Fracture wound section stress measurement and control device

A stress measurement and control device technology, applied in the field of medical devices, can solve the problems of delayed fracture healing, small pressure, non-union, etc., and achieve the effects of dynamic control, high measurement and control accuracy, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

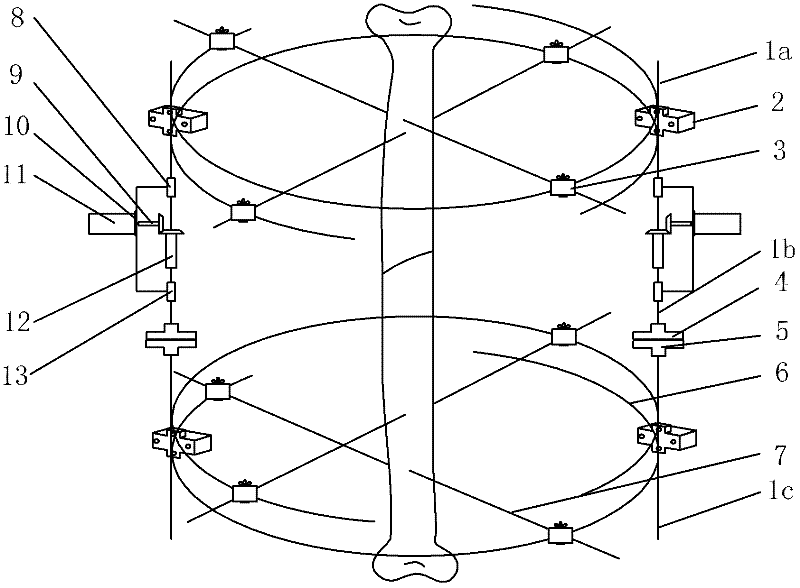

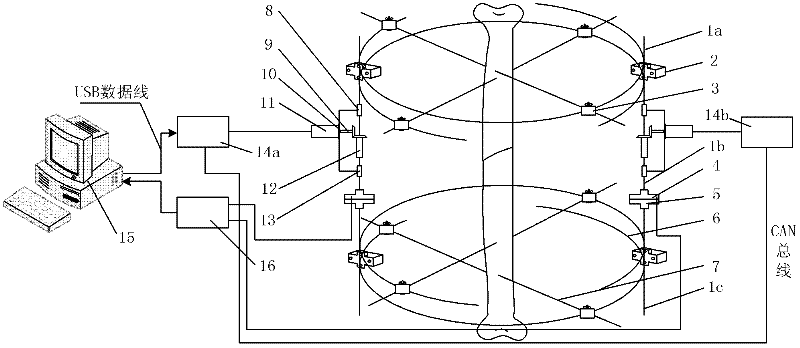

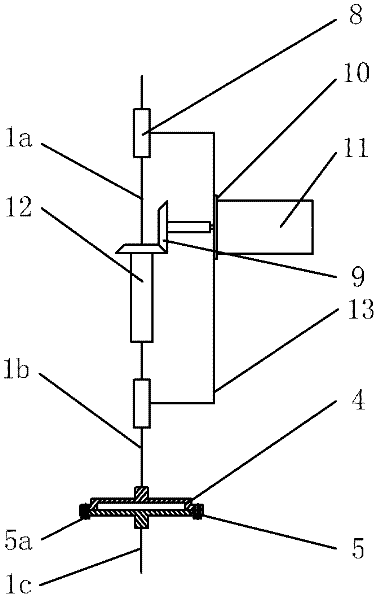

[0042] Such as Figure 1-11 As shown, a fracture trauma section stress measurement and control device includes a bone two-dimensional force sensor 4 (see Chinese patent CN 102138802A for details), an external bone fixation device, an automatic force control system, a data acquisition device and a computer. Wherein, the external bone fixation device includes support rods (upper support rod 1a and lower support rod 1c), the upper half and the lower half of the external bone fixation device respectively include two half-rings 6, and the half-rings 6 pass through the cross chuck 2 And it is integrated with the support rods 1a and 1c on both sides, the bone needle 7 passes through the broken bone and is fixed on the half ring 6 through the elastic nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com