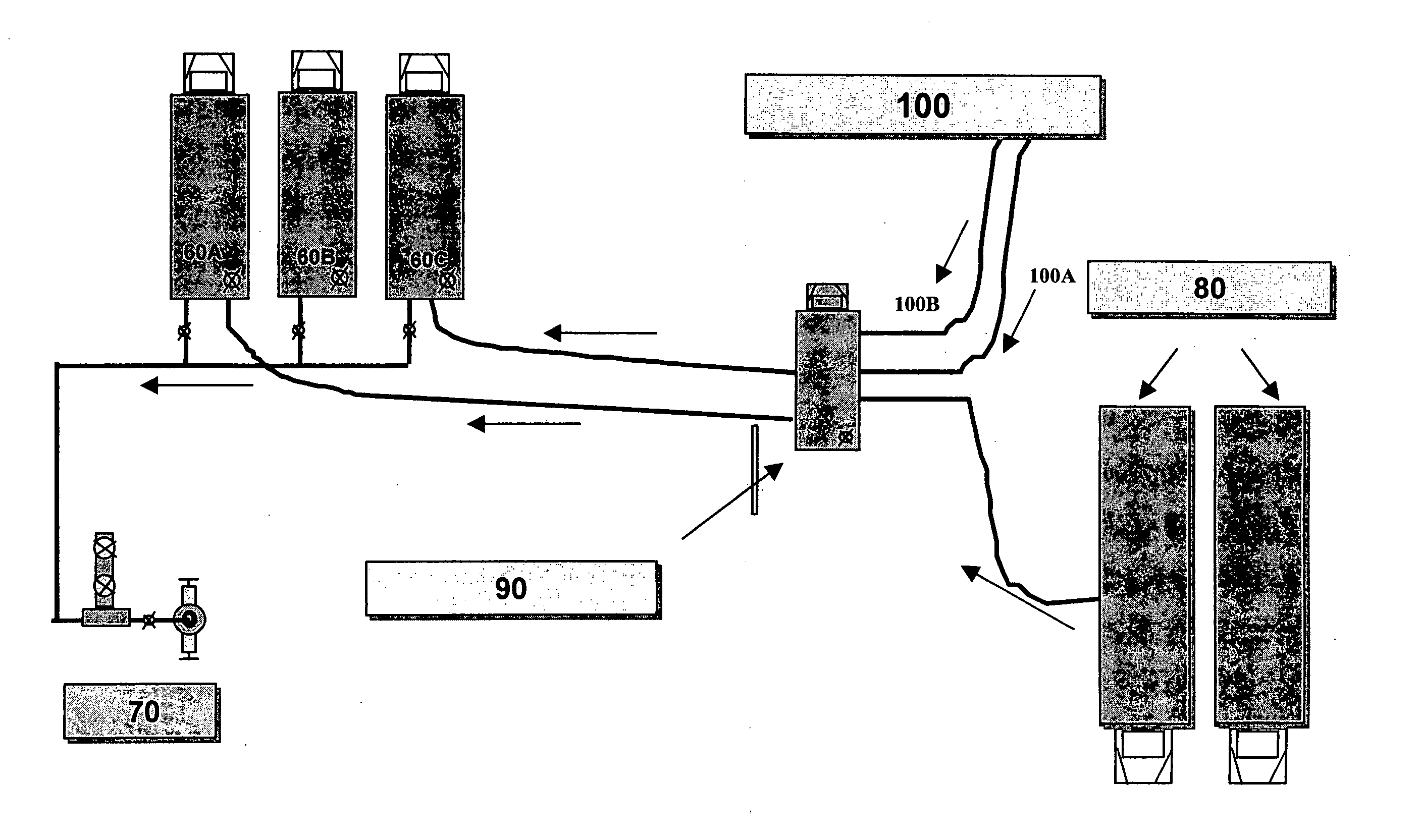

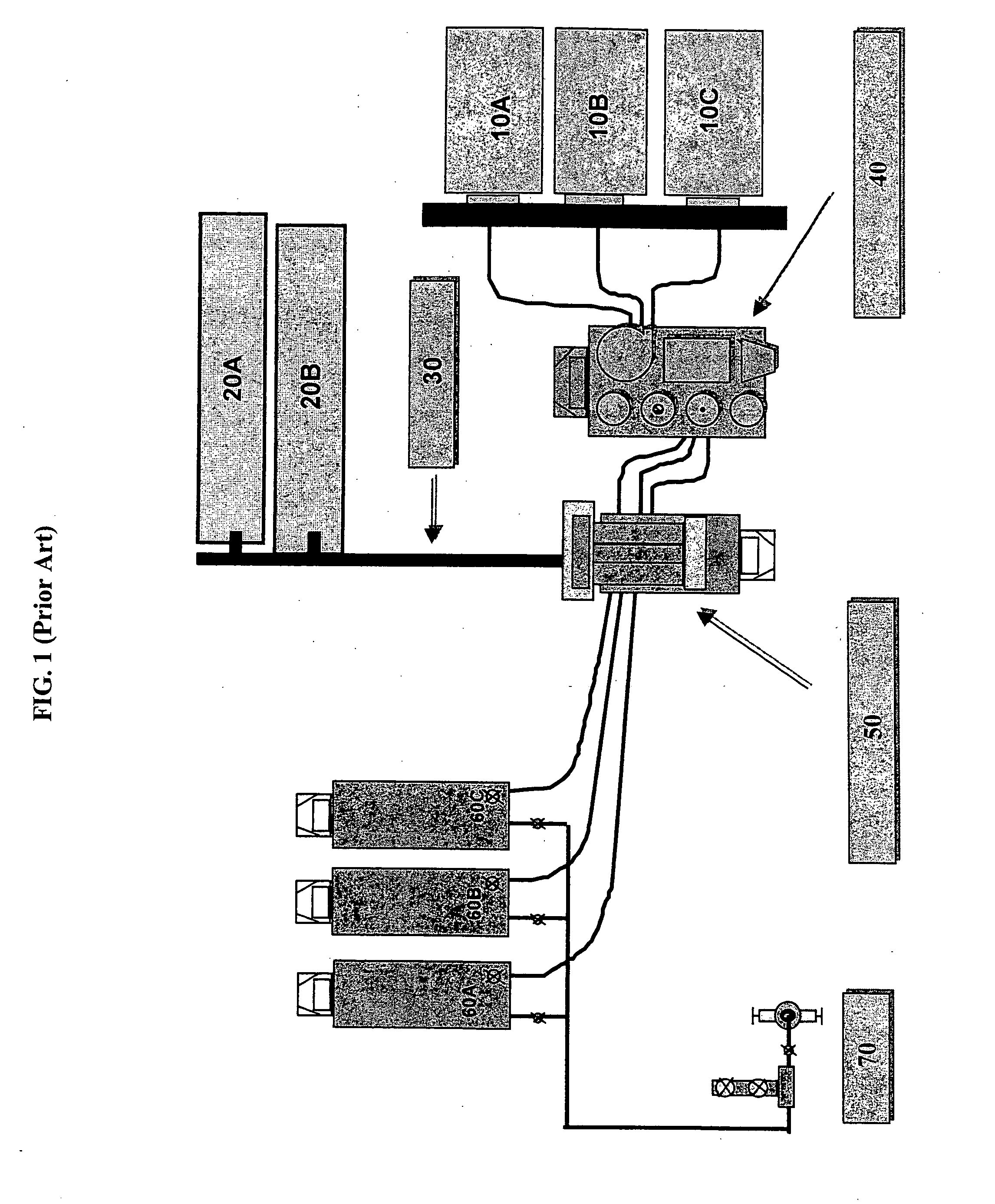

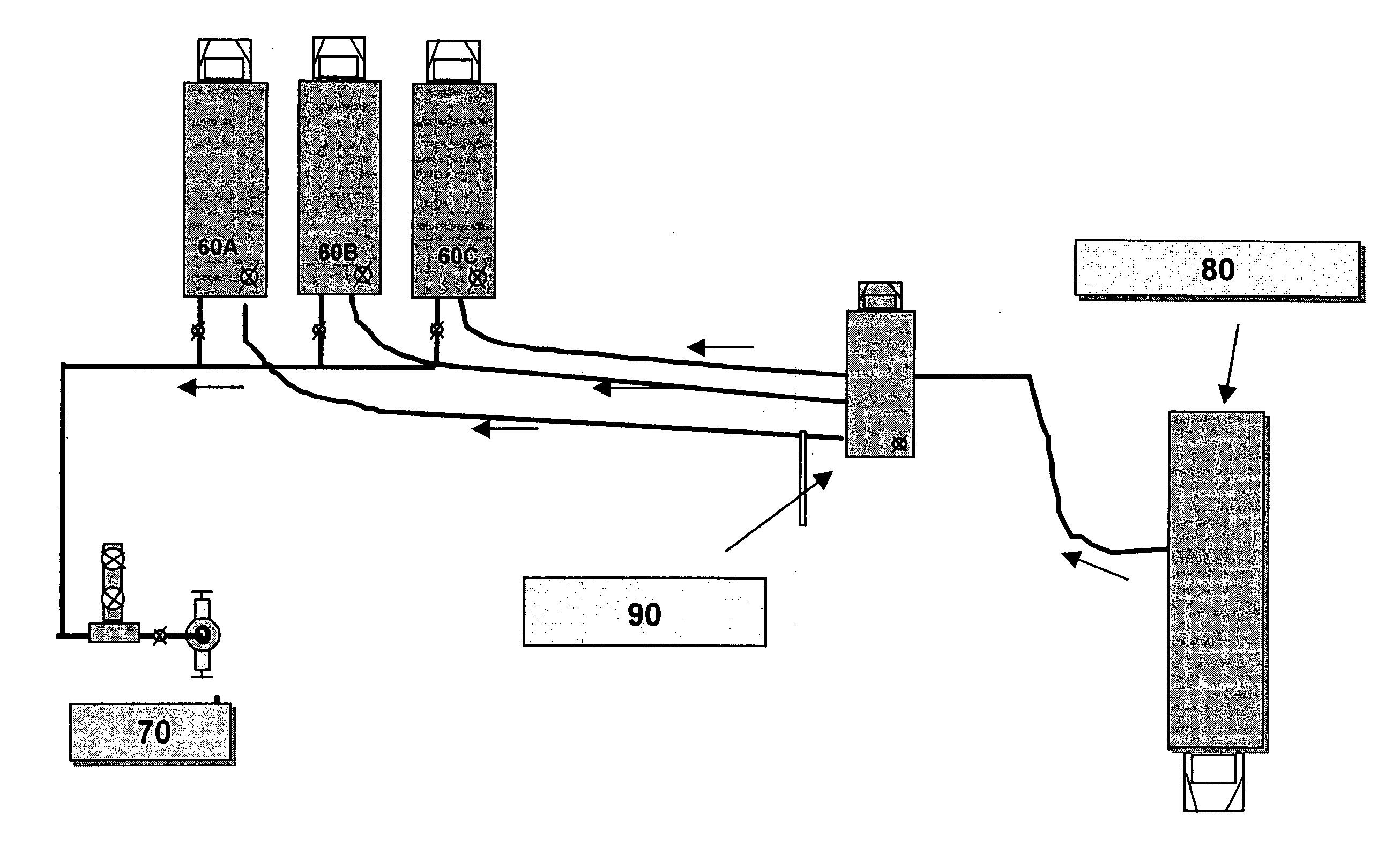

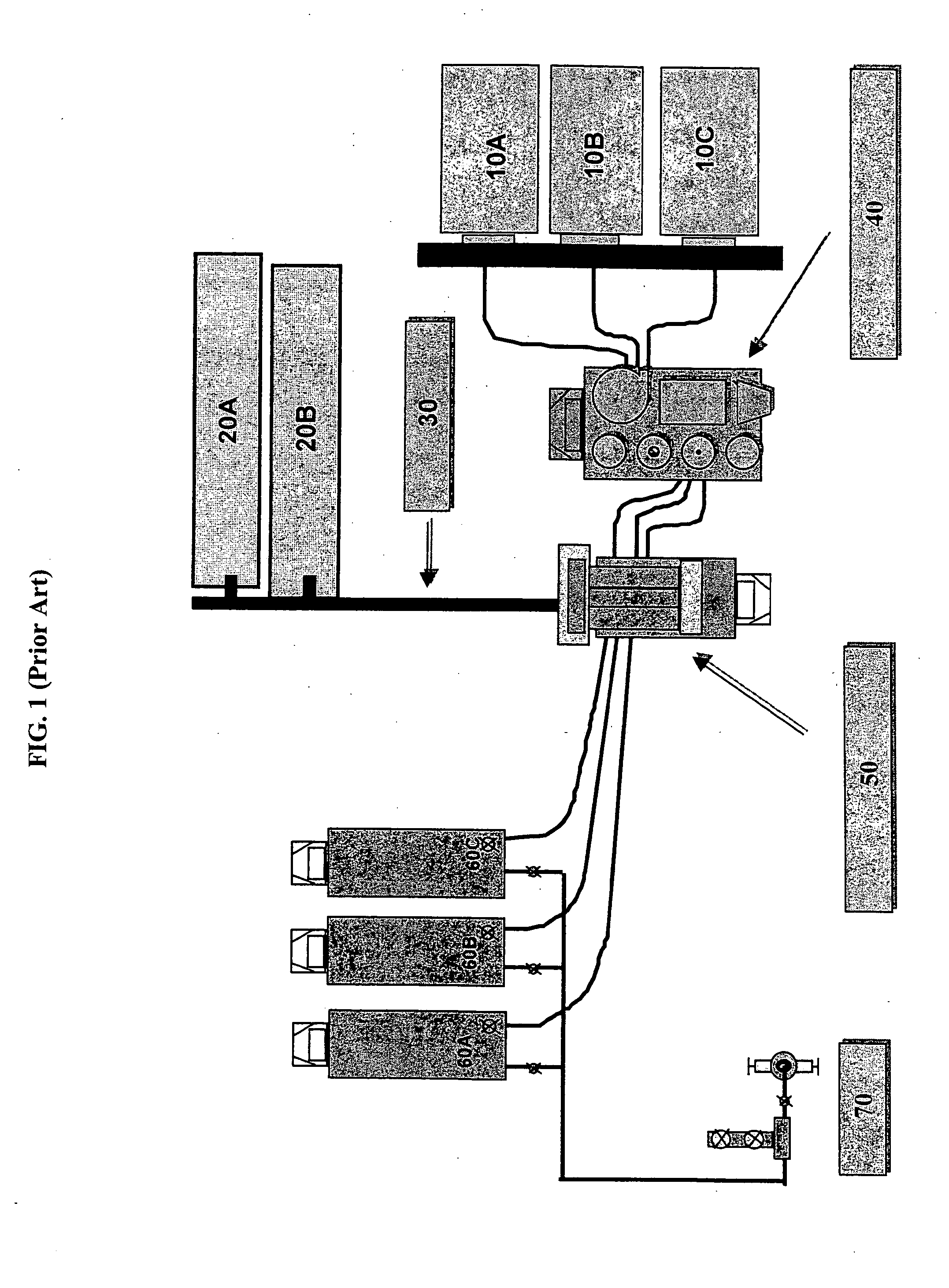

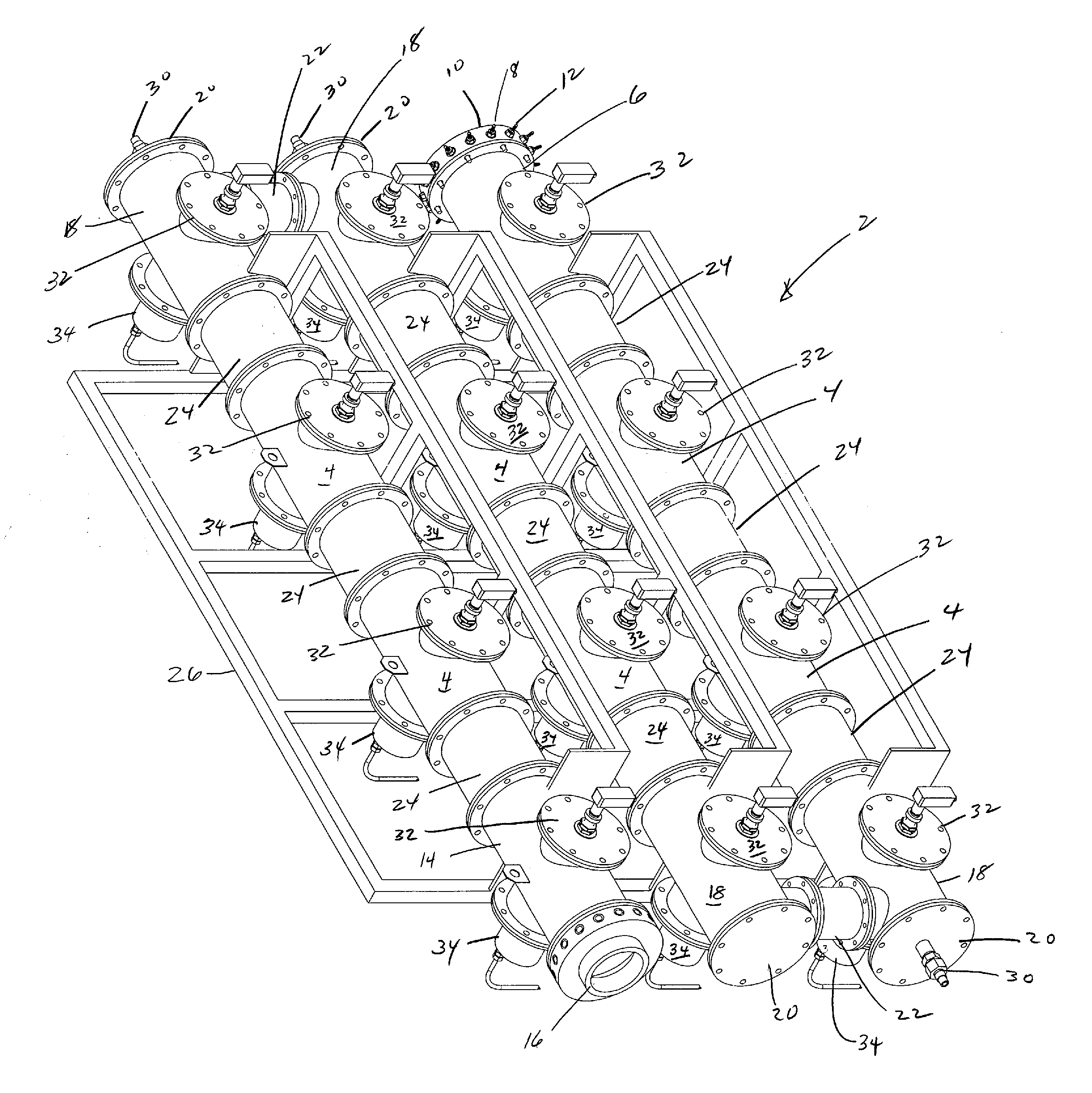

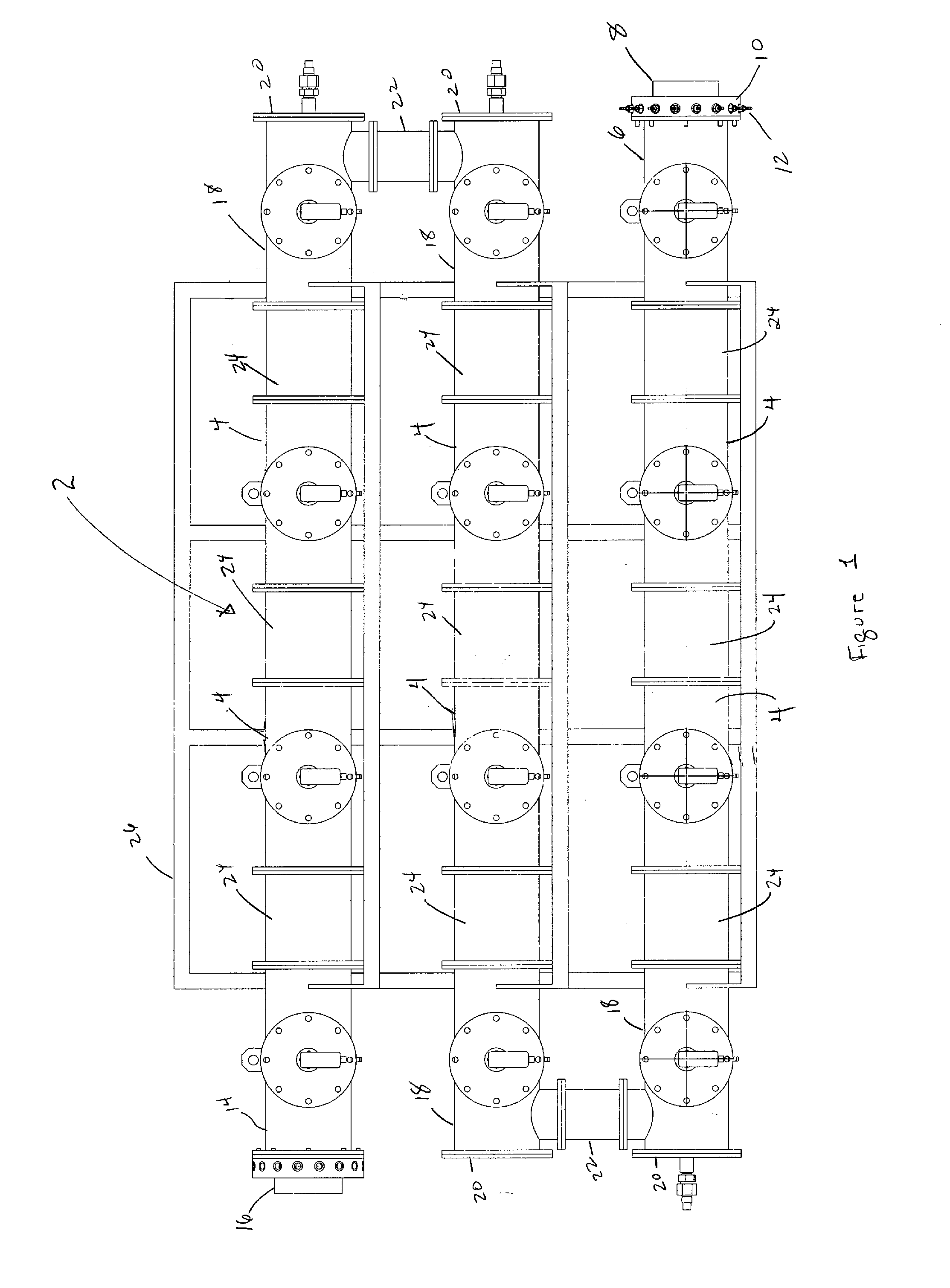

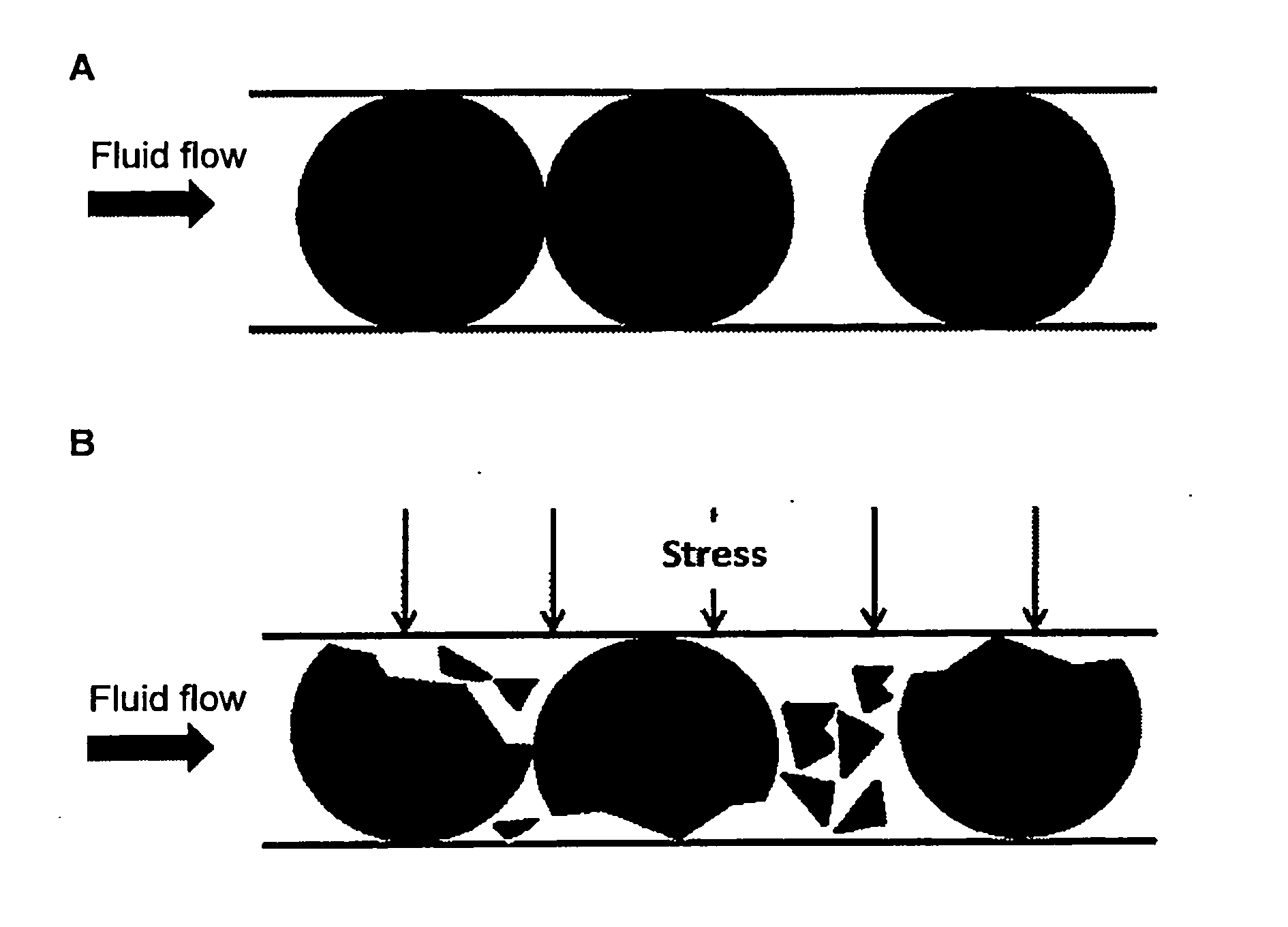

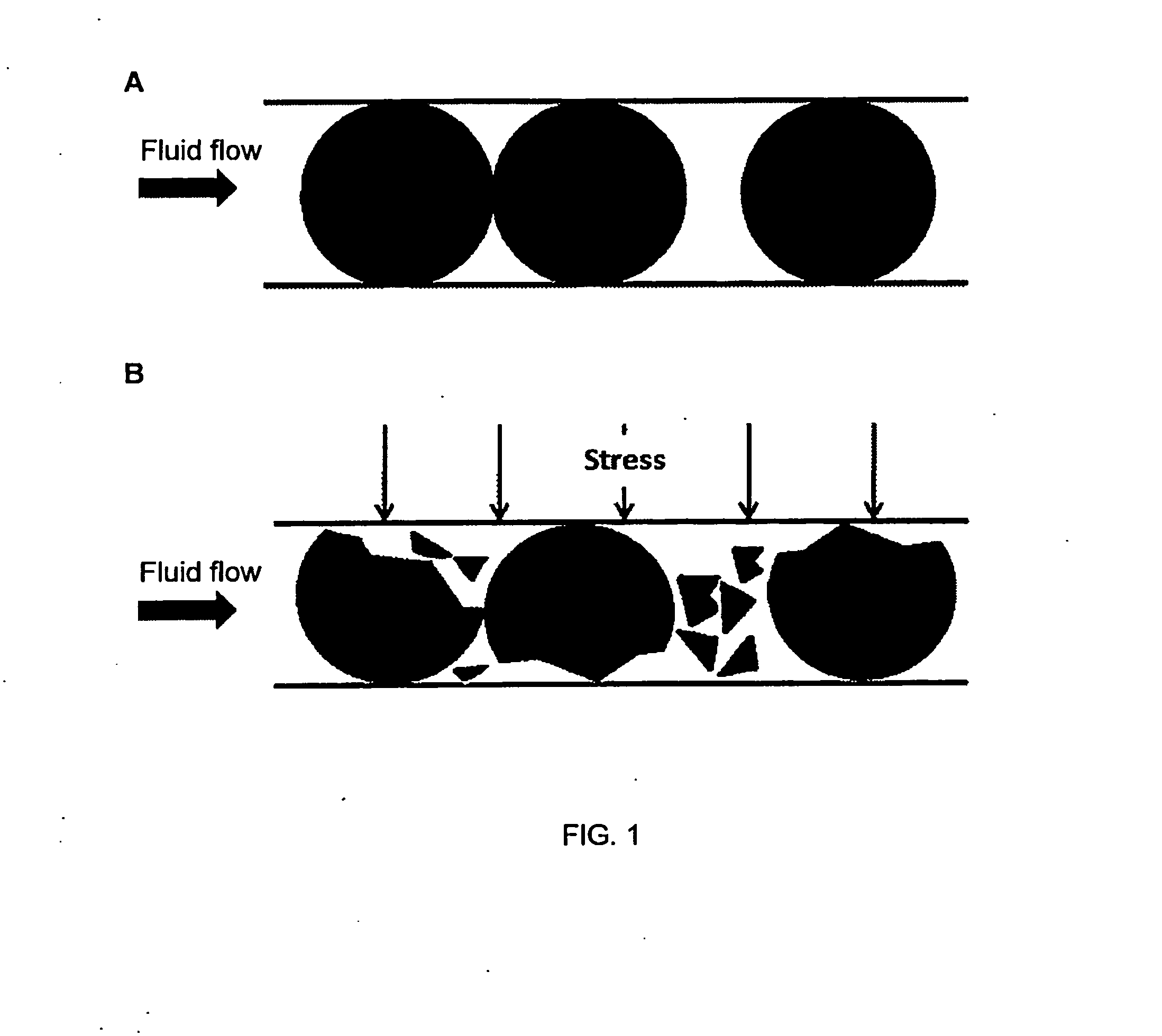

Hydraulic fracturing system

ActiveUS20130014946A1Increase injection rateFluid removalDrilling compositionFlow stressHydrostatic pressure

A method is given for fracturing a formation, in particular far-field in a tight formation, in which at least a portion of the proppant is crushable in situ at some point during pumping, during fracture closure, or at higher Fluid flow stresses experienced later during fracture closure. The closure stress or hydrostatic stress is estimated, then a proppant is selected that is at least partially crushable at that closure stress, and then the fracturing treatment is performed with at least a portion of the total proppant being the selected crushable proppant.

Owner:SCHLUMBERGER TECH CORP

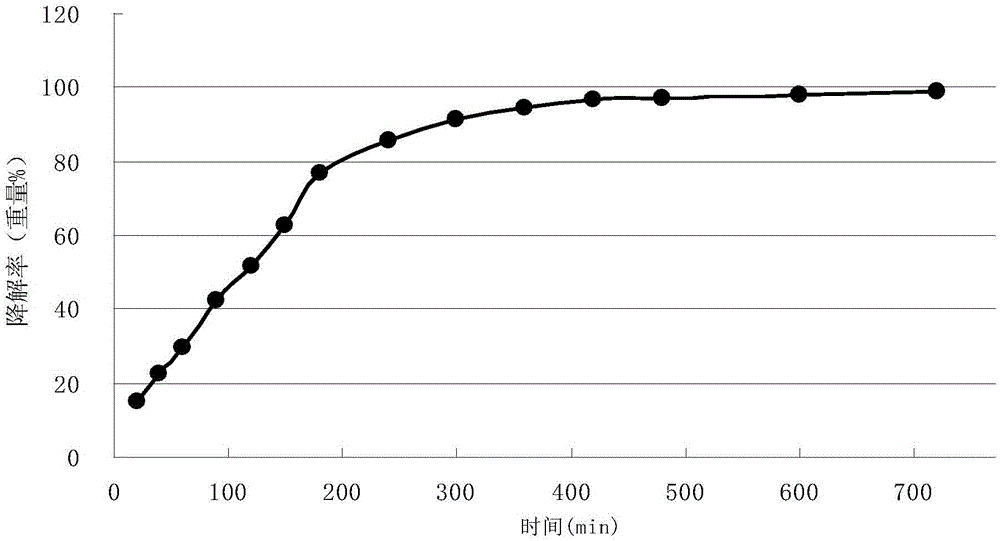

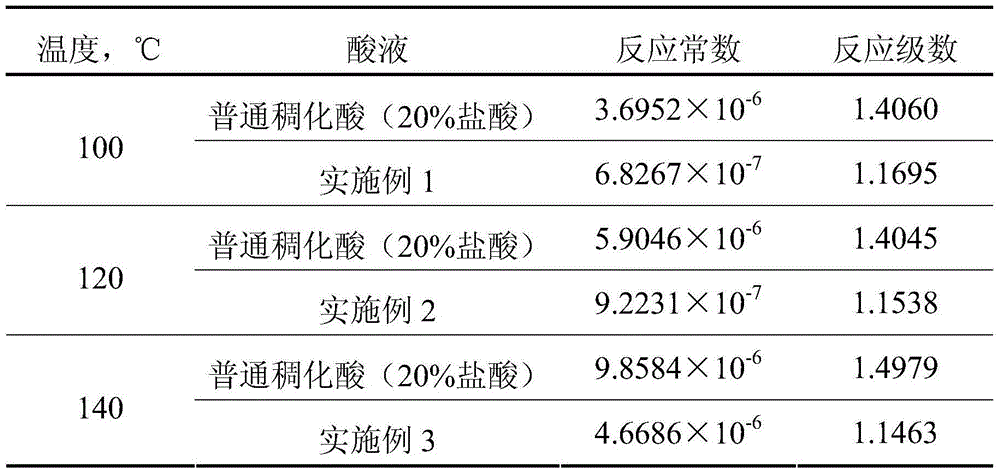

Slow-speed low-friction acid solution system for acid fracturing

InactiveCN104629711AStable high temperature rheological propertiesImprove shear resistanceDrilling compositionStrong acidsAcid strength

Disclosed is a retardant low-friction acid liquid system for acid fracturing. The retardant low-friction acid liquid system for acid fracturing consists of 20-40 parts of emulsified acid and 60-80 parts of thickened acid, the total volume of emulsified acid and thickened acid being 100 parts. The retardant low-friction acid liquid system for acid fracturing has high viscosity, low leak-off, good retardancy, low friction and good discharge capacity under conditions of normal temperature and strong acid, facilitating fracture initiation, and can be used to enlarge the acid fracturing treatment radius and improve acid etched fracturing conductivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

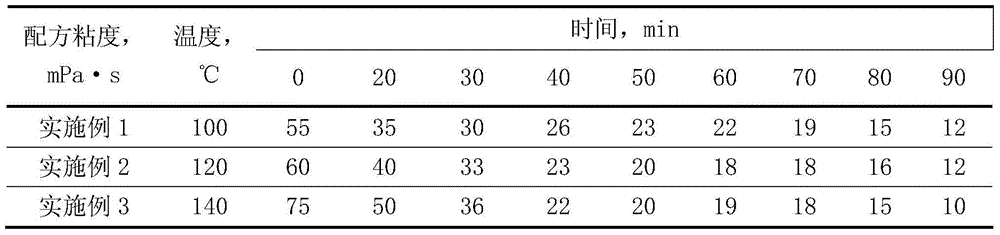

Physical simulation device for multiple seam gas well drainage and production and experimental method thereof

ActiveCN106812523AAccuracy of experimental resultsRestore formation conditionsSurveyConstructionsGas cylinderMethane gas

The invention provides a physical simulation device for multiple seam gas well drainage and production. The device comprises a controlling computer, an experimental table, a hydraulic cylinder support rack, a boosting water pump, a vacuum pump, a first level coal seam methane recycling bottle, a second level coal seam methane recycling bottle, a methane gas supply cylinder, a helium gas storage bottle, a hydraulic cylinder, a coal seam boosting water tank, a water returning tank, a thermal water tank and a coal seam boosting chamber. The side portion of the coal seam boosting chamber is connected with a water gas multi-purpose pipeline. A three-channel gas recycling pipe is arranged in the coal seam boosting chamber. The invention further discloses an experimental method of the multiple seam gas well drainage and production. According to the physical simulation device for multiple seam gas well drainage and production and experimental method thereof, the coal samples with physical property parameters similar to the coal seam to be simulated is selected to make the experiment results more accurate, the fracture treatment is imposed on the coal sample before the experiment to form an artificially modified seam network in the condition of a reservoir stratum. The device and method can be directly used for the simulation of the water drainage and gas mining in multiple seams, provide the basis for predicting the drainage and mining effects in actual production process and making reasonable drainage and mining regulation.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

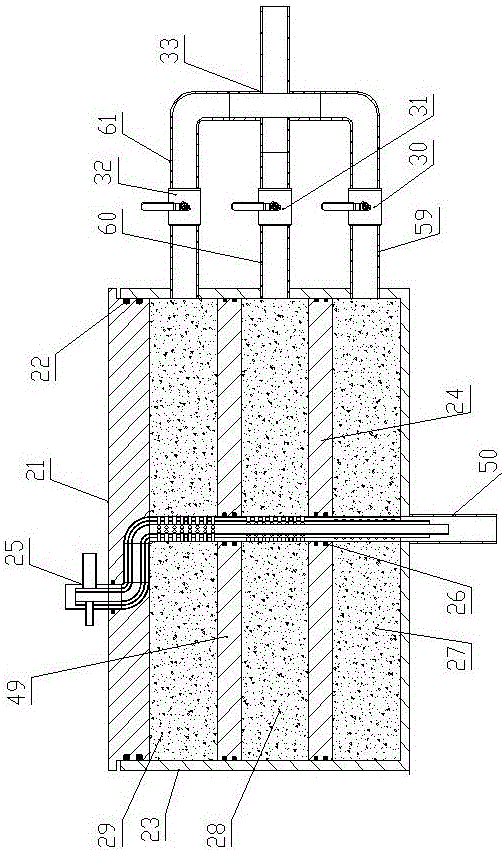

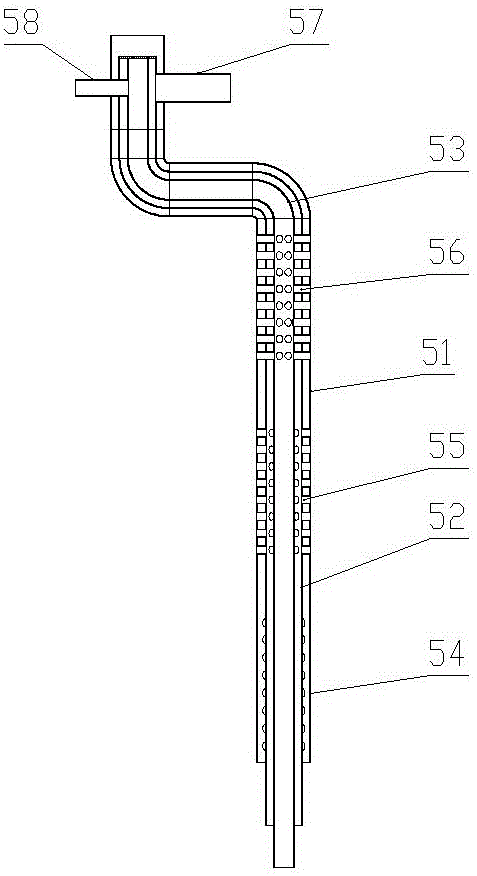

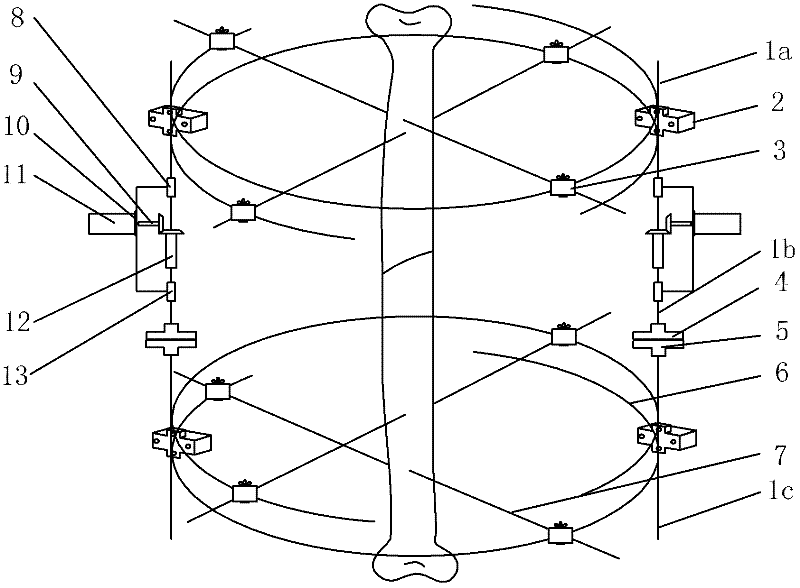

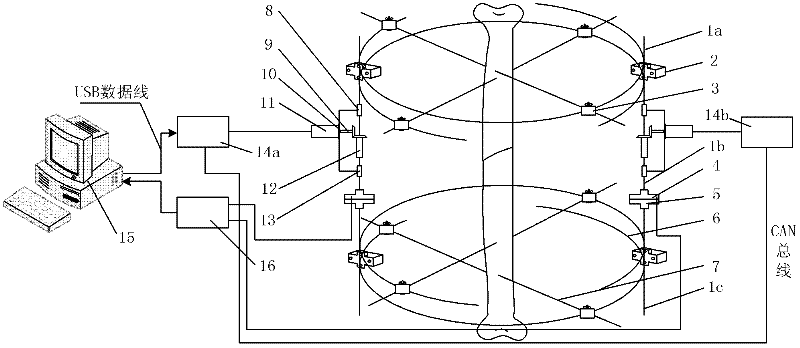

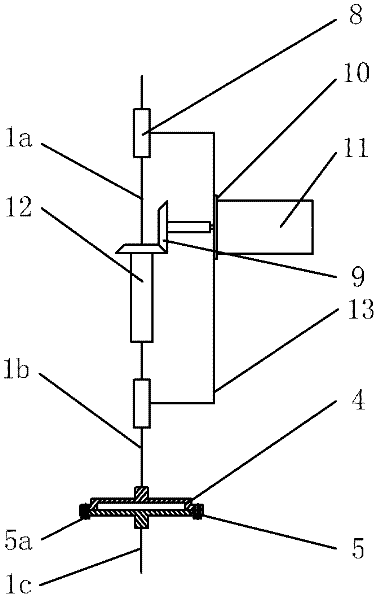

Fracture wound section stress measurement and control device

InactiveCN102512184AWell developedReduce volumeMuscle exercising devicesExternal osteosynthesisStress measurementControl system

The invention discloses a fracture wound section stress measurement and control device based on a bone external fixing mode, which comprises a bone two-dimensional force sensor, a bone external fixing device, an automatic stress application control system and a computer. The bone two-dimensional force sensor is serially connected onto supporting rods on two sides of the bone external fixing device in a threaded manner so as to form a detecting system for the fracture wound section stress measurement and control device, the detecting system detects force exerted on the supporting rods, and accordingly stress applied to a fracture wound section is obtained via calculation and analysis; automatic stress application mechanisms are fastened on the supporting rods, the computer acquires detecting signals of the sensor, servo motor control signals are outputted by the computer via high-precision intelligent control algorithm so as to form the automatic stress application control system, and the stress applied to the fracture wound section is controlled by means of controlling a servo motor. The fracture wound section stress measurement and control device not only can meet requirements of fixation during fracture treatment, but also can realize real-time noninvasive detection of fracture wound section stress and dynamic stress control, and is small in volume, light in weight and high in measurement and control precision.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com